Patents

Literature

212 results about "Air Travels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

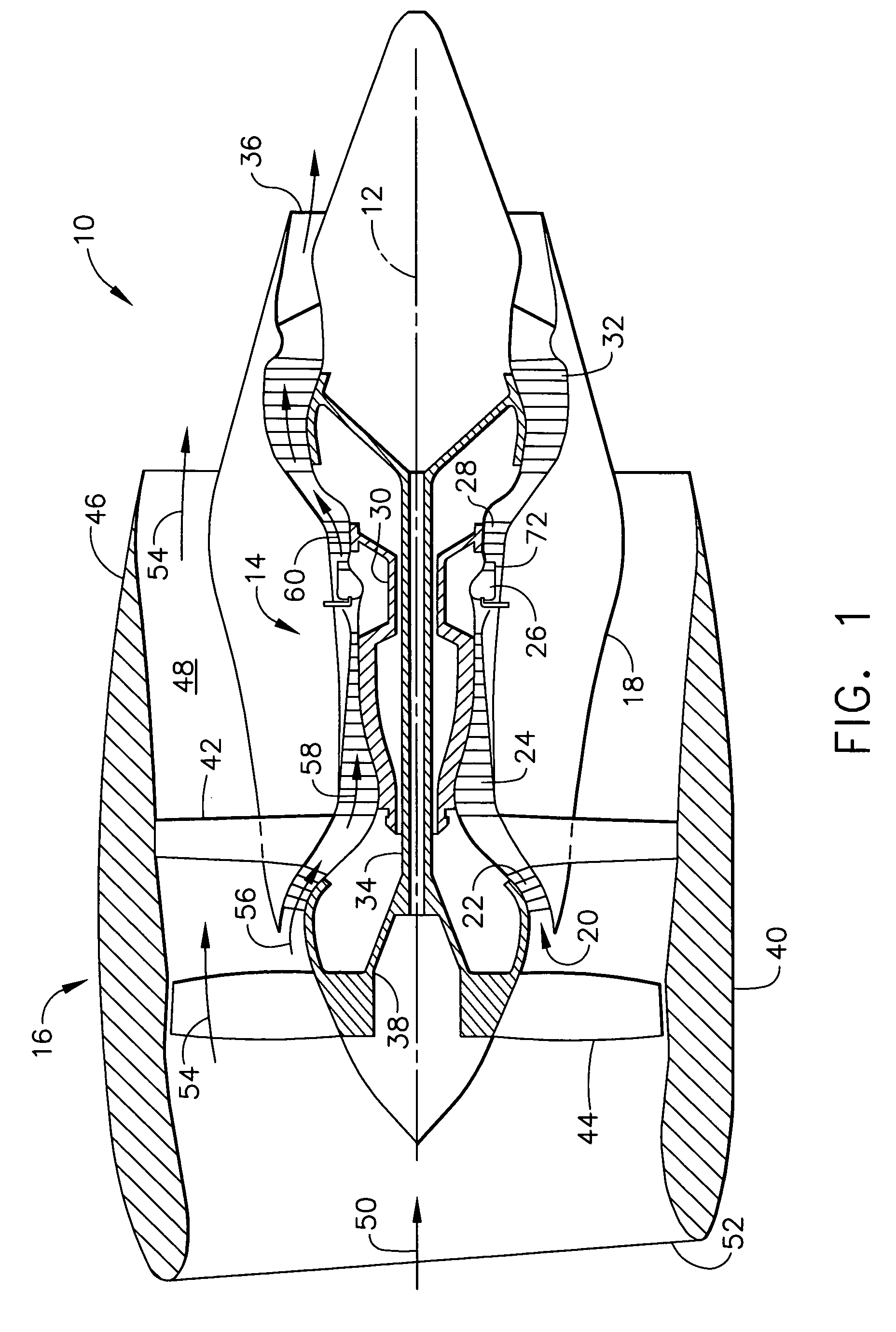

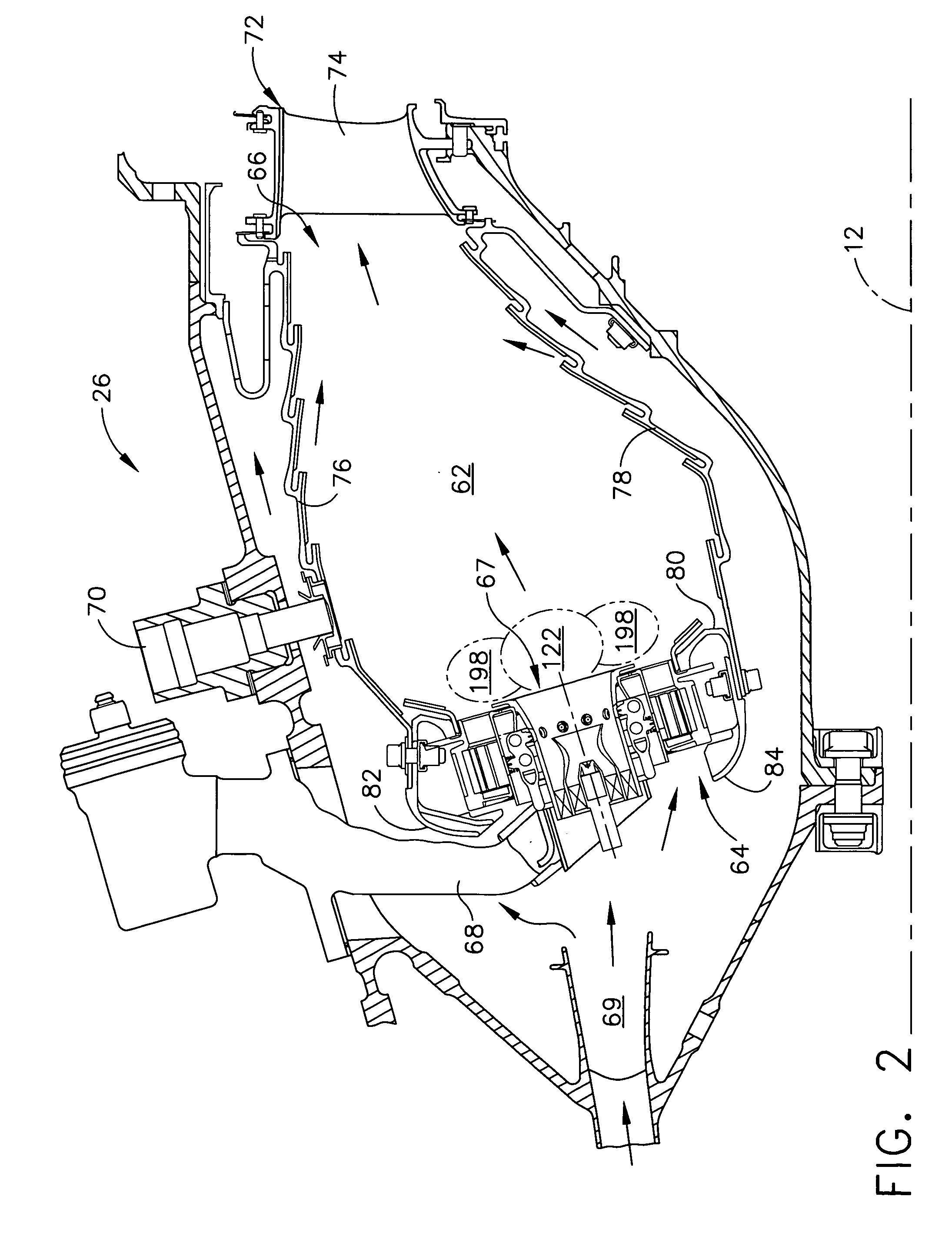

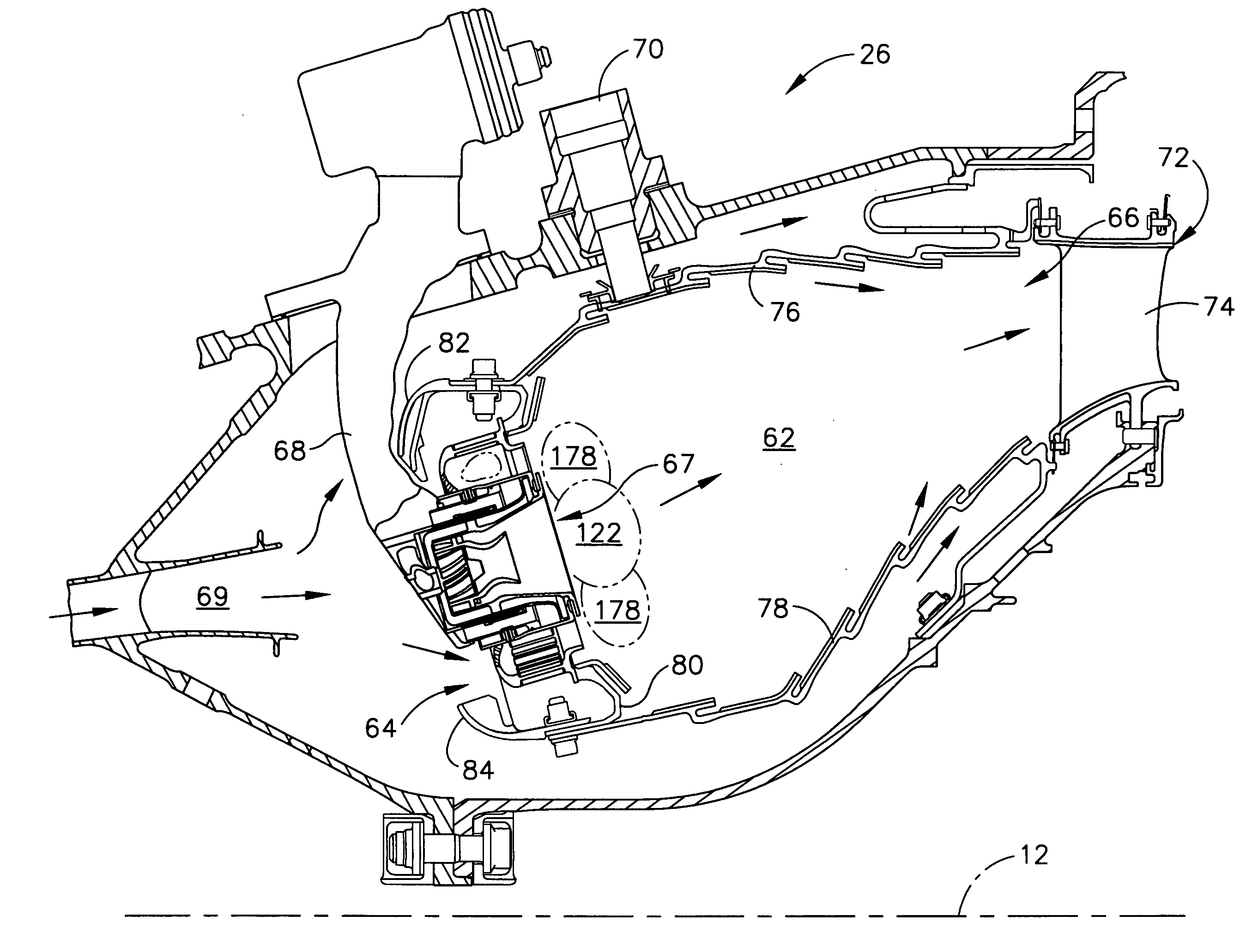

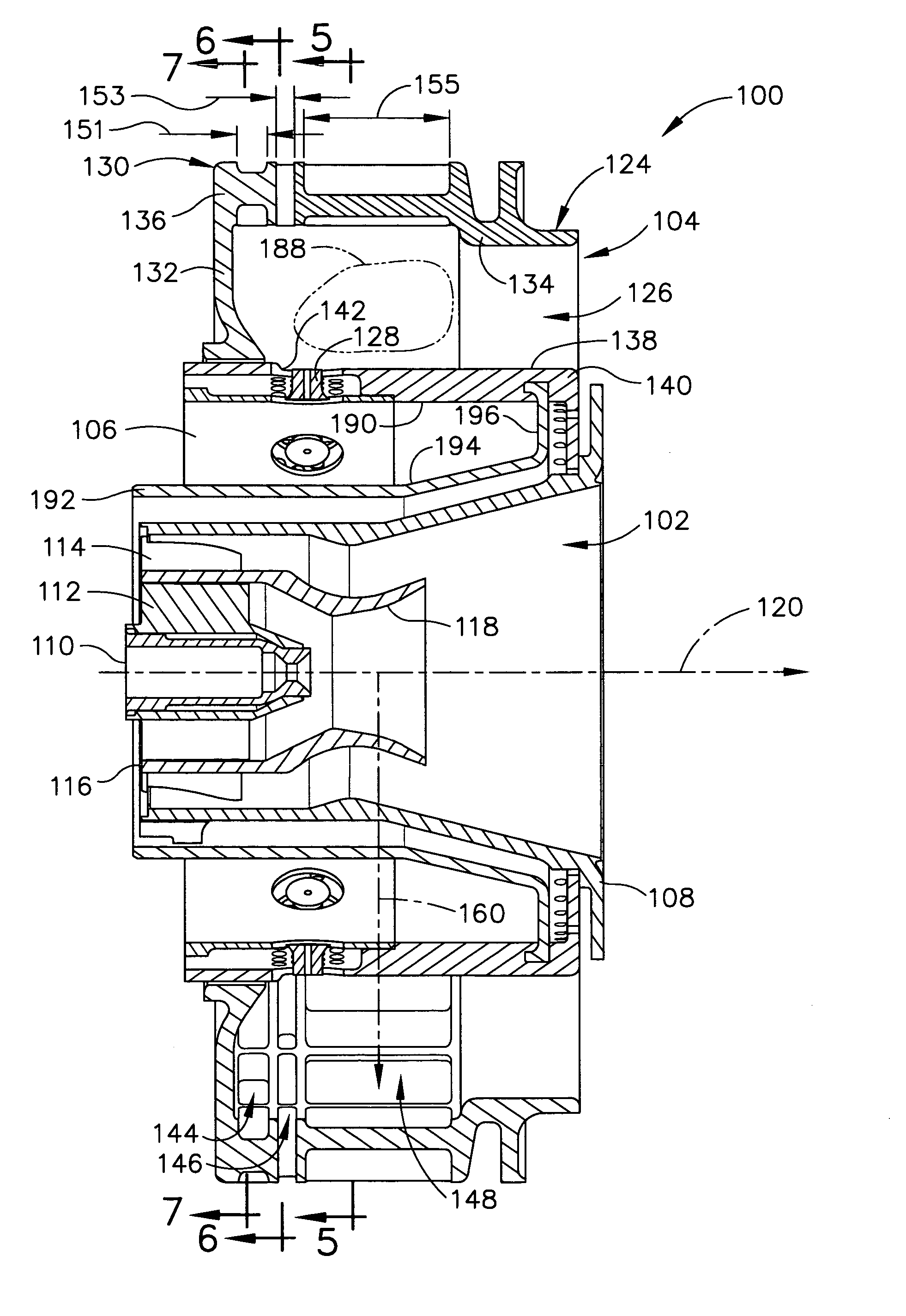

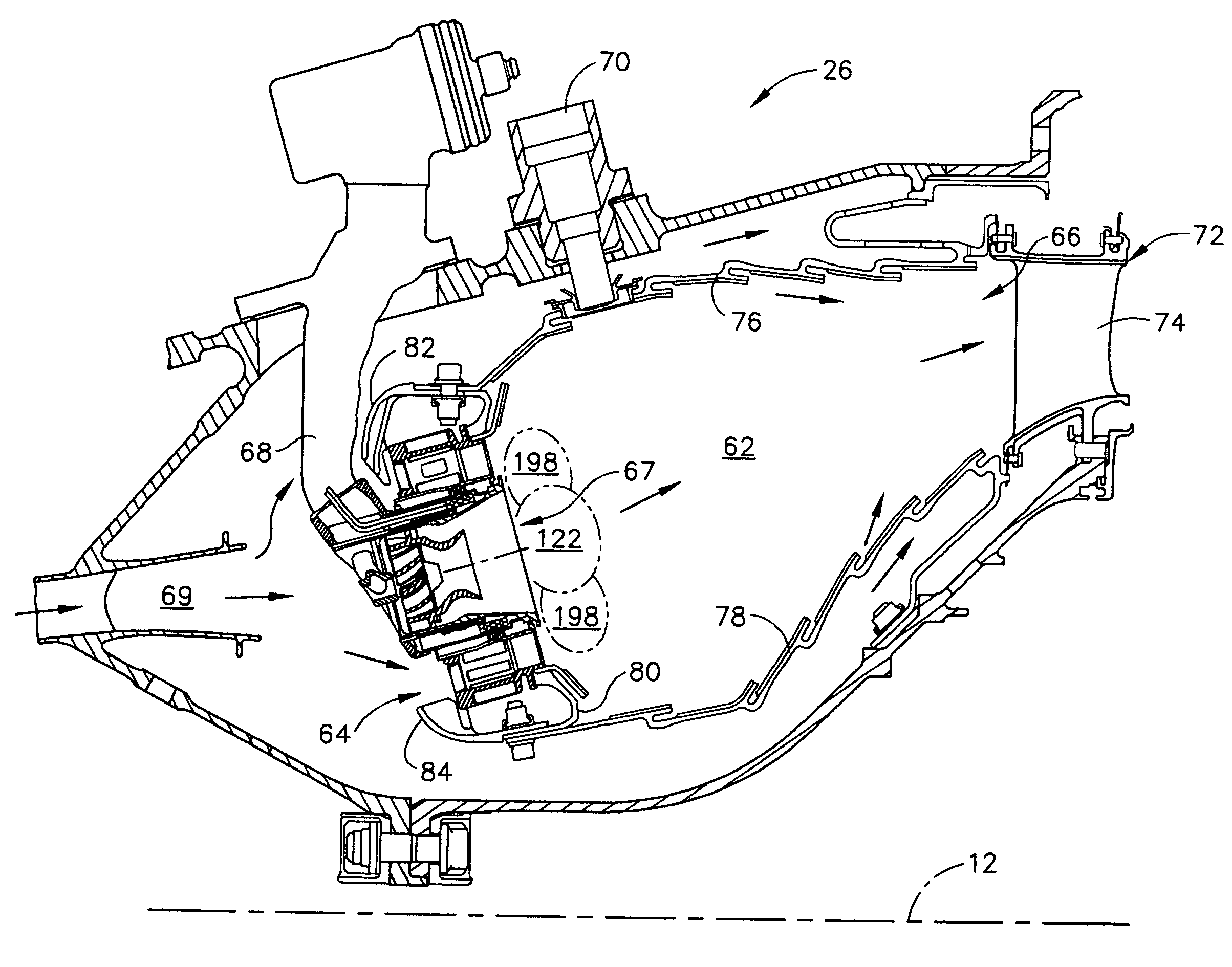

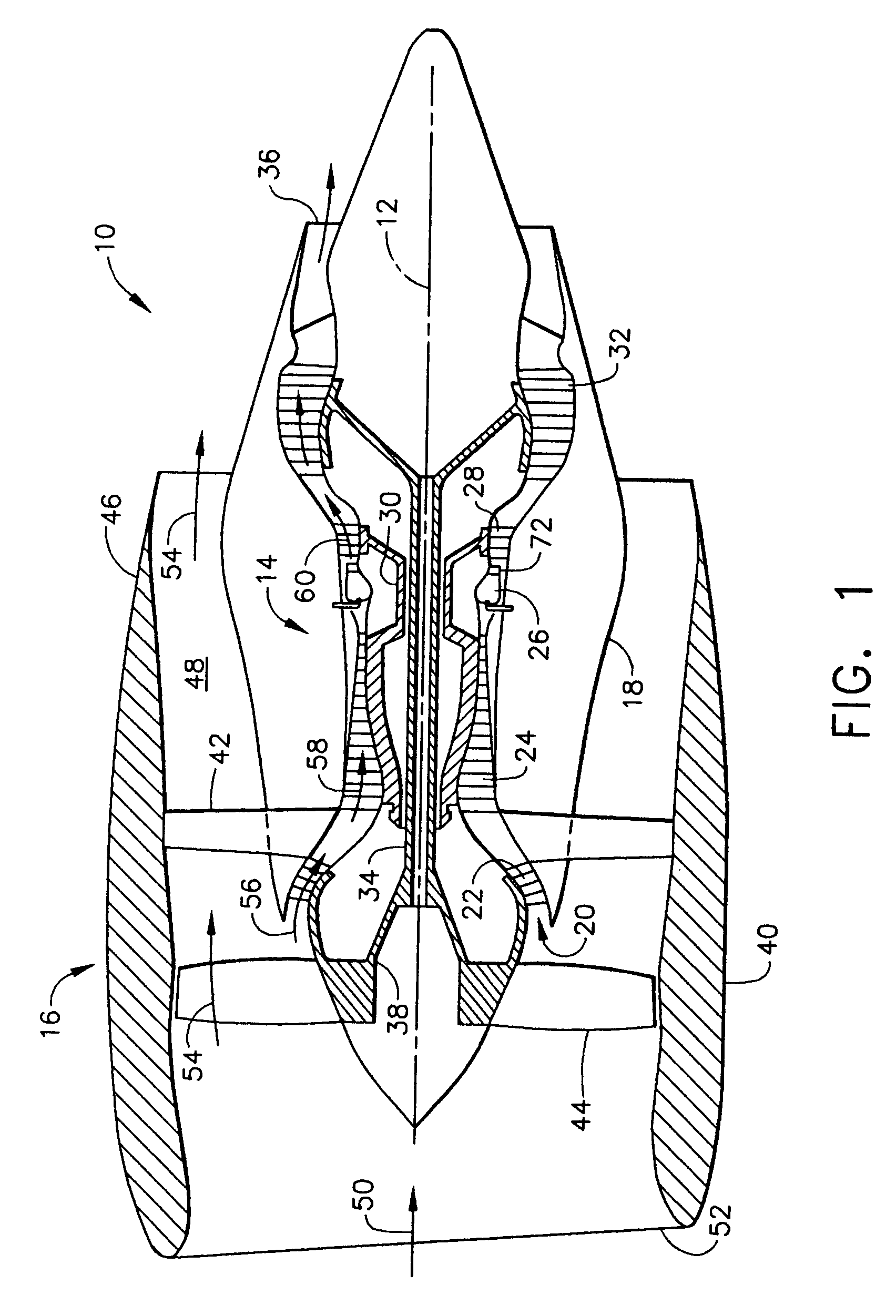

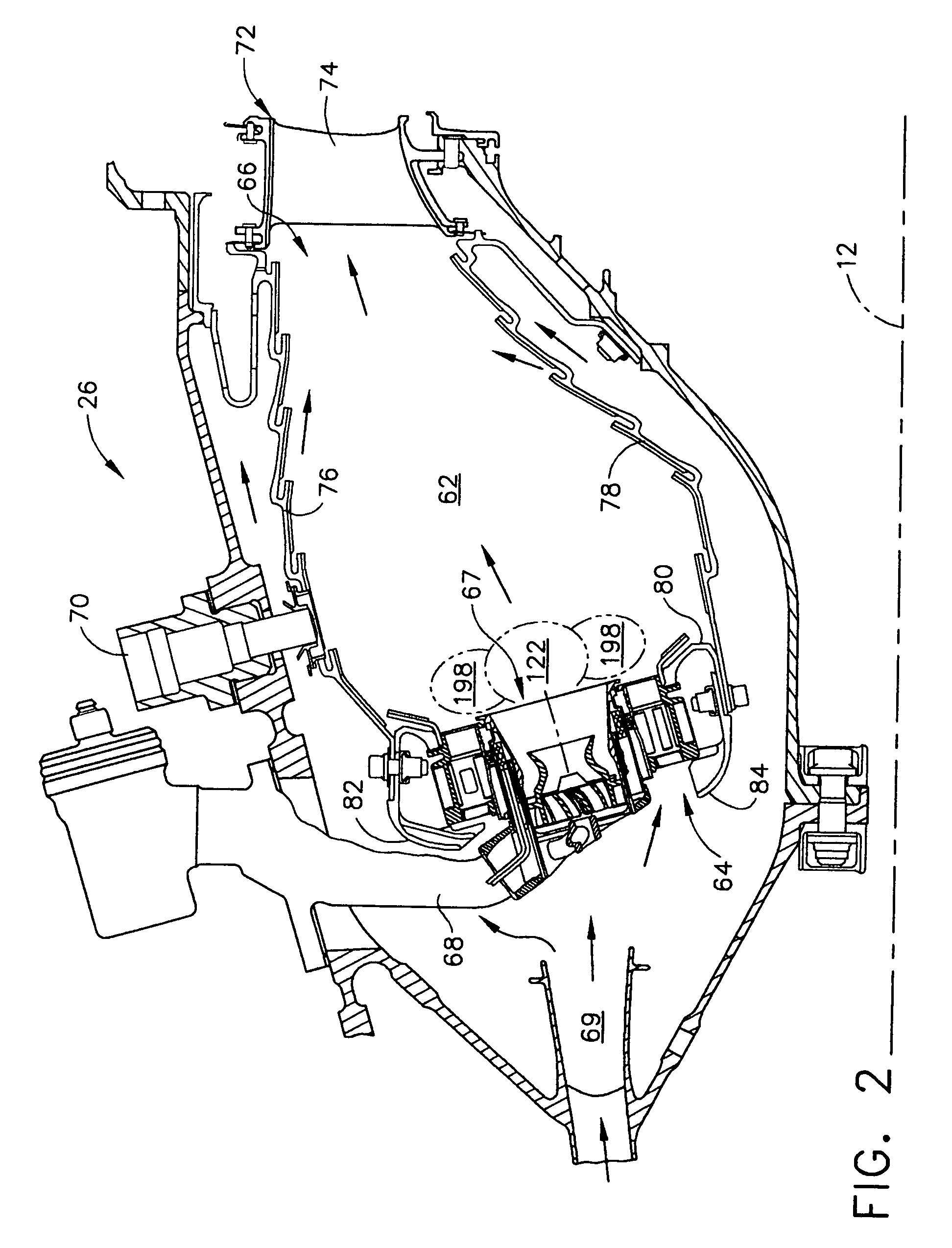

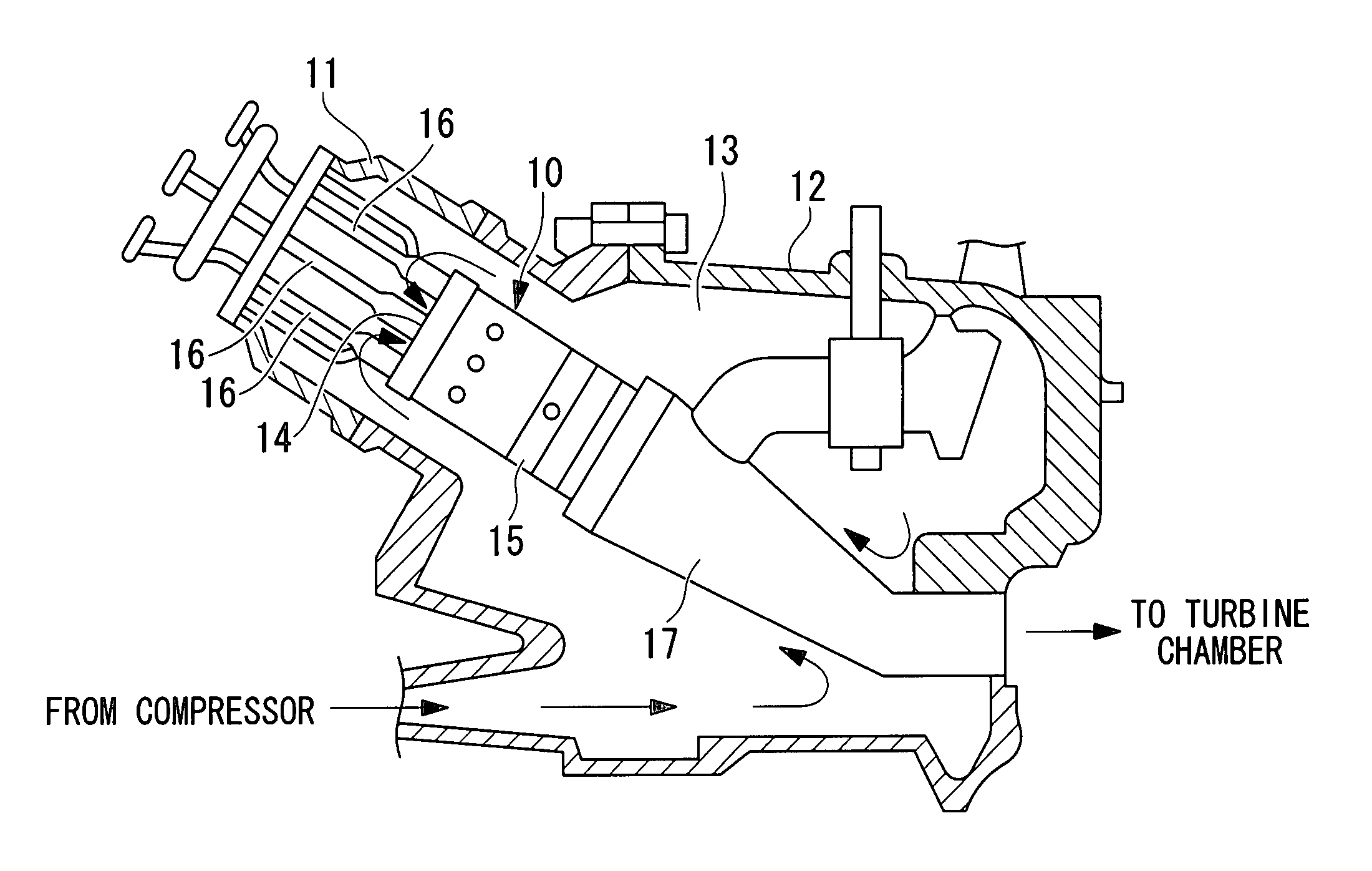

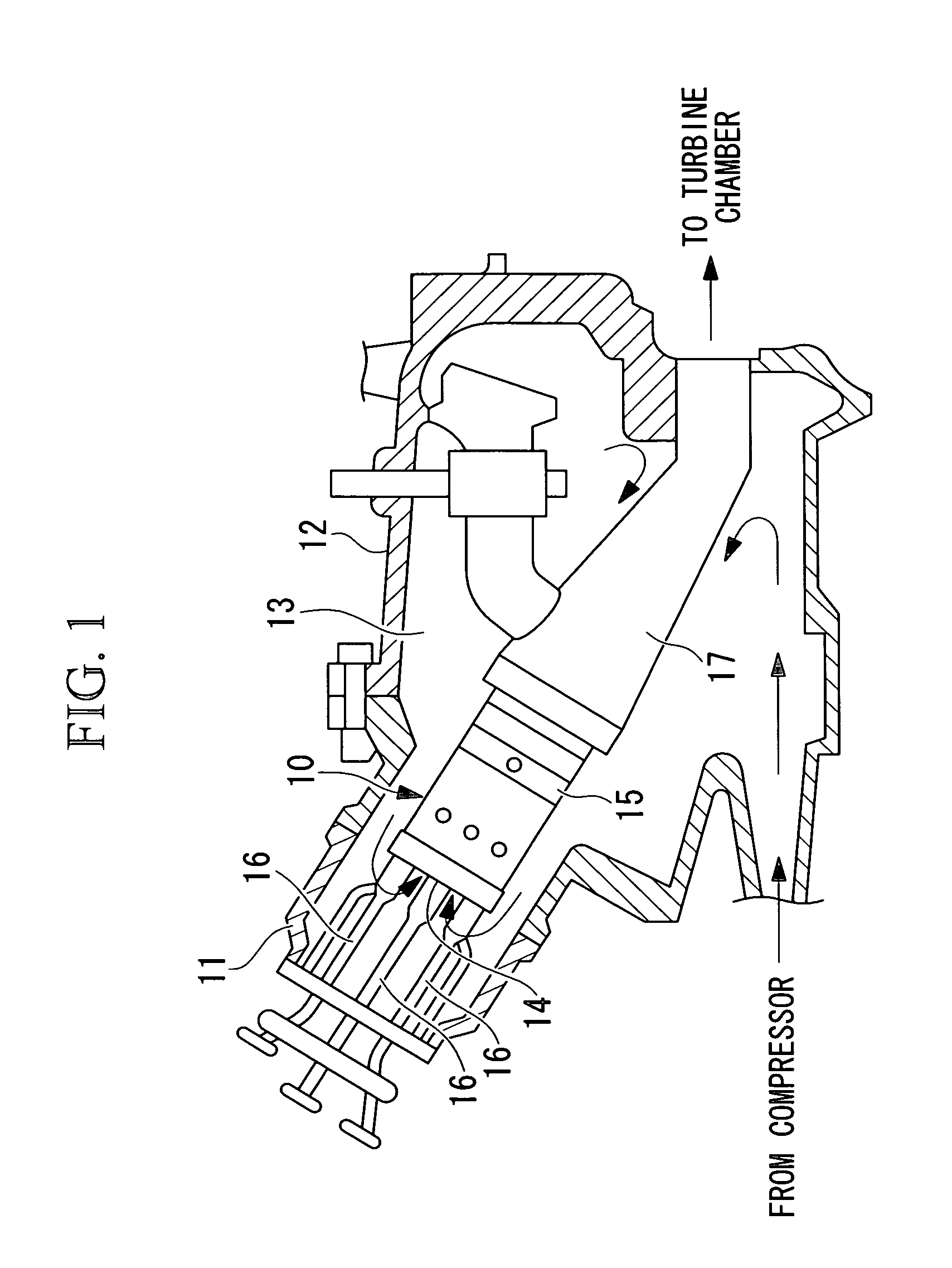

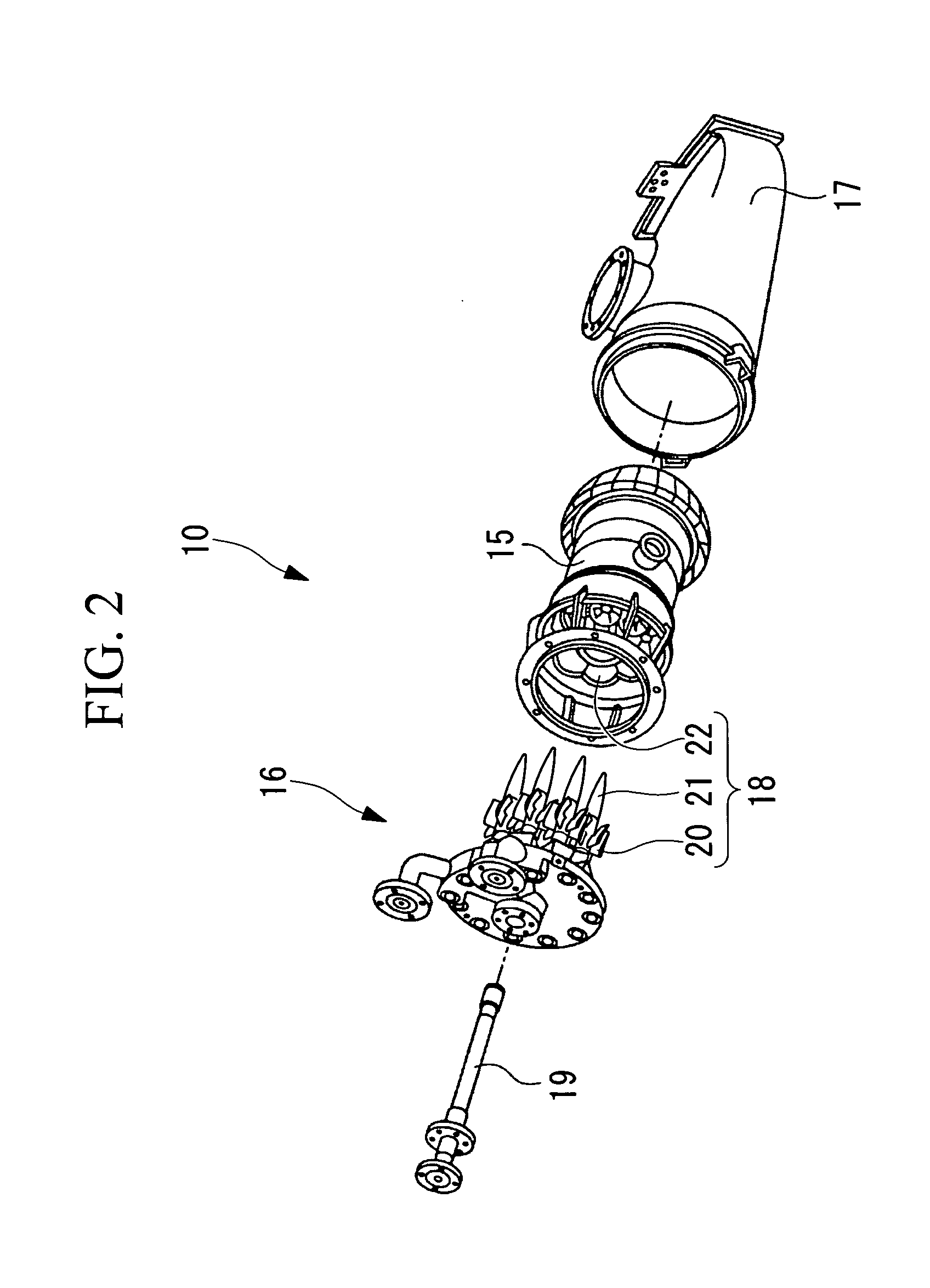

Pilot mixer for mixer assembly of a gas turbine engine combustor having a primary fuel injector and a plurality of secondary fuel injection ports

