Patents

Literature

31 results about "Ideal machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term ideal machine refers to a hypothetical mechanical system in which energy and power are not lost or dissipated through friction, deformation, wear, or other inefficiencies. Ideal machines have the theoretical maximum performance, and therefore are used as a baseline for evaluating the performance of real machine systems.

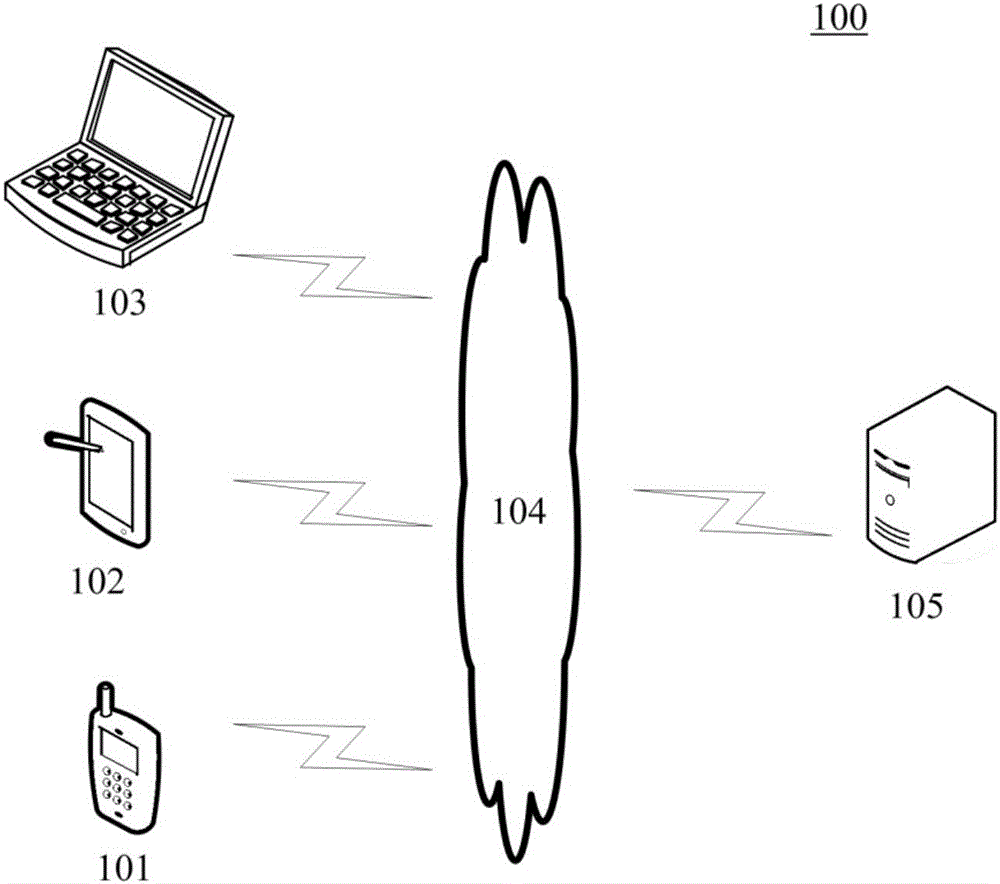

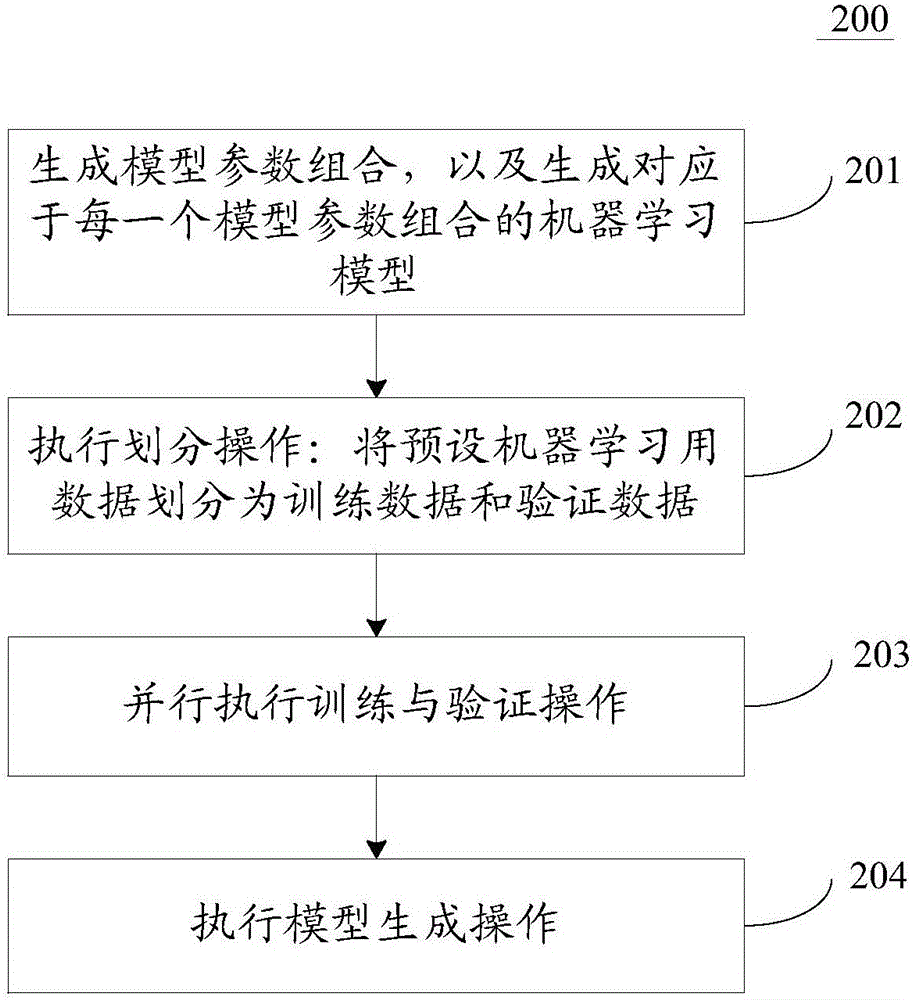

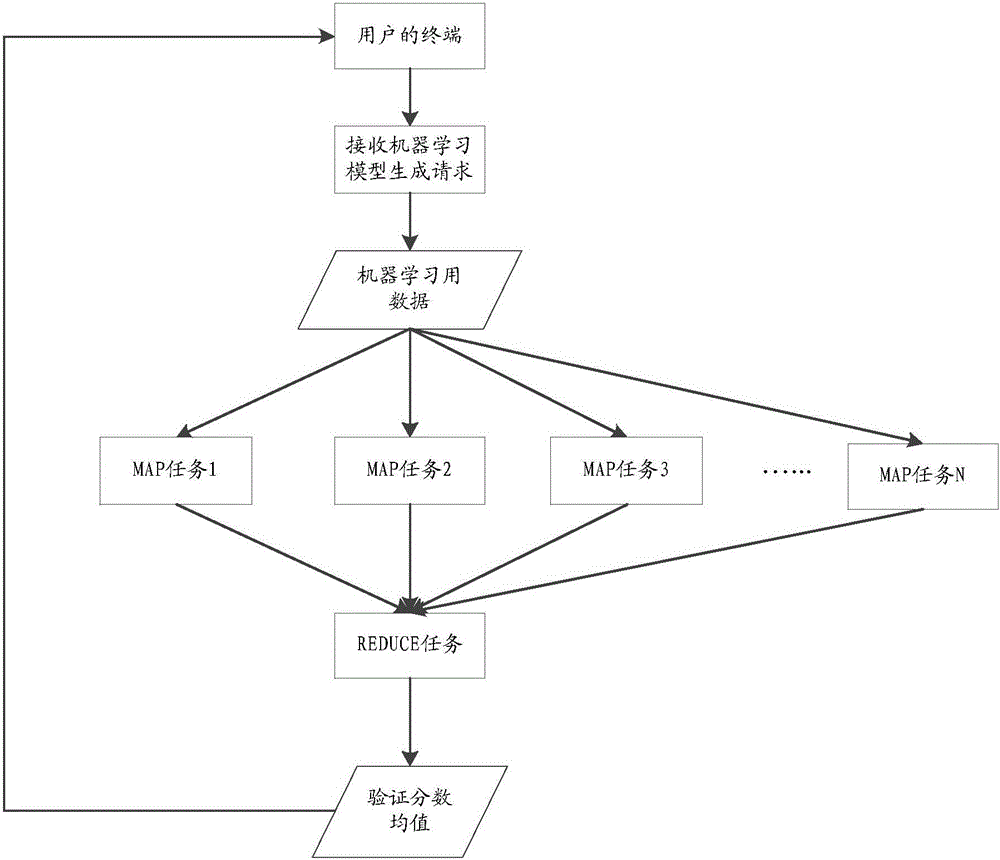

Machine learning model generation method and machine learning model generation device

ActiveCN105912500AQuick buildSpeed up searchDigital computer detailsMachine learningLearning dataModel parameters

The invention discloses a machine learning model generation method and a machine learning model generation device. According to a specific embodiment, the method comprises the following steps: generating model parameter combinations, and generating machine learning models respectively corresponding to the model parameter combinations; dividing preset machine learning data into training data and verification data; training the machine learning models in parallel based on the training data; verifying the learning accuracy of the trained machine learning models based on the verification data to get verification scores, and determining an optimal model parameter combination corresponding to a machine learning model to be generated based on the verification scores, and generating a machine learning model corresponding to the optimal model parameter combination. Through the method and the device, machine learning models corresponding to all model parameter combinations can be trained and verified in parallel, the whole process of parameter optimization is improved, and an ideal machine learning model can be generated quickly.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

