Patents

Literature

205results about How to "Reduce slope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

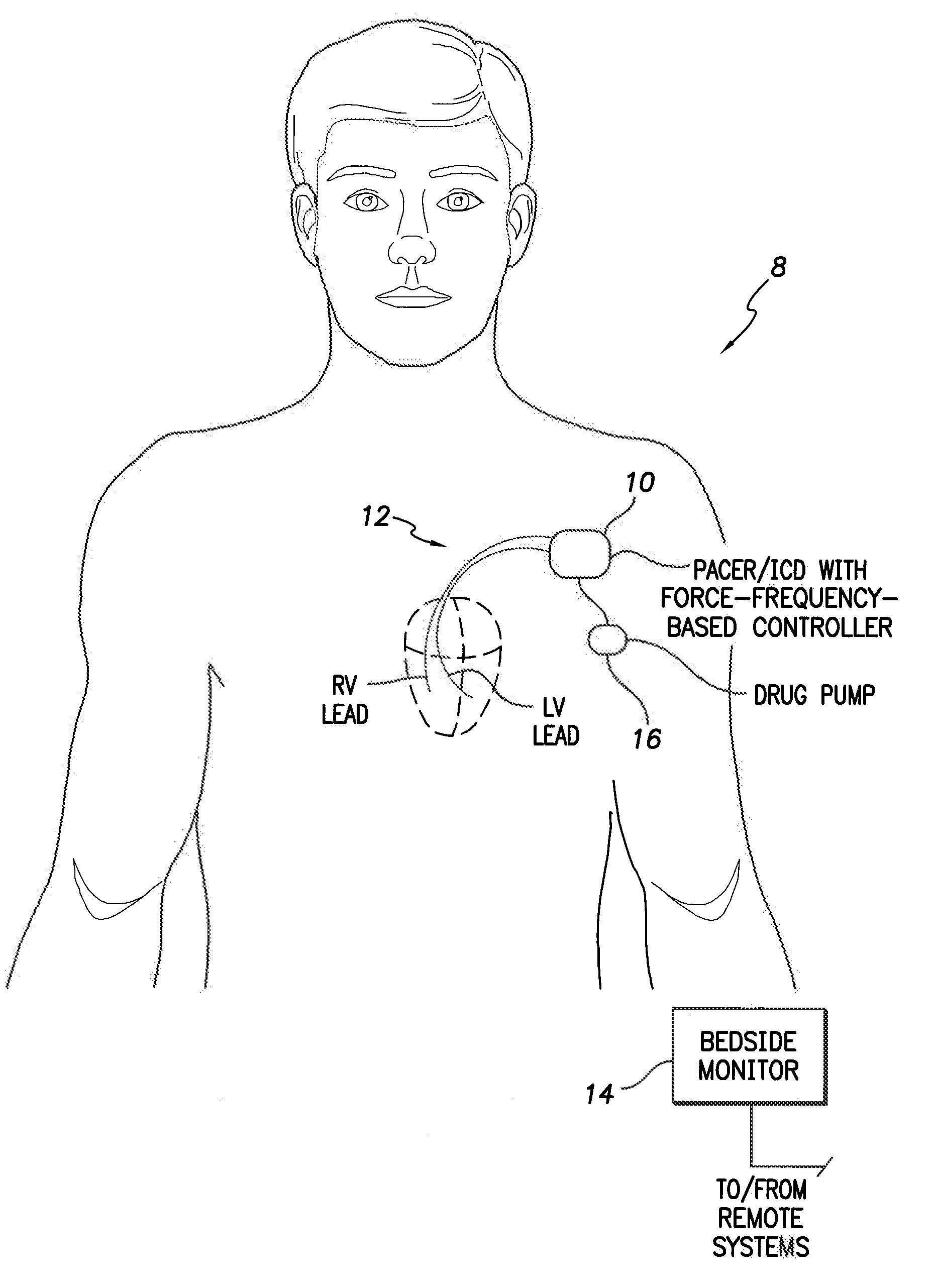

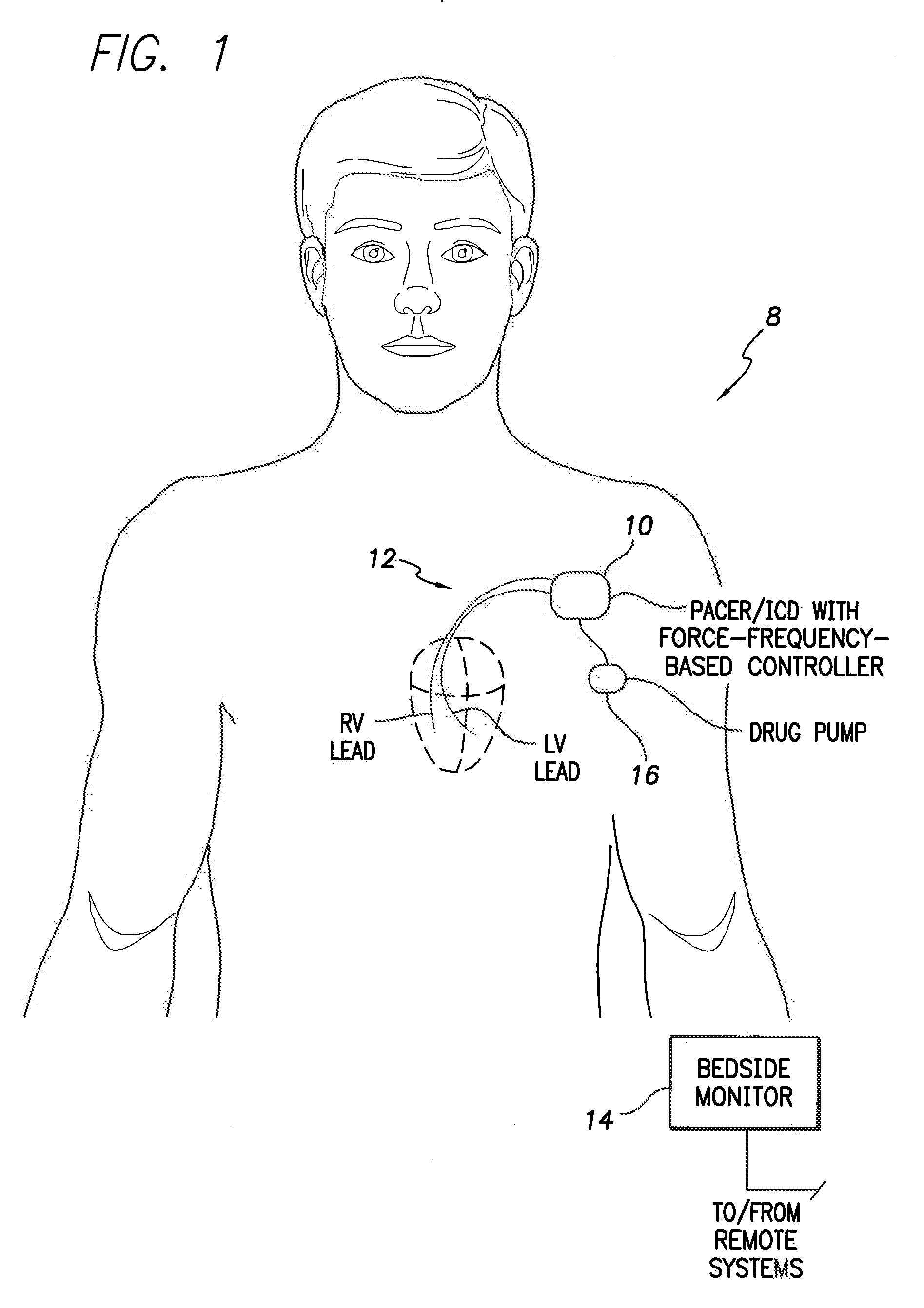

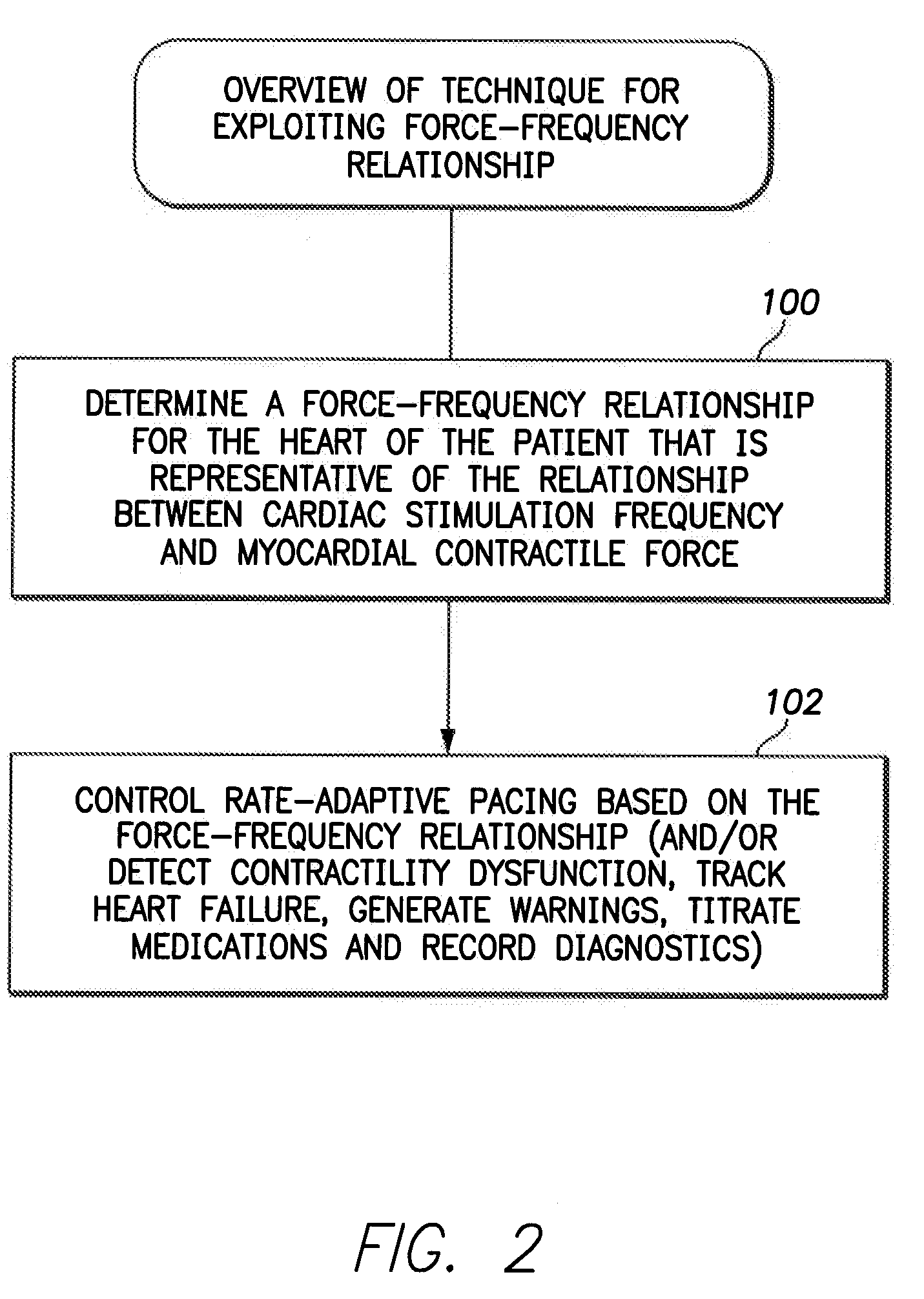

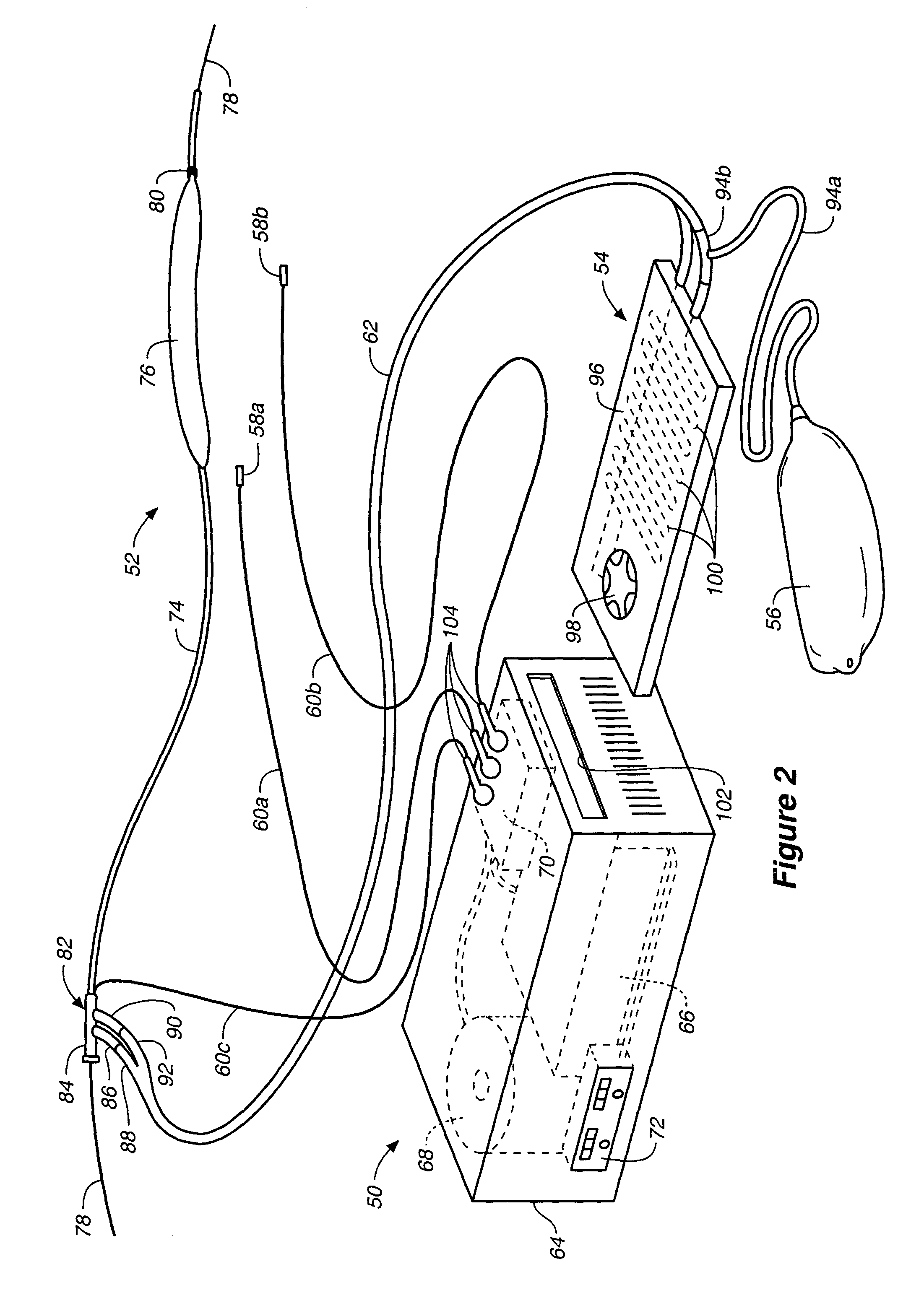

System and method for controlling rate-adaptive pacing based on a cardiac force-frequency relation detected by an implantable medical device

InactiveUS20100234906A1Reduce slopeDecrease in abscissaCatheterHeart stimulatorsCardiac pacemaker electrodeImplantable cardioverter-defibrillator

Techniques are provided for use in controlling rate-adaptive pacing within implantable medical devices such as pacemakers or implantable cardioverter-defibrillators (ICDs). In one example, a force-frequency relationship is determined for the heart of the patient, which is representative of the relationship between cardiac stimulation frequency and myocardial contractile force. To this end, various parameters are detected for use as surrogates for contractile force, including selected systolic pressure parameters and cardiogenic impedance parameters. Rate-adaptive pacing is then controlled based on the detected force-frequency relationship to, for example, deactivate rate-adaptive pacing if the slope and / or abscissa of the force-frequency relationship indicates significant contractility dysfunction within the patient. In other examples, rather than deactivating rate-adaptive pacing, control parameters are adjusted to render the rate-adaptive pacing less aggressive. In still other examples, trends in the slope and / or abscissa of the force-frequency relationship are monitored to detect contractility dysfunction and / or heart failure and titrate medications accordingly.

Owner:PACESETTER INC

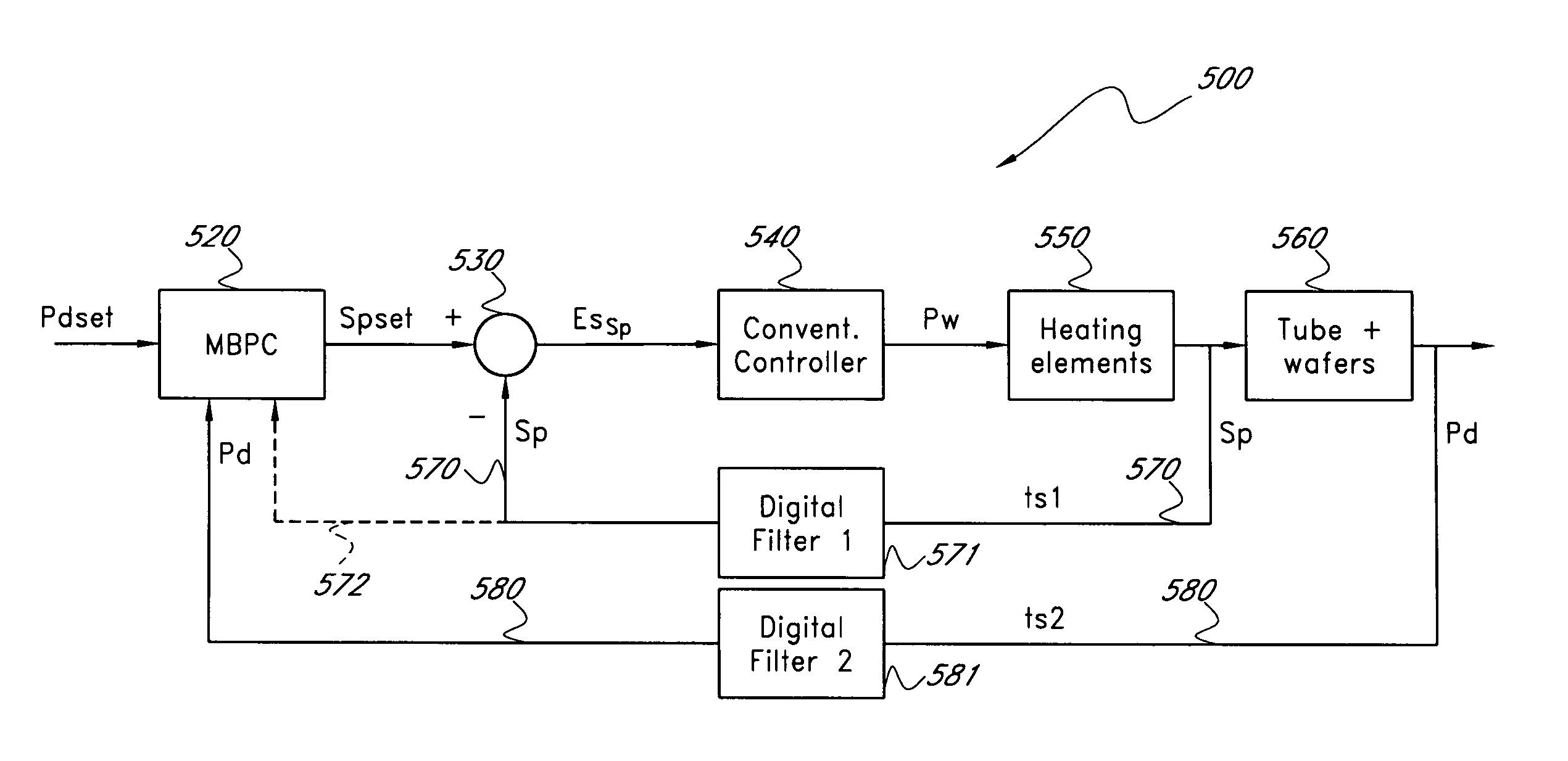

Hybrid cascade model-based predictive control system

ActiveUS7006900B2Reduce computational overheadReduce slopeControl mechanismSampled-variable control systemsMathematical modelDynamic models

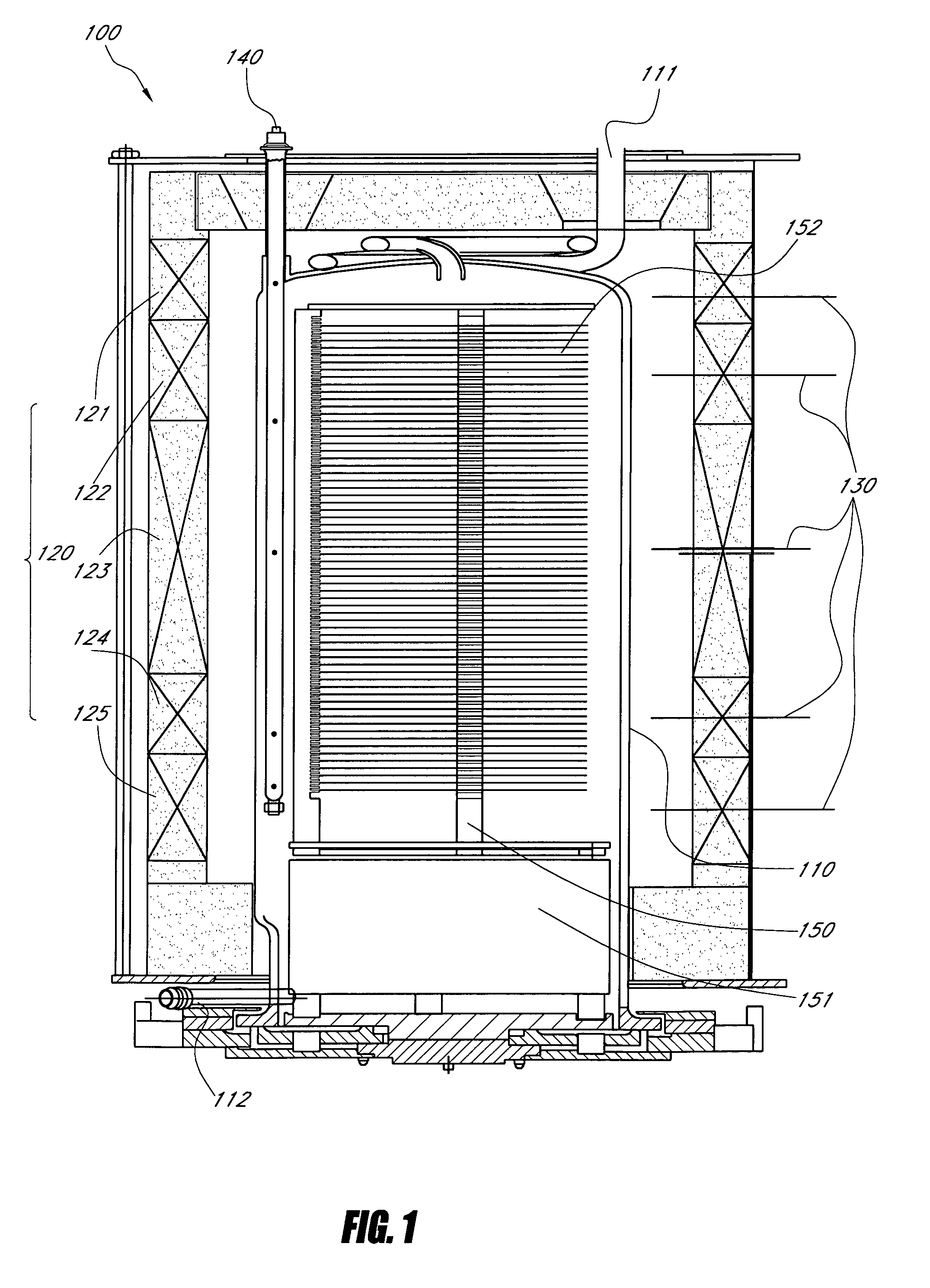

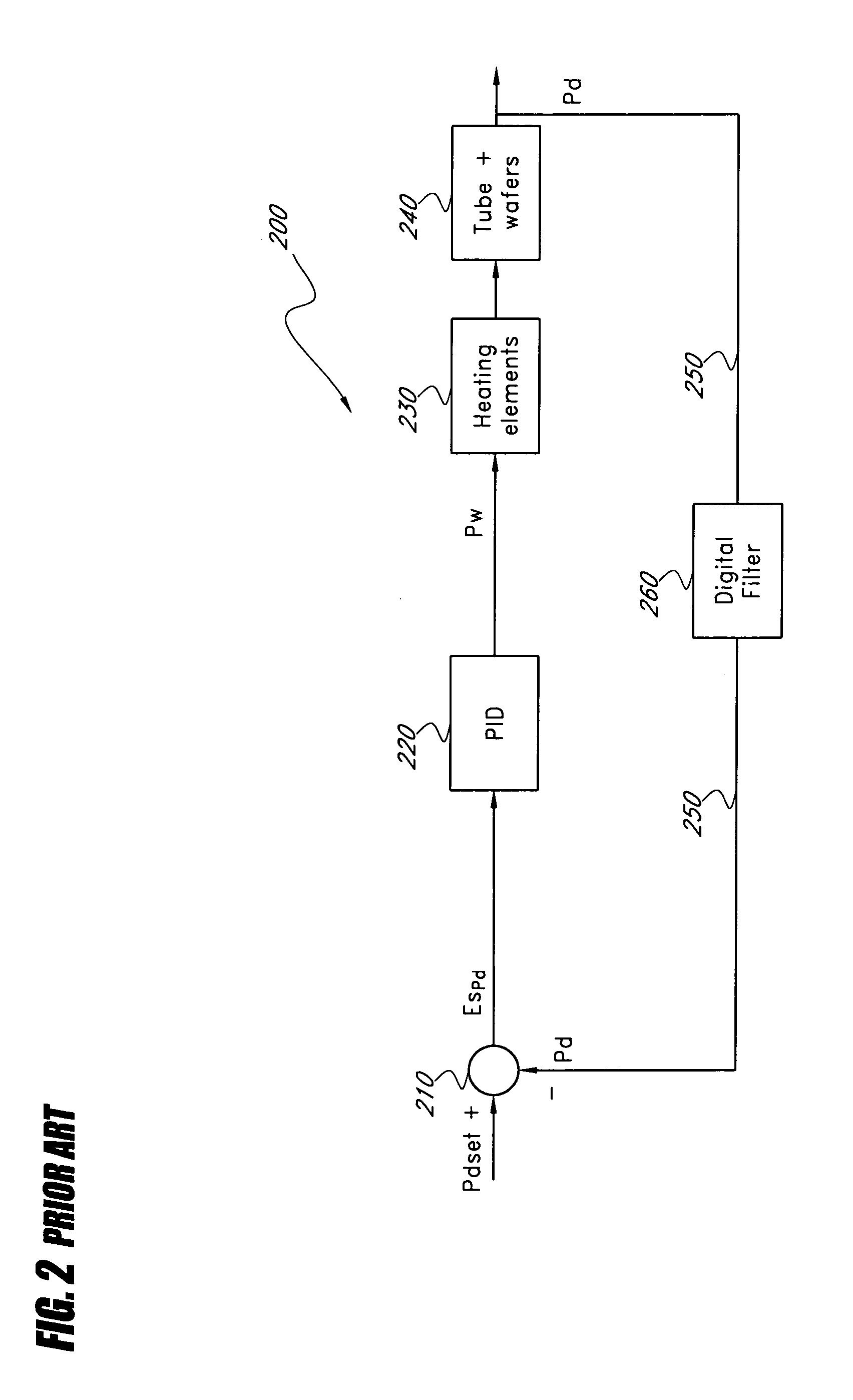

A hybrid cascade Model-Based Predictive control (MBPC) and conventional control system for thermal processing equipment of semiconductor substrates, and more in particular for vertical thermal reactors is described. In one embodiment, the conventional control system is based on a PID controller. In one embodiment, the MBPC algorithm is based on both multiple linear dynamic mathematical models and non-linear static mathematical models, which are derived from the closed-loop modeling control data by using the closed-loop identification method. In order to achieve effective dynamic linear models, the desired temperature control range is divided into several temperature sub-ranges. For each temperature sub-range, and for each heating zone, a corresponding dynamic model is identified. During temperature ramp up / down, the control system is provided with a fuzzy control logic and inference engine that switches the dynamic models automatically according to the actual temperature. When a thermocouple (TC) temperature measurement is in failure, a software soft sensor based on dynamic model computing is used to replace the real TC sampling in its place as a control system input. Consequently, when a TC failure occurs during a process, the process can be completed without the loss of the semiconductor substrate(s) being processed.

Owner:ASM INTERNATIONAL

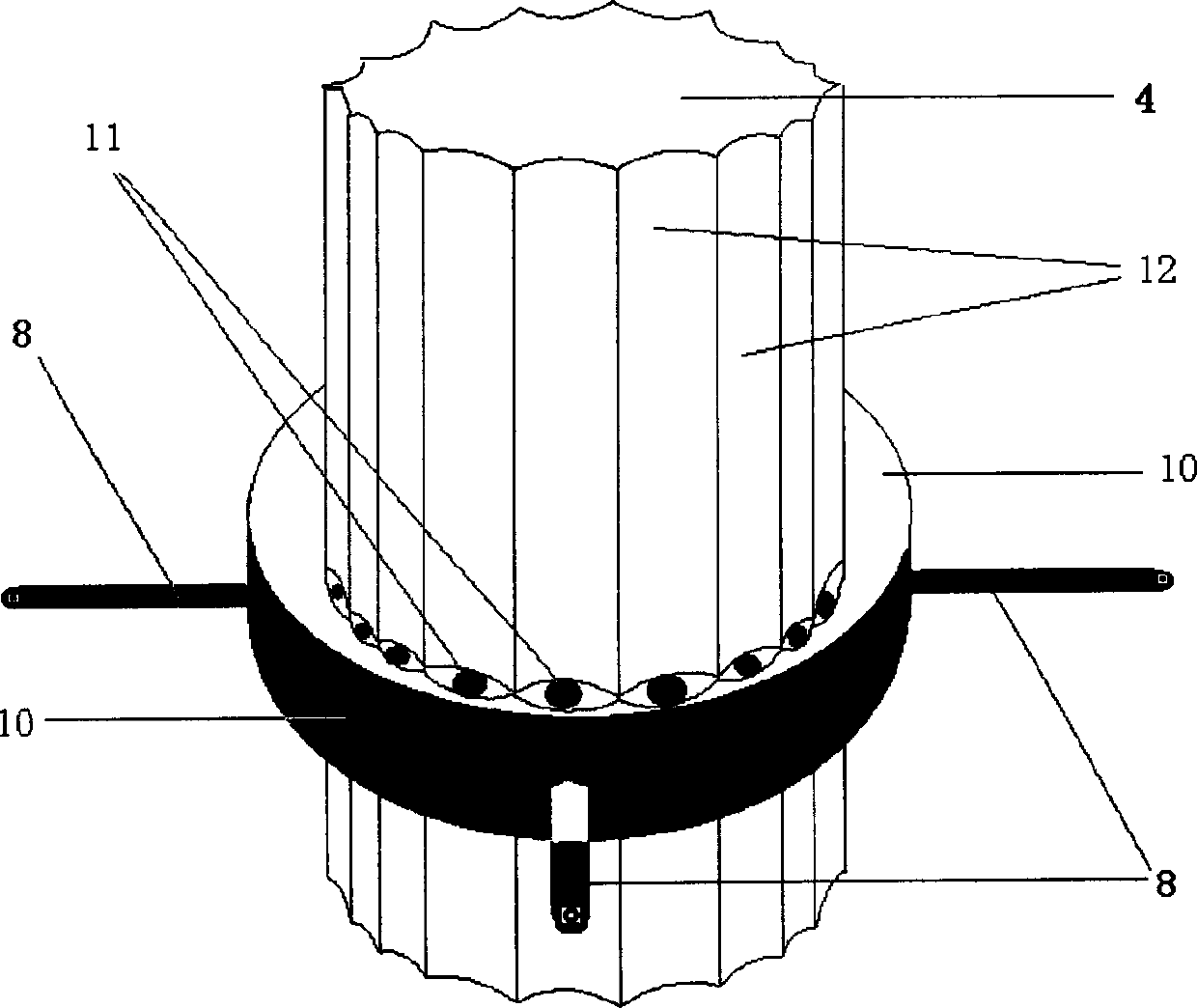

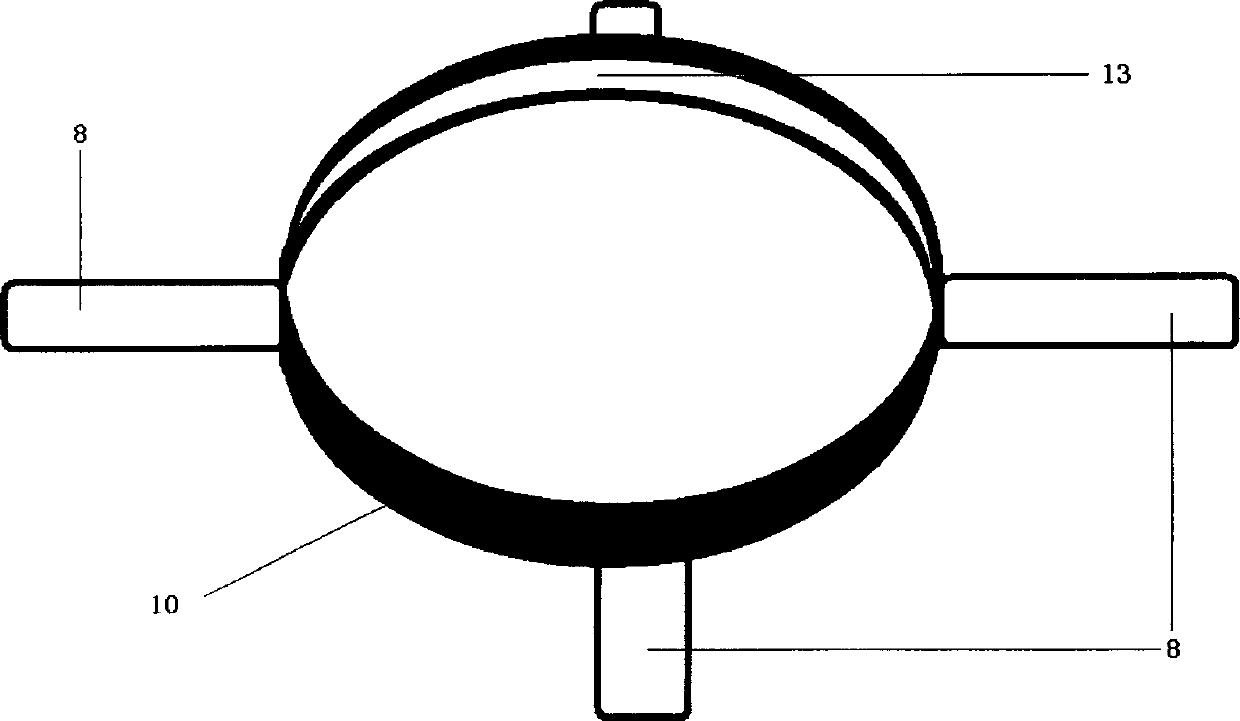

Method and system for control of a patient's body temperature by way of transluminally insertable heat exchange catheter

