Laser processing error control method for flexible conformal antenna based on surface mapping

A technology of conformal antenna and laser processing, which is applied in the direction of program control, digital control, computer control, etc., can solve the problems that the analysis and control of flexible antenna cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention will be described in detail in conjunction with the technical scheme and the accompanying drawings.

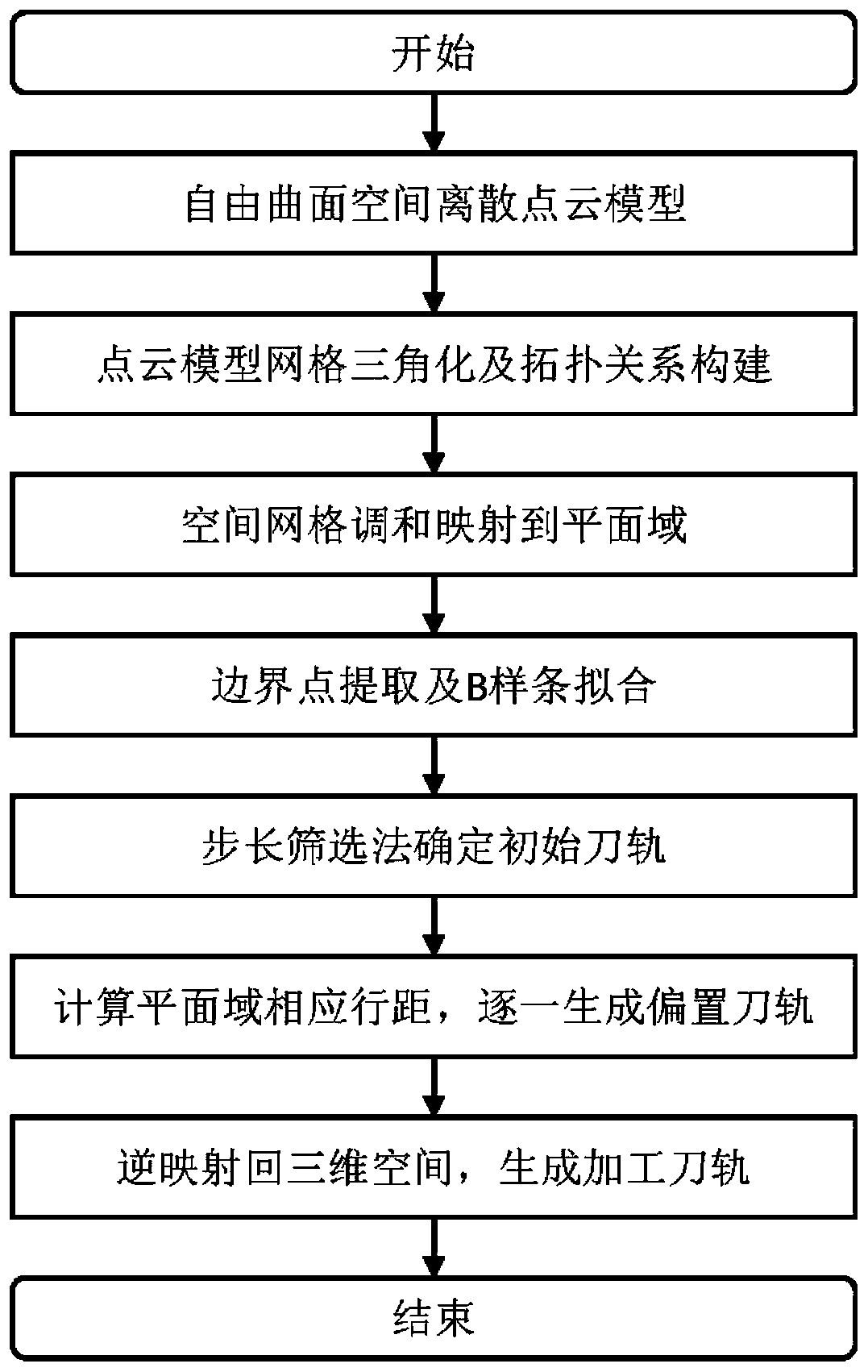

[0043] The flexible conformal antenna produces irregular deformation in the clamped state, and the conventional processing method is processed according to the ideal antenna line, which is prone to processing errors. Aiming at the limitations of existing technologies, a laser processing error control method for flexible conformal antennas based on surface mapping was invented. The overall process is shown in the attached figure 1 shown.