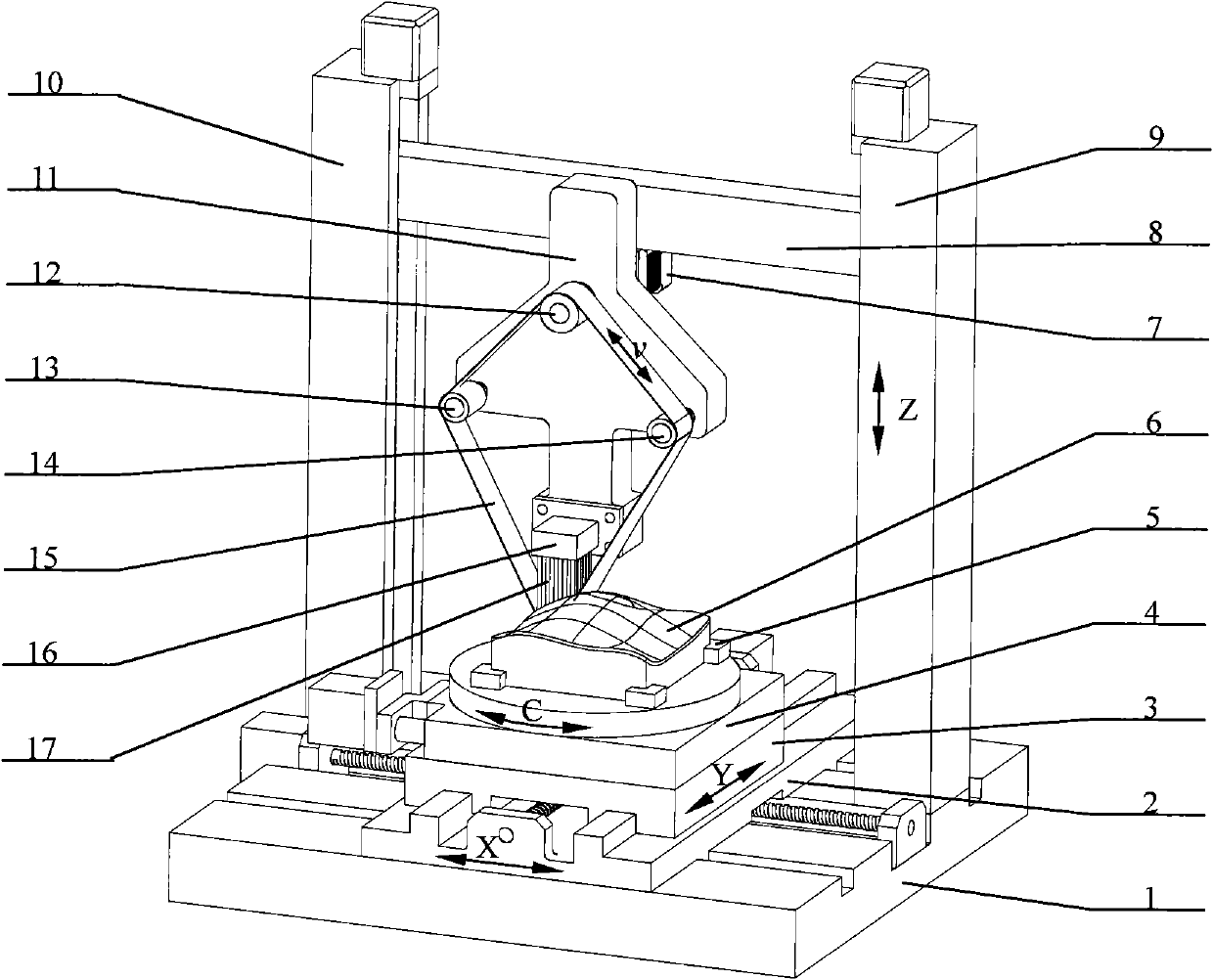

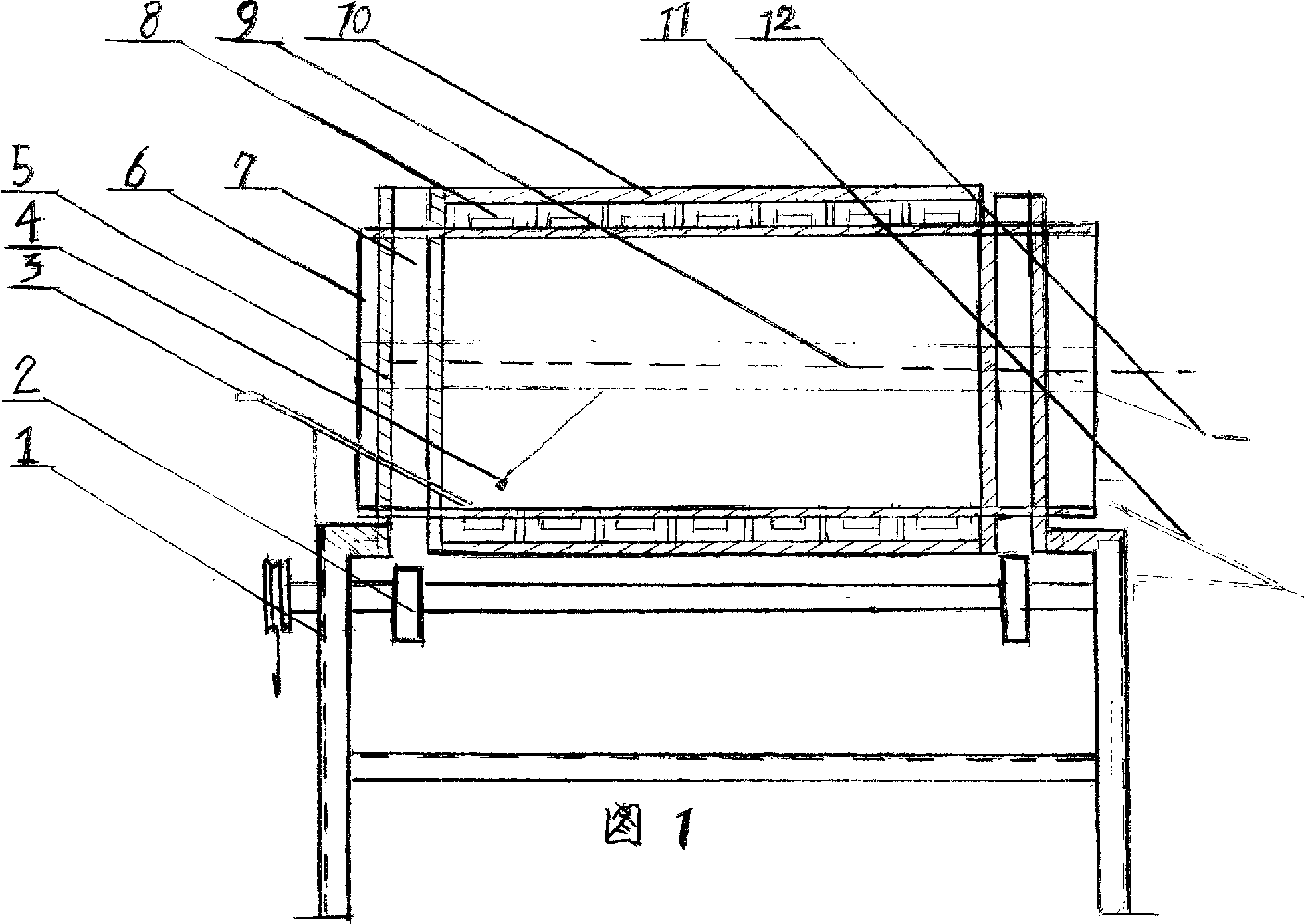

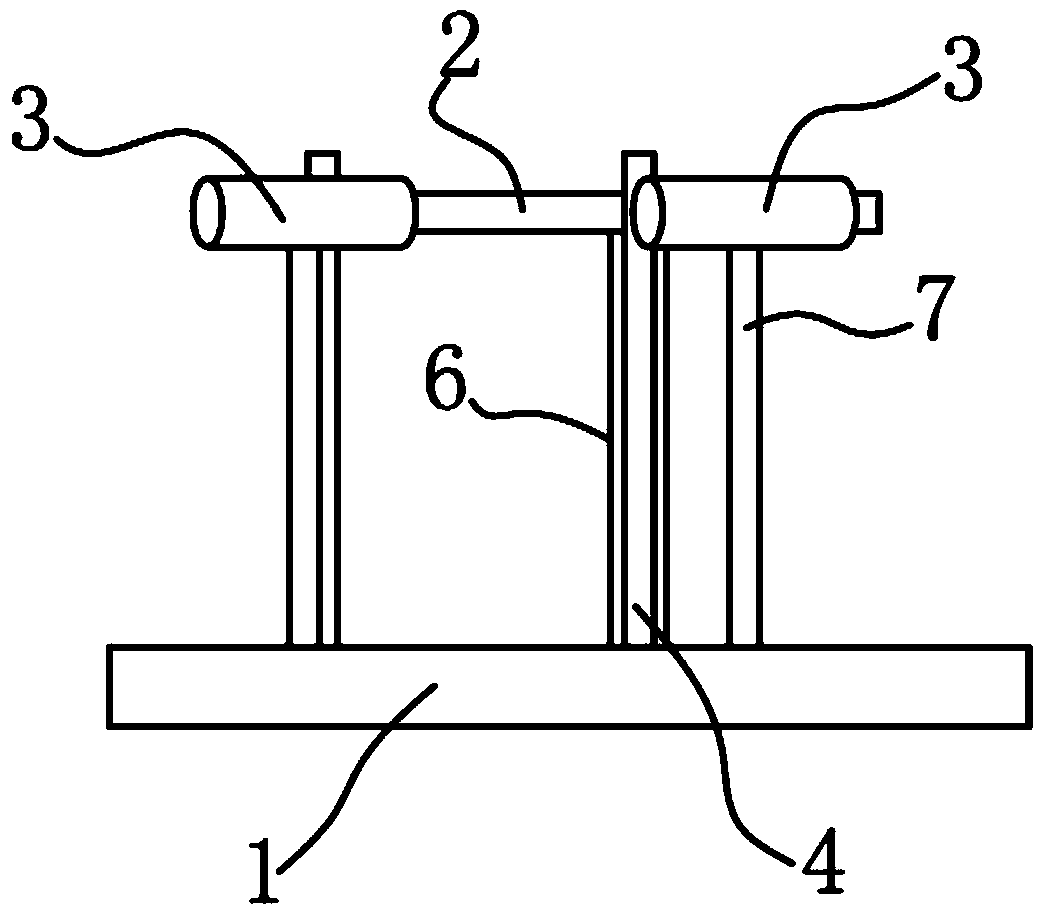

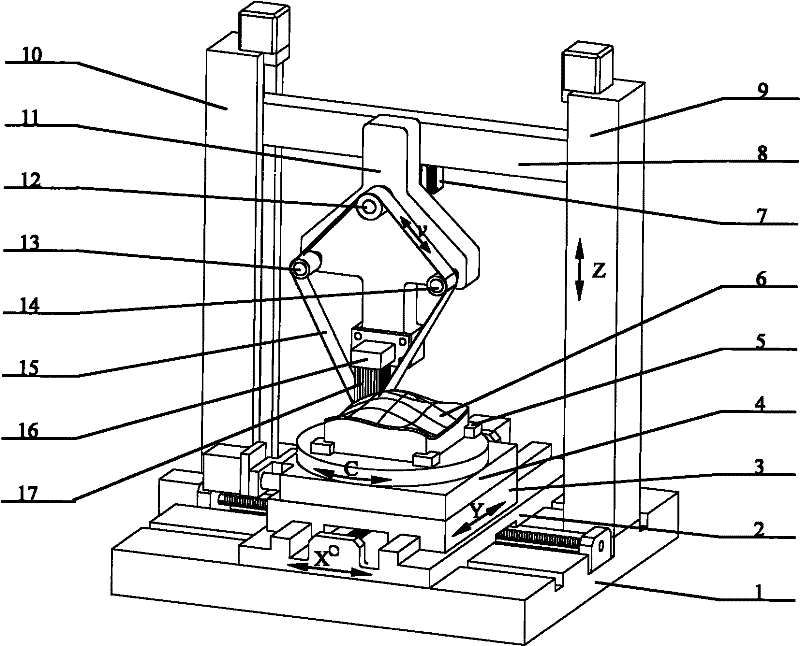

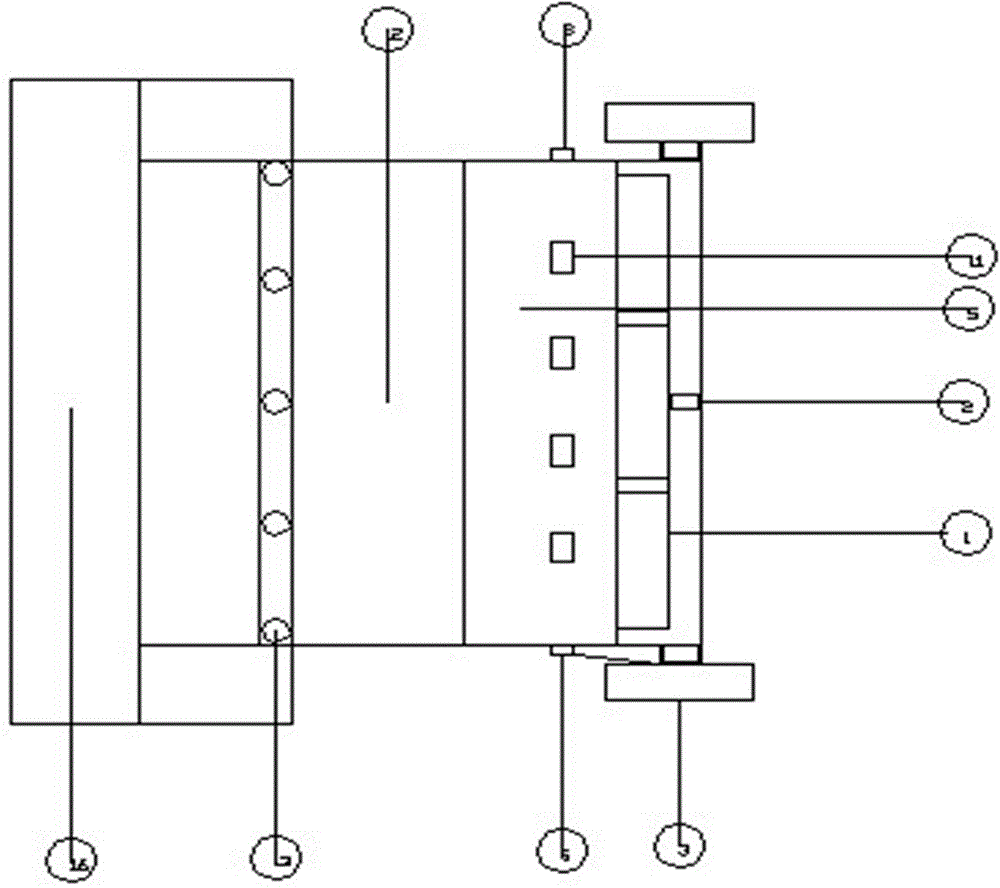

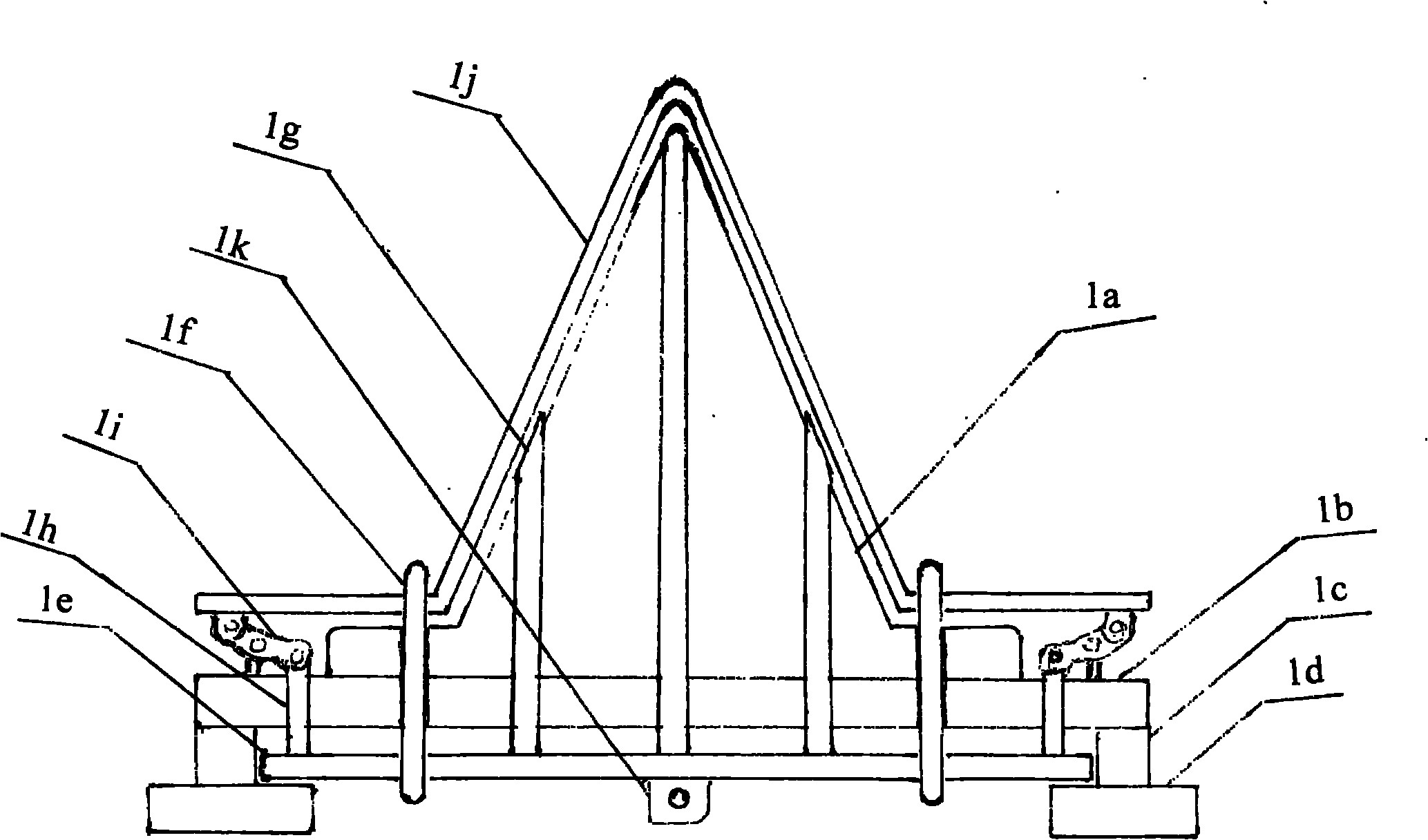

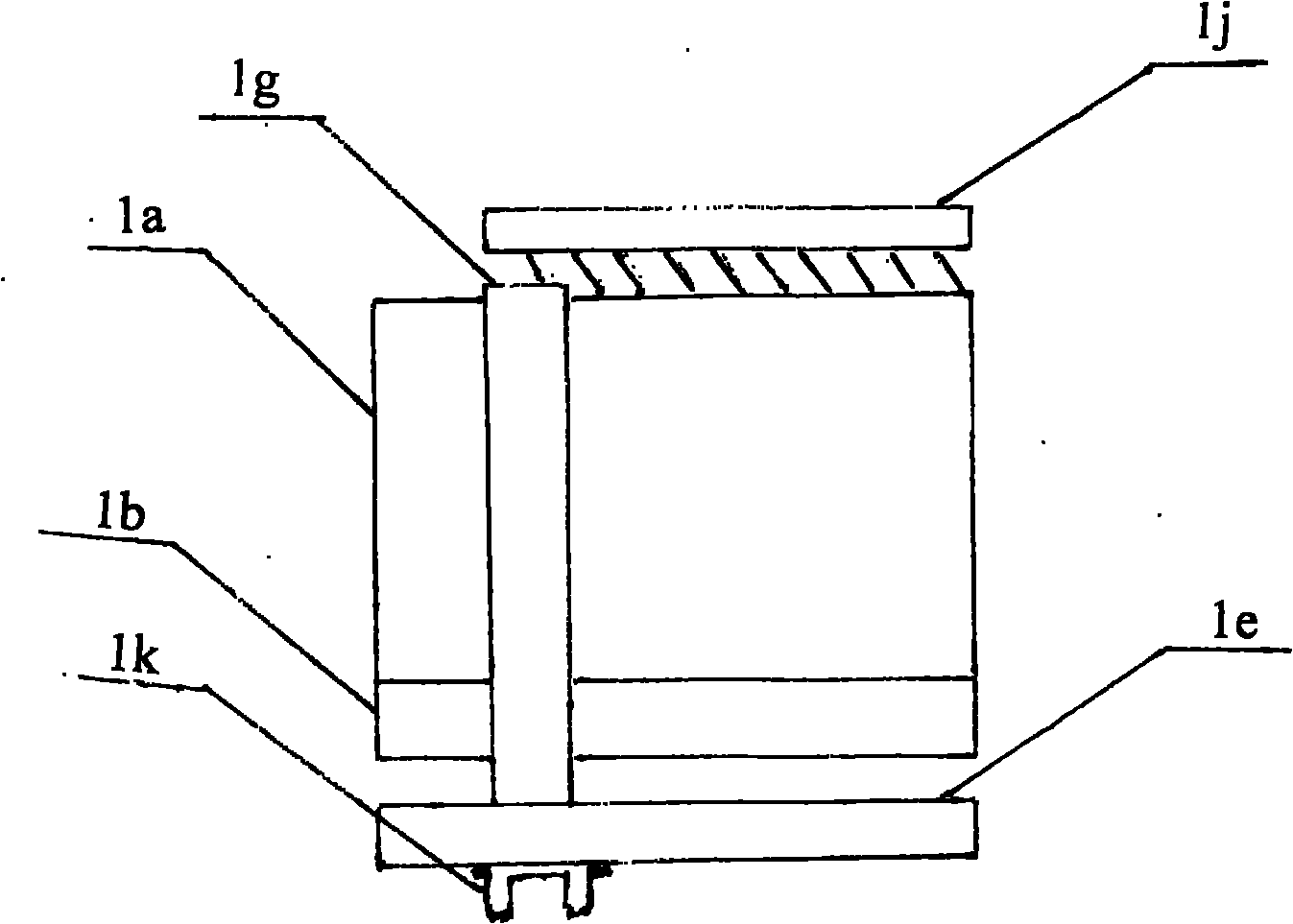

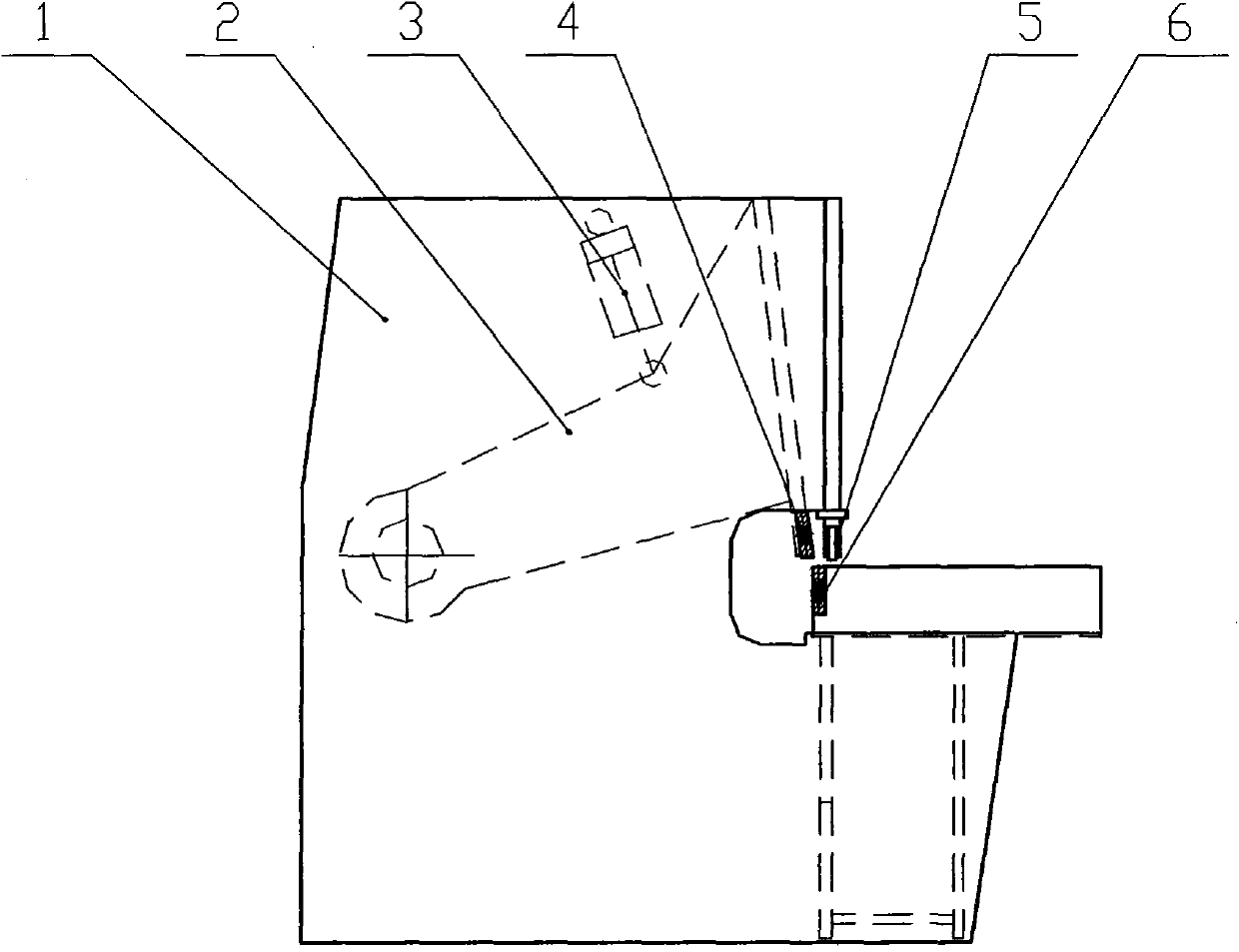

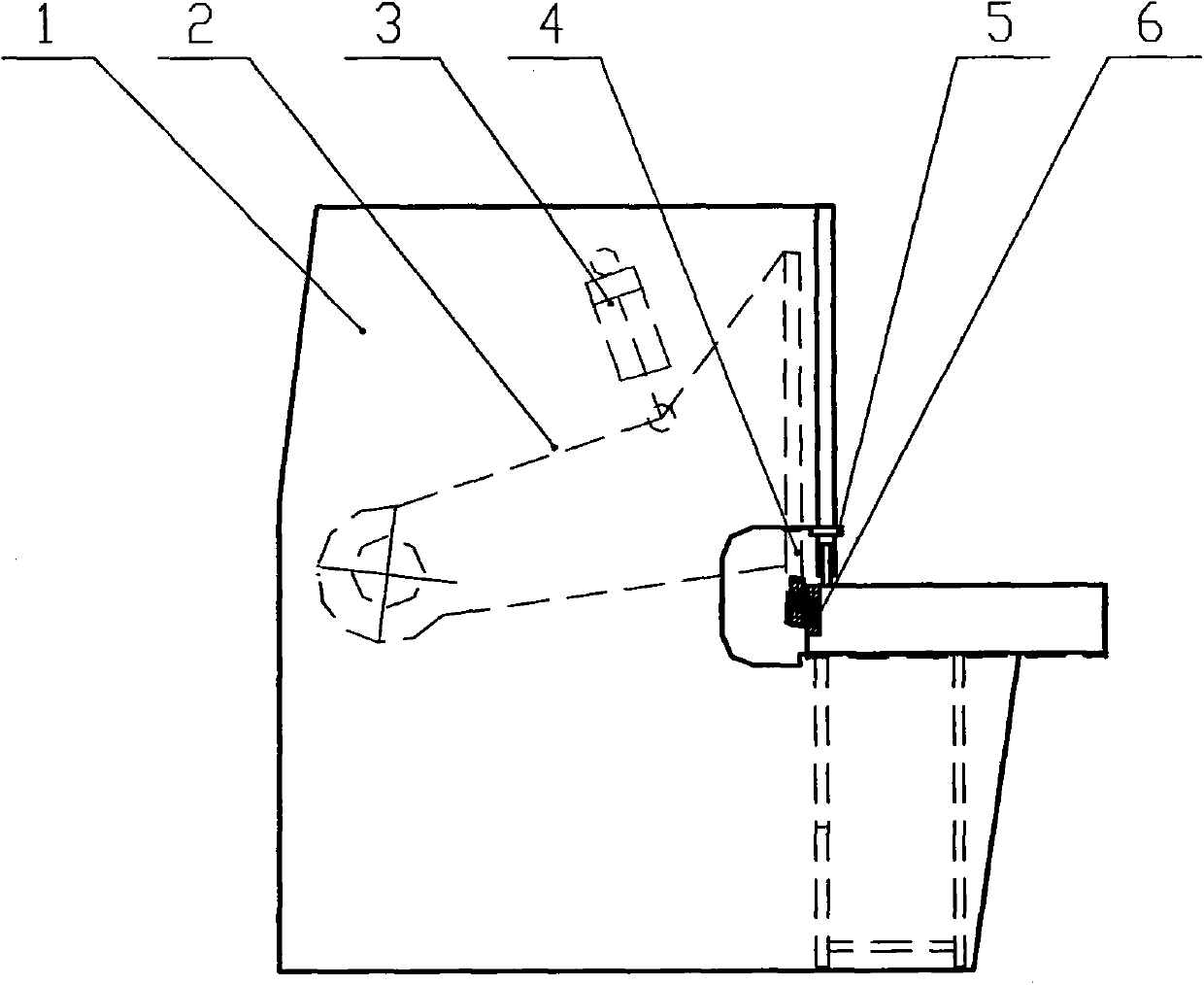

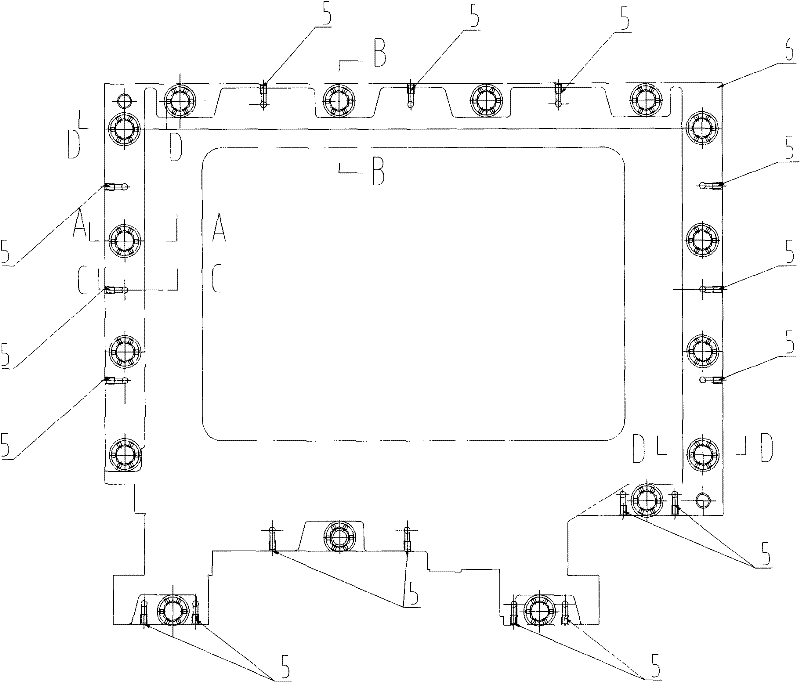

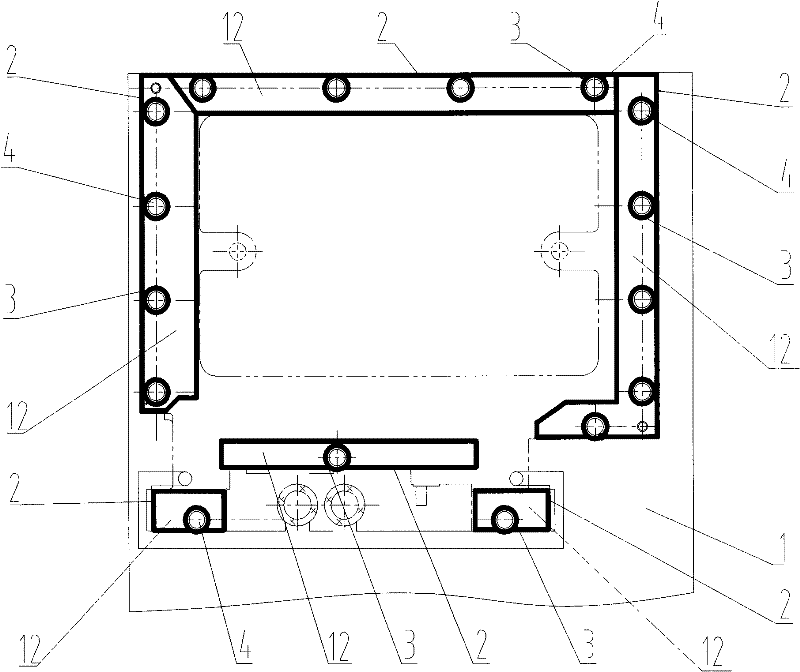

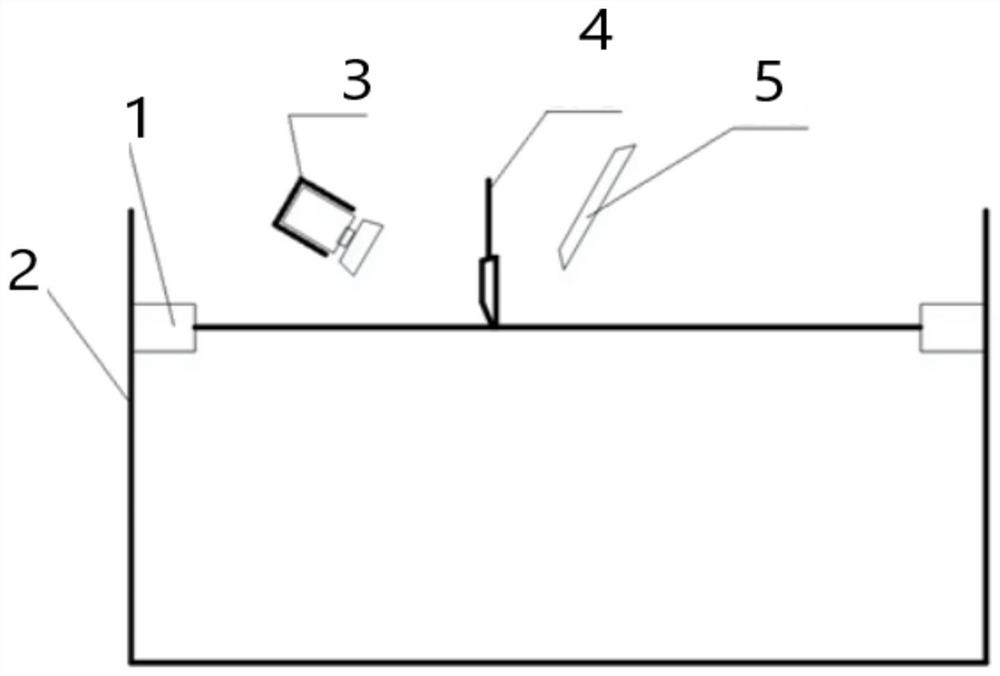

Adaptive machine tool for grinding and polishing complex surfaces

InactiveCN102019571AImprove efficiencyImprove machining accuracyGrinding machinesMachined surfaceEngineering