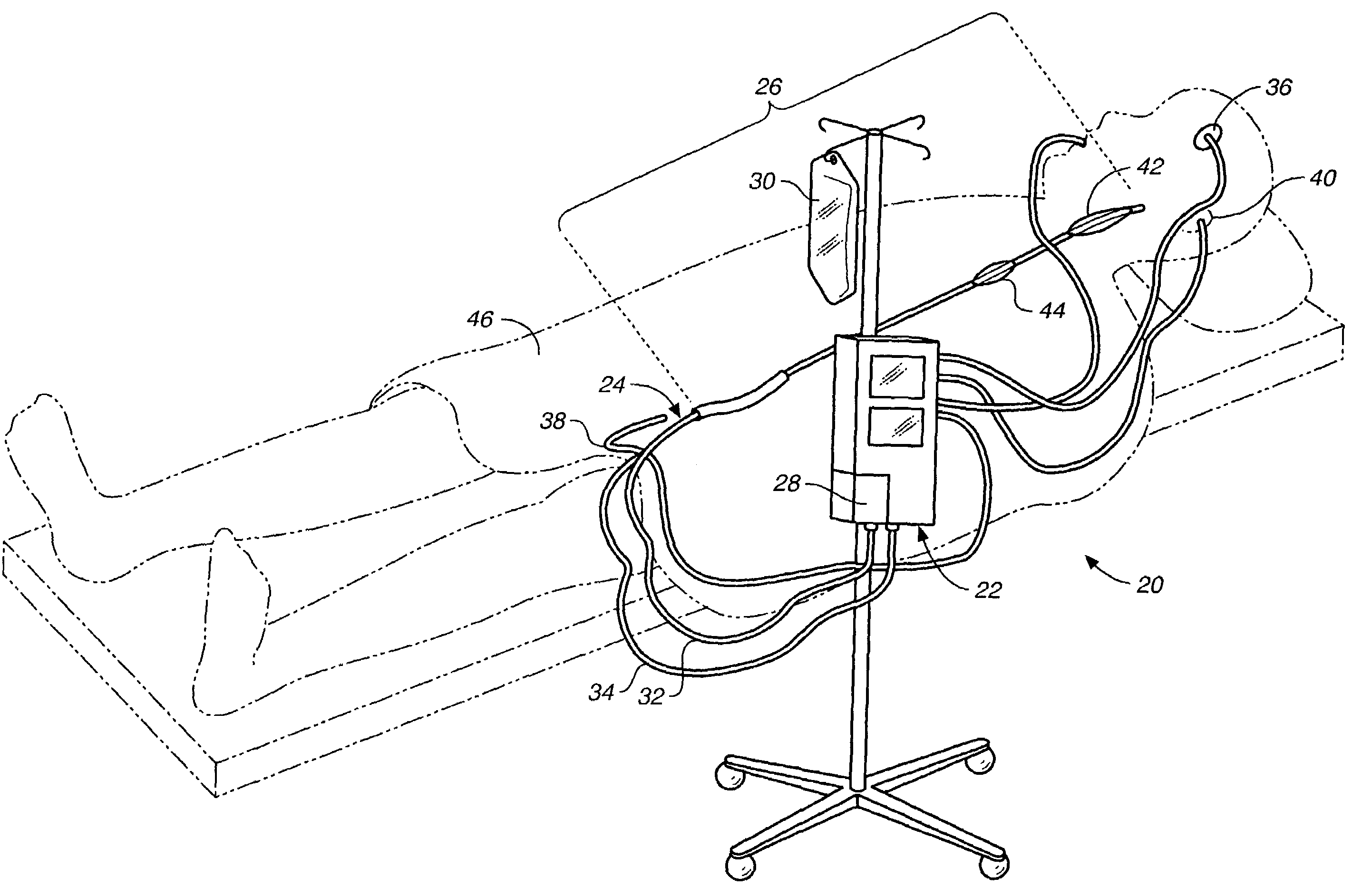

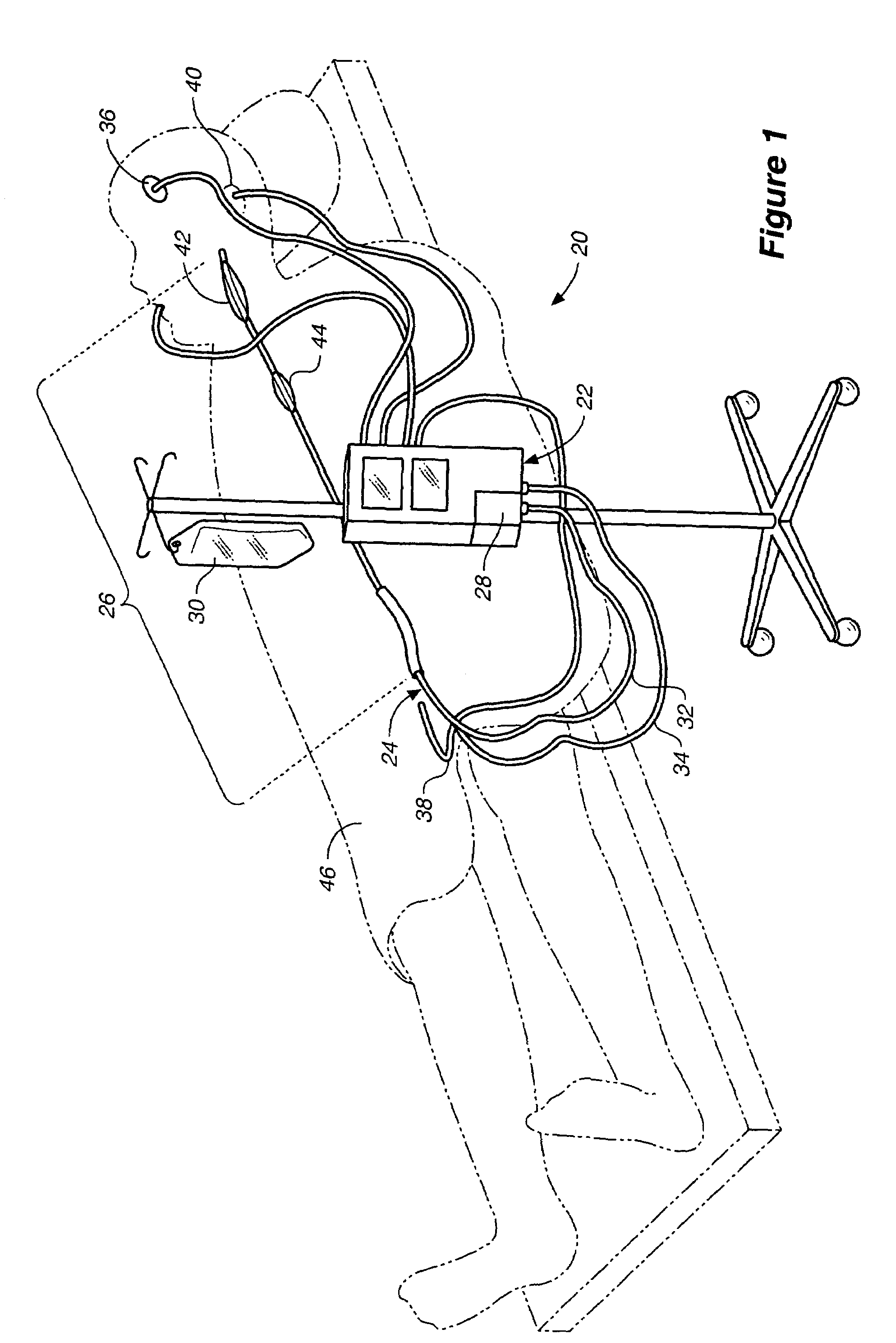

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette of any one of several disclosed variations is attached to the circulatory flow lines of the catheter, the heat exchange cassette being sized to engage a cavity within one of various described re-usable control units. The control units include a heater / cooler device, a user input device, and a processor connected to receive input from various sensors around the body and the system. The heater / cooler device may be thermoelectric to enable both heating and cooling based on polarity. A temperature control scheme for ramping the body temperature up or down without overshoot is provided. The disposable heat exchange cassettes may include an integral pump head that engages with a pump drive mechanism within the re-usable control unit. More than one control unit may be provided to receive the same heat exchange cassette so that a large capacity control unit can be used initially, and a smaller, battery-powered unit can be substituted once the patient reaches the desired target temperature.

Owner:ZOLL CIRCULATION

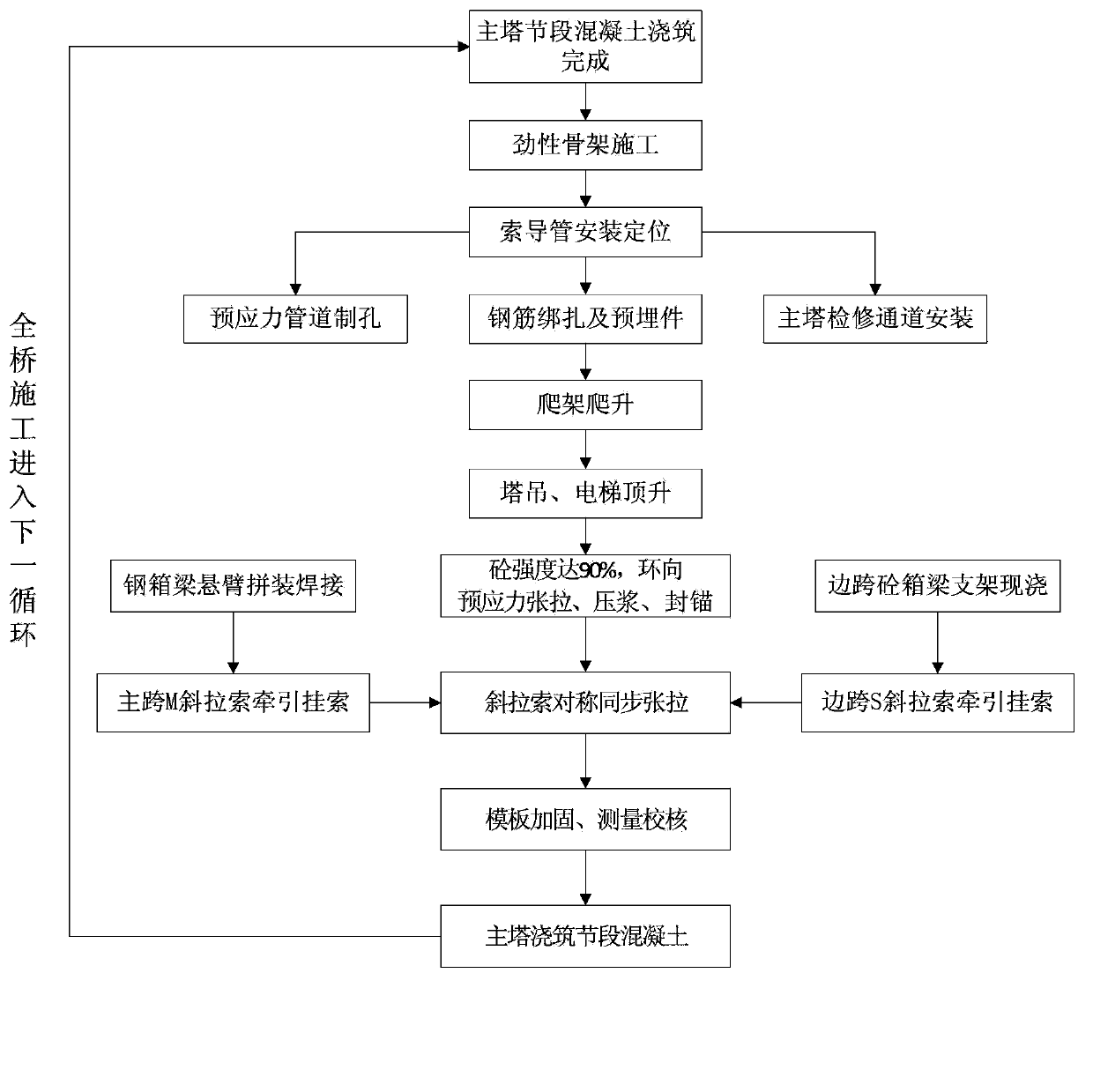

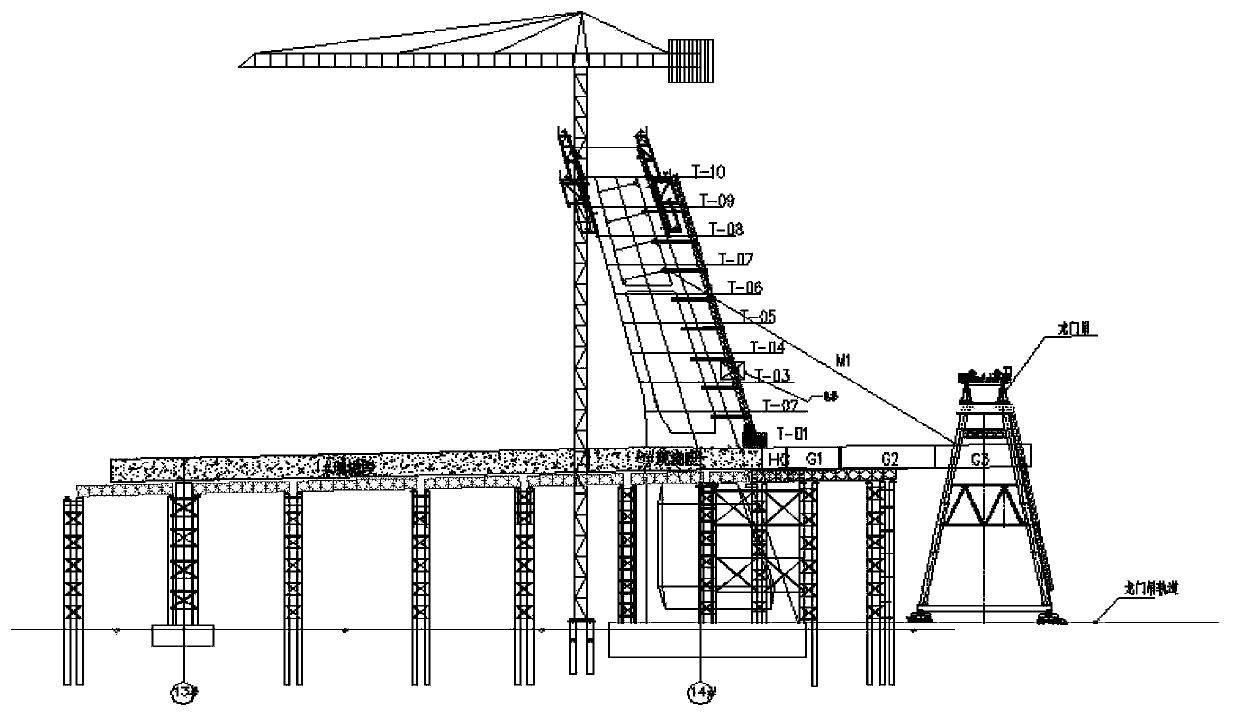

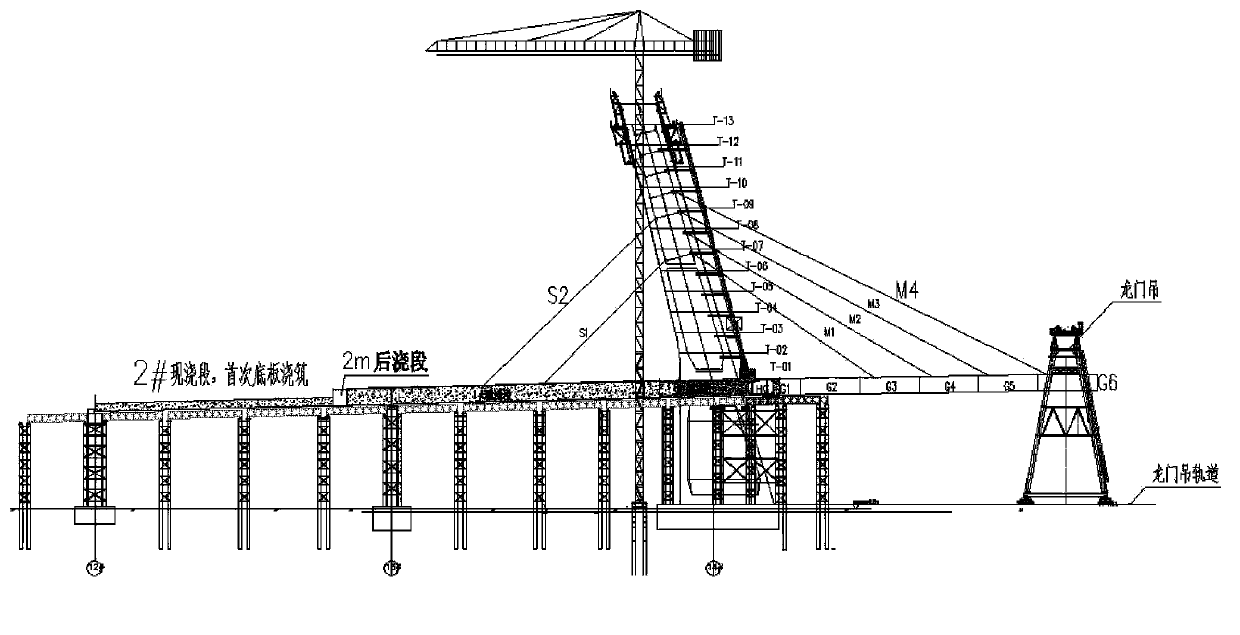

Tower, beam and cable synchronous bridge forming technology

ActiveCN103741601ASatisfied with the resultsMeet the design requirementsBridge erection/assemblyFull bridgeTower

The invention discloses a tower, beam and cable synchronous bridge forming technology. According to the technology, main tower creeping formwork construction, steel box beam cantilever assembly, side span concrete box beam cast-in-place support construction and stay cable and hung cable stretch-draw construction are conducted alternately and synchronously. The tower, beam and cable synchronous bridge forming technology achieves safe and reliable full-bridge construction.

Owner:CCCC THIRD HARBOR ENG +1

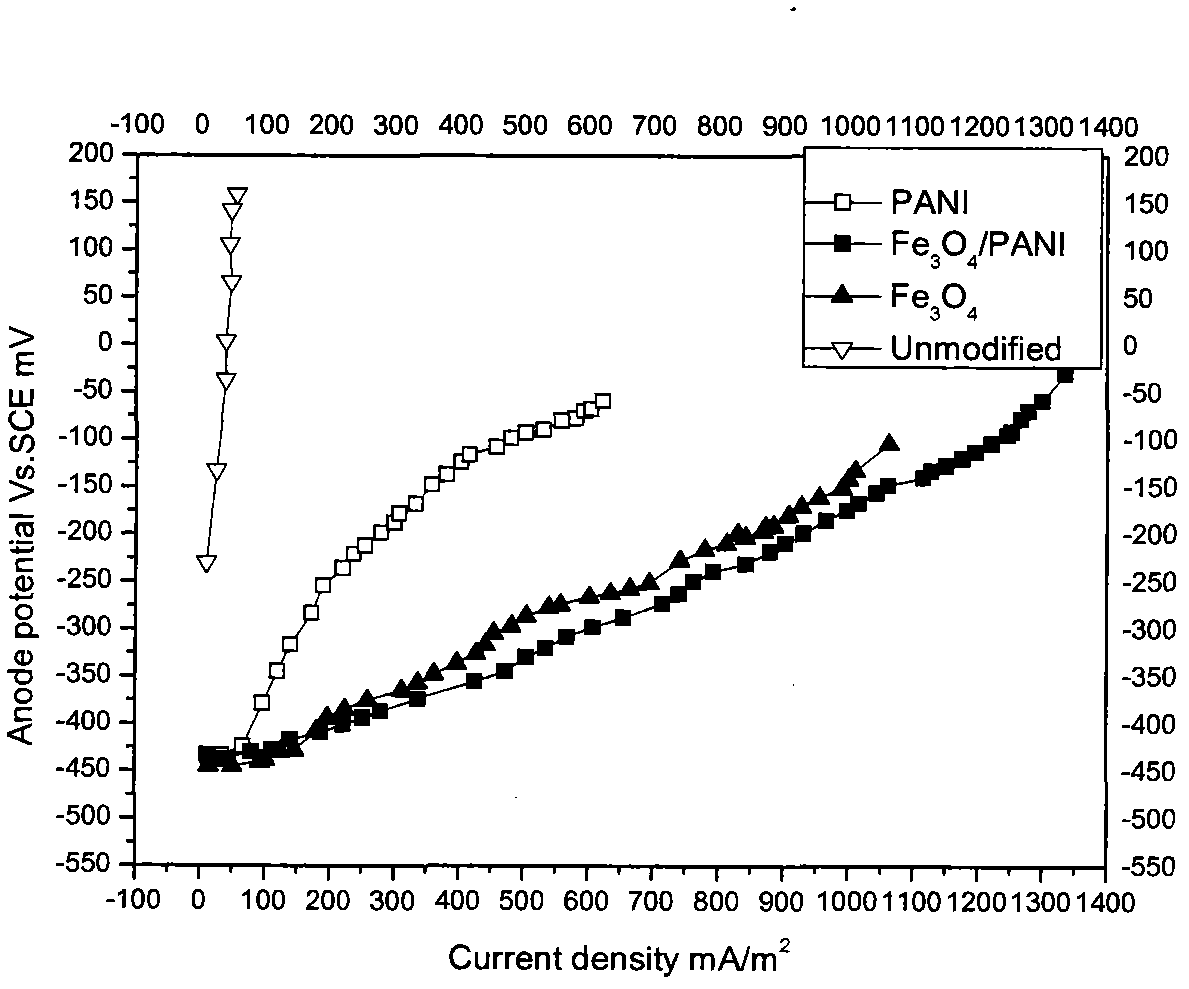

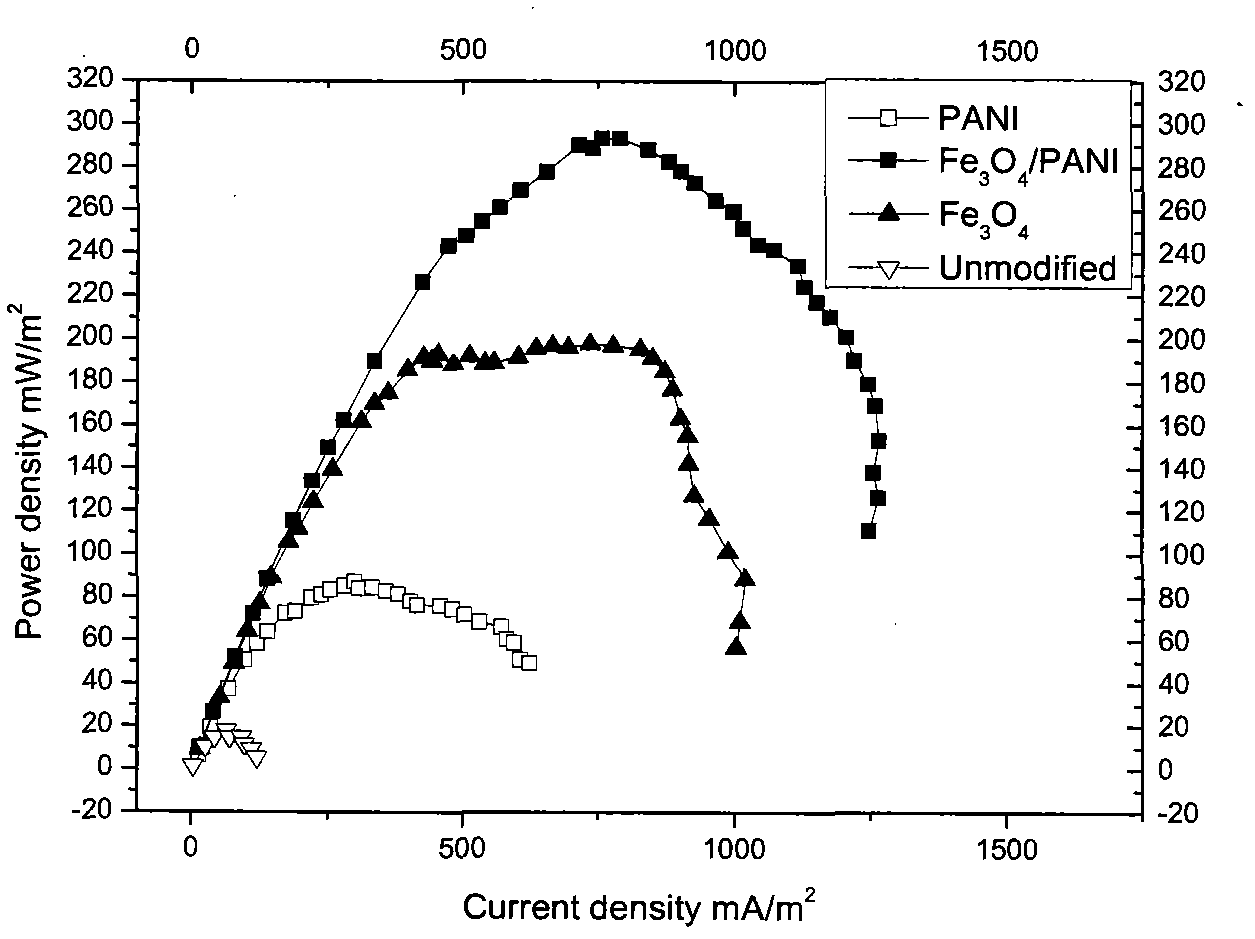

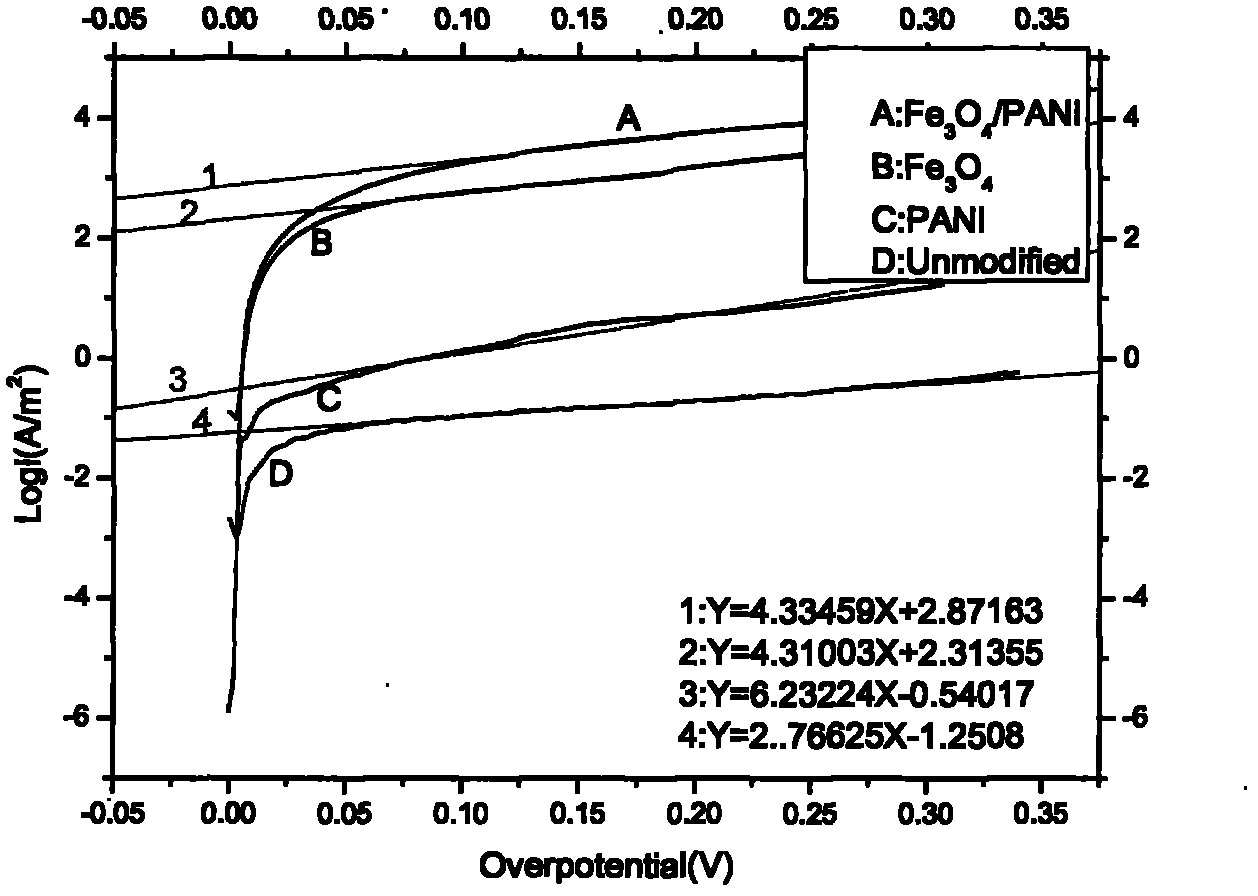

Preparation and application of iron oxide/polyaniline composite anode

InactiveCN102074711AImprove performancePolarization slope decreasesCell electrodesBiochemical fuel cellsPolyaniline compositeSeabed sediment

The invention relates to the technical field of microbial fuel cells and provides preparation and application of a microbial fuel cell composite anode. The composite anode contains an iron oxide / polyaniline composite material so as to remarkably improve the output power density of the cell. The preparation method of the composite anode comprises the preparation of the iron oxide / polyaniline composite material and the pressing of the composite anode. By using the composite anode, a marine bottom microbial fuel cell and a sewage microbial fuel cell which contain marine bottom sediments are assembled and the specific test analysis method for the cell performance can be given out. The result shows that the output power density of the cell is greatly improved and the output power density of the assembled cell of the iron oxide / polyaniline composite anode reaches 300mW / m<2> which is 30 times that of the unmodified anode.

