Water collecting device for nuclear power plants and high tower with same

A water collection device and nuclear power plant technology, applied in the field of high-level towers, can solve problems such as high head of circulating water pumps, loud noise in rainy areas, and deterioration of cavitation conditions, and achieve the goals of saving installation engineering, reducing pump head, and reducing noise levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

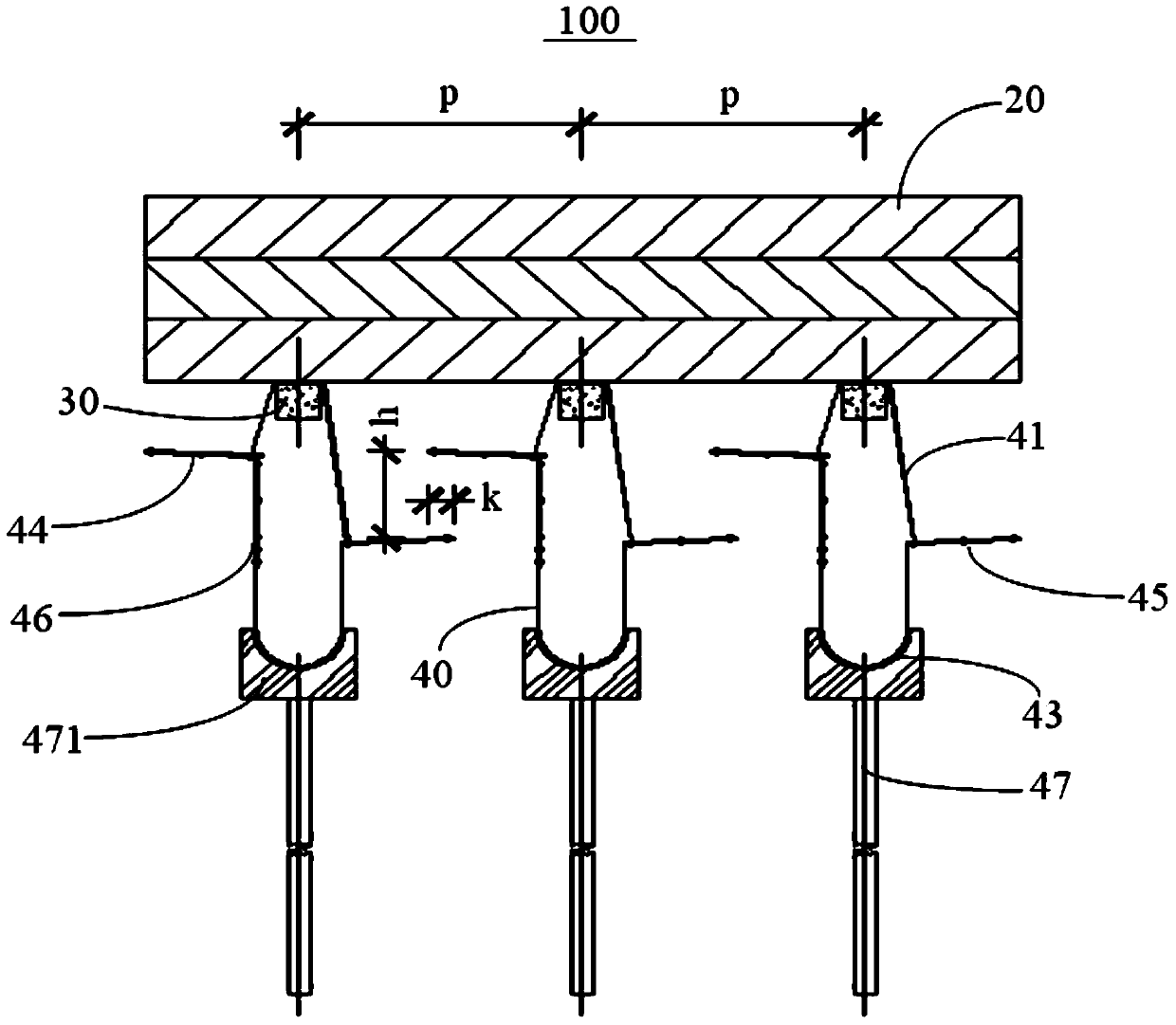

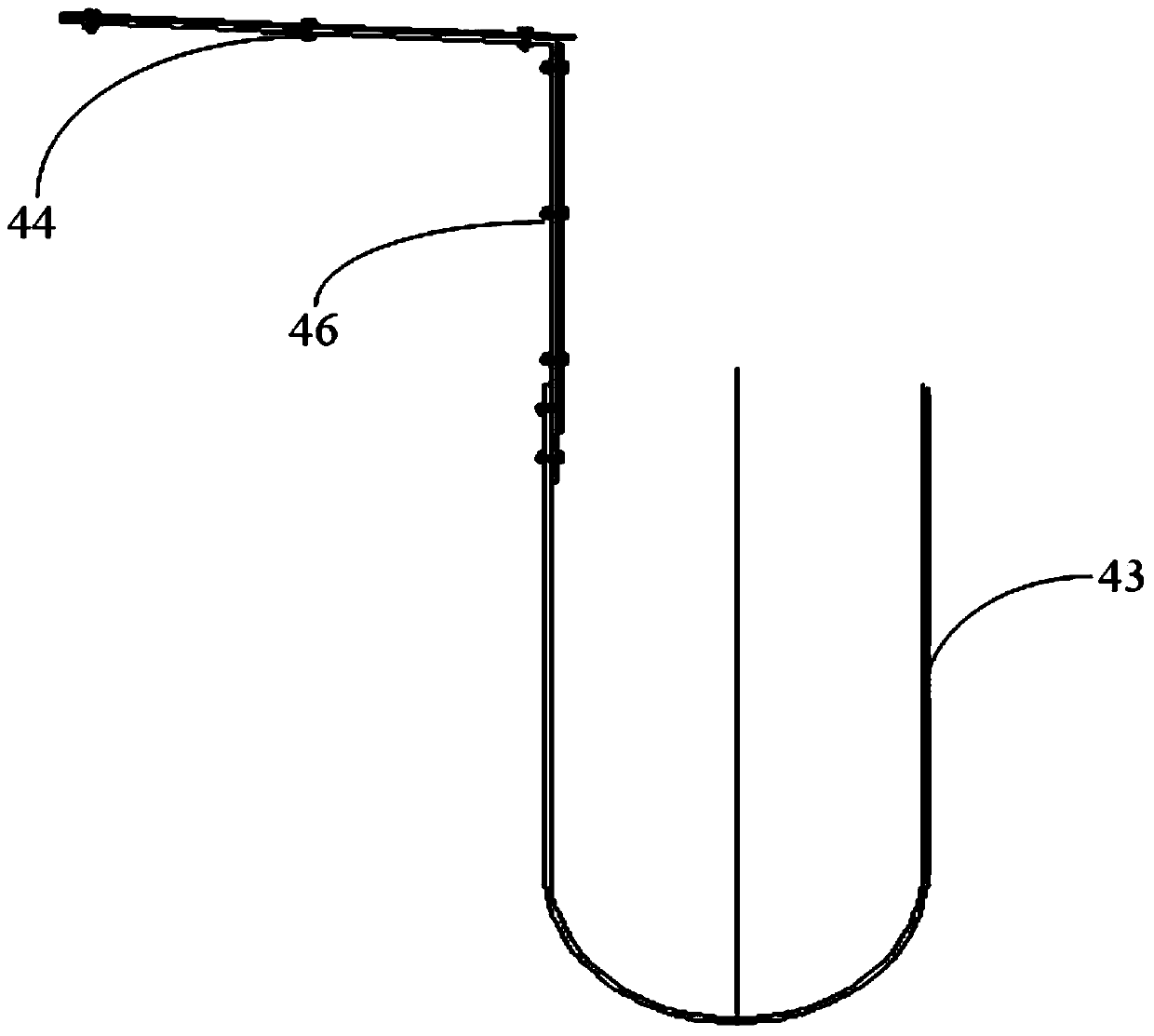

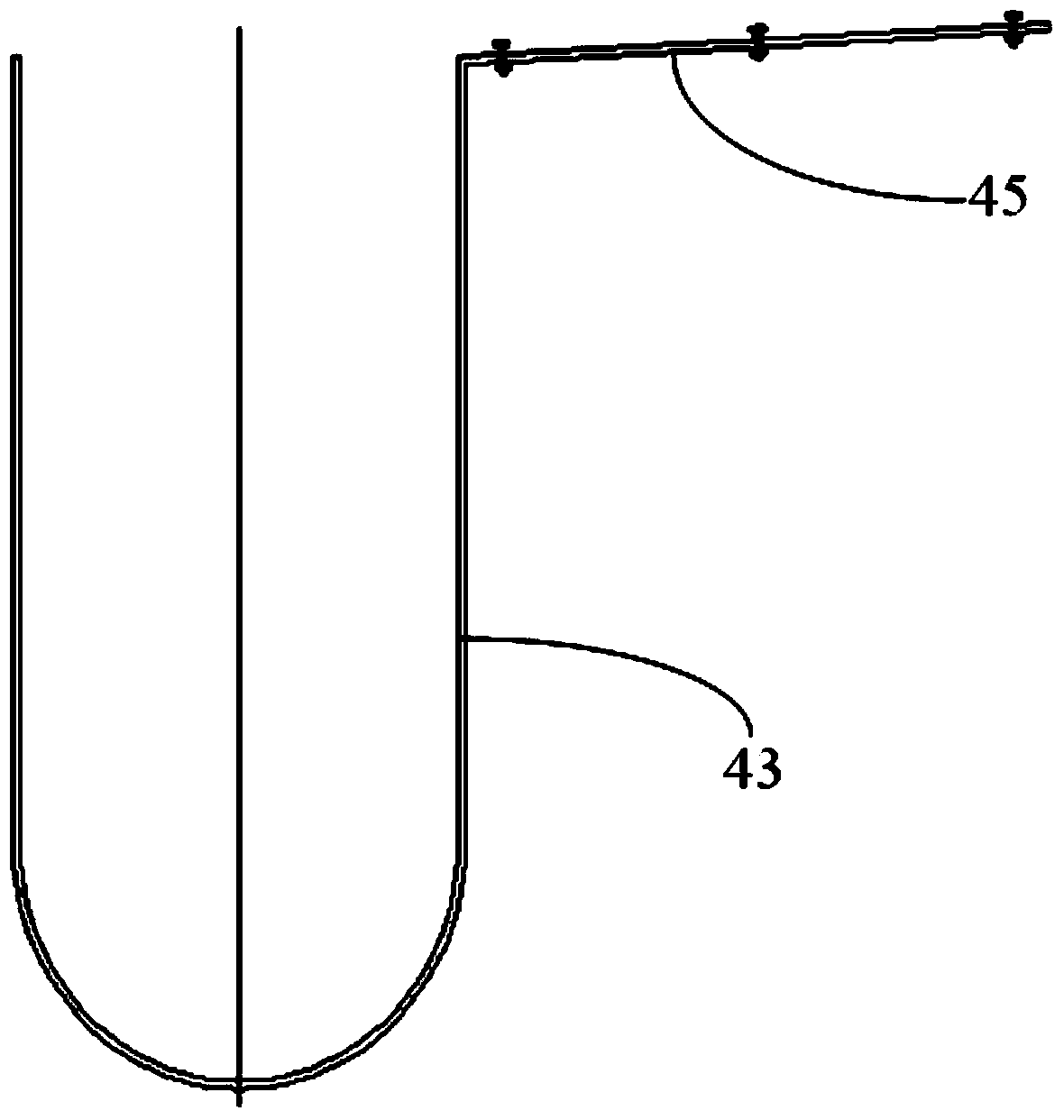

[0054] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0055] Before carrying out the description of the present invention, first explain the theoretical basis of the present invention, and the present invention comes from the inspiration of the arrangement of leaves. In order to obtain sufficient photosynthesis and respiration, the leaves need to fully stretch the leaf surface itself, so that the leaves can maintain the maximum light-receiving surface. In order to satisfy the same photosynthesis and respiration for different phyllotaxy leaves, the most common and effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com