Magnet field adjustable magnetic separator

A magnetic separator and magnetic field technology, applied in the field of magnetic field adjustable magnetic separator, can solve the problems of background magnetic field loss, inability to balance output and grade, and grade decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

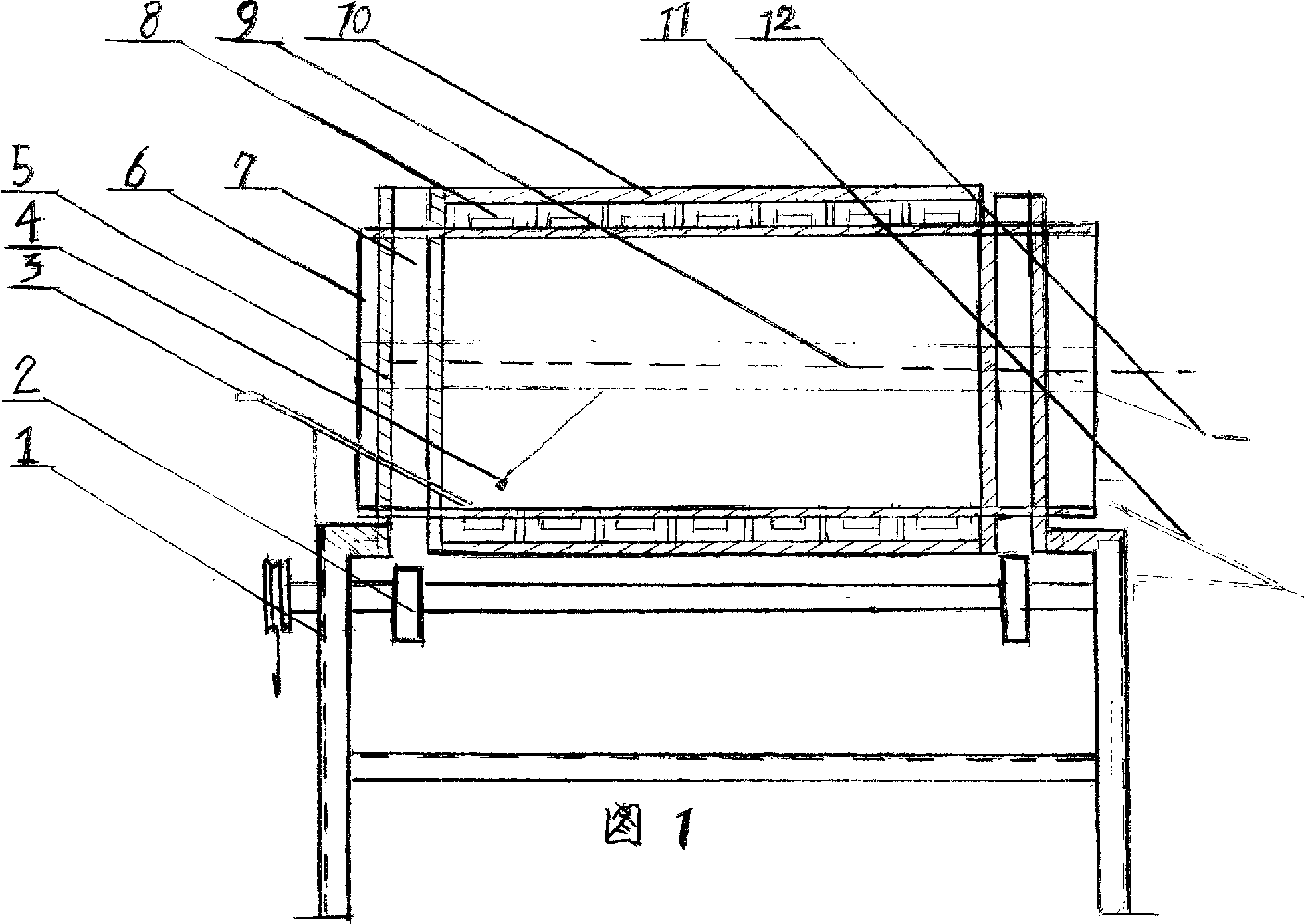

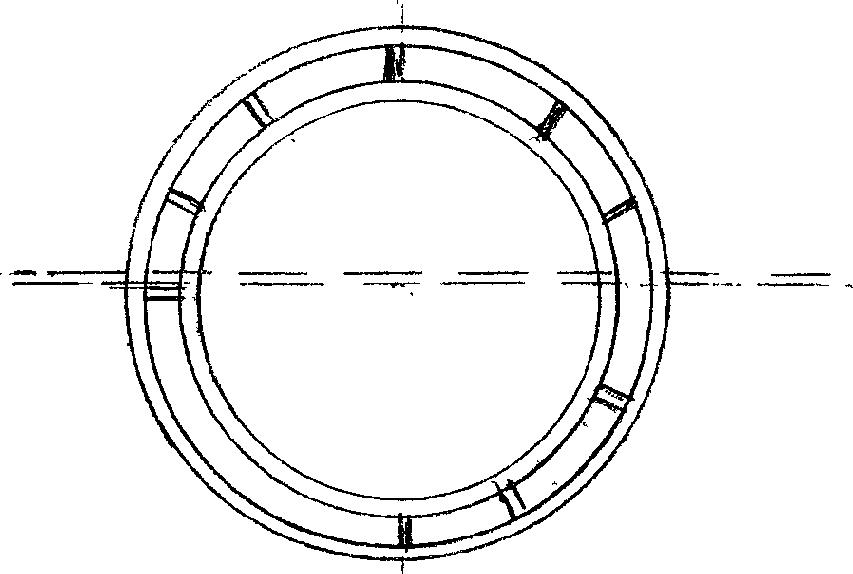

[0009] The adjustable magnetic separator described in Figure 1 includes a stainless steel inner cylinder (6) which is fixed at both ends by a trough-shaped frame (7) and rolls on wheels (2) matched with (7) The shaft end assembly pulley of operation (2) cooperates with the power motor and the reduction gear in the direction indicated by the arrow, and this figure of this part does not provide. The outer part of (6) separates and closes two magnet holders of semicircular type, and the magnetic field effect (6) upper figure number (9) it produces is the non-magnetic zone of this part, and its groove is used for iron powder to come off and discharge here. (9) The dotted line in the middle indicates that the split gap (8) is a permanent magnet, and the figure number (3) is a feeding guide plate (4) is a magnet scraping plate for adsorption. When the raw material enters from (3), it rotates (6) ) continuously absorbs the iron ore and moves forward and flows out on the sand outlet (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com