Owner:OCEAN UNIV OF CHINA

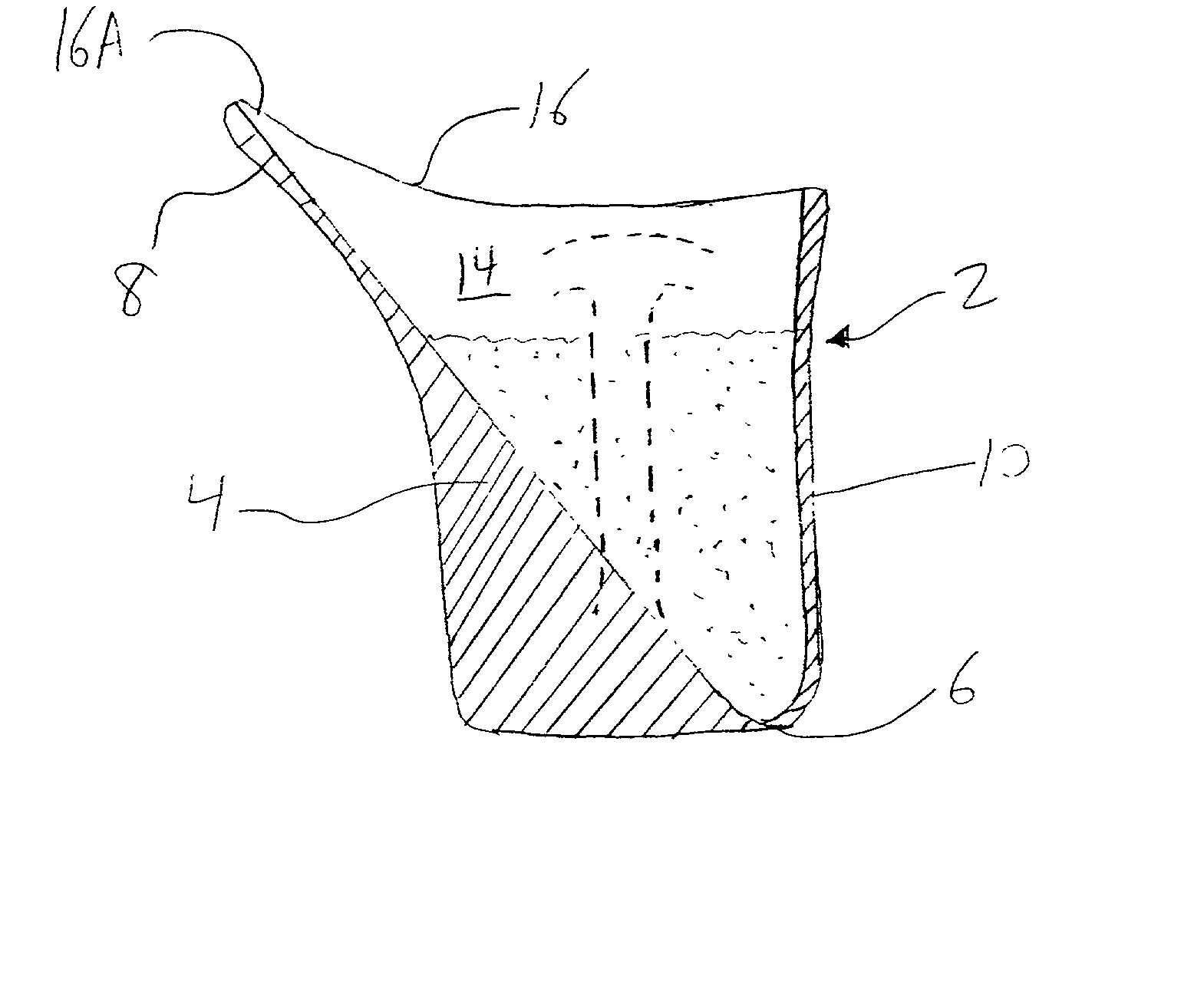

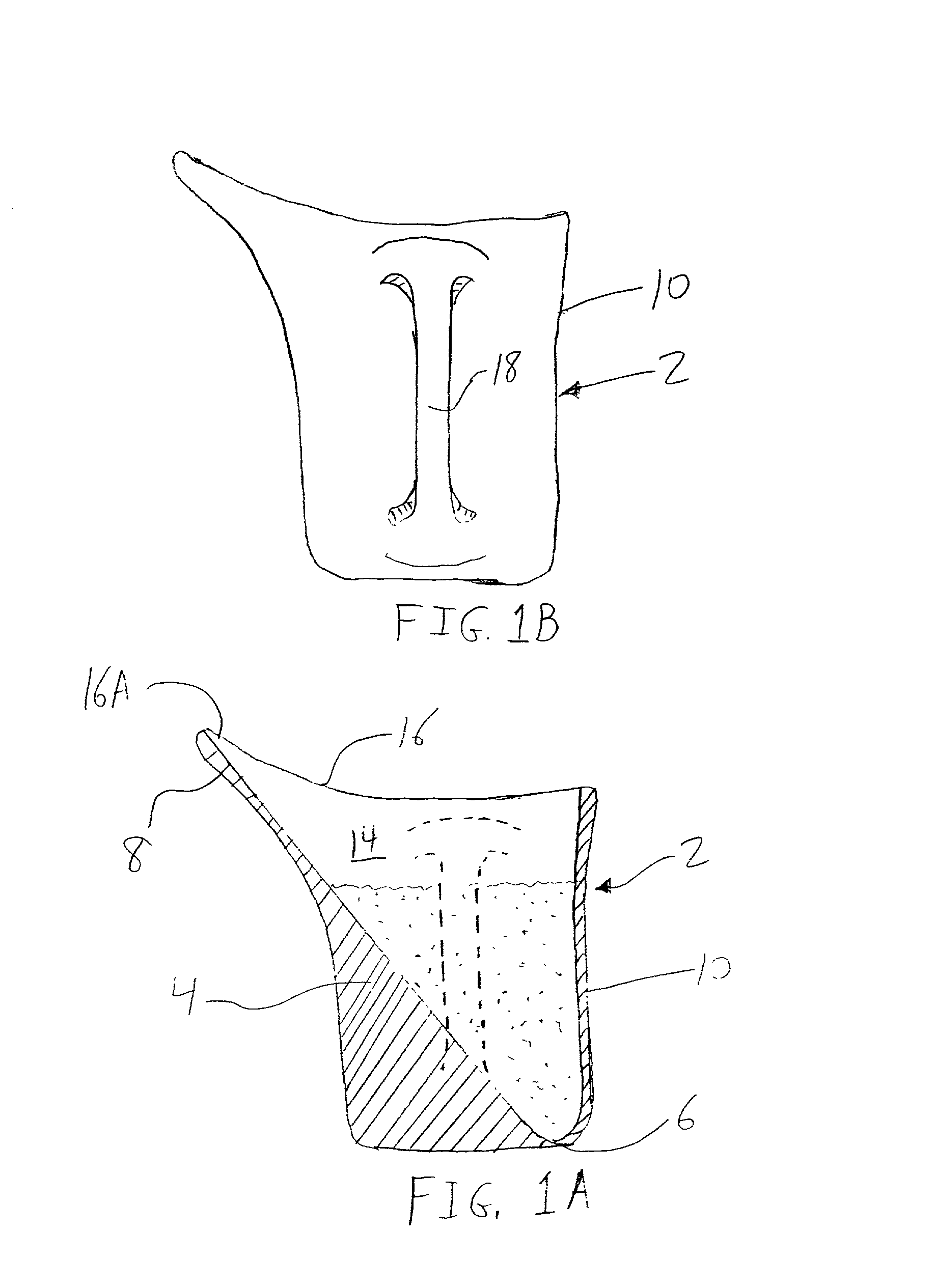

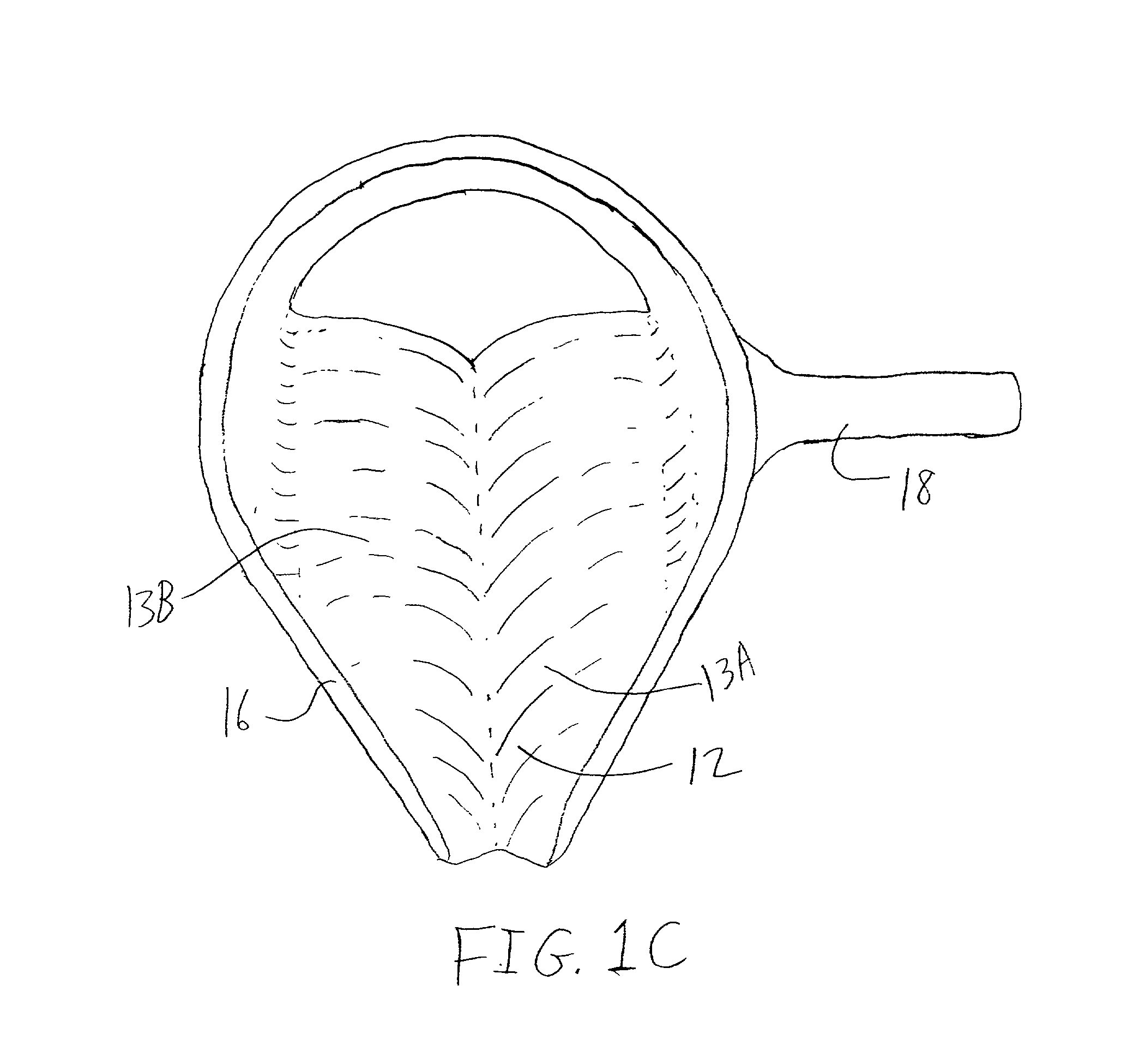

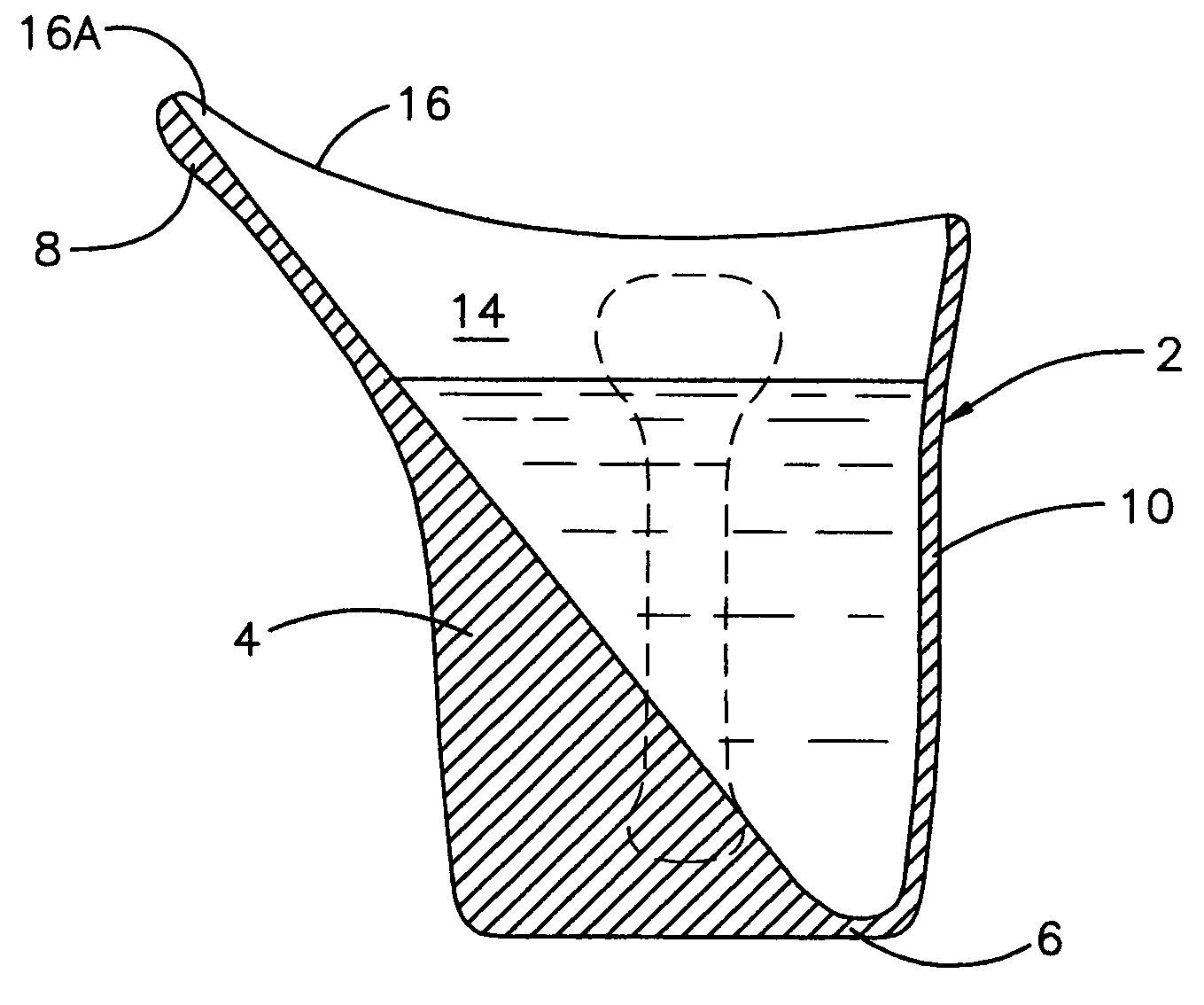

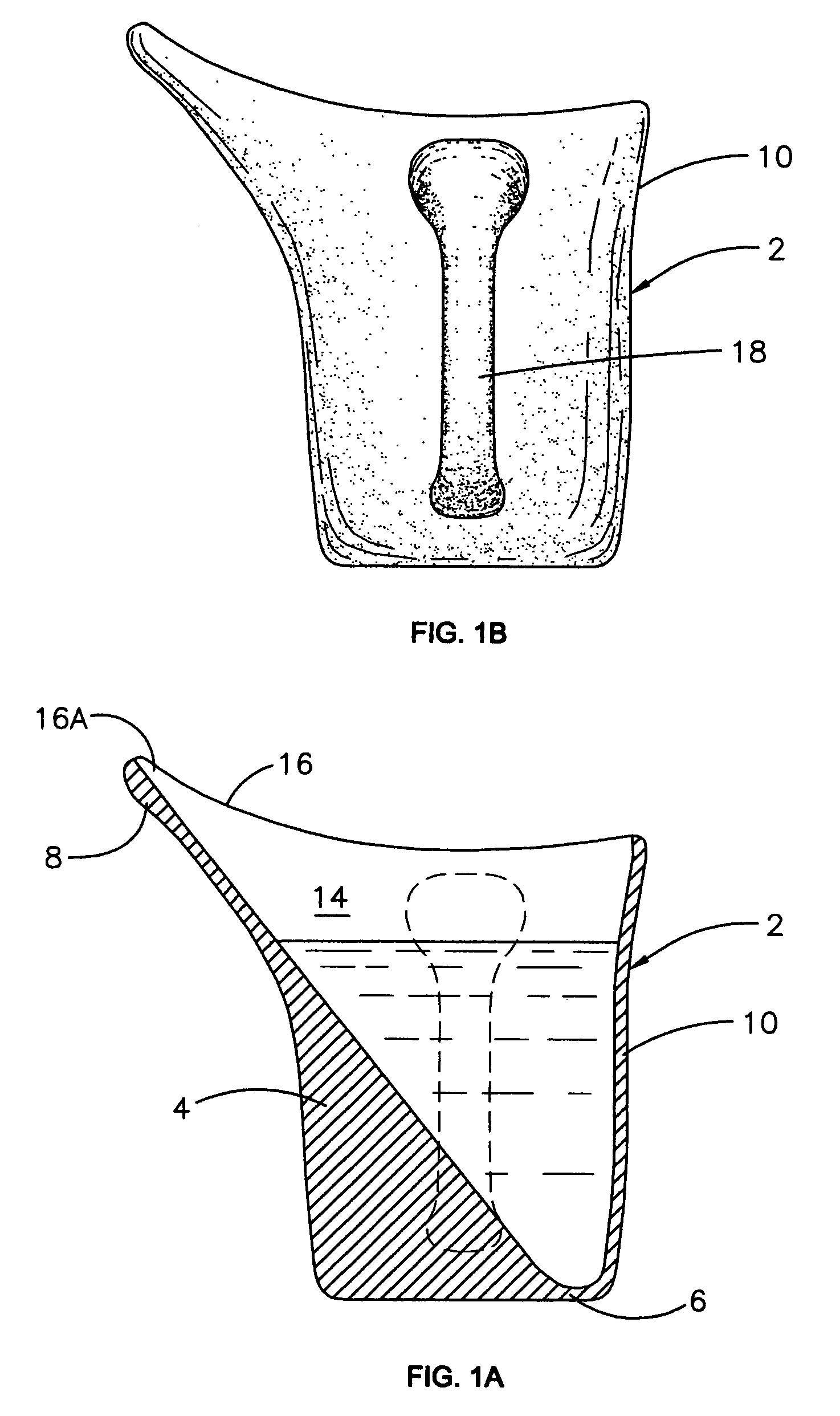

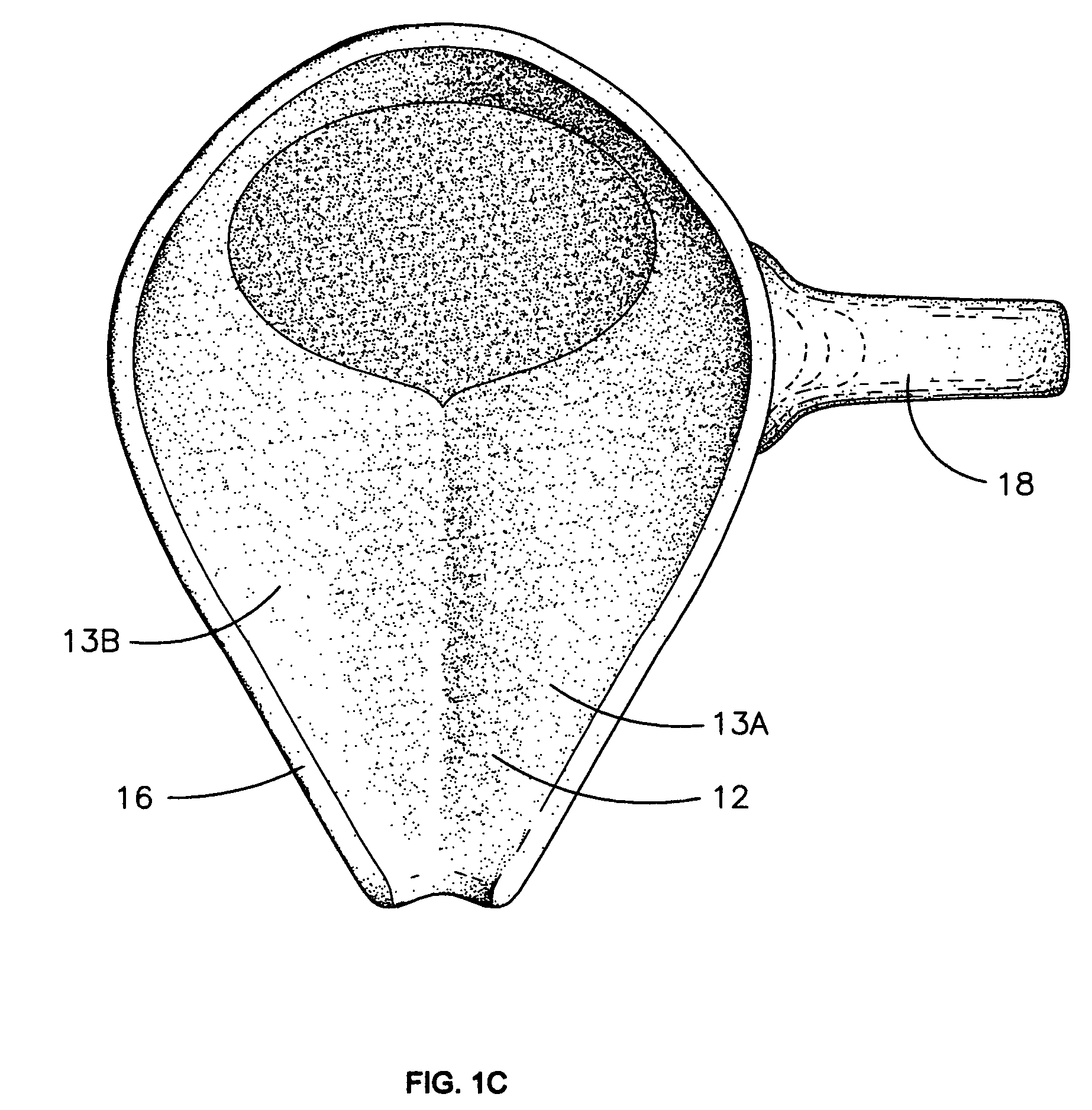

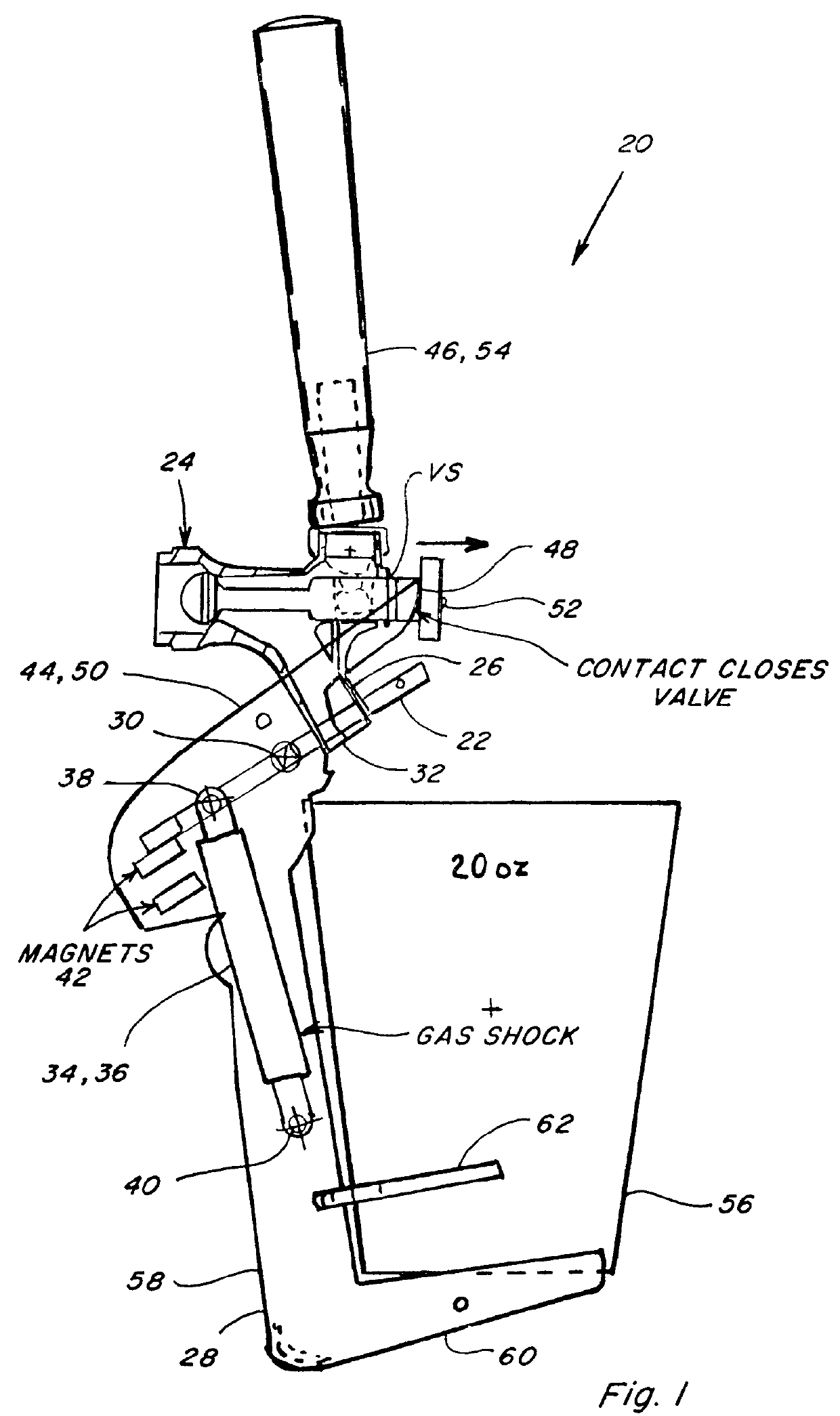

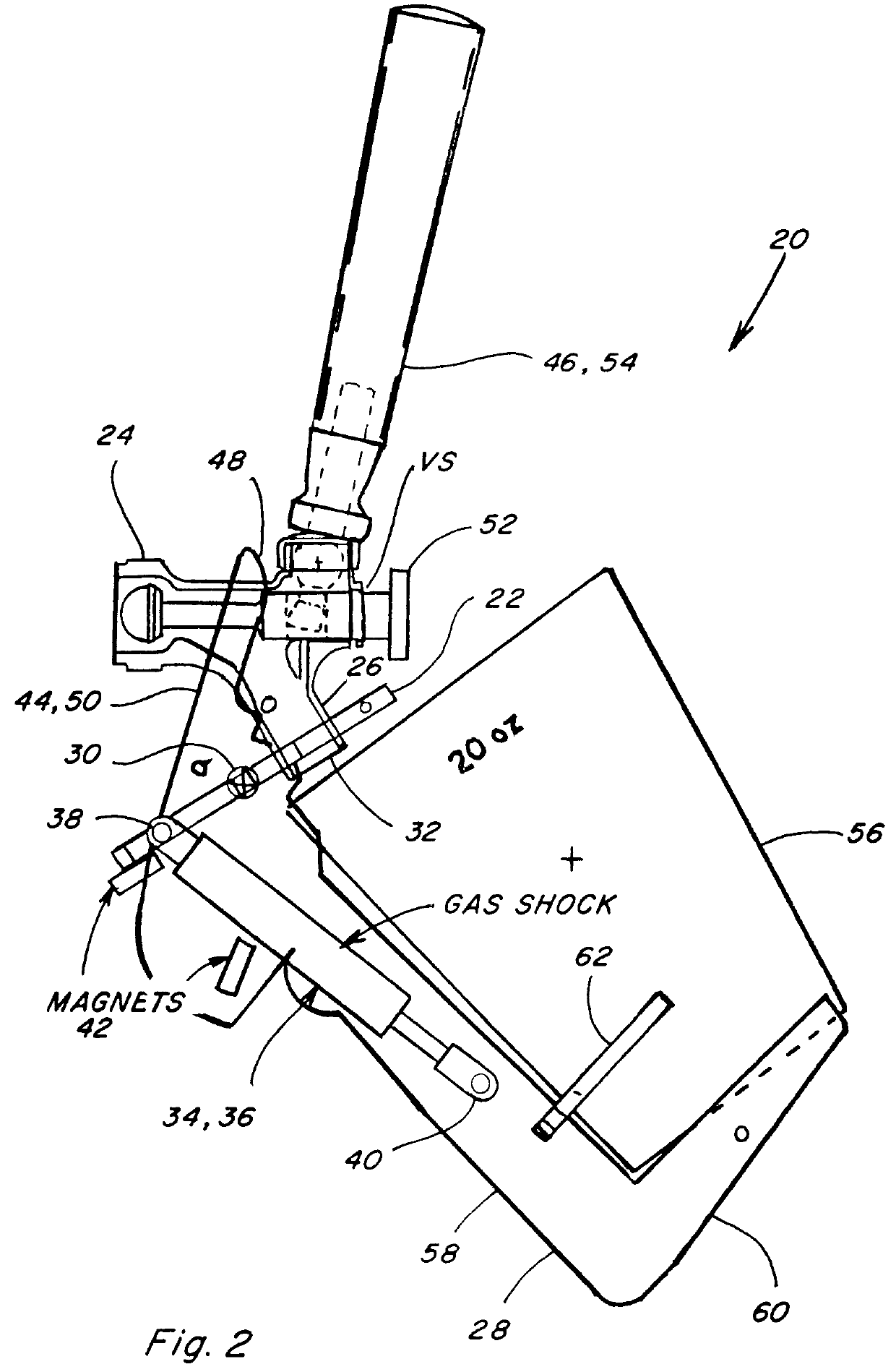

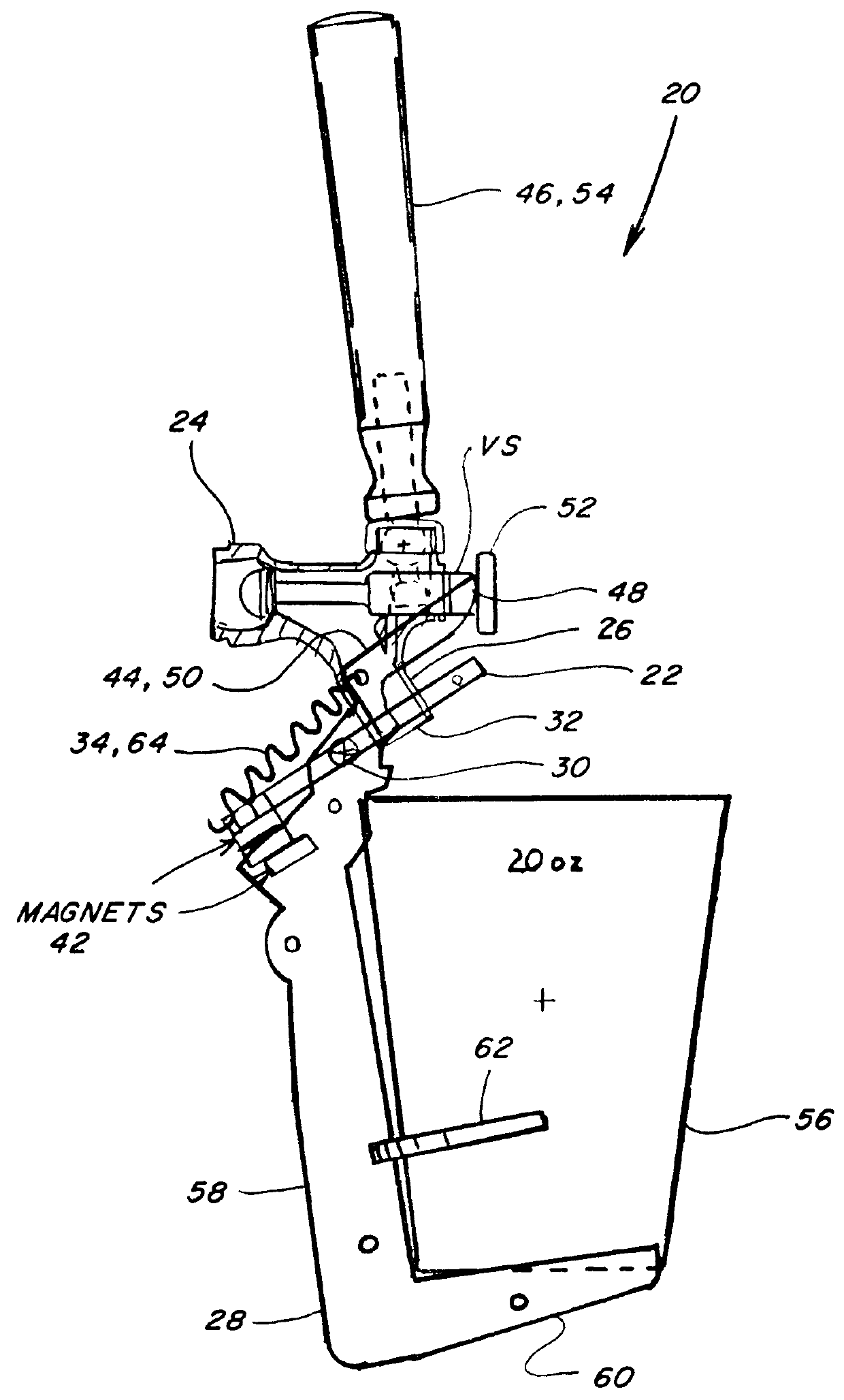

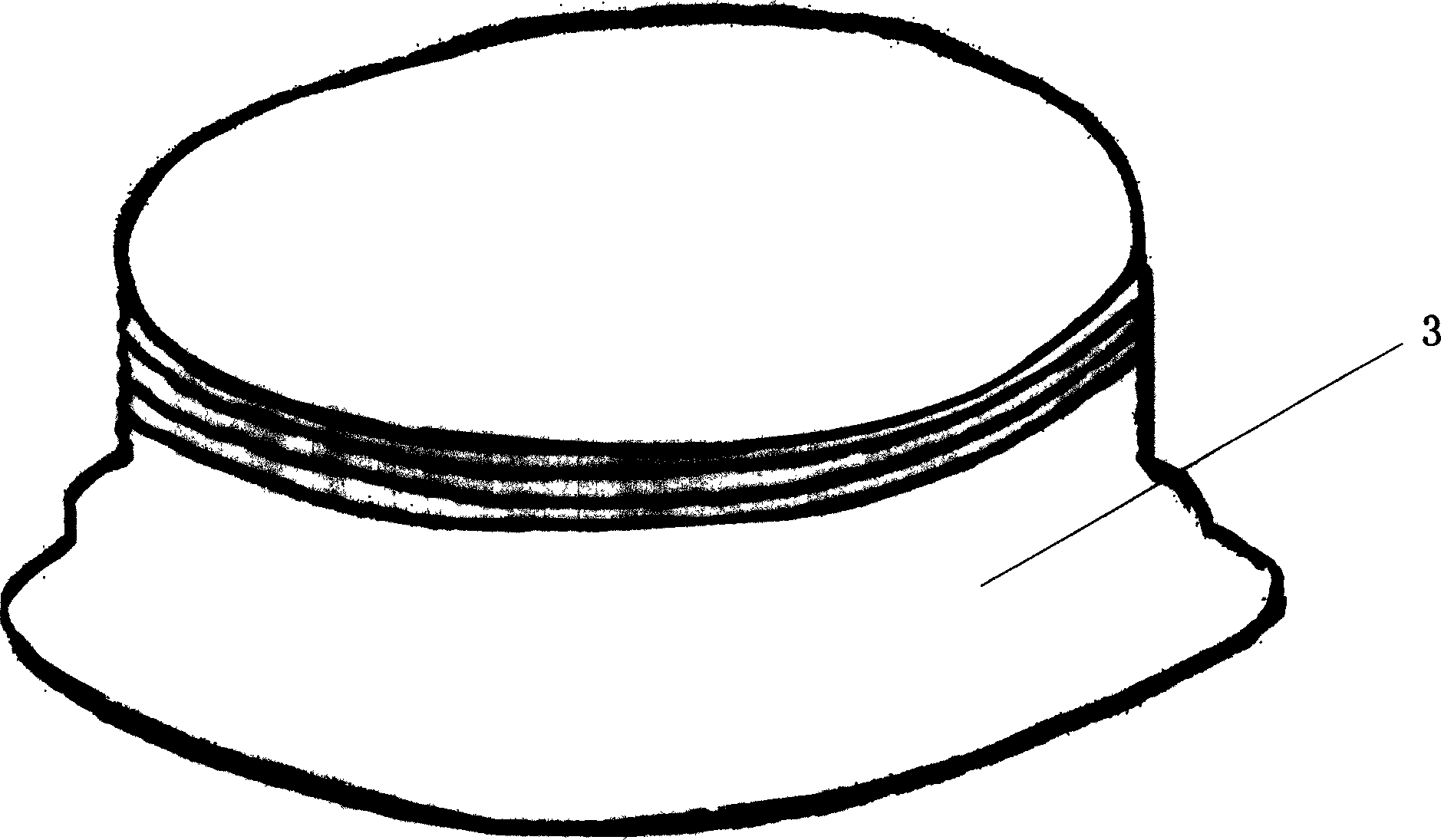

Drinking container

ActiveUS20020070225A1Readily emptyEasy to emptySealingContainers preventing decayBiomedical engineeringWedge shape

