Cream-fat separation and cheese forming all-in-one machine based on traditional technology

An integrated machine and process technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, etc., and achieve the effect of ensuring sanitary conditions, increasing efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

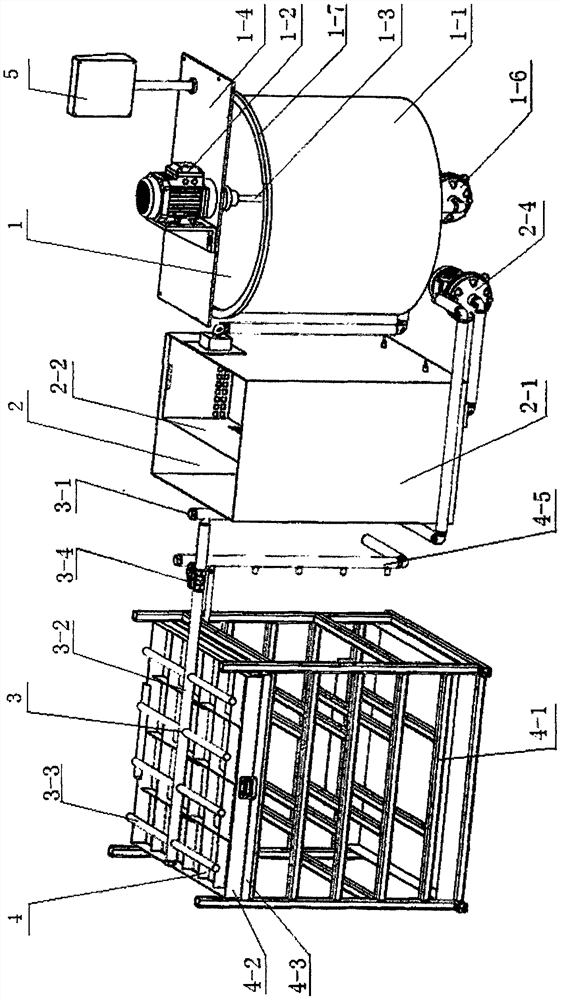

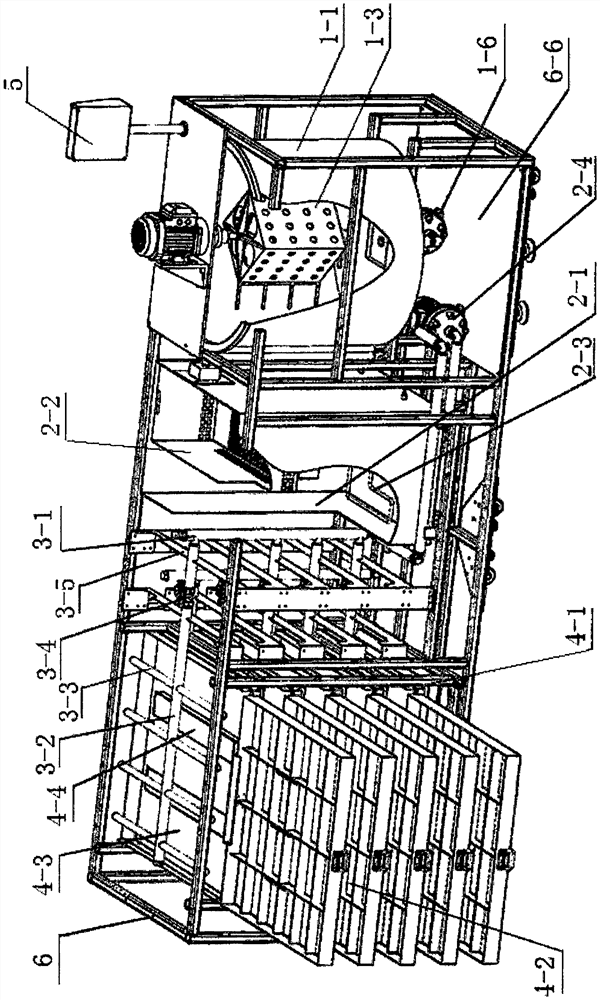

[0042] Embodiment 1: The milk fat separation and cheese forming integrated machine based on traditional technology in this embodiment is composed of a raw milk stirring system 1, a heating and disinfection system 2, a material distribution system 3, a mold device 4, a control system 5 and an overall frame 6;