ActiveUS20090113893A1Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCombustion chamber

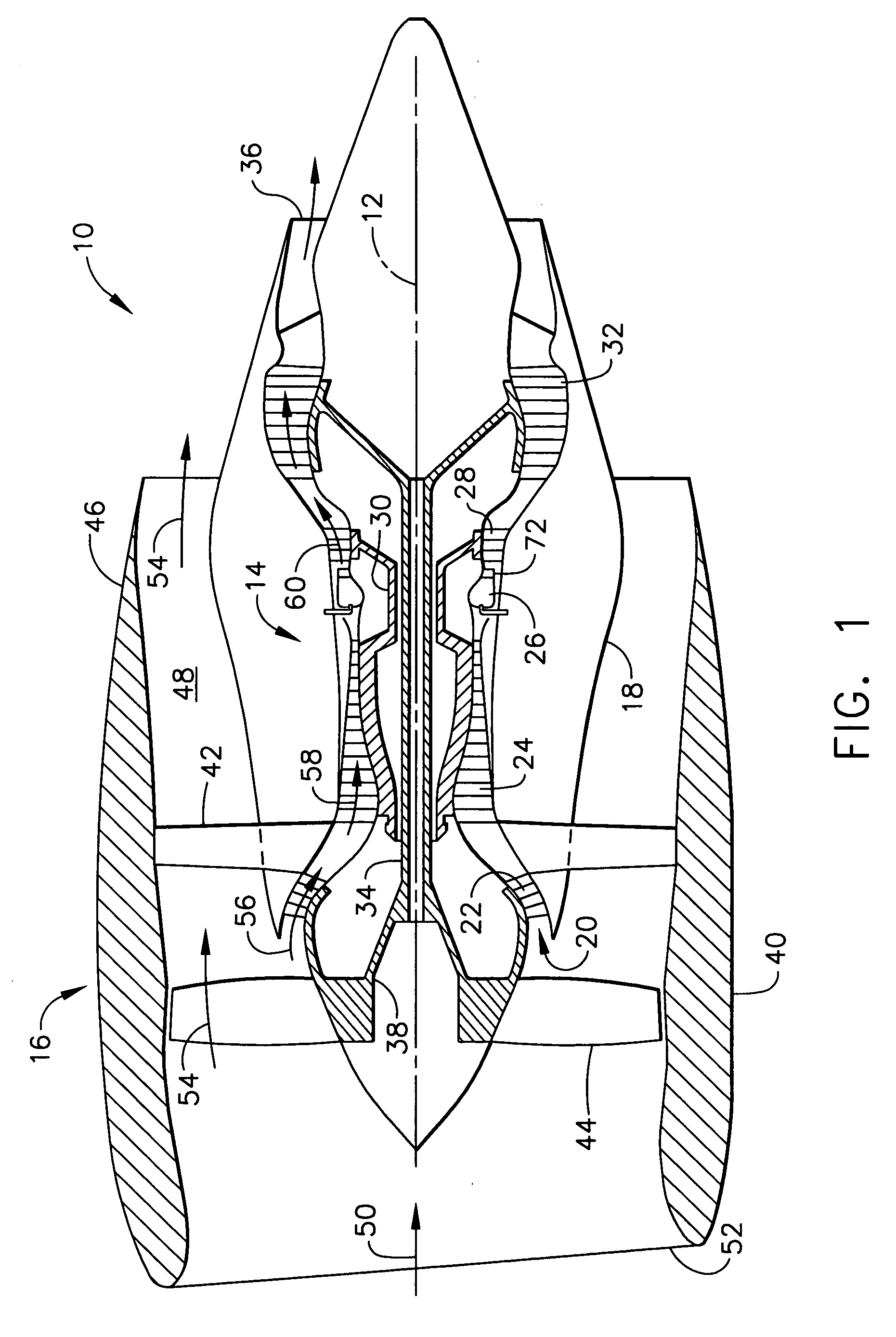

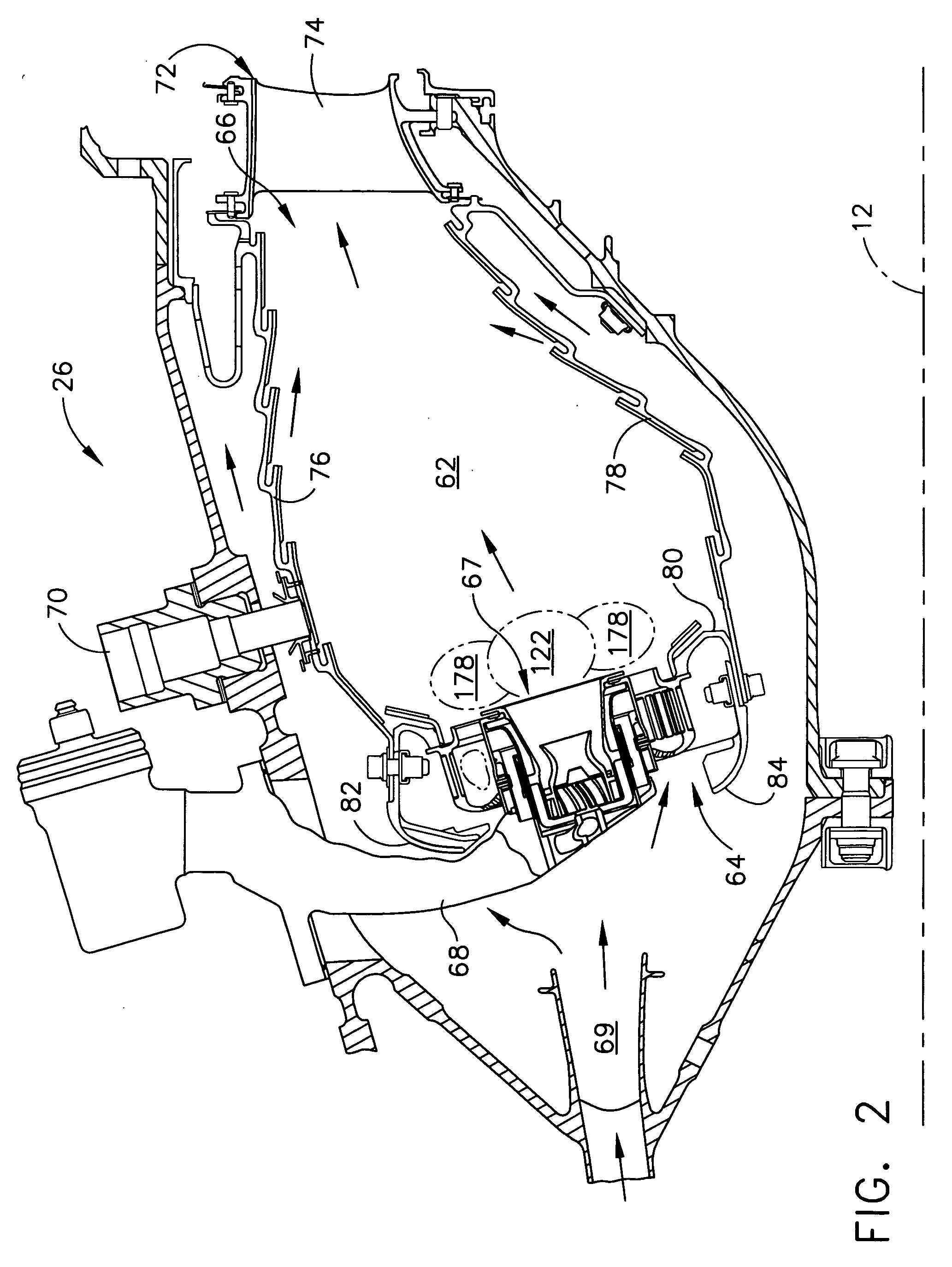

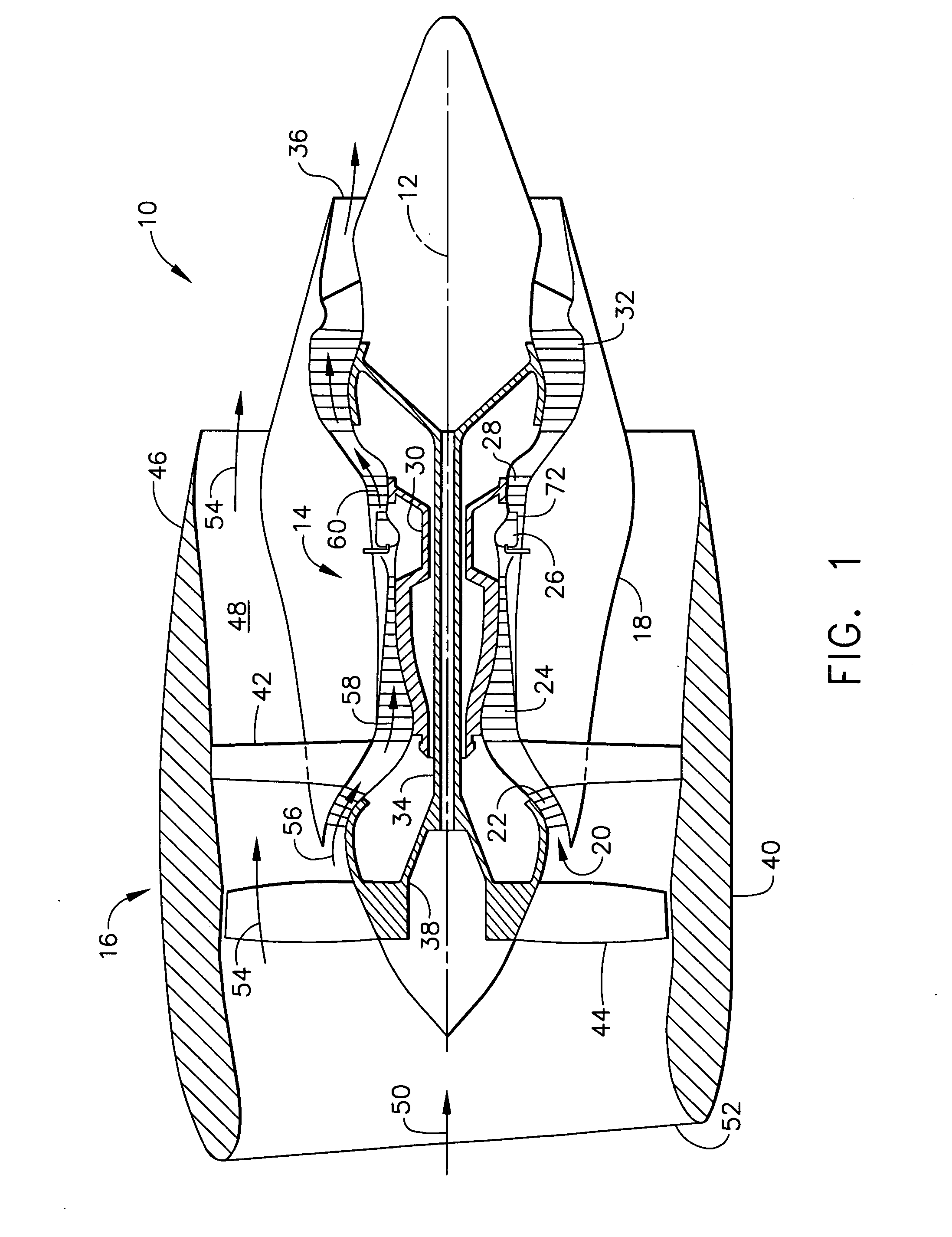

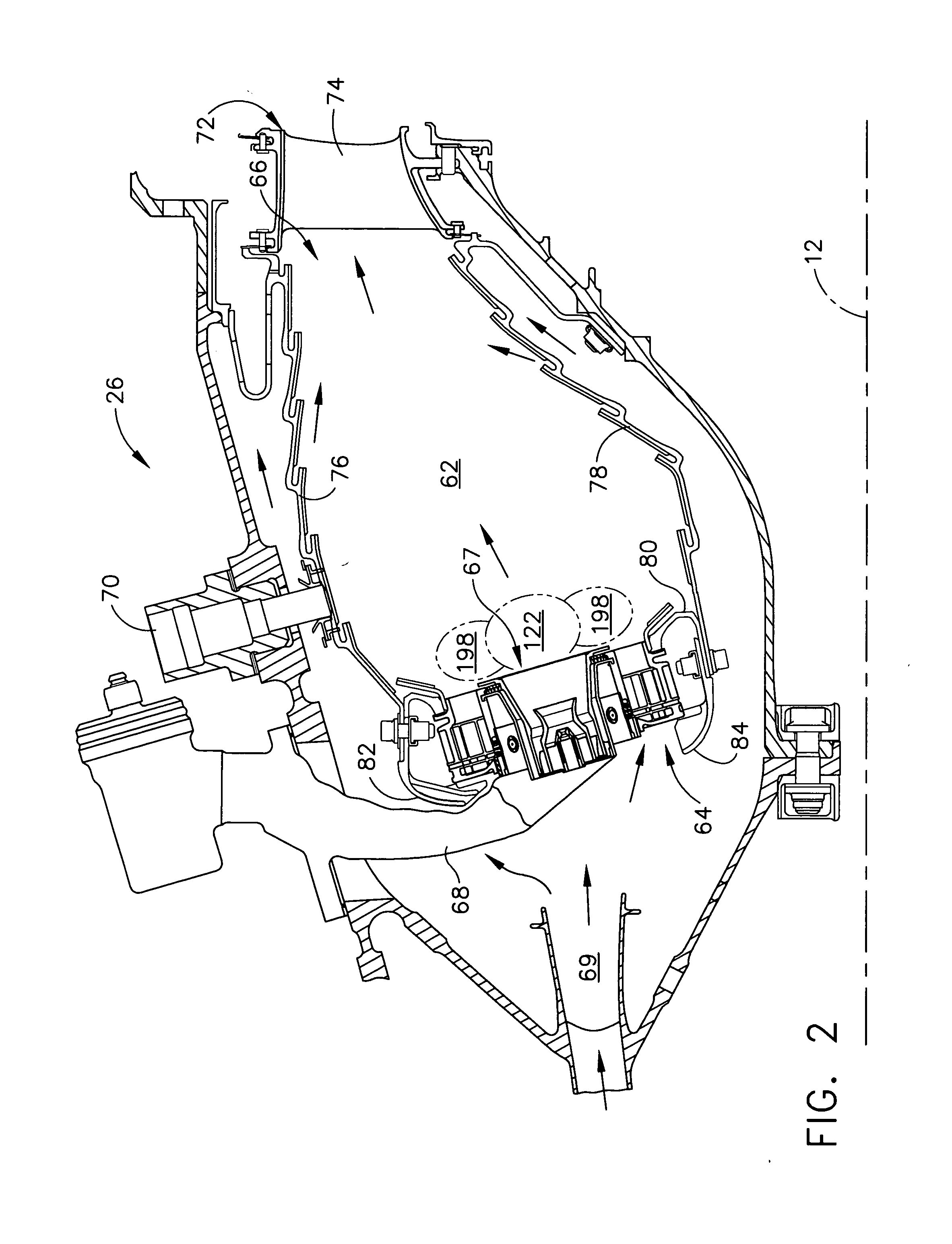

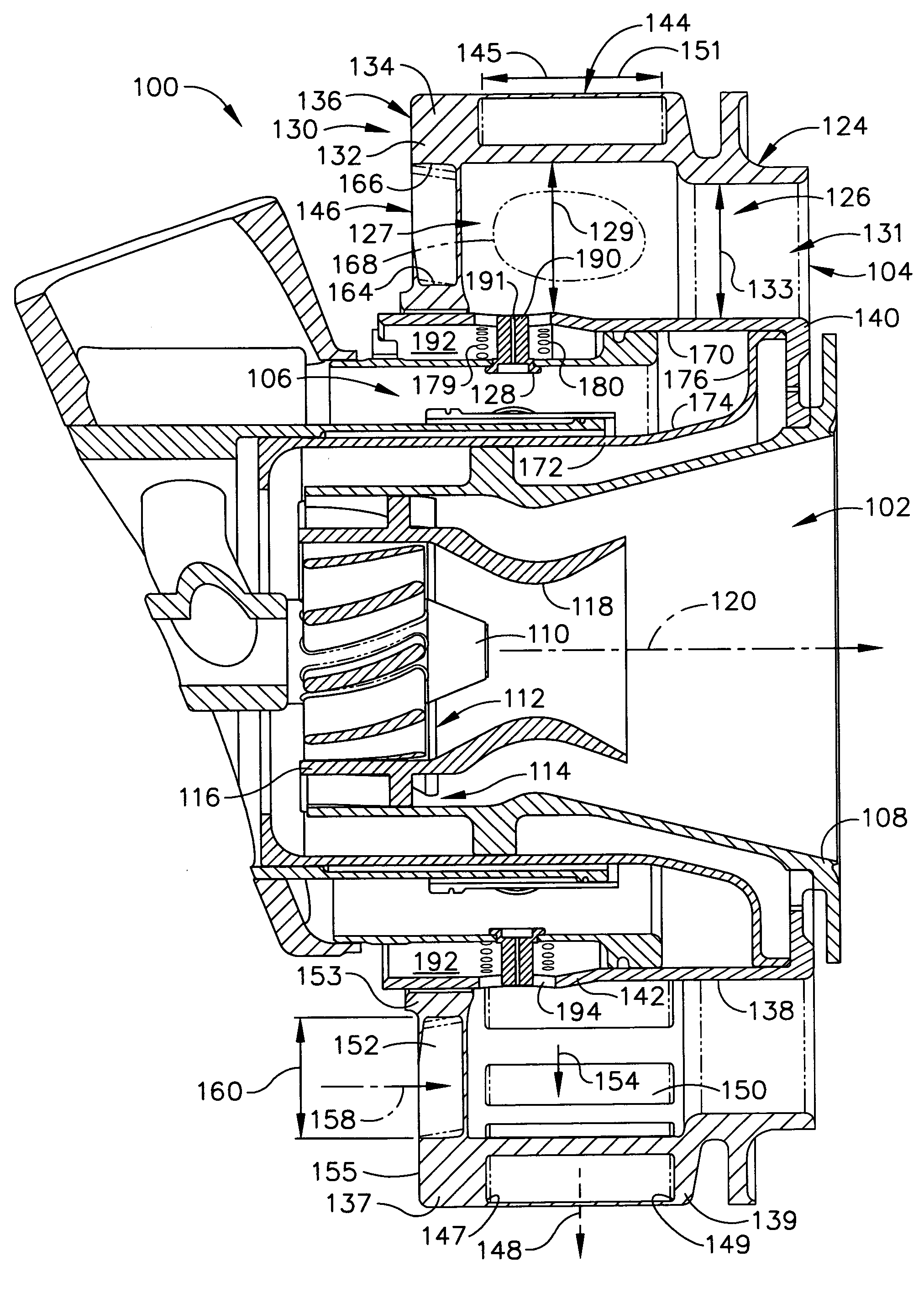

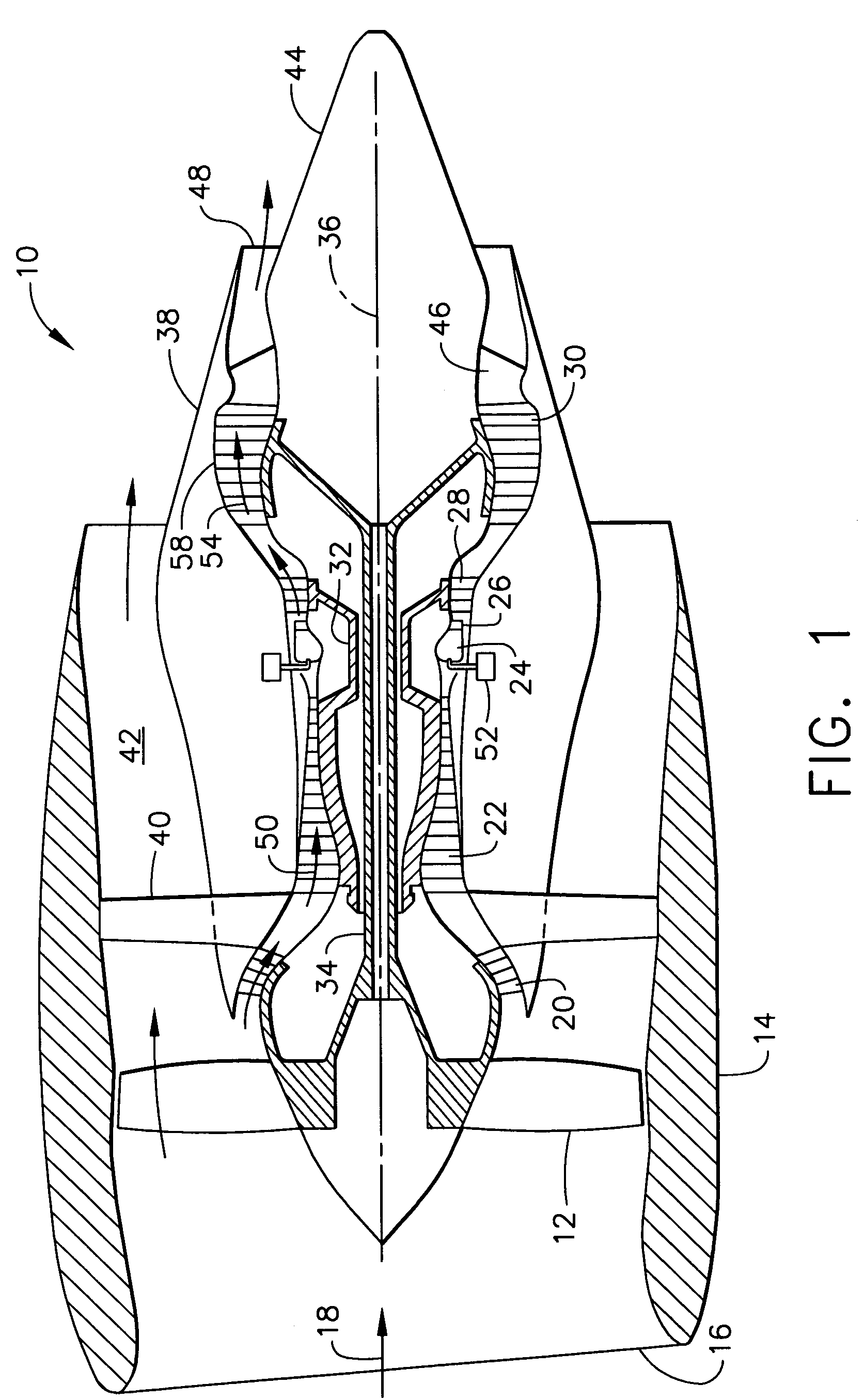

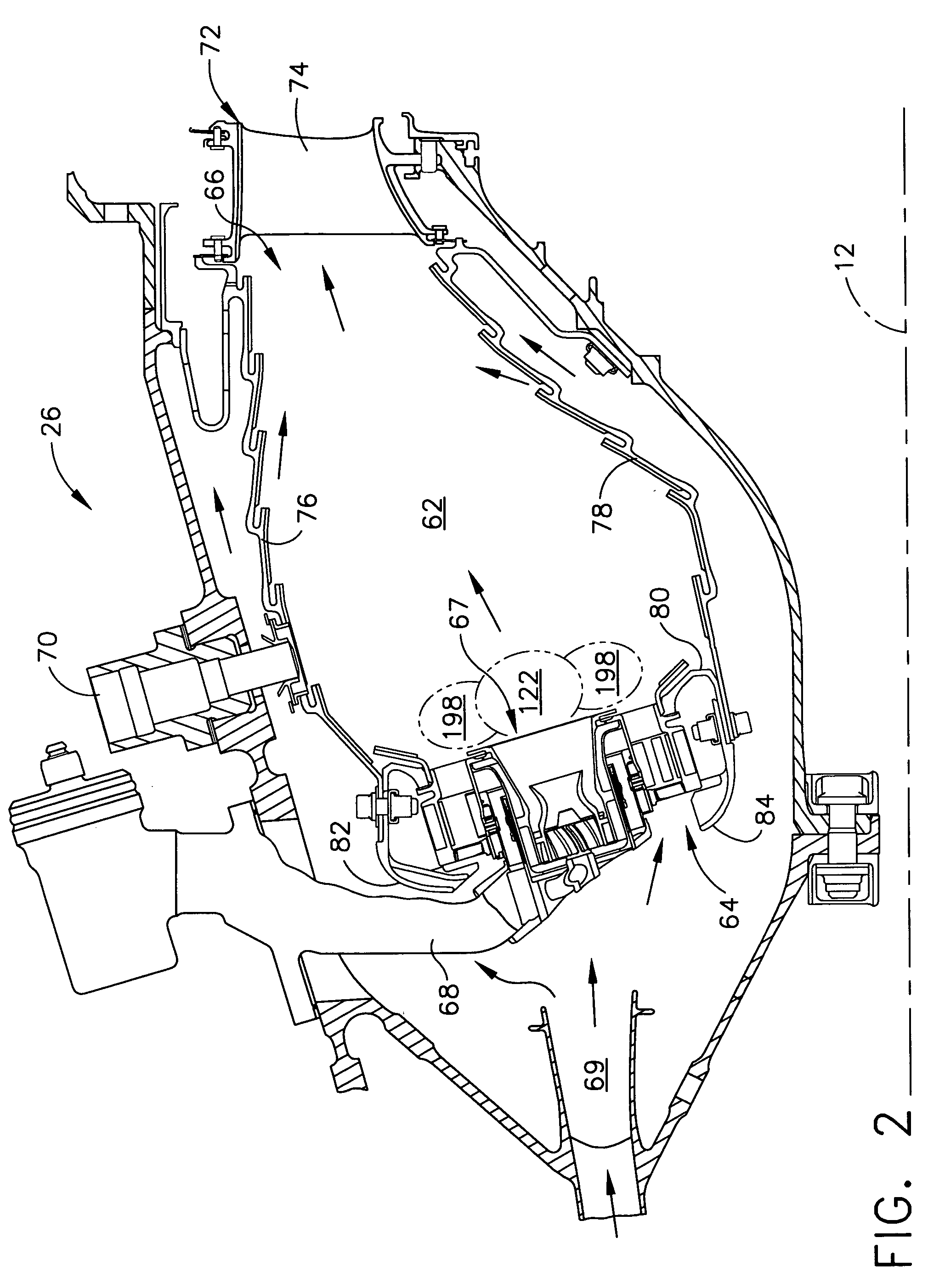

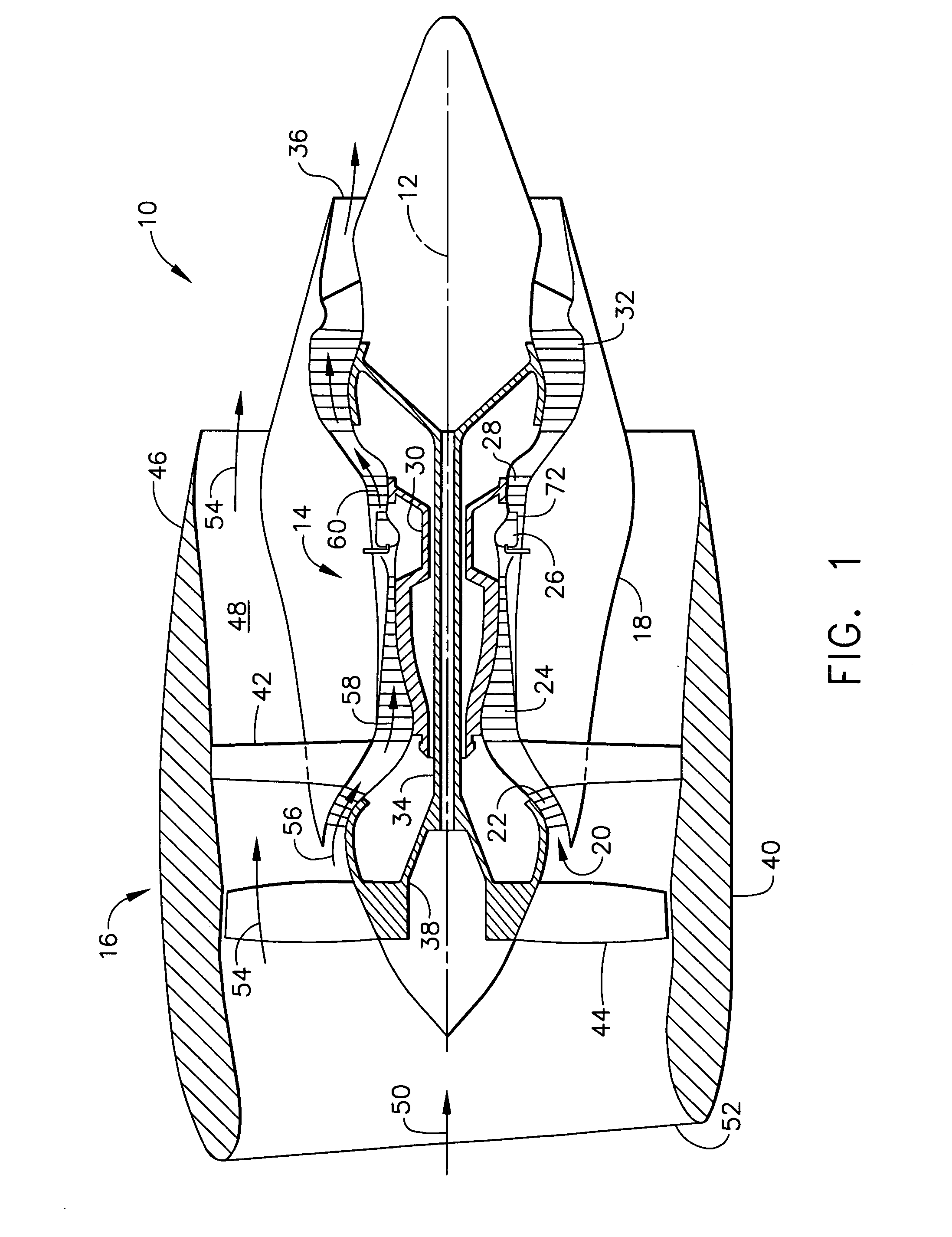

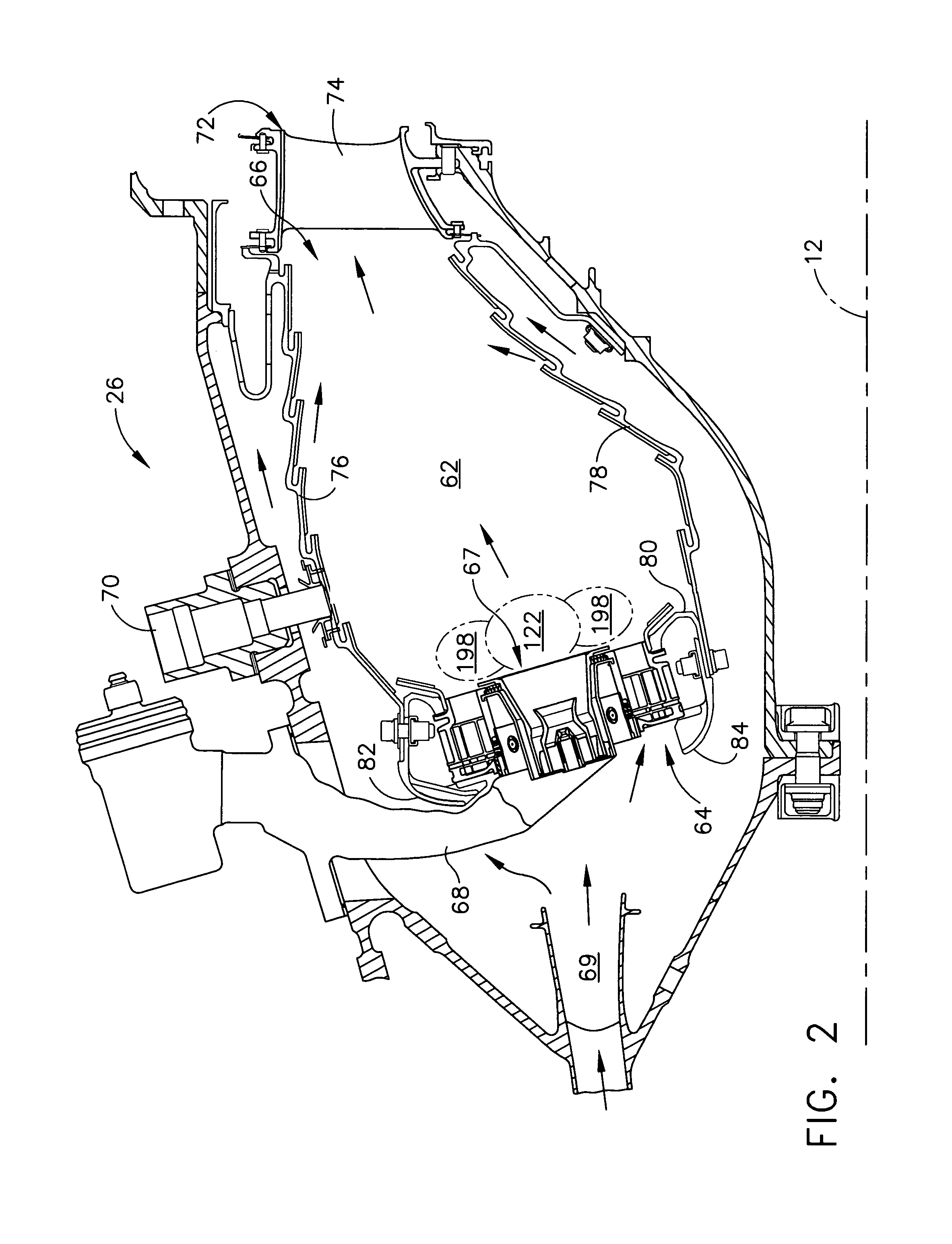

A mixer assembly for use in a combustion chamber of a gas turbine engine including a pilot mixer, a main mixer, and a fuel manifold. The pilot mixer includes: an annular pilot housing having a hollow interior; a primary fuel injector mounted in the pilot housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing; a plurality of axial swirlers positioned upstream from the primary fuel injector, each of the plurality of swirlers having a plurality of vanes for swirling air traveling through the respective swirler to mix air and the droplets of fuel dispensed by the primary fuel injector; and, a plurality of secondary fuel injection ports for introducing fuel into the hollow interior of the pilot housing. The main mixer further includes: a main housing surrounding the pilot housing and defining an annular cavity; a plurality of fuel injection ports for introducing fuel into the cavity; and, at least one swirler positioned upstream from the plurality of fuel injection ports, each of the main mixer swirlers having a plurality of vanes for swirling air traveling through the respective swirler to mix air and the droplets of fuel dispensed by the main mixer fuel injection ports. The fuel manifold is in flow communication with the plurality of secondary fuel injection ports in the pilot mixer and the plurality of fuel injection ports in the main mixer.