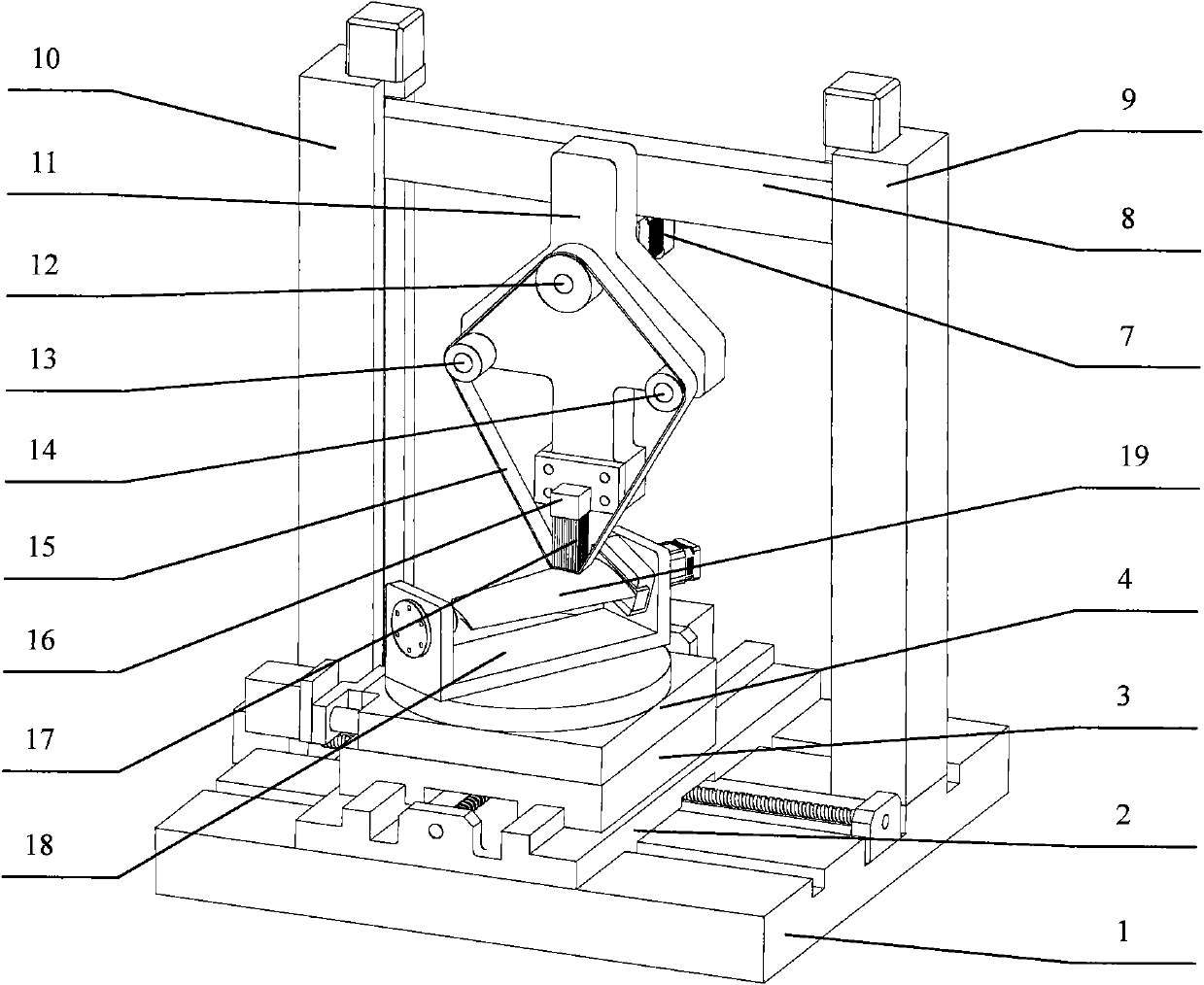

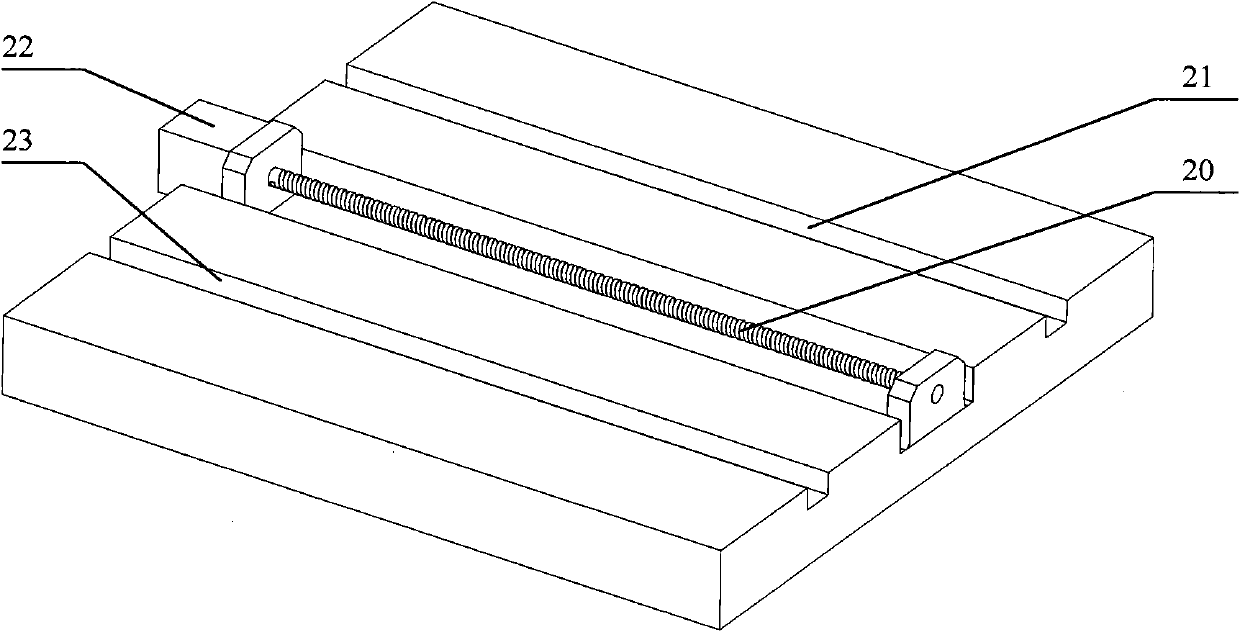

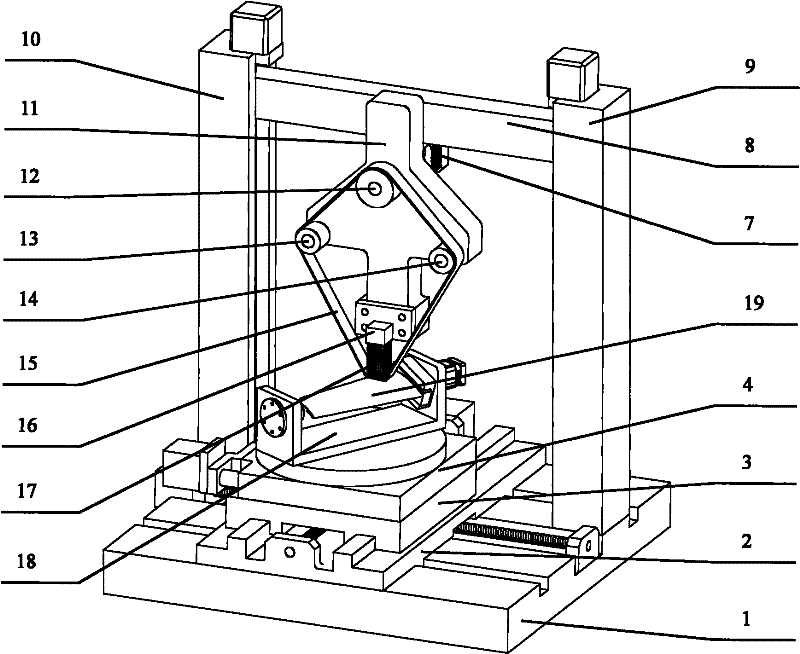

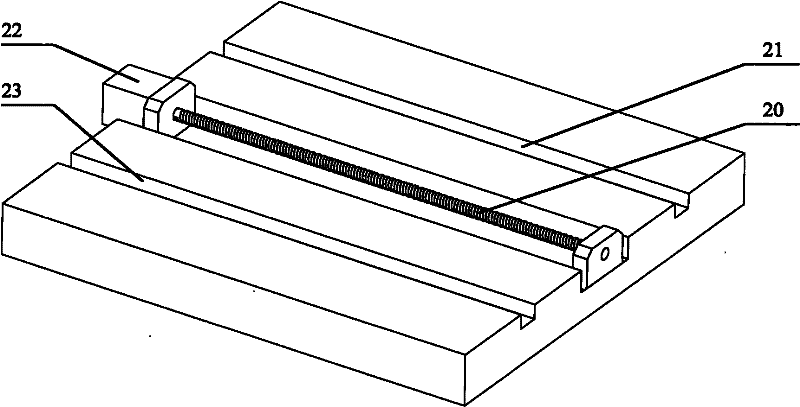

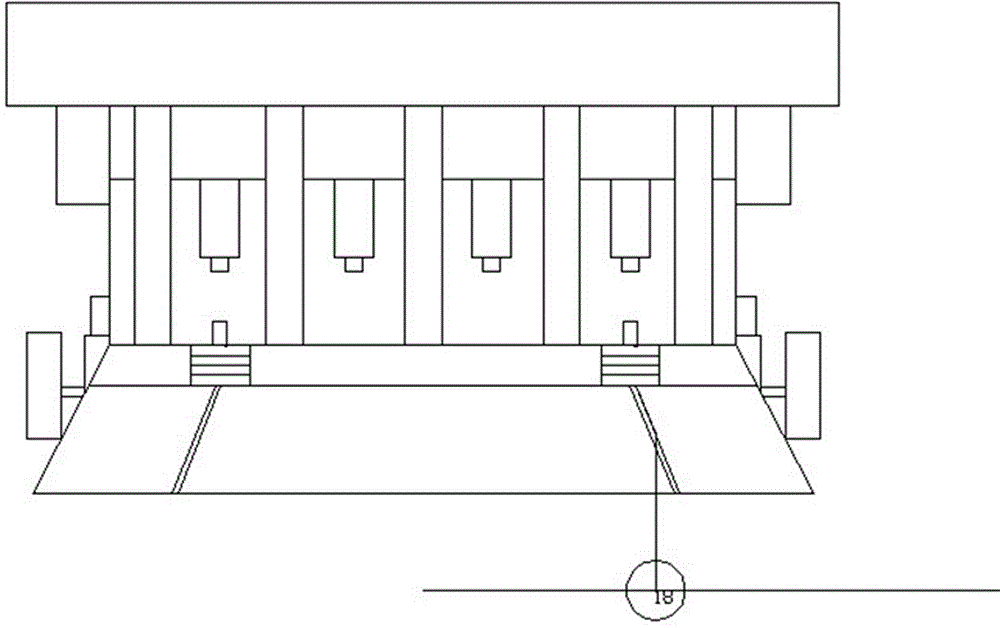

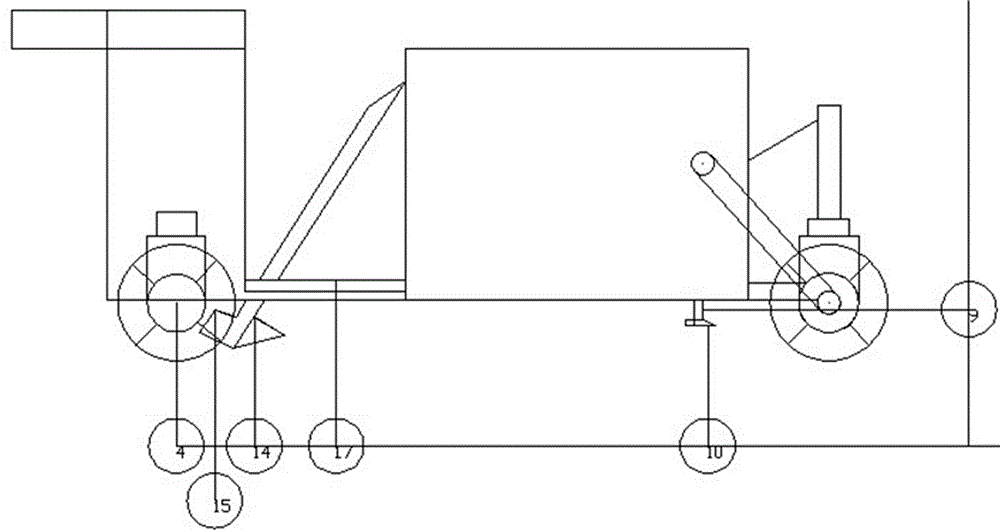

The invention provides an adaptive machine tool for grinding and polishing complex surfaces, belonging to the technical field of mechanical manufacture. The adaptive machine tool is characterized in that the lower ends of a left column and a right column are fixedly connected with a base; the left column is connected with the left end of a cross beam via a screw and a slide guide of the left column; the right column is connected with the right end of the cross beam via a screw and a slide guide of the right column; the middle of the cross beam is fixedly connected with a tool plate; a lower slide carriage is connected with the base via a screw, a front guide and a rear guide of the lower slide carriage; an upper slide carriage is connected with the lower slide carriage via a screw, a left guide and a right guide of the upper slide carriage; and a rotary table is fixedly connected with the upper slide carriage. The adaptive machine tool has the following advantages: the zones at the four sides are divided to serve as the grinding and polishing contact surfaces to grind and polish the parts with complex surfaces, so that the machine tool has high grinding and polishing efficiency and strong adaptability and can maintain the sharp shape characteristic of the complex surfaces; and the appearance of the contact tool head of the novel grinding and polishing tool system built based on multipoint forming technology can be regulated in real time according to the shape of the ideal machined surface, thus reducing the degree of freedom of design of the machine tool and enhancing the flexibility of the machine tool.

Owner:JILIN UNIV

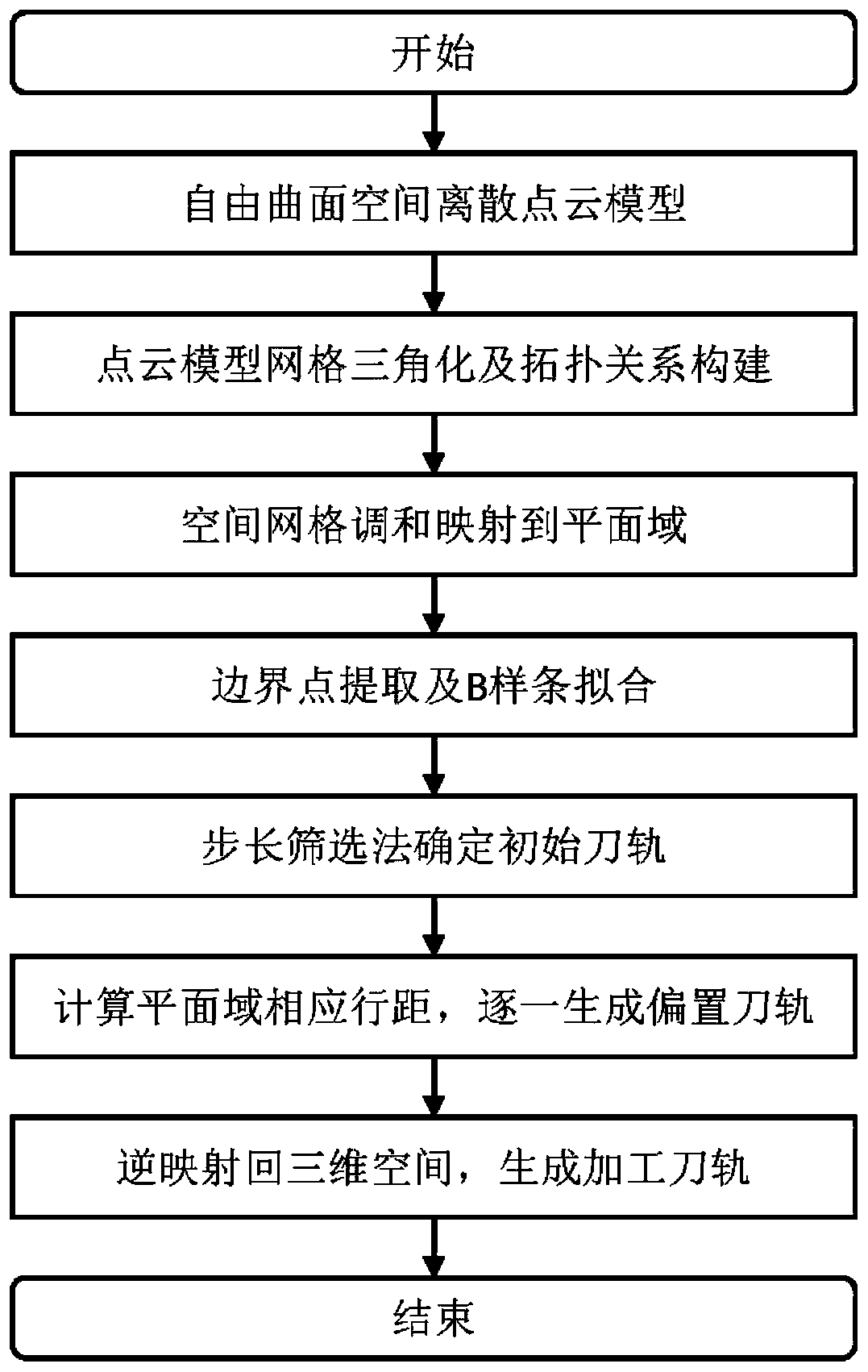

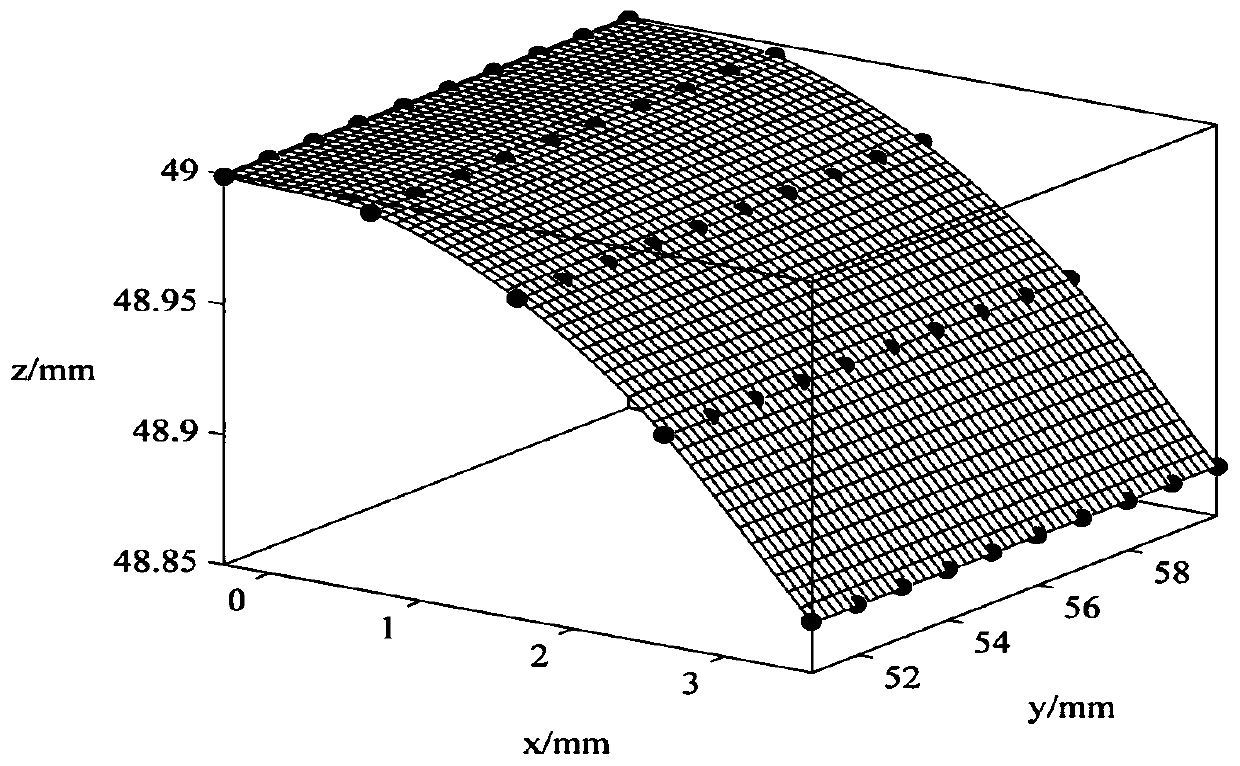

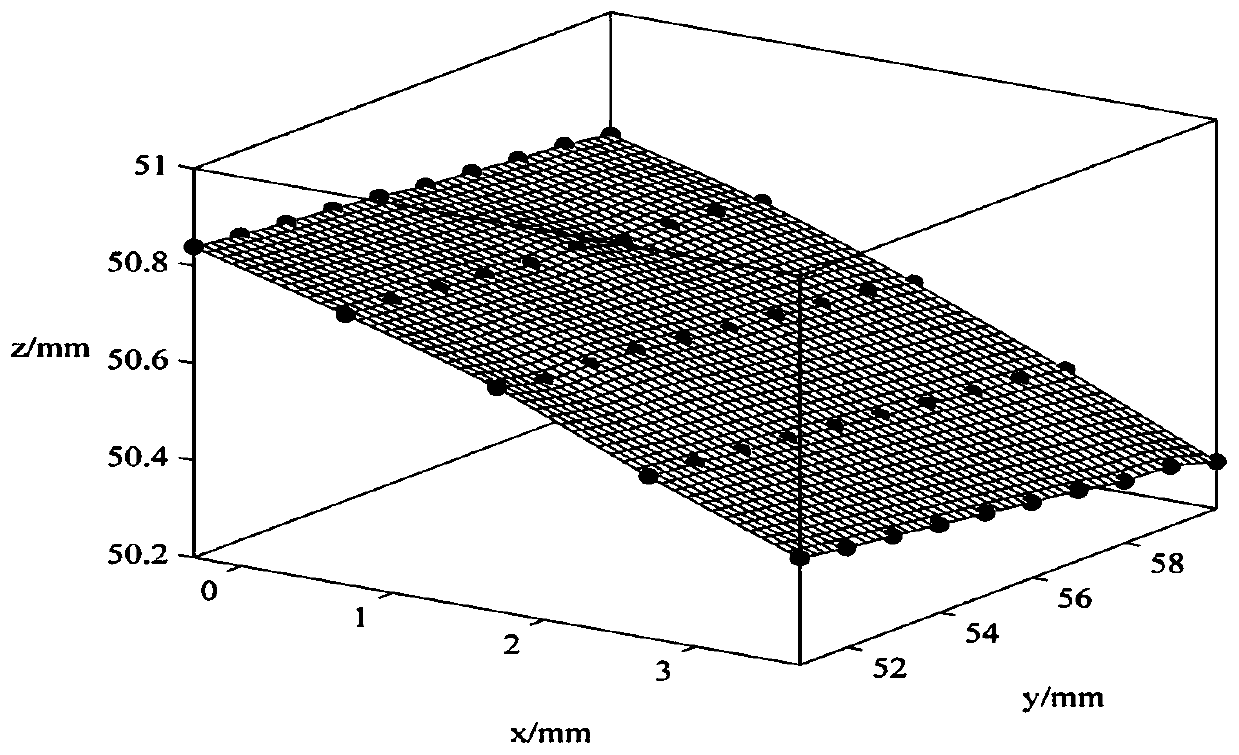

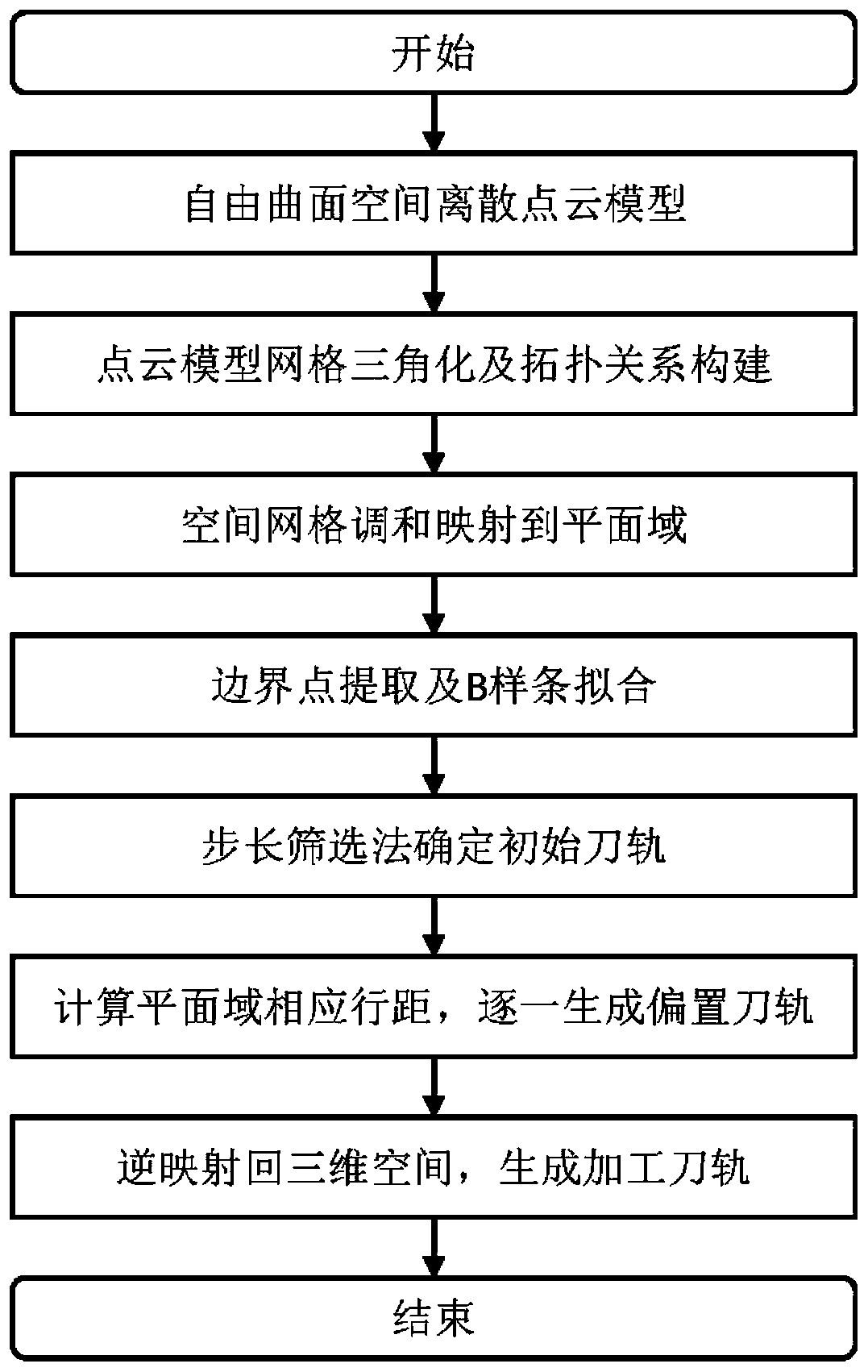

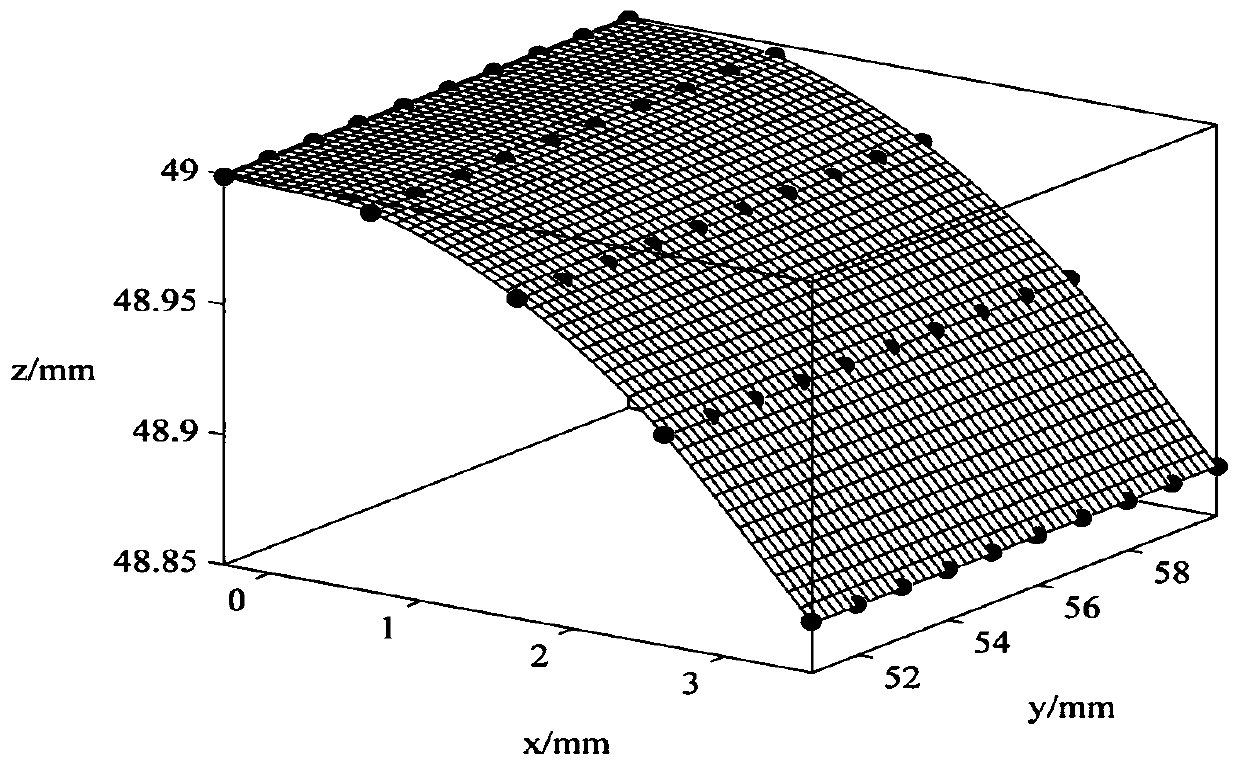

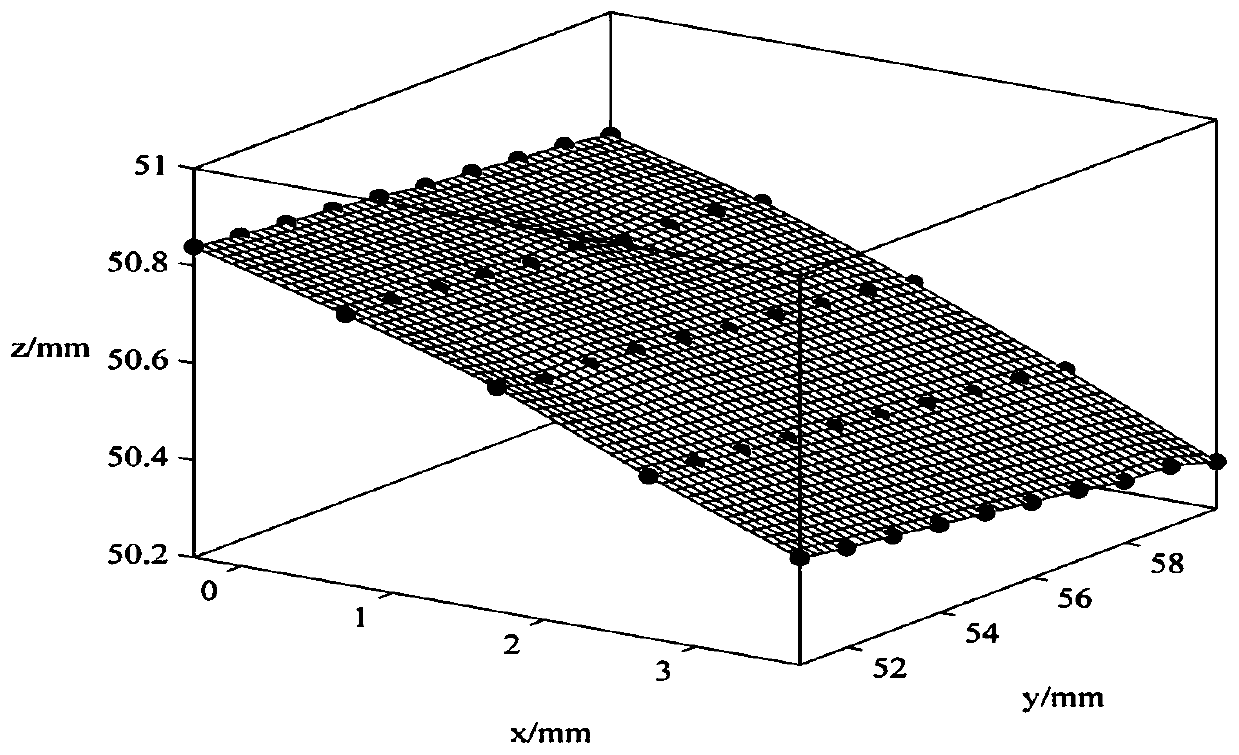

Thin-wall curved surface surface pattern laser processing track solving method

ActiveCN111581874AAccurate solutionReduce laser processing errorsDetails involving processing stepsDesign optimisation/simulationSurface patternLaser processing

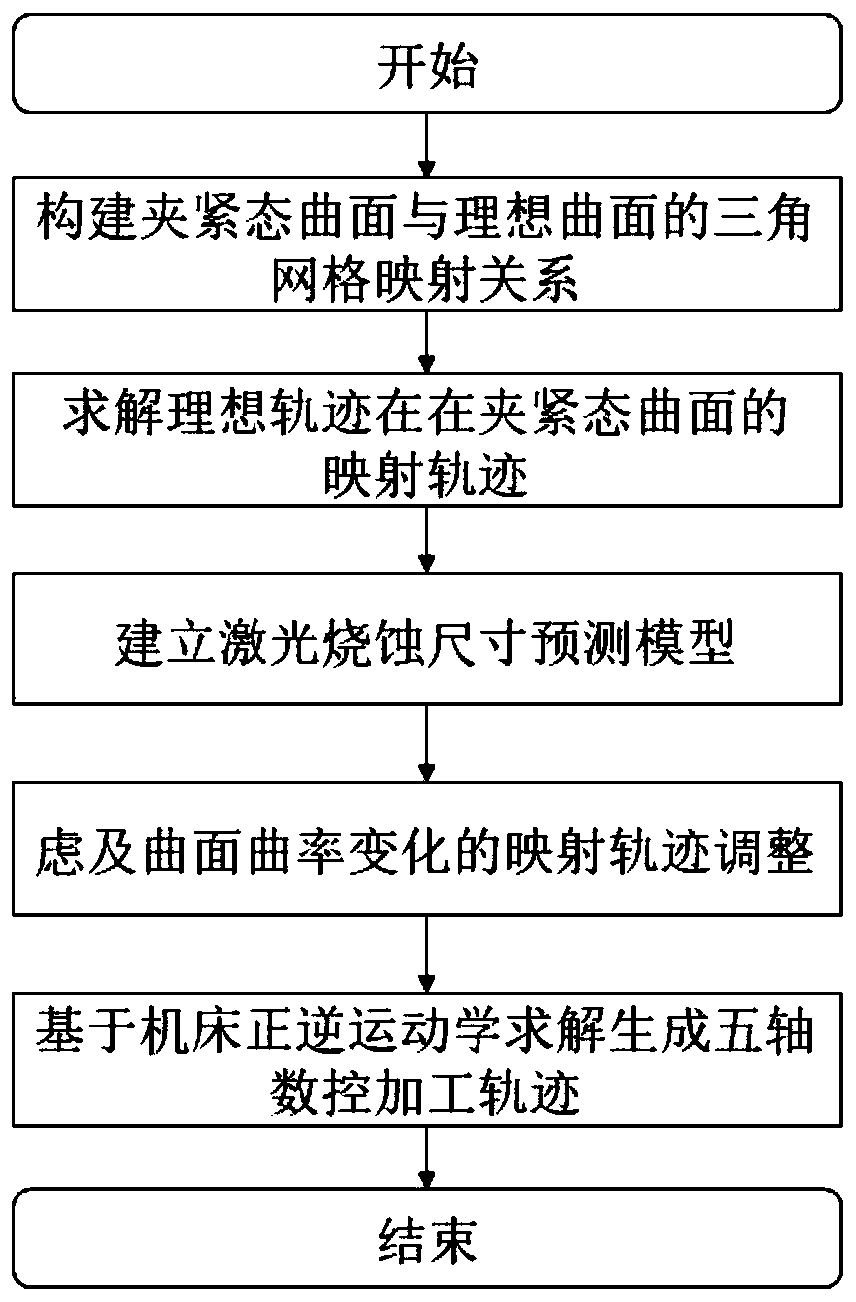

The invention belongs to the technical field of thin-wall curved surface layer pattern precision manufacturing, and relates to a thin-wall curved surface layer pattern laser processing track solving method. According to the method, clamping state curved surface point cloud data are obtained through a three-coordinate measuring machine according to the clamping deformation characteristics of the thin-wall curved surface part and mapped to an ideal curved surface in the radial direction, the mapping relations between the clamping state curved surface and an ideal curved surface triangular mesh are constructed, and the mapping track of an ideal machining track on the clamping state curved surface is solved. A model is predicted according to laser ablation size; and discretizing solving is performed on the ablation depth and the ablation width of the material at any cutter location point on the mapping track, instantaneous machining parameter change caused by surface curvature change is considered and local machining track point adjustment is made on the out-of-tolerance position of the pattern curve size or contour to finally generate a five-axis numerical control machining track conforming to the machining precision. The method reduces machining errors caused by clamping deformation, and is suitable for precision machining of thin-wall curved surface surface patterns.