Owner:WEDGE GRP

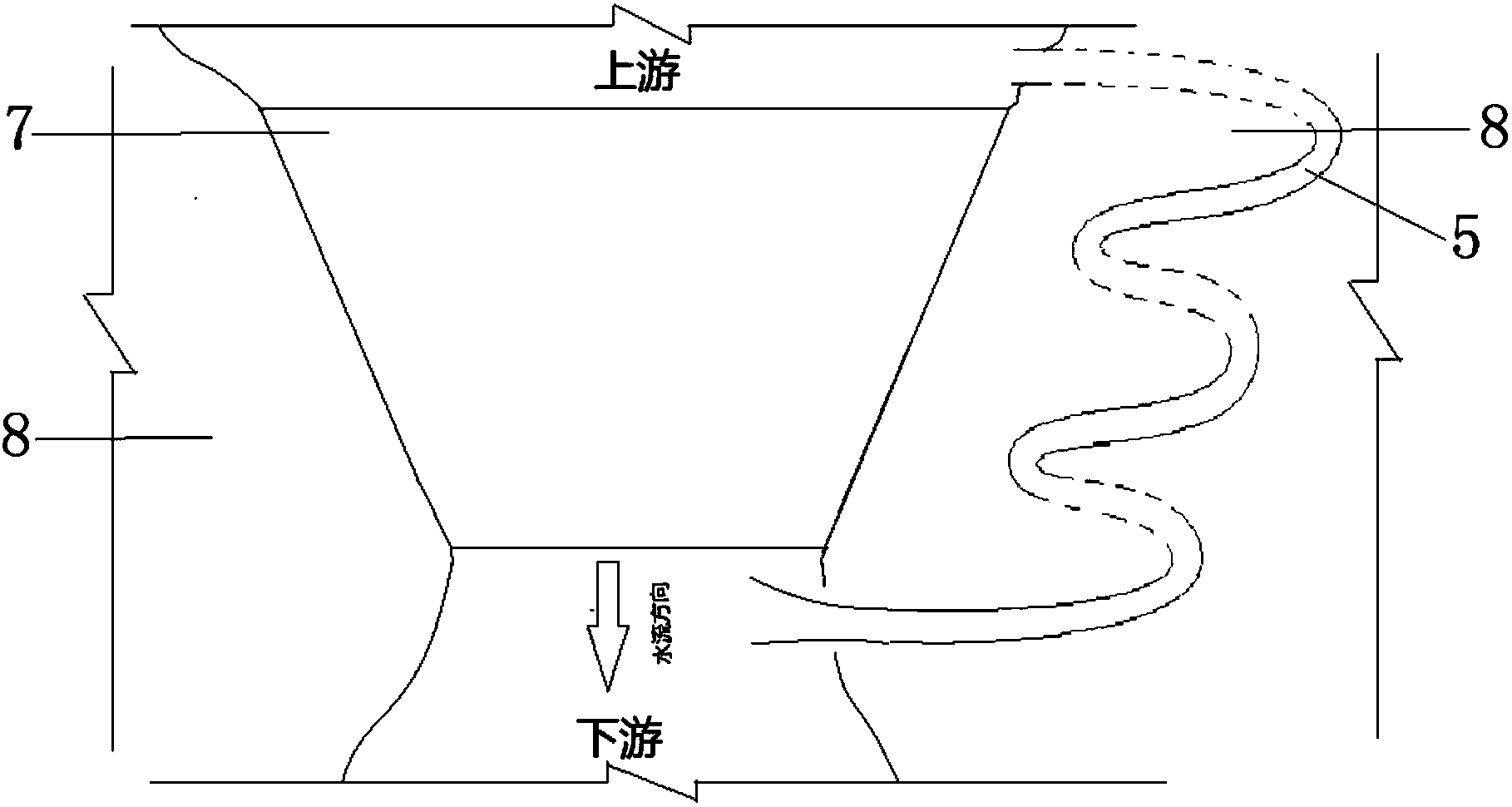

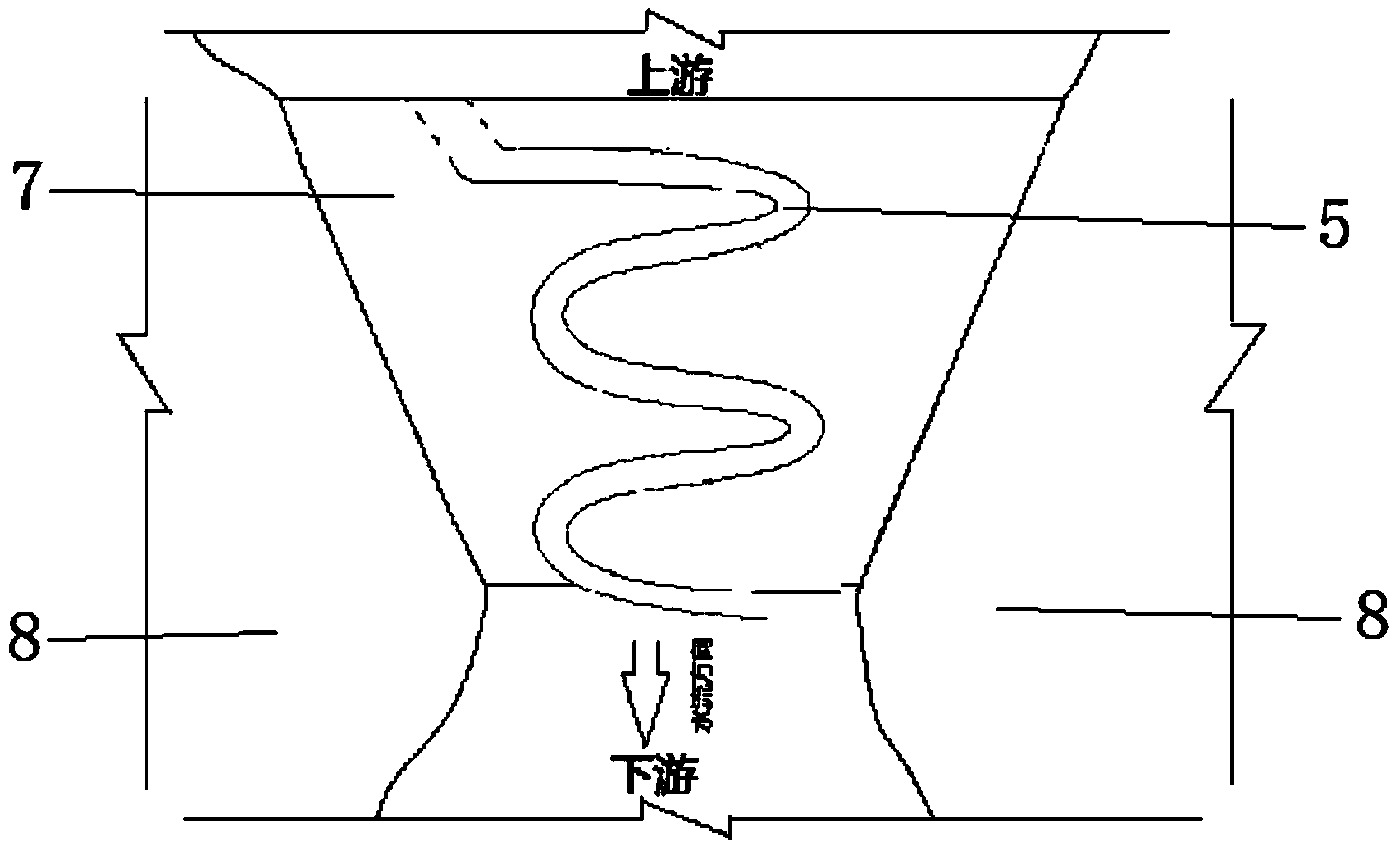

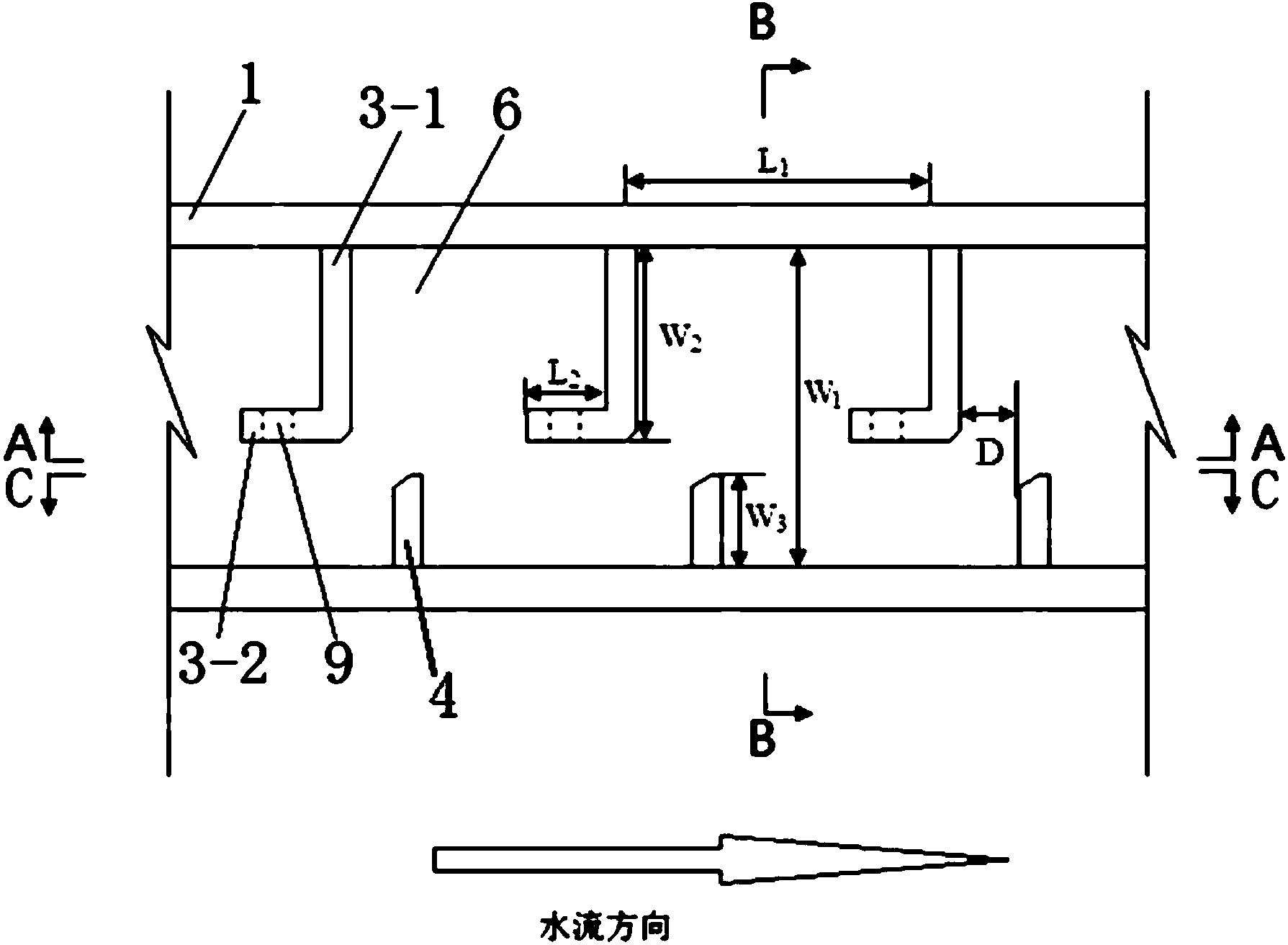

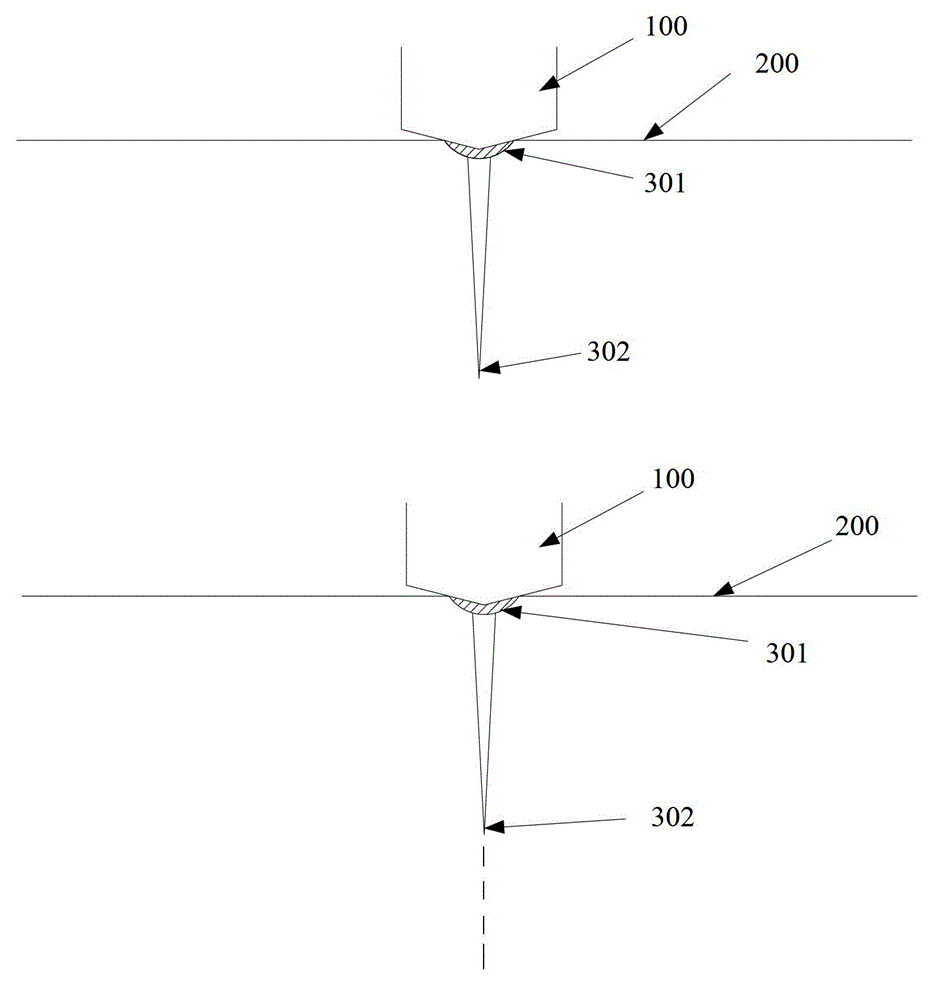

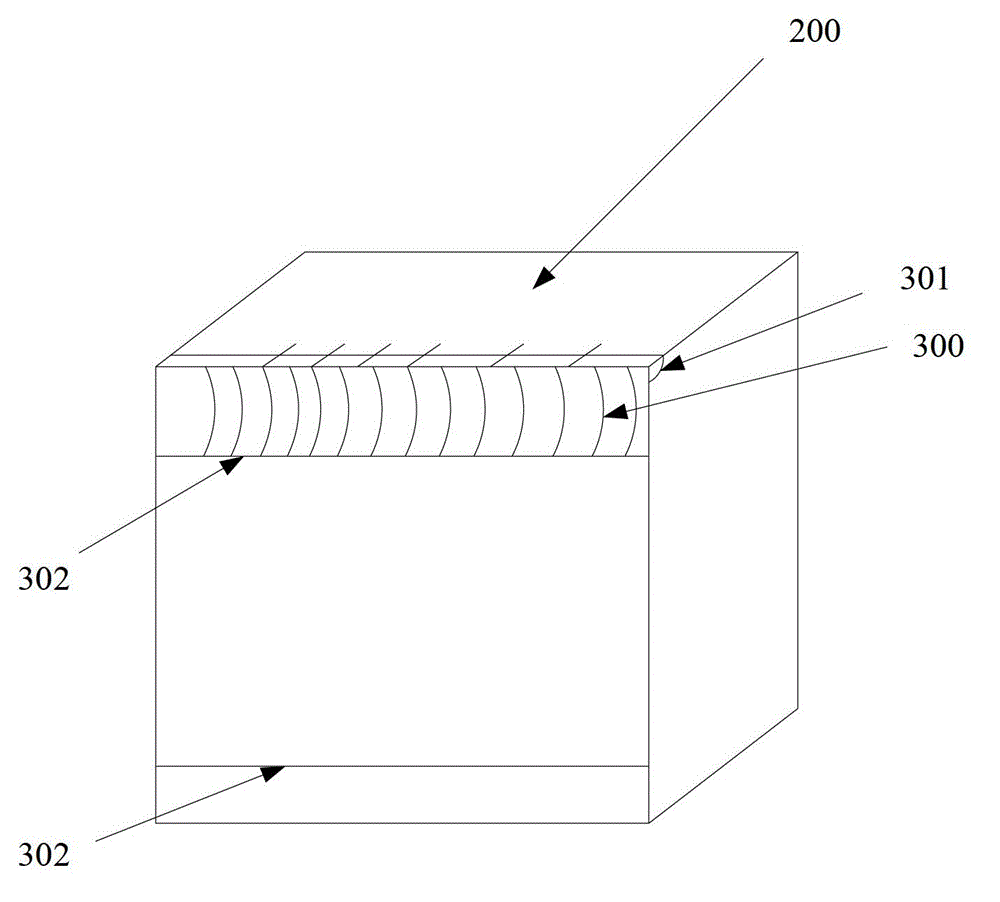

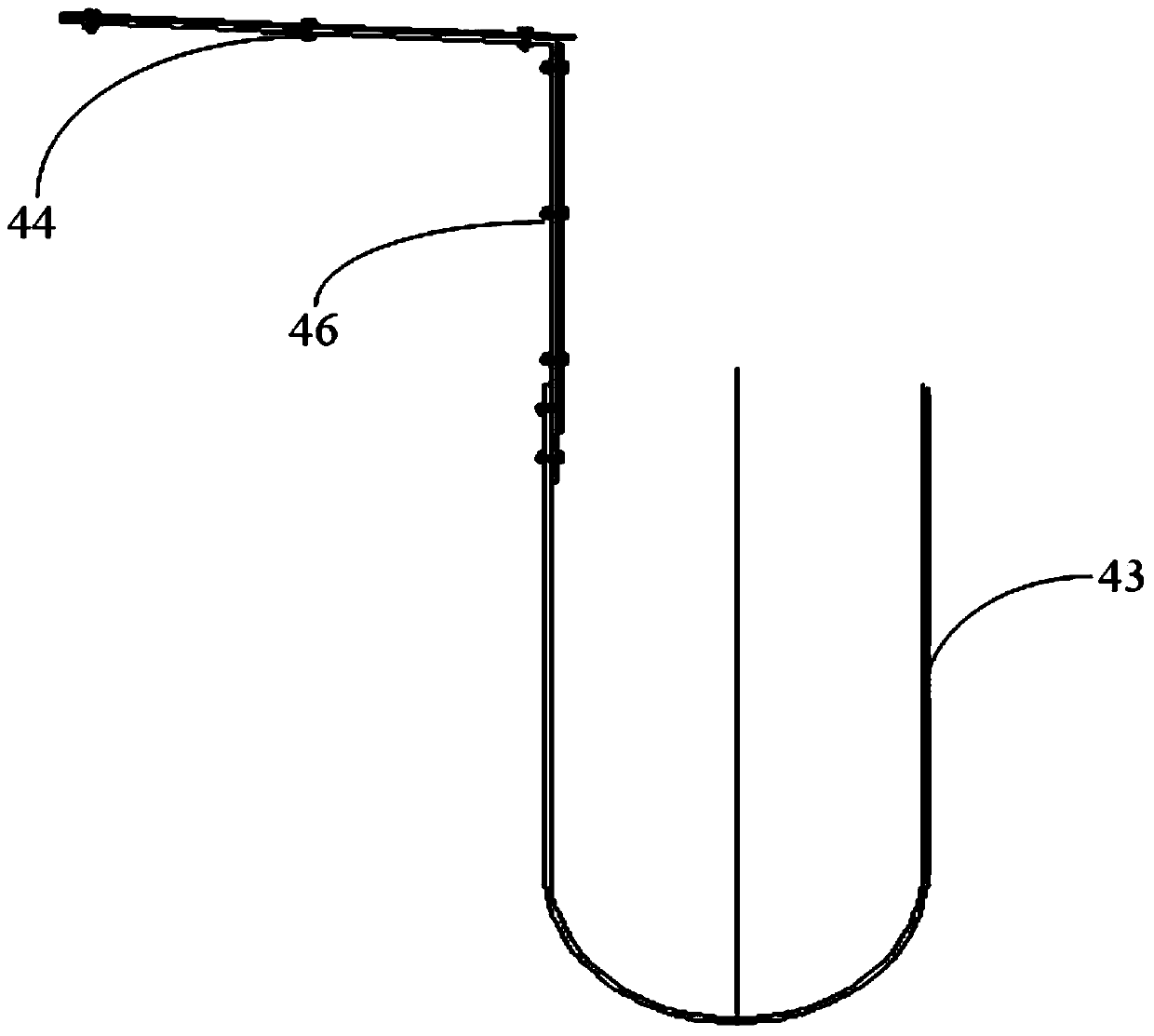

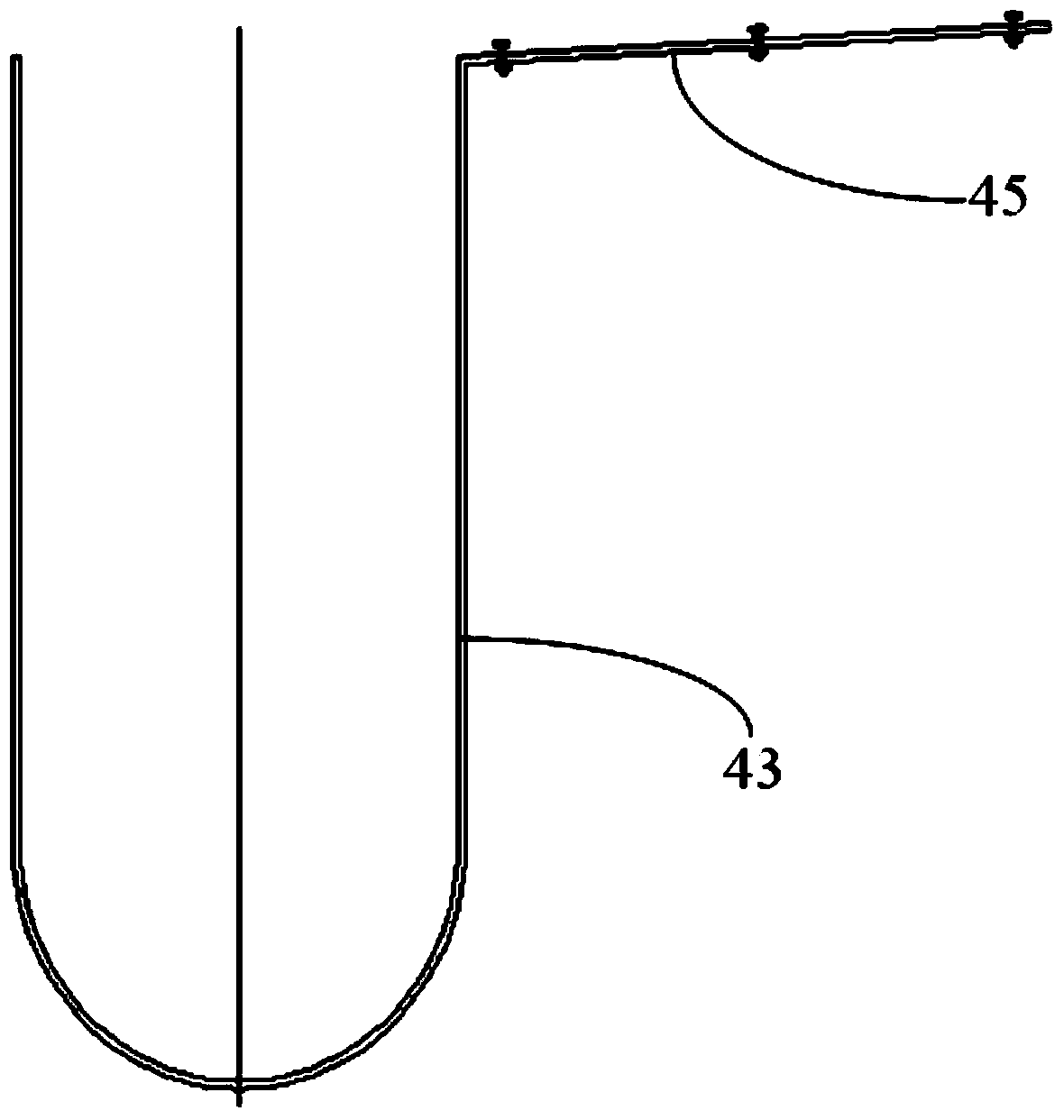

Winding type fishway

The invention belongs to the technical field of hydroengineering and provides two winding type fishways. Each winding type fishway comprises side walls, a base board, partition boards and guide boards, wherein the side walls are located on the two sides of the base board, the partition boards and the guide boards are arranged on the inner walls of the side walls, the fishway is divided into a plurality of pool chambers through the partition boards and the guide boards, and all the pool chambers are communicated with one another. The first fishway is arranged on a mountain on the side of a dam, the downstream end of the first fishway is located underwater in the downstream river channel of the dam, the upstream end of the first fishway is located underwater in the downstream river channel of the dam, and the shape of the first fishway is spiral or in a screw-like shape. The second fishway is composed of a first section, a third section and a second section, wherein the first section is located on the surface of the dam body, located on the downstream side, of the dam, the third section is located on the surface of the dam body, located on the upstream side, of the dam, the second section is located in the dam body and enables the first section and the third section to be communicated with each other, the downstream end of the second fishway is located underwater in the downstream river channel, the upstream end of the second fishway is located underwater in the upstream river channel, and the shape of the fishway is in the shape of a broken line.