Owner:GENERAL ELECTRIC CO

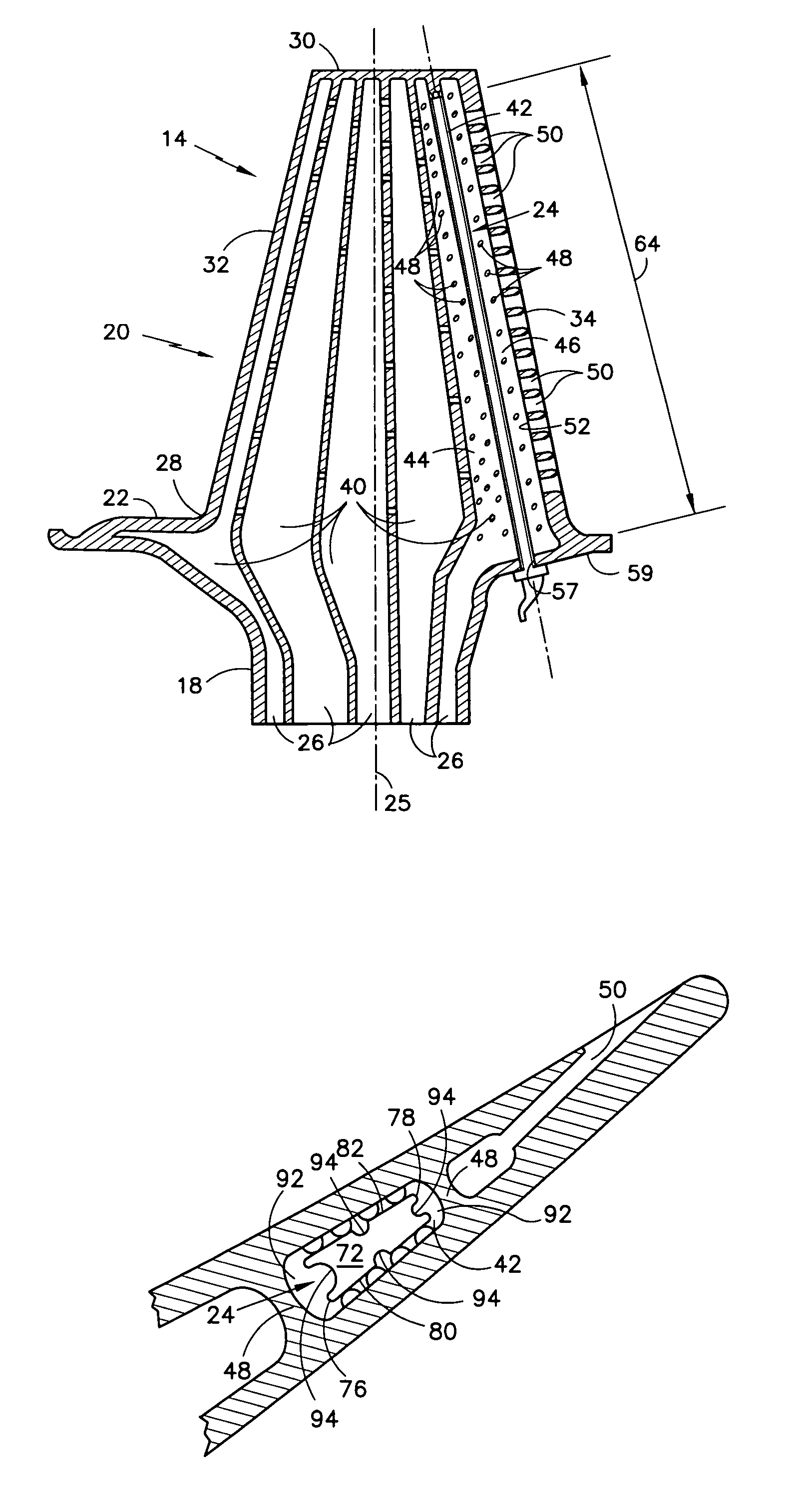

Mixer assembly for combustor of a gas turbine engine having a main mixer with improved fuel penetration

A mixer assembly for use in a combustion chamber of a gas turbine engine includes a pilot mixer, a main mixer, and a fuel manifold positioned between the pilot mixer and main mixer. The pilot mixer includes an annular pilot housing having a hollow interior and a pilot fuel nozzle mounted in the housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing. The main mixer includes: a main housing surrounding the pilot housing and defining an annular cavity having an upstream end and a downstream end including an upstream wall, an outer wall and an inner wall; a plurality of fuel injection ports for introducing fuel into the cavity, with the fuel injection ports being circumferentially spaced at a designated axial location of the inner wall of the annular cavity; and a swirler arrangement including at least one swirler in flow communication with the annular cavity, the swirler being incorporated into the outer wall of the annular cavity and extending from an upstream end to a downstream end, wherein each swirler of the arrangement has a plurality of vanes for swirling air traveling through such swirler to mix air and the droplets of fuel dispensed by the fuel injection ports. The main housing further includes a first plurality of passages oriented to provide air jets in a substantially axial direction into the annular cavity and a second plurality of passages oriented to provide air jets in a substantially radial direction into the annular cavity

Owner:GENERAL ELECTRIC CO

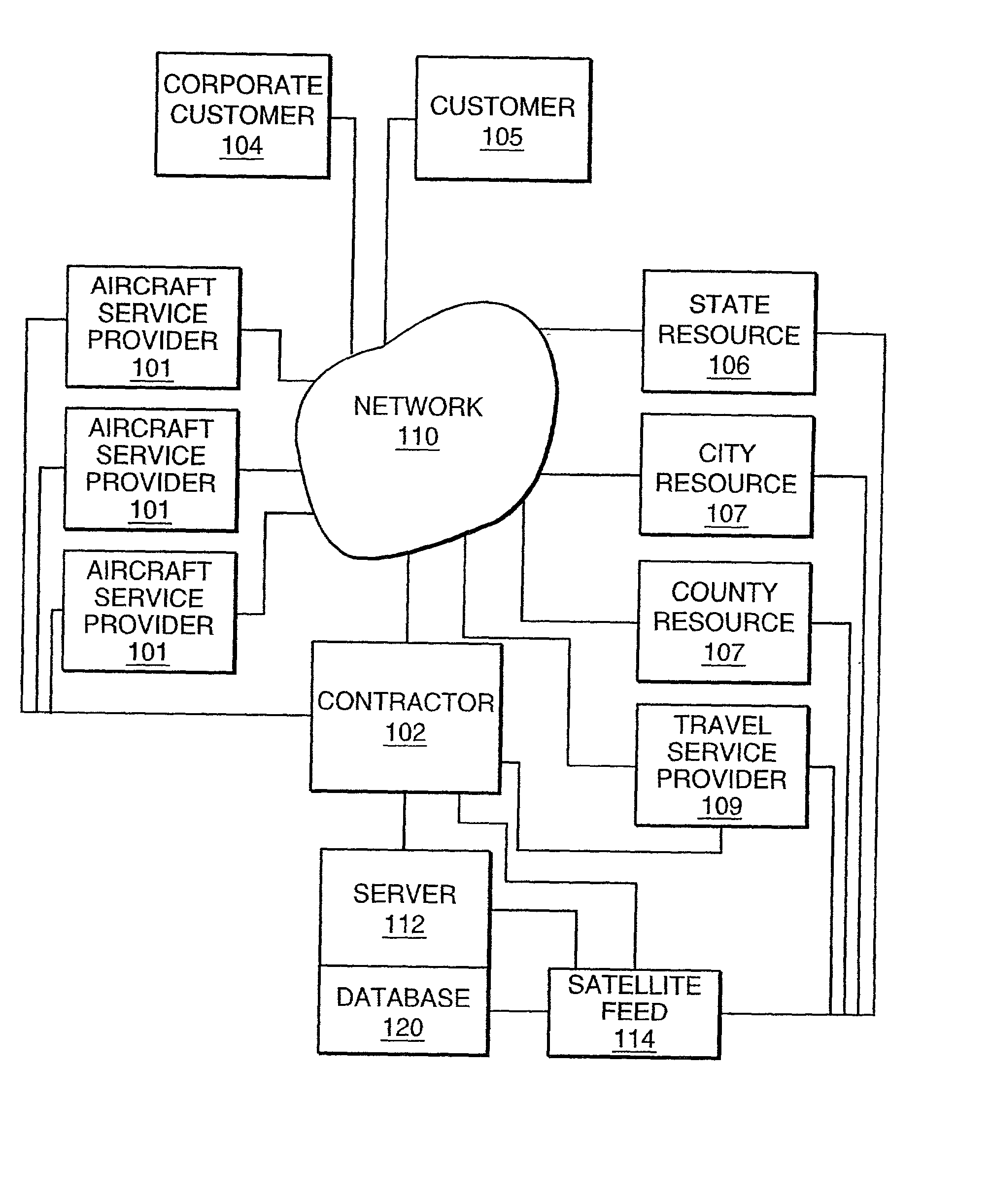

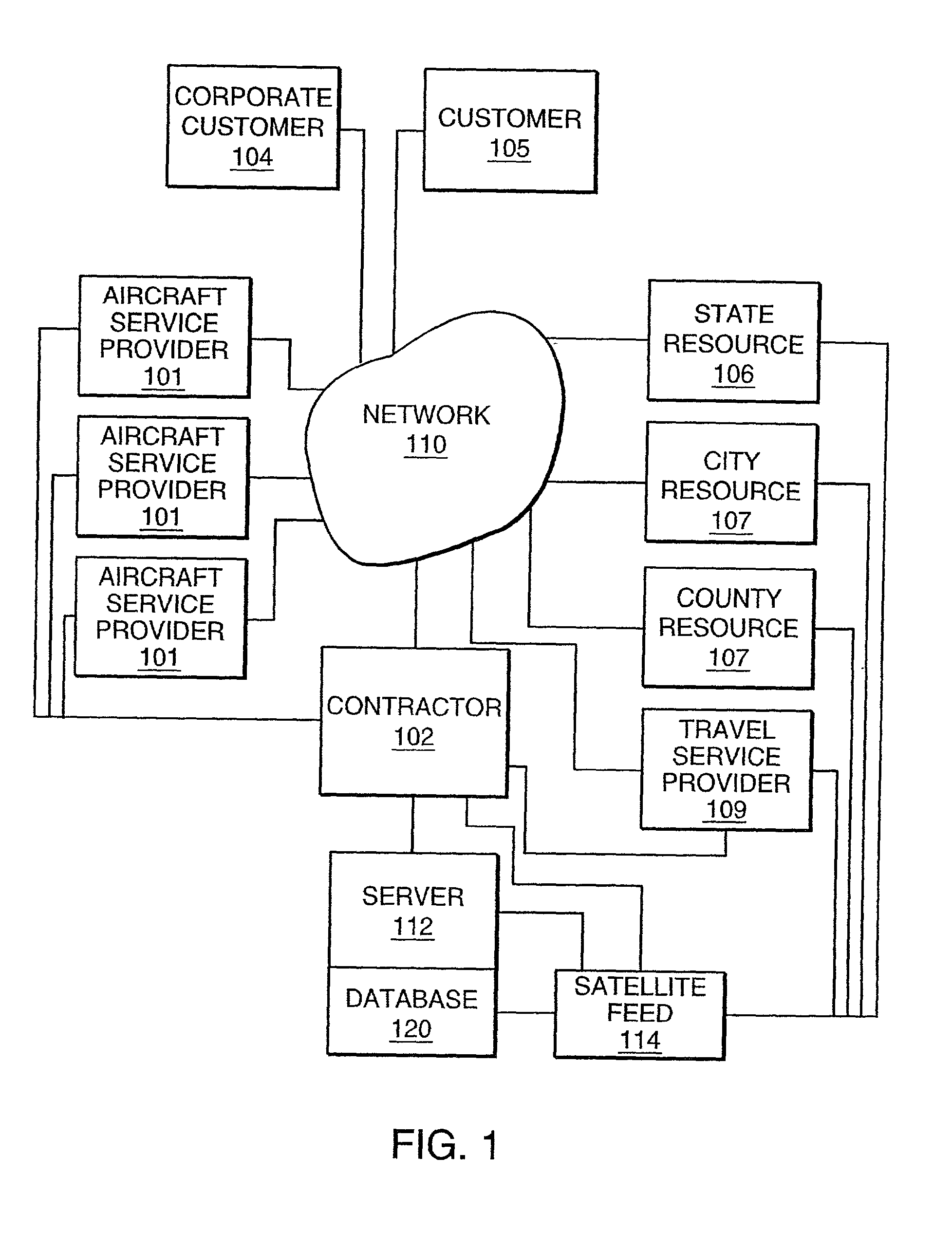

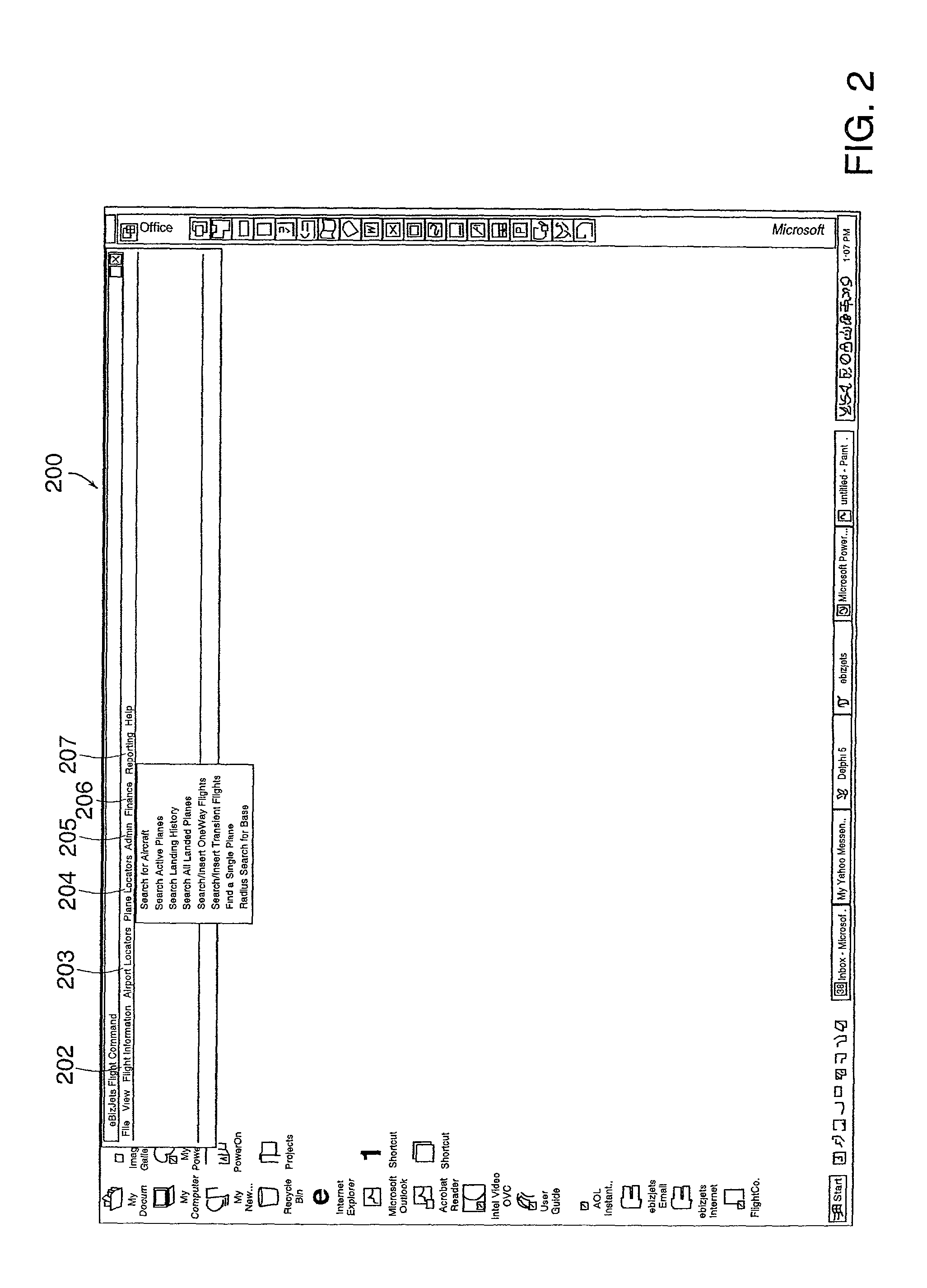

Method and apparatus for arranging flexible and cost-efficient private air travel

A method and system for providing private air travel to a plurality of customers includes establishing a pool of aircraft service providers and obtaining an aircraft service request from each customer. One or more aircraft that conform to each set of customer-specified parameters is selected from the pool of aircraft service providers and matched to the aircraft service request in a manner that minimizes the occurrence of passenger-less flights.

Owner:SENTIENT JET

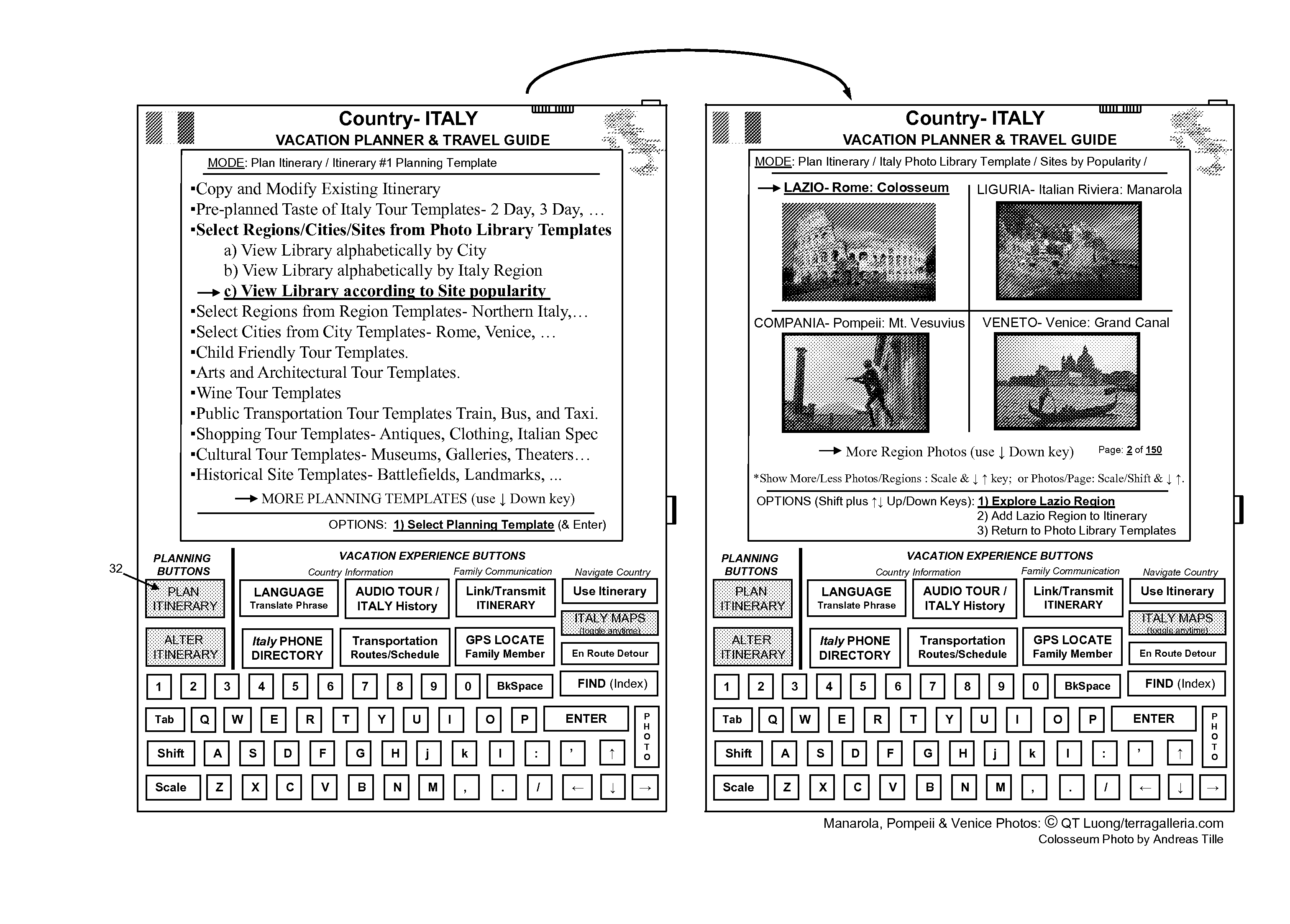

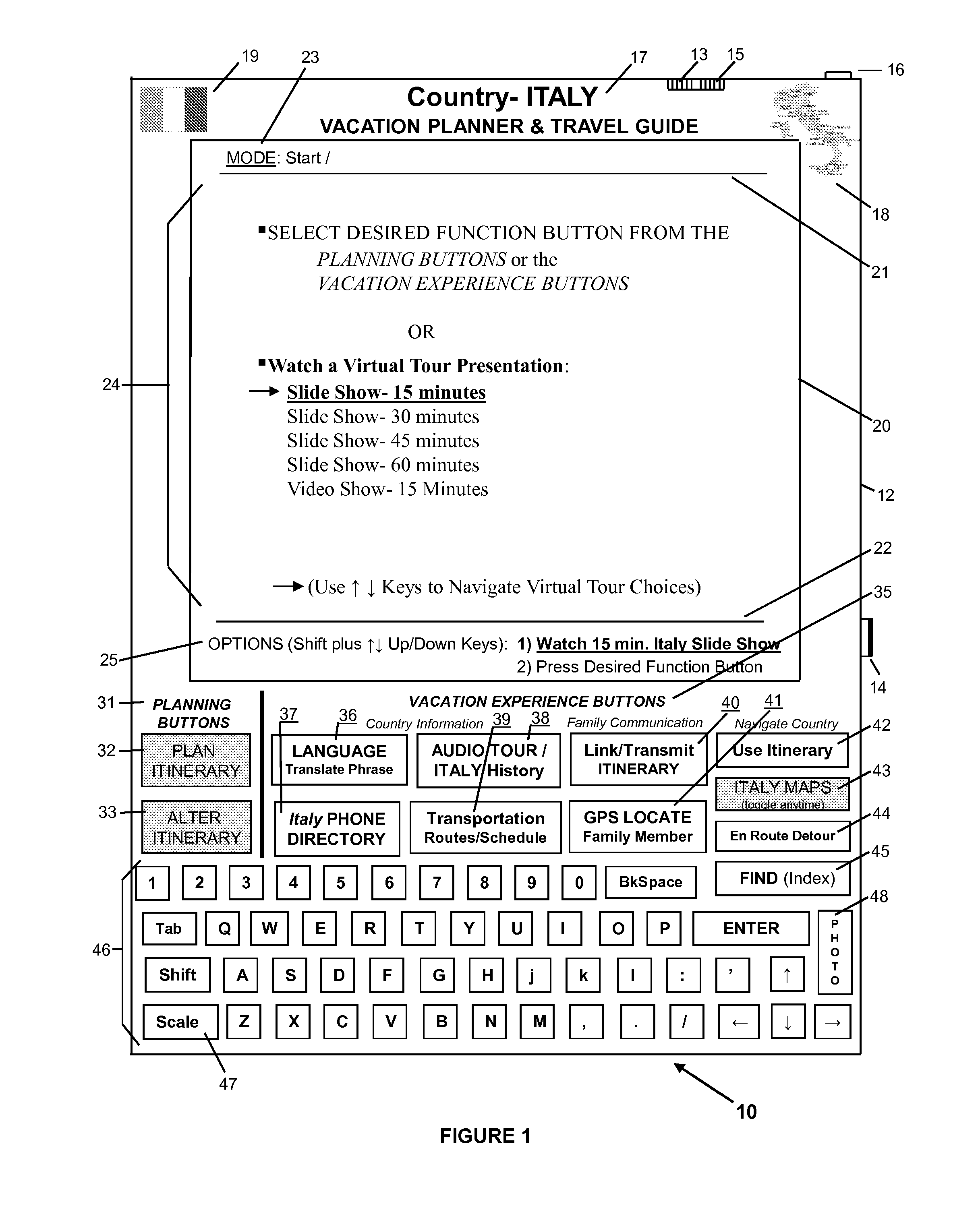

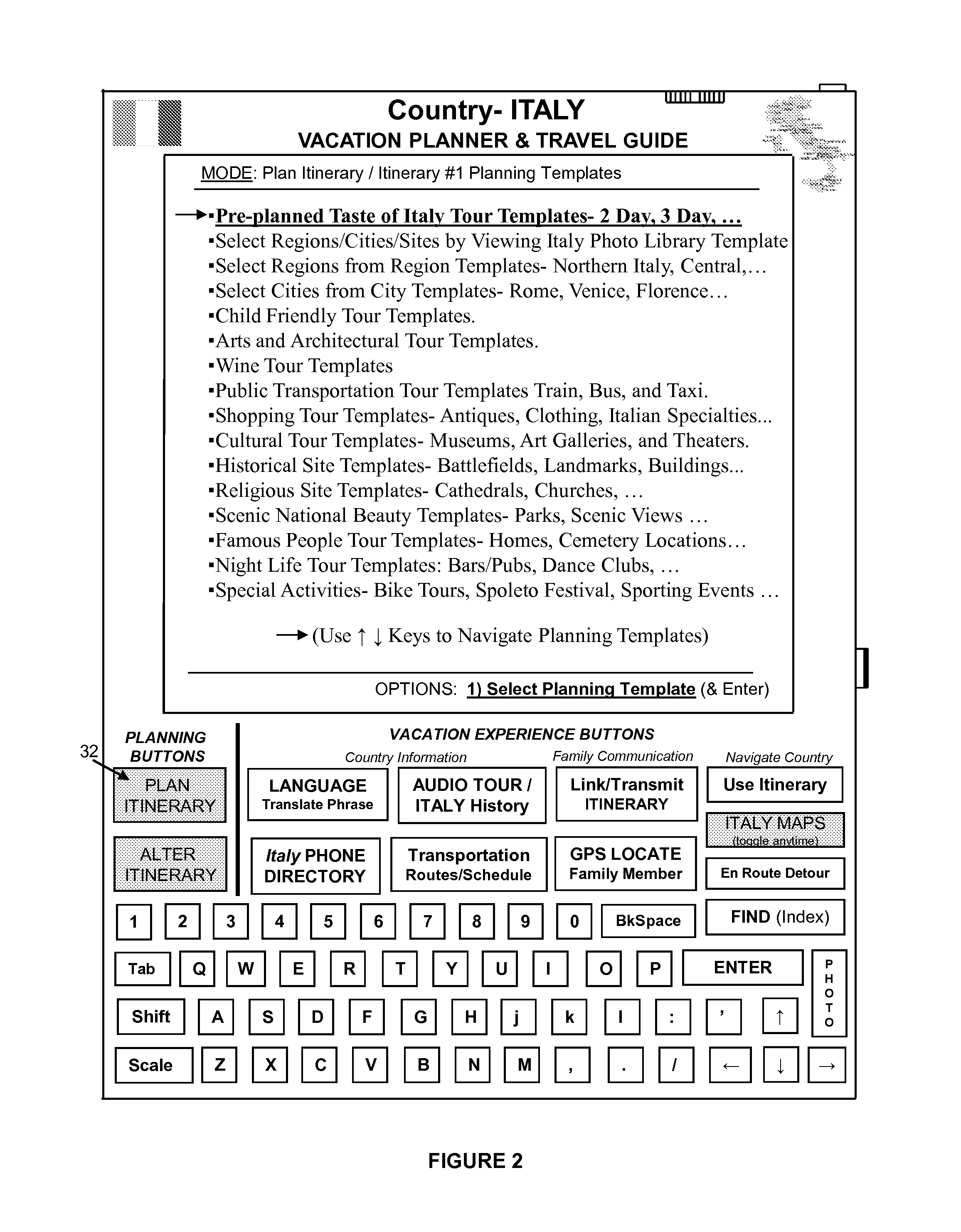

Portable vacation/travel planner, and family tour guide device

PendingUS20110301835A1Improve travel experienceAssisted navigationDigital data processing detailsReservationsAudio tourThe Internet

A portable device for planning a vacation / business travel itinerary, which begins with customizable itinerary templates that utilize a stored database of destination information, including a country's regions / cities, tourist sites, and other sites of interest located therein, and a corresponding photographic library. One such template returns itineraries based upon: duration, arrival / departure cities, total number of cities to be visited, and intensity of touring. The software assists users during travel by providing cueing of itinerary segments, along with directions, and on-demand pre-recorded audio tours to enhance site tour experiences. En route detours from planned sites are supported for spontaneous additions / substitutions. Country-specific information includes city / regional maps, public transportation information, key word / phrase language translation capability, and yellow / white page phone listings. Password protected device-to-device linking permits family members to track each other by GPS location of the other's device. Internet capability permits inclusion, within itineraries, of reservation-specific information for air-travel, hotels, and events.