Owner:DALIAN UNIV OF TECH

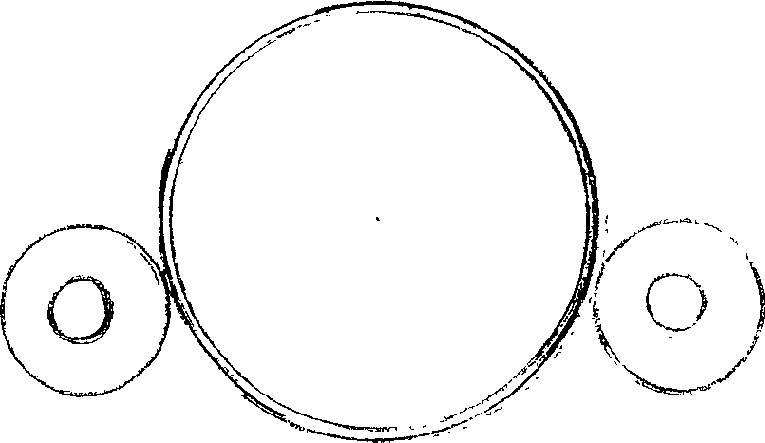

Magnet field adjustable magnetic separator

This invention concerns rotation roller type magnetic separator comprised by magnet, whose fix magnetic field can not be adjusted led to conflict that field strengthen is not fit to selected minerals. To match of field strengthen flexibly minerals characters that field strengthen varieties with mineral character and match to take ideal selection, in this invention, reset the received magnetic cylinder inside and ejection magnetic cylinder outside, and the part is switching to adjust magnetic field distance for field strengthen according to need. It is ideal machine to adjust field strengthen any moment.

Owner:李文武

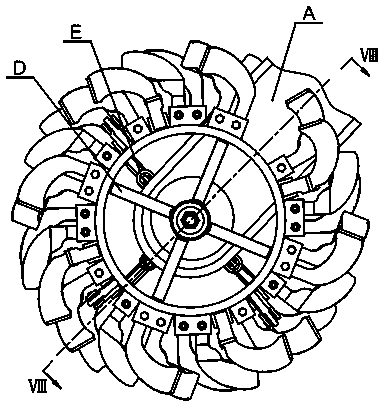

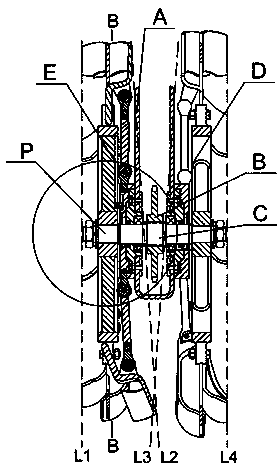

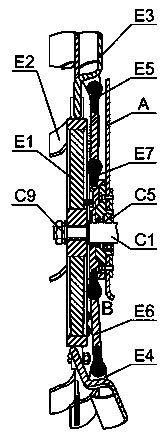

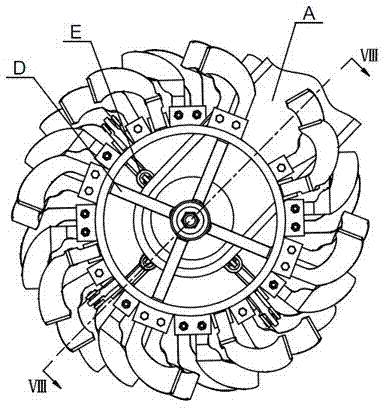

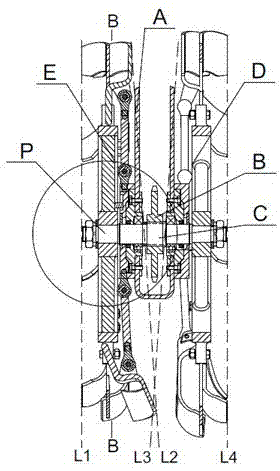

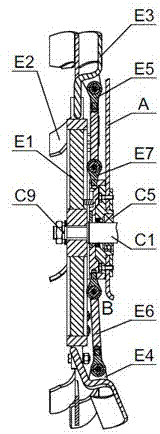

Inner deflection swinging cutter blade type ditching cutter head and driving device thereof

InactiveCN103621202AGuaranteed assembly accuracySolve the problem of missing tillageTilling equipmentsPower equipmentEngineering

The invention provides an inner deflection swinging cutter blade type ditching cutter head and a driving device thereof. The inner deflection swinging cutter blade type ditching cutter head comprises a driving box, a driving sprocket, a driving main shaft, a left cutter head device and a right cutter head device, wherein the driving box is arranged on external power equipment, the driving main shaft is arranged on the driving box, the driving box is used for providing power transmission and meanwhile completing the installation and supporting of the other parts, the left cutter head device and the right cutter head device are identical in structure, are arranged at the two sides of the driving box and are respectively arranged on the driving main shaft, the driving sprocket is arranged in the middle of the driving main shaft, and the external power equipment is used for driving the driving sprocket through a chain, so that the driving main shaft is driven to rotate. The inner deflection swinging cutter blade type ditching cutter head is simple in structure, convenient to operate, driven by an eccentric wheel and used for driving a movable cutter blade to deflect so as to realize the variable cross-section soil cutting and has strong practicability; a cutting gearbox is used for blocking part of soil blocks; and the inner deflection swinging cutter blade type ditching cutter head can be used for completely solving the problem that a small-sized self-propelled ditcher cannot be adapted to southland moist clay, and is an ideal machine tool for the ditcher for wooden lands, tea gardens and vegetable gardens.

Owner:HUNAN AGRICULTURAL UNIV

Ultra-thin stone cutting machine and processing method thereof

InactiveCN105643817AAvoid the risk of being fragile and easy to moveFirst-class precisionWorking accessoriesStone-like material working toolsElectricityFixed frame

The invention provides an ultra-thin stone cutting machine and a processing method thereof. The ultra-thin stone cutting machine comprises a first motor group, a second motor group, a sliding support, a first fixing frame, a second fixing frame, a working table, a first controller and a second controller. The ultra-thin stone cutting machine is automatic four-cutter continuous-cutting equipment, and a sectioning processing procedure of ultra-thin stone comprises steps as follows: after a left surface and a right surface of the ultra-thin stone are sectioned by cutting blades driven by the first motor group, the working table is moved to the second motor group for sectioning of the upper surface and the lower surface. The problems that an ultra-thin plate is prone to movement and is fragile, the working efficiency is low and the raw material utilization rate is low when a conventional single-blade cutter is adopted for processing are solved, and the plate after sectioning can be subjected to one-time processing molding on the machine, and precision and efficiency are the best. During working, the plate is cut by two blades simultaneously, the risks that the ultra-thin plate is fragile and is prone to movement are eliminated, the finished product rate is greatly increased, and the ultra-thin stone cutting machine is the most ideal machine model at present for cutting the ultra-thin plate.

Owner:QINGDAO BOLEI PRECISION MACHINERY MFG CO LTD

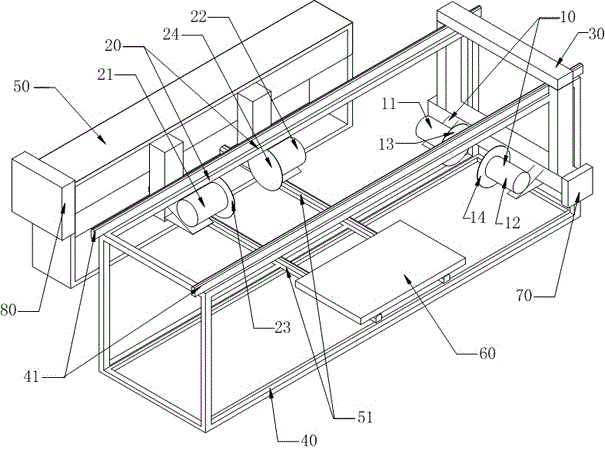

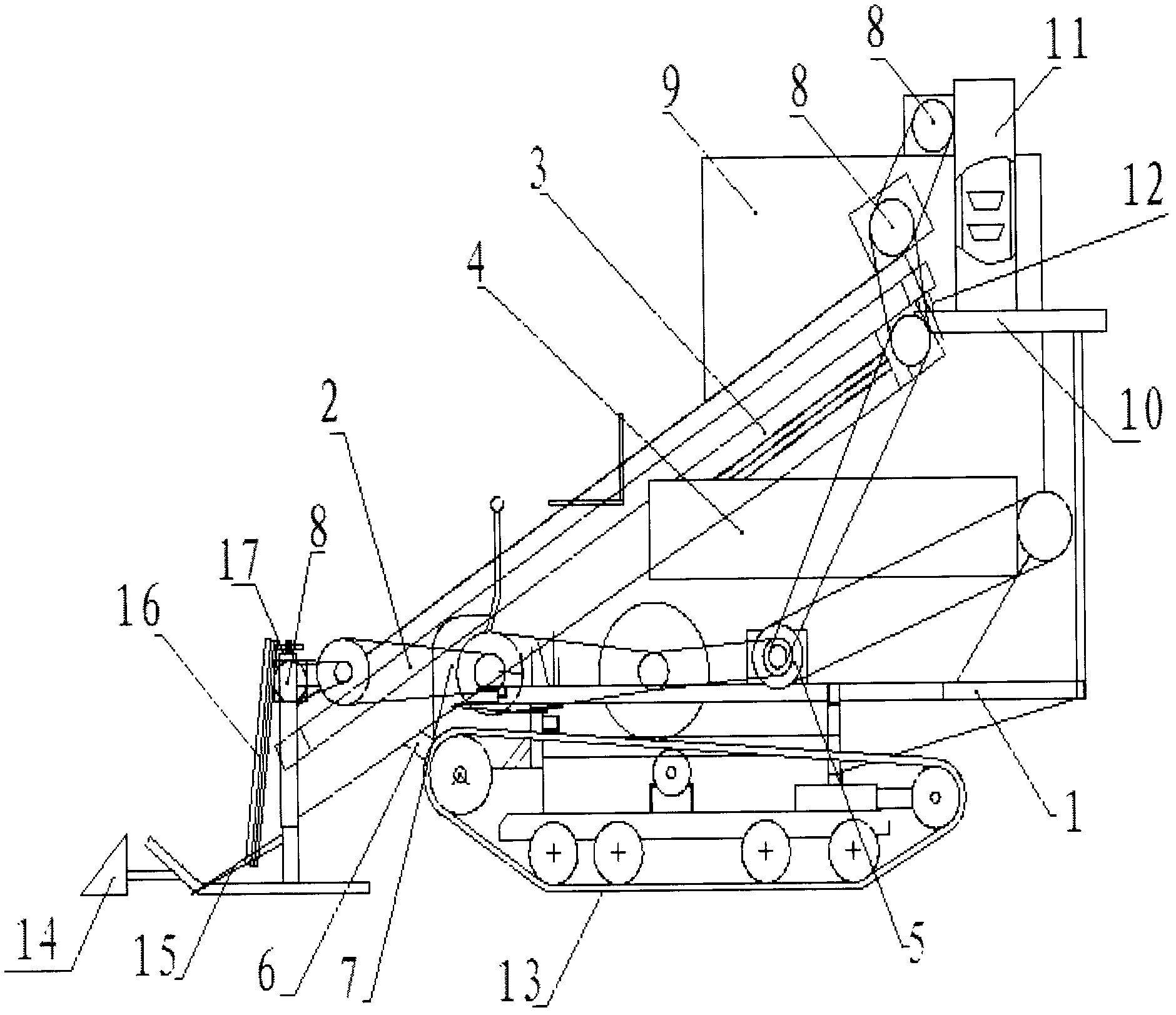

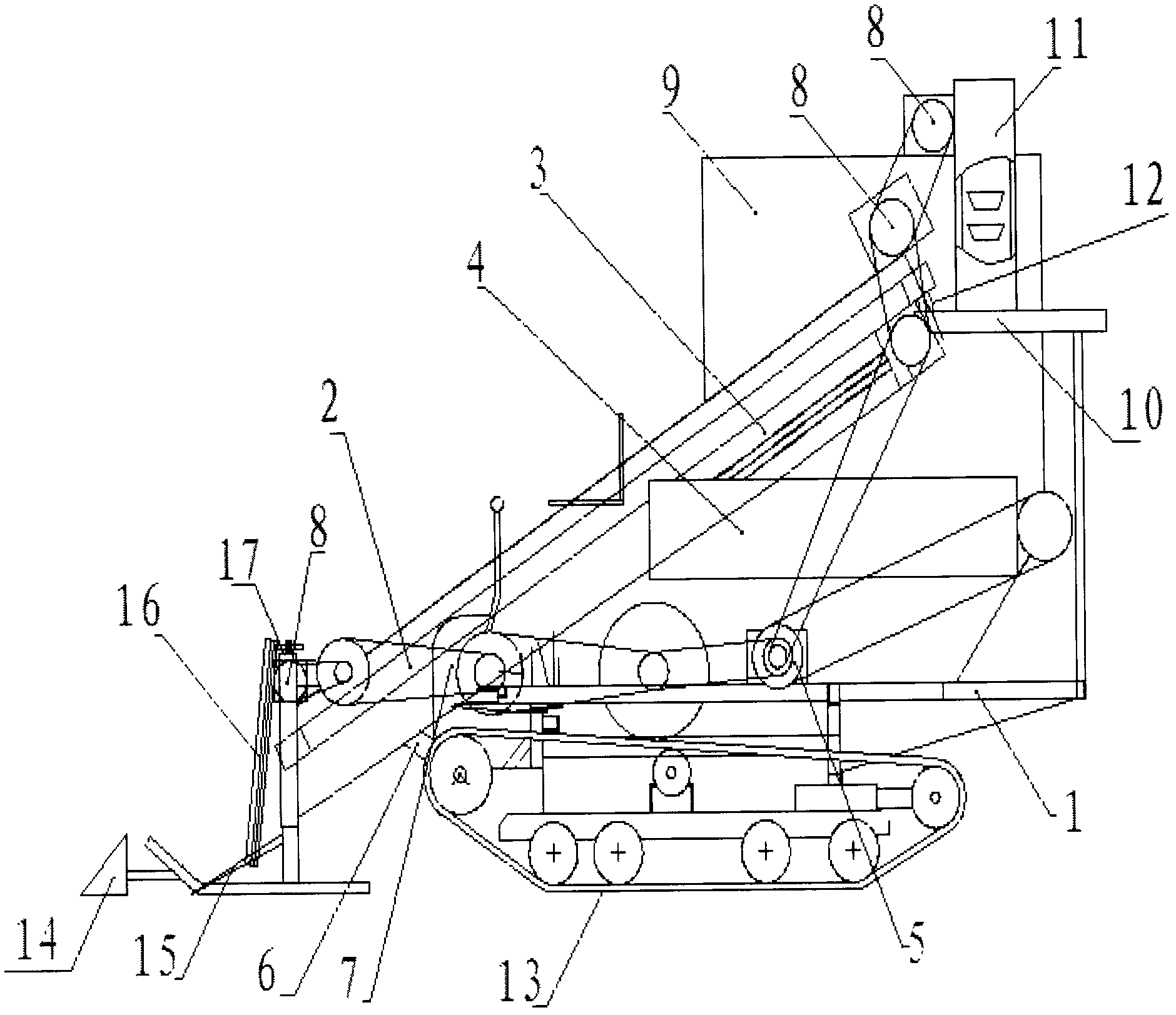

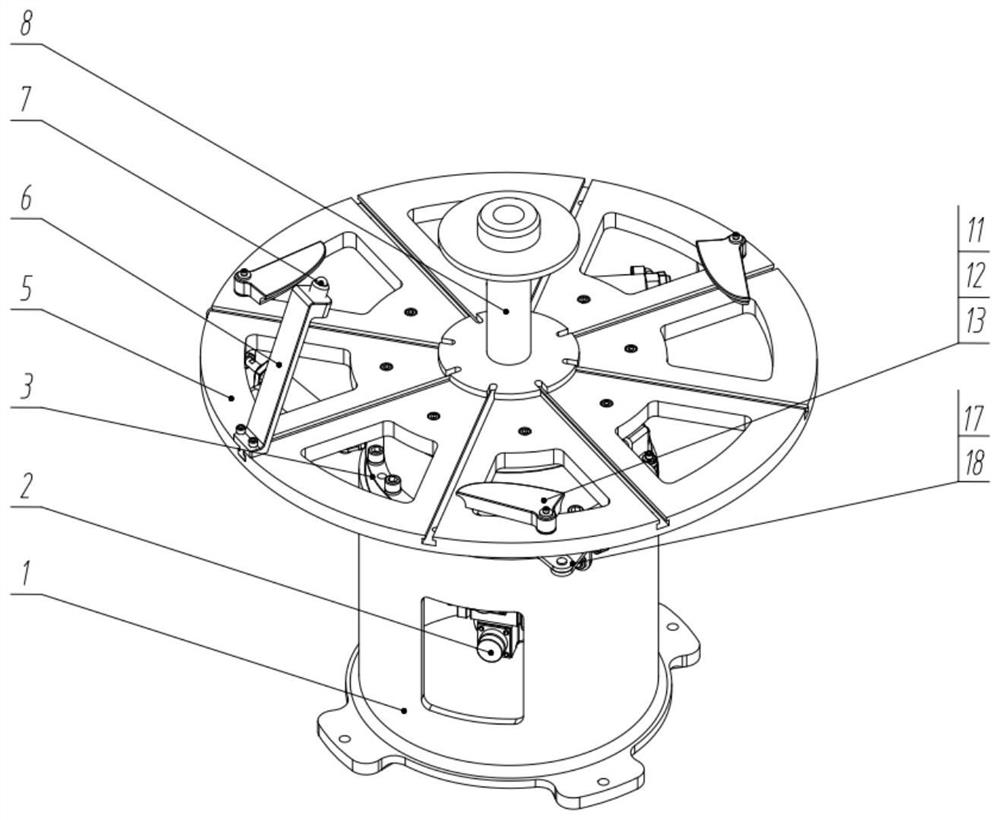

Peanut combined harvester

InactiveCN102057795AReduce fruit loss rateReduce fruit drop rateDigger harvestersUniversal jointAgricultural engineering

The invention discloses a peanut combined harvester. The peanut combined harvester comprises a frame, wherein the frame is provided with an excavating mechanism, a clamping conveying system, a fruit picker and a cleaning screen from front to back in turn; the frame is also provided with a clutch, a hydraulic lifting system, a gearbox, a steering gearbox, a fruit collecting box, a seedling throwing device, a lifter and a universal joint; in addition, a crawler base plate traveling mechanism is arranged below the frame; and the excavating mechanism comprises a seedling separator, an excavating shovel and a seedling supporter. The peanut combined harvester can finish operation such as excavating, soil removal, fruit picking, cleaning, fruit collecting and the like of peanuts at one time, avoids the phenomenon that dropped fruits are lost during transition of each piece of operation in the prior art, has the characteristics of high production efficiency, low operation loss, high transfer speed, low investment cost and the like, is convenient and flexible, and safe and reliable in use, and is an ideal machine tool for mechanically harvesting the peanuts at present.

Owner:宋振美

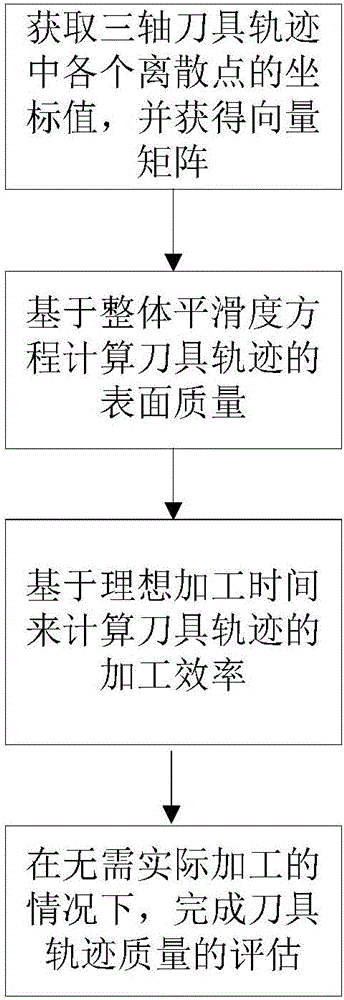

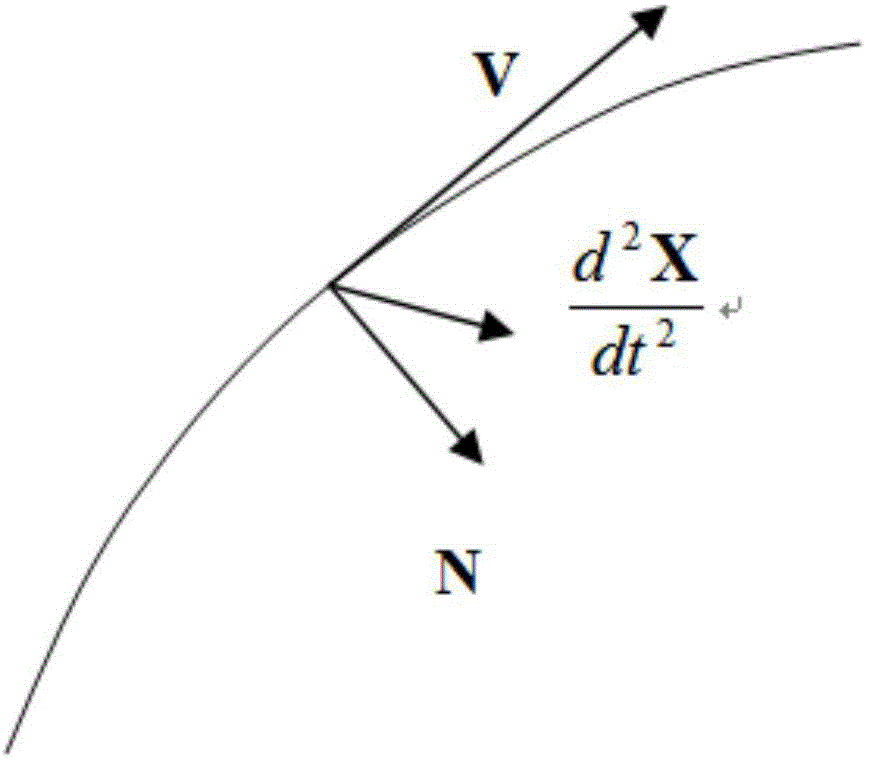

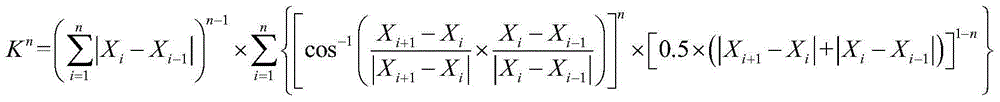

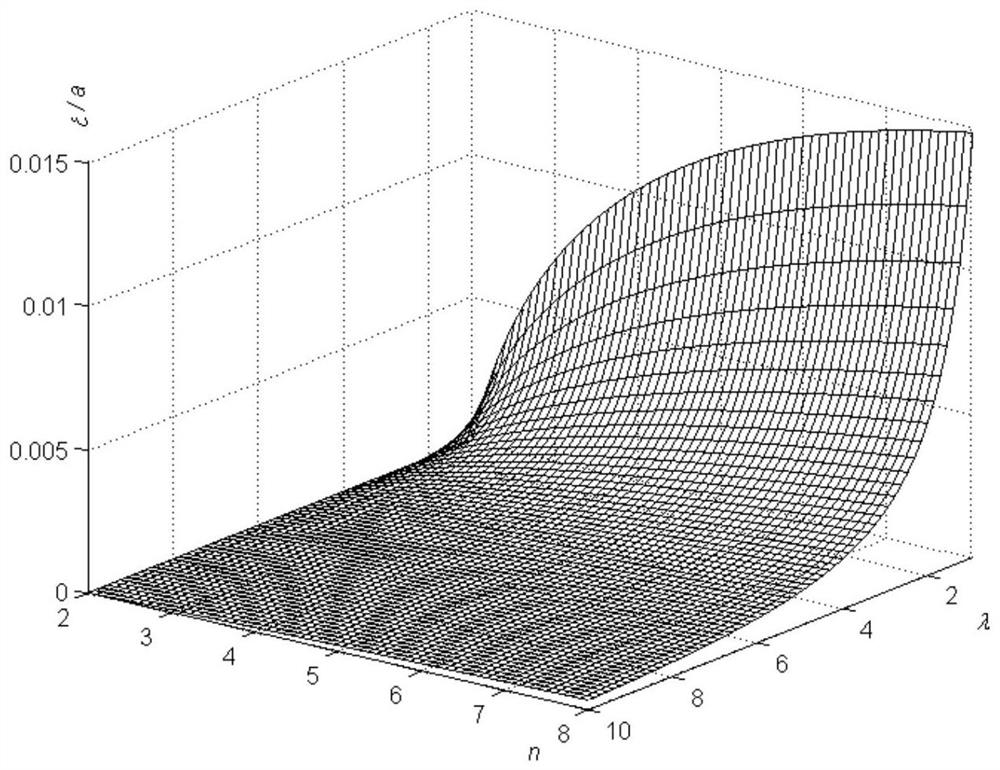

Process method for evaluating trajectory quality of numerical control machining three-axis tool

ActiveCN104678891AGuaranteed accuracyQuality improvementNumerical controlNumerical controlMachining time

The invention discloses a process method for evaluating trajectory quality of a numerical control machining three-axis tool. The process method for evaluating the trajectory quality of the numerical control machining three-axis tool is characterized in that the process method comprises the following steps: (a) acquiring a three-axis tool trajectory sequentially and jointly formed by n discrete points, recording coordinate values of all discrete points in a machining coordinate system, and viewing each discrete point as a vector directed from a coordinate origin to a position of each discrete point; (b) calculating the overall smoothness of the trajectory of the three-axis tool by using the obtained vector matrix, and using the overall smoothness as a surface quality evaluation index during part machining; (c) calculating ideal machining time corresponding to the trajectory of the three-axis tool and using the ideal machining time as an evaluation index of machining efficiency; (d) completing the overall evaluation process of the trajectory quality of the three-axis tool. By adopting the method, the surface quality and machining efficiency of the part machined according to the trajectory of the three-axis tool can be accurately, efficiently and economically evaluated, actual machining verification does not need to be performed and thus the process method is especially applicable to the actual application places of three-axis numerical control machine tools.