Owner:SICHUAN UNIV

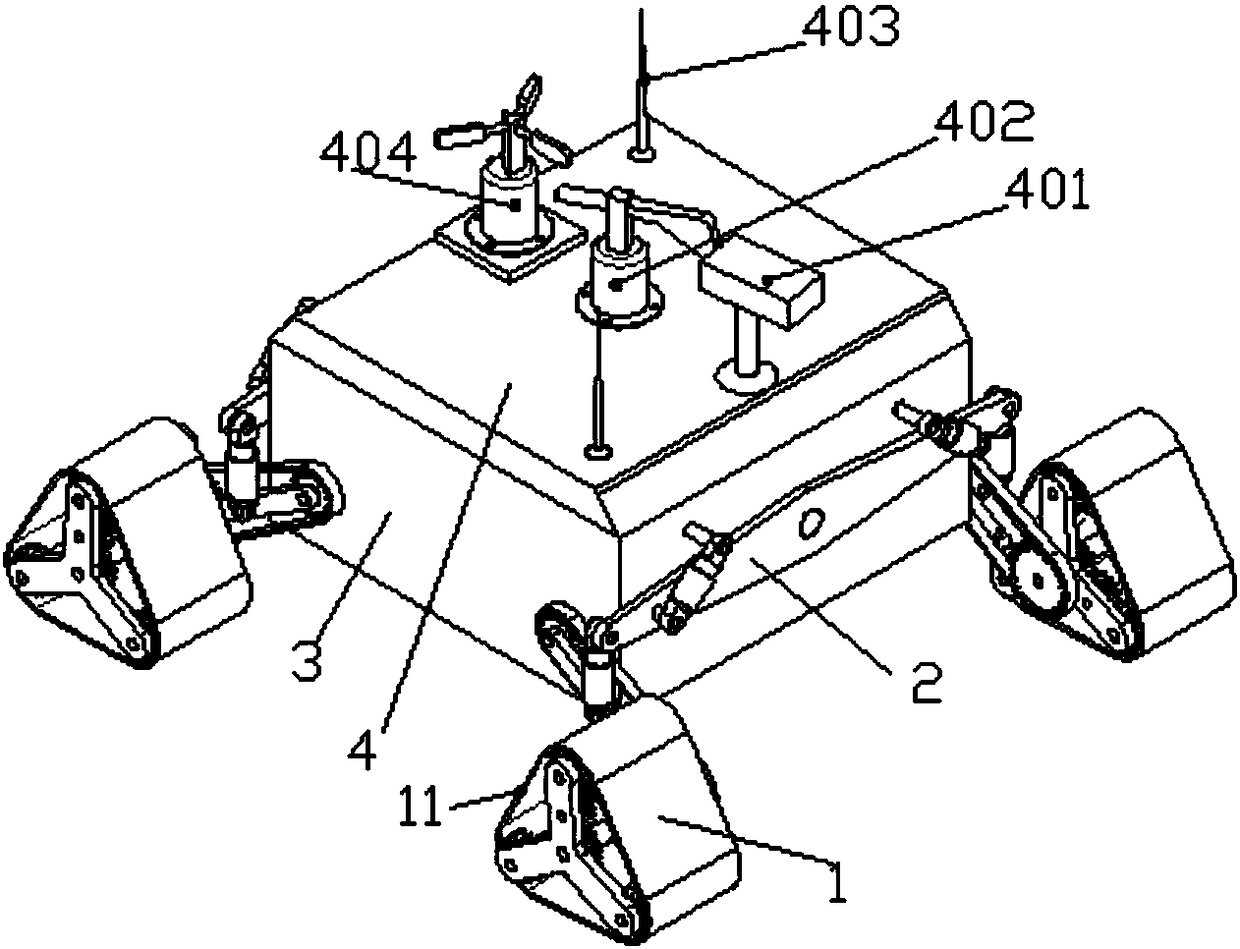

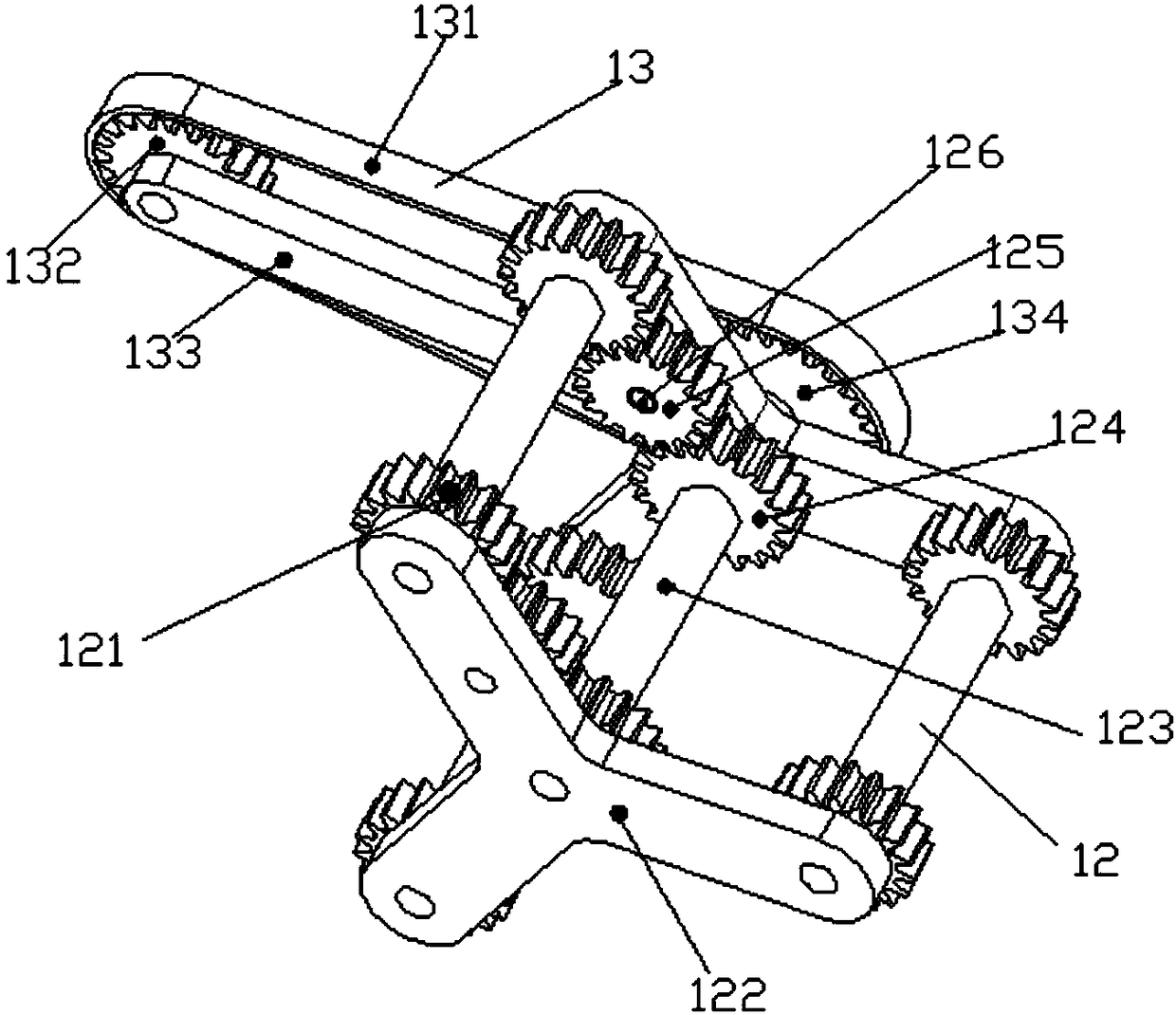

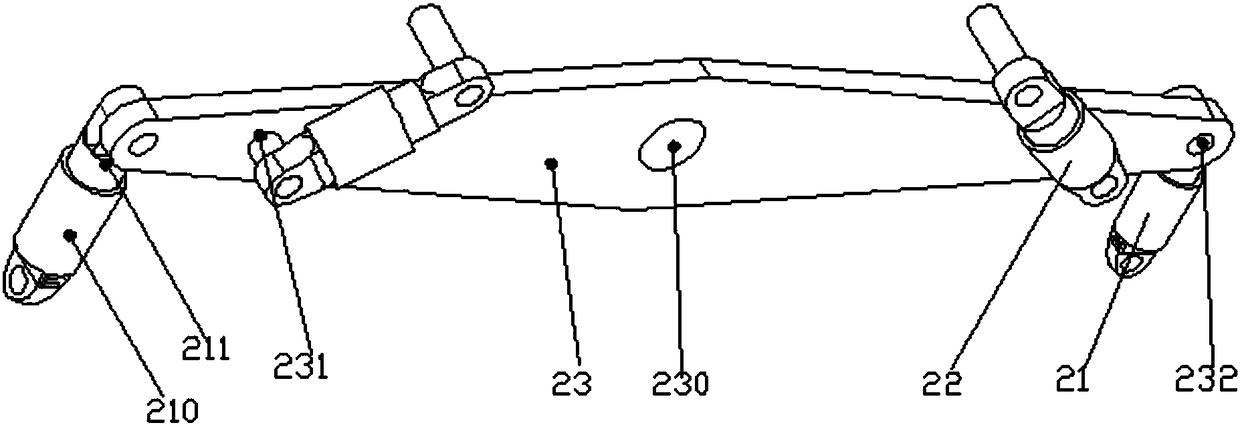

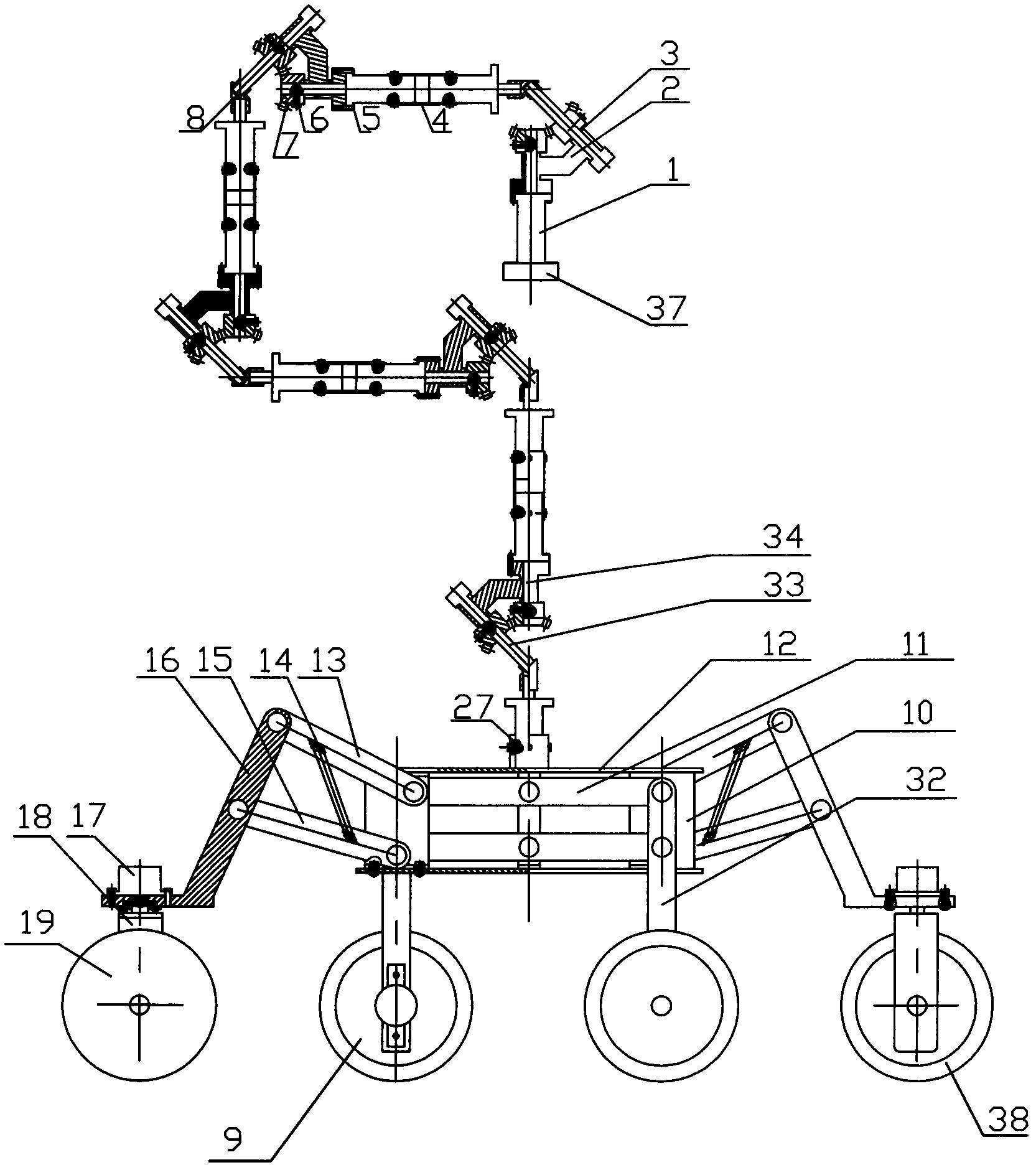

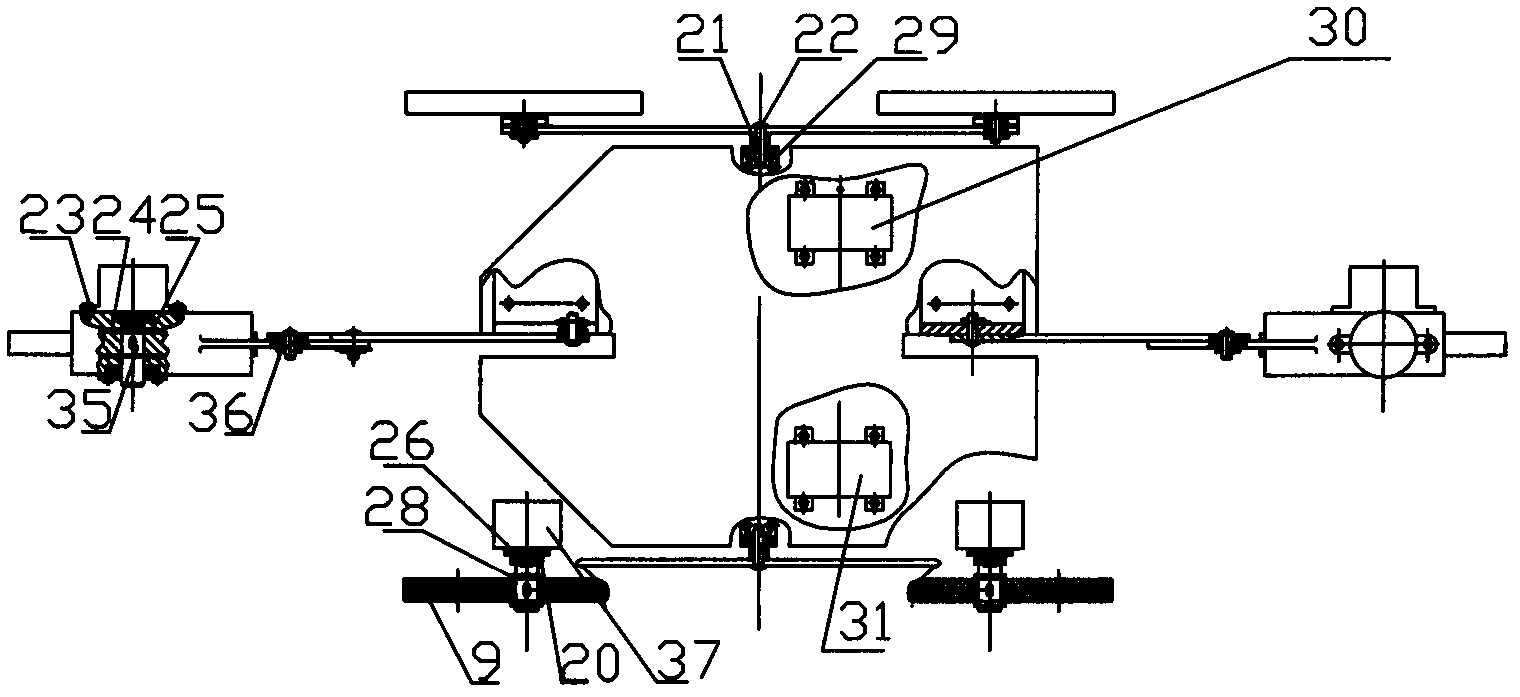

Crawler type passive self-adaptive robot

The invention relates to a crawler type passive self-adaptive robot which comprises a vehicle body module, two damping modules installed on the front side and the back side of the vehicle body modulerespectively, an information collection module installed at the upper part of the vehicle body module and four crawler type wheels installed on the two sides of the vehicle body module respectively; the two ends of each damping module are connected with two corresponding crawler type wheels respectively; the four crawler type wheels have a thoroughly identical structure and are arranged around thevehicle body module in a front and back as well as left and right symmetrical manner; each crawler type wheel comprises a crawler, a belt wheel structure and a belt transmission body, and the belt transmission body is connected with the vehicle body module on one hand and is connected with the belt wheel structure on the other hand; each crawler is installed on the outer surface of the corresponding belt wheel structure; and each belt wheel structure comprises six transmission gears, two planetary supporting frames, four center shafts, two center gears and two planetary gears. By adopting therobot, each crawler type wheel is driven by a motor to move; through connection of the damping modules, damping arms stretches and varies, swing rods swing from left to right, and the robot can passacross a complex terrain.

Owner:HEBEI UNIV OF TECH

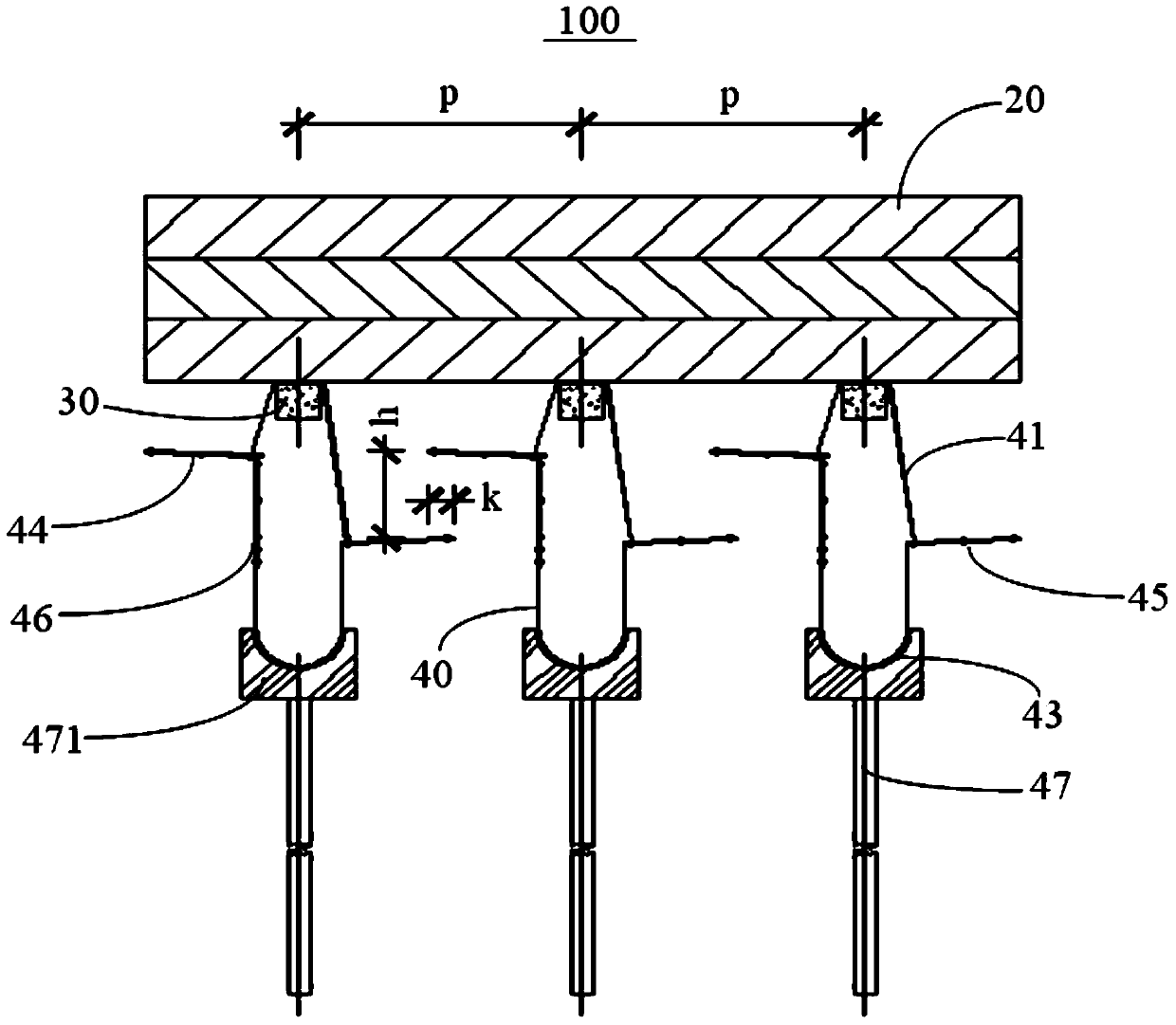

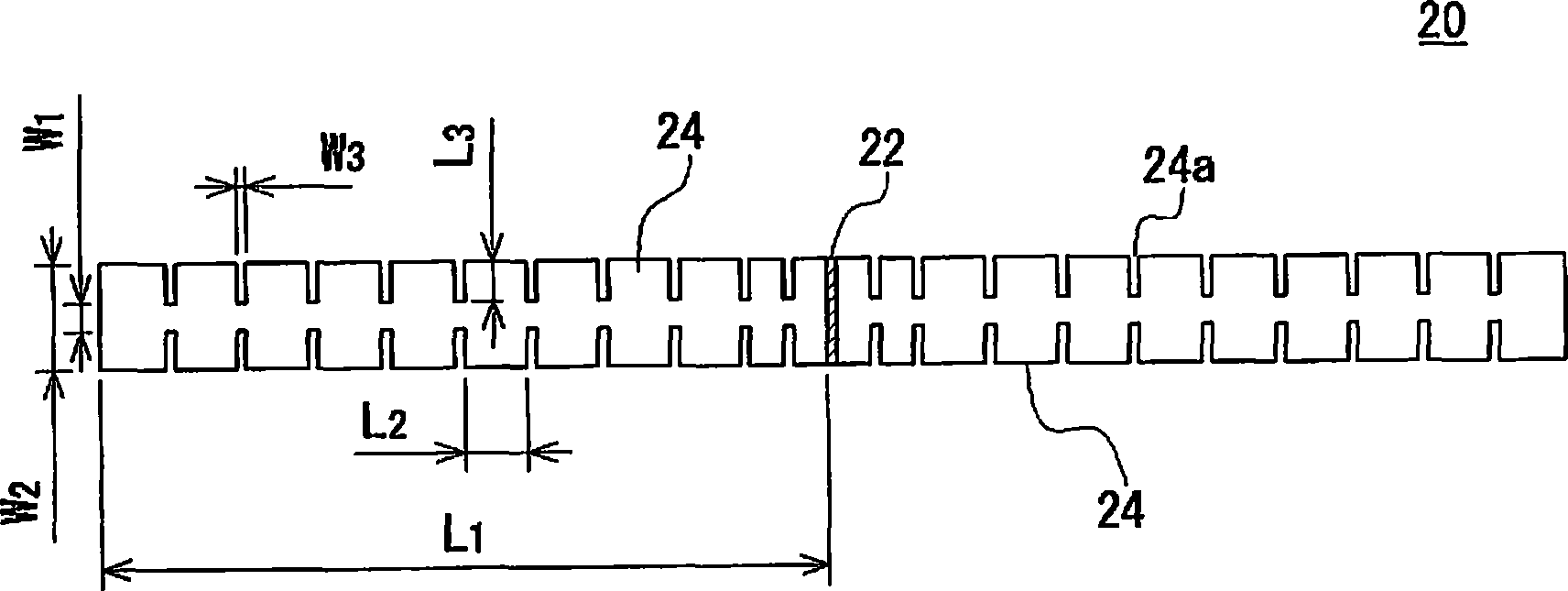

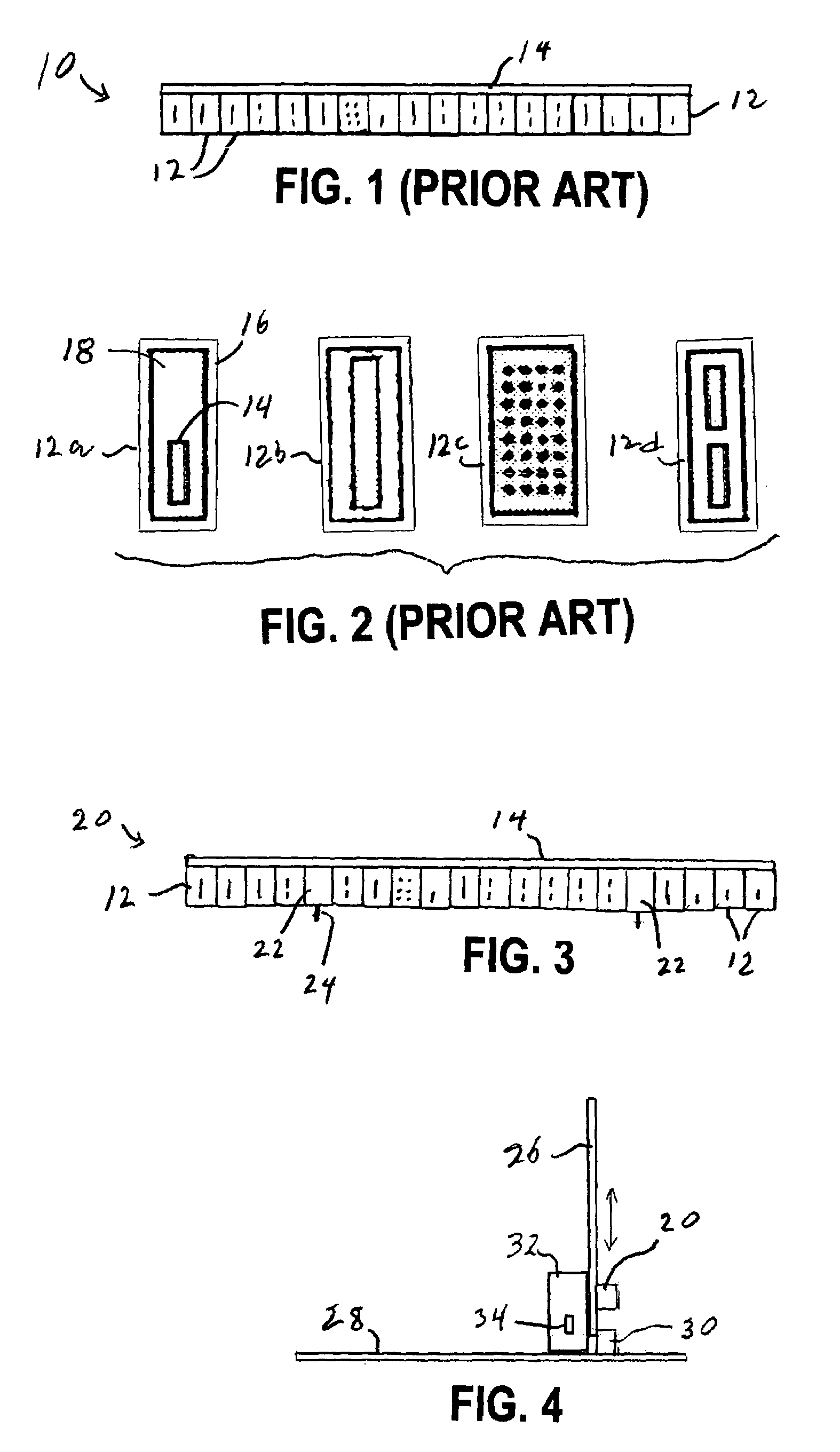

Post-CMP cleaning brush

InactiveCN102792424AMinimize damageAvoid meshingSemiconductor/solid-state device manufacturingAnatomyBiomedical engineering

Embodiments of the invention include a CMP brush that has a combination of central nodules at an inner region of the brush and one or more edge nodules at an end region of the brush where the central nodules and edge nodules are in a staggered or matched arrangement with each other and an upper surface of each edge nodule on the brush has the same or a greater contact area than an upper surface of a central nodule. The area of contact of the upper surface of each edge nodule with the substrate edge region is the same or greater than the area of contact of the upper surface of a central nodule with the substrate center region.

Owner:ENTEGRIS INC

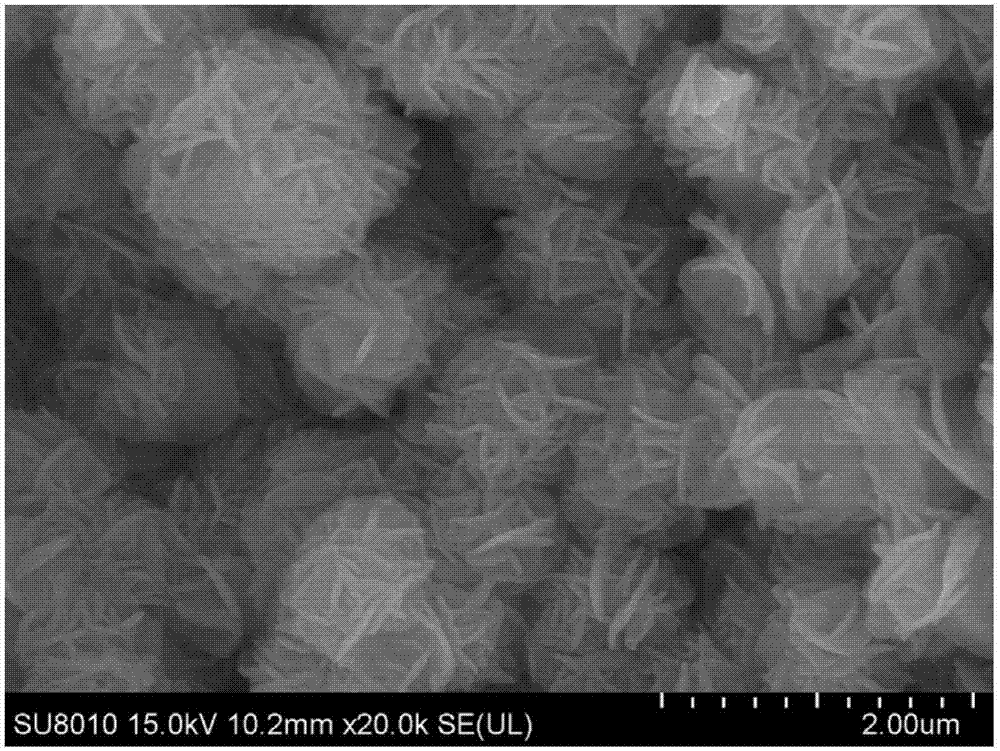

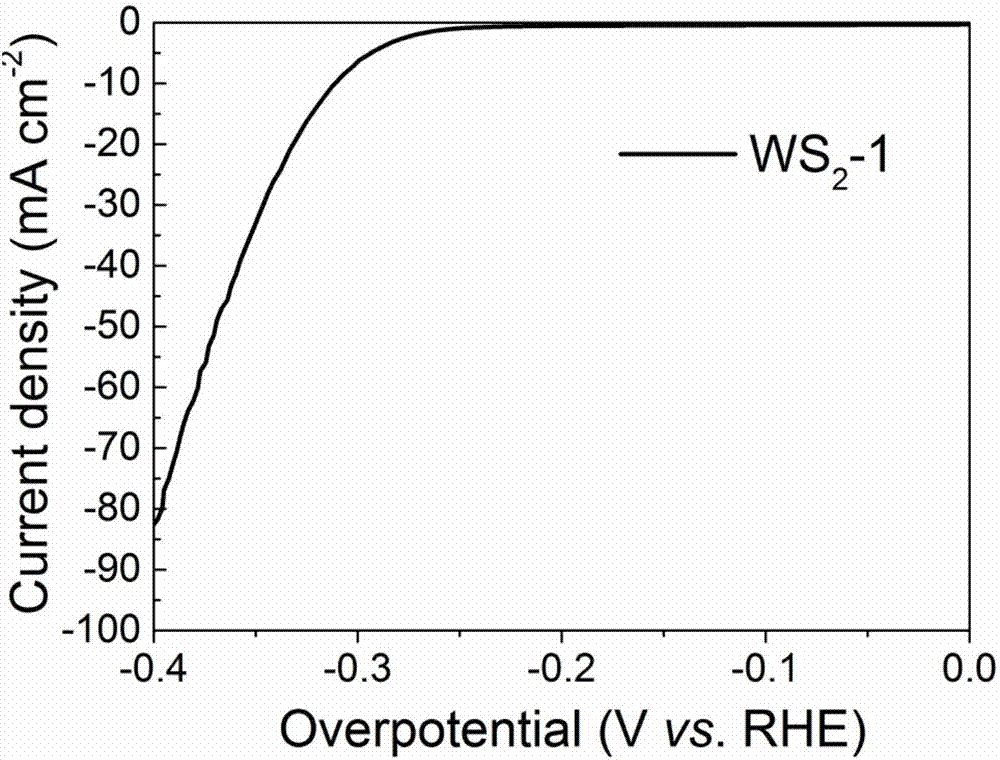

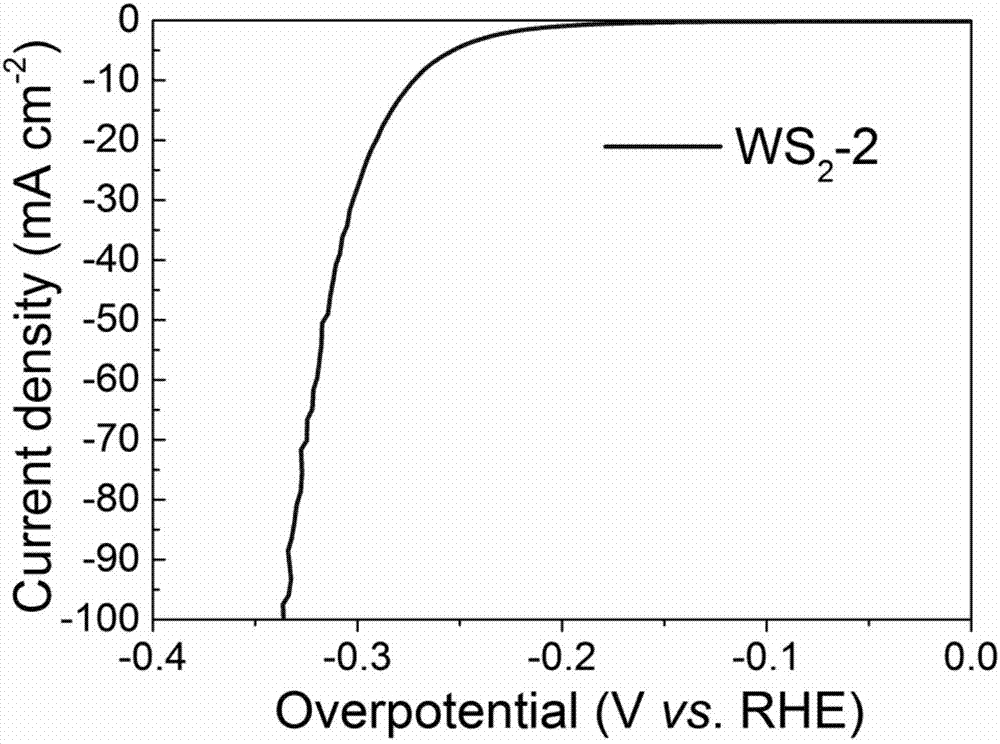

Petal-shaped tungsten sulfide nano-sphere, preparation method and application of nano-sphere

InactiveCN107188232ALow costSimple preparation processPhysical/chemical process catalystsTungsten compoundsThioureaTungstate

The invention relates to a tripetaloid tungsten sulfide nano-sphere, a preparation method and an application of the nano-sphere. The preparation method includes the steps: (a) dissolving tungstate and thiourea in water to form mixed solution; (b) placing the mixed solution in a high-pressure autoclave, performing hydrothermal reaction at the temperature of 220-250 DEG C, and centrifuging, washing and drying the mixed solution. The weight ratio of the tungstate to the thiourea is 4.2:(1.3-5.3). The preparation process is simple, needed equipment is conventional, raw materials are rich, the price is low, a petal-shaped tungsten sulfide nano electro-catalyst is synthesized at low cost, the prepared petal-shaped tungsten sulfide catalyst has good electro-catalytic stability, and stable electro-catalytic hydrogen evolution activity is still kept after circulation is performed for 40000 seconds.

Owner:SUZHOU UNIV

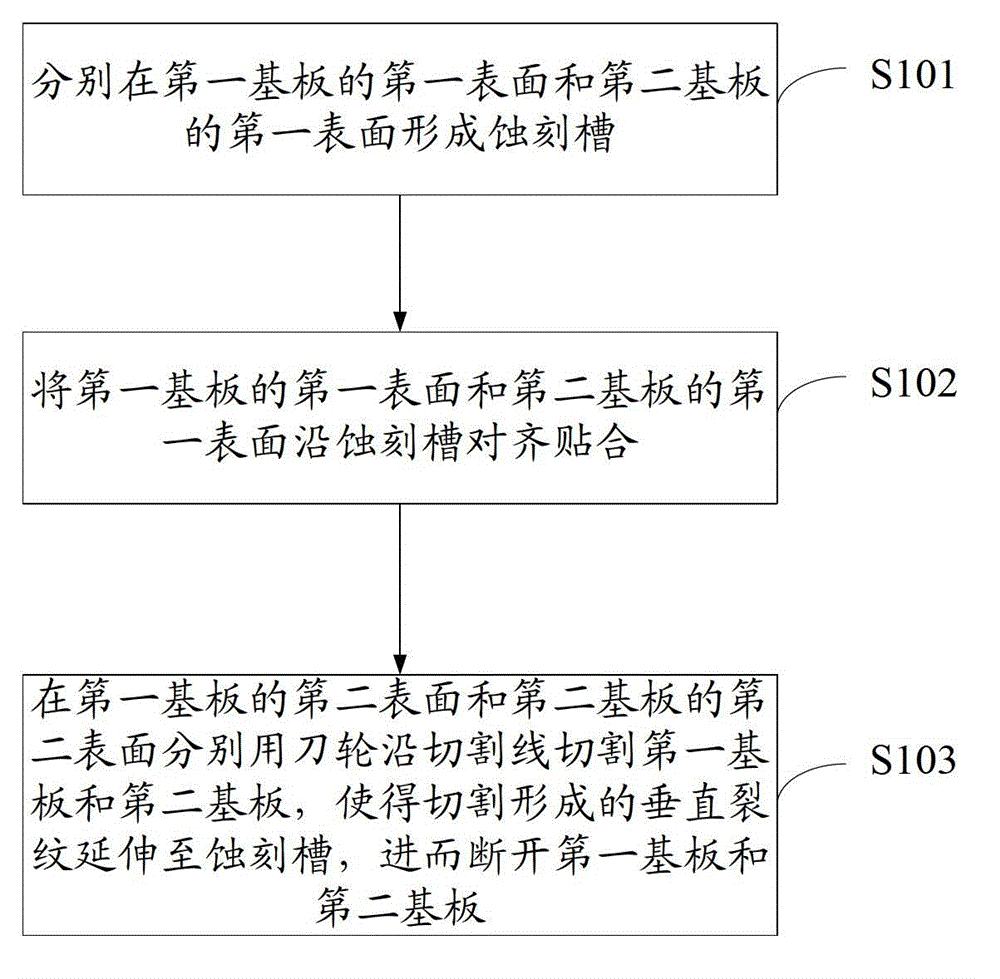

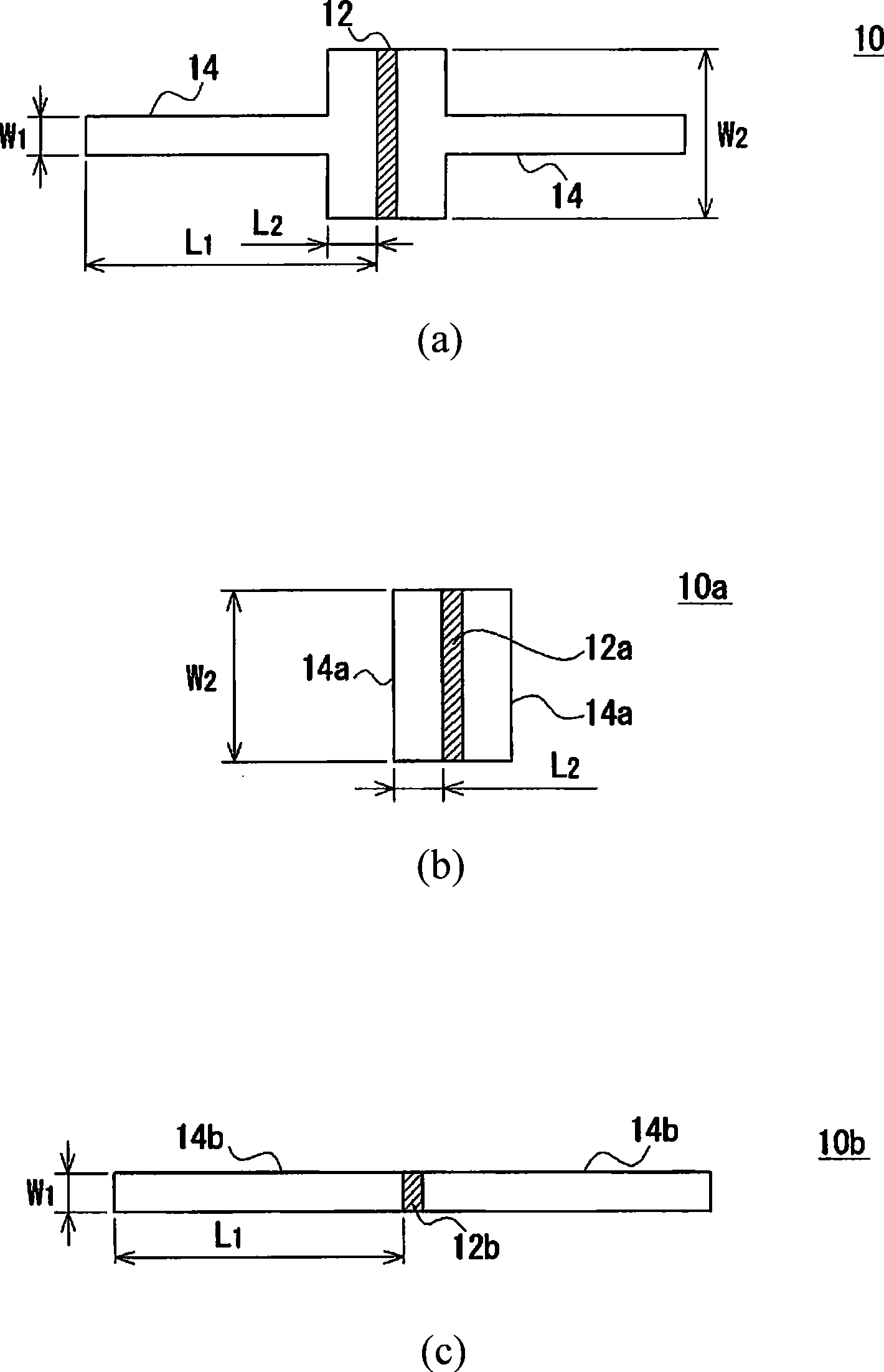

Base plate and cutting method thereof

ActiveCN102910809ASpeed up the cuttingShorten the extension distanceGlass severing apparatusNon-linear opticsFlywheelEngineering

The embodiment of the invention discloses a cutting method of a base plate; the base plate comprises a first base plate and a second base plate; the cutting method comprises the steps of: respectively forming an etching groove on the first surface of the first base plate and the first surface of the second base plate; aligning and sticking the first surface of the first base plate and the first surface of the second base plate along the etching grooves; and respectively using a knife flywheel to cut the first base plate and the second base plate on the second surface of the first base plate and the second surface of the second base plate along cutting lines, and enabling the vertical crack formed by cutting to extend to the etching grooves to break the first base plate and the second base plate. The embodiment of the invention also discloses the base plate. In such a way, the cutting method disclosed by the invention can be used for accelerating the cutting speed of the base plate and reducing the inclination and the offset after cutting, thus reducing the erroneous judgment of a checking machine and lightening the burden of workers.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Drinking container

ActiveUS7080752B2Easy to emptyMinimal tiltingSealingContainers preventing decayBiomedical engineeringWedge shape

Owner:WEDGE GRP

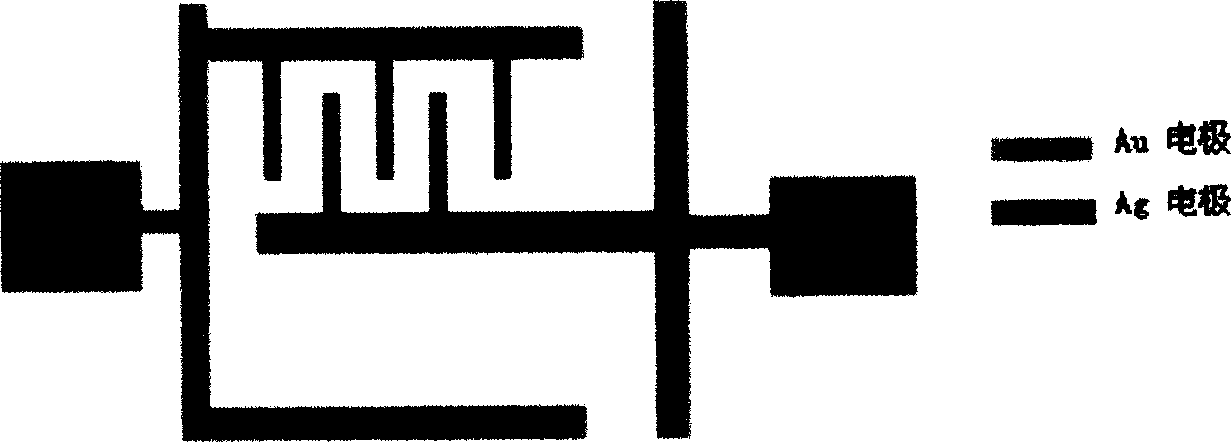

Preparation of silver nanometer electrodes

InactiveCN1681095AAtomic level flatteningImprove hydrophilicityNanostructure manufactureSemiconductor/solid-state device manufacturingConductive atomic force microscopyOrganic solvent

The method includes following steps: (1) preparation of self-assembly substrate, offering a P type Si(100) substrate that is treated by ultrasonic in organic solvent; after treated by placing into Piranha solution, and it is dried by blowing non-oxidizability gas, and then is treated by OTS solution and is cleaned up by using organic solvent; (2) nano-line etching, the nano-line is etched on self assembly substrate by using current of conduct atomic force microscope, the radius of curvature of pinpoint is less than 50 nm; (3) nanometer generating, the etched substrate is placed in the silver acetate for dipping, and then is taken out to place in ethanol in short time, and then is placed in sodium borohydride aqueous solution for dipping, washing, and then is dried by blowing non-oxidizbility gas, finally the silver enhancement solution is inputted for heighten the electrode line.

