Method and device for processing slash marks on surface of pseudo-classic board

The technology of a processing device and a processing method is applied in the processing field of the machete mark processing device and the surface of the antique wooden board, which can solve the problems of high labor intensity, low production efficiency and high production cost, and achieves reduced labor intensity, high production efficiency, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

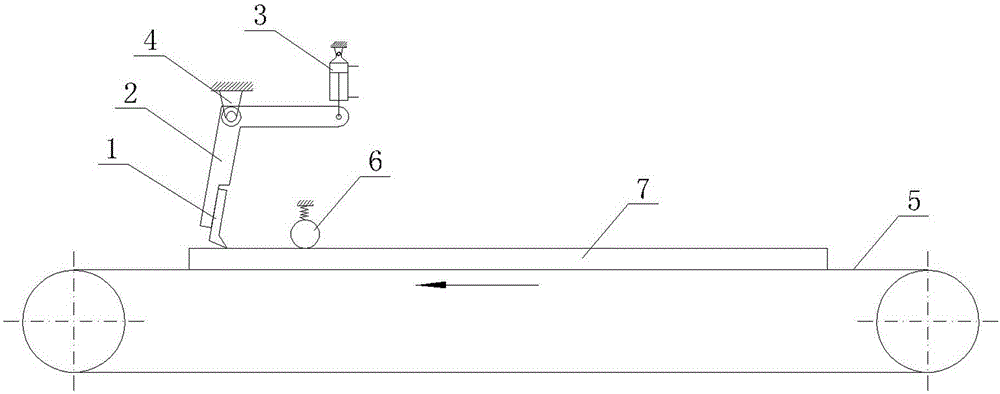

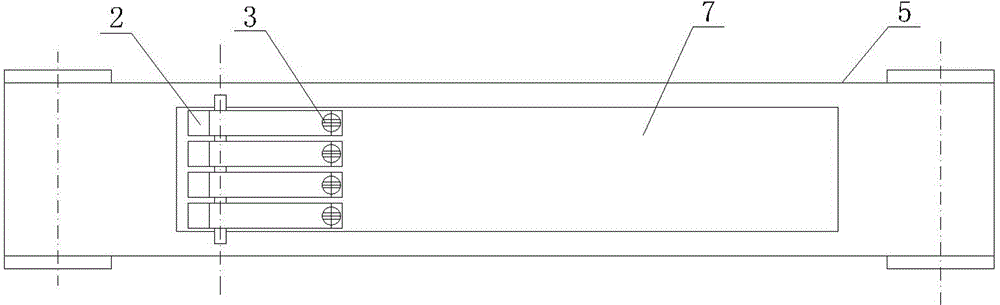

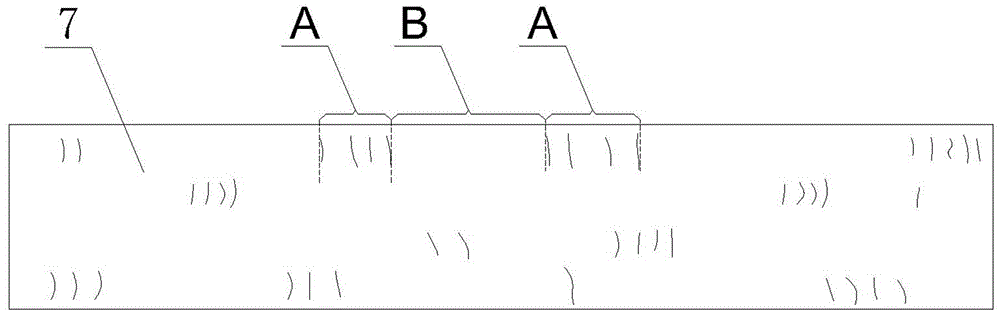

[0022] The method for processing the machete marks on the surface of the antique wood board provided by the present invention mainly uses the scraper 1 to process the artificial jumping knife through the machete mark processing device. The requirements for the machete marks on the surface of the antique wood board are: depth≤0.6mm, width≤50mm , the length of the area is ≤100mm, and the distance between the areas of the cutting marks along the length of the board is 200mm to 300mm, and they are staggered from each other in the width direction of the board. The machete mark processing device of this embodiment includes a scraper, a pendulum, a cylinder and a conveying mechanism, and its specific processing process is as follows:

[0023] Put the wooden board 7 on the conveyor belt 5, and the wooden board 7 moves forward steadily along the rotation direction of the conveyor belt 5 under the action of the pressing roller 6; , the swing frame 2 rotates counterclockwise around the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com