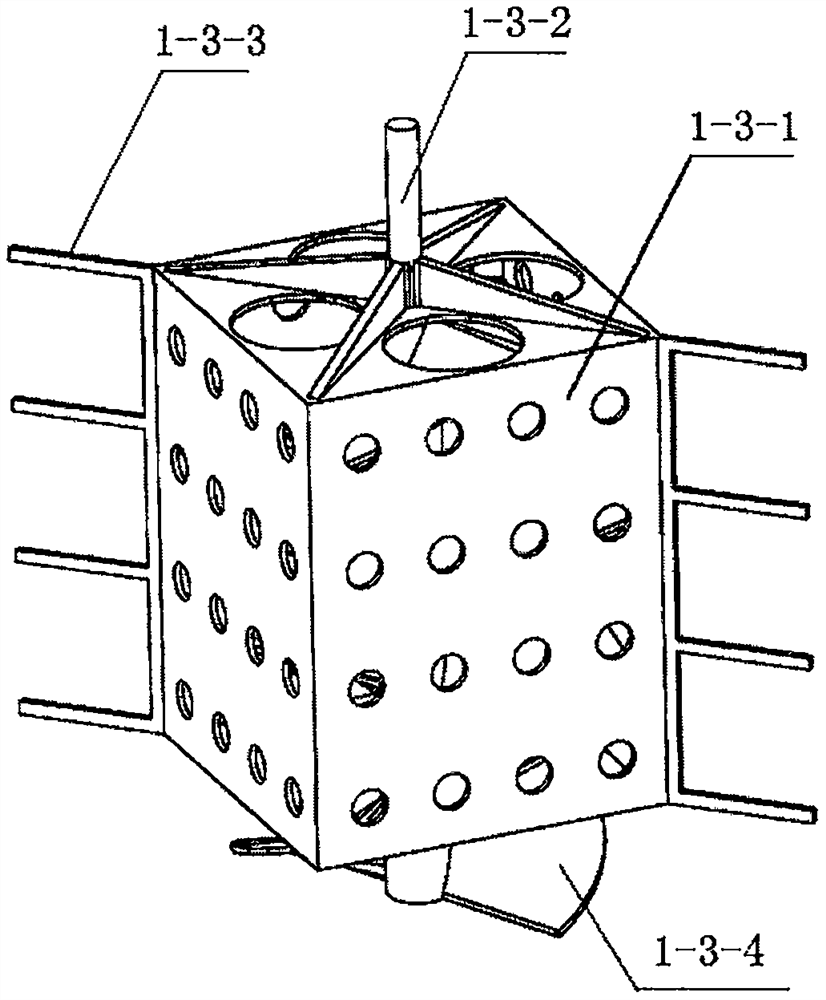

[0043] Wherein the raw milk mixing system 1 is composed of a raw milk mixing cylinder 1-1, a stirring motor 1-2, an agitator 1-3, a motor mounting plate 1-4, a raw milk mixing cylinder cover plate 1-5, a primary pump 1-6 and a sealing liner It consists of sets 1-7; the raw milk mixing tank 1-1 is a drum-shaped container with an open upper part, and a discharge port is provided at the bottom; the discharge port is connected with the feed port of the primary pump 1-6; the motor mounting plate 1- 4 and the cover plate 1-5 of the raw milk mixing tank are arranged side by side on the upper part of the raw milk mixing tank 1-1, and the stirring motor 1-2 is fixedly installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com