Method for smashing, detaching and recycling lithium battery

A recycling method, lithium battery technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of resource waste environment, resource waste environment, large dust and harmful substances, etc., to improve processing efficiency, The effect of preventing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

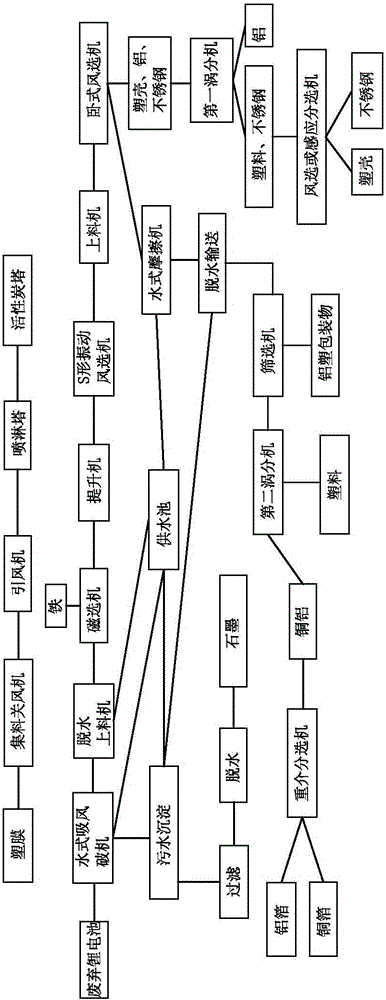

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] combine figure 1 As shown, the lithium battery crushing, dismantling and recycling method disclosed in this embodiment includes the following steps:

[0022] The first step is to put the charged or uncharged lithium battery into the water-type suction crusher, and the waste lithium battery can be crushed through the water-type suction crusher without pre-dismantling the lithium battery. Compared with the existing technology, it is necessary to discharge and dismantle the waste lithium battery, which can effectively improve the treatment efficiency, and adopts water crushing, which can fuse the crushed lithium battery materials through water, which can prevent the process of generation of dust pollutants;

[0023] In the second step, the water-type suction crusher crushes the lithium battery, and protects the lithium battery during the crushing process throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com