Owner:BONGIORNO JAMES

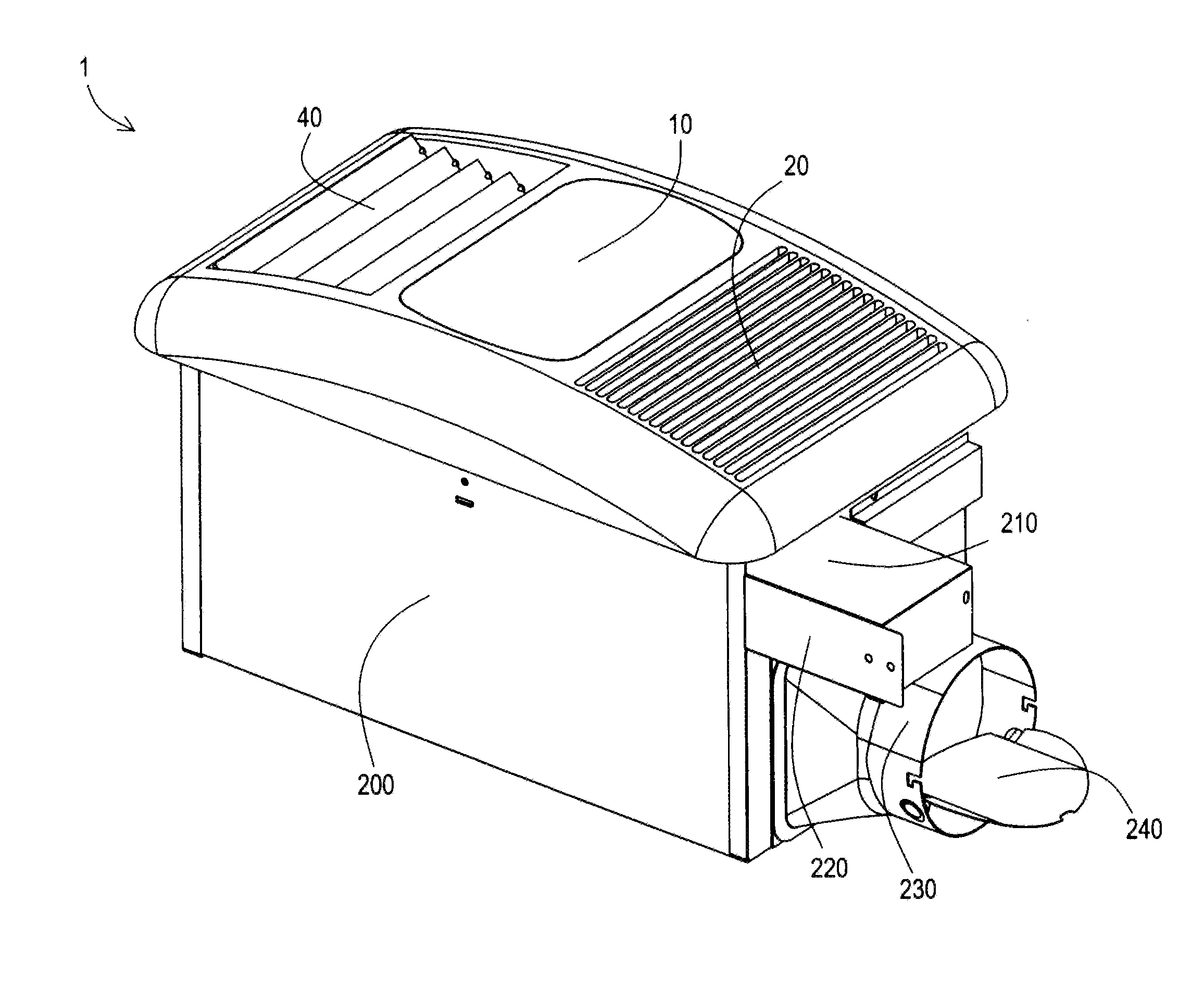

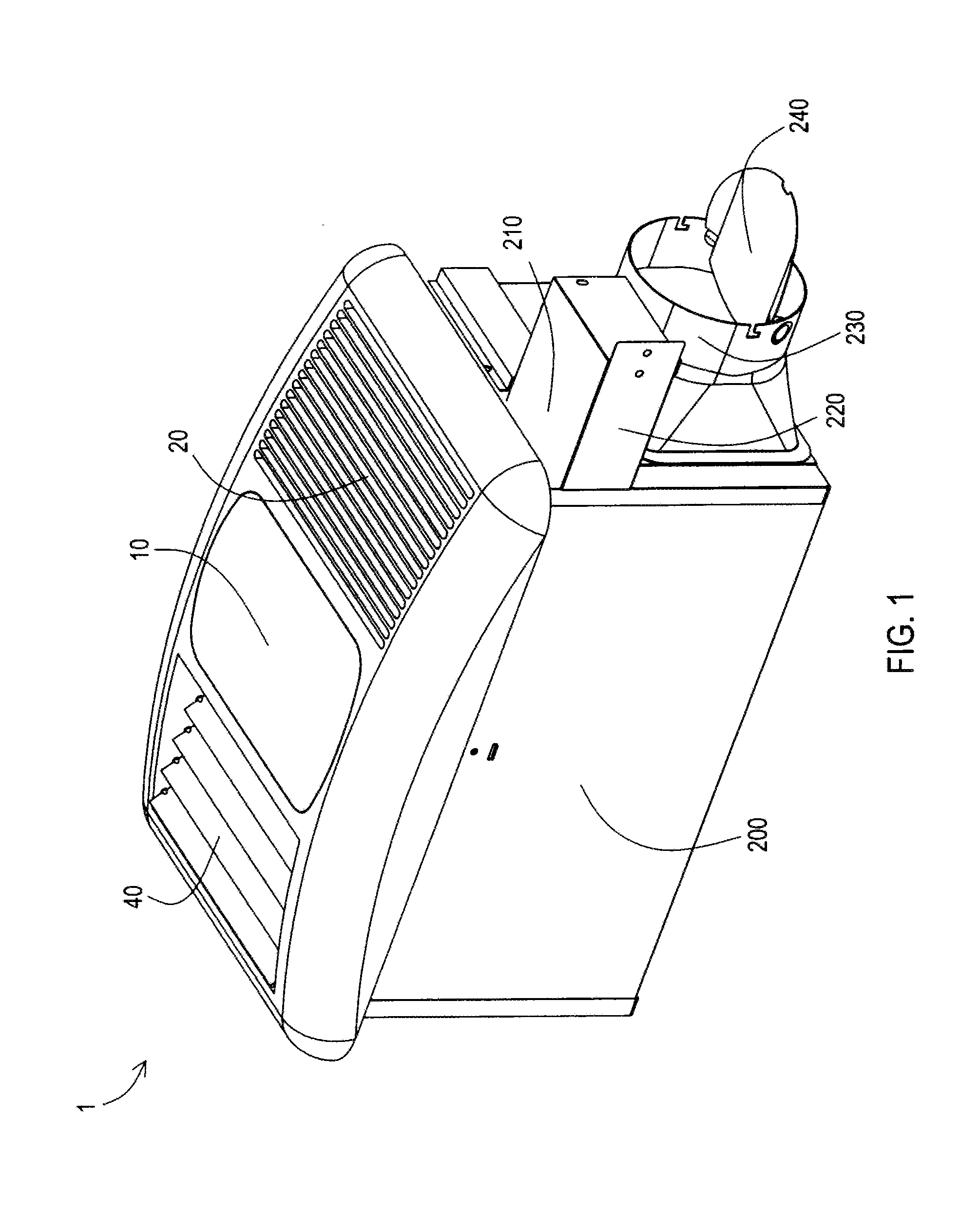

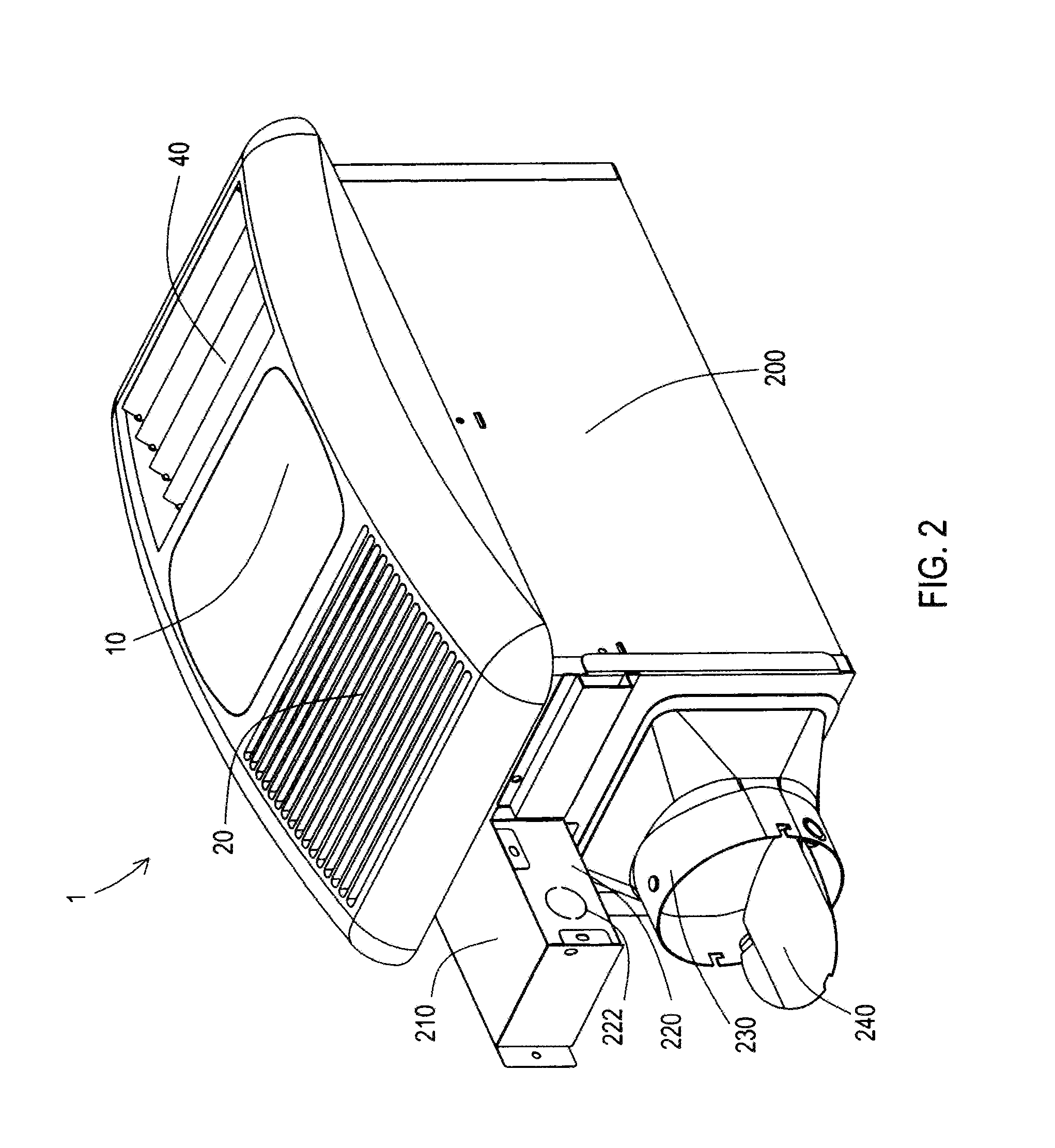

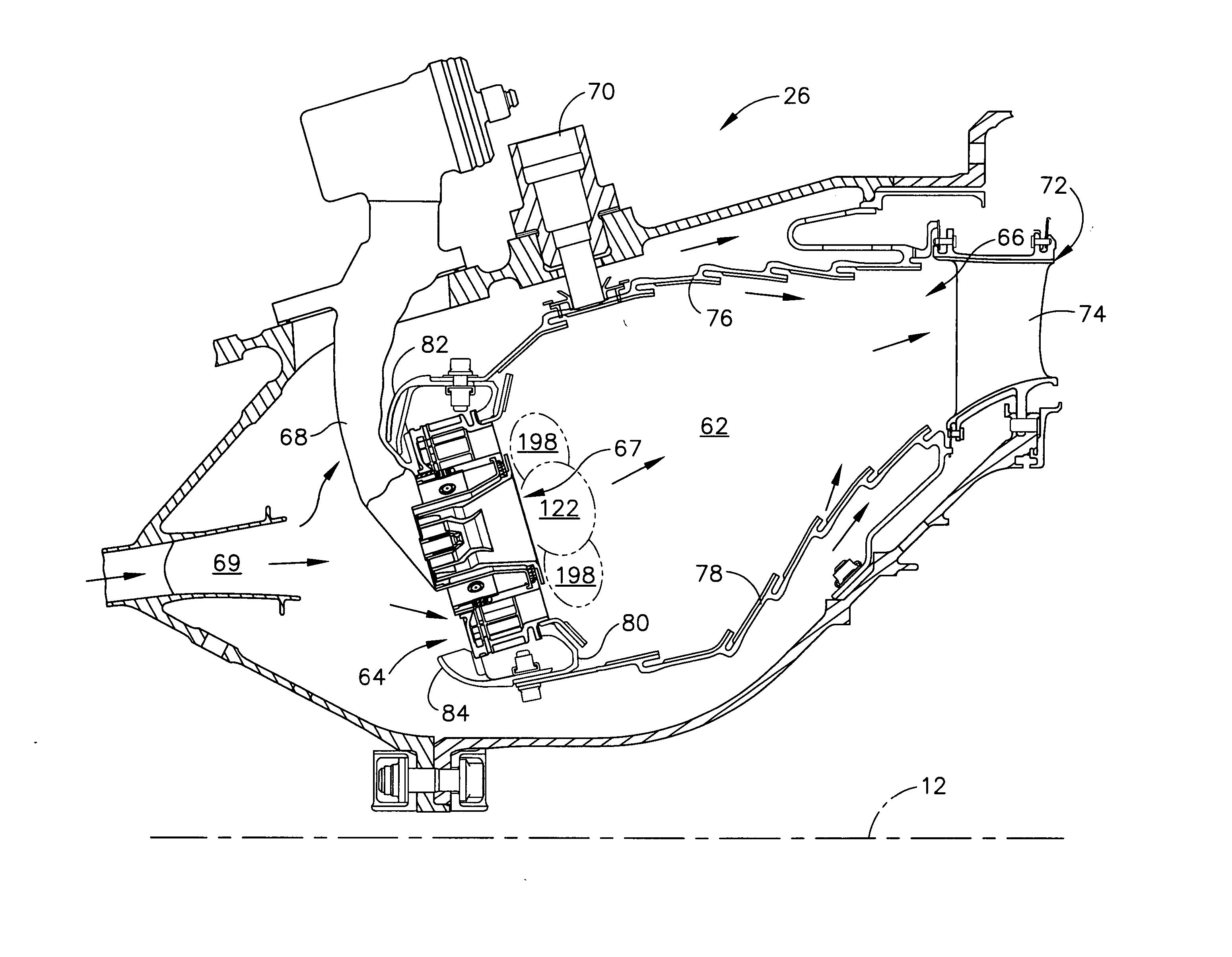

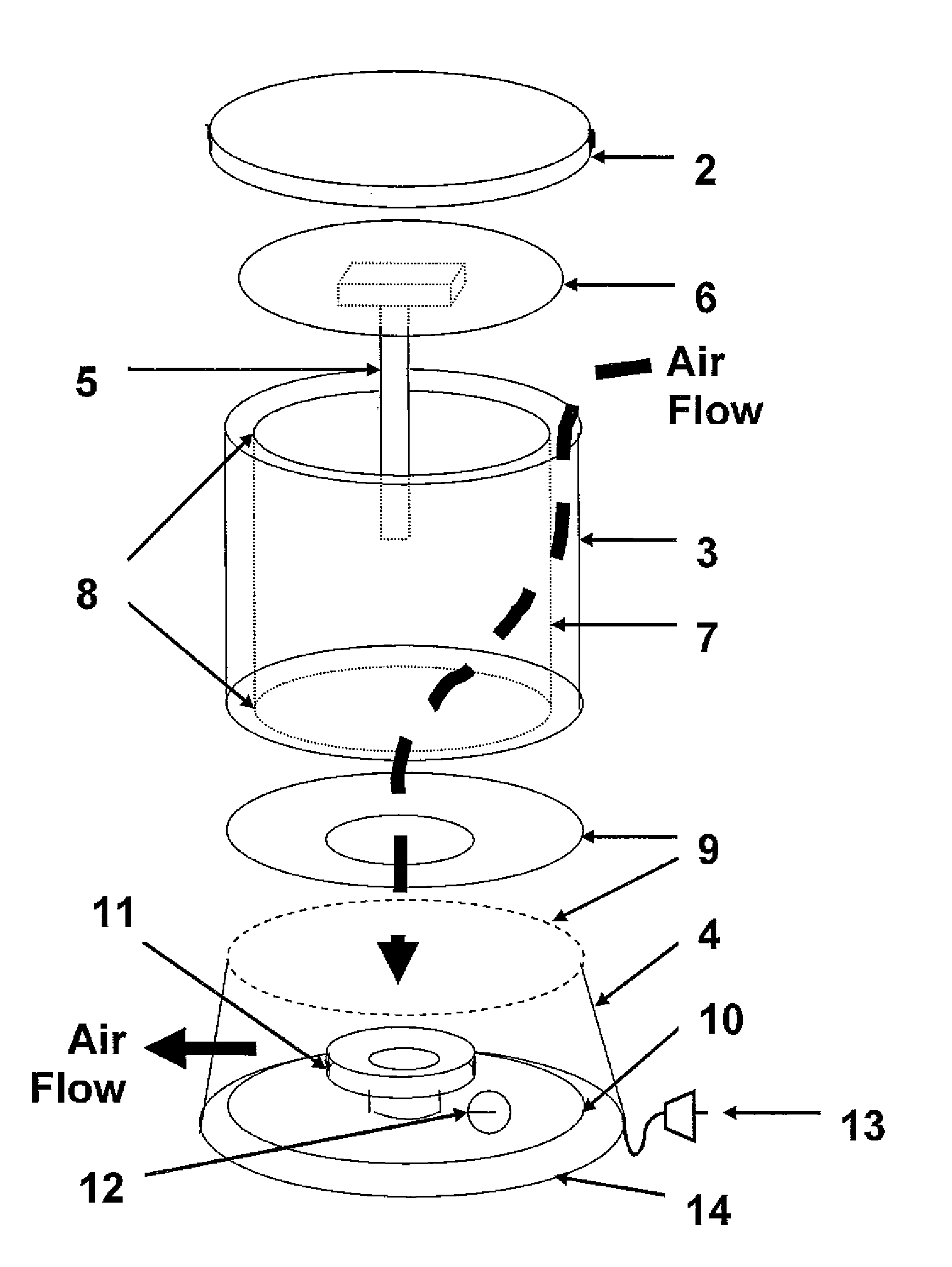

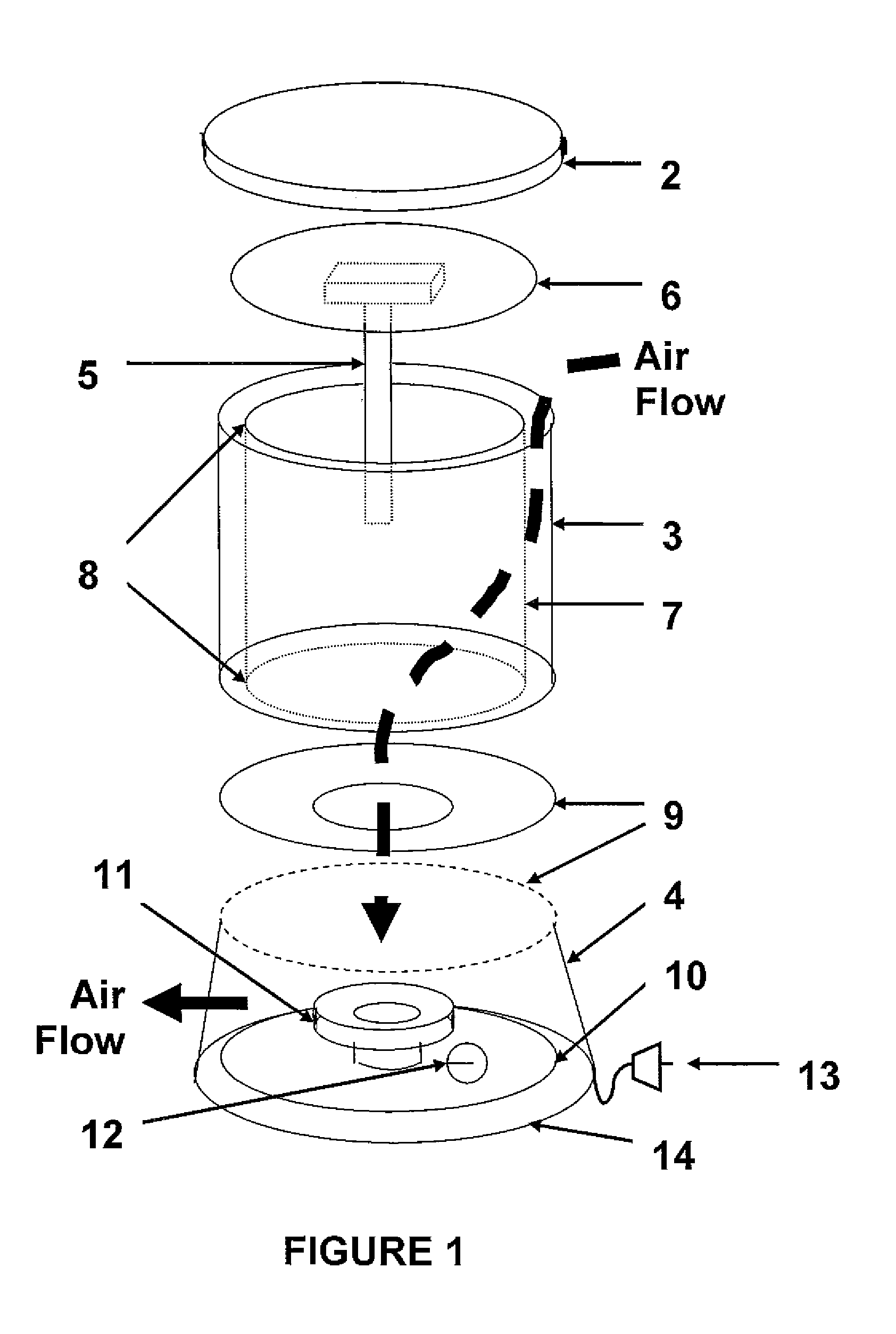

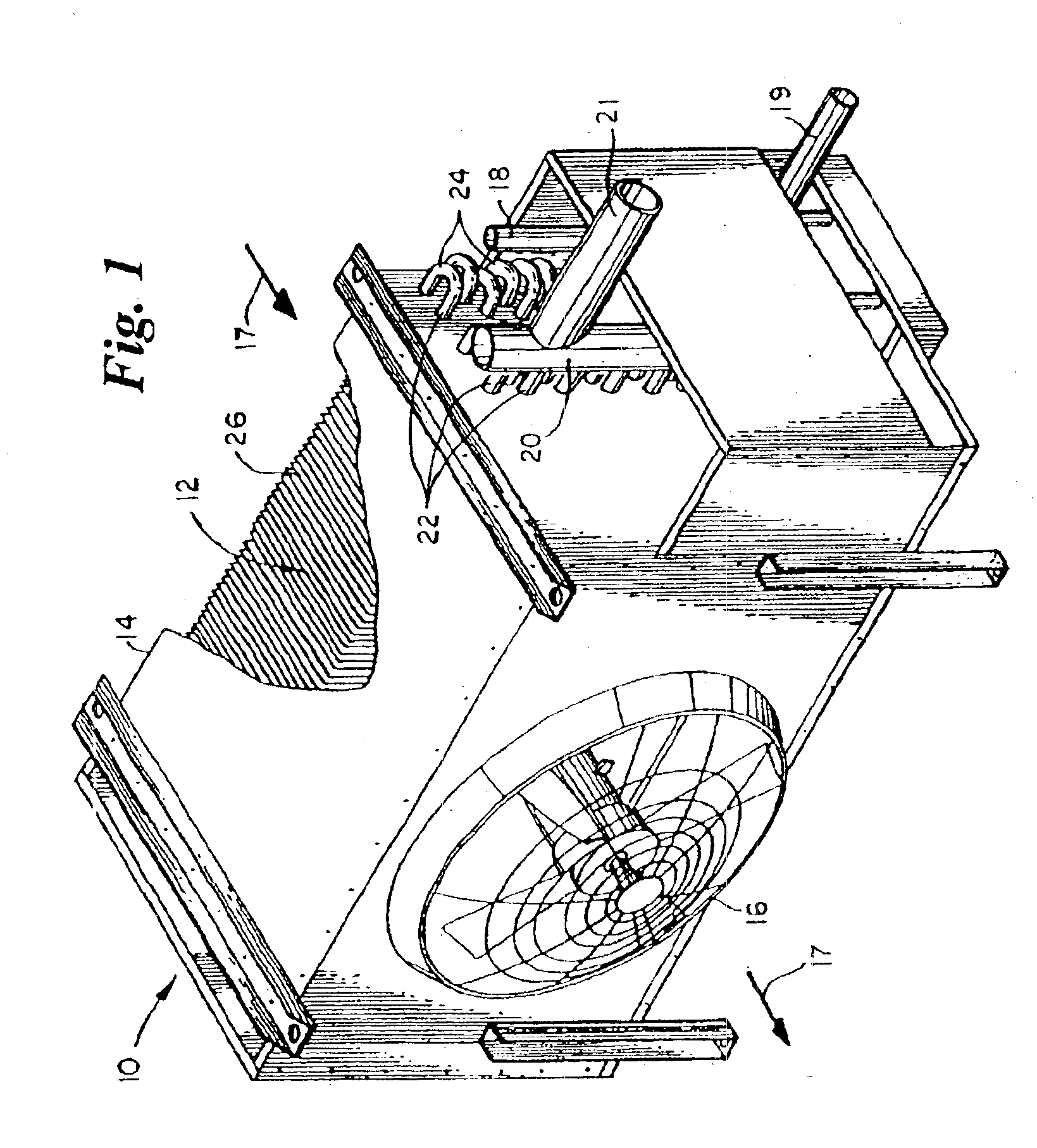

Bath fan and heater with cover having adjustable luver or depressible fastener and depressible release

ActiveUS9103104B1Avoid excessive noiseMaximum performanceAir heatersLavatory sanitoryJoistEngineering

Apparatus, systems and methods of using 70 CFM ventilation fans with heaters for bathrooms having depressibly engageable and depressibly releaseable light covers. The novel ventilation fans and heaters can be mounted to structure in ceilings and inside walls with telescoping suspension brackets that are affixed directly to separate sides of the housing to support the housing against joists and structural supports behind the ceiling. Adjustable louvers on the grill cover allow for outgoing heated air to travel in a different direction into a space from the incoming air travelling into the housing. Plastic type housings around blower wheels reduce undesirable noise effects. The light covers can be easily opened and closed by using depressible engageable fasteners, and depressible release fasteners.

Owner:CHIEN LUEN INDS

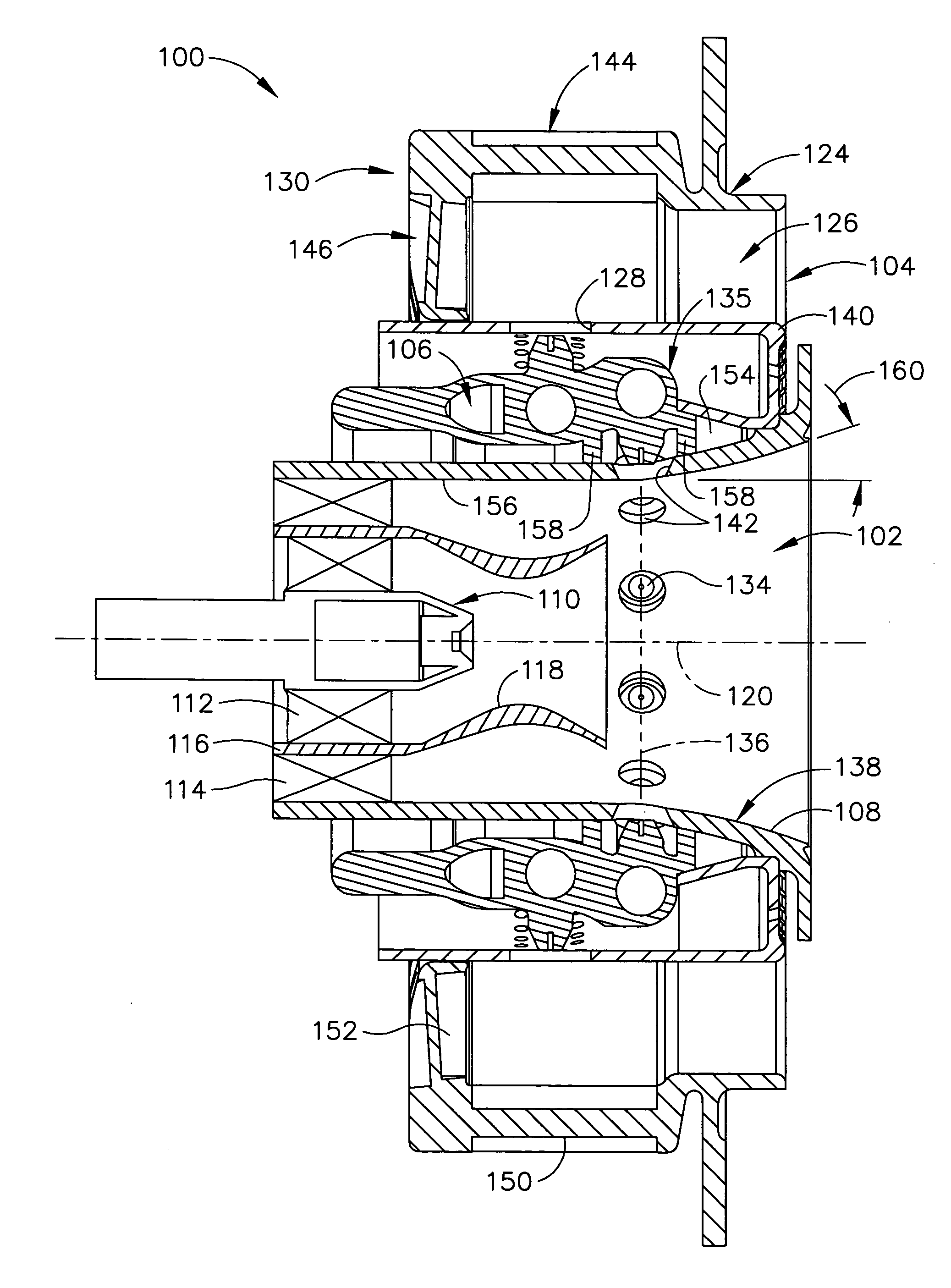

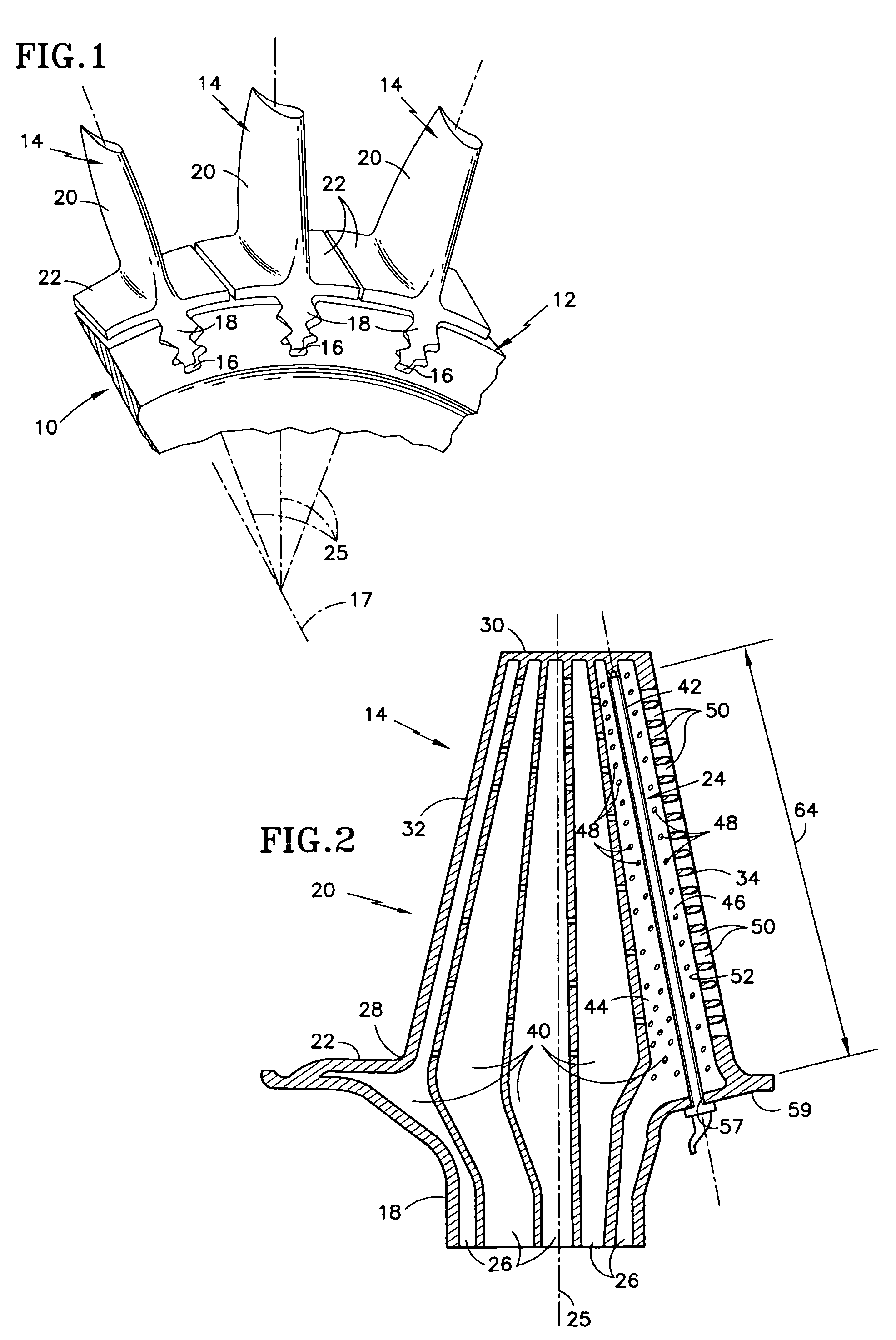

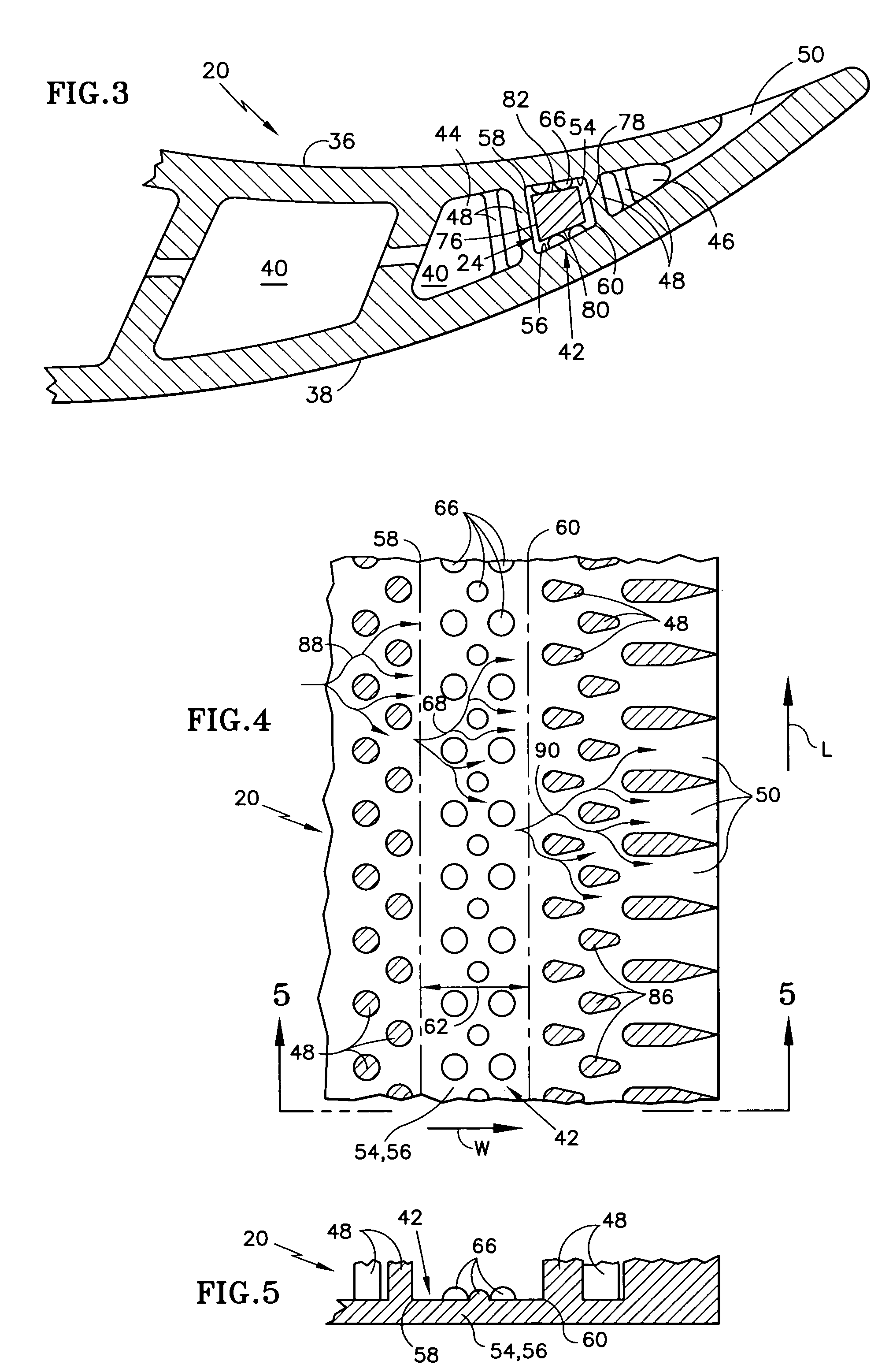

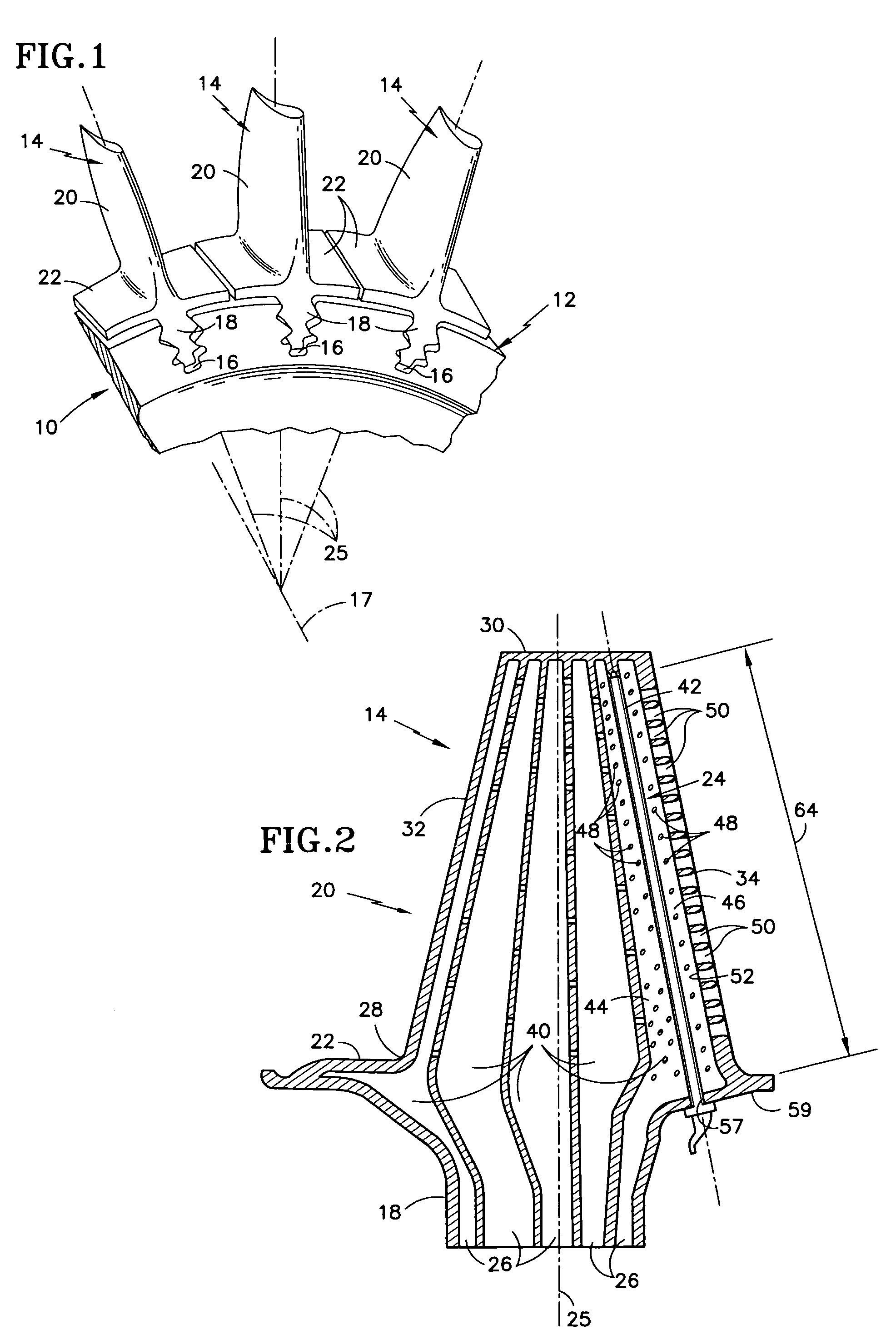

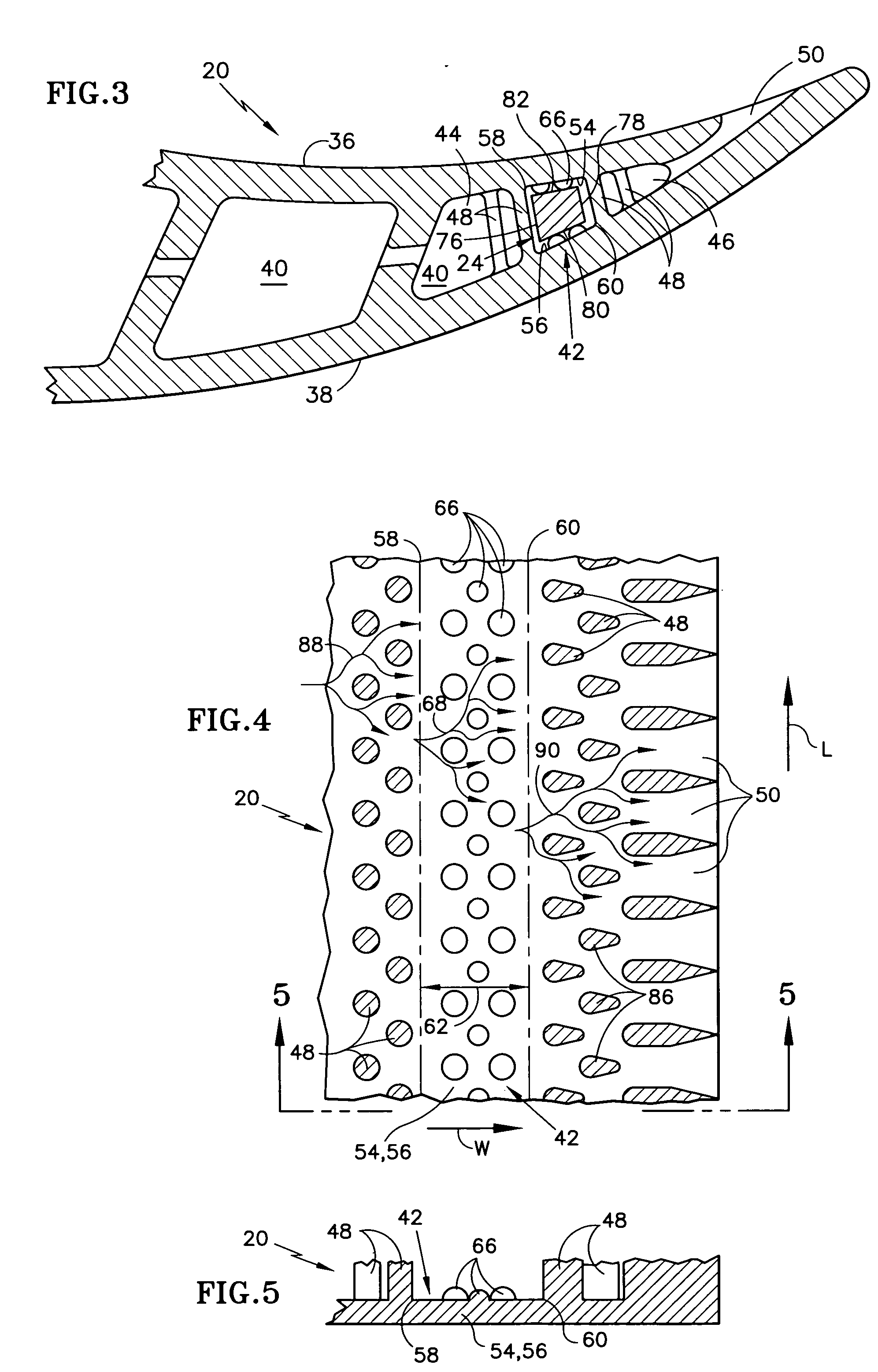

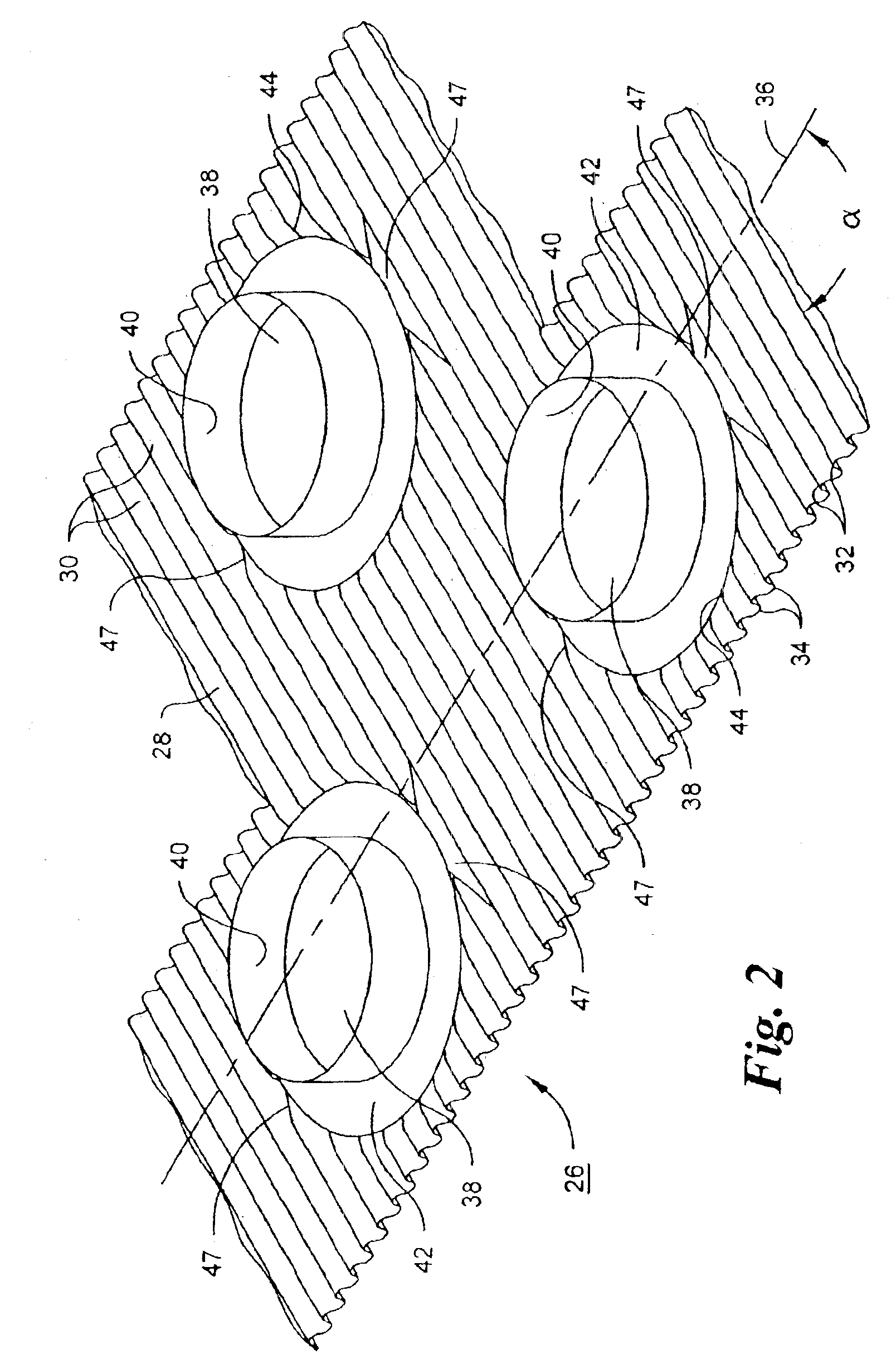

Mixer assembly for combustor of a gas turbine engine having a plurality of counter-rotating swirlers

