A construction method for prefabricated box girders in high-cold and high-altitude areas

A box girder construction and high-altitude technology, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as difficulty in guaranteeing box girder construction quality and efficiency, large temperature difference between day and night, improve processing accuracy and welding quality, and reduce arching , Improve the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

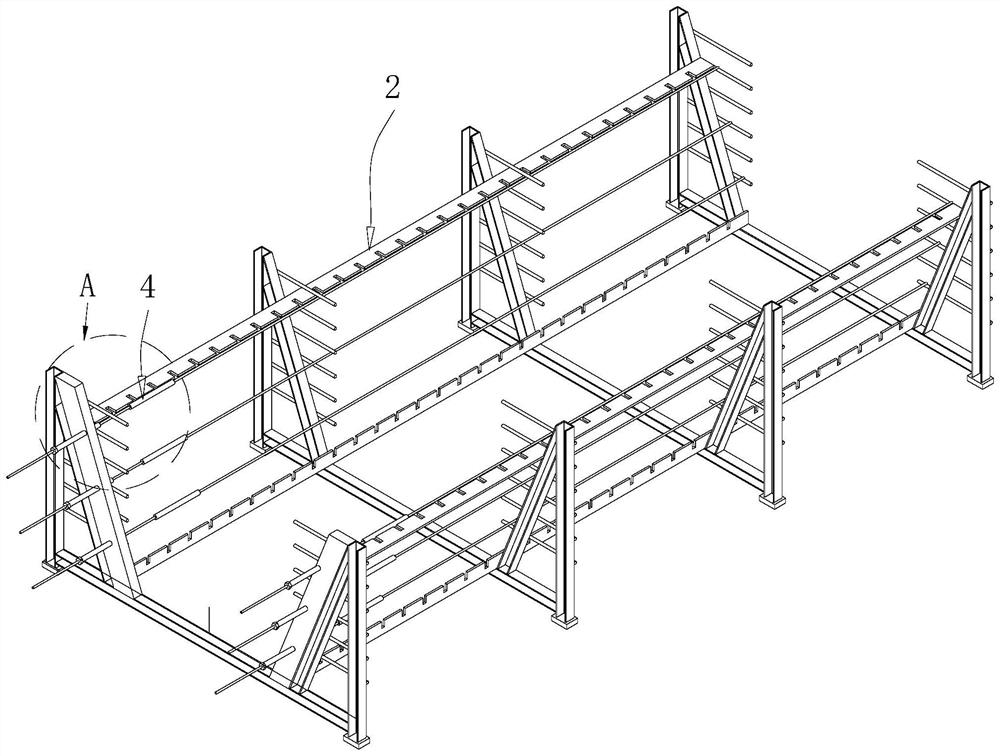

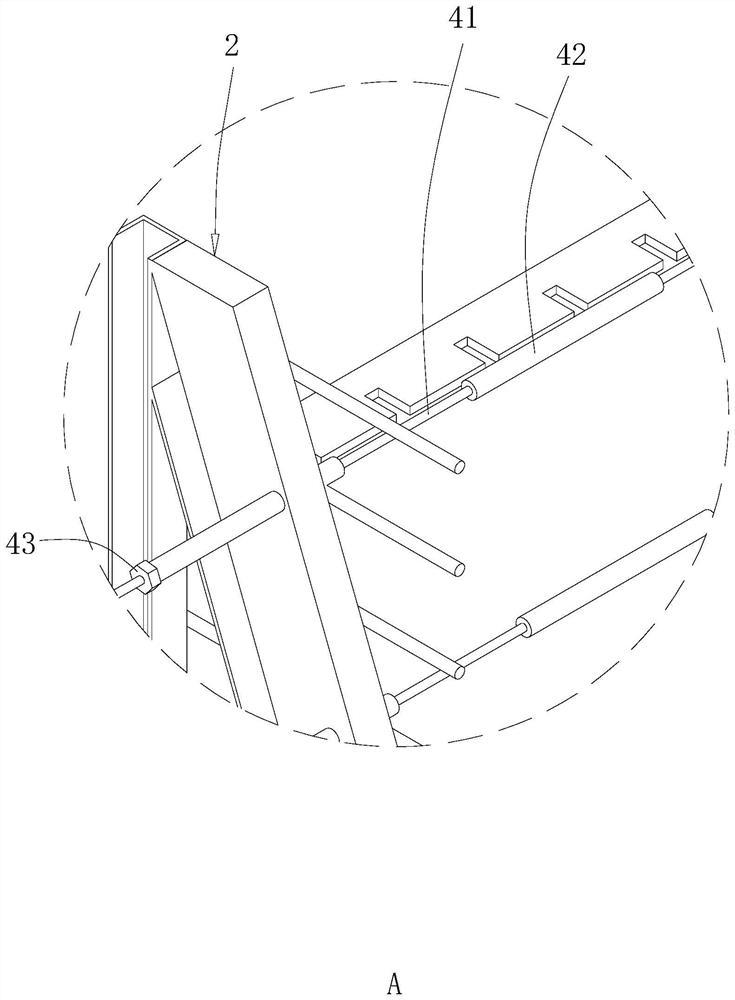

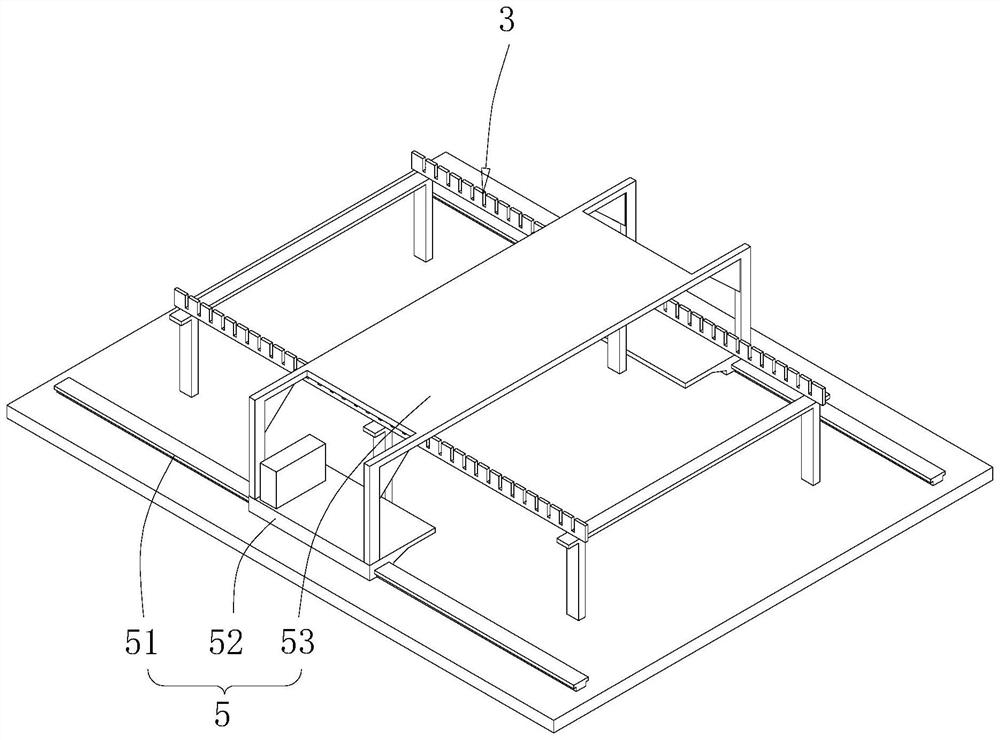

[0050] The following is attached Figure 1-6 , please elaborate further.

[0051] The embodiment of the present application discloses a construction method of a prefabricated box girder in an alpine and high-altitude area. The construction method of prefabricated box girders in high-cold and high-altitude areas includes the following steps:

[0052] step one,

[0053] Construct a closed steel structure greenhouse, in which the columns and main beams are welded with round pipes to form a truss structure, the purlins are made of square pipes, and the sides and roof are made of color steel.

[0054] Pouring beam-making pedestal 1: Bind the pedestal reinforcement cage at the design position of beam-making pedestal 1 in the closed steel structure shed, install and fix the embedded parts, and arrange welding and fixing in the pedestal reinforcement cage along the length direction of the pedestal reinforcement cage at intervals of 2.5m Plate 12 and fixed screw rod 11, fixed screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com