Automatic hub clamping positioner for robot grinding and polishing

A positioner and robot technology, applied in the direction of grinding drive device, grinding/polishing equipment, grinding machine tool parts, etc., can solve the problems of inability to position and fix the hub, inconvenient operation of the fixing method, and low machining accuracy , to achieve the effect of simple structure, fast and convenient clamping, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

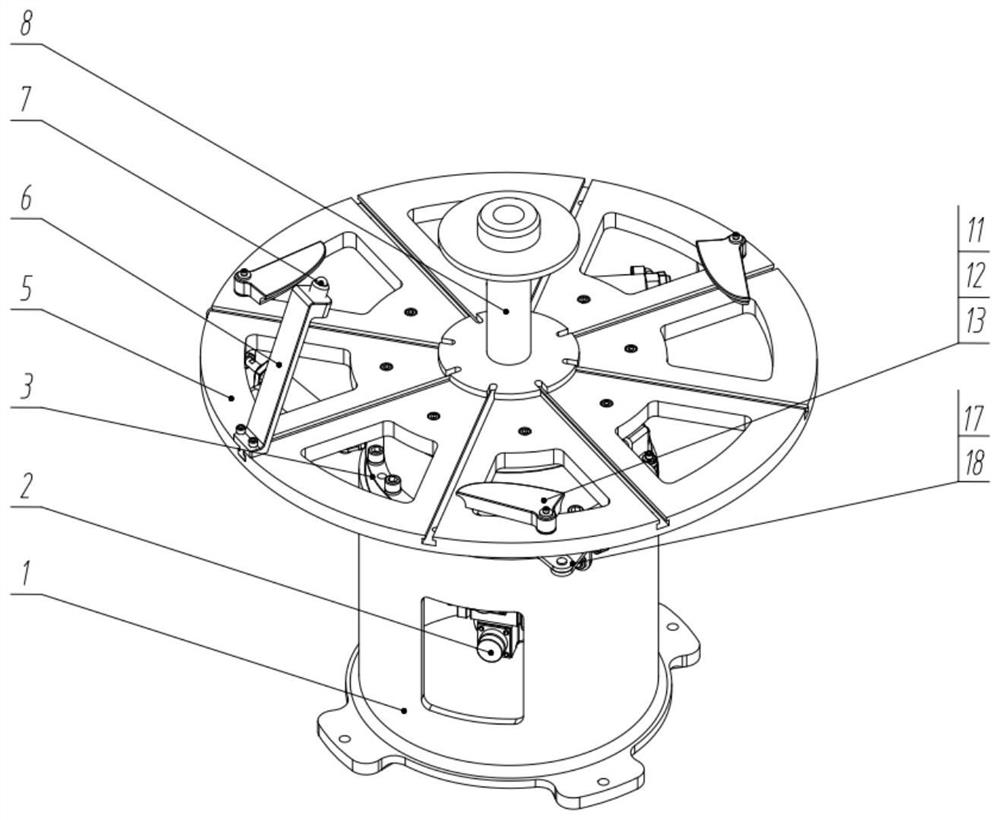

[0025] Specific implementation mode 1: refer to Figure 1 to Figure 5 This embodiment will be described. This embodiment provides an automatic wheel hub clamping and positioning machine for robot grinding and polishing. The automatic clamping and positioning machine includes a base 1, a driving mechanism, a turntable 5, an auxiliary fixing mechanism, and a central positioning shaft. 8 components and N clamping and fixing components, N is a positive integer greater than 3;

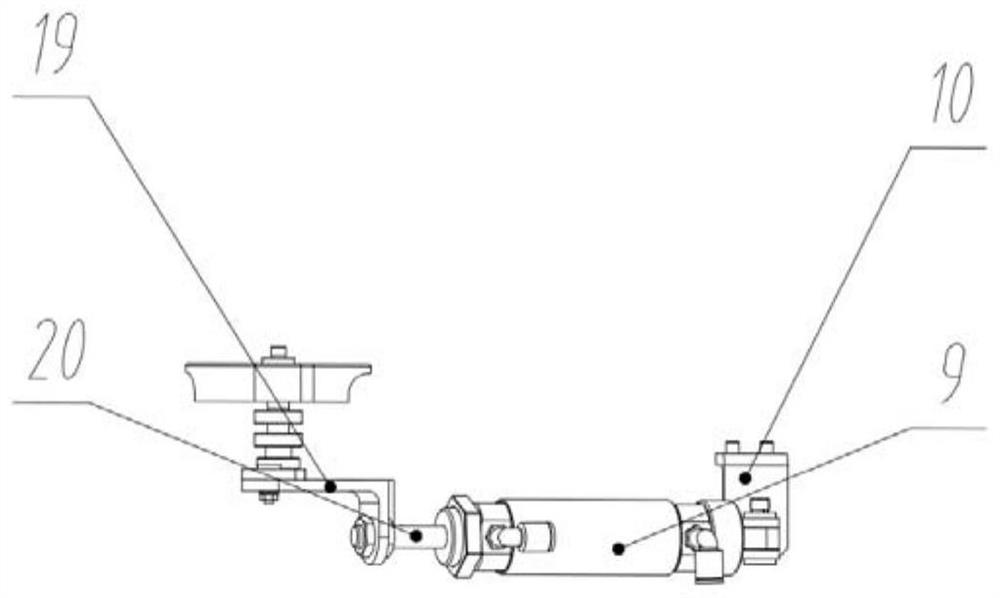

[0026] The drive mechanism is installed in the base 1, and the power output end of the drive mechanism passes through the top surface of the base 1 and is arranged outside the base 1, the turntable 5 is arranged above the base 1, and the turntable 5 is connected to the drive. The power output end of the mechanism is detachably connected, the auxiliary fixing mechanism is arranged at the edge of the upper surface of the turntable 5, and the auxiliary fixing mechanism is detachably connected with the turntabl...

