Numerical control machining square algorithm with high precision

A turning and algorithm technology, applied in the field of high-precision CNC turning algorithms, can solve the problems of large radius size of the cutter head, low machining accuracy, and large cutter head, so as to improve the machining accuracy and meet the requirements of the turning machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

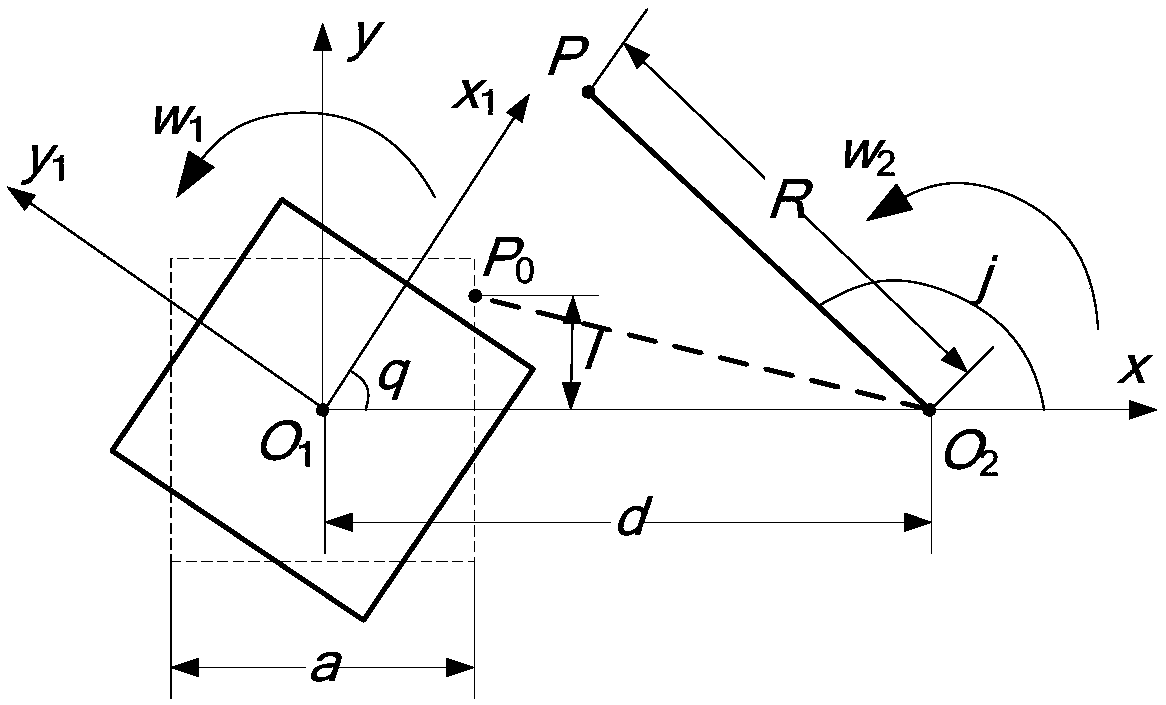

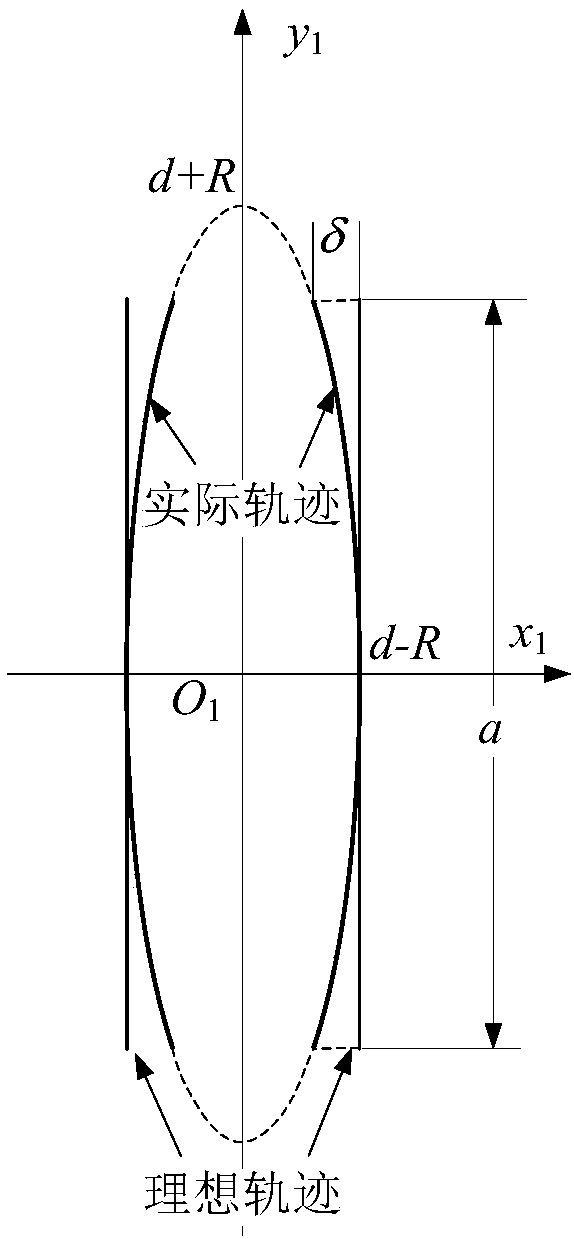

[0040] like figure 1 As shown, assuming that the workpiece is a regular n-gon, and the side length is a, when the car is square, the workpiece revolves around its center O 1 Rotate, the tool is fixed on the cutter head, and the cutter head revolves around the fixed point O 2 Rotate, its radius of gyration is R, both of them turn the same, and their rotation angles are Two rotation centers O 1 o 2 The center-to-center distance is d. Fixed coordinate system xO 1 y (denoted as the coordinate system A) is fixed on the machine bed, and the motion coordinate system x 1 o 1 the y 1 (Denoted as coordinate system B) is fixedly connected to the workpiece and rotates with the rotation of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com