Owner:HUAZHONG UNIV OF SCI & TECH

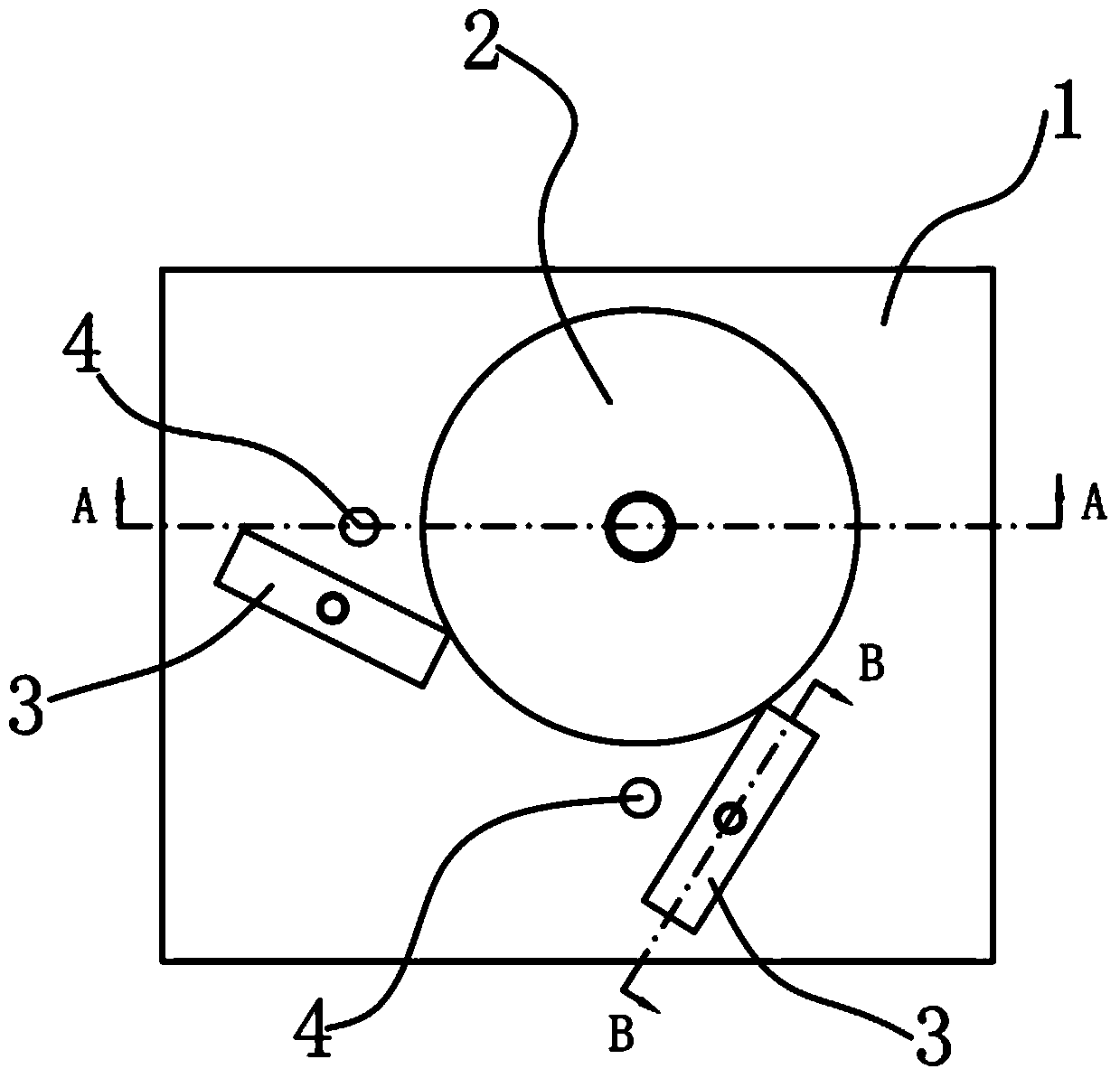

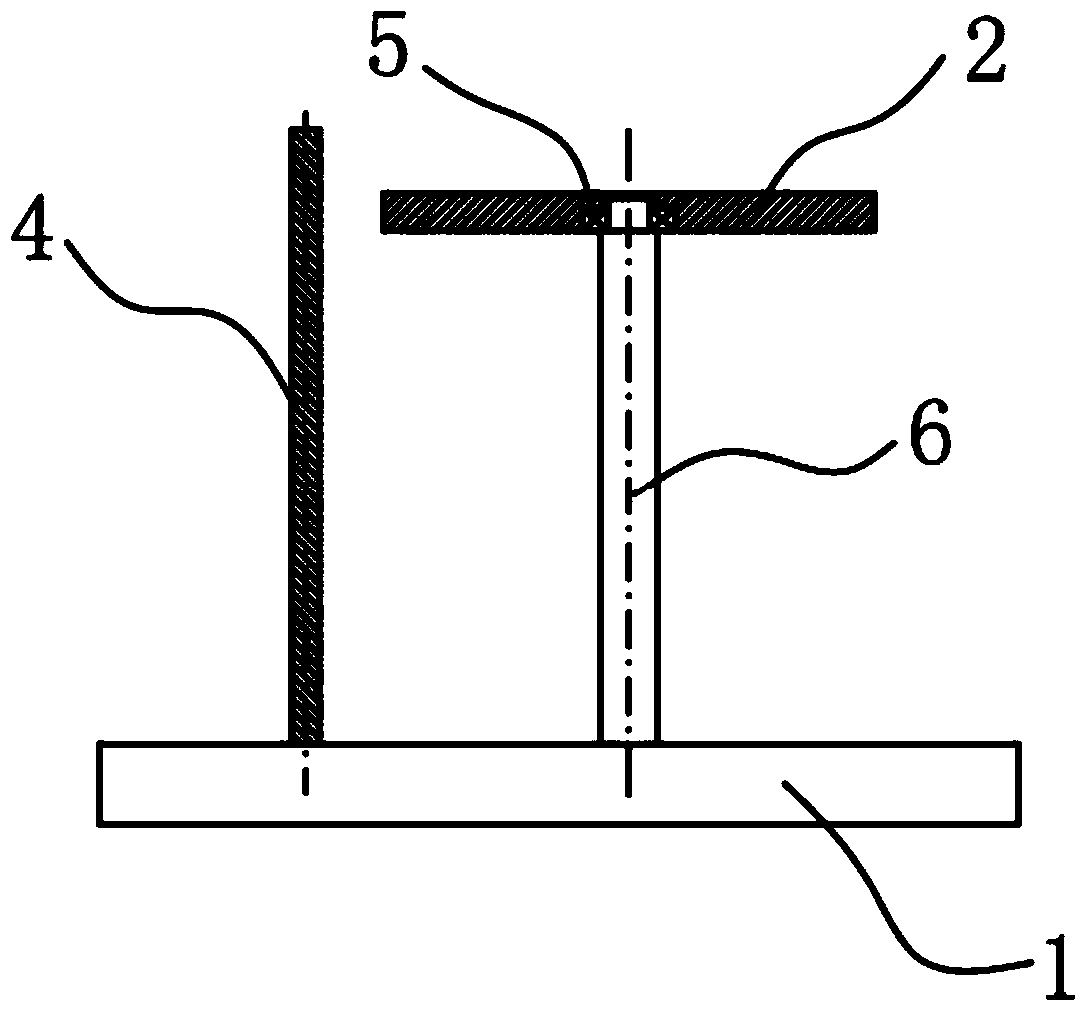

Motion conversion experiment device in thermodynamic system

InactiveCN104021710AProof of correctnessSimple structureEducational modelsMechanical energyEngineering

The invention discloses a motion conversion experiment device in a thermodynamic system, which mainly comprises a base, a circulation motion device, a plurality of elastic column bodies distributed around the circulation motion device and barriers corresponding to the elastic column bodies, wherein the circulation motion device and the elastic column bodies are all movably connected with the base; the barriers are arranged at the same sides of the elastic column bodies; when the elastic column bodies rotates under the effect of external force, the barriers are used for limiting the elastic column bodies to enable the elastic column bodies to impact the circulation motion device in single direction. An ideal machine is amplified to manufacture a simulation device normally observed by the naked eye, the elastic column bodies rotating around fixed axes impact the circulation motion device in single direction, continuous single-direction rotation can be realized, an amplification model manufactured by converting fluctuation in an air system into directionally-rotating mechanical energy in the way is realized, the process is successfully simulated, and accuracy of microscopic particles from disordered motion to ordered motion.

Owner:李纪军

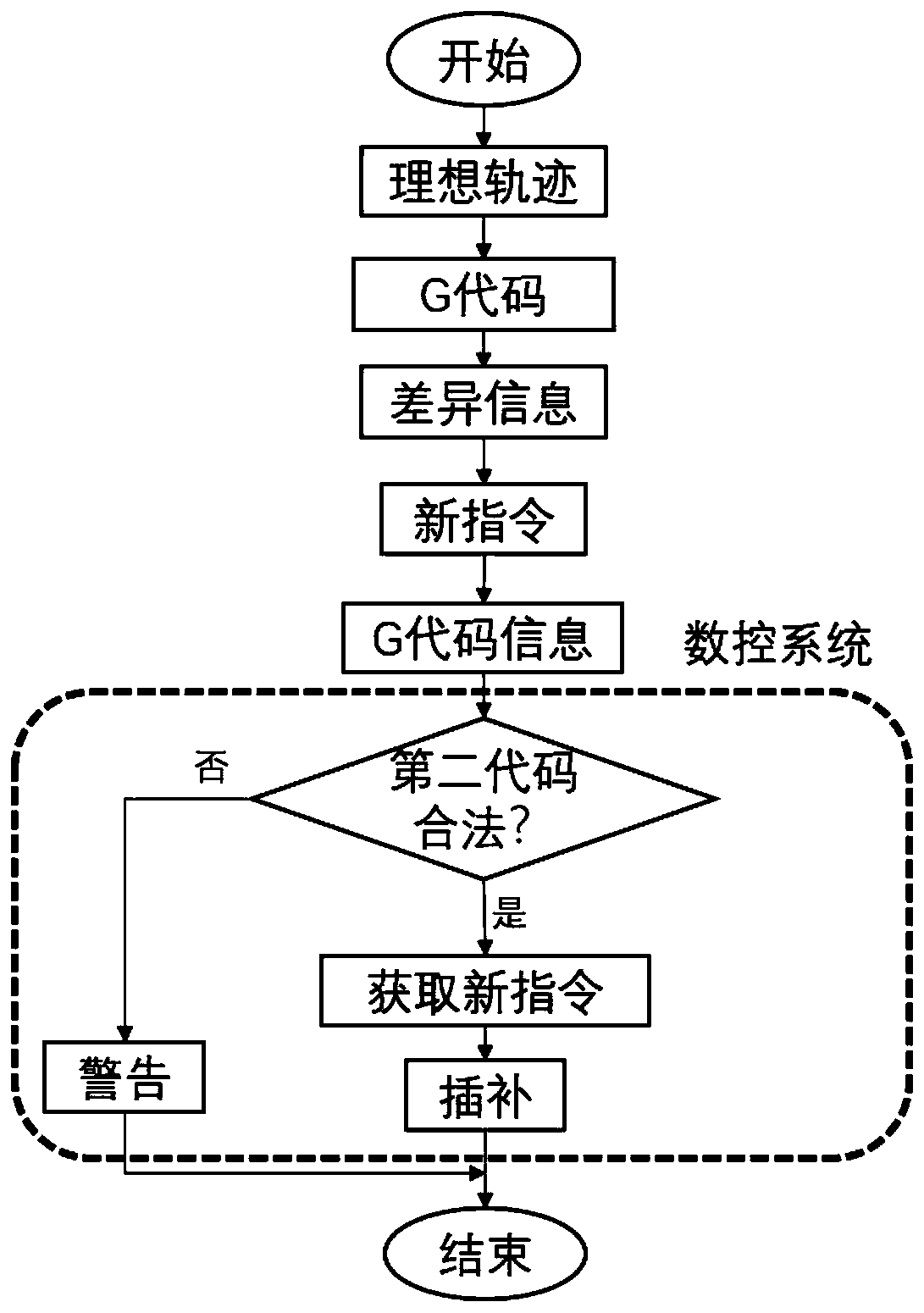

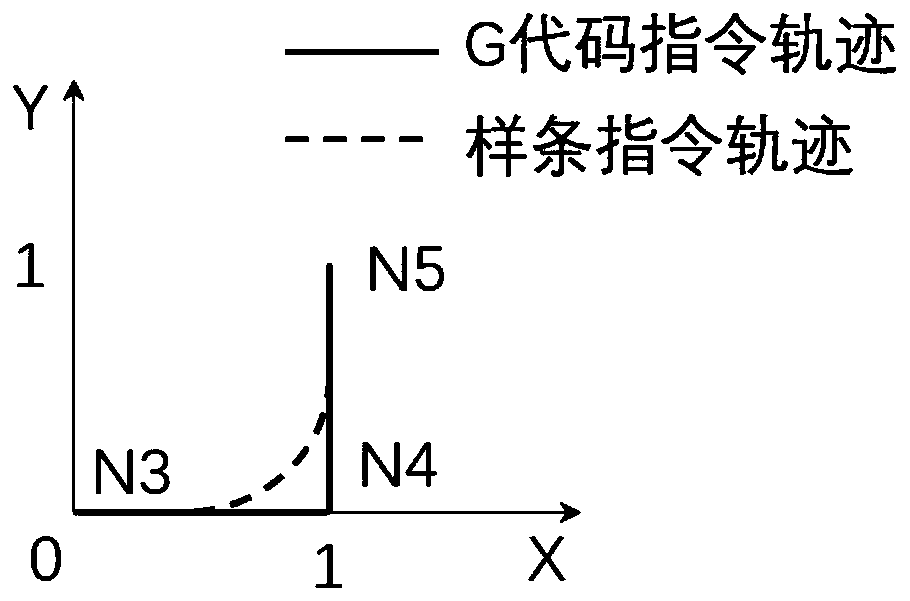

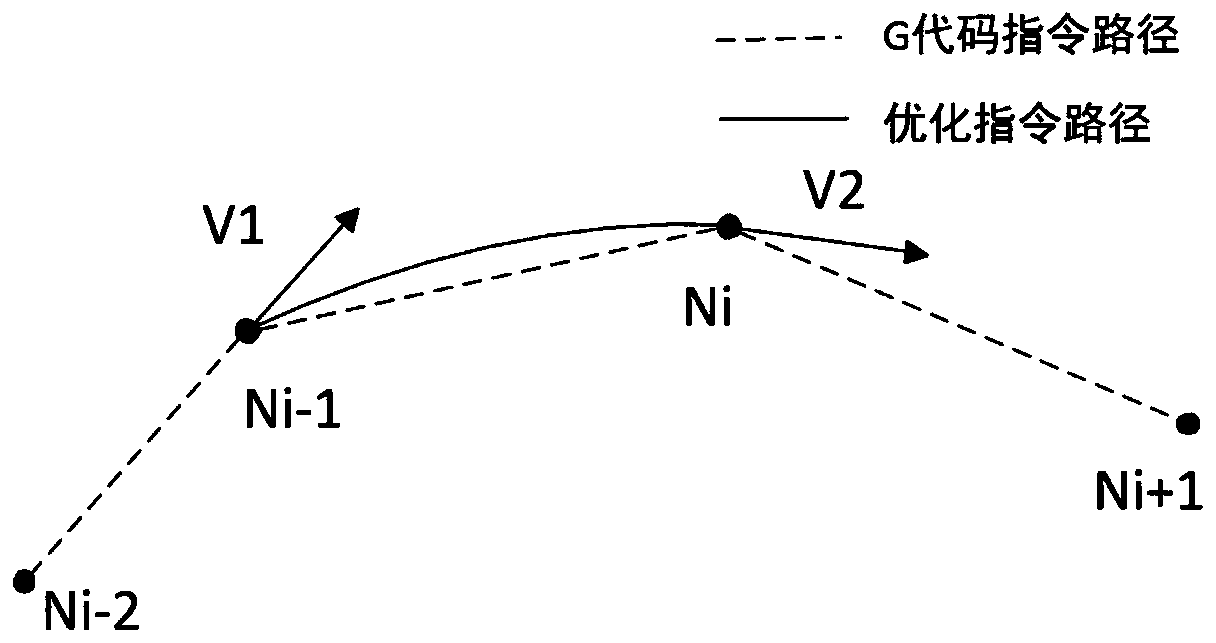

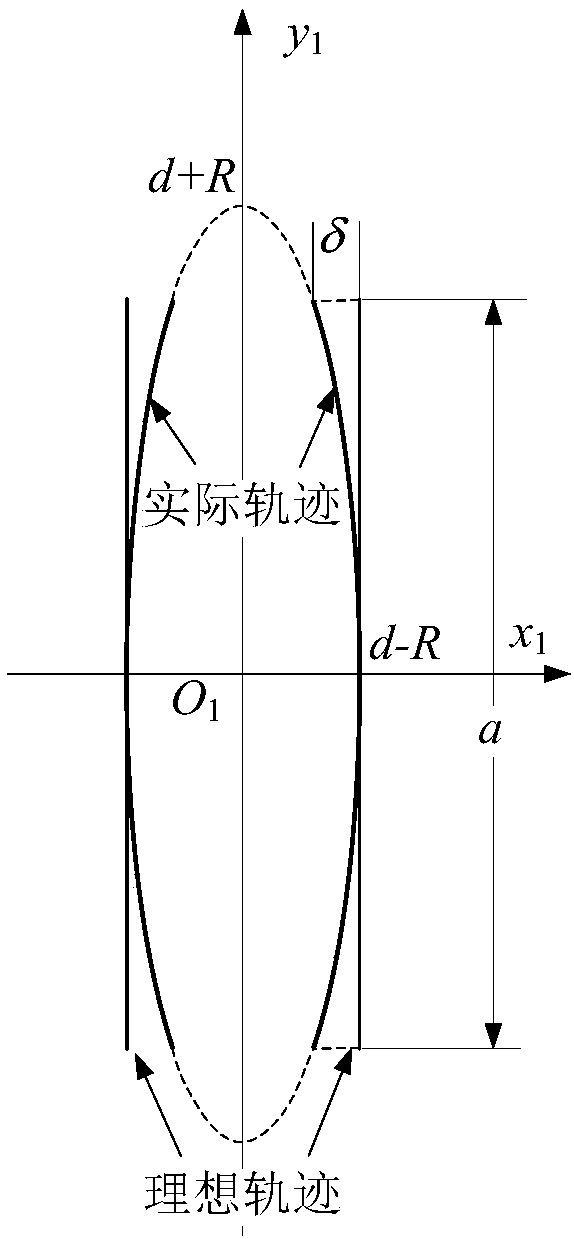

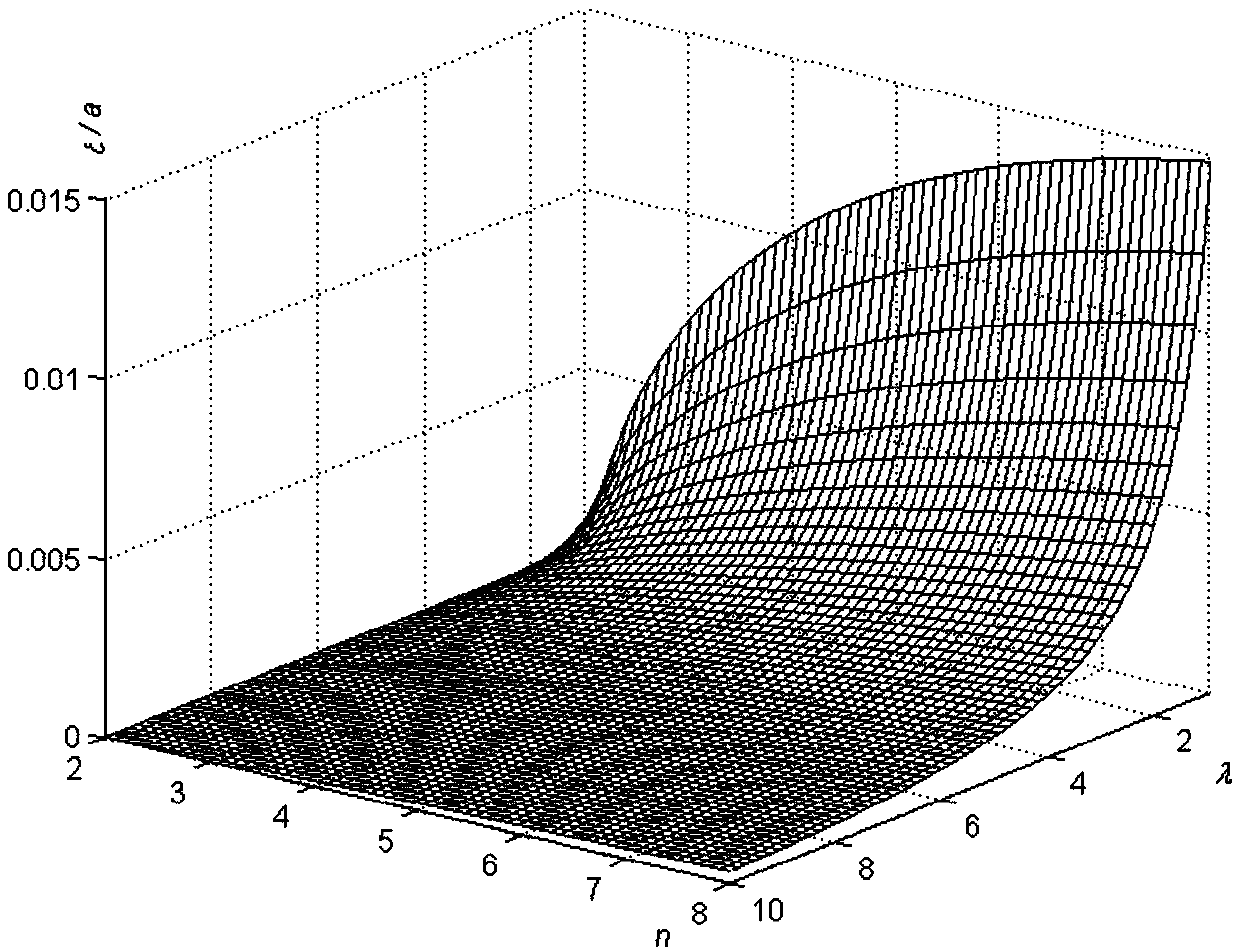

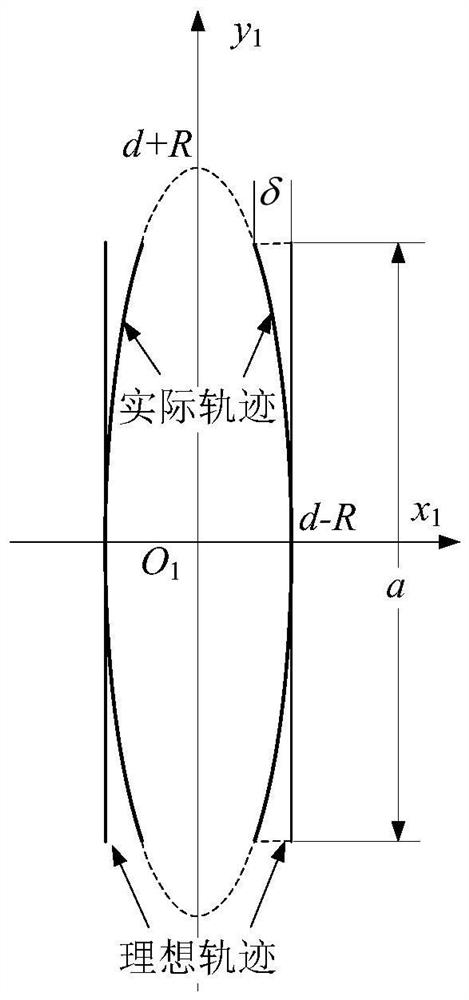

Spline track control instruction optimization method based on double-code joint effect

ActiveCN111487927AImprove machining accuracyReduce machining errorsProgramme controlComputer controlSoftware engineeringG-code

The invention belongs to the related technical field of numerical control machining, and discloses a spline track control instruction optimization method based on a double-code joint effect. The method comprises the following steps: (a) setting an ideal machining track of an object to be machined, and generating a G code according to the set ideal machining track; (b) drawing a processing track corresponding to the G code to obtain an actual processing track, comparing the actual processing track with the ideal processing track to obtain a distinguishing feature, and searching a code, namely adistinguishing feature code, corresponding to the distinguishing feature in the G code; and (c) according to the distinguishing feature, rewriting the distinguishing feature code to obtain a new machining code which enables the actual machining track of the numerical control machine tool to be the same as the ideal machining track so that the optimization of the machining track is realized. By means of the method, the machining track is optimized, machining precision is improved, and machining errors are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Adaptive machine tool for grinding and polishing complex surfaces

InactiveCN102019571BAdaptableImprove processing efficiencyGrinding machinesMachined surfaceEngineering