ActiveUS20070028624A1Emission reductionContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorAcute angle

A mixer assembly for use in a combustor of a gas turbine engine, including a pilot mixer, a main mixer, and a fuel manifold positioned between the pilot mixer and the main mixer. The pilot mixer further includes an annular pilot housing having a hollow interior and a pilot fuel nozzle mounted in the pilot housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing. The main mixer further includes a main housing surrounding the pilot housing and defining an annular cavity, a plurality of fuel injection ports for introducing fuel into the cavity, and a swirler arrangement including at least three swirlers positioned upstream from the plurality of fuel injection ports, wherein each swirler of the swirler arrangement has a plurality of vanes for swirling air traveling through the respective swirler to mix air and the droplets of fuel dispensed by the fuel injection ports. The swirlers are oriented substantially radially to a centerline axis through the mixer assembly or at an acute angle to the centerline axis through the mixer assembly. Alternatively, at least two swirlers are included substantially parallel to the centerline axis through the mixer assembly along with one or more radial or conical swirlers. In another alternative, the swirler arrangement includes a first swirler oriented substantially parallel to a centerline axis through the mixer assembly, a second swirler oriented at an acute angle to the centerline axis through the mixer assembly, and a third swirler oriented substantially radially to the centerline axis through the mixer assembly.

Owner:GENERAL ELECTRIC CO

Intelli-voyage travel

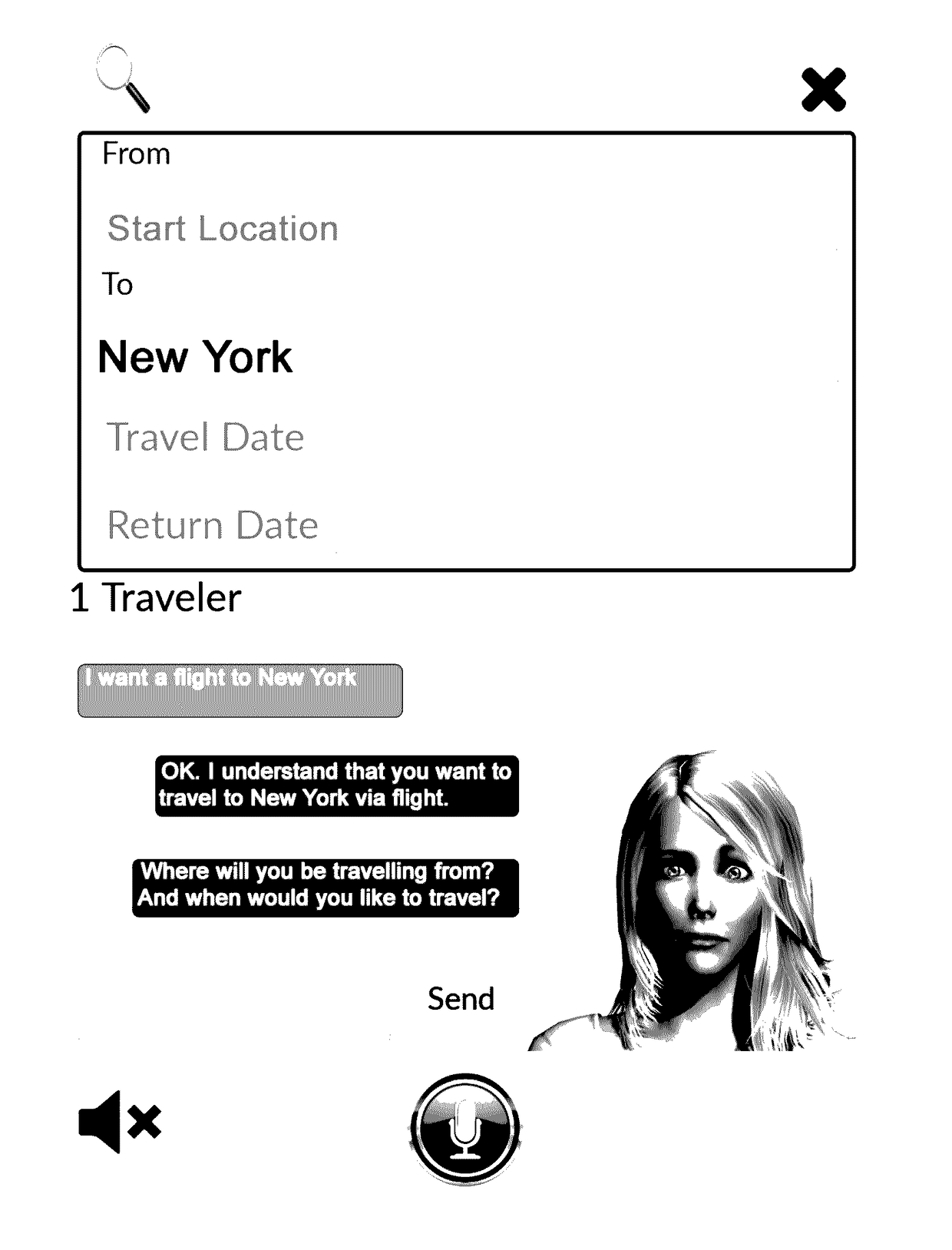

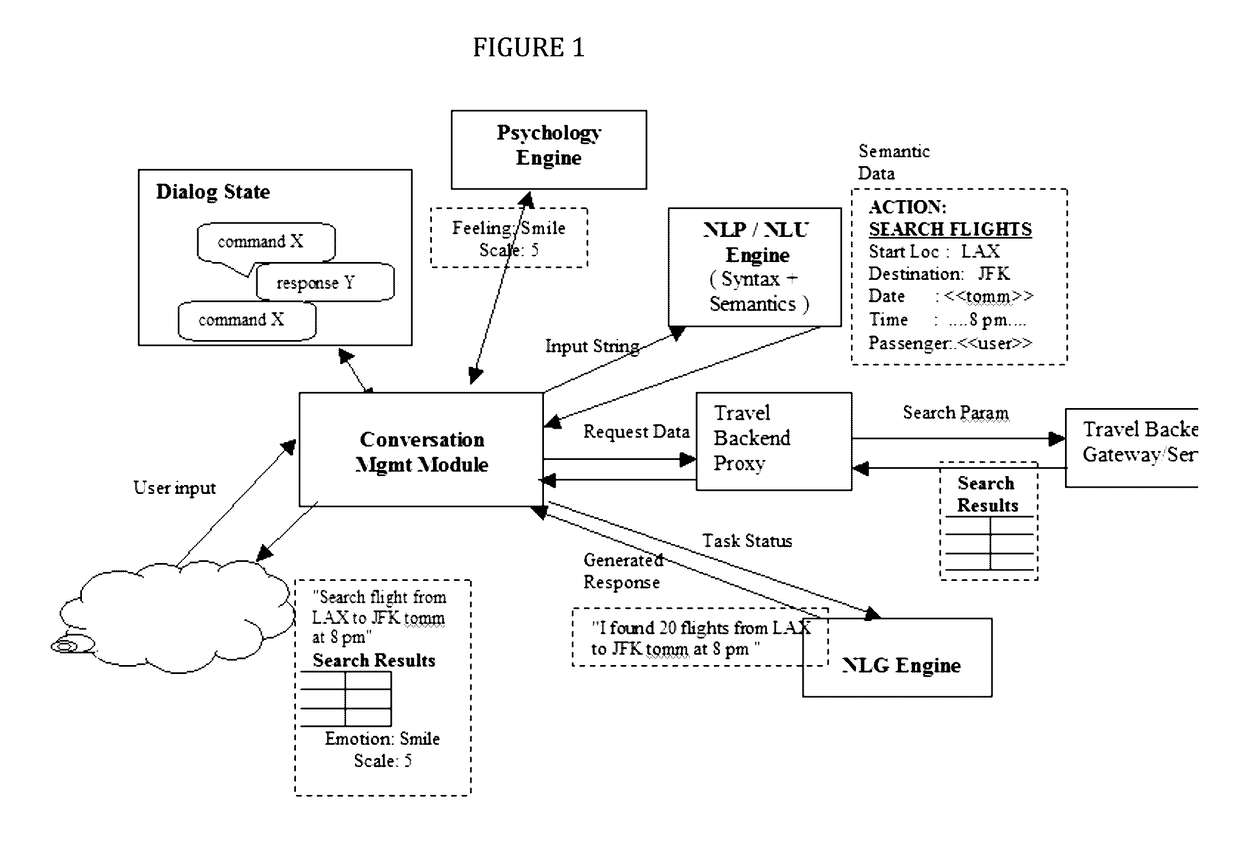

A system to improve user messaging in a mobile device by providing an intelligent interactive travel as a GUI that receives verbal and text input and outputs offers to provide travel-related information, offers to provide travel-related actions, offers to send a travel-related communication, or offers to save travel-related information, wherein processing content of the user input comprises analyzing message content to collect travel-related parameters relating to geographic travel path, airport information, air travel route information, airline flight information, flight availability, flight status, flight booking information, flight cancelling information, airport fees, baggage fees, local and remote ground transportion options, local and remote weather information, message priority, channel type, channel availability, user schedule, user time zone, user time and date, user travel-related preferences, type of content, and number of recipients, and saving said collected parameters to memory, wherein the travel-related parameter is calculated using a travel-related index, the travel-related index comprising a numerical value based on travel-related hierarchy, wherein the one or more programs include instructions for providing feedback to the user wherein the feedback comprises a graphical or spoken output from the portable electronic device, said output comprising information linked to the user schedule and one or more travel-related parameters, wherein the user schedule parameter is compared to a travel-related parameter and a scheduling database is populated with an entry that uses the comparison data and, wherein specific customized travel-related profile parameters are set to establish priority overrides where a user schedule has a different priority than a travel-related parameter.

Owner:VADODARIA VISHAL

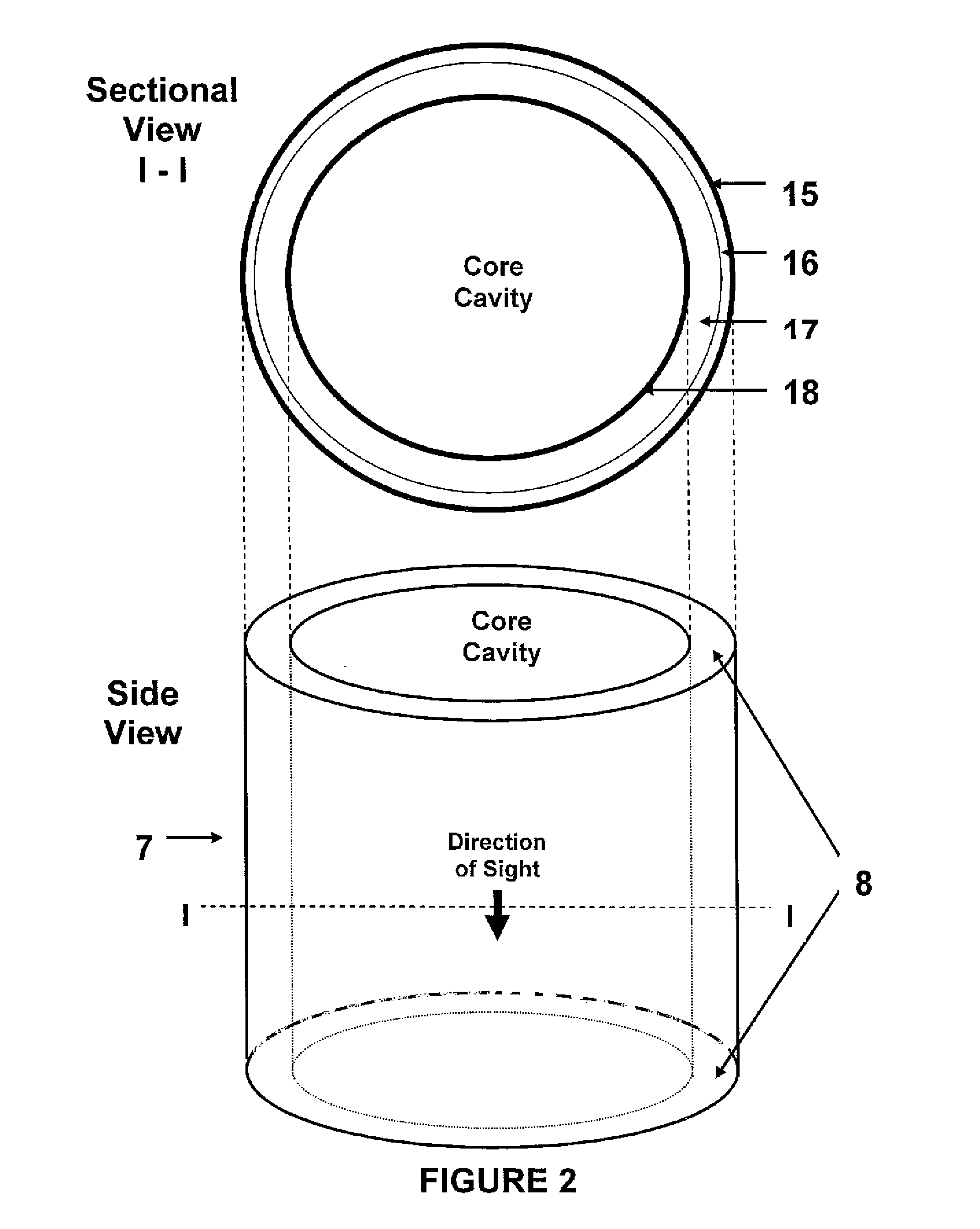

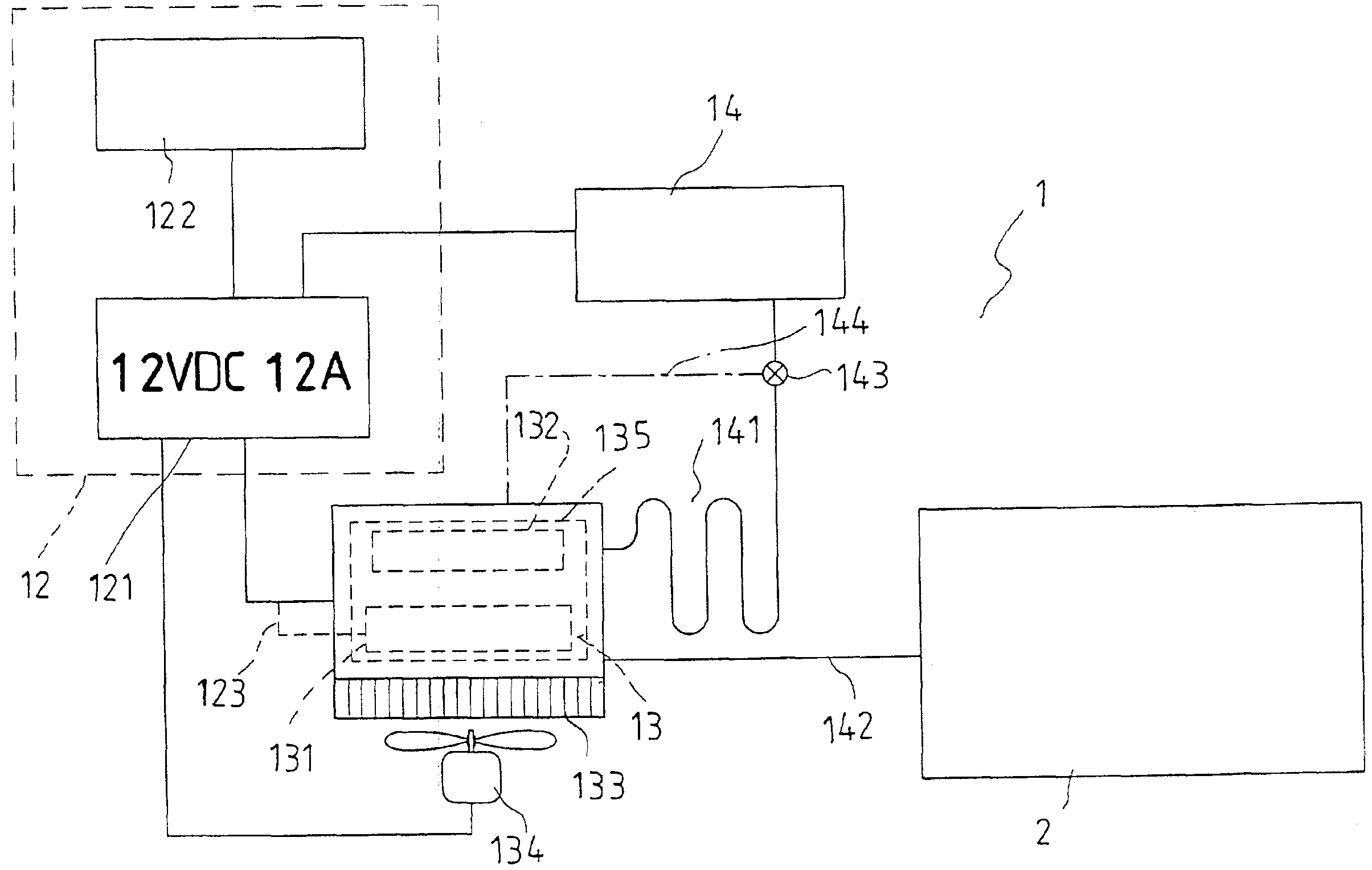

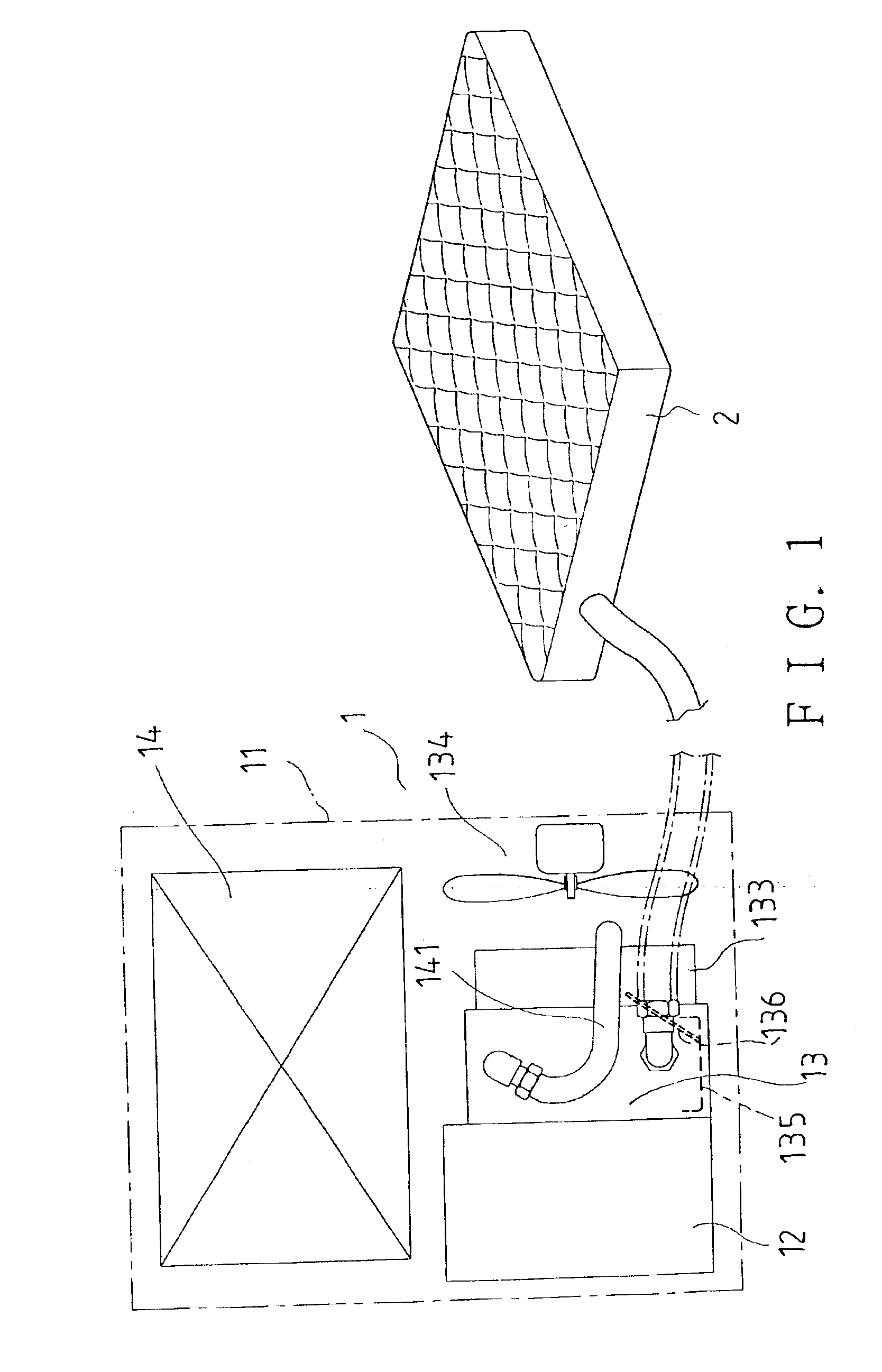

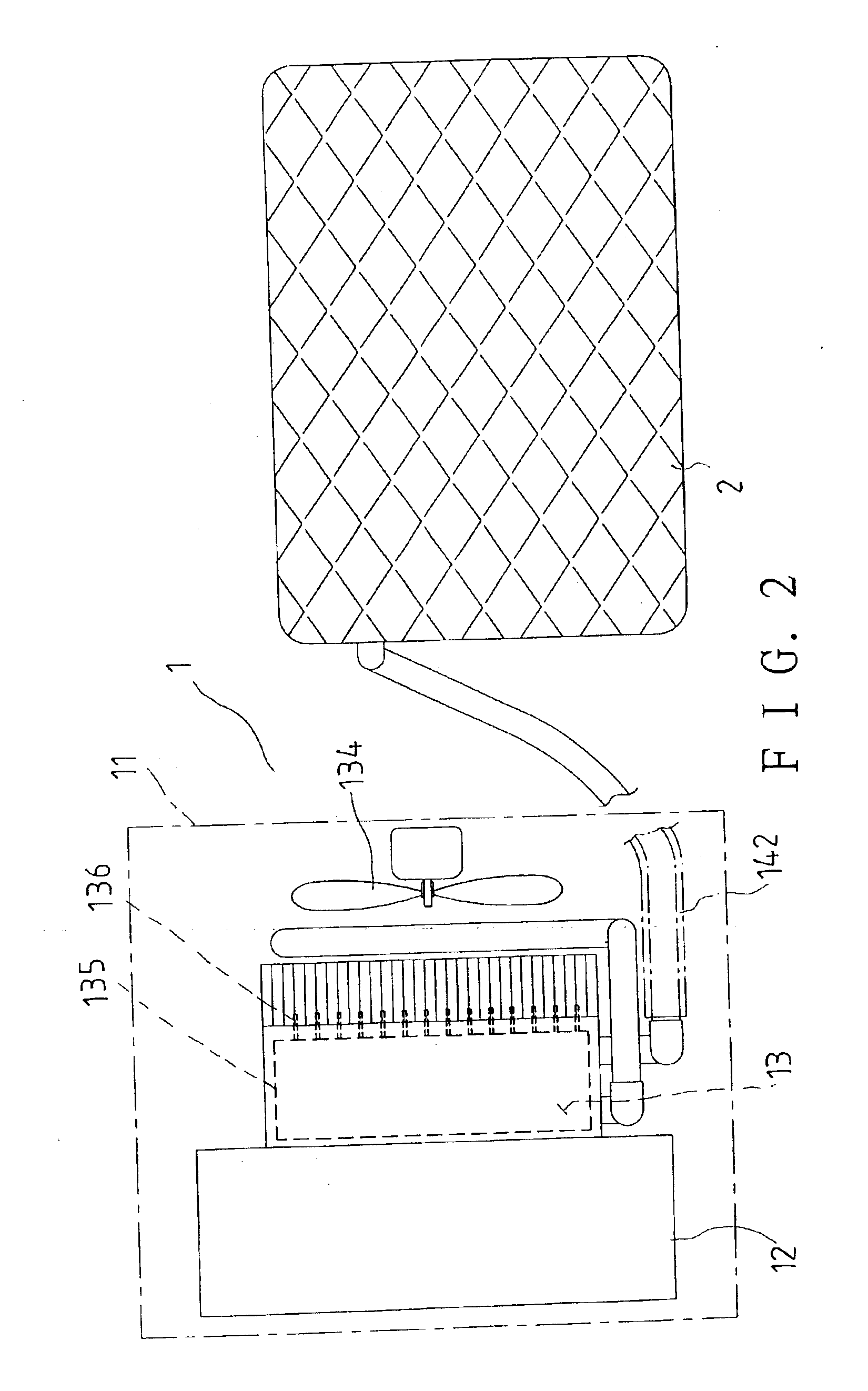

System for purifying air through germicidal irradiation and method of manufacture

ActiveUS20100260644A1Maximize surface contactEnhances air-surface contactMechanical apparatusLighting and heating apparatusNuclear engineeringIrradiation

An air purifying system includes one or more air permeable photocatalytic elements defining a core cavity having a sealed top end and an open bottom end. A sealed air flow path ensures that air travels from an outside of the core cavity, through the one or more photocatalytic elements, into the core cavity, to be expelled through the open bottom end. A UV radiation source disposed within the core cavity irradiates air travelling along the sealed flow path and an interior of the one or more photocatalytic elements. Each photocatalytic element is manufactured using a substrate, that is conductive of and transparent to UV radiation, coated with a photocatalyst. A non-photocatalytically active material is initially coated on the substrate and is then converted to a photocatalyst by calcination.