specific Embodiment approach 2

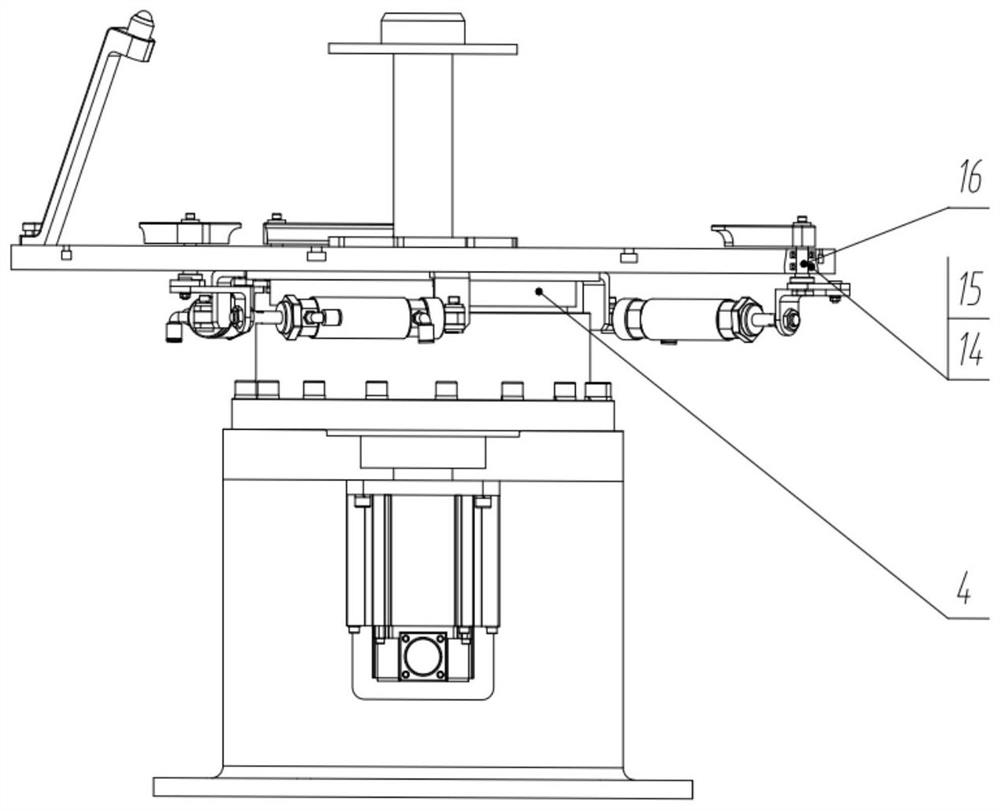

[0028] Specific implementation two: refer to Figure 1 to Figure 5 This embodiment is described. This embodiment further defines the driving mechanism described in the specific embodiment 1. In this embodiment, the driving mechanism includes a motor 2, a reducer 3 and a Farah disc 4. The motor 2 is fixed by a motor mounting bracket. Installed in the base 1, and the output shaft of the motor 2 is arranged vertically upward, the reducer 3 is arranged on the output shaft of the motor 2, and the power input shaft of the reducer 3 is connected with the output shaft of the motor 2 through a coupling, The power output shaft of the reducer 3 is arranged vertically upward, the shell of the reducer 3 is disassembled and connected to the upper surface of the base 1 through bolts, the Fara disc 4 is sleeved on the power output shaft of the reducer 3, and the axis of the Fara disc 4 is connected to the upper surface of the base 1. The axes of the power output shafts in the reducer 3 are ar...

specific Embodiment approach 3

[0030] Specific implementation mode three: refer to Figure 1 to Figure 5This embodiment is described. This embodiment further defines the turntable 5 described in the second embodiment. In this embodiment, a center hole is machined in the center of the upper surface of the turntable 5, and the center positioning shaft assembly 8 is correspondingly inserted in the In the center hole on the turntable 5, the upper surface of the turntable 5 is machined with a plurality of guide chutes equidistantly along the circumferential direction. At the edge of 5, a weight-reducing through hole is machined on the fan-shaped table body between two adjacent guide chutes. Other compositions and connection methods are the same as those in the second embodiment.

[0031] In this embodiment, the center hole in the turntable 5 is used for cooperating with the center positioning shaft assembly 8, and the guide chute is a T-shaped groove, which is used to provide a guide and sliding space for the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com