Owner:JILIN UNIV

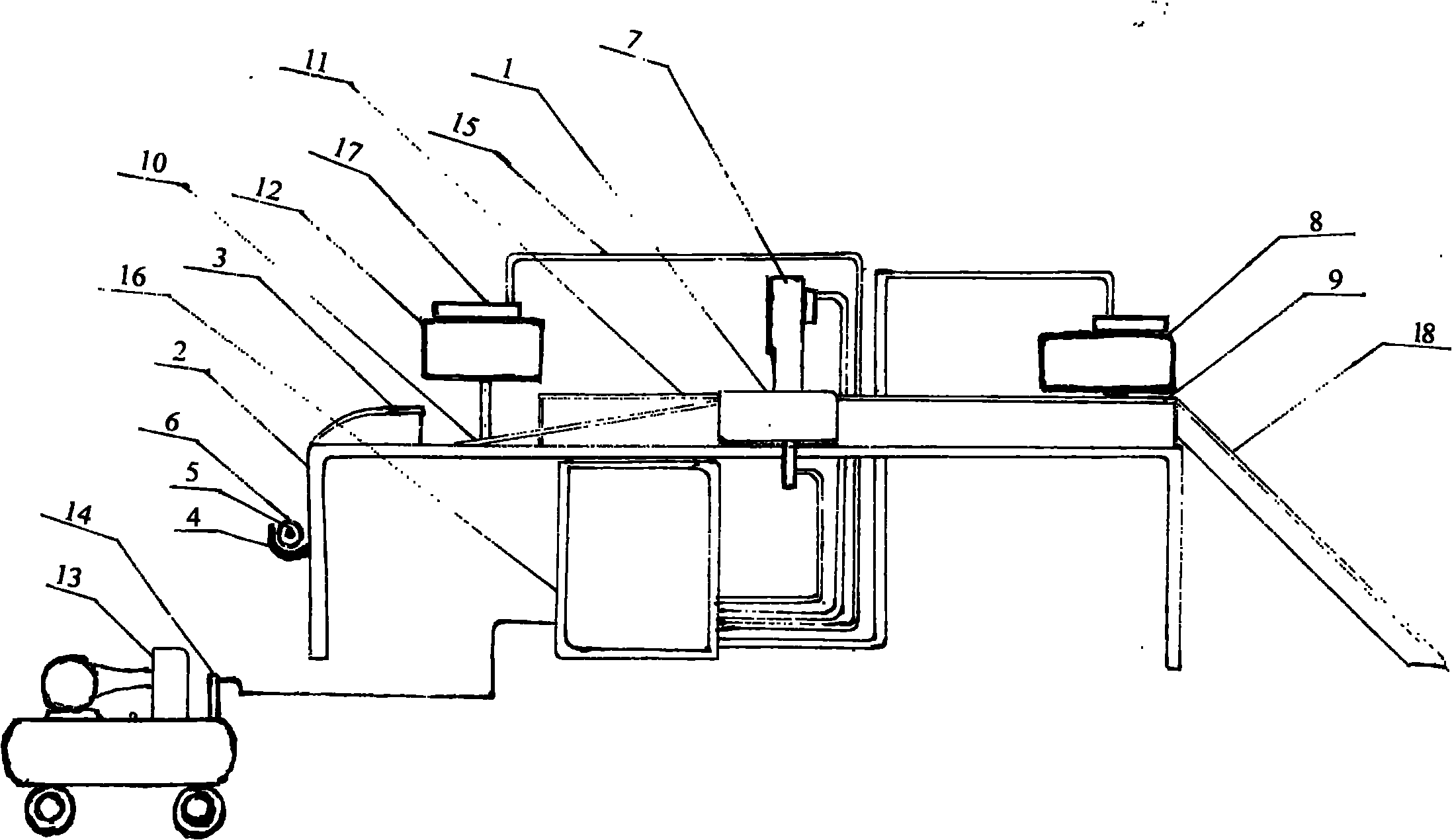

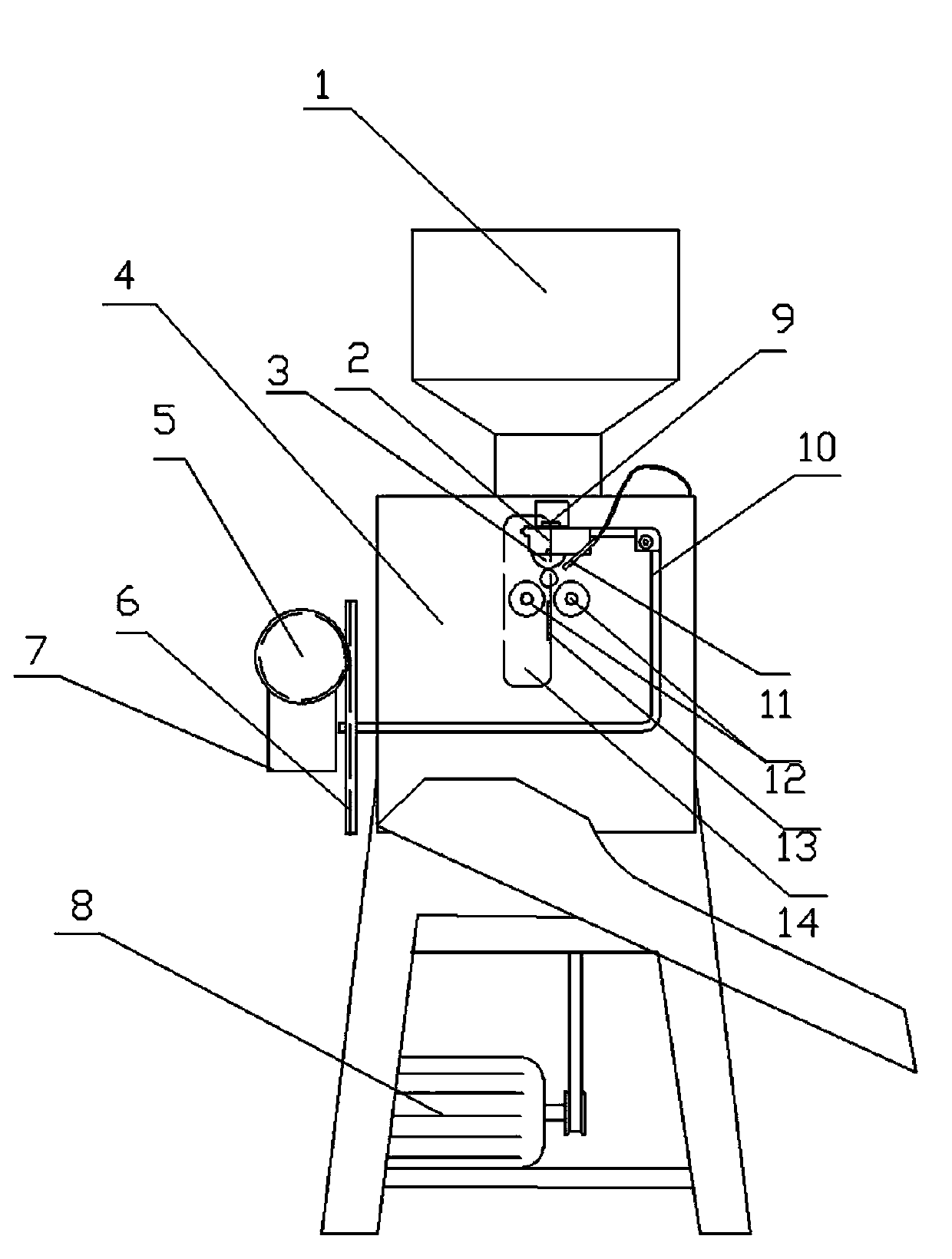

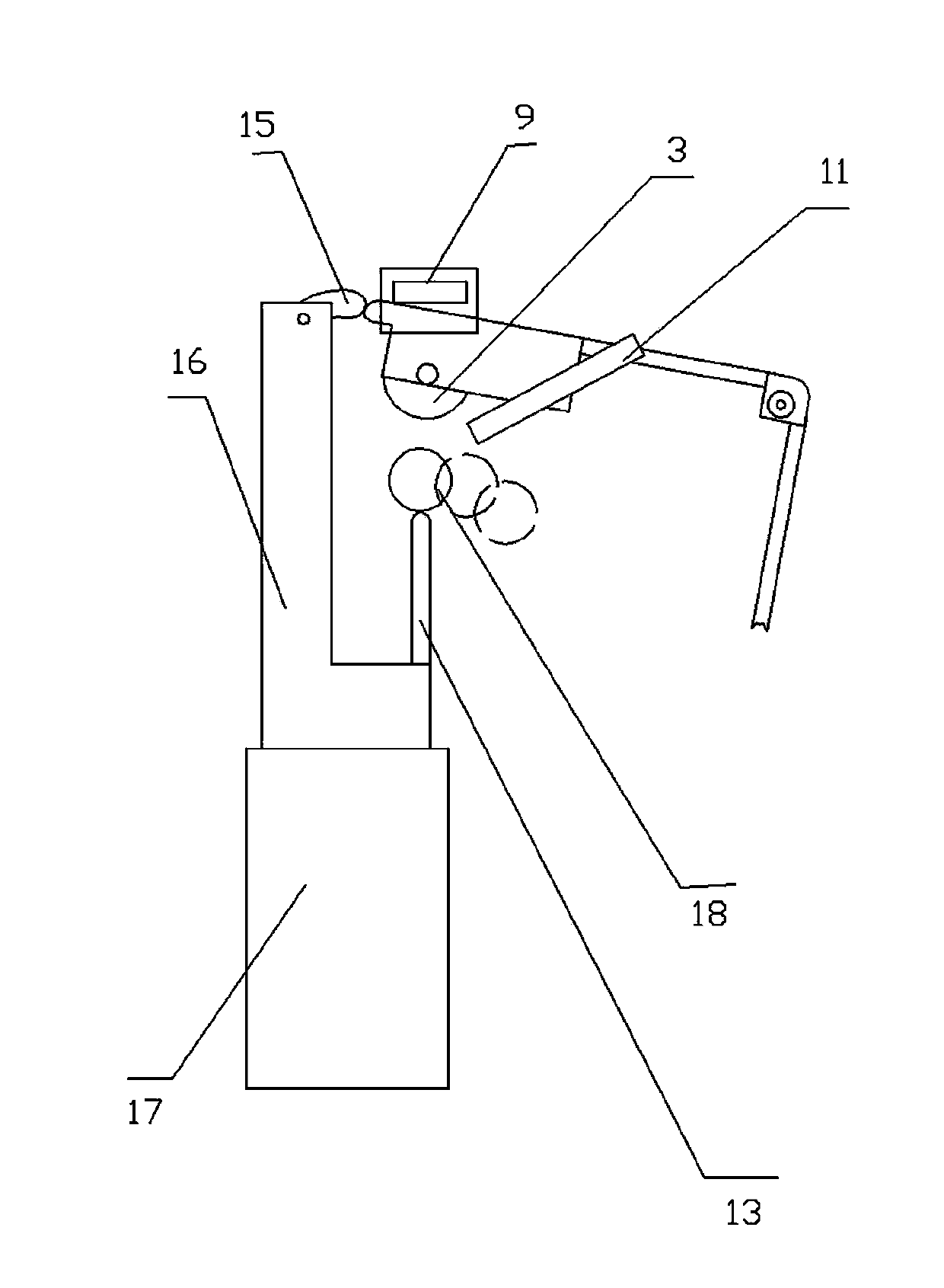

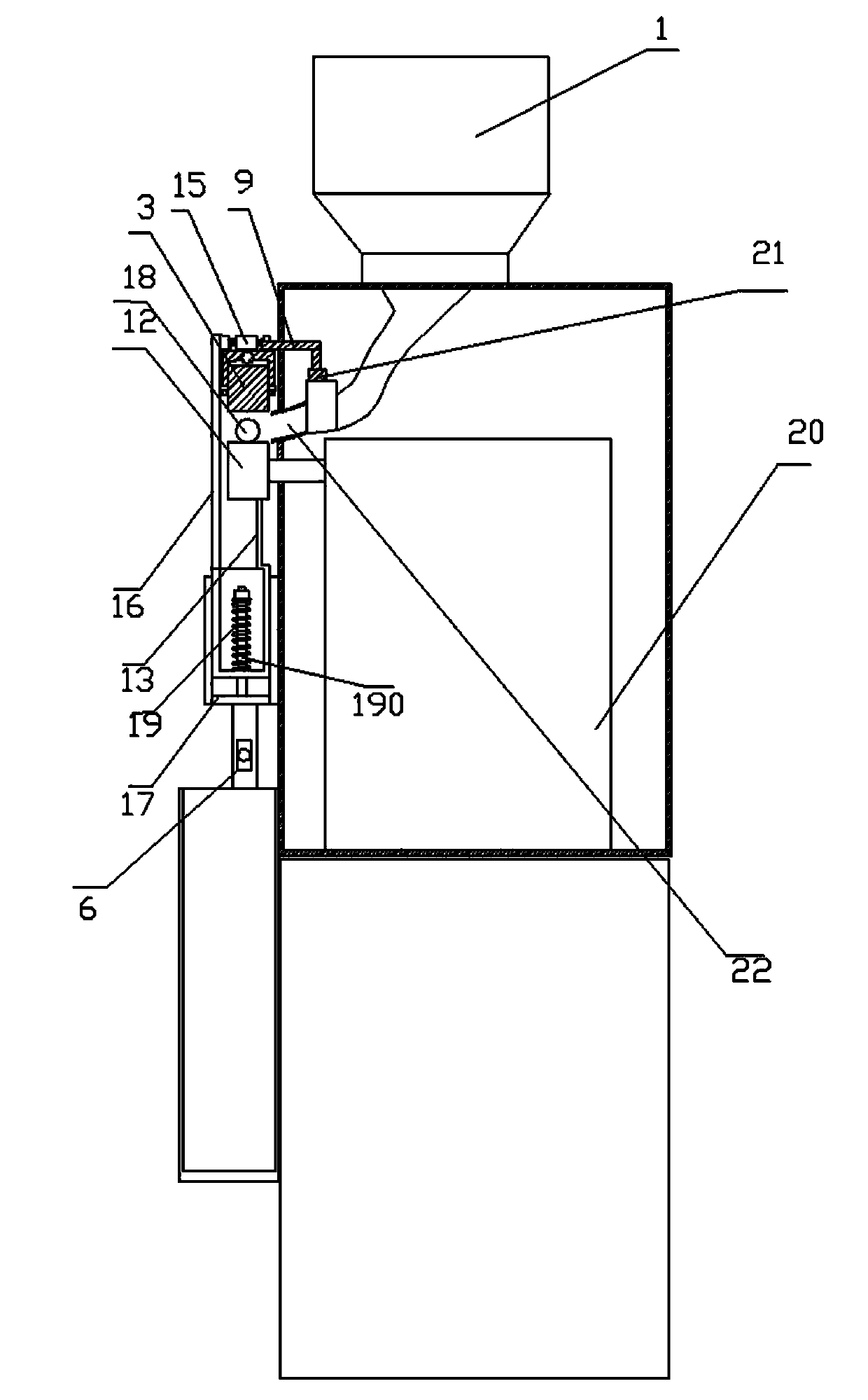

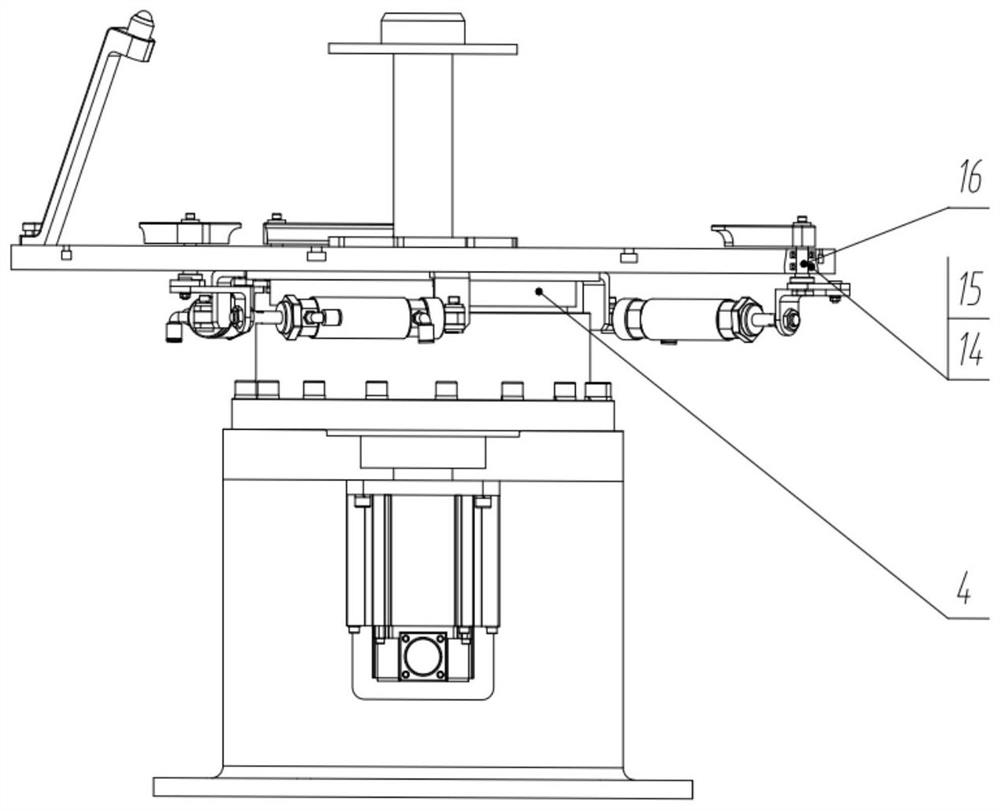

Novel multifunctional medicinal material planting machine

InactiveCN103947319AImprove planting efficiencyWith weeding functionSpadesPloughsAgricultural engineeringEconomic benefits

The invention discloses a novel multifunctional medicinal material planting machine. The machine comprises the following components: a rack (1), a traction device (2), front trundles (3), rear trundles (4), a fertilization box (5), a bearing chain wheel (6), a six-edged roller (7), a precise sowing device (8), a fertilization pipe (9), a ditching soil clearing device (10), fertilization devices (11), a seedling storing disc (12), a seedling discharging pipe (13), a seedling discharging ditching soil clearing device (14), a soil board (15), a seat (16), a pedal plate (17) and spring pressure flatting devices (18). The novel multifunctional medicinal material planting machine has a planting function, a fertilization function and a weeding function and also has a land planishing function, labor and time are saved, the smoothness of the land and the quagginess of soil are ensured, the line spacing and the depth of medicinal materials are uniform and consistent, the multifunctional weeding is facilitated, the medicinal material planting efficiency is greatly improved, and the economic benefits of farmers are improved. The novel multifunctional medicinal material planting machine is an ideal machine used for developing standard medicinal material plantation, and the machine is simple to operate, and easy to popularize and use.

Owner:甘肃省昱昇农机有限公司

Flexible conformal antenna laser machining error control method based on curved surface mapping

ActiveCN110497088AReduce machining errorsSolve problems such as underablationLaser beam welding apparatusLaser processingMeasurement point

The invention belongs to the technical field of flexible conformal antenna laser machining, and relates to a flexible conformal antenna laser machining error control method based on curved surface mapping. The method includes the steps that clamping state curved surface coordinates are measured, and a transformation matrix between a measuring head-workpiece-machine tool coordinate system is established. A clamping state curved surface measuring point and a mapping point thereof are subjected to triangular meshing, and the curved surface characteristics of a flexible conformal antenna in different states are illuminated. The mapping relationship between vertexes and internal points of meshes of a clamping state curved surface and a theoretical curved surface is solved, and the mapping relationship between the clamping state curved surface and the theoretical curved surface of the flexible conformal antenna is established. An ideal machining track is generated through a theoretical curved surface model, and an actual laser machining track of the flexible conformal antenna is solved based on the mapping relationship. According to the method, machining errors caused by deformation of the flexible conformal antenna can be reduced, and great practical application value is achieved for improving the performance of the flexible conformal antenna.

Owner:DALIAN UNIV OF TECH

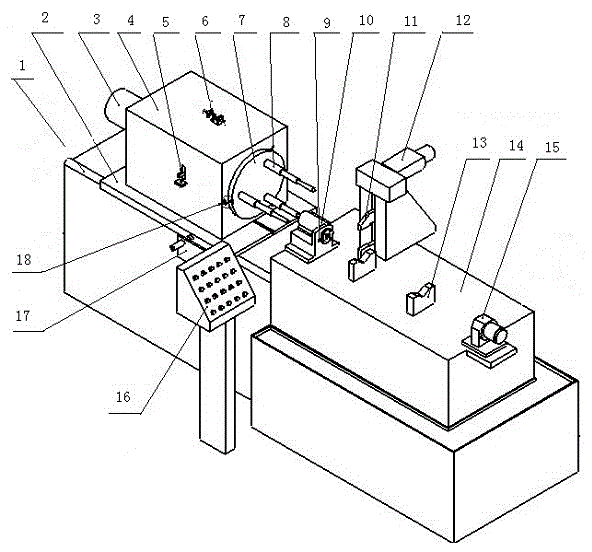

Integral figure eight-shaped sand block mesh assembling machine

InactiveCN101838982ASmooth speed adjustmentReasonable structureSoil preservationAutomatic controlUltrasonic welding

The invention aims to provide an integral figure eight-shaped sand block mesh assembling machine comprises an assembly mould, an auxiliary traction machine, an auxiliary sending machine, an auxiliary ultrasonic welding machine, a guide shape plate, a mesh clamp seat, a transition board and an electric appliance control box which are fixed on a frame, an air compressor and supporting parts; the assembly mould, the auxiliary traction machine, the auxiliary sending machine and the auxiliary ultrasonic welding machine are deployed by a pressure cylinder for driving, take compressed air as a power source, sequentially and alternatively move back and forth, work is progressive action, so that a plastic mesh sets spacing in a balanced way and is assembled with a mesh supporting clamp. The speed and the stroke of the parts of the whole machine are stably regulated manually and automatically controlled by an electric appliance. The integral figure eight-shaped sand block mesh assembling machine has the advantages of reasonable structure, safety, reliability, low energy consumption and high efficiency performance, and is ideal machinery for integral figure eight-shaped sand block mesh assembling (production).

Owner:谢爱良

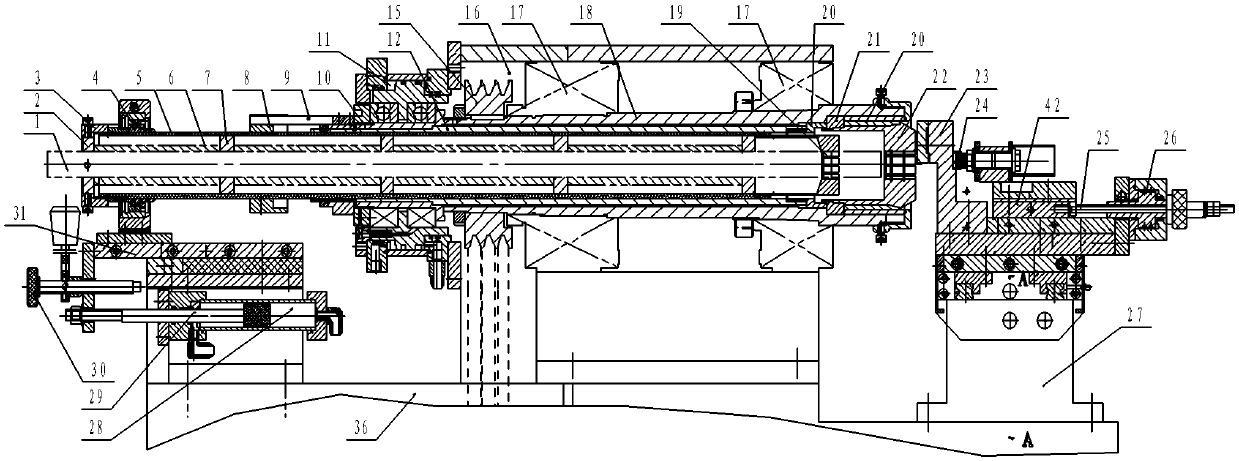

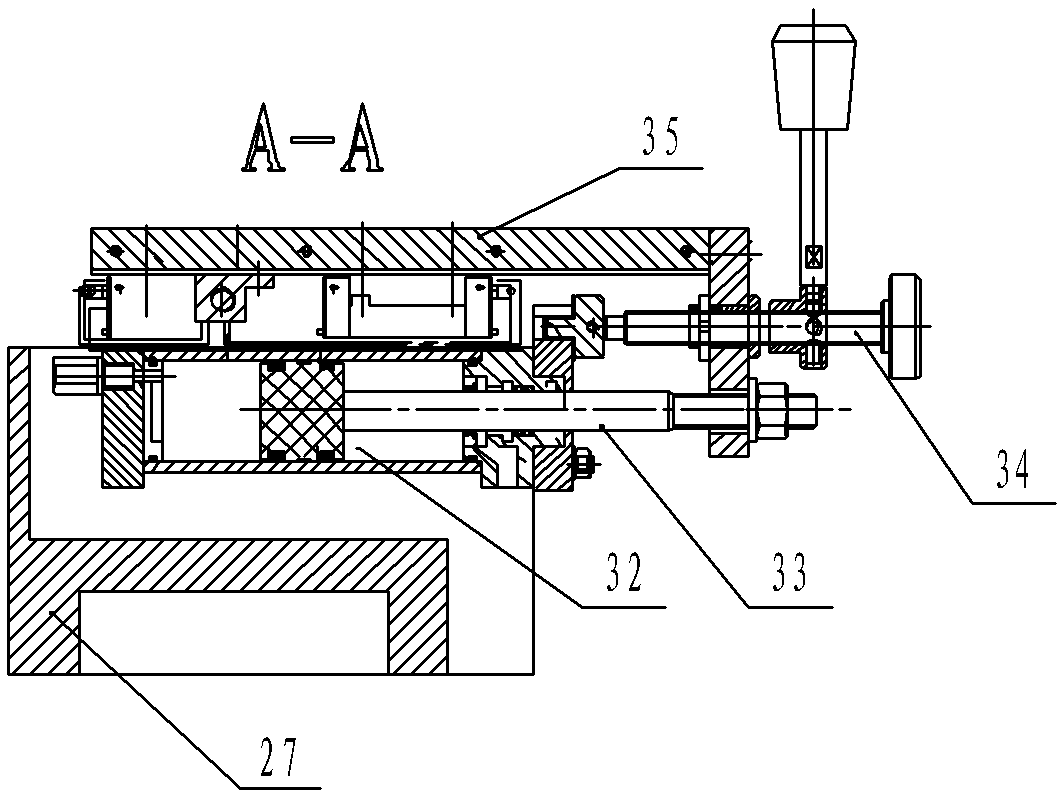

Crankshaft flange plate steady nail hole machining machine tool

InactiveCN106514257AHigh precisionGuaranteed positionOther manufacturing equipments/toolsPositioning apparatusEngineeringDrive motor

The invention relates to a crankshaft flange plate steady nail hole machining machine tool. The machine tool comprises a main lathe bed, a drive motor, a rotation power head box body, a workpiece clamping and fixing device and the like; a sliding guide rail is arranged on the left side of the main lathe bed, a sliding table driven by a feeding oil cylinder is arranged on the sliding guide rail, the rotation power head box body is mounted on the sliding table, a rotation power head is mounted in the rotation power head box body, and is a three-station power head driven by a rotation oil cylinder to achieve position changing, a drill bit is mounted on a first station of a cutter disc, a counterboring reamer is mounted on a second station, a precision reaming boring tool is mounted on a third station, and three non-contact induction switches correspond to the three stations; the machine tool is reasonable in structure, convenient to assemble and reliable in work; automatic drilling is carried out firstly, and then is replaced with counterboring for hole reaming, the reamer is used for precise machining, the technology sizes of the position degree, the hole depth, the diameter size and the like of a crankshaft stable nail hole are ensured, and the crankshaft flange plate steady nail hole machining machine tool is an ideal machine tool special for crankshaft flange plate steady nail hole machining.