Owner:HAMPSHIRE DEV LTD

Air-assisted fuel injector for mixer assembly of a gas turbine engine combustor

Owner:GENERAL ELECTRIC CO

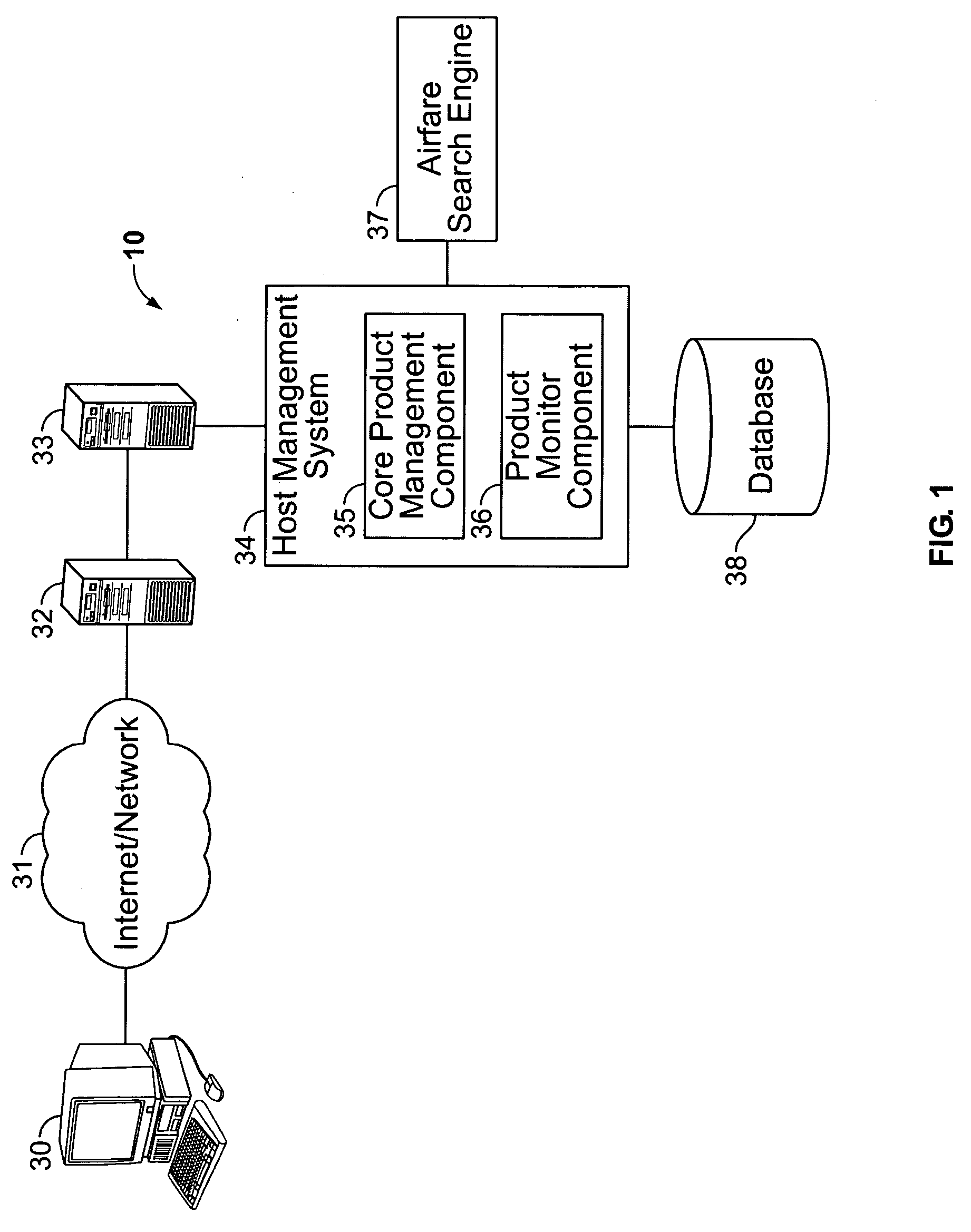

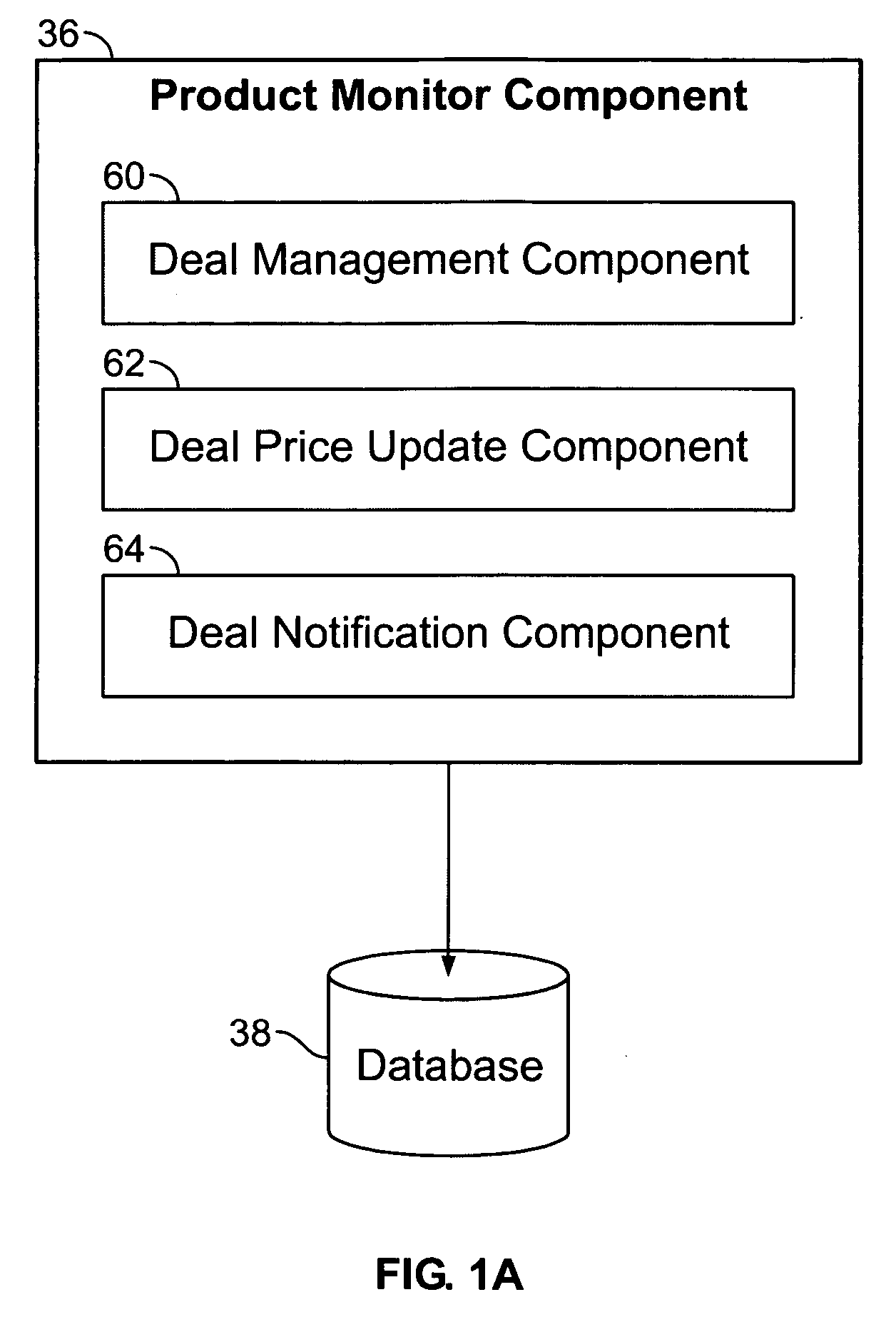

Product availability tracking and notification system and method

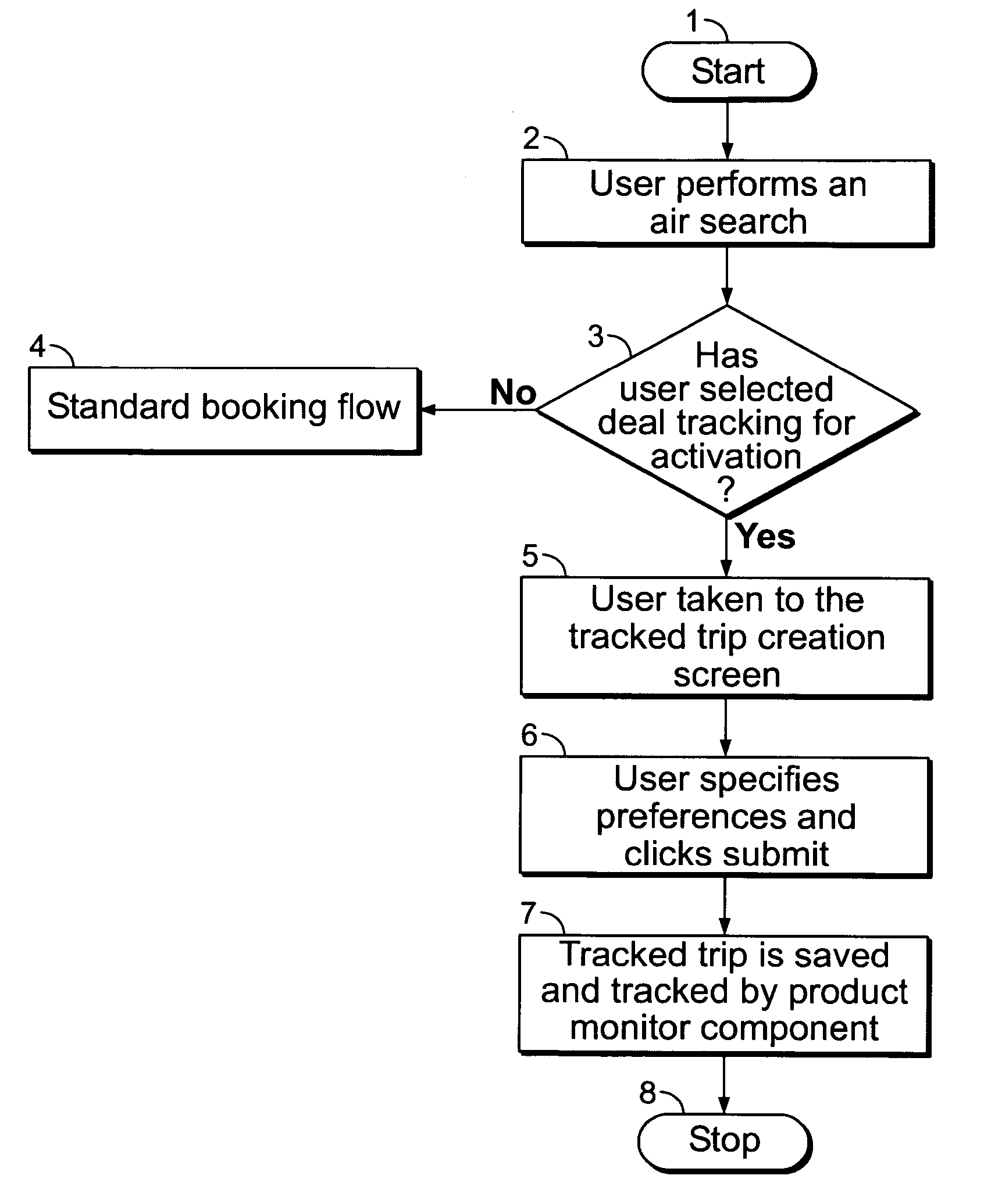

A product availability tracking and notification system and method is provided that automatically alerts consumers of product availability, such as air travel fares, that is automatically searched after an initial search is performed which meets the criteria of the user. To obtain current price information, internally generated queries and user generated queries that match trips being tracked with corresponding search criteria are provided. In tracking airfares for a trip, applicable taxes and fees are included to provide the consumer an accurate total cost. Notification of current pricing is displayed and communicated to the user once the product is available at a specified target price and after a predetermined time period if the defined target price is not found. Searches and pricing for multiple traveler types and travel date flexibility are provided.

Owner:ORBITZ

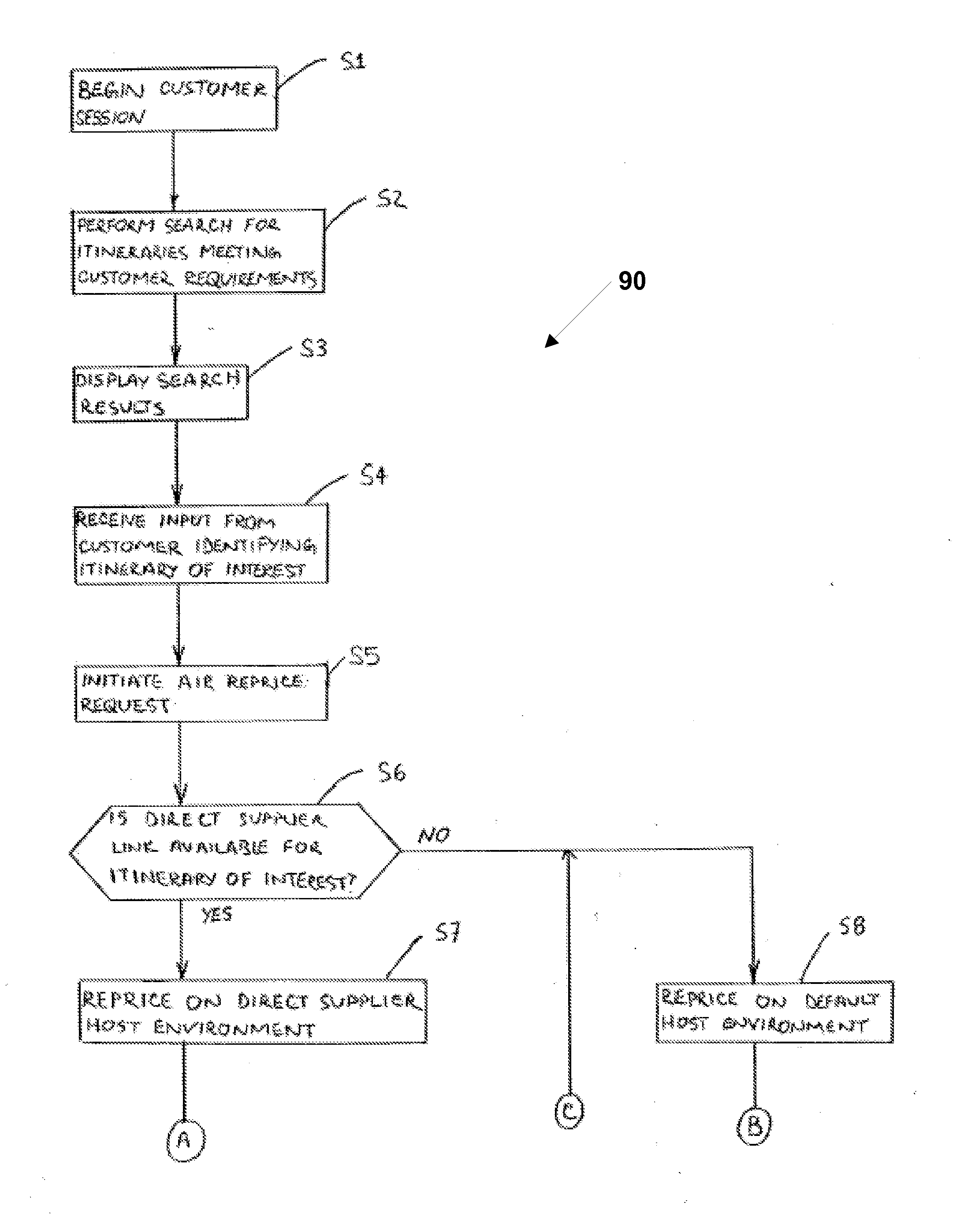

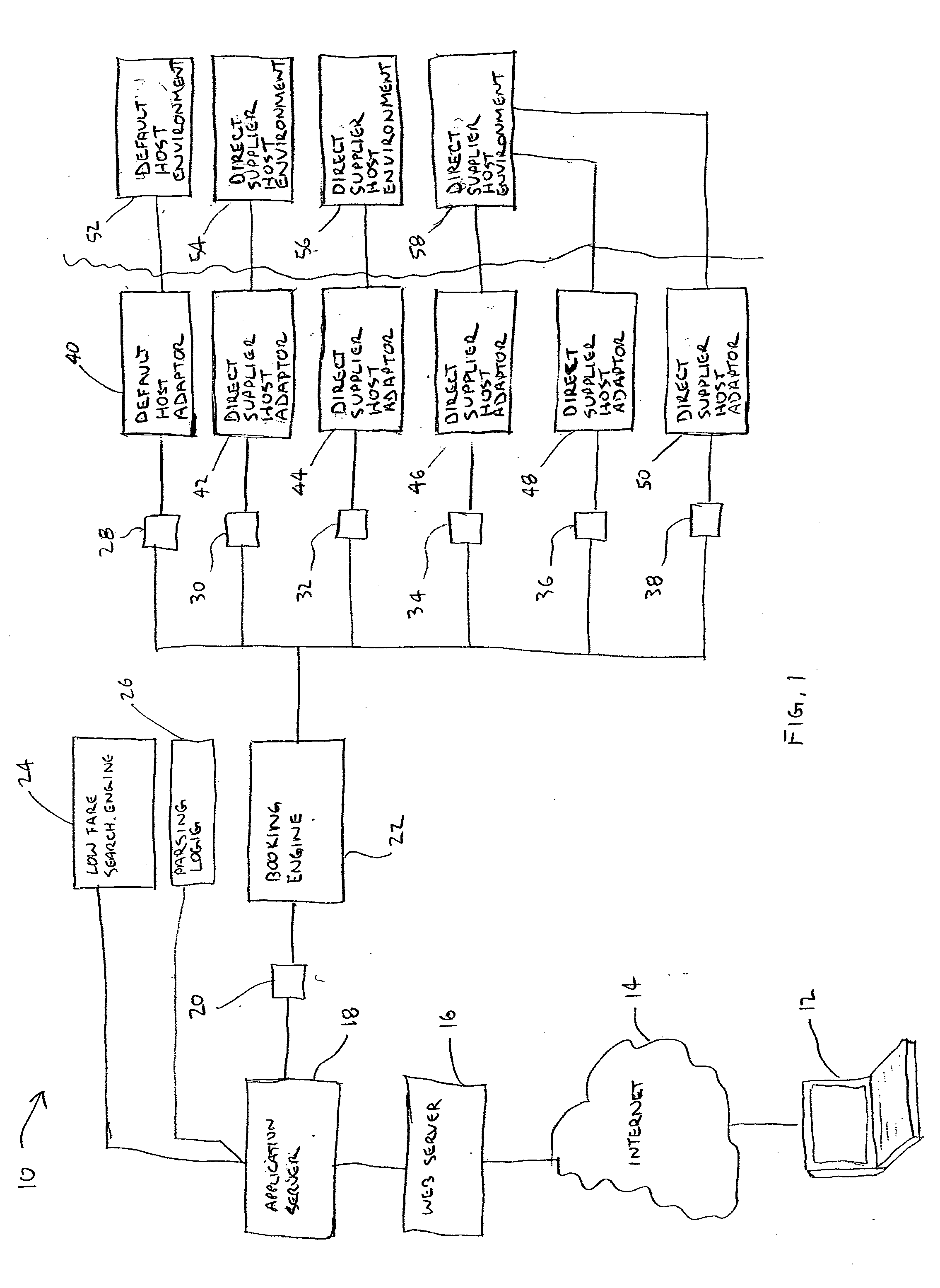

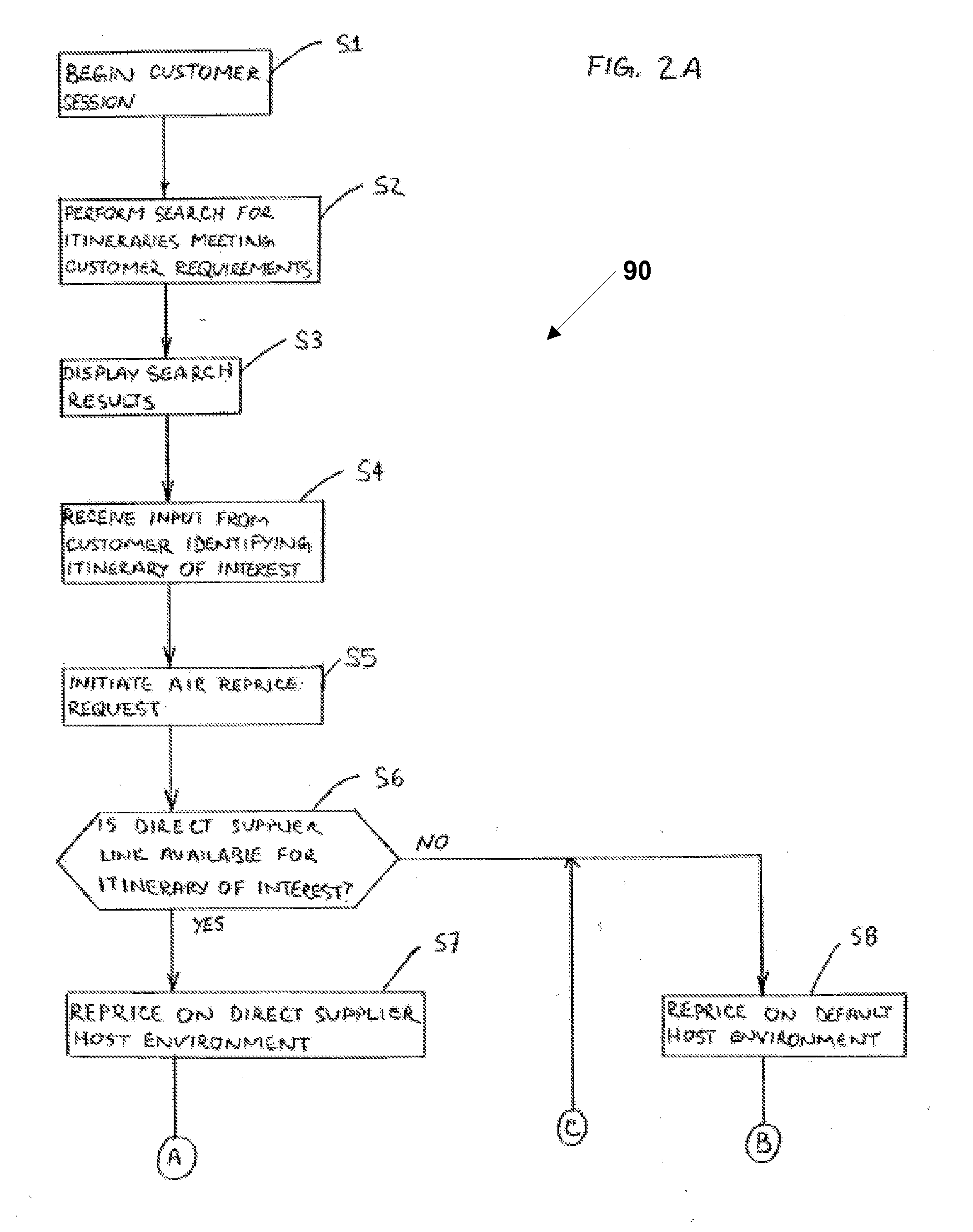

Booking engine for booking airline tickets on multiple host environments

A system and method of booking an itinerary on at least one of a multiplicity of host environments include a plurality of host adaptor modules. Each host adaptor module is configured to interact with one of the plurality of host ticketing environments. A booking engine is provided for receiving commands related to booking the air travel itinerary and determining an appropriate host ticketing environment for processing the commands based on a number of predefined criteria. When the booking engine receives a command it forwards the command to a first host adaptor module which is associated with first host ticketing environment selected by the booking engine for processing the command. The host adaptor module receives the command and issues the command to said first host ticketing environment. The first host adaptor module in turn receives a response from the first host ticketing environment and determines whether the response comports with an expected response. If the response does not comport with the expected response, the booking engine identifies a second appropriate host environment for processing the command and forwards the command to a second host adaptor module associated with the second host ticketing environment. The second host adaptor module then issues the command to the second host ticketing environment.

Owner:ORBITZ

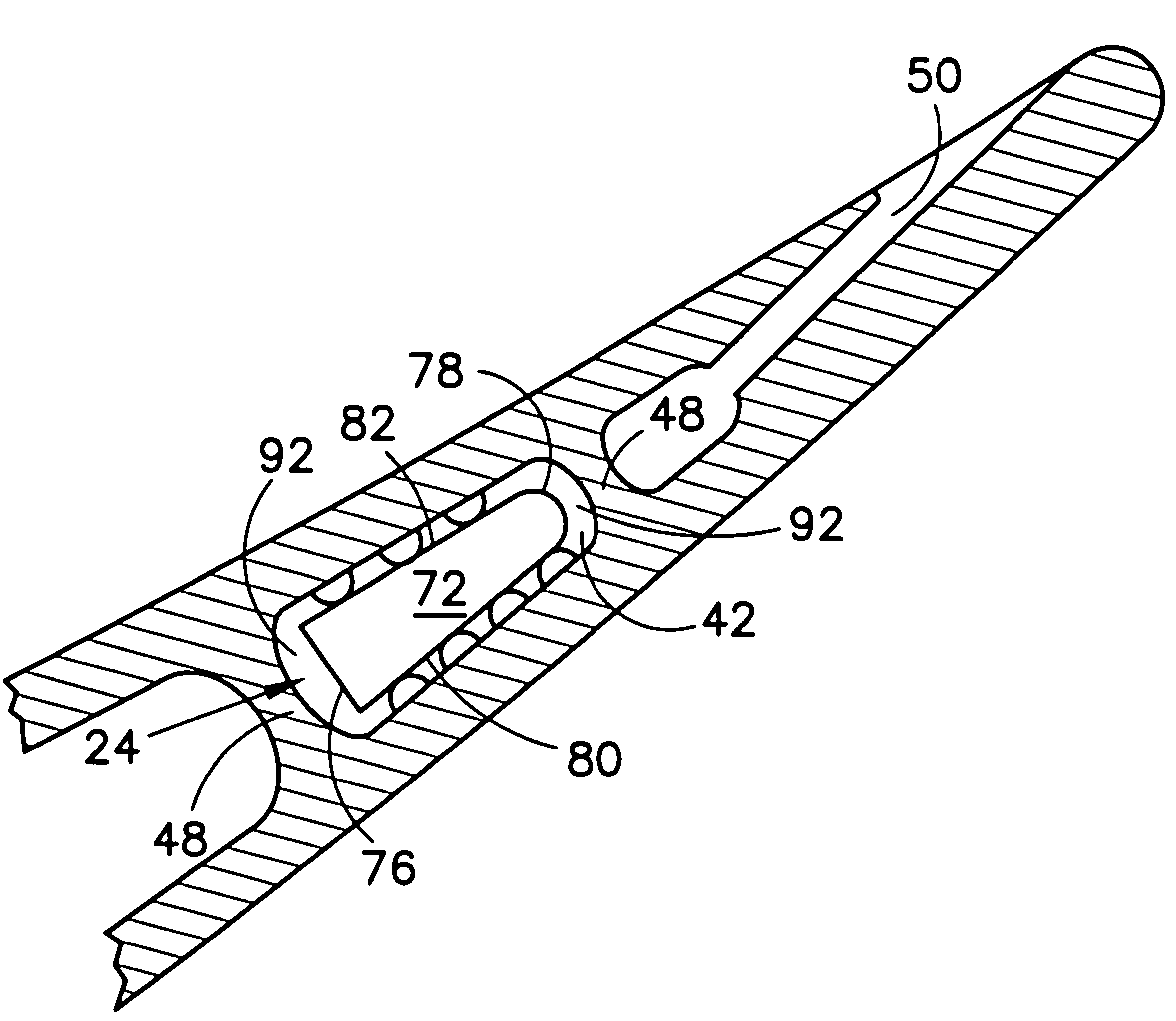

Cooled rotor blade with vibration damping device

ActiveUS7125225B2Evenly dispersedReduce chancePropellersEngine manufactureEngineeringBearing surface

A rotor blade for a rotor assembly is provided that includes a root, an airfoil, and a damper. The airfoil has a length, a base, a tip, a first side wall, a second side wall, and at least one cavity. The length extends the base and the tip. The at least one cavity is disposed between the side walls, and the channel is defined by a first wall portion and a second wall portion. The damper, which is selectively received within the channel, includes a first bearing surface, a second bearing surface, a forward surface, and an aft surface, all of which extend lengthwise. At least one of the surfaces is shaped to form a lengthwise extending passage within the channel. The passage has a flow direction oriented along the length of the at least one surface to permit cooling air travel along the at least one surface in a lengthwise direction. According to one aspect of the present invention, the damper has an arcuate lengthwise extending centerline.

Owner:RTX CORP

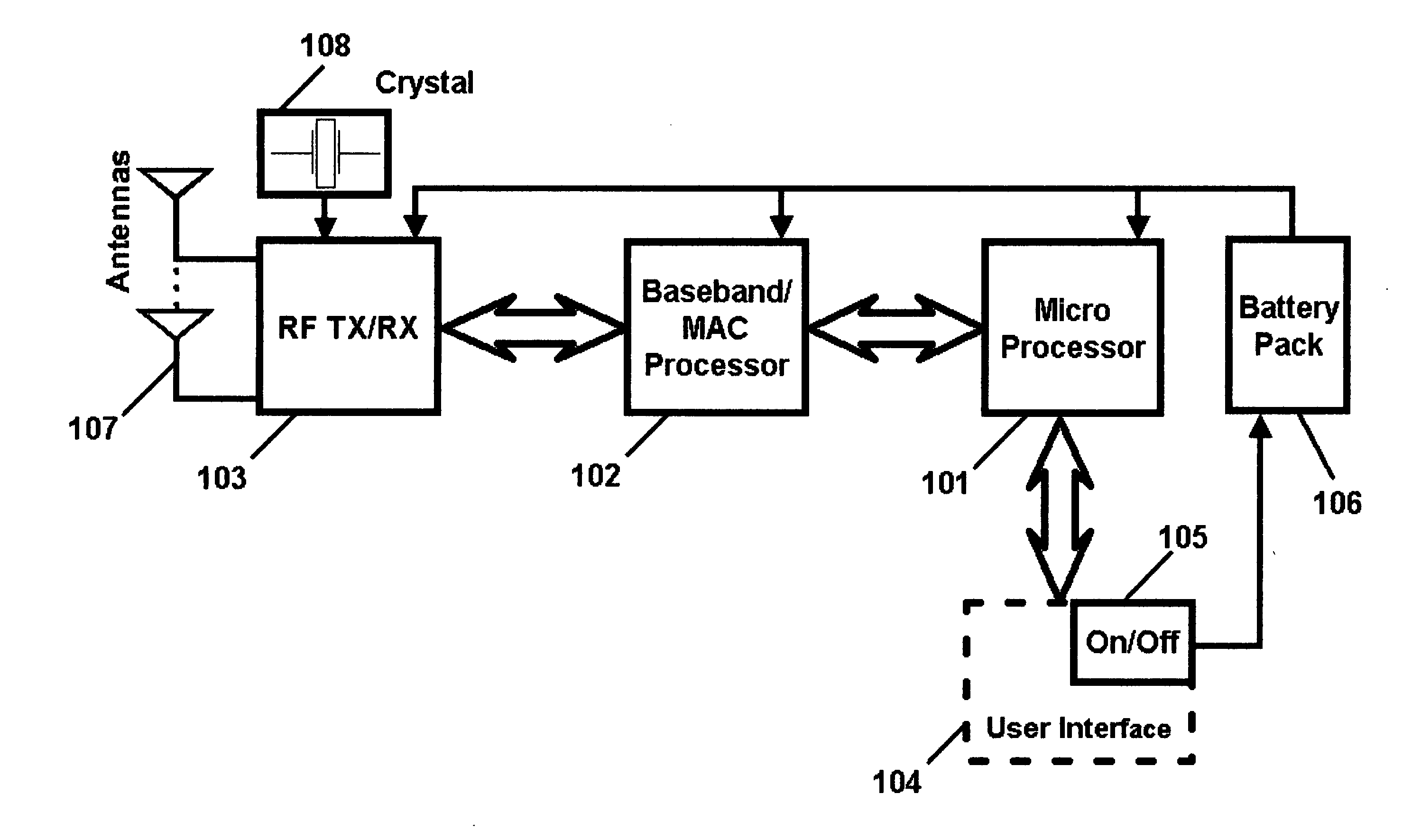

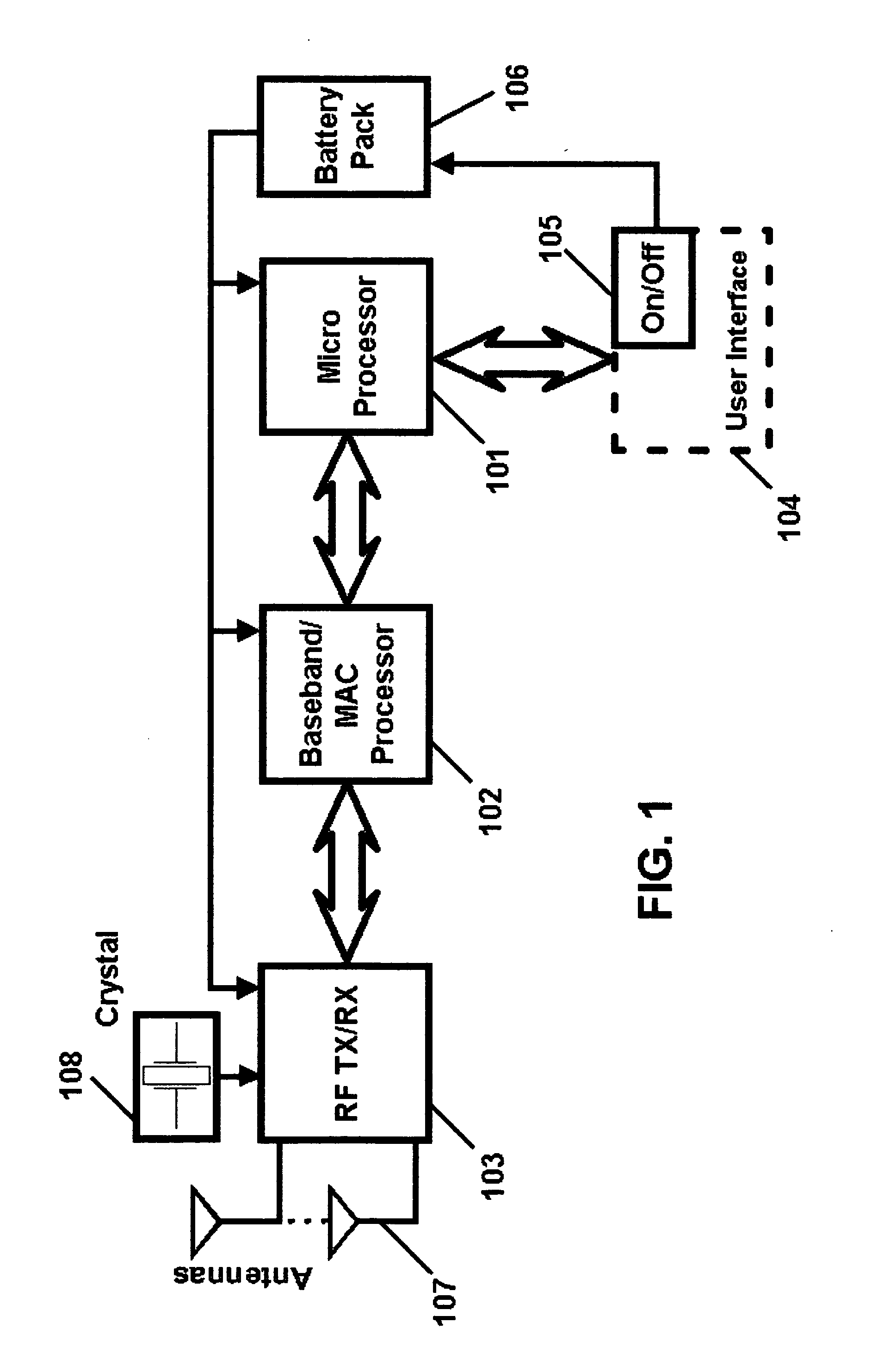

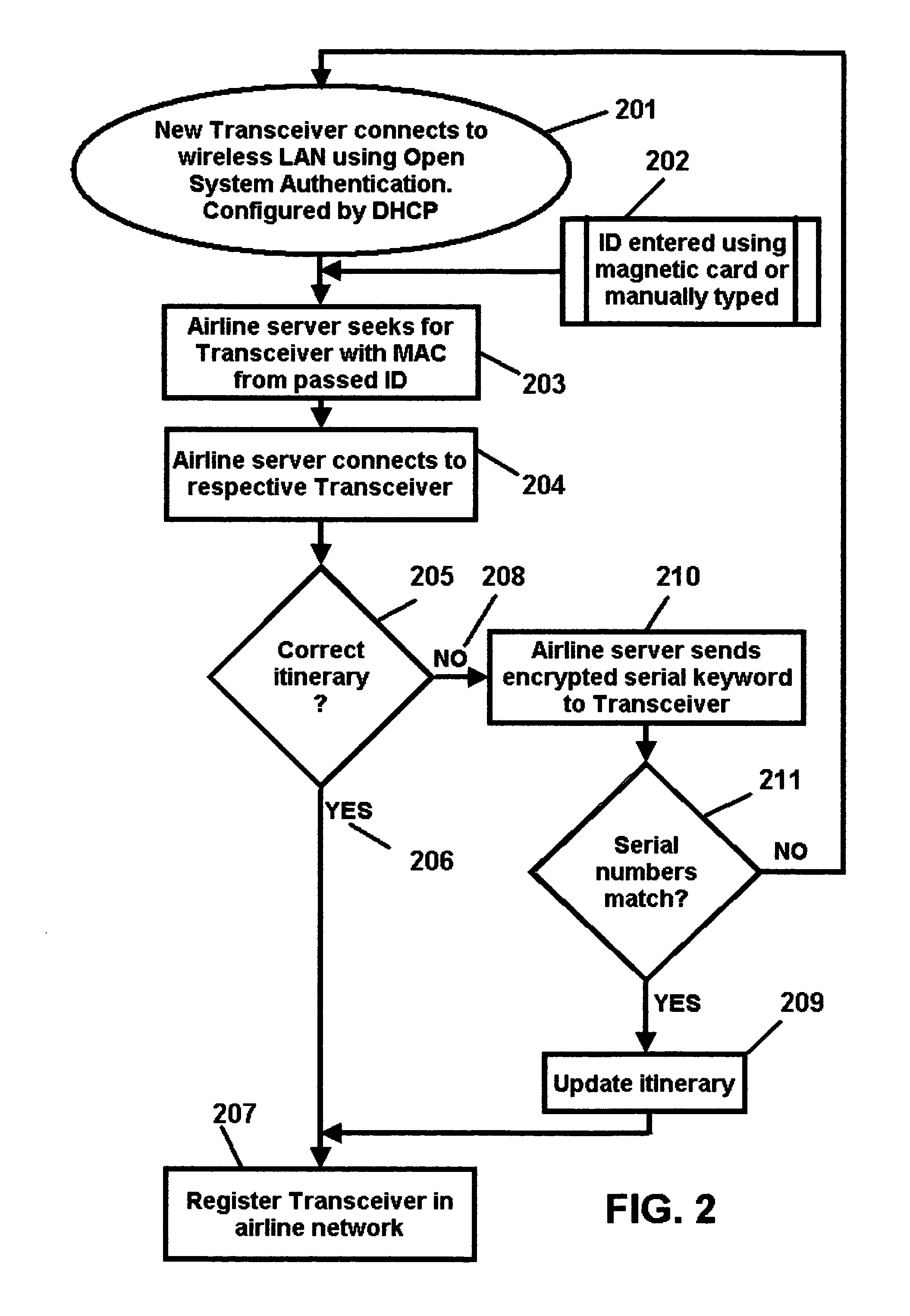

Intelligent air travel tag for asset self-tracking

InactiveUS20060097046A1SpeedLow-powerNetwork topologiesElectric/electromagnetic visible signallingAviationTransceiver

A system for luggage self-tracking / identification during air travel involves a programmable, wireless LAN active transceiver preferably located inside each piece of luggage, with controlled access to the airlines' luggage tracking networks. Prior to a flight, each transceiver is loaded with the passenger's itinerary, and logged in the airline's network at check-in. Each transceiver is uniquely identifiable by the luggage tracking network. An example of a preferred identifier would be the utilization of its Medium Access Control (MAC) and its alphanumeric serial keyword to provide unique and secure registration / identification of the transceiver in the airline's network. During the trip, which may include different stopovers before reaching the final destination, the transceiver is able to automatically compare its programmed itinerary with its current location via wireless access to the airports and aircraft wireless LANs. In this way, the transceiver is able to notify airline personnel if there is a disagreement between its programmed itinerary and its current location, thus preventing misrouting. The transceiver's itinerary can be wirelessly re-programmed by airline personnel / network to account for flight changes or delays. Finally, the transceiver has an internal timer that starts counting down from the expected “total traveling time”, accounting for flight changes or delays. If this timer elapses without the itinerary being complete, the transceiver connects to a wireless access point (hotspot) to report itself as a missing luggage, avoiding a worldwide tracking initiative and speeding up recovery time.