Owner:HENAN UNIVERSITY

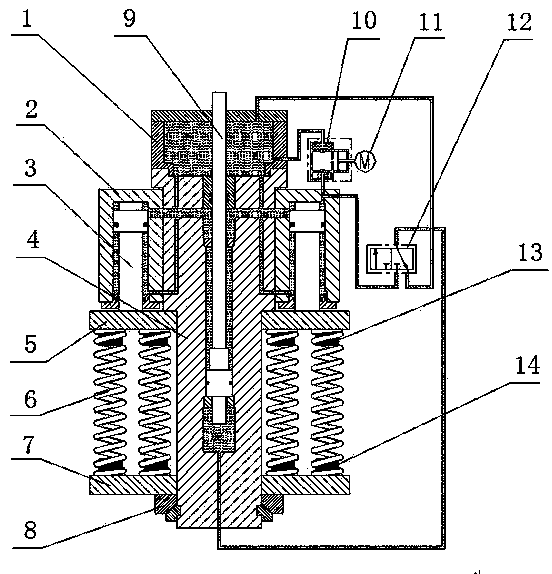

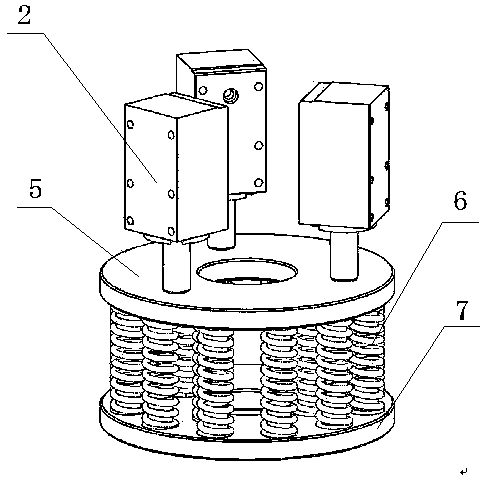

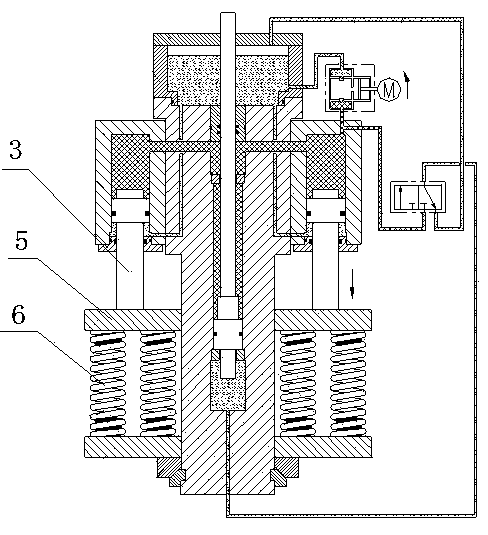

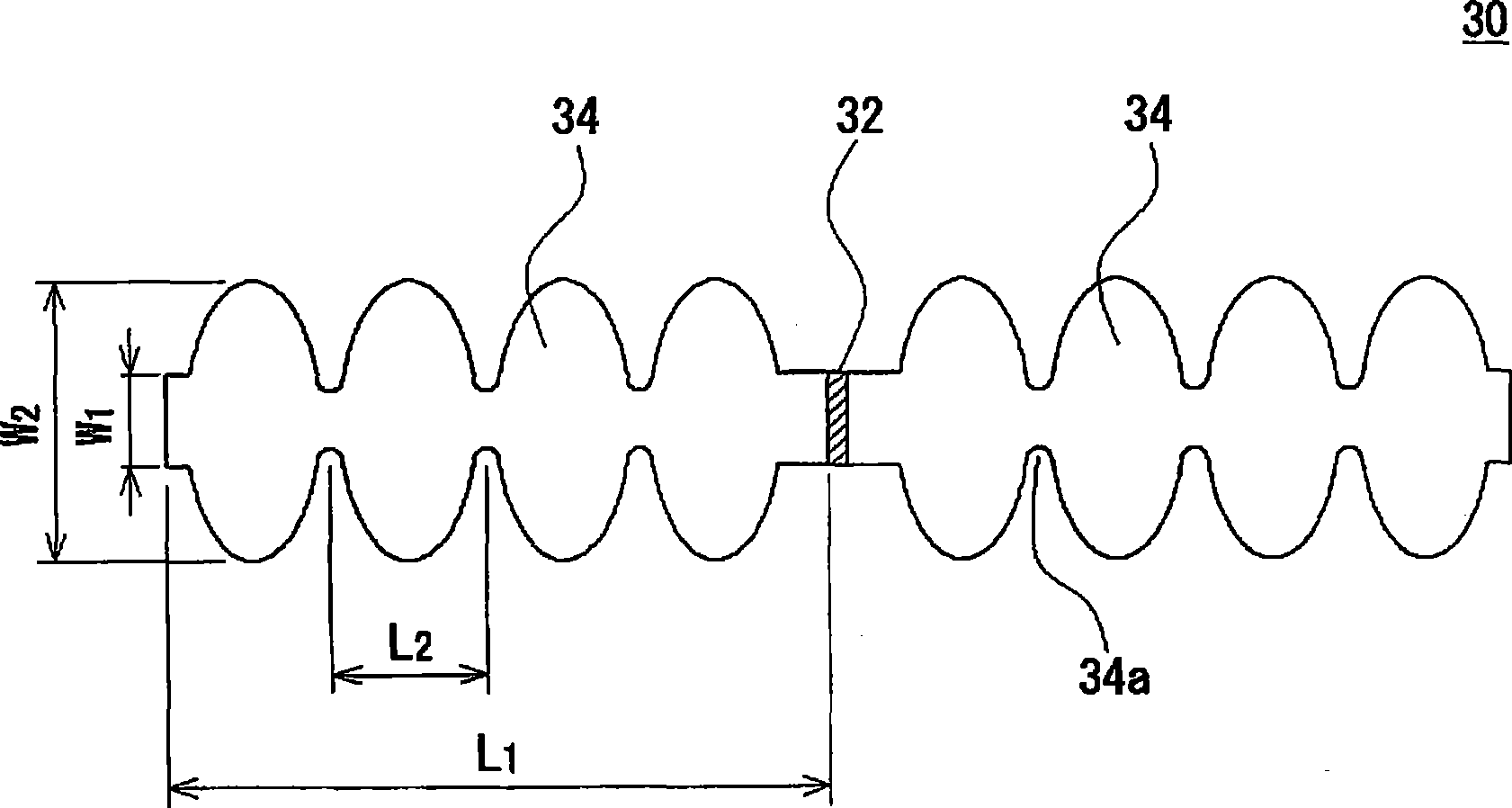

Spring energy storage hydraulic operation mechanism and energy storage spring unit

InactiveCN104143468ASmall length errorReduce slopeHigh-tension/heavy-dress switchesAir-break switchesLinear relationshipCylinder block

The invention discloses a spring energy storage hydraulic operation mechanism and an energy storage spring unit. The energy storage spring unit comprises an upper press plate, a lower press plate, and an energy storage spring installed between the upper press plate and the lower press plate in an abutting mode, wherein the upper press plate and the lower press plate are arranged on a cylinder block of a working cylinder in a sleeved mode, the energy storage spring is formed by spiral compression springs which are arranged into an array between the upper press plate and the lower press plate in an abutting mode, and the center line of the spiral compression spring array coincides with the axis of the cylinder block of the working cylinder. On one hand, the machining error of a single spiral compression spring is small, a linear relationship is formed between output force and displacement, performance is stable, the influence of environment temperature is avoided in normal use, and therefore the energy storage spring unit is an ideal energy storage element; on the other hand, the multiple spiral compression springs are arranged in parallel, the slope of the characteristic curve of a single spiral compression spring can be reduced exponentially, ideal output characteristics can be obtained through reasonable design, the effect that large output force is obtained through small displacement is achieved, and the more the springs are, the smaller the length error of the spring assembly is and the higher the output precision is.

Owner:STATE GRID CORP OF CHINA +2

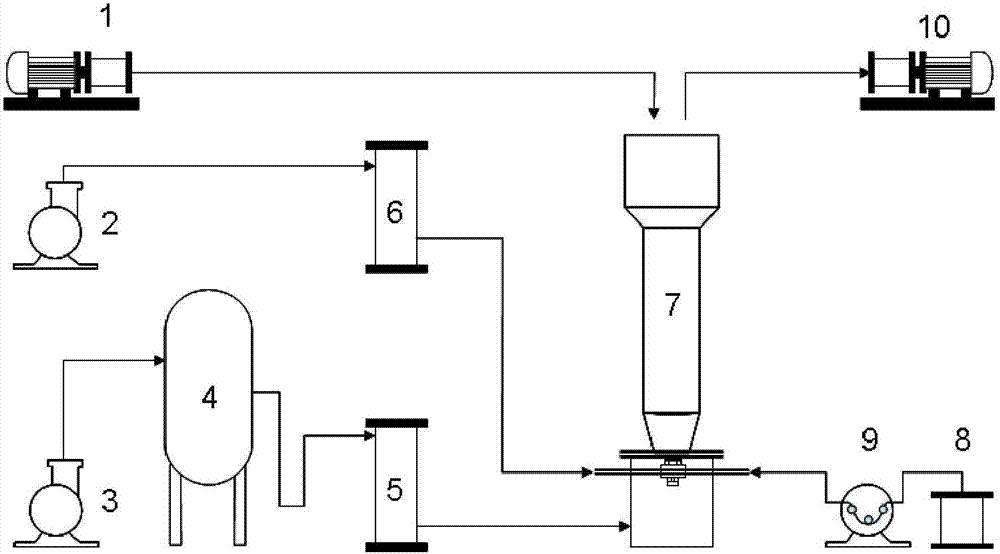

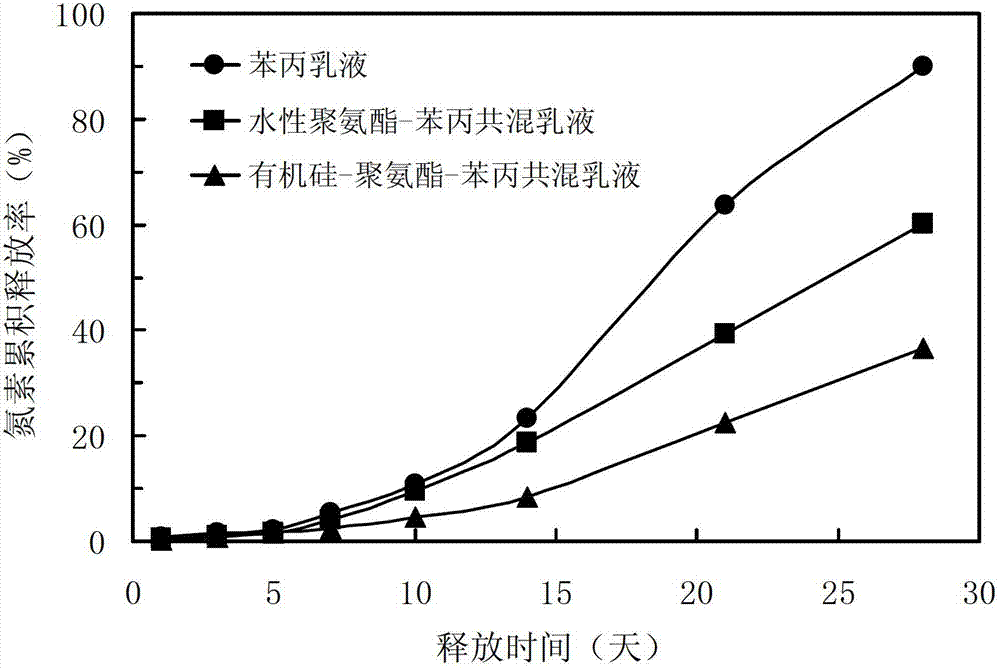

Urea-coated composite emulsion and preparation method and application thereof

The invention relates to urea-coated composite emulsion and a preparation method and application thereof. The urea-coated composite emulsion consists of waterborne polyurethane emulsion, styrene-acrylic emulsion, nonionic surfactant and the like, or consists of waterborne polyurethane emulsion, styrene-acrylic emulsion, nonionic surfactant, organic silicon emulsion and the like. The urea-coated composite emulsion provided by the invention delays quick release of fertilizer, obviously increases the release time, and can be matched with the nutrient intake of plants particularly by ternary blending. The coated composite emulsion provided by the invention can be used for coating any water-soluble fertilizer and has very broad application prospect.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Simulated obstacle crossing probe vehicle

InactiveCN102991599AReduce the overall heightReduce slopeElectrical steeringVehicular energy storageEngineeringMotor shaft

The invention disclose a simulated obstacle crossing probe vehicle, which consists of an obstacle crossing system and a probe system, wherein a first bracket and a second bracket are fixed on a box body of the obstacle crossing system; a storage battery and a circuit board are arranged inside both sides of the box body respectively; connecting rods are connected to the brackets through second connecting rod shaft sleeves and pin shafts; one ends of connecting swing stems are movably connected to the connecting rods, and the other ends of the connecting swing stems are supported on middle tires; motors are connected with wheels through motor shafts, snap springs and first connecting rod sleeve shafts; the front part of the box body is connected to the a steering motor through first connecting rods, second connecting rods and third connecting rods; and the motors are connected tire frames through the motor shafts, bearings, the snap springs and gaskets. A probe head is fixed at the front end of a direct-current stepping motor of the probe system; the direct-current steeping motor is movably connected with a straight-teeth cone gear; a corner connecting rod is connected with the direct-current stepping motor and a shaft sleeve; a motor connecting rod is connected with another shaft sleeve through a screw; and a plurality of the structures are combined and connected to form a trunk-shaped structure which is fixed on the box body through a first cone gear shaft, a second cone gear shaft and a corner base.

Owner:HUNAN INST OF TECH

Water collecting device for nuclear power plants and high tower with same

The invention discloses a water collecting device for nuclear power plants and a high tower with the same. The water collecting device is used for collecting fallen cooling water from rain filler. The water collecting comprises a plurality of horizontal abreast-staggered water collecting units. The water collecting units comprise hanging rods, supports, water collecting tanks, high-level water collecting plates, low-level water collecting plates and junction plates. One ends of the hanging rods are suspended on a supporting beam, the other ends of the hanging rods are connected to the supports, the water collecting tanks, the high-level water collecting plates, the low-level water collecting plates and the junction plates are connected to the supports, the high-level water collecting plates and the low-level water collecting plates are arranged in a staggered manner from top to bottom, the high-level water collecting plates are communicated with the water collecting tanks through the junction plates, and the low-level water collecting plates are communicated with the water collecting tanks directly. The water collecting device for nuclear power plant and the high tower with the same have the advantages that lift of a circulating pump can be reduced, noise can be lowered and cold air can enter the filler freely.

Owner:中广核工程有限公司 +1

Tilter for holding a container in a progressively less tilted orientation while receiving a beverage from a dispensing system

ActiveUS9376304B2Reduce slopeFacilitate joint and cooperative operationLiquid flow controllersLiquid dispensingActuatorEngineering

Owner:ANHEUSER BUSCH INC

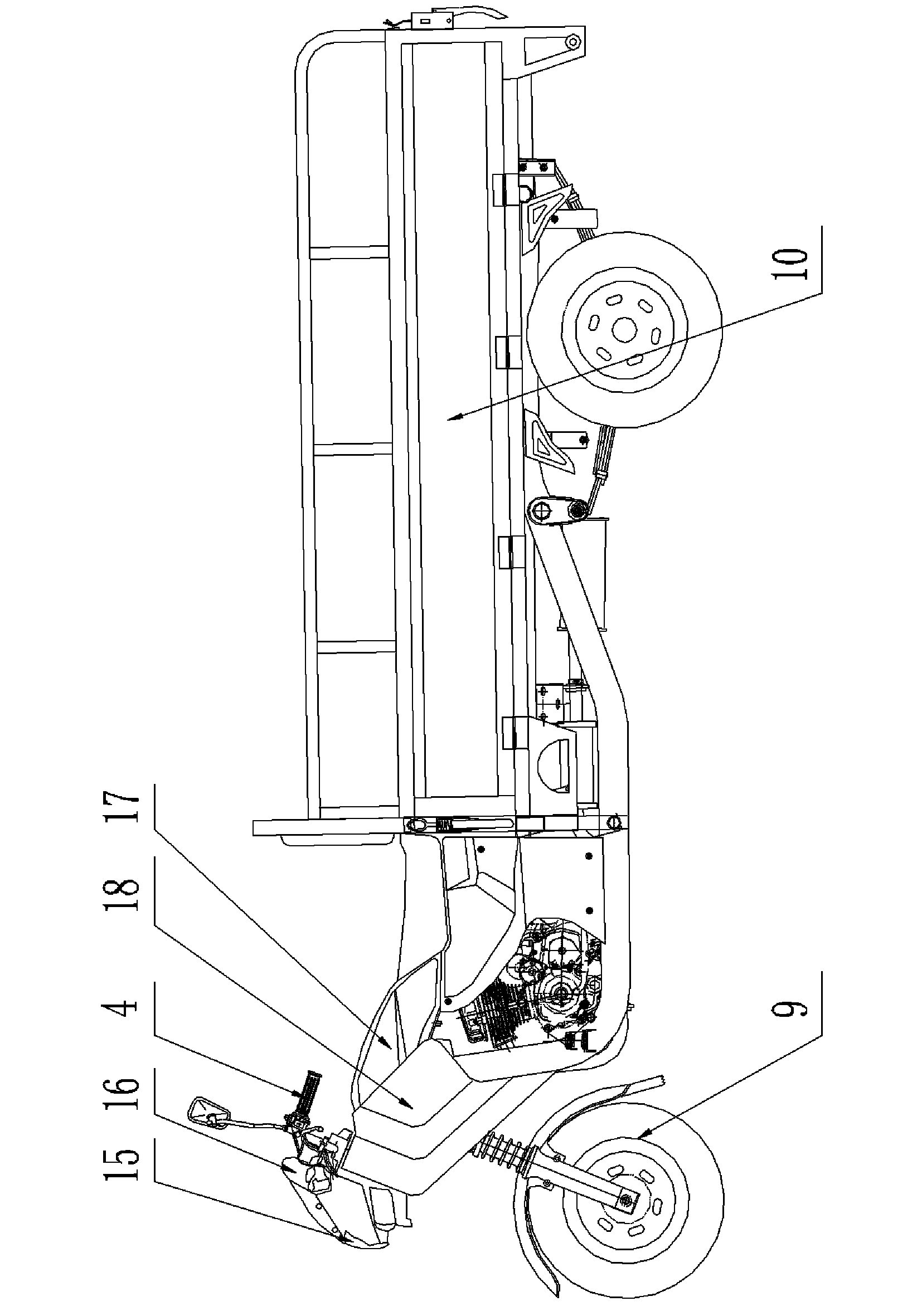

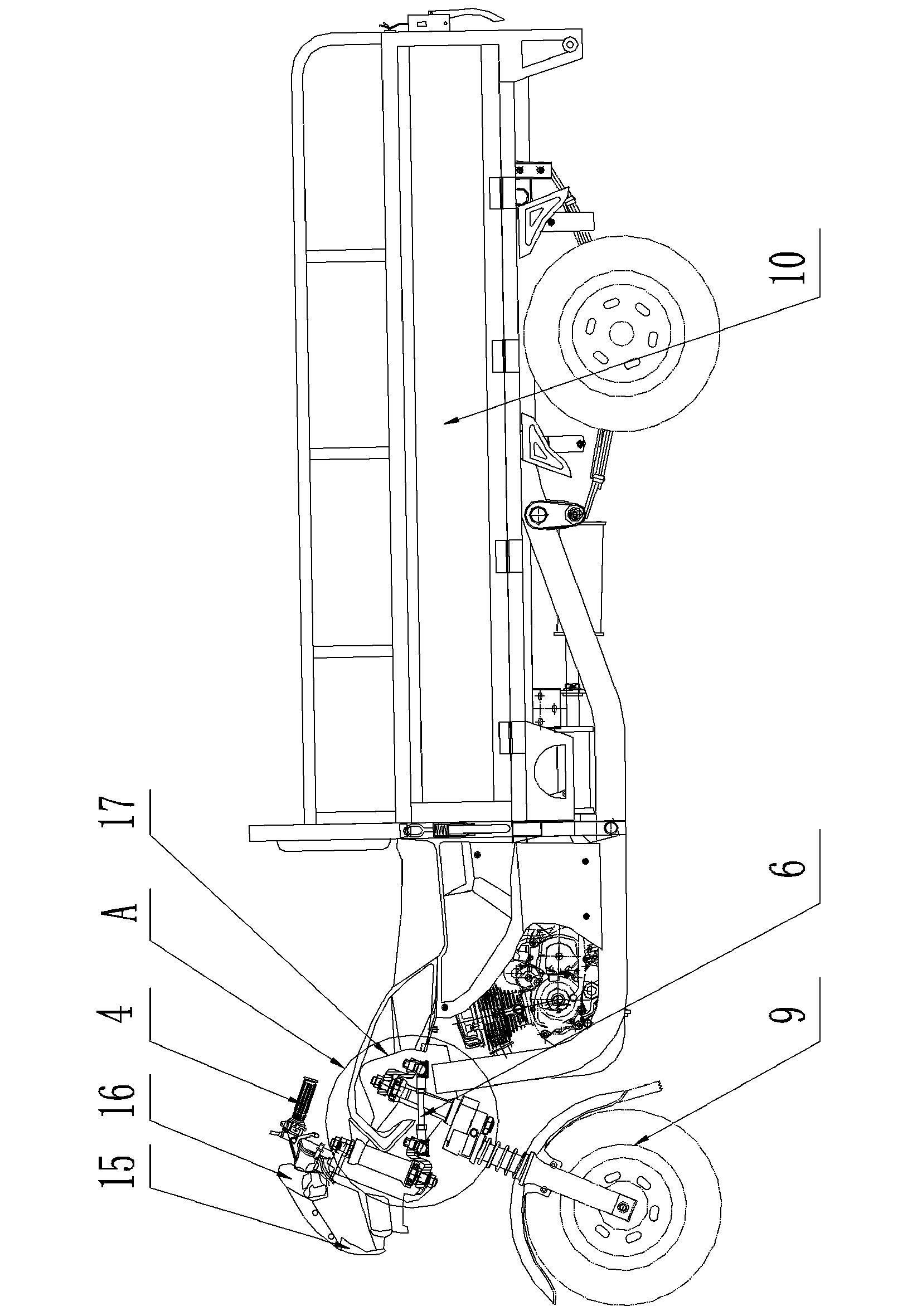

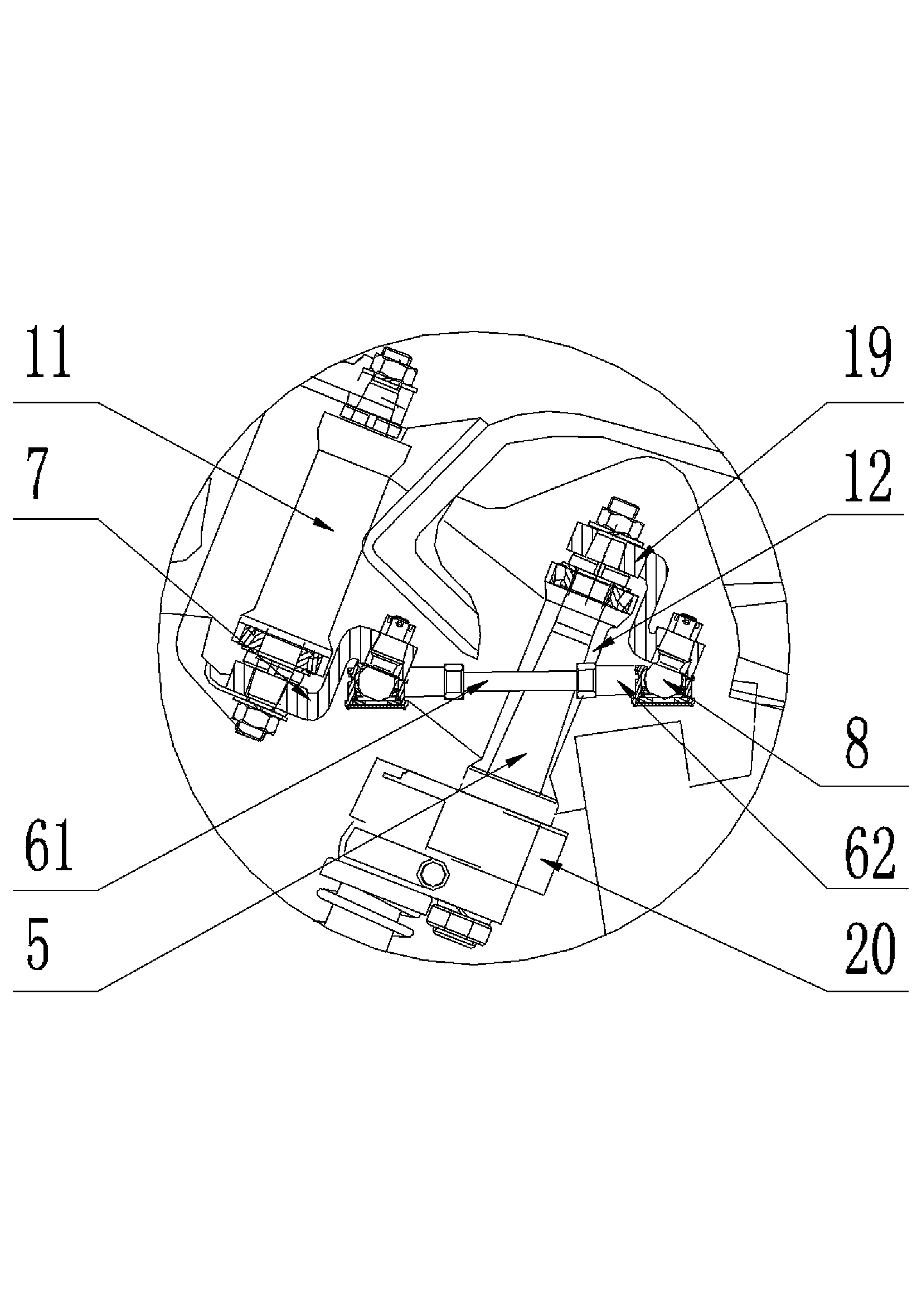

Right three-wheeled motorcycle

ActiveCN103192917AShorten invalid lengthConducive to driving safetyPassenger cyclesChain/belt transmissionVehicle frameControl engineering

The invention discloses a right three-wheeled motorcycle. The right three-wheeled motorcycle comprises a frame with a main beam and a container support beam, wherein a headstock stand pipe for installing a steering post is welded at the front end of the main beam; a handle pipe steering post for installing a handle pipe is rotatably matched in the headstock stand pipe; a handle pipe is arranged at the upper end of the handle pipe steering post; a front fork stand pipe for installing a front fork steering post is welded on the main beam at the back of the headstock stand pipe; a front fork steering post is rotatably matched in the front fork stand pipe; and the handle pipe steering post is connected with the front fork steering post through a linkage device. Compared with a conventional right three-wheeled motorcycle, the front fork steering post of the motorcycle moves backward, so that the invalid length between the front end of a front wheel and the front end of a head lamp of the right three-wheeled motorcycle is shortened; and therefore, a container of the right three-wheeled motorcycle can be lengthened within the specified overall length of the motorcycle, the transportation efficiency can be improved, and the requirements of customers can be met.

Owner:CHONGQING ASTRONAUTIC BASHAN MOTORCYCLE MFG

Thin film magnetic sensor

InactiveCN101520493AReduce slopeMagnetic measurementsSubstrate/intermediate layersMagneto resistancePhysics

The thin film magnetic sensor comprising a GMR film having a Giant Magneto-Resistance effect; and thin film yokes formed of a soft magnetic material connected electrically to both ends of the GMR film; wherein the thin film yoke has a high sensitivity portion with a demagnetizing factor of NL in a magnetic sensitive direction, and a low sensitivity portion with a demagnetizing factor of NH(>NL) in the magnetic sensitive direction, the low sensitivity portion being connected electrically in series with the high sensitivity portion.

Owner:DAIDO STEEL CO LTD

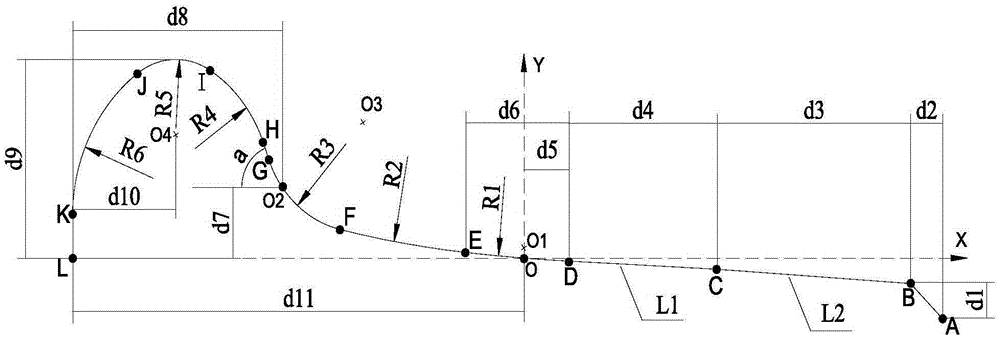

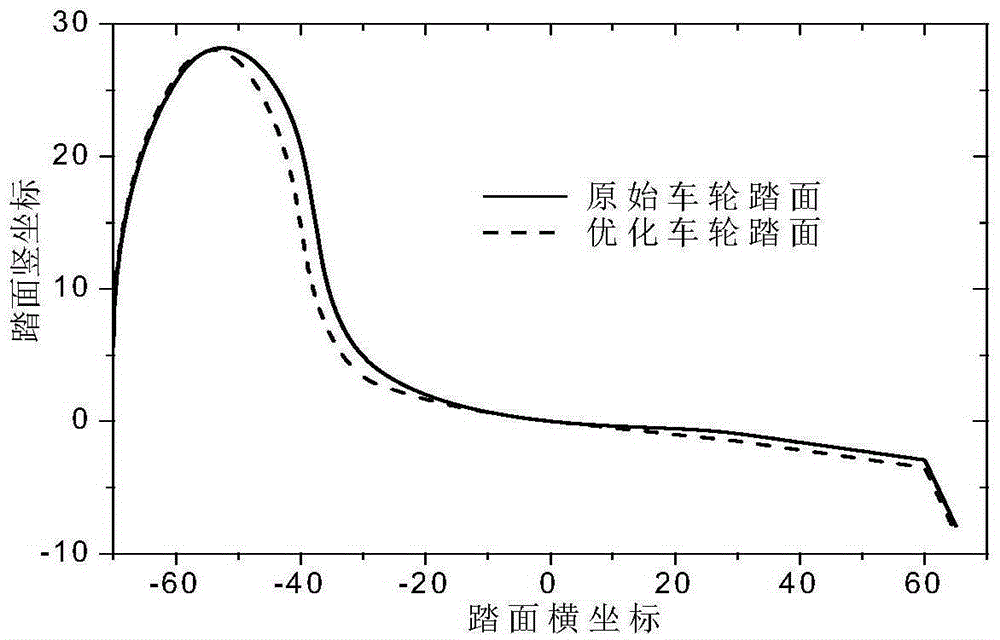

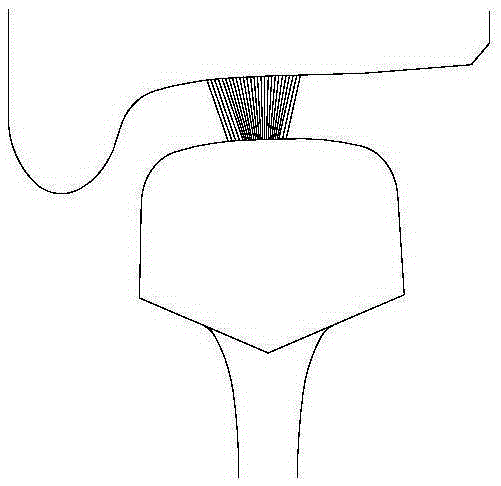

Optimal design method of motor car group wheel tread

InactiveCN105354384AImprove adaptabilityAlleviate Kinetic IssuesGeometric CADDesign optimisation/simulationOptimal designLine segment

The invention provides an optimal design method of a motor car group wheel tread, and belongs to the technical field of the high-speed vehicle of a railway. The optimal design method can effectively solve the problem that the original wheel tread of a CRH3 (China Railway High-Speed) type motor car group has a poor adaptive capability on the profile shape change of a steel rail. The optimal design method comprises the following steps: firstly, the profile shape of a common working area of the wheel tread is selected to be optimized so as to cause the wheel tread to basically coincide with an original wheel tread; secondly, in order to lower the throat root circle inclination of the wheel tread, the optimized rim thickness d8 of the wheel tread is determined to be 32.5mm to adapt to a situation that no overlarge equivalent conicity is always generated when the wheel tread is matched with the unpolished steel rail of which the rail shoulder is extruded, and the capability of the wheel tread on adapting to the unpolished steel rail is improved; and thirdly, the inclination of the outer end of the wheel tread is improved, the optimized inclination of the straight-line segment CD of the outer end of the wheel tread is determined as 1:20 so as to adapt to a situation that the too small equivalent conicity is unlikely to generated when the wheel tread is matched with the excessively polished steel rail, and the capability of the wheel tread on adapting to the excessively polished steel rail is improved. The optimal design method is mainly used for producing the CRH3 type motor car group wheel.