Owner:TIANRUN IND TECH CO LTD

Gas-liquid pressurization swing type plate shearing machine

The invention discloses a gas-liquid pressurization swing type plate shearing machine which comprises a rack, an upper tool rest, a gas-liquid pressurization cylinder, an upper blade, a material pressing air cylinder and a lower blade. The upper blade is fixed to the upper tool rest, the lower blade is fixed to the rack and corresponds to the upper blade, the material pressing air cylinder is fixed to the rack and is arranged above the lower blade, one end of the gas-liquid pressurization cylinder is connected with the upper tool rest, the other end of the gas-liquid pressurization cylinder is connected with the rack, and the gas-liquid pressurization cylinder pushes the tool rest to carry out swing type movement to complete a shearing motion. The gas-liquid pressurization cylinder is adopted as a power element, and compared with a mechanical plate shearing machine, the gas-liquid pressurization swing type plate shearing machine is low in noise, safe and reliable. Compared with a hydraulic swing type plate shearing machine, the gas-liquid pressurization swing type plate shearing machine is free of the trouble of hydraulic system temperature rise and oil pollution, and is an ideal machine for shearing a thin steel plate with a shearing width within the range of 1500mm.

Owner:陈道宝 +2

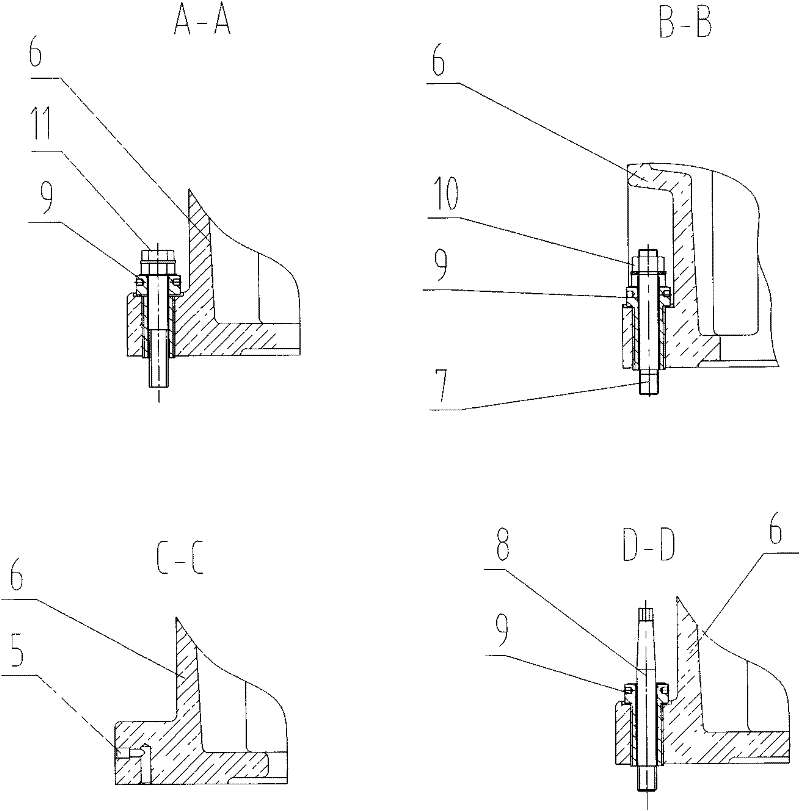

Column and sliding seat bonding face adhesive filing structure and process

InactiveCN102501076ASimplify the assembly processSave installation timeLiquid surface applicatorsLarge fixed membersAdhesiveMachine tool

The invention belongs to column and sliding seat bonding face adhesive filing structure and process. The structure and the assembly process mainly solve the problem of 'forward and backward leaning' accuracy adjustment of columns of a machine tool. The structure comprises columns, a sliding seat, screw sleeves, fasteners and the like, one or more than one region comprising an adhesive tape and a seal ring are arranged on the sliding seat, and two or more than two adhesive inlet holes and adhesive outlet holes are arranged in each region. An adhesive is filled into the region formed from the adhesive tape and the seal ring. The columns are installed according to the process and the steps provided by the invention, so that the troublesome of repeated machining the sliding seat below the columns in the prior art can be solved, and ideal machine tool installation accuracy is obtained through the steps and the process of adjusting the columns, filling positioning adhesive and the like during installation. The structure and the process have the advantages of simple structure, convenience for use, good processibility, working hour saving and increased machine tool and equipment accuracy.

Owner:WUHAN HEAVY MACHINE TOOL GRP

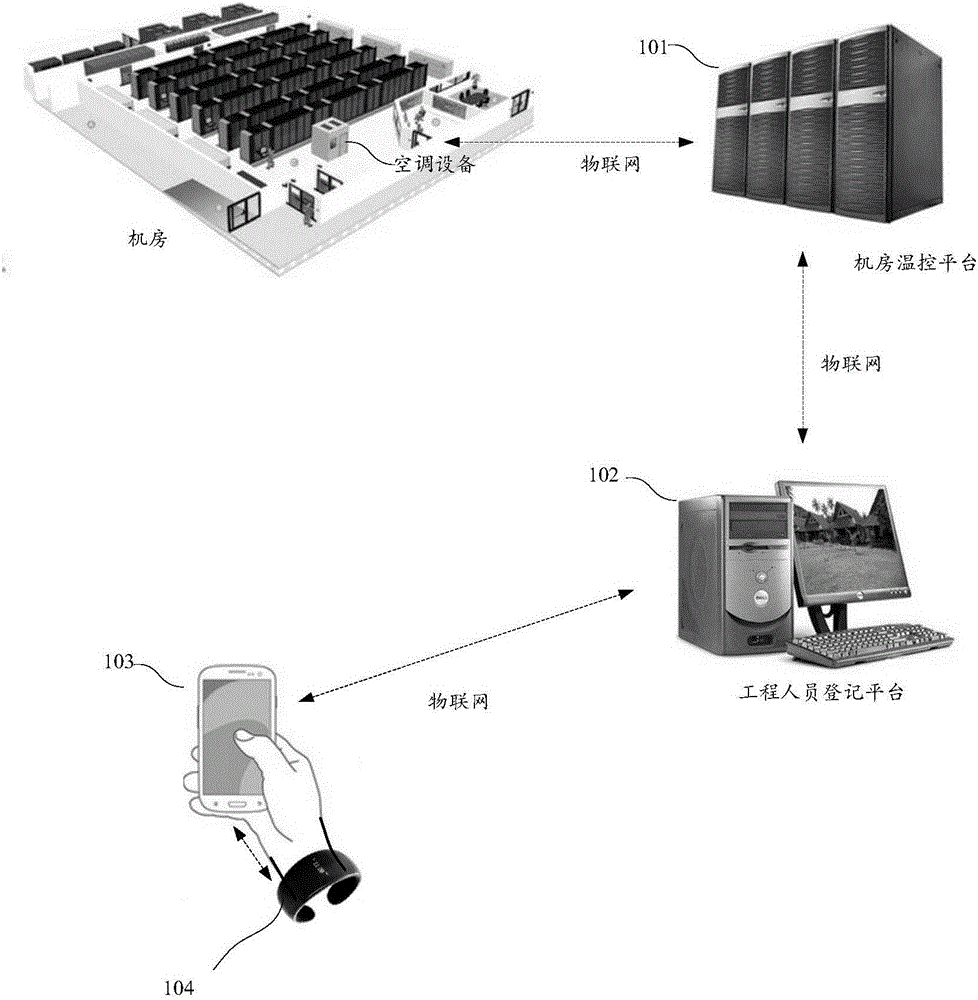

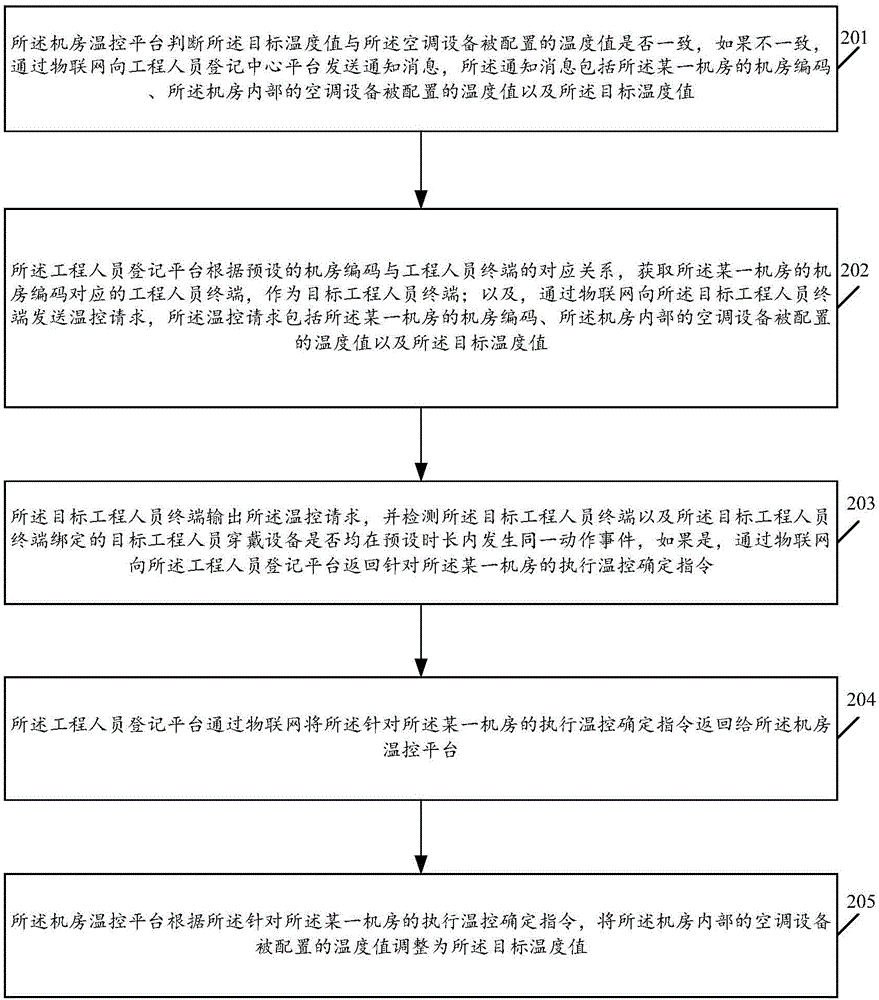

Machine room temperature control system and method based on Internet of Things

InactiveCN106440261AImprove regulation efficiencyReduce pollutionMechanical apparatusSpace heating and ventilation safety systemsTemperature controlControl system

Disclosed is machine room temperature control system and method based on the Internet of Things. In the system, a machine room temperature control platform acquires a real-time number value of currently running equipment inside a certain machine room and a temperature value configured for air conditioning equipment inside the machine room and determines an ideal machine room temperature value corresponding to the real-time number value as a target temperature value, wherein the real-time number value is inversely proportional to the target temperature value; when the circumstance that the target temperature value is different from the temperature value configured for the air conditioning equipment inside the machine room, a temperature control request is determined through an engineering personnel registration platform and sent to a target engineering personnel terminal corresponding to the machine room; when the target engineering personnel terminal detects itself and target engineering personnel wearing equipment bound with the terminal that occur a same action event within a preset time duration, the engineering personnel registration platform informs the machine room temperature control platform to adjust the temperature value configured for the air conditioning equipment inside the machine room to the target temperature value. By the machine room temperature control system and method, efficiency in adjusting the temperature value of the air conditioning equipment inside the machine room can be improved, and environment pollution of the machine room can be reduced.

Owner:WINSTRONG TECH

Numerical control machining square algorithm with high precision

ActiveCN109542044AMeet the requirements of the car partyImprove machining accuracyNumerical controlNumerical controlEngineering

The invention discloses a numerical control machining square algorithm with high precision. The algorithm comprises the following steps of: calculating a machining track of a cutter cutting point on aworkpiece, setting the ideal machining track of the workpiece, and calculating a interpolation coordinate on the ideal track. The algorithm only needs to guarantee that the turning radius of the cutter is greater than 1 / 7 of the side length of the machining square, the size of a cutterhead is basically not required, so that the requirement of the machining square of the small-size machine tool can be well met. The calculation of the interpolation coordinates on the ideal track is achieved, and the machining precision is improved by calculating a interpolation coordinate on the ideal track.

Owner:NANJING AGRICULTURAL UNIVERSITY

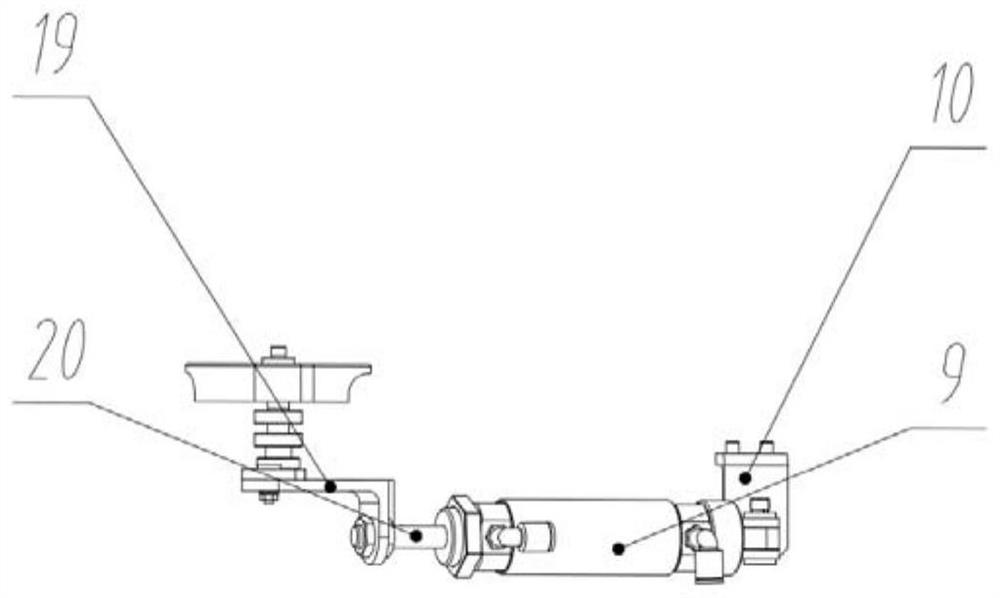

Lotus nut husking lever device of husking machine

A lotus nut husking lever device of a husking machine comprises a frame, wherein a U-shaped lotus nut husking lever is arranged on the front surface of the frame, the fulcrum of the lotus nut husking lever is fixed on the front surface of the frame, a hob wheel frame is arranged at the end portions of a resistance arm of the lotus nut husking lever, a hob wheel is arranged in the hob wheel frame, and a power arm of the lotus nut husking lever extends to the side of the frame. The lotus nut husking lever device of the husking machine has the advantages of being compact in structure, high in speed, reliable and durable, convenient to use, capable of saving energy and the like, and especially adopts an optical, mechanical and electrical integrated structure to enable the processed lotus nuts without lotus nut cores to be good in quality and low in reprocessing rate. Therefore, the lotus nut husking lever device of the husking machine is an ideal machine for lotus nut processing industry and lotus planters.

Owner:马末珍

A control method of high-precision numerical control lathe

ActiveCN109542044BMeet the requirements of the car partyImprove machining accuracyNumerical controlNumerical controlAlgorithm

The invention discloses a high-precision numerical control turning algorithm, which comprises the following steps: calculating the machining trajectory of a tool cutting point on a workpiece, setting the ideal machining trajectory of the workpiece, and calculating the interpolation coordinates on the ideal trajectory. The algorithm of the present invention only needs to ensure that the turning radius of the tool is greater than 1 / 7 of the side length of the car side, and there is basically no requirement for the size of the cutter head, so it can well meet the requirements of the car side of small-sized machine tools; the calculation of interpolation coordinates on the ideal trajectory , improving the machining accuracy.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for improving uniformity of ALOx film depositing of ideal machine table

InactiveCN107475689AImprove uniformityImprove efficiencyChemical vapor deposition coatingEngineeringSilicon

The invention discloses a method for improving uniformity of ALOx film depositing of an ideal machine table. The method for improving the uniformity of ALOx film depositing of the ideal machine table comprises the following steps that a, a carrying plate in a cavity of the machine table is controlled to swing for 1-5s in the beginning of the technology; b, technology gas is introduced, and the carrying plate swings in the cavity, ALOx plating film is deposited on a silicon slice; c, depositing is finished, the technology gas is stopped from being introduced into the cavity, the carrying plate continues to swing for 1-5s; and d, the carrying plate is stopped to swing, and the deposited plating film silicon slice is taken. According to the method for improving the uniformity of ALOx film depositing of the ideal machine table, by changing sequence of actions of carrying plate swinging and technology gas supplying, the problem of poor within-slice uniformity caused by gas supplying and carrying plate swinging is solved, the purpose of promoting the uniformity of the carrying plate is achieved accordingly, the within-slice uniformity is improved, and solar cell efficiency and appearance uniformity are improved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

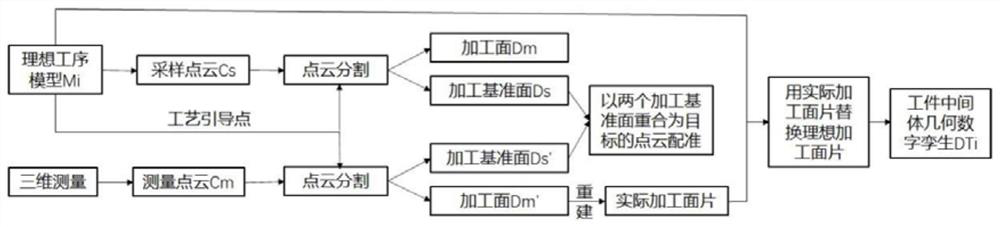

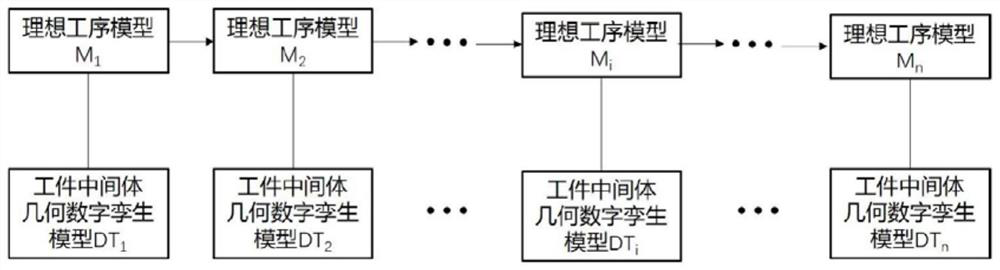

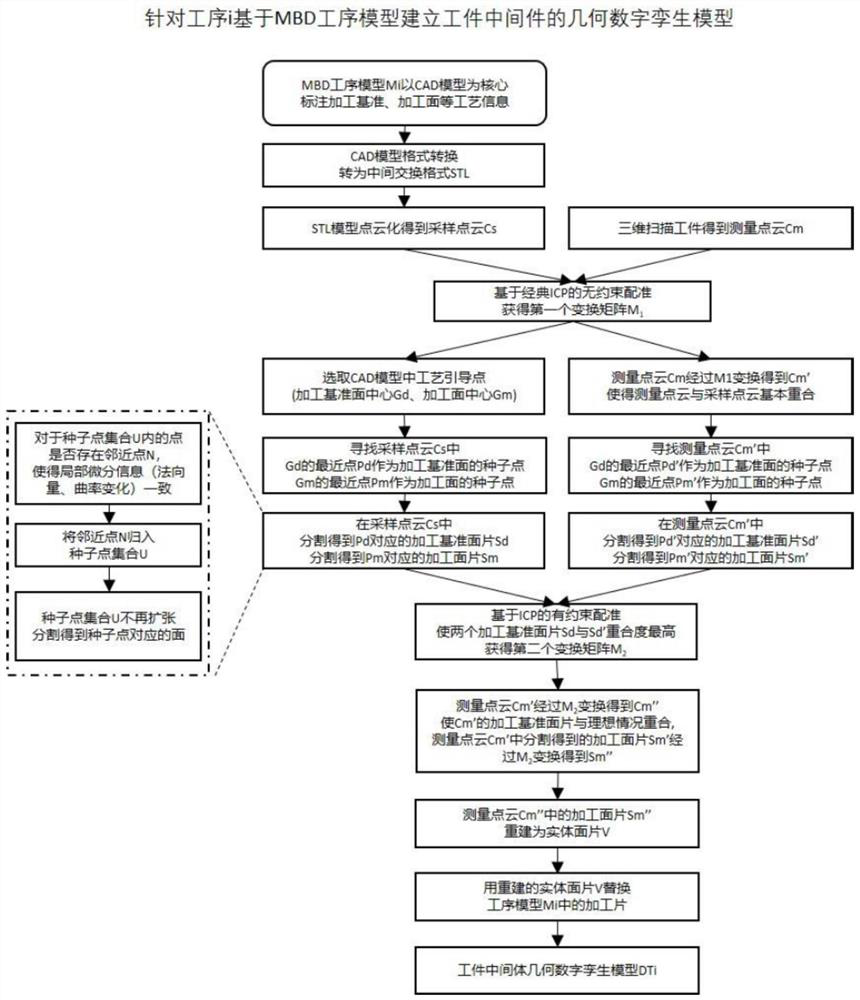

Method for constructing geometric digital twinning model of workpiece based on MBD process model

PendingCN112016169AImprove targetingImprove effectivenessGeometric CADData processing applicationsManufacturing technologyThree dimensional measurement

The invention discloses a construction method of a workpiece geometric digital twinning model based on an MBD process model. The method is based on a CAD model and process information in an MBD process model. The actual geometrical shape of the workpiece is obtained through three-dimensional measurement; obtaining an ideal processing surface, an ideal processing reference surface, an actual processing surface and an actual processing reference surface through point cloud initial registration and process guidance point cloud segmentation; actual and ideal machining datum planes coincide to serve as constraints for fine registration, so that a coordinate system of three-dimensional measurement data is corrected to be consistent with a design coordinate system, a machining surface obtained through measurement is reconstructed on the basis, the machining surface in an ideal process model is replaced, and finally a workpiece intermediate geometric twinning model for each process is obtained. According to the method, the pertinence and effectiveness of registration are improved on the basis of process information, the geometric state change of the workpiece in the manufacturing process is digitally reserved, and manufacturing process tracing and manufacturing process improvement are facilitated.

Owner:苏州智制云科技有限公司

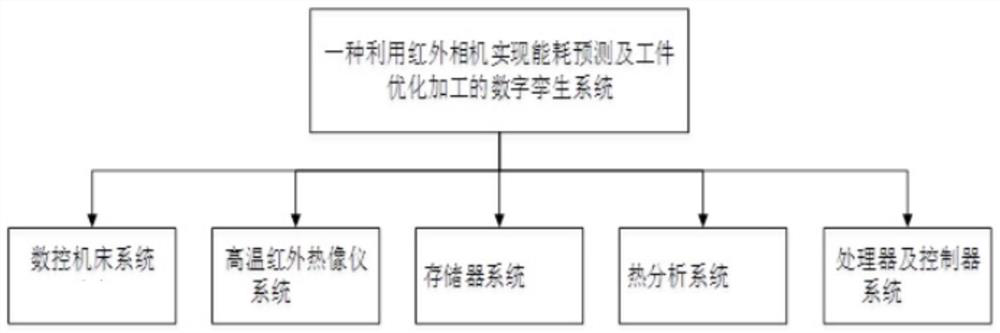

Device for achieving optimized machining of workpiece through high-temperature infrared thermal imaging

PendingCN113325803AReal-time temperature monitoringAccumulate data experienceProgramme controlComputer controlMachine controlHeat analysis

The invention discloses a device for achieving optimized machining of a workpiece through high-temperature infrared thermal imaging, and belongs to the field of digital twinning technology application. The device comprises a numerical control machine tool system, a high-temperature infrared thermal imager system, a memory system, a thermal analysis system, a processor and a controller system, the high-temperature infrared thermal imager system is adjacent to the machine tool system; The temperature of a machining area in the machine tool system can be collected, the numerical control system is used as a machining place, and the storage system is connected with the thermal analysis system and the processor and controller system at the same time. The thermal analysis system is used for obtaining the ideal machining working condition temperature and storing the ideal machining working condition temperature in the storage device system. The processor and controller system is used for obtaining control parameters of the numerical control machine tool system and implementing machining control on the numerical control system so as to realize optimization of technological parameters and optimization control of machining energy consumption in the machining process. According to the device, real-time energy consumption prediction in the workpiece machining process and subsequent process optimization of similar workpieces can be achieved.

Owner:WUHAN UNIV OF SCI & TECH

Laser processing error control method for flexible conformal antenna based on surface mapping

ActiveCN110497088BReduce machining errorsSolve problems such as underablationComputer controlSimulator controlLaser processingEngineering

The invention belongs to the technical field of flexible conformal antenna laser machining, and relates to a flexible conformal antenna laser machining error control method based on curved surface mapping. The method includes the steps that clamping state curved surface coordinates are measured, and a transformation matrix between a measuring head-workpiece-machine tool coordinate system is established. A clamping state curved surface measuring point and a mapping point thereof are subjected to triangular meshing, and the curved surface characteristics of a flexible conformal antenna in different states are illuminated. The mapping relationship between vertexes and internal points of meshes of a clamping state curved surface and a theoretical curved surface is solved, and the mapping relationship between the clamping state curved surface and the theoretical curved surface of the flexible conformal antenna is established. An ideal machining track is generated through a theoretical curved surface model, and an actual laser machining track of the flexible conformal antenna is solved based on the mapping relationship. According to the method, machining errors caused by deformation of the flexible conformal antenna can be reduced, and great practical application value is achieved for improving the performance of the flexible conformal antenna.

Owner:DALIAN UNIV OF TECH

Automatic pipe cutting machine

The invention relates to a full-automatic pipe cutter, which is characterized in that a gripping head tightly-pushing pipe is movably fitted with the inner hole of a main shaft; a feed gripping head pushing pipe is movably fitted with the inner hole of the gripping head tightly-pushing pipe, and is fixed on a feeding planker through a pushing pipe bearing seat; an feeding oil cylinder drives the feeding planker to drive the feeding gripping head pushing pipe to feed; a grip cylinder is assembled at the circumference at the left part of the gripping head tightly-pushing pipe, and drives the gripping head tightly-pushing pipe; a gripping head tightly-pushing taper sleeve pushes the gripping head to be clamped; a group of shuttling planker stroke induction switch formed by two sensors is arranged in the feeding and sliding direction of a shuttling planker of a carriage saddle; and a left-right moving planker and the shuttling planker are driven by an oil cylinder respectively. Due to the adoption of the structure, the tail section of a workpiece to be cut can be shortened to the utmost extent, the automatic feeding is achieved, manpower and material resources are saved, the operation is simple, the production efficiency is high, the machining precision is good, the time is saved. The full-automatic pipe cutter is a present pipe cutting production ideal machine.