Owner:DEFERO SYST

Mixer assembly for combustor of a gas turbine engine having a plurality of counter-rotating swirlers

ActiveUS7581396B2Emission reductionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorAcute angle

Owner:GENERAL ELECTRIC CO

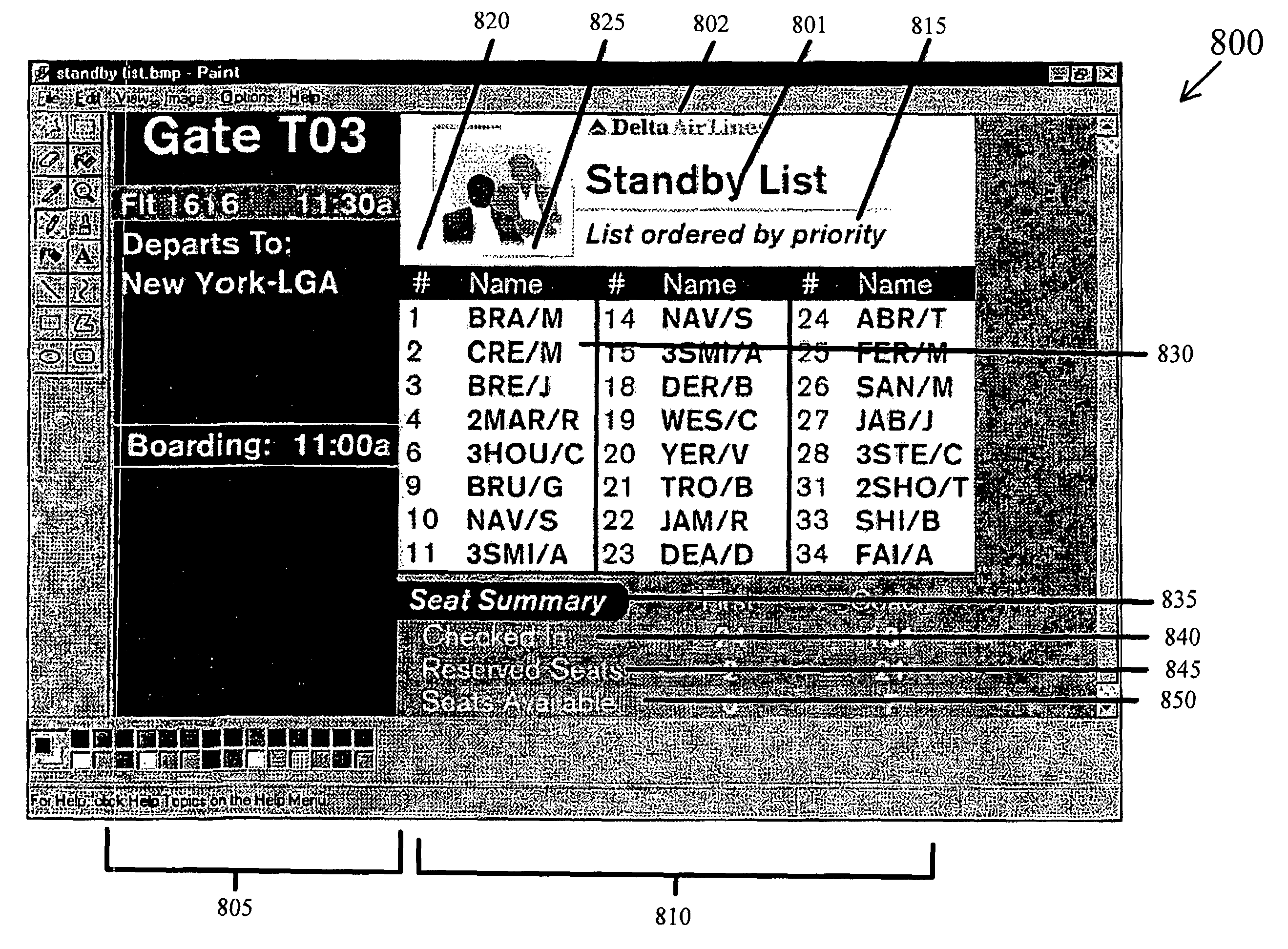

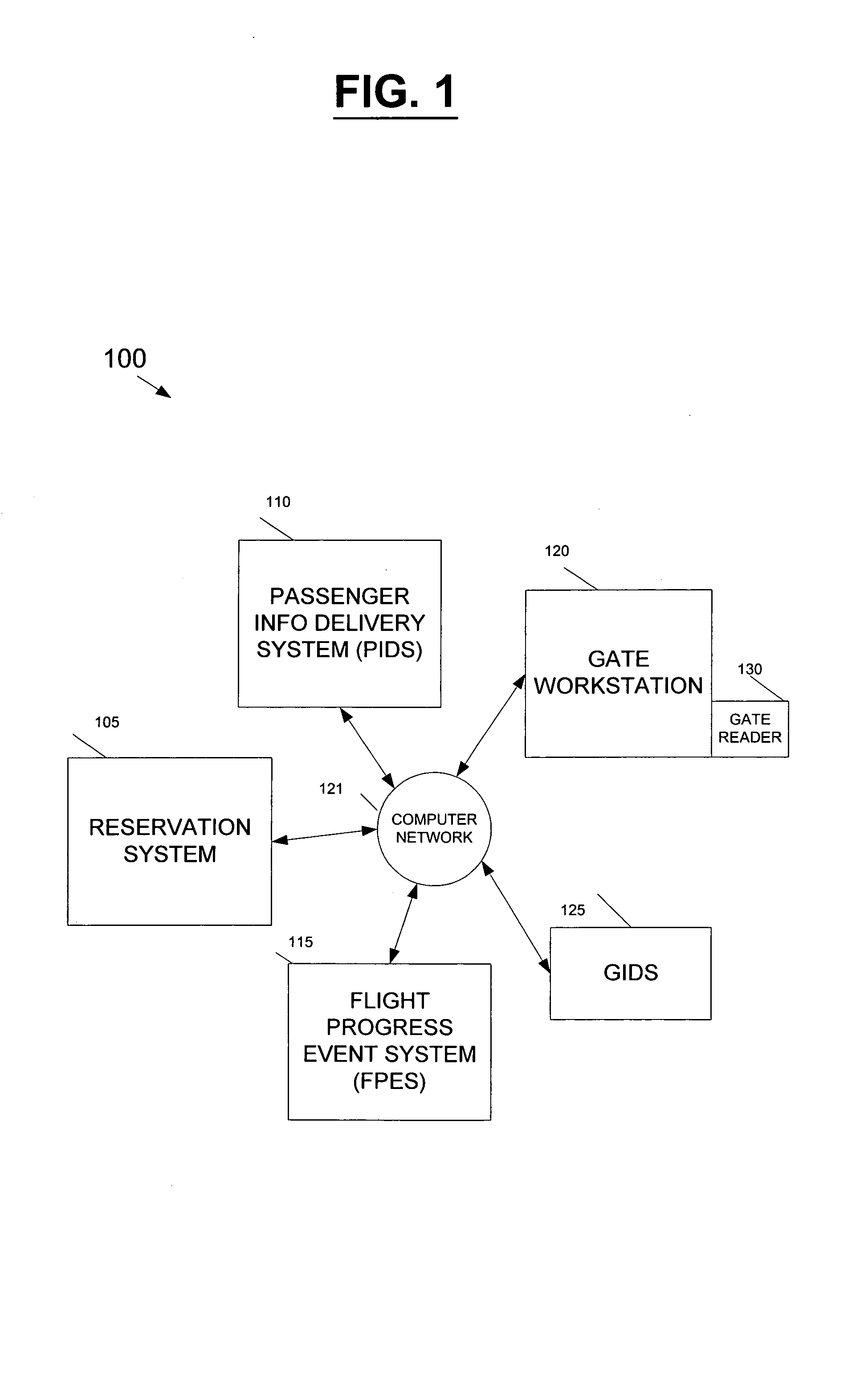

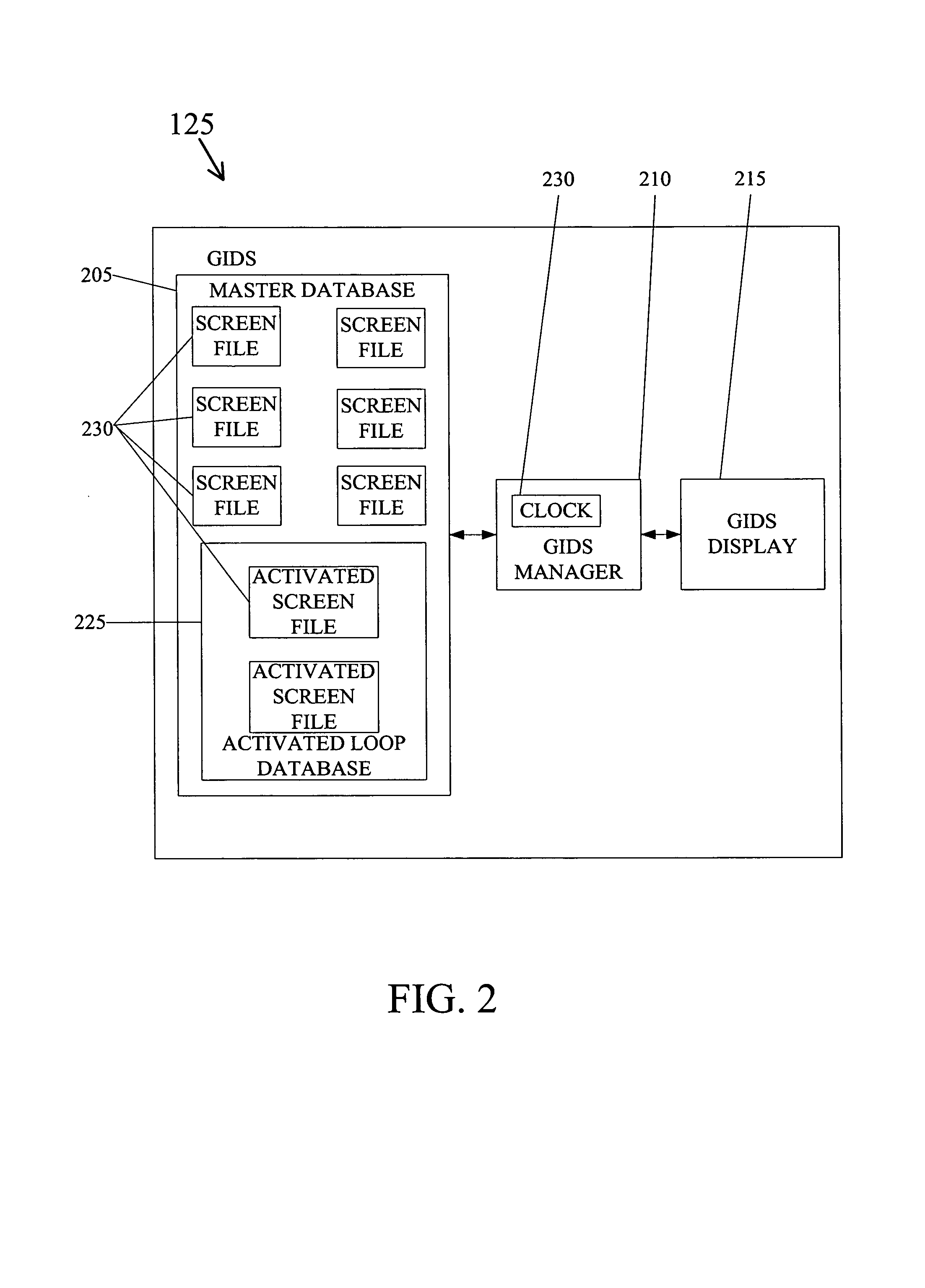

Method and system for providing dynamic and real-time air travel information

Providing passengers and other interested parties with dynamic and real-time air travel information. This dynamic and real-time air travel information is shown in various screens on a computer monitor, and includes flight information, passenger information, other general air information, and advertising. The information is presented to passengers in a manner which reduces passenger wait time and allows gate agents to focus on other responsibilities. Information on seat standby status, upgrade standby status, and cleared standby status is provided on the computer monitor.

Owner:DELTA AIR LINES

Centerbody for mixer assembly of a gas turbine engine combustor

A mixer assembly for use in a combustion chamber of a gas turbine engine includes a pilot mixer, a main mixer and a centerbody positioned between the pilot mixer and the main mixer. The pilot mixer includes an annular pilot housing having a hollow interior and a pilot fuel nozzle mounted in the housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing. The main mixer includes: a main housing surrounding the pilot housing and defining an annular cavity; a plurality of fuel injection ports for introducing fuel into the annular cavity; and, a swirler arrangement including at least one swirler positioned upstream from the fuel injection ports, wherein each swirler of the arrangement has a plurality of vanes for swirling air traveling through such swirler to mix air and the droplets of fuel dispensed by the fuel injection ports. The centerbody includes a fuel manifold therein for providing fuel to the fuel injection ports and an air manifold therein for providing air to an aft portion of the pilot mixer and / or the aft portion of the annular cavity in the main mixer.

Owner:GENERAL ELECTRIC CO

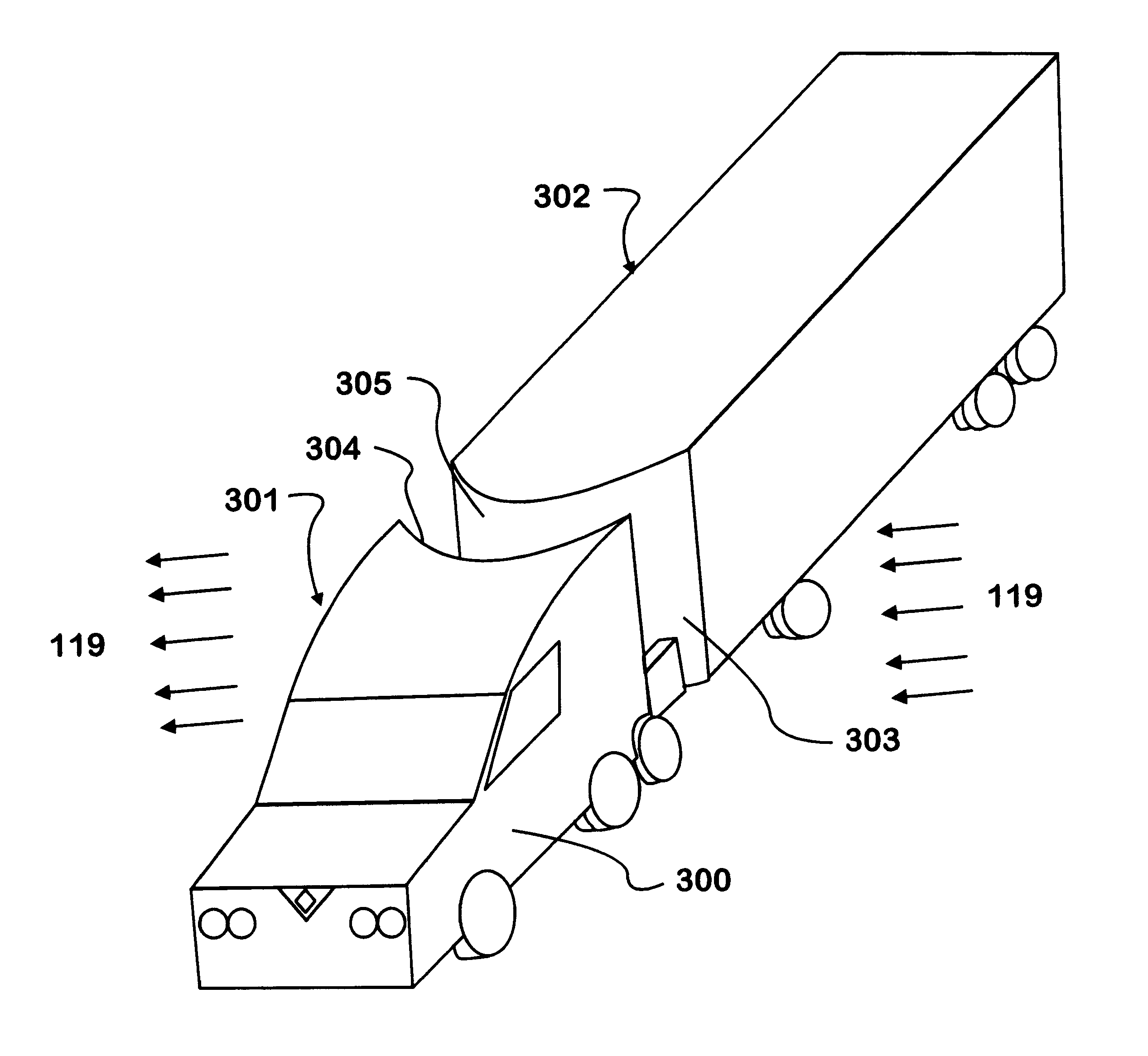

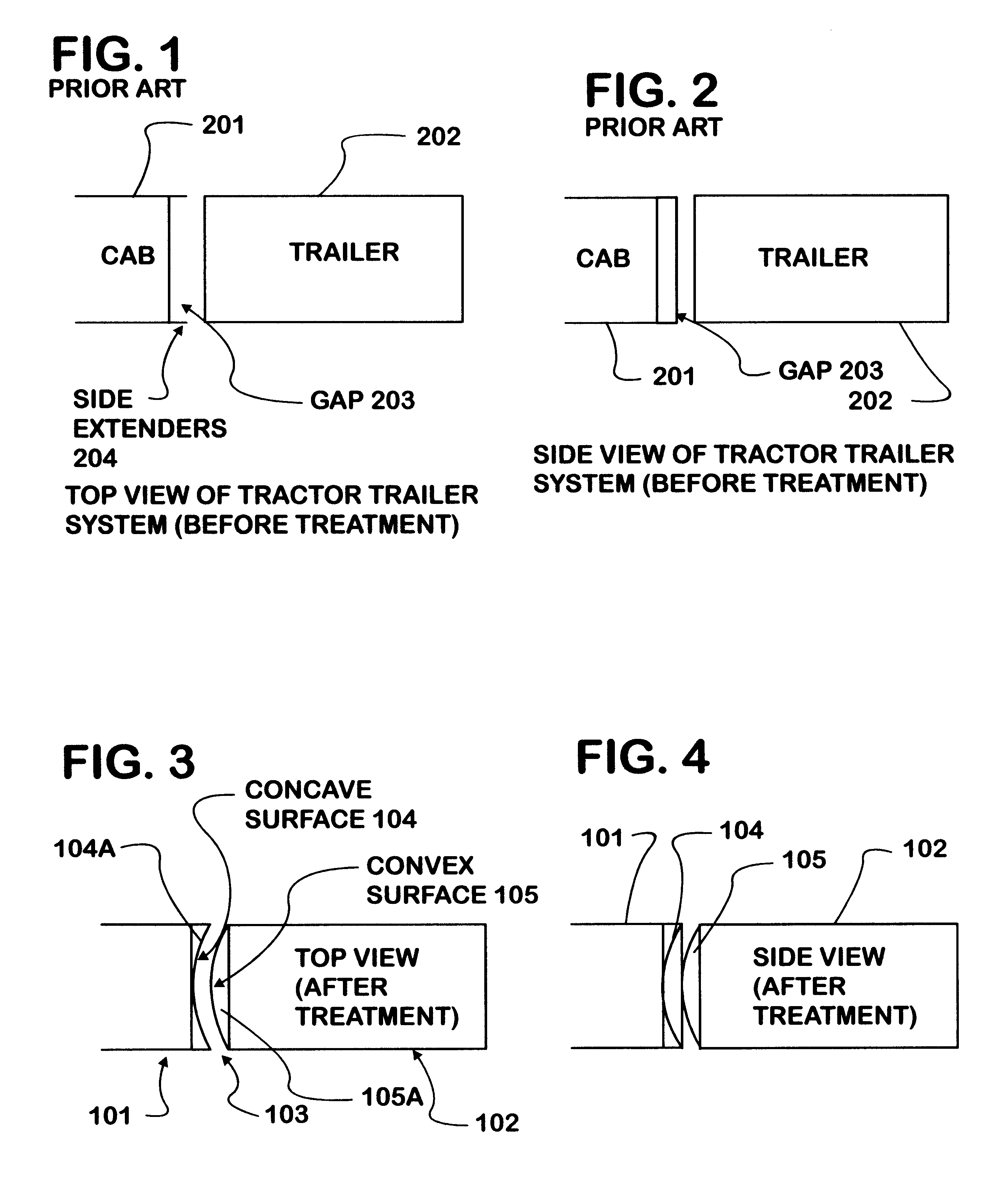

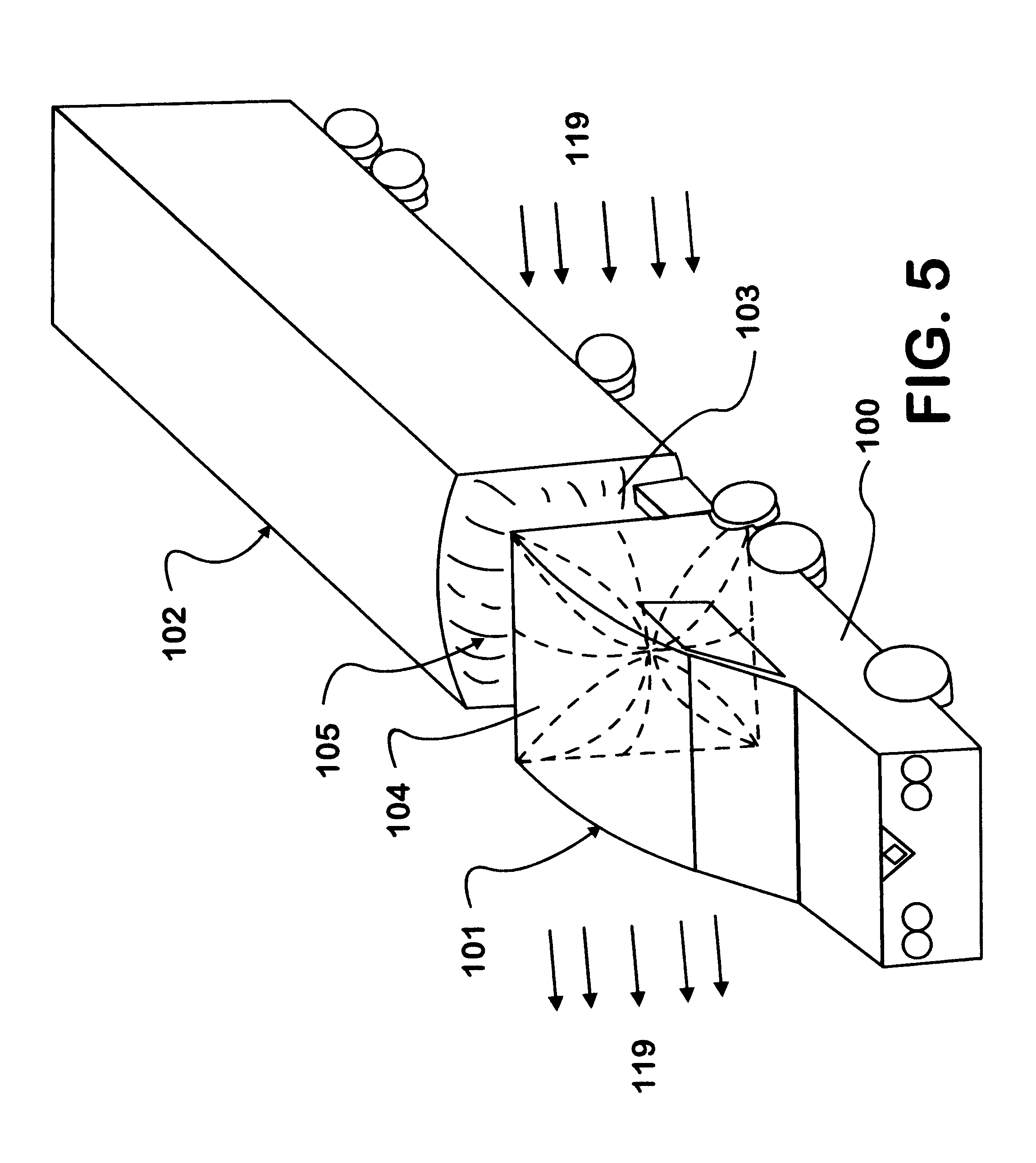

Tractor trailer gap treatment

A tractor-trailer system uses aerodynamic principles to use crosswind to its advantage. The system has a curvilinear duct by having a attaching a convex body on the trailer front and a concave body on the back of the cab. When a cross wind enters the gap, it creates a negative pressure (compare to ambient) on the convex surface (trailer front) and a positive pressure on concave surface (back of the cab). Both of these pressures will help reduce the drag. Further having the crosswind flow smoothly can lead to less turbulence intensity in the gap, which can help in improving handling qualities of the system. There is a similar situation both for drag as well as handling qualities can be given for the air traveling in vertical direction (even at zero cross wind).

Owner:INT TRUCK INTPROP LLC

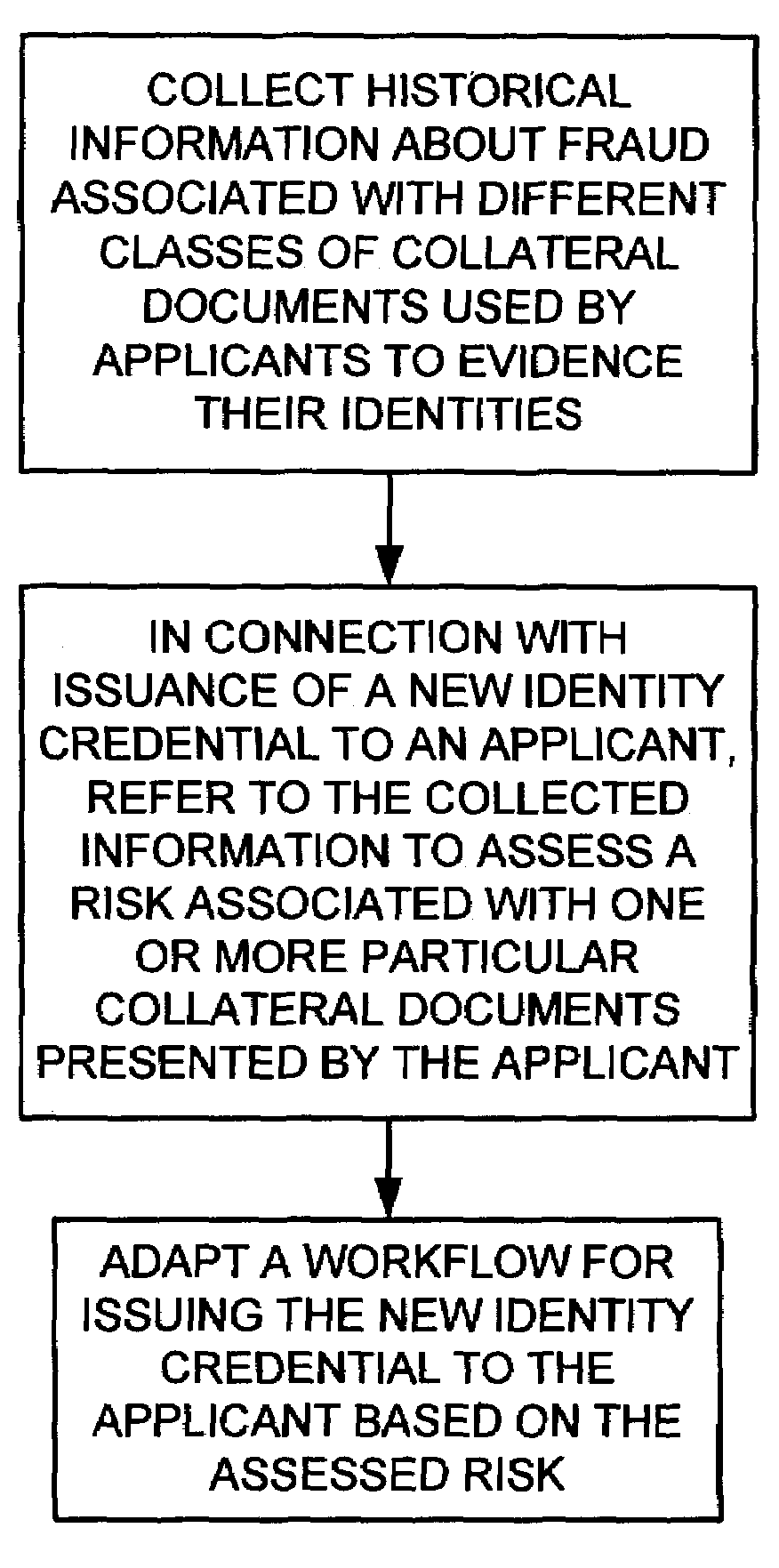

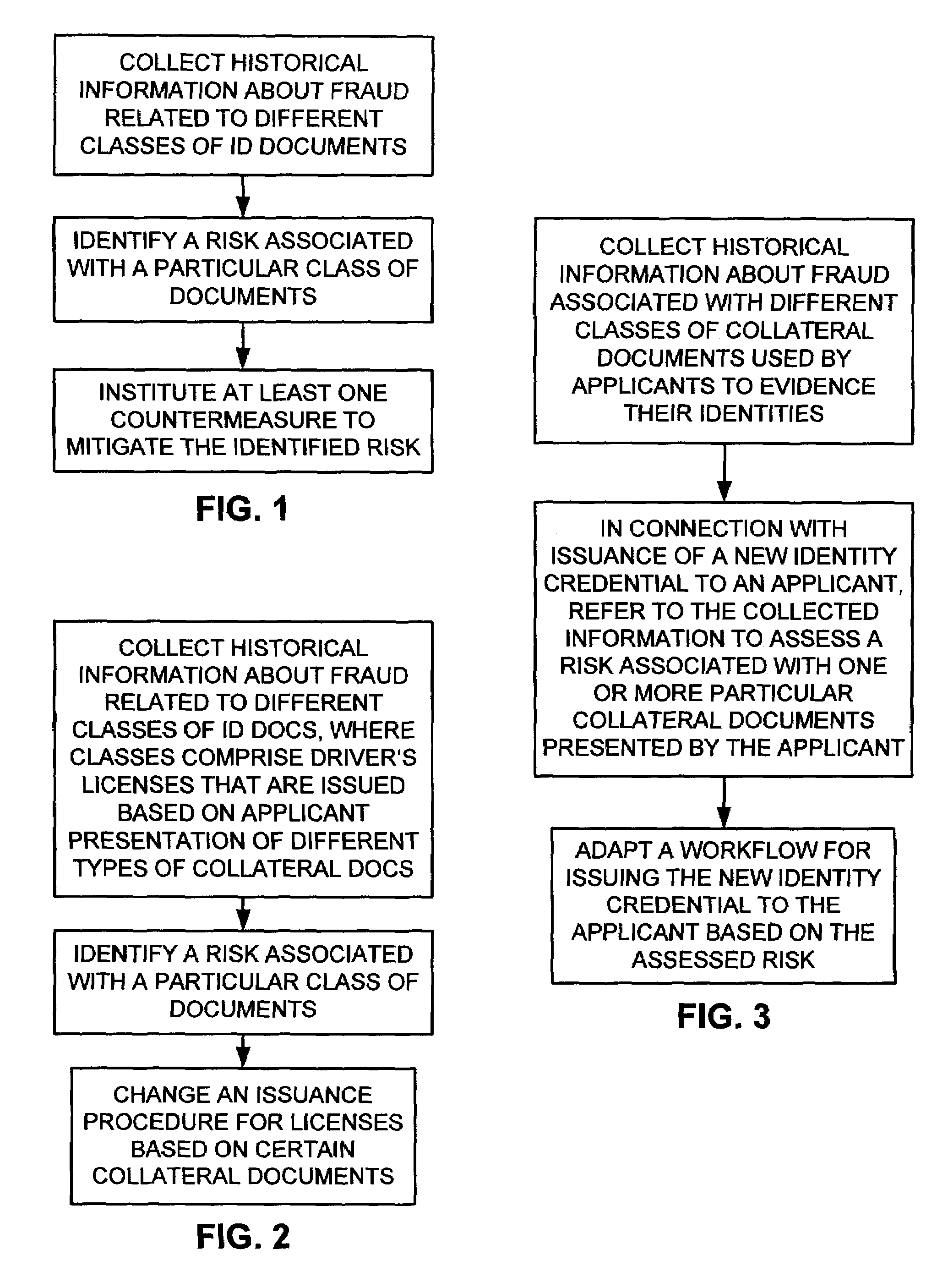

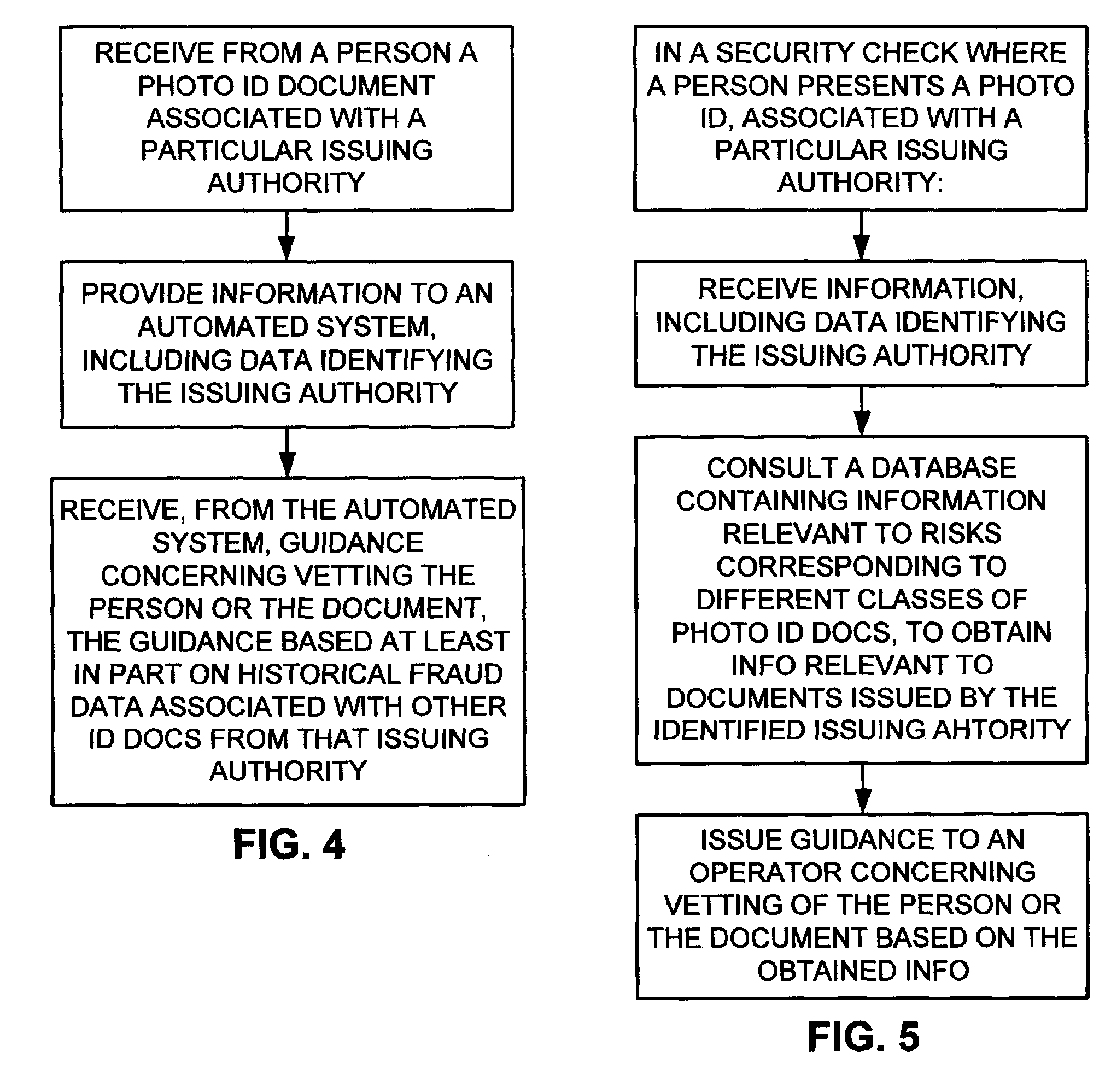

Fraud deterrence in connection with identity documents

According to one aspect, an air travel agent who reviews photo IDs of prospective travelers is advised by an expert system that directs the agent to give certain travelers more or less (or different) scrutiny, depending on the type of photo ID they present (e.g., depending on the jurisdiction from which their driver's license was issued). The system relies on a database in which historical incidents of fraud associated with different types of identification documents are logged, thereby serving as a resource by which future frauds might be better identified. Events that may signal increases in fraud beyond historical norms for particular types of ID documents, such as reported thefts of security laminates or other consumables used in their production, can also (or alternatively) be tracked in the database, and considered by the expert system. Such techniques allow security personnel to focus their efforts where they will do the most good. A variety of other technologies for mitigating fraud risks are also detailed.