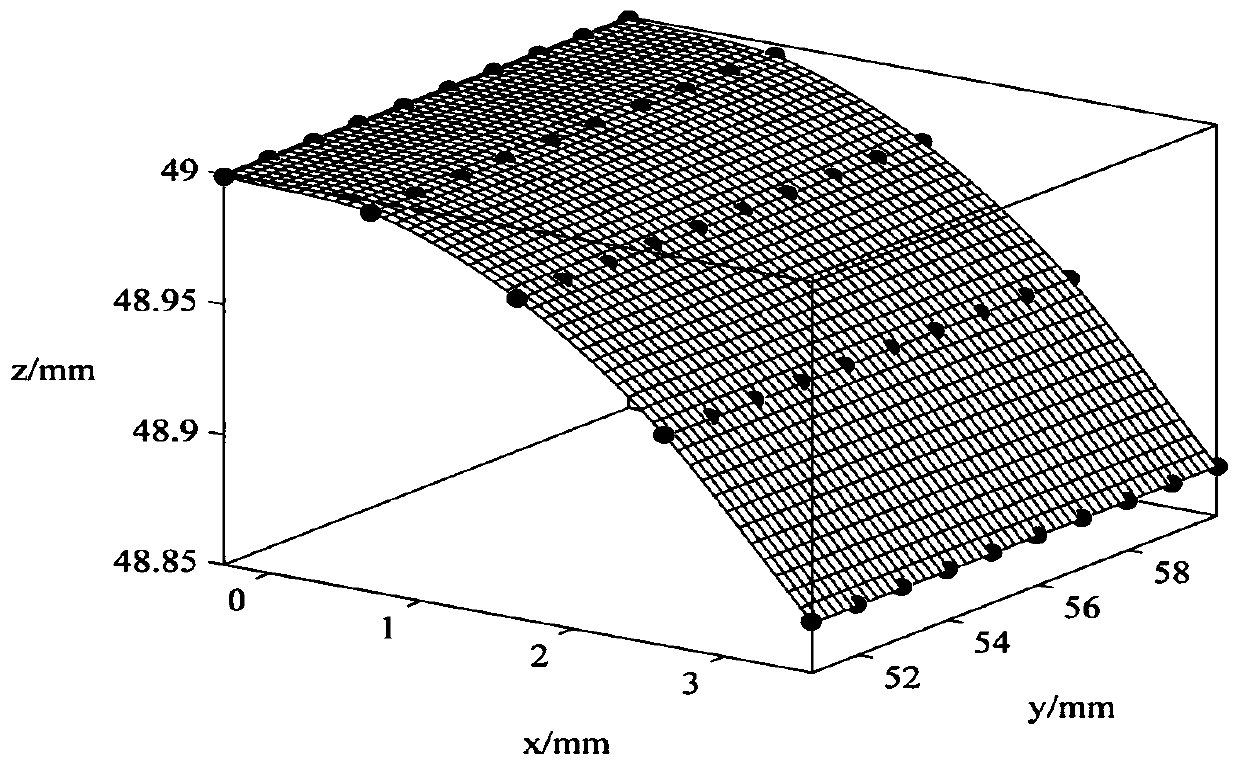

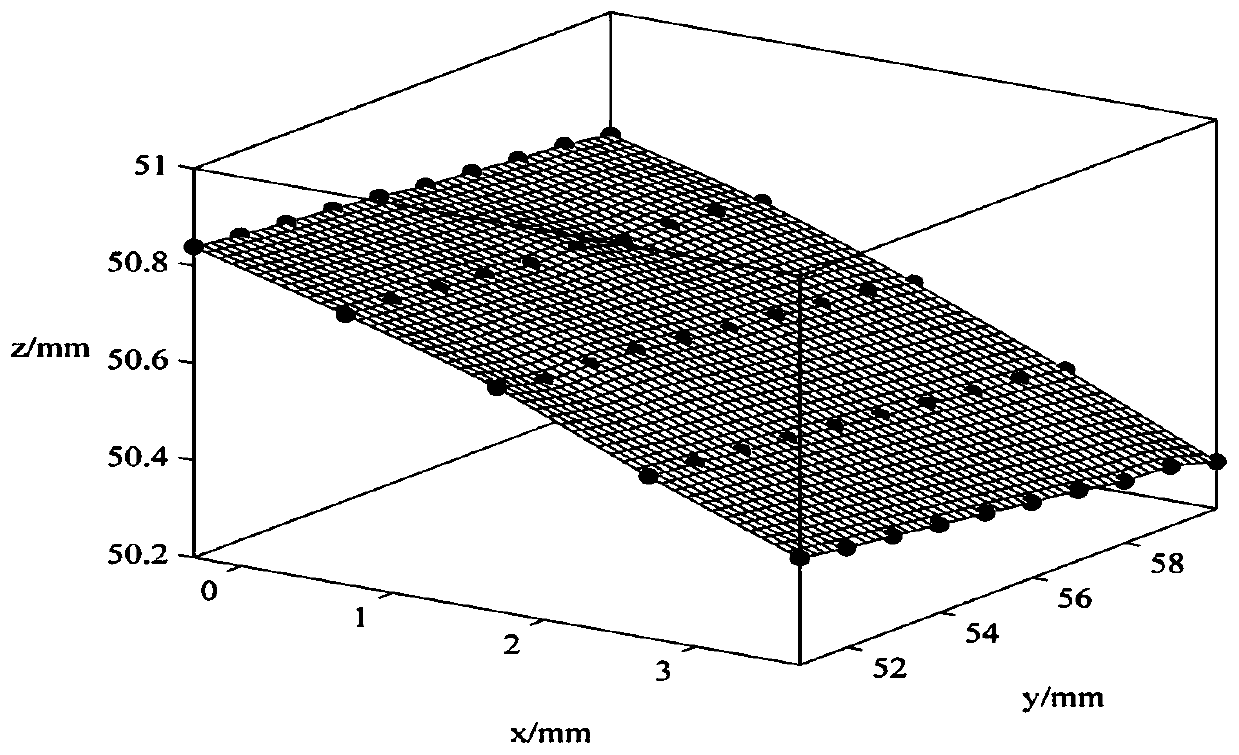

[0044] Taking the processing of a flexible conformal antenna with a size of 98×1×200 (outer diameter×wall thickness×length, in mm) and a copper plating layer as an example, the implementation process of the present invention will be described in detail.

[0045] First, determine the probe coordinate system by step 1, and determine the transformation relationship between the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com