Owner:SOUTHWEST JIAOTONG UNIV

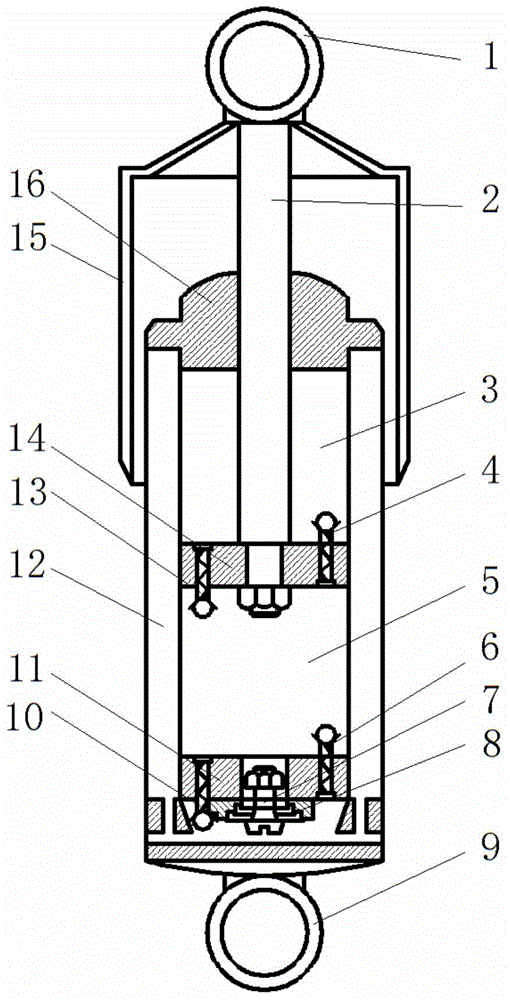

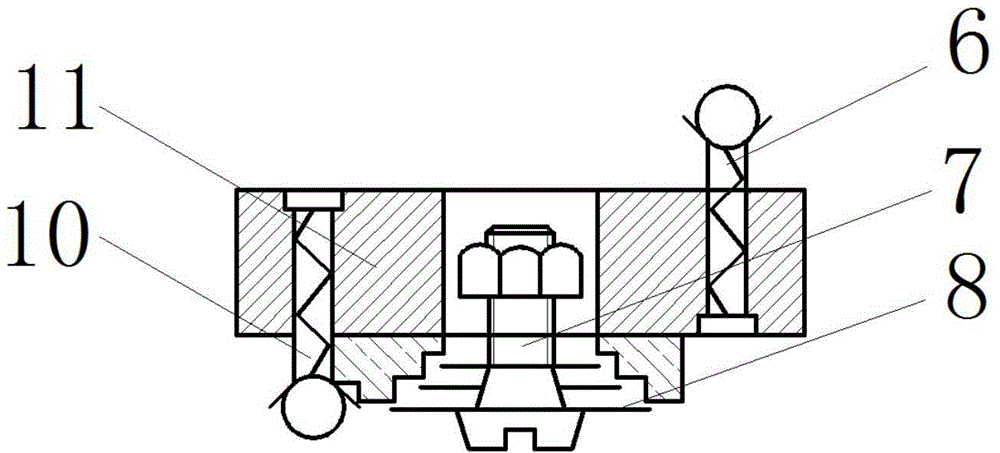

Damper automatically preventing car body from being inclined

InactiveCN104948642ABalance inertia forceReduce slopeSpringsLiquid based dampersAutomatic controlPiston rod

Disclosed is a damper automatically preventing a car body from being inclined. A one-way valve of the damper is installed at the bottom of a piston and working cylinders. The hydraulic damper adopts the dual-cylinder design, wherein the first working cylinder and the second working cylinder are separated by a piston. The first working cylinder and the second working cylinder are sleeved with the third working cylinder. The piston is connected with a damper sleeve and an upper hanging ring through a piston rod. The outer wall of the third working cylinder is connected with a lower hanging ring. By the adoption of the damper, the phenomenon that the car body is inclined due to the fact that the left wheel stress and the right wheel stress are not balanced when a car turns a corner can be avoided, the discomfort of riders is lowered, different damping forces of stretching and compressing can be automatically controlled and adjusted by the hydraulic damper, electronic control is not needed any more, and the cost is lowered.

Owner:GUANGXI UNIV

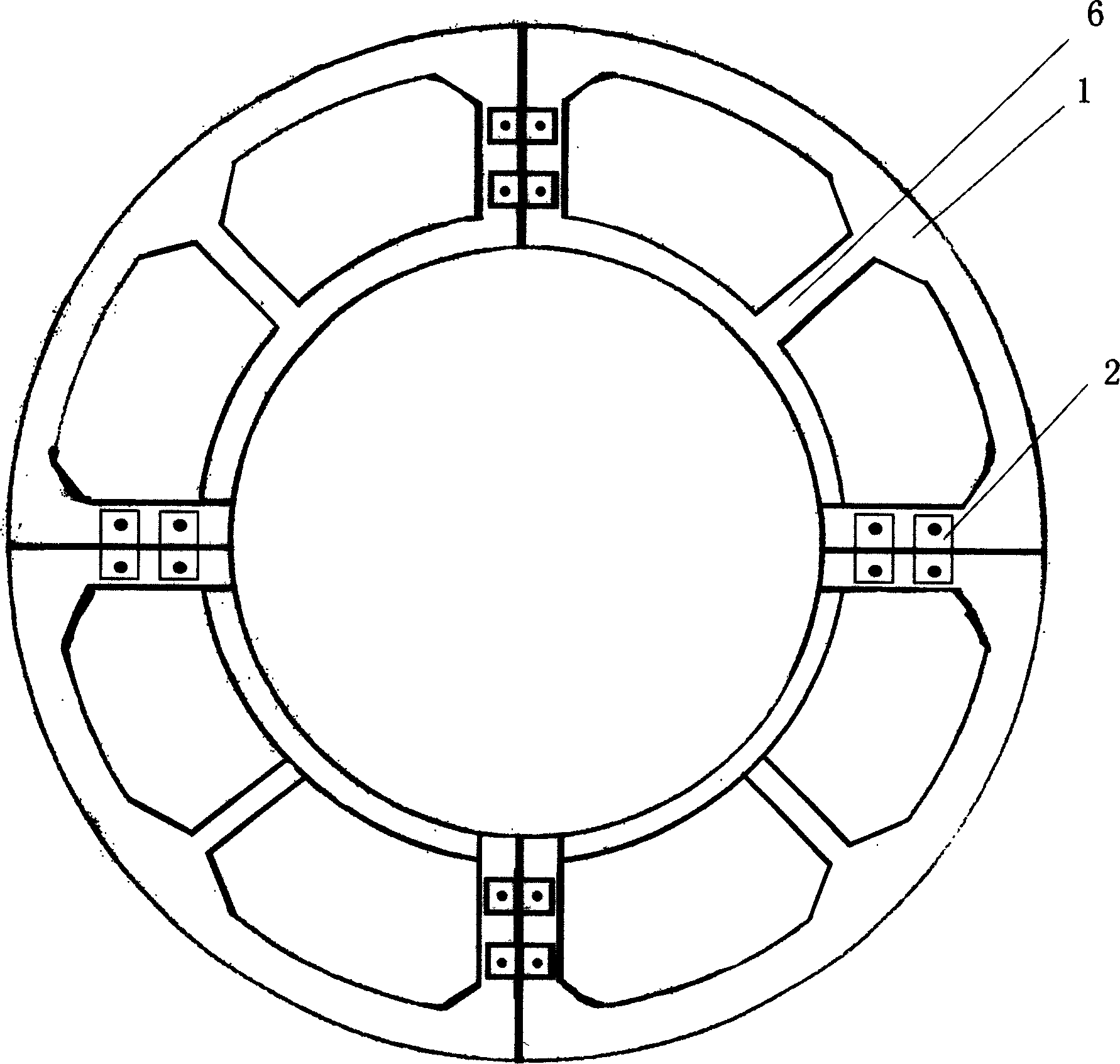

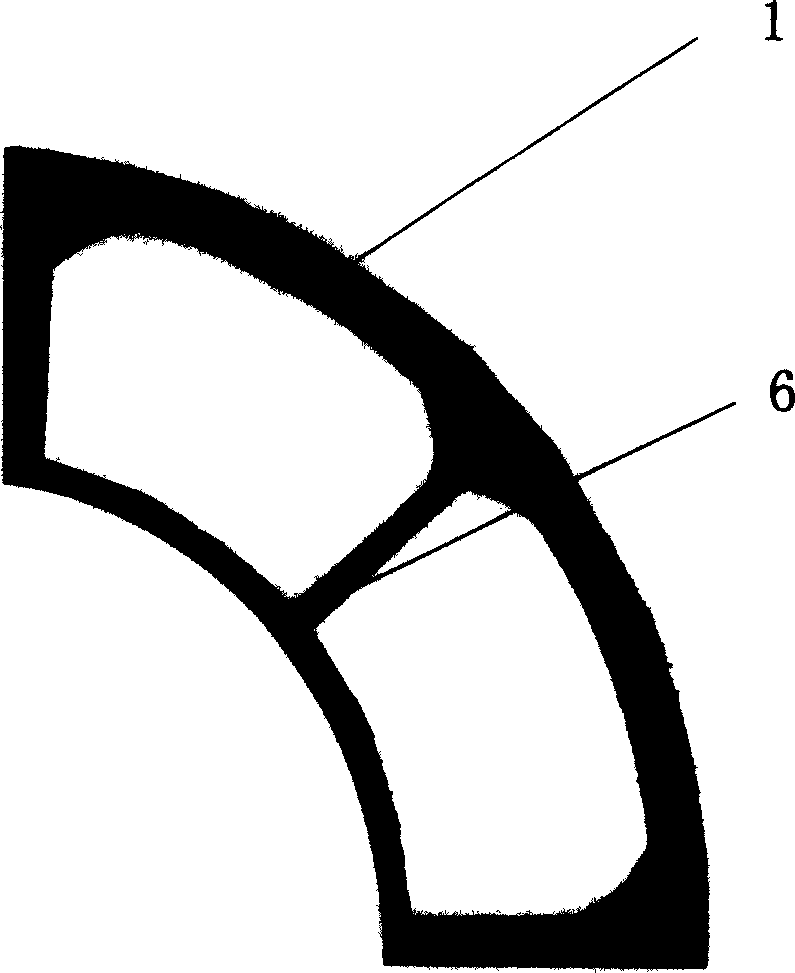

Safety wheel

InactiveCN1586929AReduced chance of rolloverReduce spare tireTyre partsRimsAtmospheric pressureAirplane

The present invention relates to safety wheel technology widely suitable for automobile, motorcycle, airplane, etc. The safety wheel consists of tyre and hub and features its combined extending hub support inside tyre and set on a hub connecting part, and outer hub and inner hub connected together via the hub connecting part. The present invention has the advantages of the support of the hub connecting part under lower running of the tyre and during bursting tyre to prevent tipple, and elimination of spare tyre to reduce vehicle weight.

Owner:戚永维

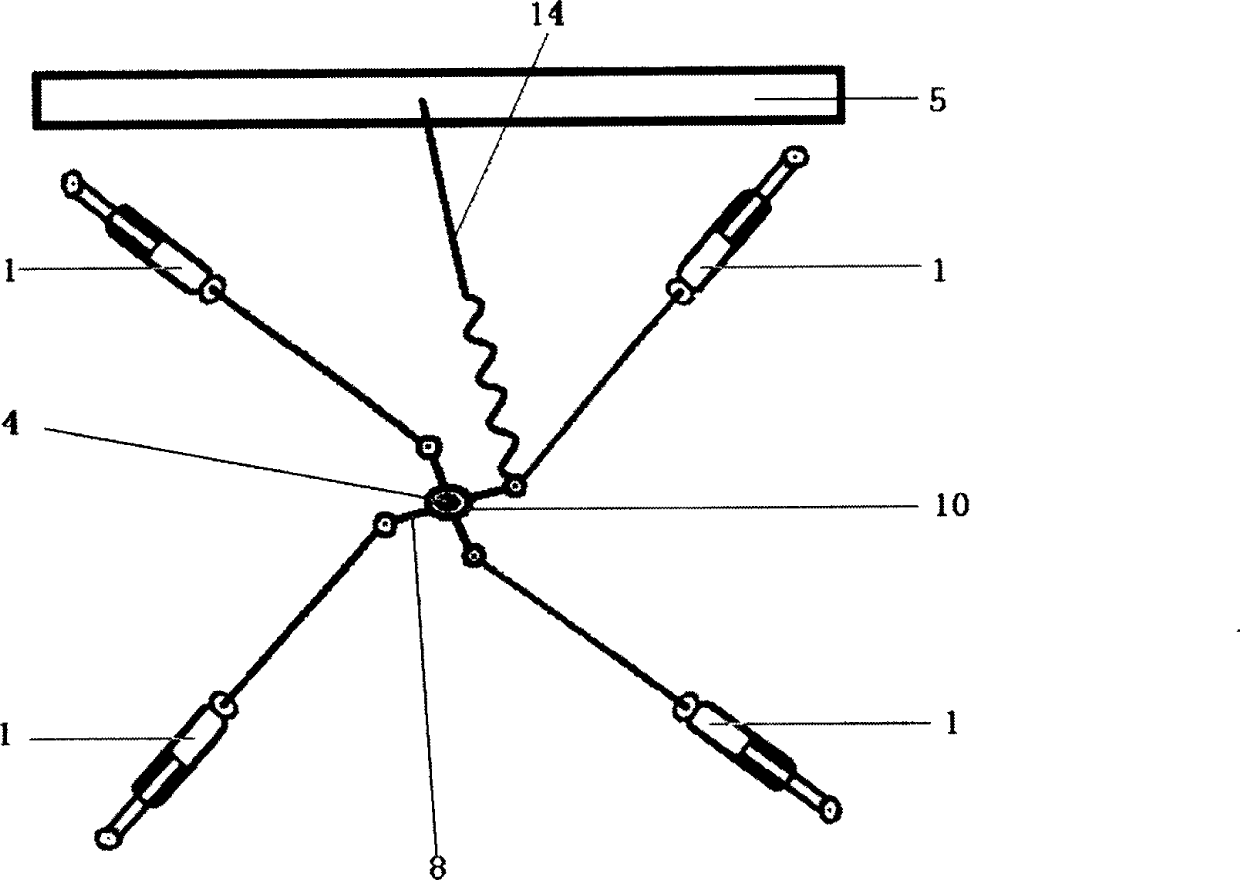

Vibration damping system with steering automatic balance

InactiveCN102653221AImprove shock absorptionAdjust the carrying capacityInterconnection systemsVertical vibrationEngineering

The invention relates to a vibration damping system with steering automatic balance, belonging to the field of vibration damping and balancing systems of vehicles. A vibration damping mechanism is constituted by three or more than three ordinary vibration dampers, and the vibration dampers constitute a star-shaped (Y-shaped) or triangular (delta-shaped) or star-shaped and triangular combined structure. When an obstacle which is higher than the ground is encountered, the vibration damping which is originally relatively vertical becomes relatively horizontal, a force component of a load, which is decomposed to the horizontal direction is greater, the force component in the vertical direction is smaller, the stroke of vibration damping operation is increased and the rigidity is reduced. Oscillation is further transferred to other vibration damping mechanisms of the same vehicle for absorption and damping. Therefore, the whole vehicle can be almost prevented from jolting along with the unevenness of a pavement. When steering is performed, the pressure on the outer side of a bend is increased, the vibration damping mechanism on the outer side is compressed, the vertical vibration damper in the vibration damping mechanism on the inner side is pulled to be in the trend of getting horizontal, and the rigidity is further weakened. Therefore, a hanging vehicle body can not be inclined to the outer bend. When the vehicle needs to bear more goods, the rigidity of the vibration damping system of the whole vehicle can also be regulated.

Owner:王运举

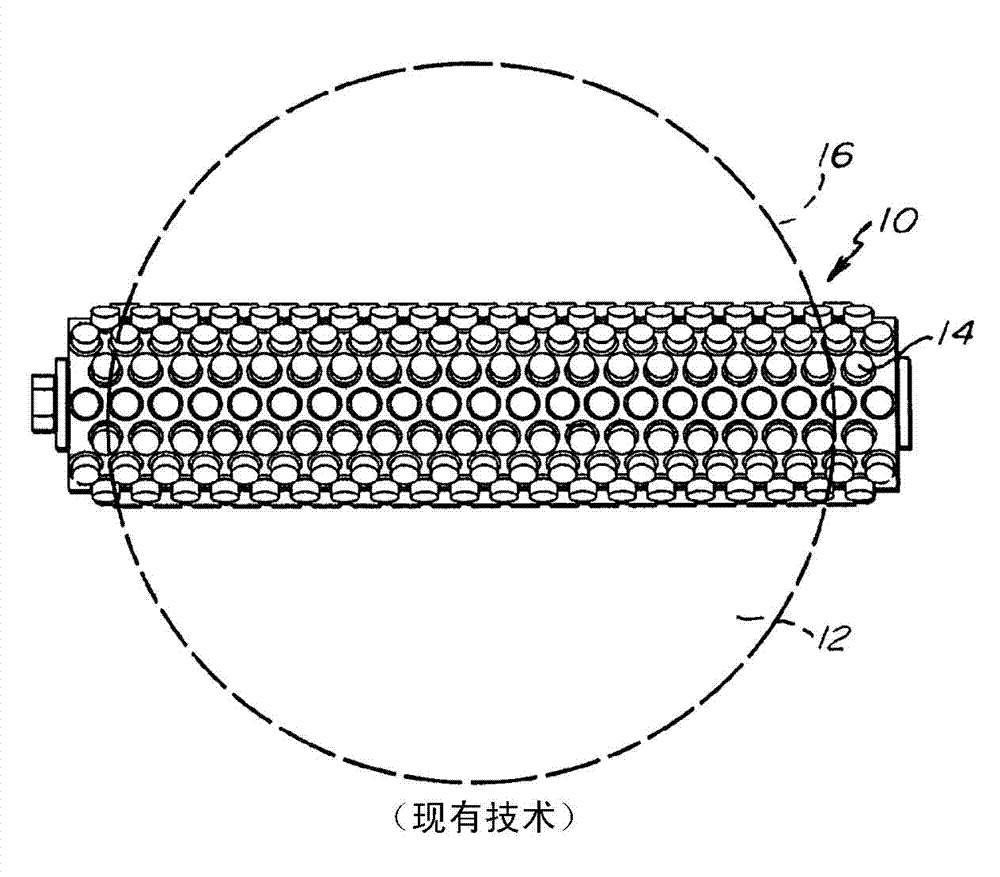

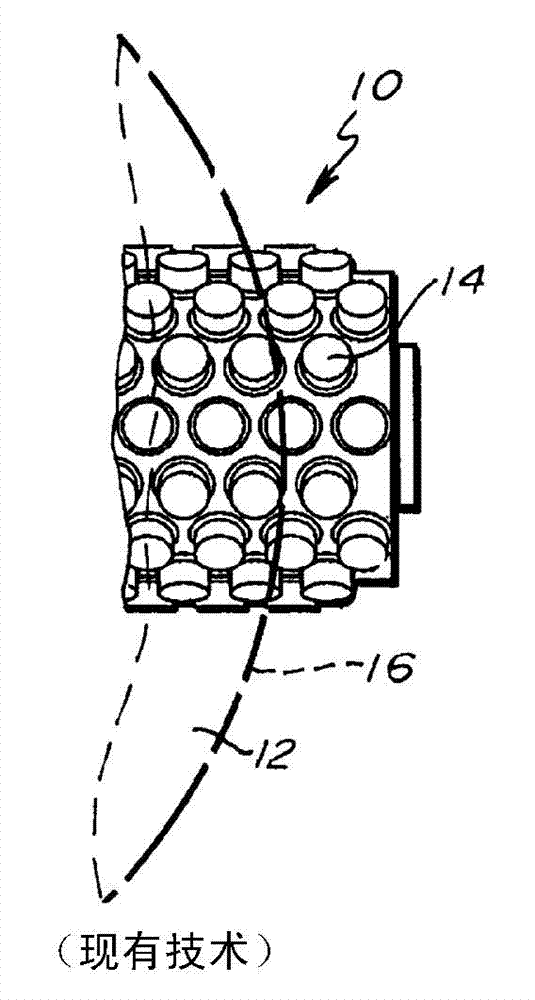

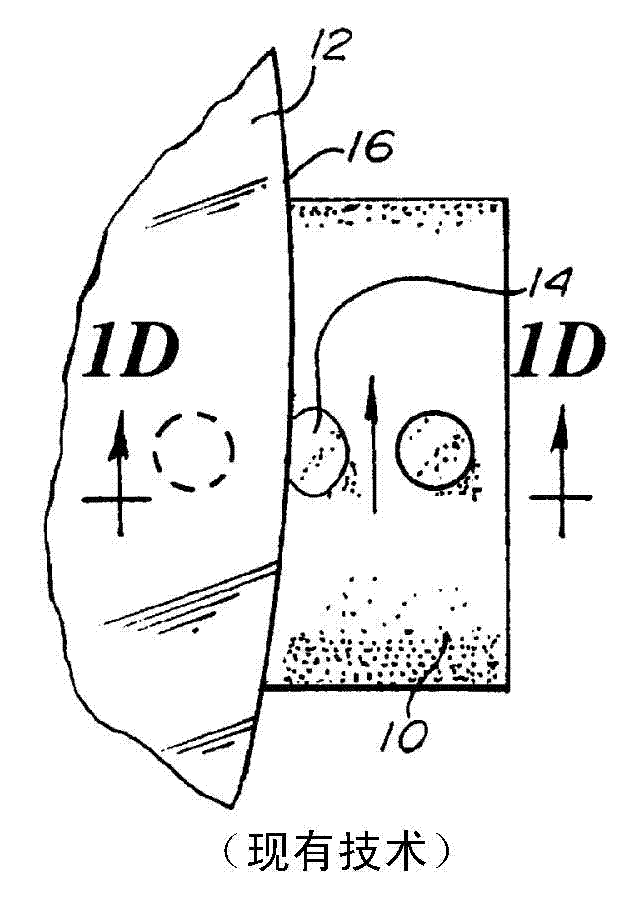

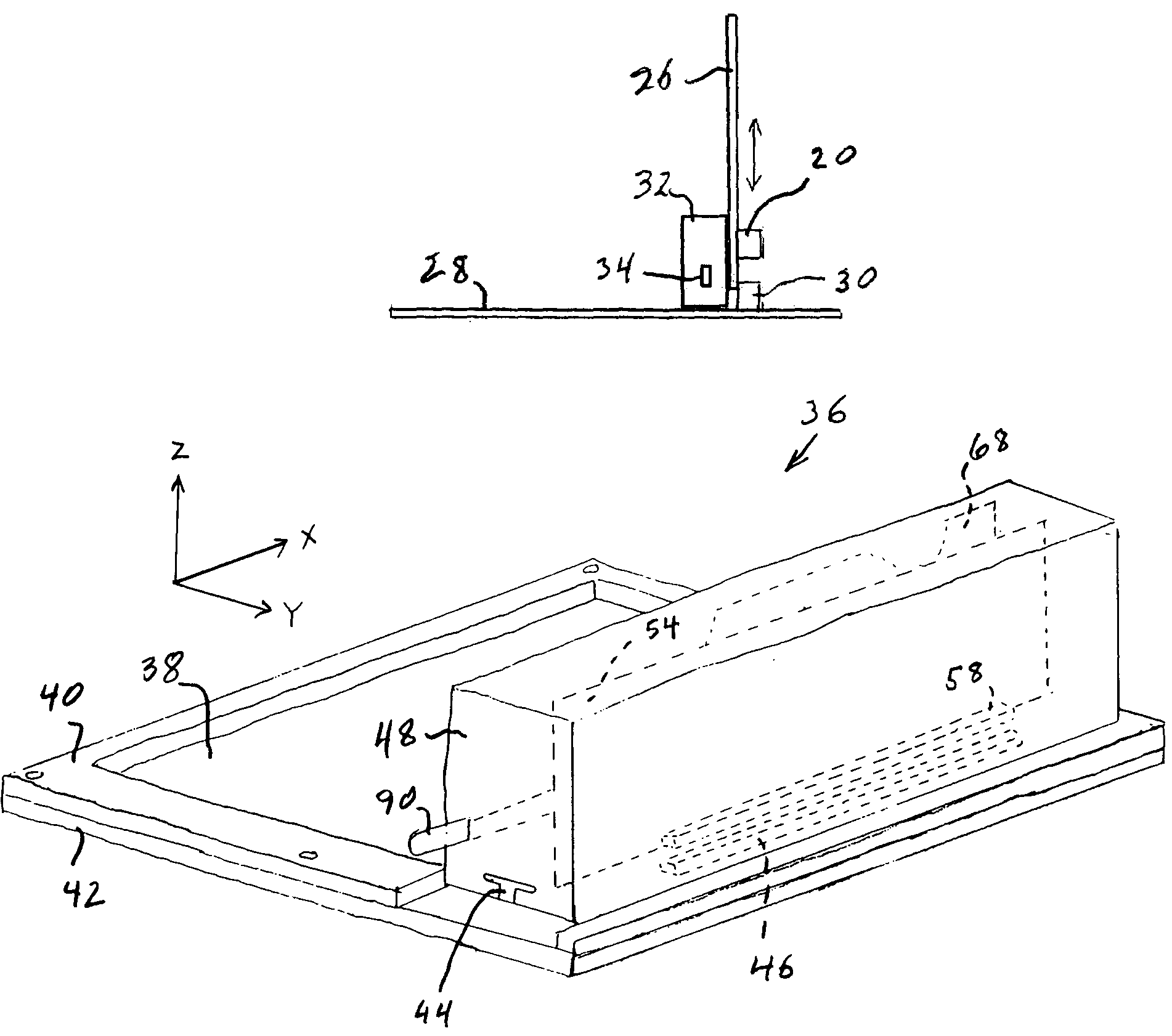

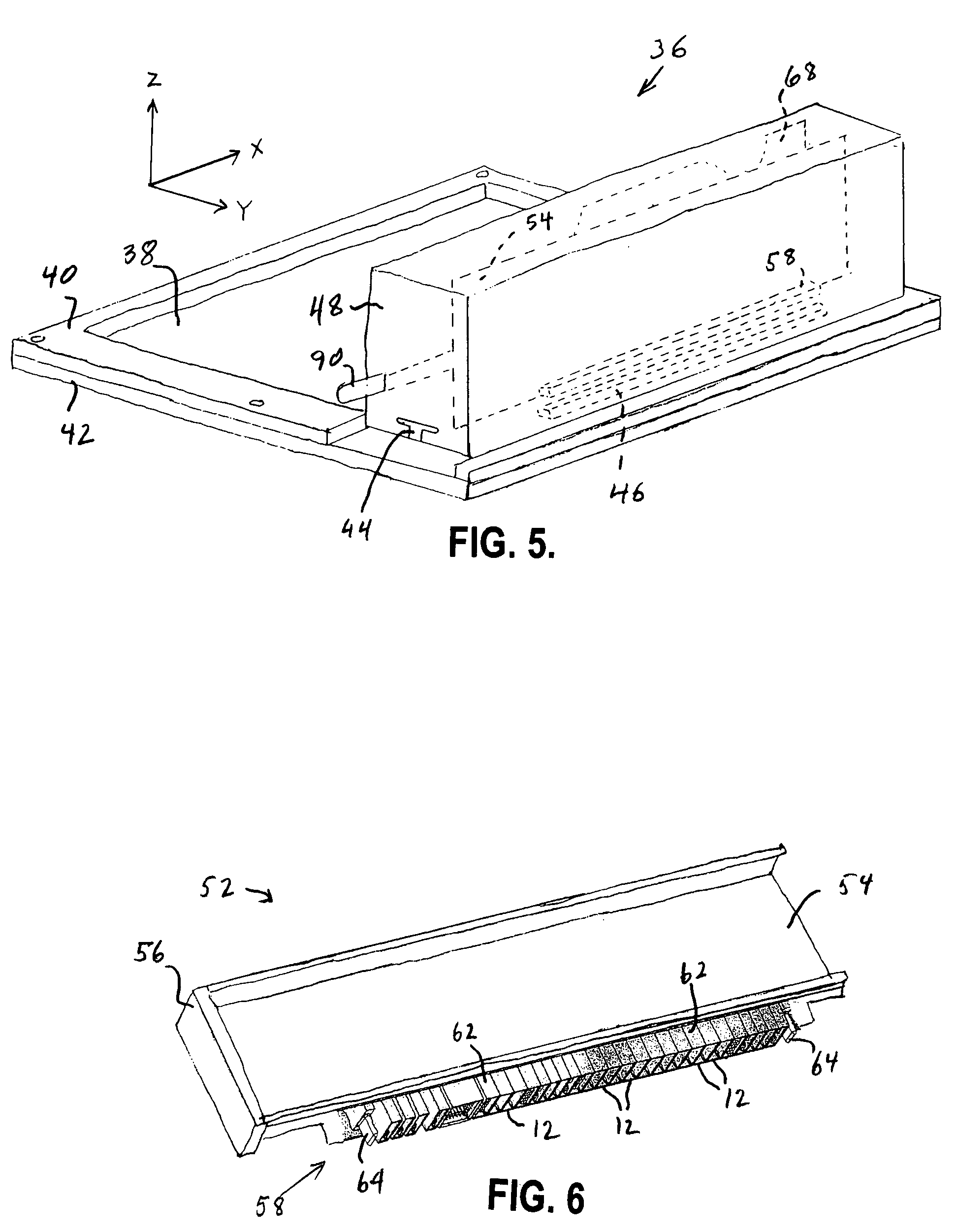

Providing mechanical support for modular interconnect systems

InactiveUS7083477B1Good mechanical supportReduce slopeElectrically conductive connectionsTwo-part coupling devicesComputer moduleModularity

A connector system includes a first connector assembly that is electrically connected to wiring on a first printed wiring board and a second connector assembly that is electrically connected to wiring on a second printed wiring board. Each connector assembly includes a number of connector modules that are joined together in a predetermined array such as a row. In one of the connector assemblies, the row also includes one or more actuation modules. The actuation module or modules are engaged by an actuator mechanism to force the connector assemblies into mating engagement or to draw them apart.

