Method for constructing geometric digital twinning model of workpiece based on MBD process model

A process model and construction method technology, applied in the field of workpiece geometric digital twin model construction, can solve the problems of not making full use of the process model process information, long registration time, low efficiency, etc., to achieve the benefit of manufacturing process traceability and manufacturing process Improved, more targeted and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples, but the examples are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

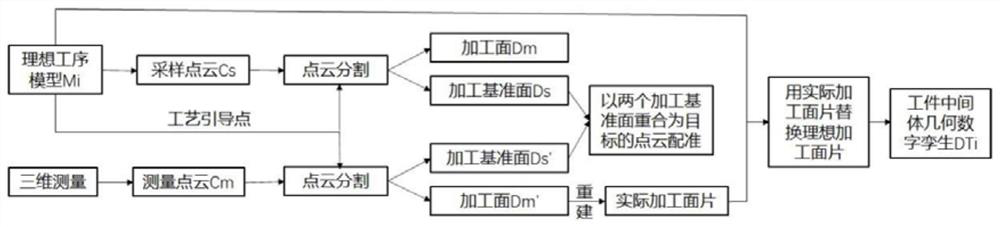

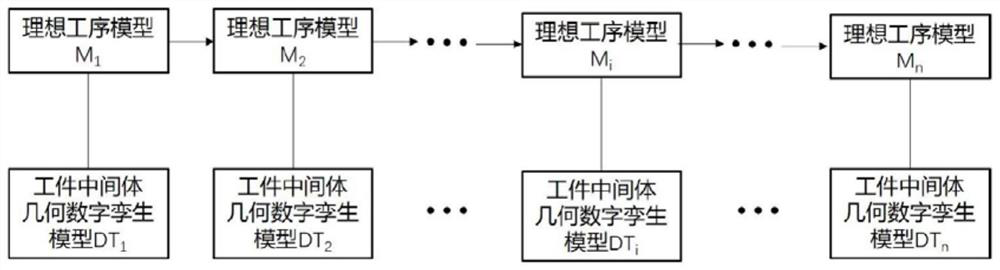

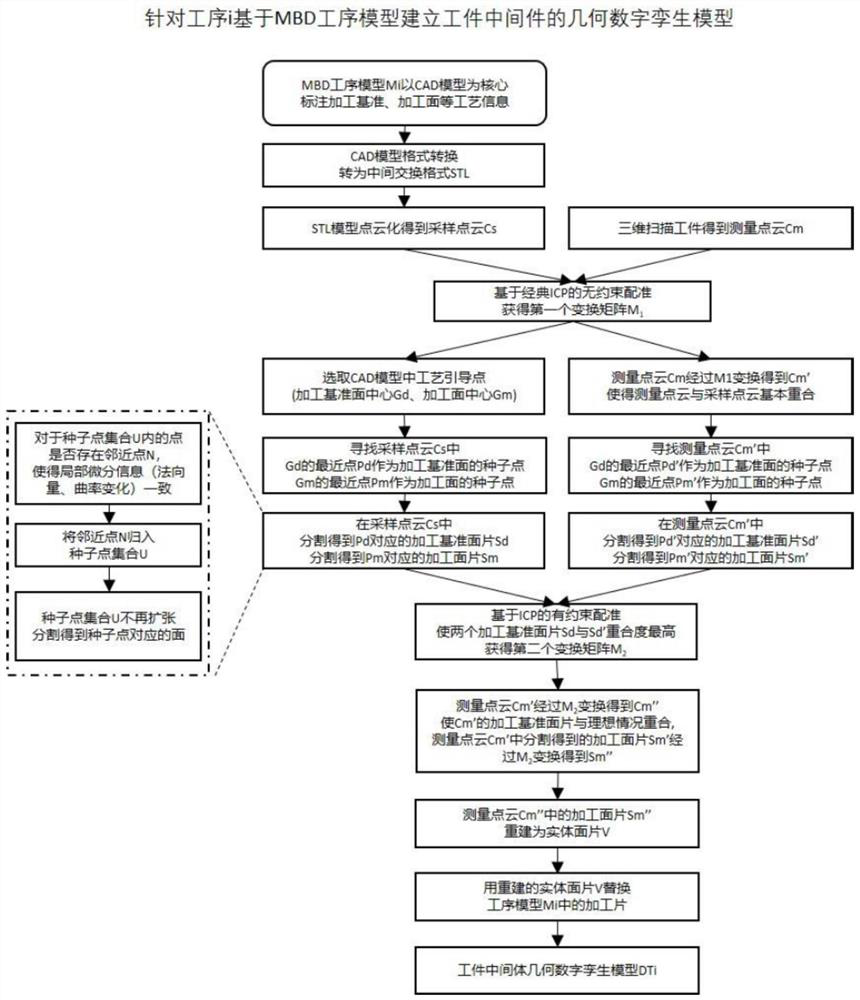

[0038]Based on the MBD process model, the present invention uses process-guided point cloud registration technology to coincide the processing reference plane of the three-dimensional measurement geometric model of the workpiece intermediate with the ideal design coordinate system; uses reverse reconstruction technology to reconstruct the actual processing surface, and finally Generate a geometric digital twin of the workpiece intermediate. The prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com