Owner:河北松华挂车制造有限公司

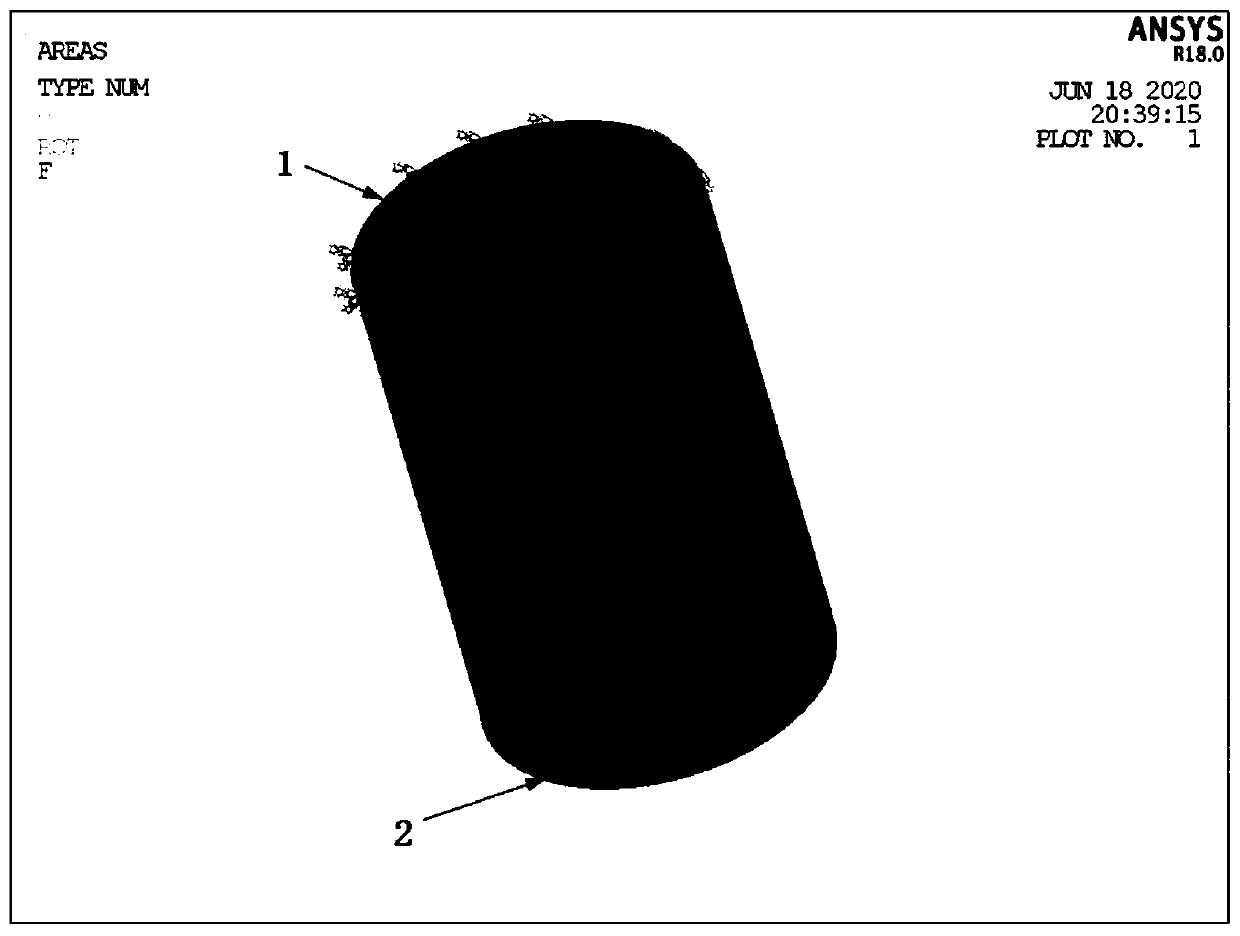

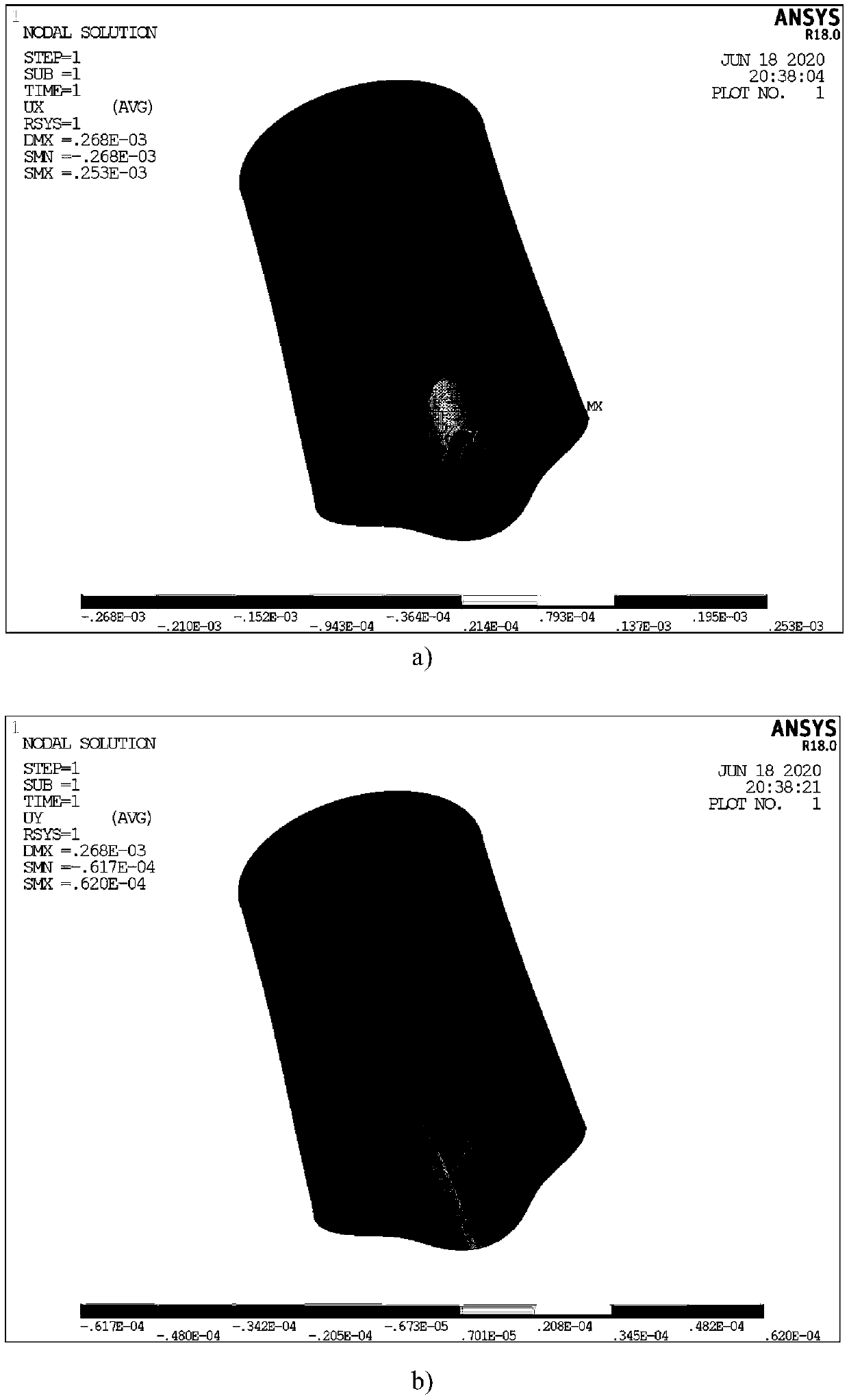

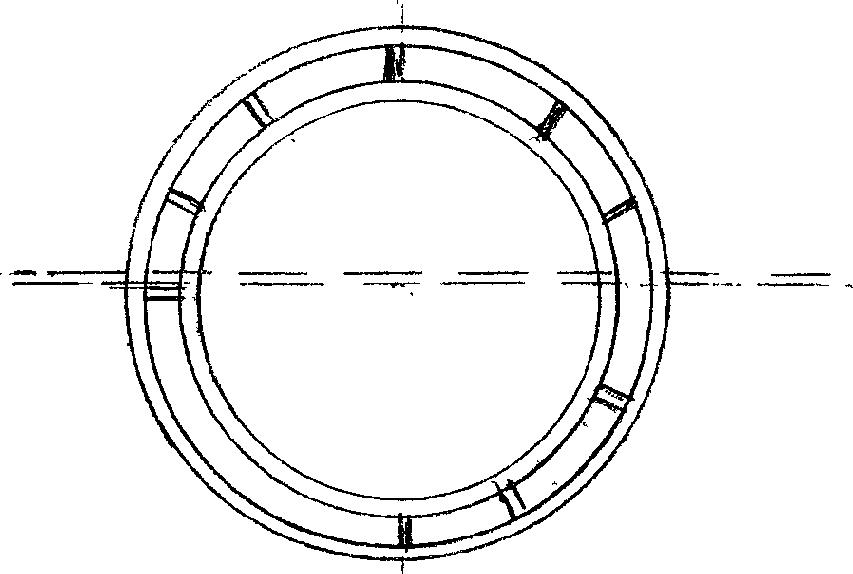

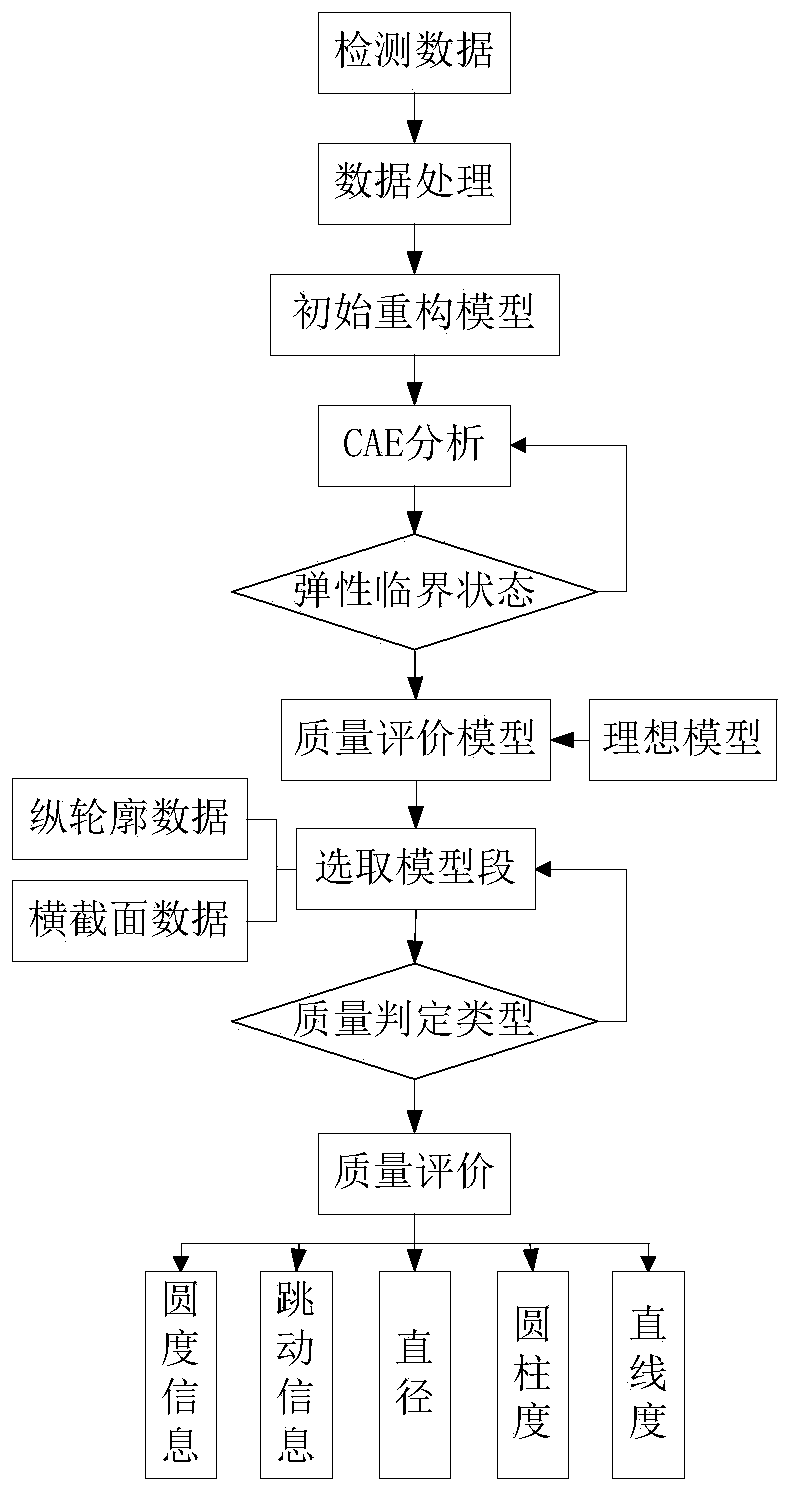

On-line virtual detection and evaluation method for the forming quality of ultra-thin-wall easily deformable cylindrical parts

ActiveCN106874624BRealize one-time comprehensive inspectionSolve inaccurateGeometric CADSpecial data processing applicationsEngineeringIdeal machine

The invention discloses a method for forming quality online virtual detection and evaluation of an ultra-thin-wall easily-deformed cylindrical element. According to an easily-deformed cylindrical element curve surface model reconstructed through online detection data and the relation among a material, the cylindrical element and elastic deformation, uniform distribution pressurizing is virtualized in the cylindrical element, so that the cylindrical element overcomes gravity and other elastic deformation, a real condition during practical use is achieved, a to-be-detected element quality evaluation model is obtained and compared with an ideal machining state model, and quality evaluation is completed. The method for forming quality (geometrical precision) evaluation of the ultra-thin-wall easily-deformed cylindrical element on the basis of a finite element is innovatively disclosed, the machining state of the ultra-thin-wall cylindrical element is provided, and the real-time state of the forming quality (geometrical precision) of the cylindrical element is also provided. The quality evaluation method is high in efficiency and precision, has the advantages of being more accurate and quicker to use, and can be widely used for quality (geometrical precision) evaluation of other easily-deformed, ultra-thin-wall and high-precision workpieces.

Owner:CENT SOUTH UNIV

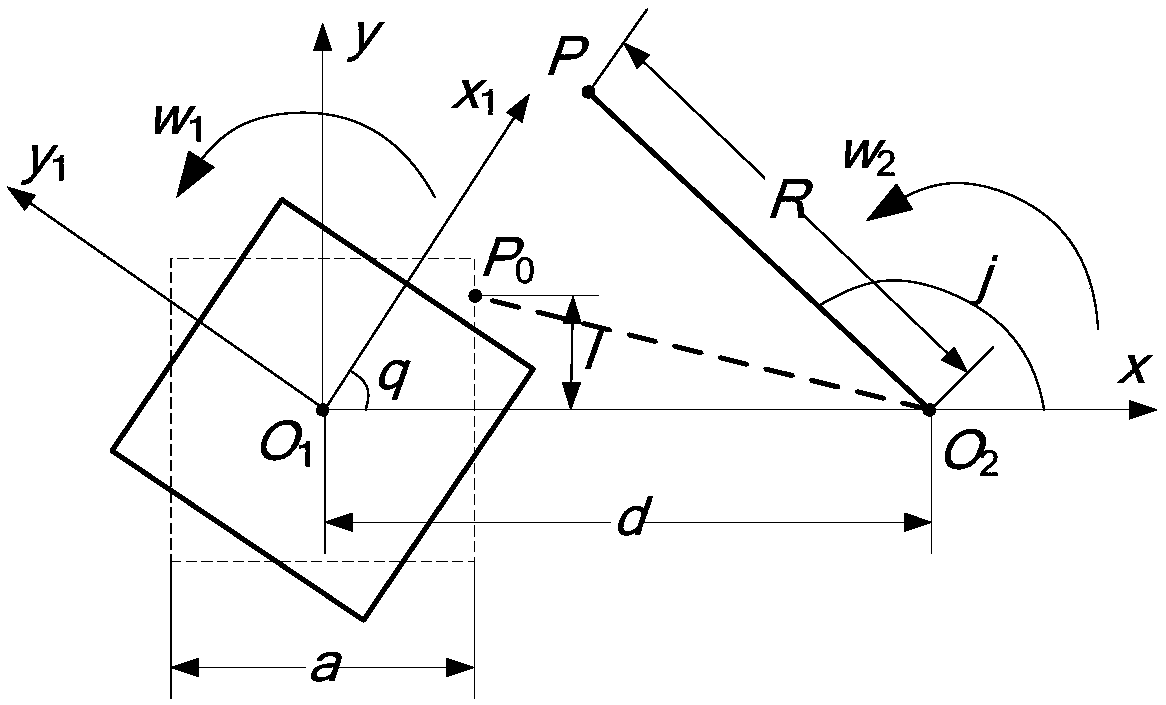

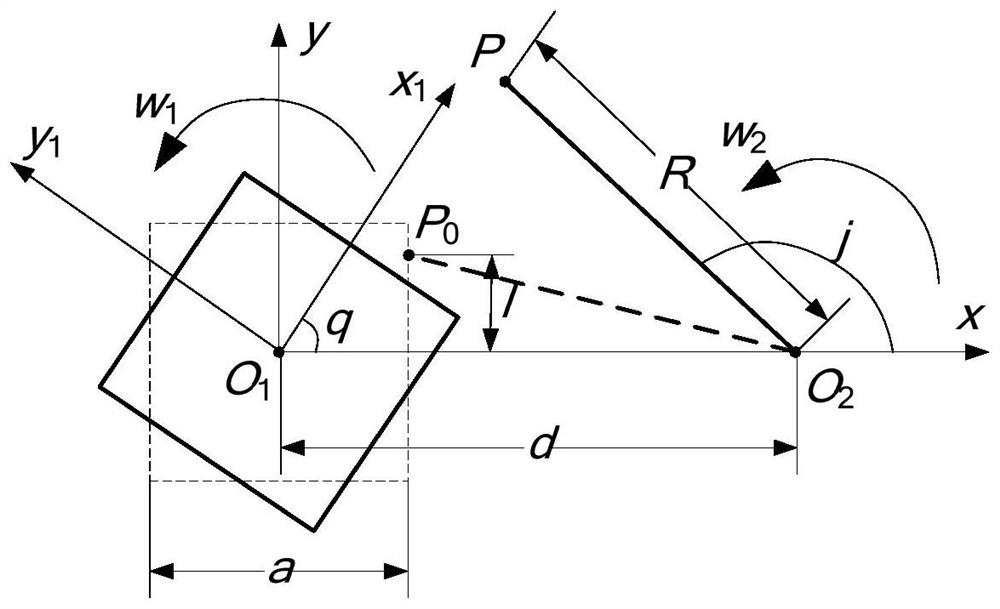

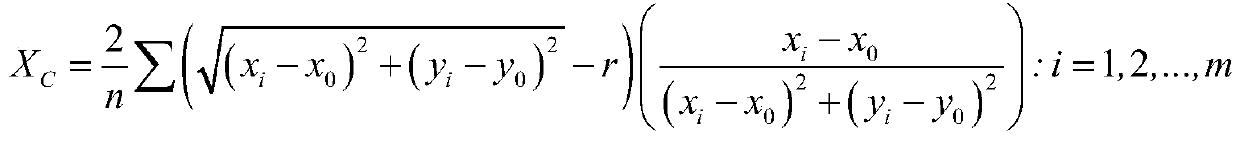

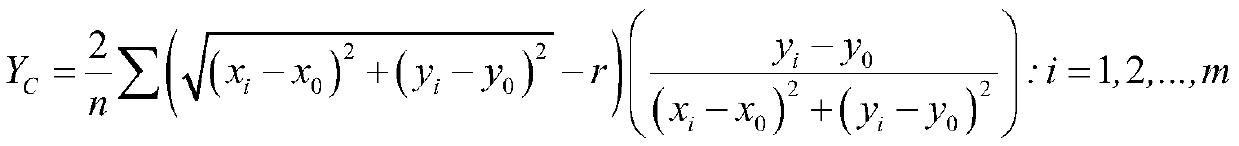

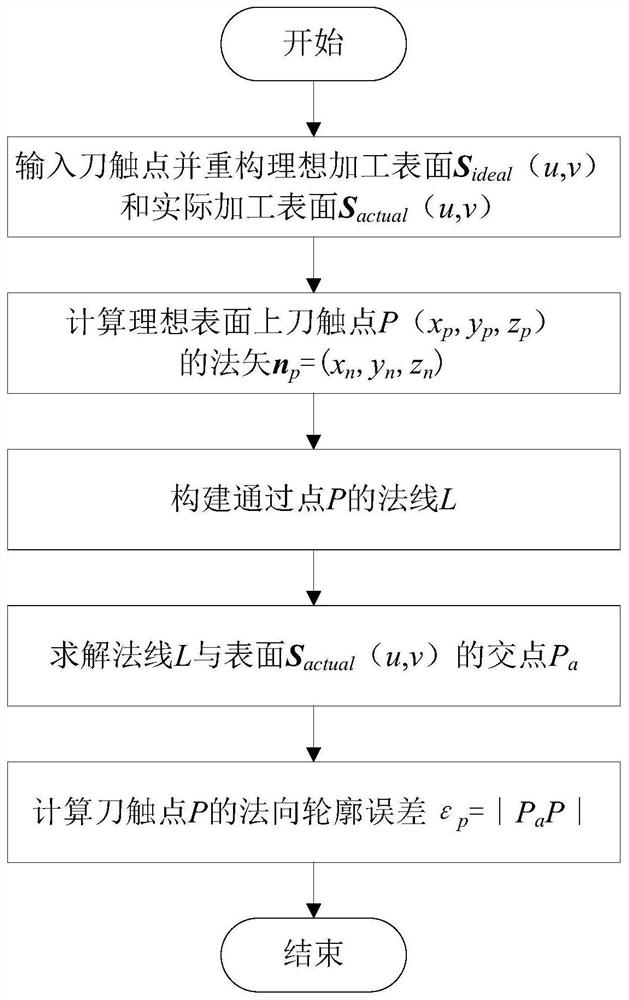

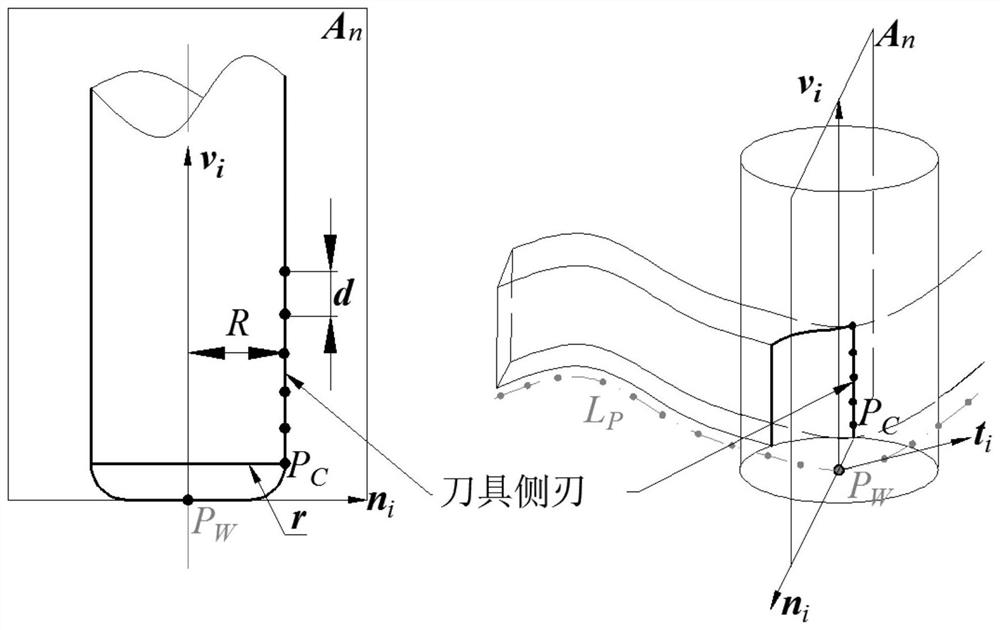

A Prediction Method of Point Contour Error on Part Side Milling Surface

ActiveCN108803487BAccurate predictionEasy to useProgramme controlComputer controlGeometric relationsAlgorithm

The invention discloses a point position contour error prediction method on the side milling surface of a part. Step 1: Obtain the ideal tool position point in the prediction area, and obtain the corresponding actual tool position point according to the multi-body theory and homogeneous coordinate transformation; Step 2: Select several points on the side edge of the tool as the knife contact, and calculate the ideal knife contact corresponding to the ideal knife position and the actual knife contact corresponding to the actual knife position according to the geometric relationship between the knife position point and the knife contact point; step 3: According to the ideal knife contact and the actual knife contact obtained in step 2, construct the ideal machining surface S i and the actual machined surface S a ;Step 4: Calculate the predicted points on the ideal machined surface obtained through step 3 P The intersection of the normal and the actual machined surface P a ;Calculate prediction points P and intersection P a distance to get the predicted point P point contour error at the position; the measurement and evaluation principle of the present invention is consistent with the contour measurement method, and the prediction is more accurate.

Owner:SOUTHWEST JIAOTONG UNIV

Inner deflection swinging cutter blade type ditching cutter head and driving device thereof

InactiveCN103621202BEasy to swing in and outAvoid collisionTilling equipmentsEngineeringPower equipment

The invention provides an inner deflection swinging cutter blade type ditching cutter head and a driving device thereof. The inner deflection swinging cutter blade type ditching cutter head comprises a driving box, a driving sprocket, a driving main shaft, a left cutter head device and a right cutter head device, wherein the driving box is arranged on external power equipment, the driving main shaft is arranged on the driving box, the driving box is used for providing power transmission and meanwhile completing the installation and supporting of the other parts, the left cutter head device and the right cutter head device are identical in structure, are arranged at the two sides of the driving box and are respectively arranged on the driving main shaft, the driving sprocket is arranged in the middle of the driving main shaft, and the external power equipment is used for driving the driving sprocket through a chain, so that the driving main shaft is driven to rotate. The inner deflection swinging cutter blade type ditching cutter head is simple in structure, convenient to operate, driven by an eccentric wheel and used for driving a movable cutter blade to deflect so as to realize the variable cross-section soil cutting and has strong practicability; a cutting gearbox is used for blocking part of soil blocks; and the inner deflection swinging cutter blade type ditching cutter head can be used for completely solving the problem that a small-sized self-propelled ditcher cannot be adapted to southland moist clay, and is an ideal machine tool for the ditcher for wooden lands, tea gardens and vegetable gardens.

Owner:HUNAN AGRICULTURAL UNIV

Automatic hub clamping positioner for robot grinding and polishing

ActiveCN114770379AIdeal processing positionIdeal processing speedGrinding drivesGrinding work supportsEngineeringIndustrial robotics

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com