Owner:IBM CORP

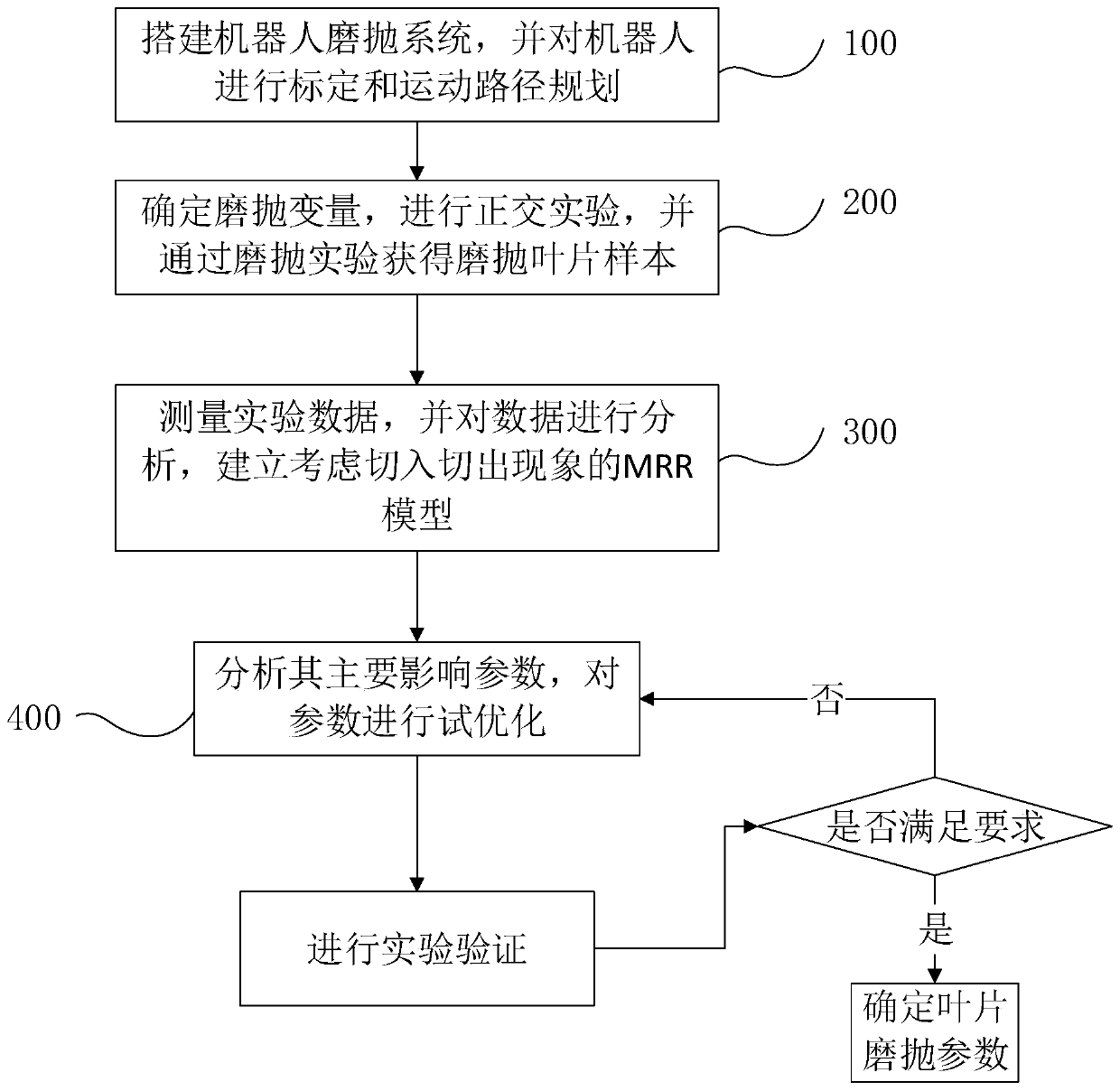

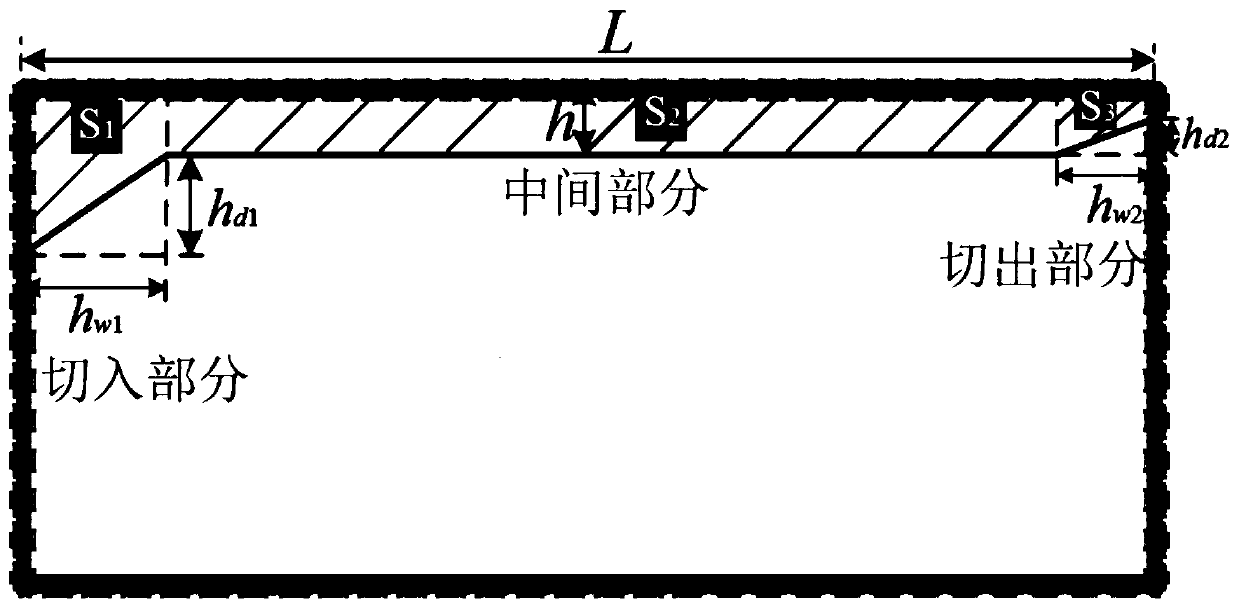

Gas compressor blade robot abrasive belt grinding and polishing machining method

ActiveCN110900379ASolve rationalitySolve the problem of underwearAutomatic grinding controlGrinding machinesMaterial removalPolishing

The invention discloses a gas compressor blade robot abrasive belt grinding and polishing machining method, which comprises the steps: S100, a robot grinding and polishing system is built, and a robotis calibrated and a motion path is planned; S200, an orthogonal experiment is carried out with the abrasive belt model, the granularity and the radius of a contact wheel of the grinding and polishingmachine as known quantities and the robot feeding speed, the abrasive belt linear speed and the grinding force as grinding and polishing variables, and a grinding and polishing experiment is carriedout on the blade through a robot grinding and polishing system, and a grinding and polishing blade sample is obtained; S300, the grinding depth, the surface roughness and the surface topography characteristics of the grinding and polishing blade sample are measured, and a cut-in, middle and cut-out part material removal rate model considering the cut-in, cut-out over-grinding or under-grinding phenomenon is established; and S400, main influence factors of the material removal rate model according to the material removal rate model is analyzed, the main influence factors during cut-in and cut-out are optimized and adjusted, and multiple groups of optimization parameters are estimated. According to the method, the phenomena of over-grinding and under-grinding are reduced to the maximum extent, and the surface quality and flatness of the workpiece are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

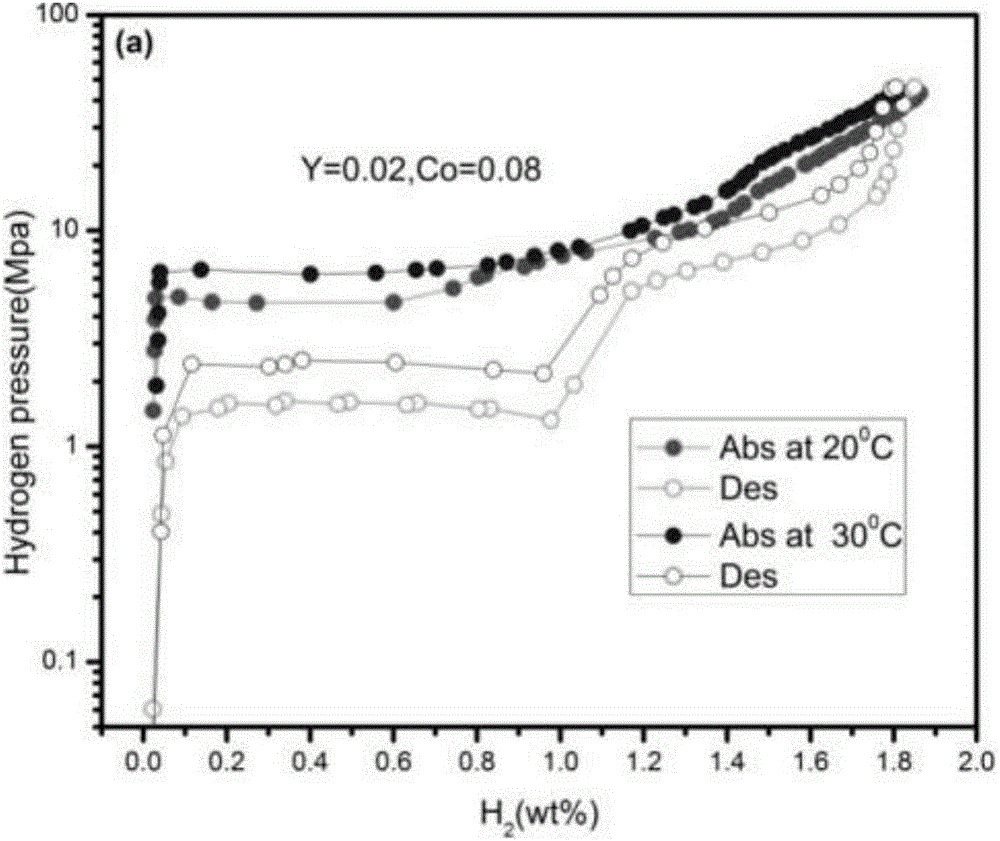

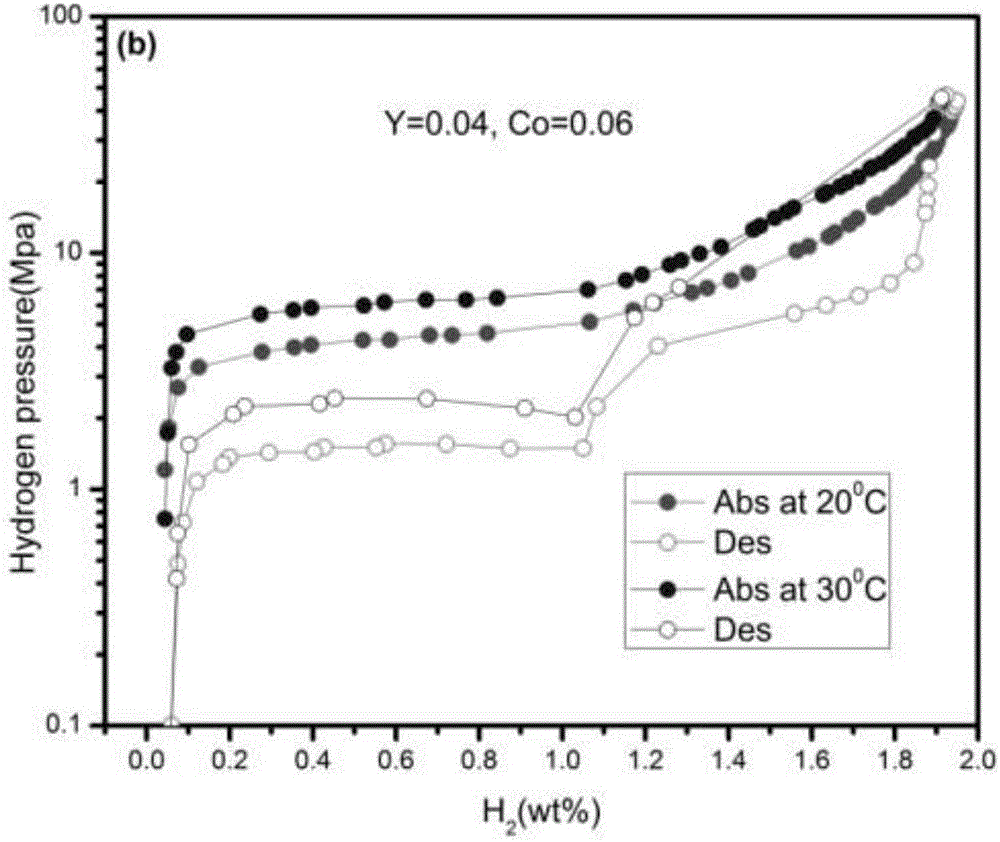

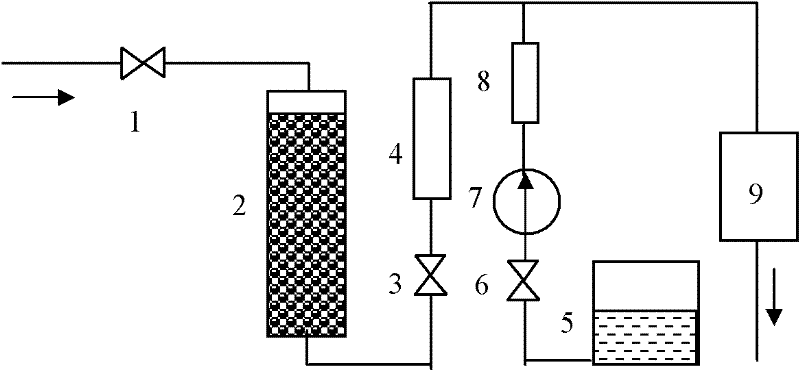

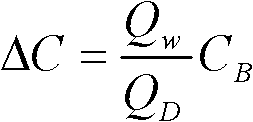

TiFe hydrogen storage alloy containing Co and Y and preparation method thereof

The invention discloses a TiFe hydrogen storage alloy containing Co and Y and a preparation method thereof. The chemical formula of the TiFe hydrogen storage alloy is TiFe0.86Mn0.1Co(0.1-x)Yx, wherein x is larger than or equal to 0.02 and smaller than or equal to 0.04. The novel TiFe0.86Mn0.1Co(0.1-x)Yx alloy is synthesized through a water-cooling copper crucible under the 99.9% high-purity argon environment. Through adding of Co and Y, the TiFe alloy is more easily activated and more easily absorbs hydrogen during first circulation. Meanwhile, the pressure of a hydrogen absorption and desorption platform of the alloy is low, and the slope of the hydrogen absorption and desorption platform is small. Under the temperature of 20 DEG C, the hydrogen storage quantity of the TiFe0.86Mn0.1Co0.06Y0.04 alloy reaches 1.95%(omega), and thus the TiFe0.86Mn0.1Co(0.1-x)Yx alloy is expected to provide efficient and practical hydrogen sources for equipment and production which take hydrogen as a raw material.

Owner:SHANGHAI UNIV

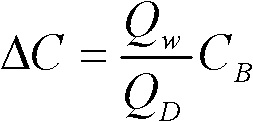

Flowing adding sodium analyzer checking method and device

InactiveCN102128871AReduce slopeImprove accuracyMaterial analysis by electric/magnetic meansHigh concentrationWater flow

The invention discloses a flowing adding sodium analyzer checking method and a flowing adding sodium analyzer checking device. The device comprises a desalting device connected with a water sample, a valve, a flow meter and a checked sodium analyzer; and a trace flow meter, a liquid delivery device, a sodium standard solution valve and a sodium standard solution water tank which are intercommunicated are connected in parallel on a pipeline between the flow meter and the checked sodium analyzer. High-concentration sodium standard solution is continuously added into water flow with extremely low sodium concentration. The dilution ratio of the water sample can be calculated by accurately metering the flow of the water sample and the adding flow of the high-concentration sodium standard solution, so that the sodium concentration increment of the low-concentration sodium standard water sample is calculated. Compared with the conventional high-concentration sodium standard solution static checking method, the sodium standard water sample of any concentration in a range of 1 to 10mug / L can be produced, so the standard water sample with the same or similar concentration as the concentration measured by an online sodium analyzer can be provided, and the accuracy and the reliability of the online sodium analyzer measurement value are greatly improved after the online sodium analyzer is checked and calibrated.

Owner:XIAN THERMAL POWER RES INST CO LTD

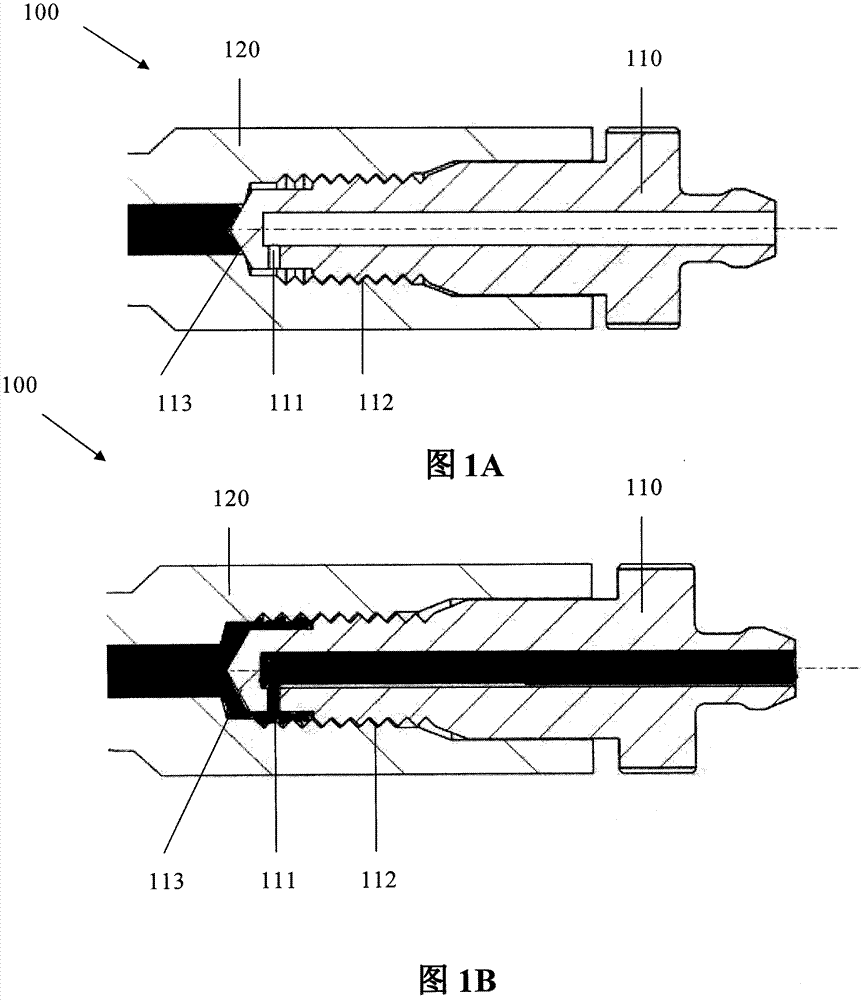

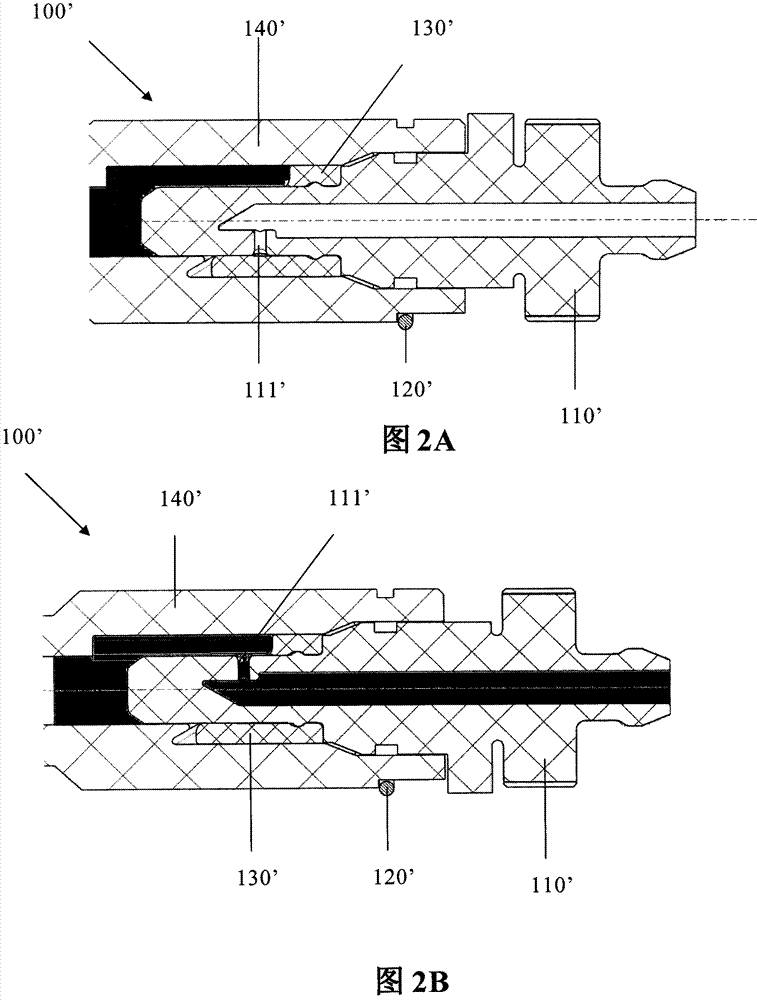

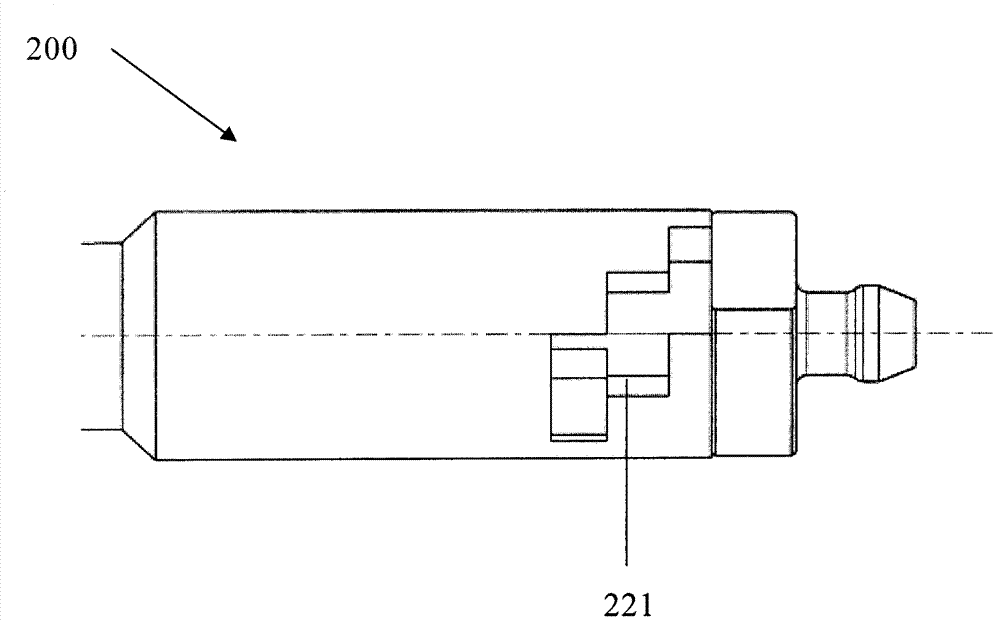

Gas discharging connector

InactiveCN102777510AHigh concentricityReduce tiltFluid actuated clutchesCouplingsEngineeringSeparation system

The invention provides a gas discharging connector (200; 300) for filling liquid and discharging gas in a hydraulic clutch separation system of a vehicle, which comprises a gas discharging valve body (210; 310) and a connector shell (220; 340). The gas discharging valve body (210; 310) is arranged in the connector shell (220; 340), can rotate and is provided with a main sealing component (230; 330). Moreover, the gas discharging valve body (210; 310) is internally provided with a hole (211; 311), the hole is sealed by the main sealing component (230; 330) and can be operated after being rotated for 180 degrees so as to discharge air or liquid in the system as needed. The gas discharging connector (200; 300) is also provided with an auxiliary sealing component (240; 350), the auxiliary sealing component is arranged on the gas discharging valve body (210; 310) and on the hole along the discharging direction to reduce the inclination of the gas discharging valve body relative to the connector shell so as to reduce the risk of leakage between the gas discharging valve body and the connector shell.

Owner:SCHAEFFLER TECH AG & CO KG

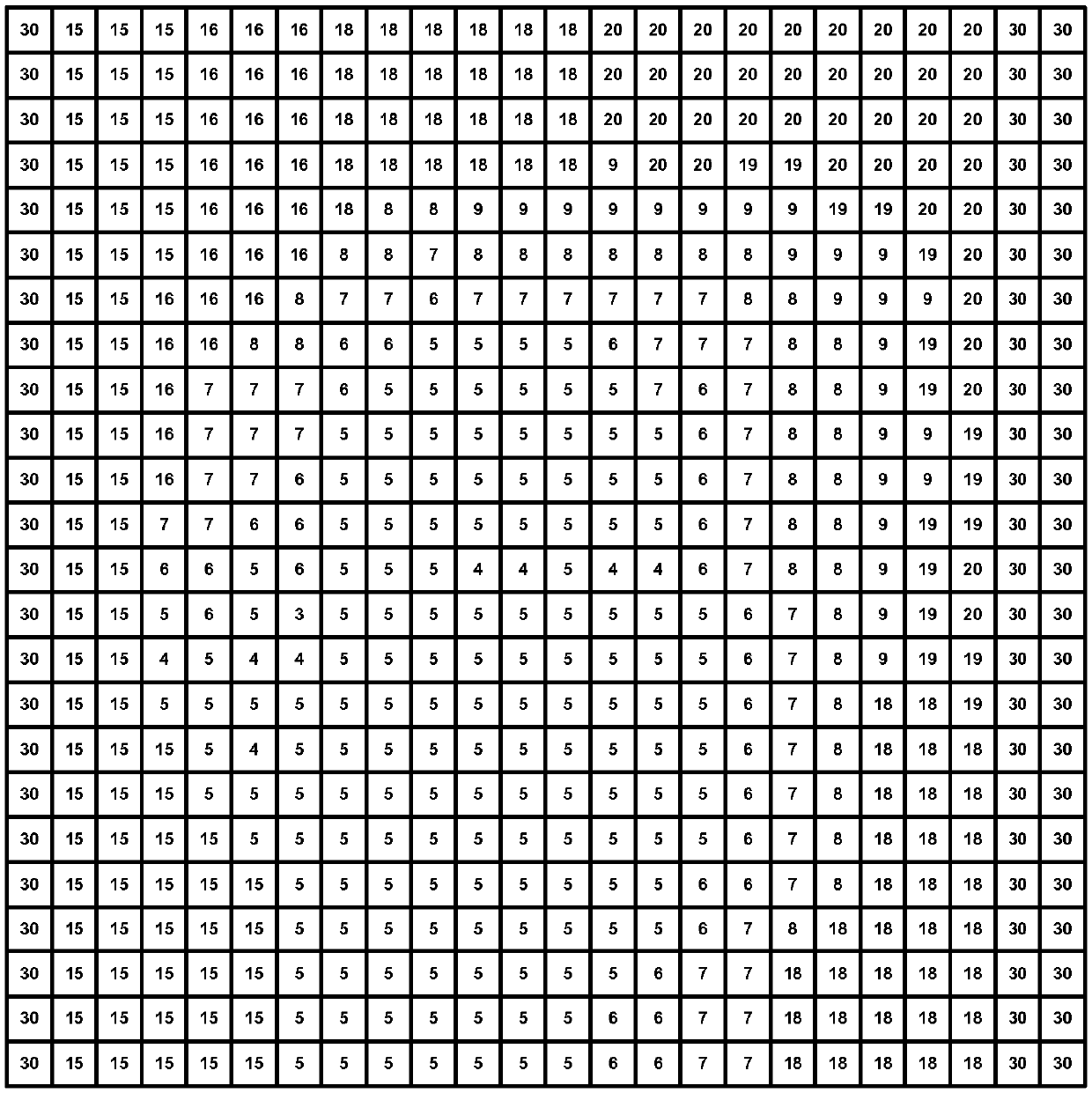

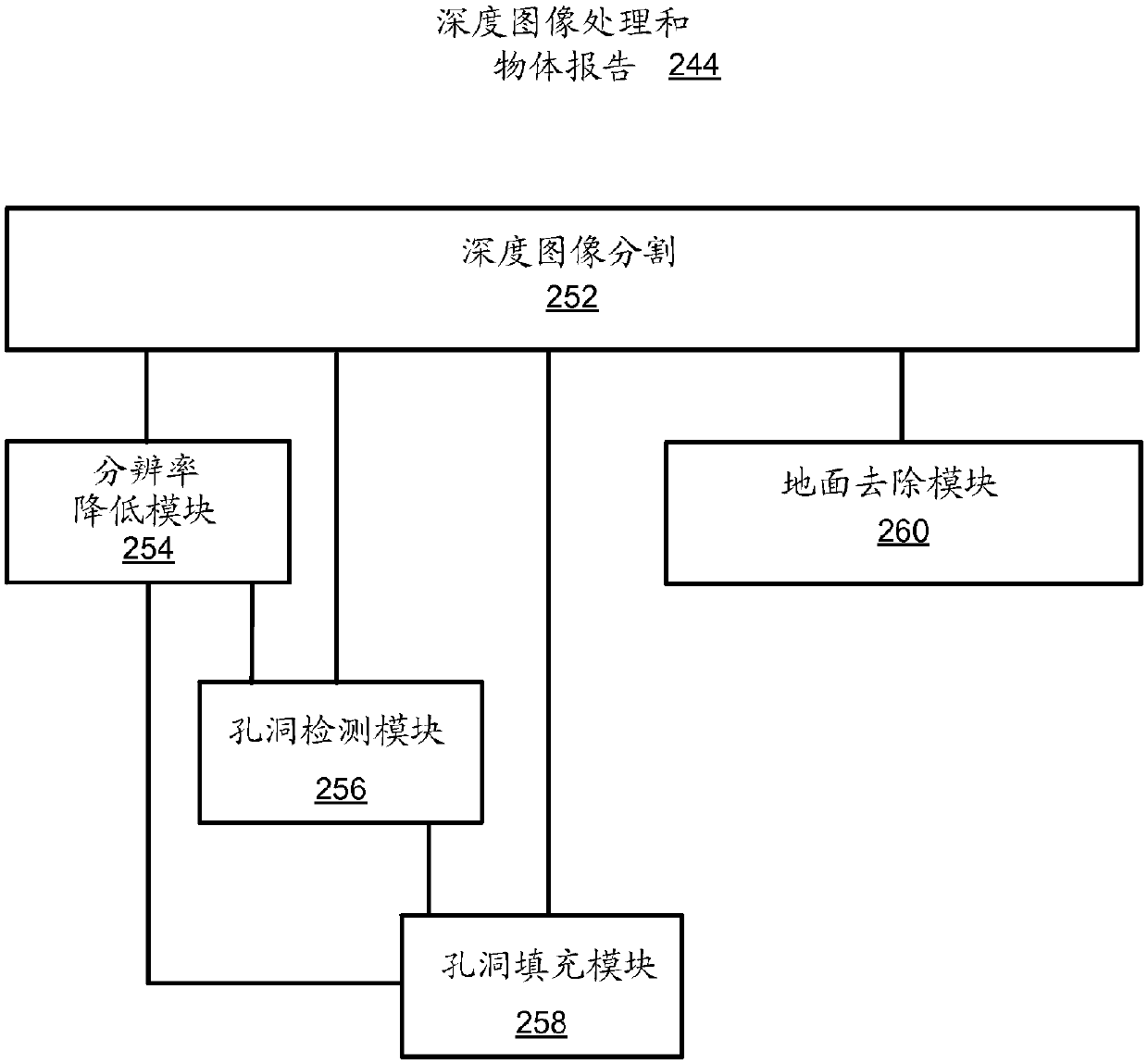

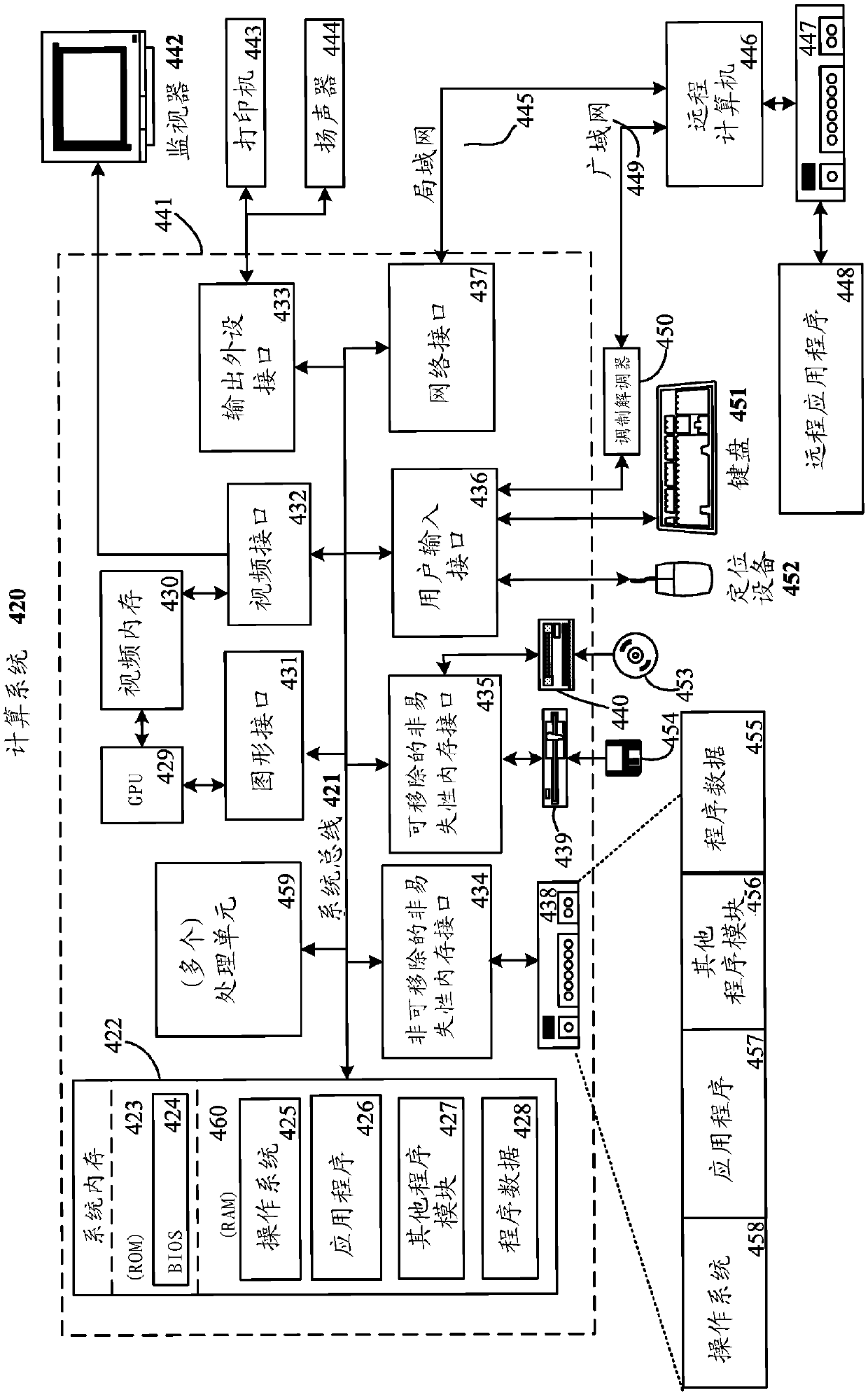

Depth image processing

ActiveCN105518743AReduce sensitivityReduce slopeImage enhancementImage analysisImaging processingImage resolution

Embodiments described herein can be used to detect holes in a subset of pixels of a depth image that has been specified as corresponding to a user, and to fill such detected holes. Additionally, embodiments described herein can be used to produce a low resolution version of a subset of pixels that has been specified as corresponding to a user, so that when an image including a representation of the user is displayed, the image respects the shape of the user, yet is not a mirror image of the user. Further, embodiments described herein can be used to identify pixels, of a subset of pixels specified as corresponding to the user, that likely correspond to a floor supporting the user. This enables the removal of the pixels, identified as likely corresponding to the floor, from the subset of pixels specified as corresponding to the user.

Owner:MICROSOFT TECH LICENSING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com