Crankshaft flange plate steady nail hole machining machine tool

A technology for processing machine tools and nail holes, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as large fluctuations in product quality, high labor intensity for operators, and susceptibility to frozen shoulder, etc., and achieve improvement Processing efficiency and automation level, convenient assembly, simple manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

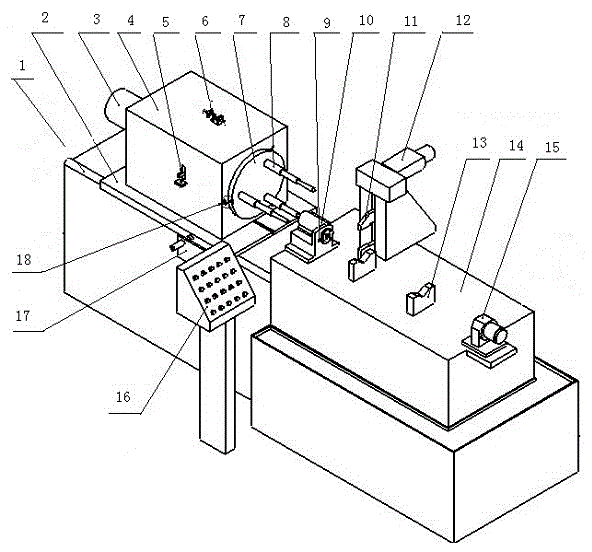

[0013] From figure 1 It can be seen from the figure that a crankshaft flange stable nail hole processing machine tool includes a main bed body 1, a drive motor 3, a rotary power head box 4, a workpiece clamping and fixing device, a PLC control cabinet, a feed cylinder, a rotary Oil cylinder etc. On the left side of the main bed body 1, a sliding guide rail is installed, on which the slide table 2 driven by the feed oil cylinder is installed, and the rotary power head casing 4 is installed on the slide table 2. The workpiece platform 14 is installed on the right side of the main bed body 1, and the workpiece platform 14 is equipped with a workpiece clamping and fixing device. Drive to drive the gear and rack to center the clamping structure to complete the horizontal positioning of the workpiece. Action requirements for automatic clamping and loosening. The workpiece clamping and fixing device includes a headstock pad iron 9, a positioning sleeve 10, a claw 11, a claw clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com