Owner:L 1 SECURE CREDENTIALING

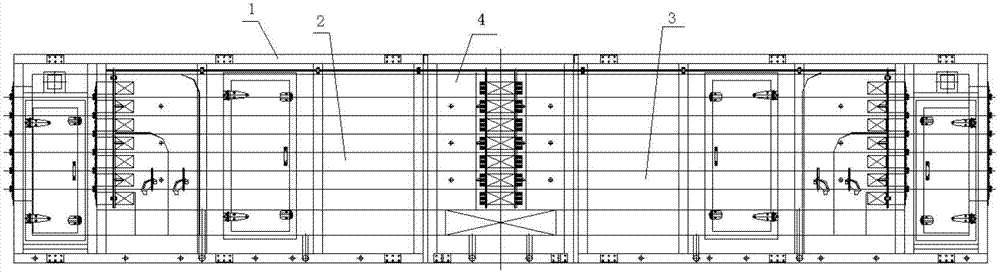

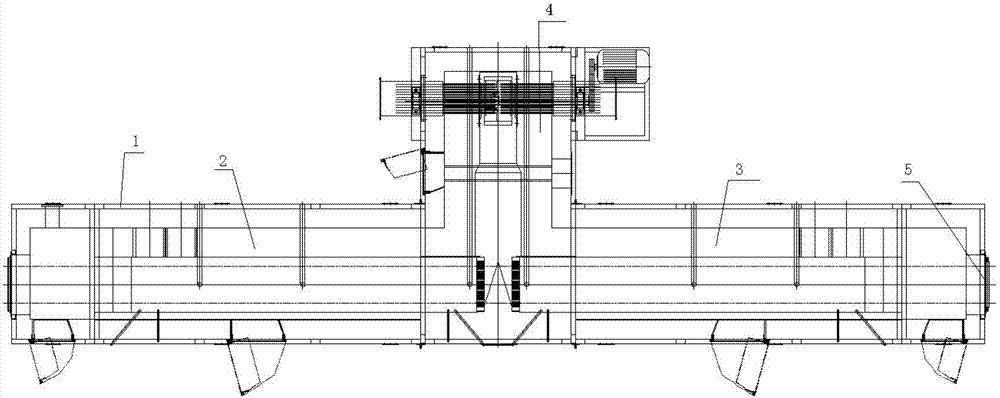

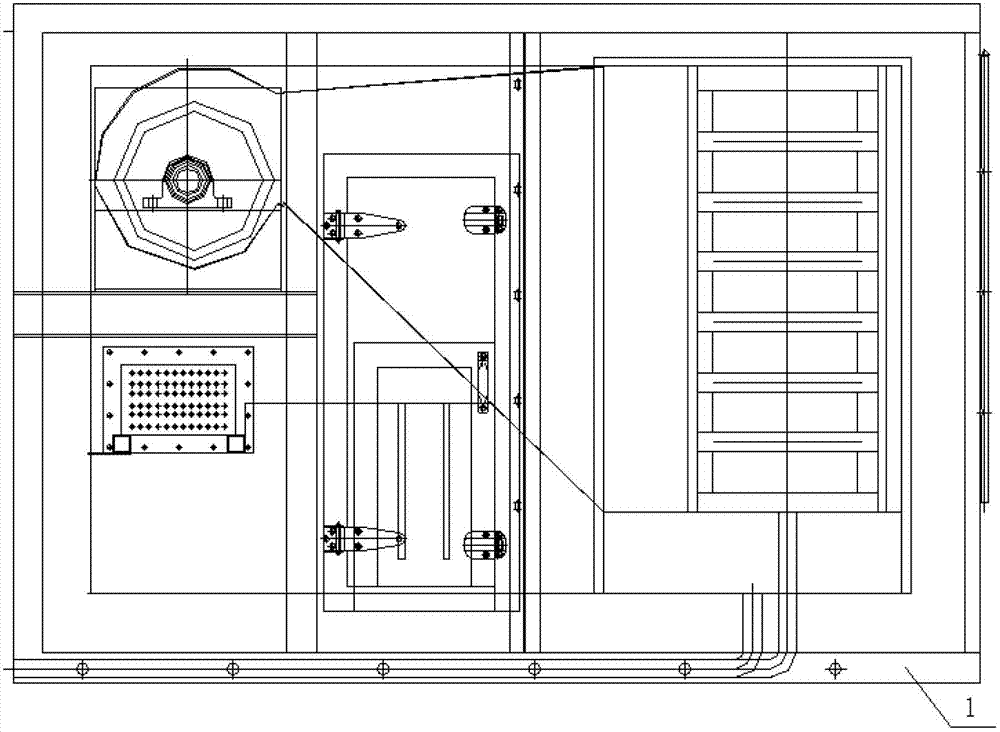

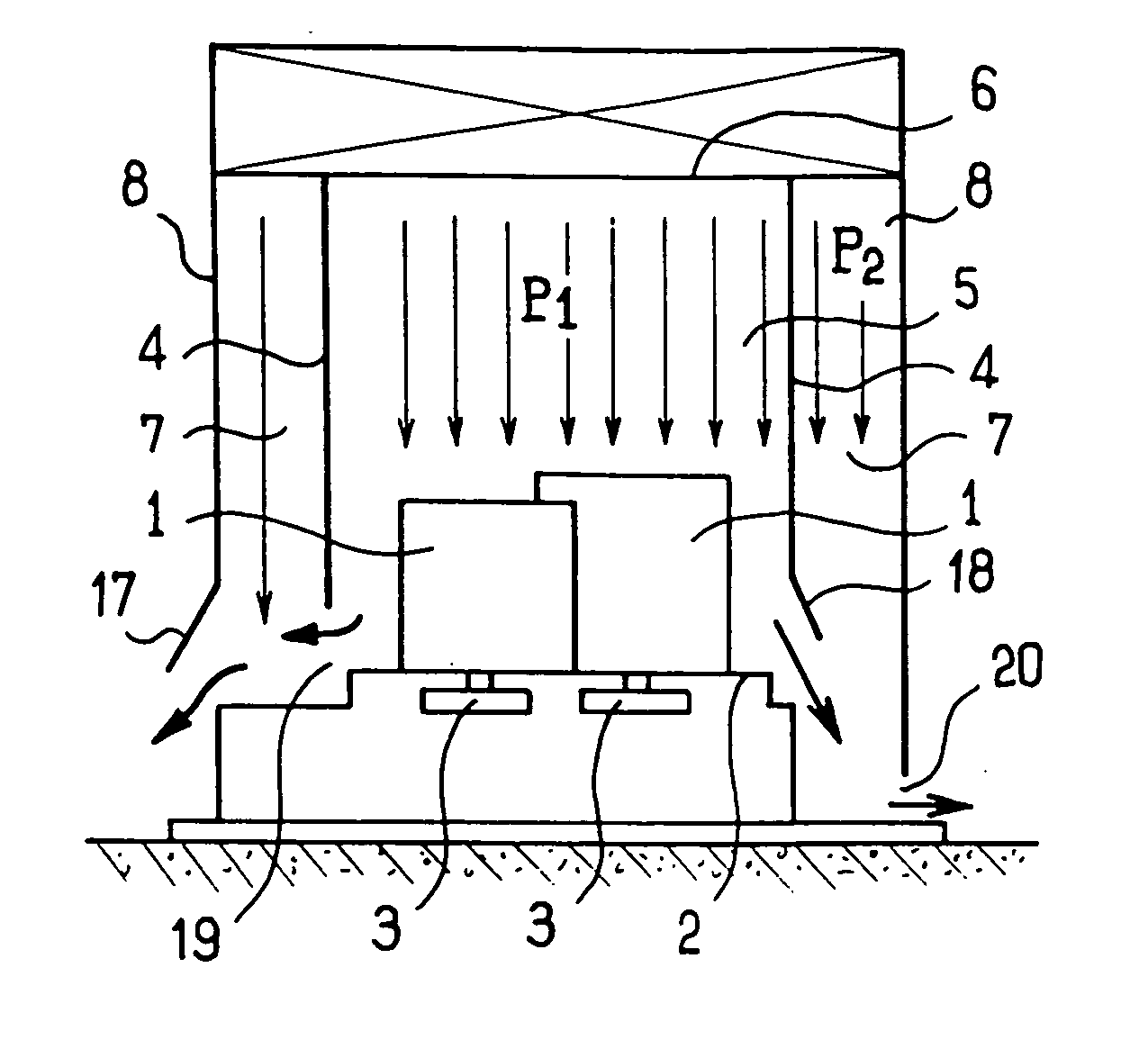

High-performance carbon fiber pre-oxidation furnace

ActiveCN102758270AAvoid burnsPrevention of legitimate discharge problemsFibre chemical featuresFiberCarbon fibers

The invention discloses a high-performance carbon fiber pre-oxidation furnace which is specially designed for carrying out heat treatment on a high-performance carbon fiber material at a temperature below 350 DEG C. A furnace body is designed into a building block structure and is convenient to assemble and disassemble. For the design of the furnace, the requirements of a preparation process of the high-performance carbon fiber material are fully considered and understood and the key special requirements of the preparation process of the high-performance carbon fiber material are met to the greatest extent. According to the requirements of the preparation process of the material, a circulating hot air heating mode is adopted for the pre-oxidation furnace; for a circulating air traveling mode, air is blown to two ends of the furnace body from the middle of the furnace body; and a plurality of heat treatment cavities are connected in series and in parallel to form a system with a certain temperature gradient. An anticorrosion stainless steel structure is adopted for an inner hearth totally; a full-fiber superlight material is adopted as a heat insulating material to carry out heat insulation; a PLC (Programmable Logic Controller) temperature control module is used for temperature control and has the characteristics of high temperature control accuracy, high temperature stability and the like; and according to the pre-oxidation furnace, in a pre-oxidation process, the problems of low heat treatment efficiency, inaccurate temperature control and unideal temperature uniformity in the heat treatment cavities are solved, protofilament combustion is prevented, sufficient supplementation of the oxygen content in the hearth is realized and waste gas is reasonably discharged. The integral high-performance carbon fiber pre-oxidation furnace has relatively low energy consumption and is durable.

Owner:HEFEI RISINE HEATEK

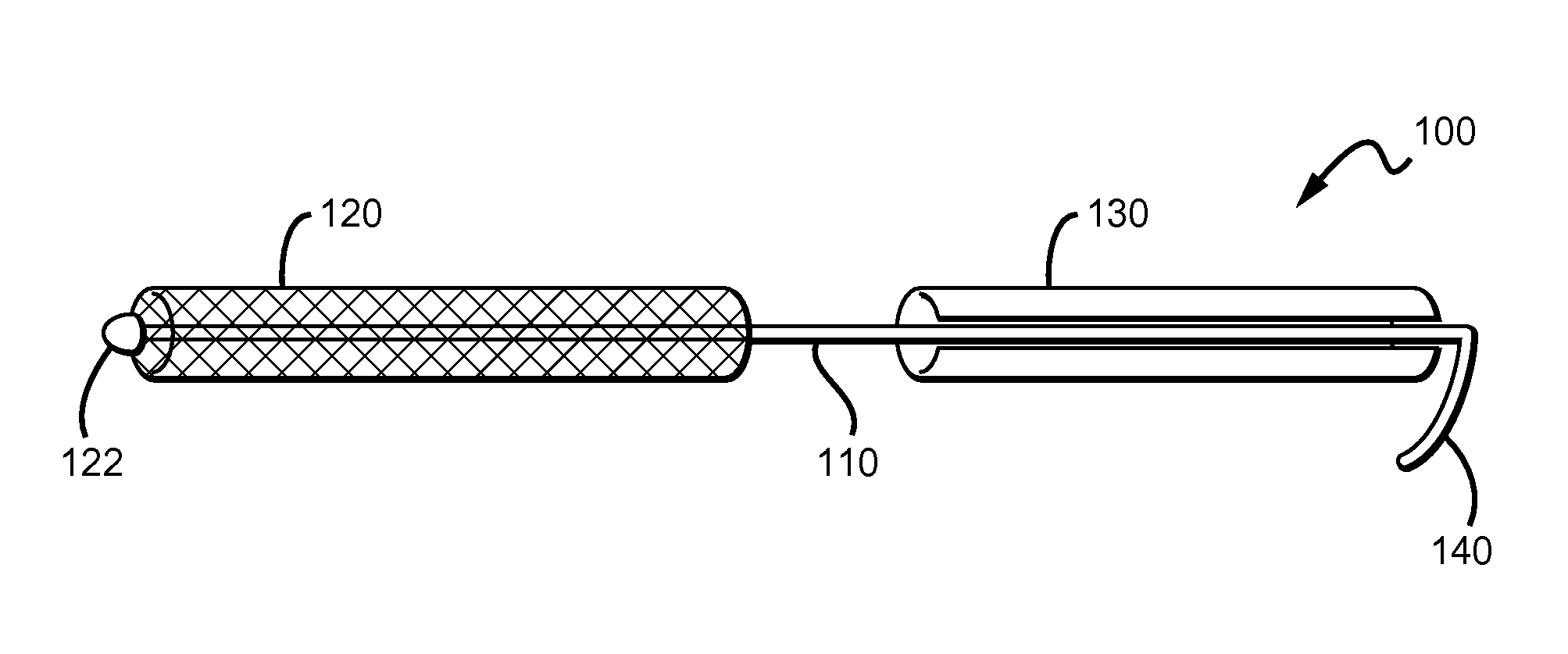

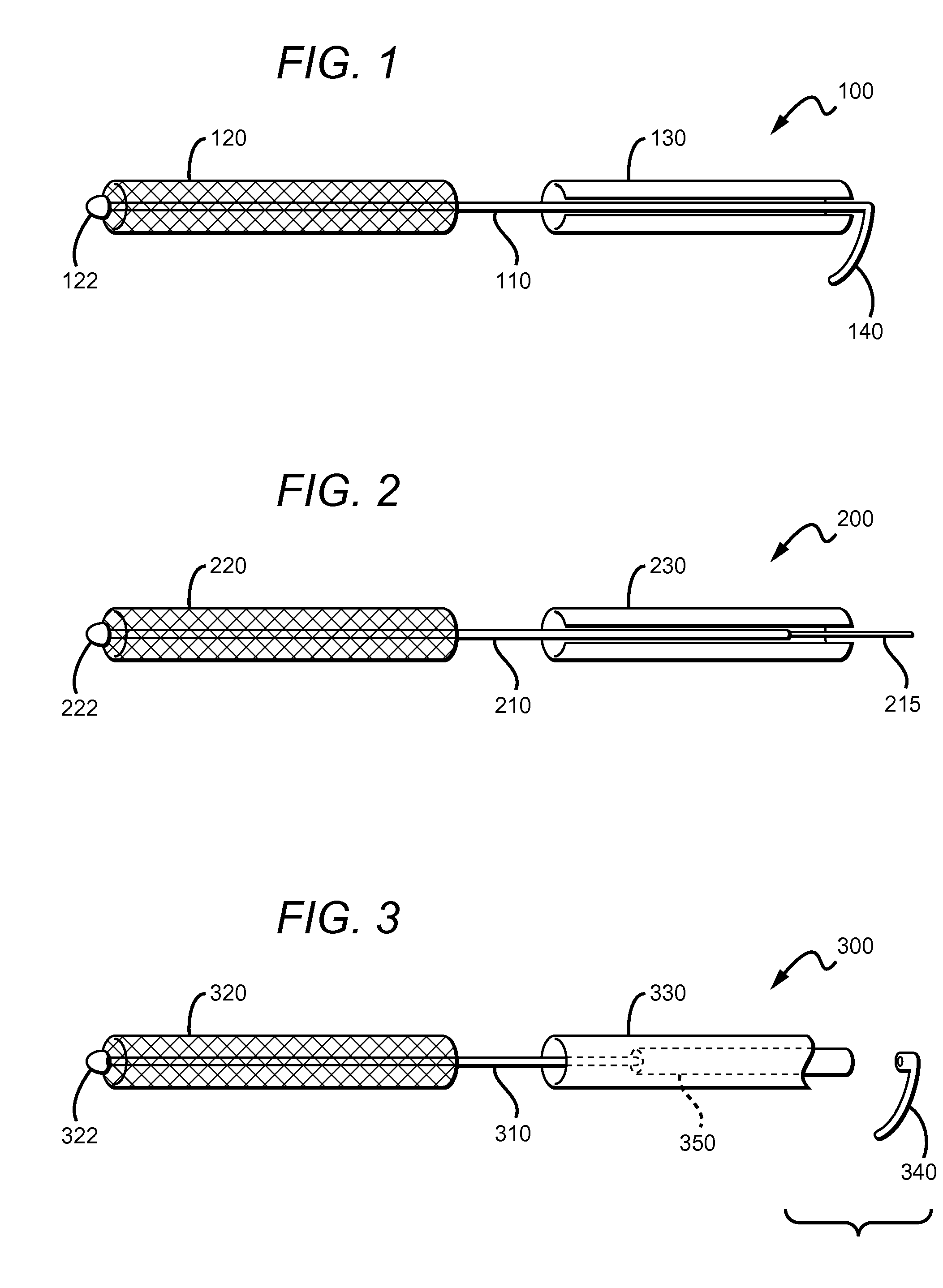

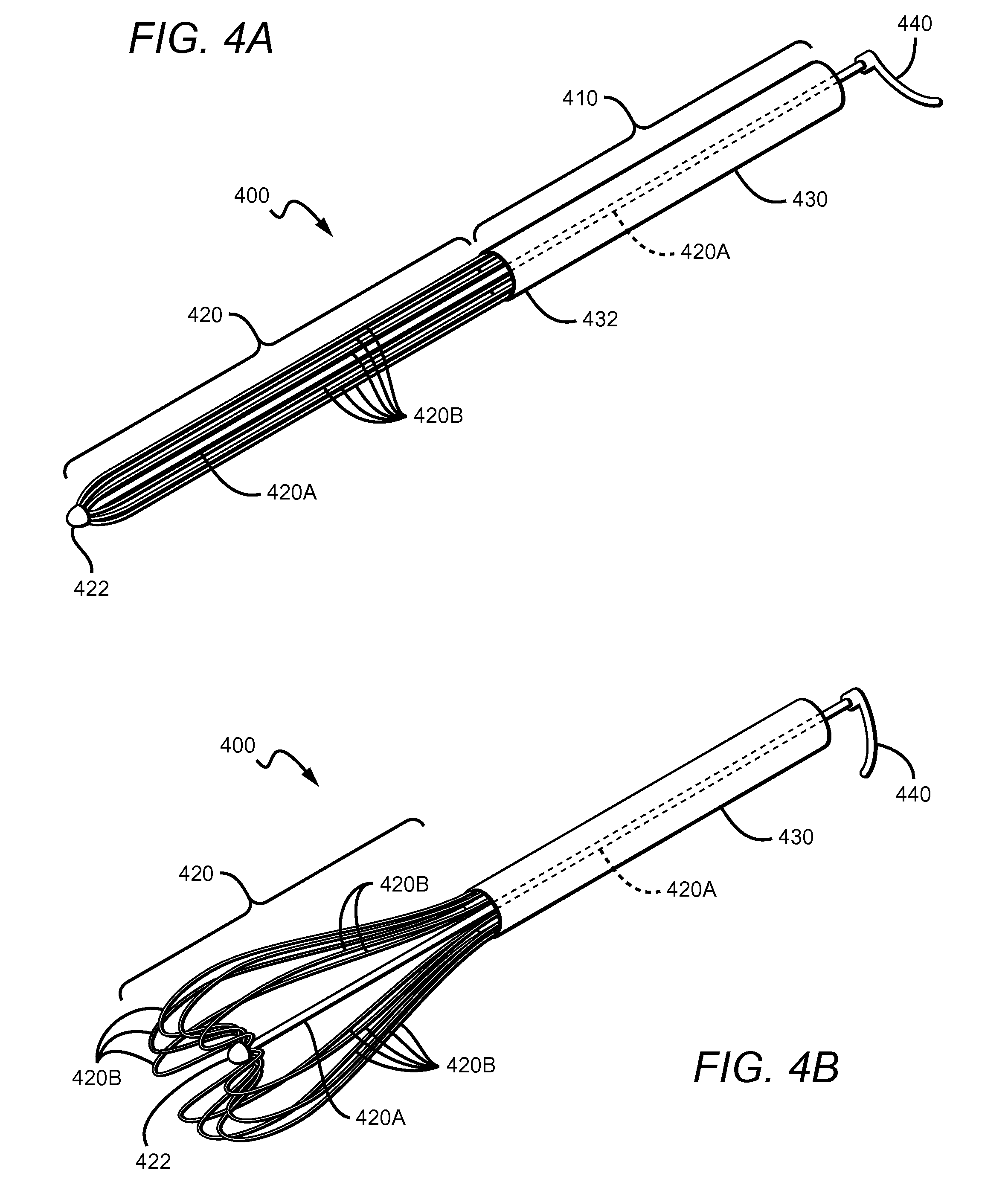

Nasal Catheter With Internal And External Air Flows

A nasally introduced catheter (nasal catheter) has a portion in which a user's breath (breathing air) air travels internally and a portion in which the breath travels externally. The portion in which air flow travels internally preferably includes a mesh or a whisk-like portion that expands and contracts, and the portion in which air flow travels externally preferably comprises a proximal tubular element having a sufficiently small cross-sectional area that at least 50% of the breathing air flows externally to the proximal portion. A sheath can optionally be positioned about the distal portion, and pulled back along the proximal portion to allow the distal portion to expand. In other aspects users can anchor the proximal and distal portions relative to the sheath using a nose clip or by removably coupling an extension arm to proximal portion

Owner:RESPIRION

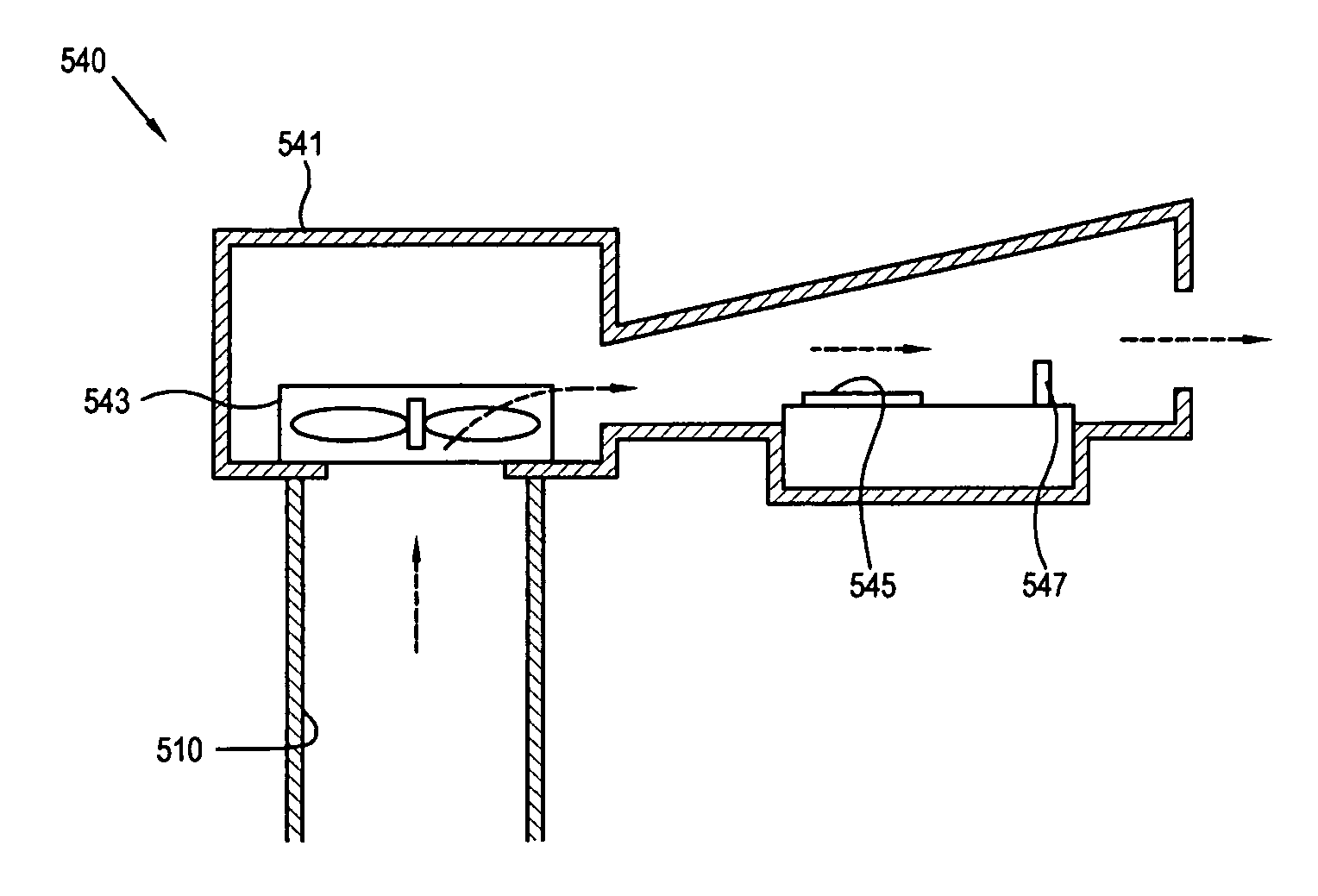

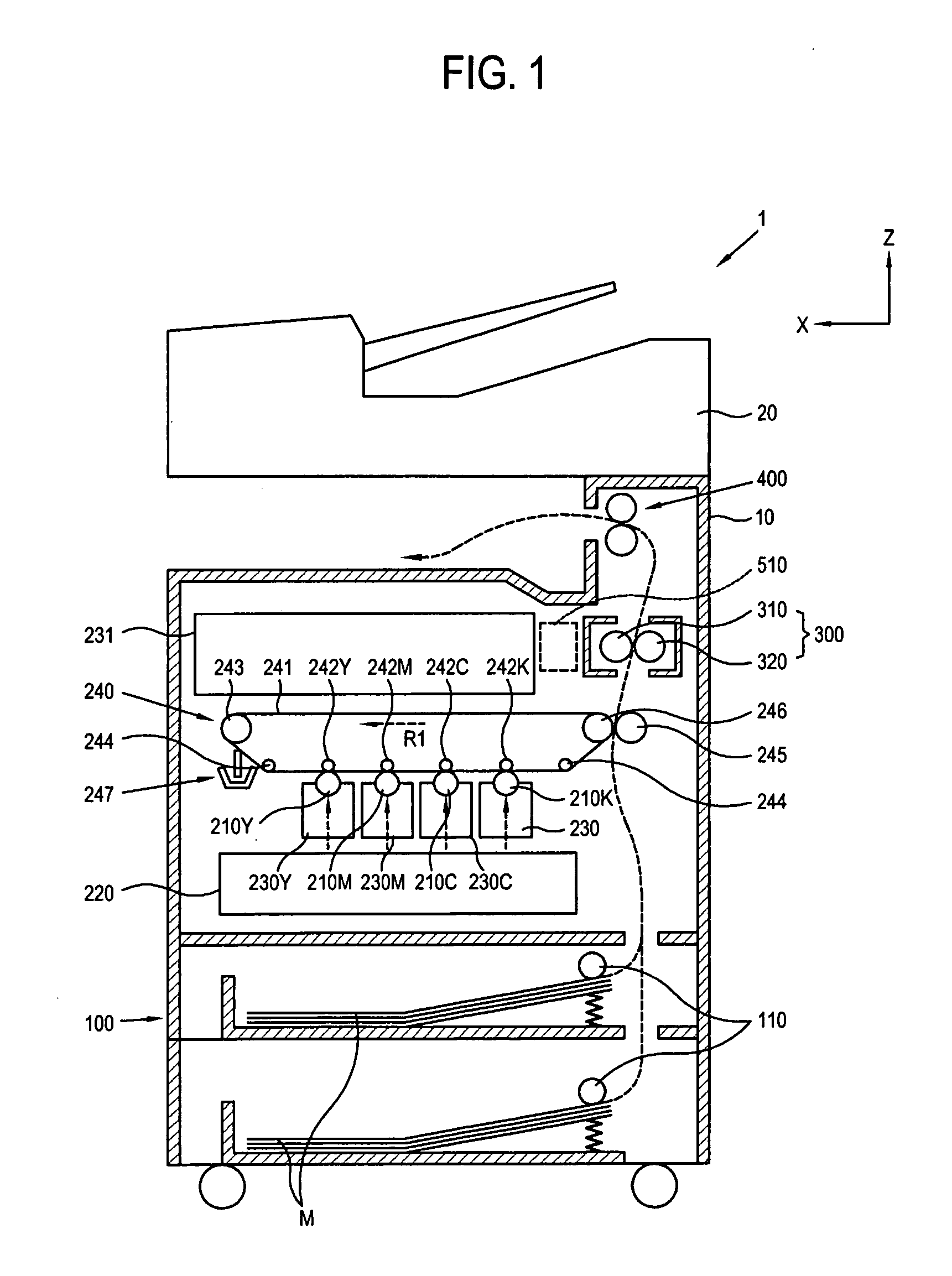

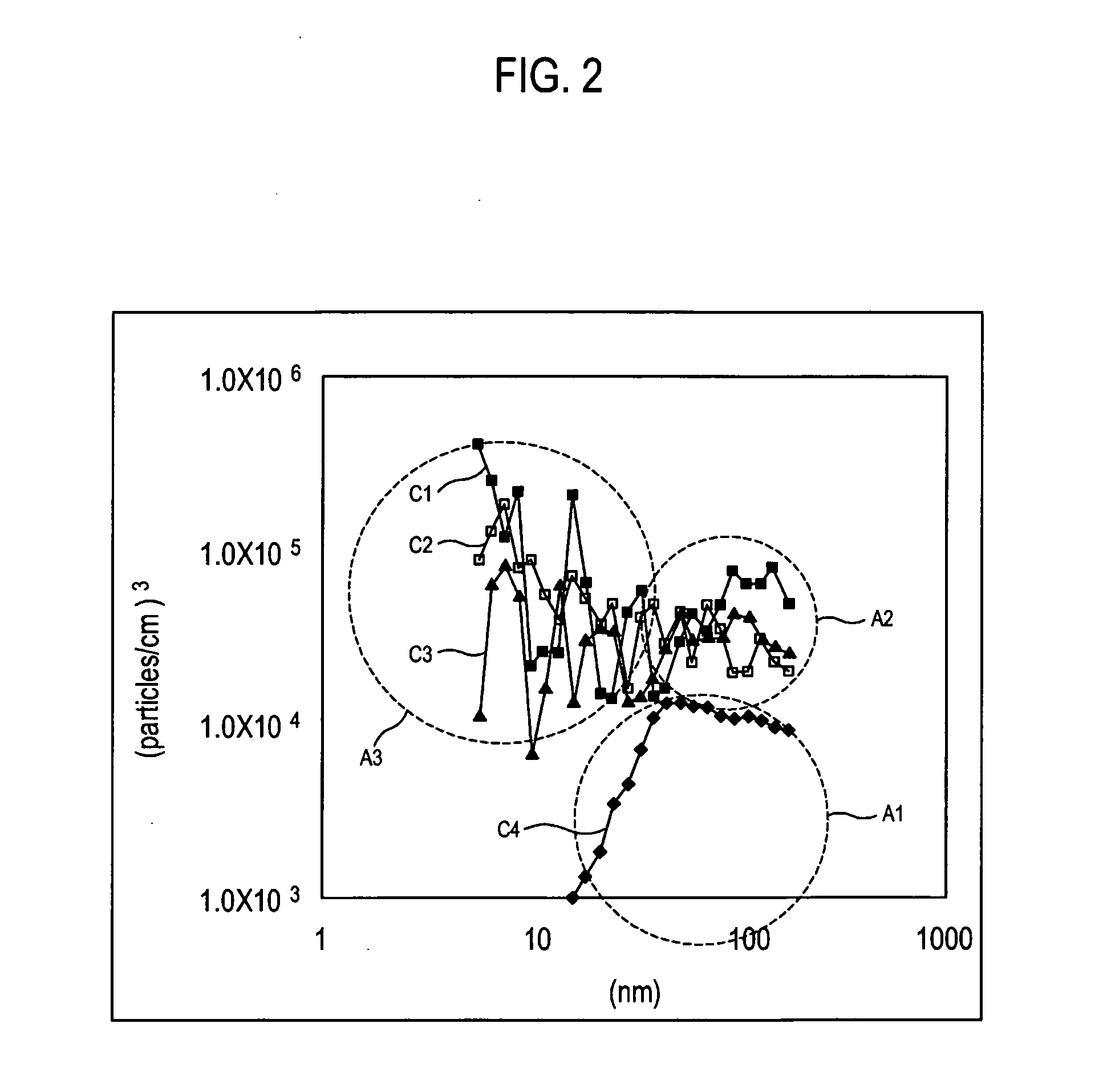

Image forming apparatus

ActiveUS20110255895A1Efficient releaseDisinfectionElectrographic process apparatusImage formationEngineering

An image forming apparatus including: a body housing; a paper feeding unit accommodated in the body housing and providing a recording medium; an image forming unit accommodated in the body housing and forming an image on the recording medium; a fixing unit accommodated in the body housing and fixing the image formed by the image forming unit; and a cooling unit including a channel including an inhalation part and a discharging part which are formed in the body housing for air to flow, extending between the inhalation part and the discharging part and formed adjacently to the fixing unit, and an air purification module installed in the channel and generating ions reacting to foreign substances in air traveling through the channel to purify the air, and discharging heat generated in the fixing unit to the outside.

Owner:HEWLETT PACKARD DEV CO LP

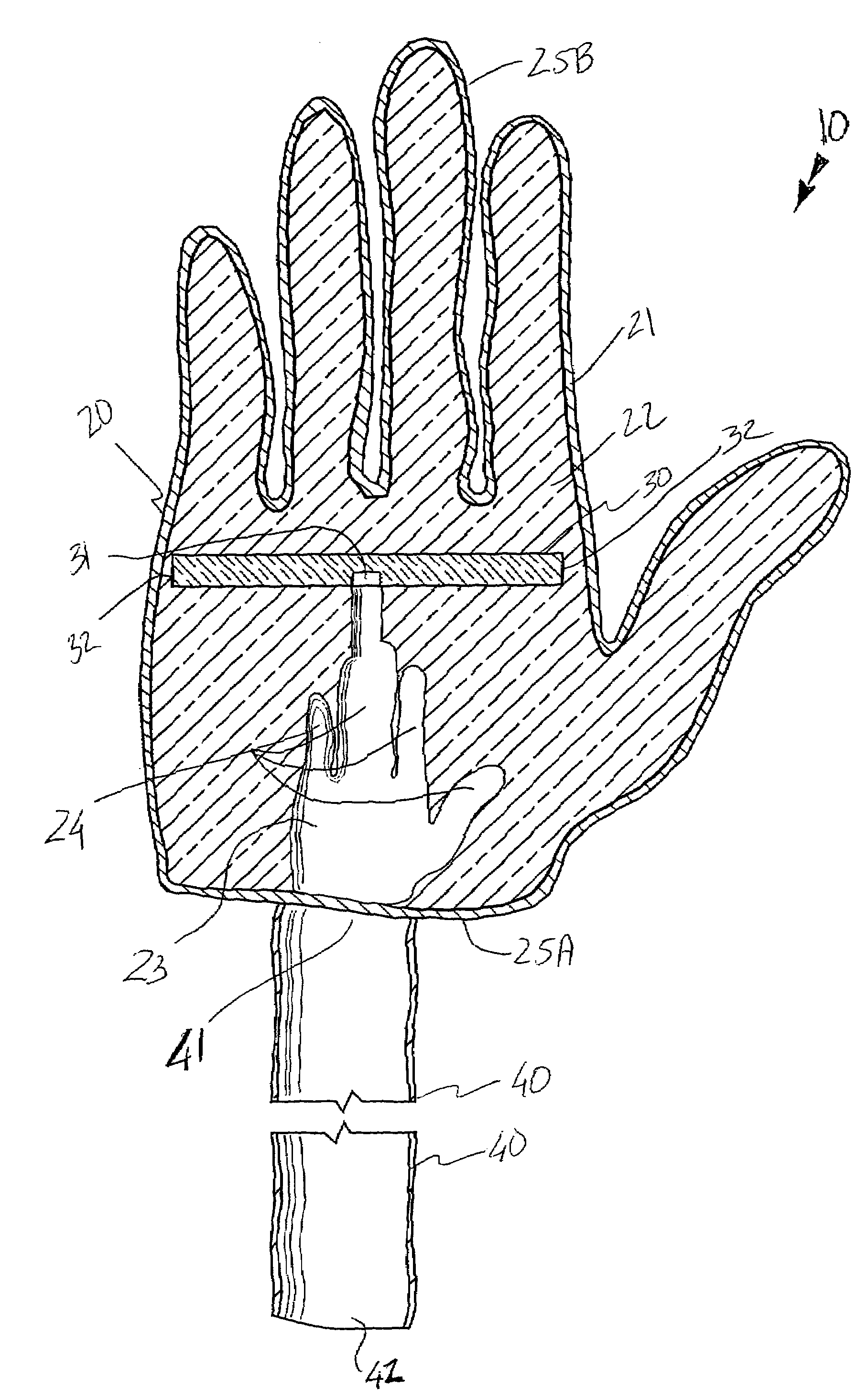

Noise generating novelty apparatus

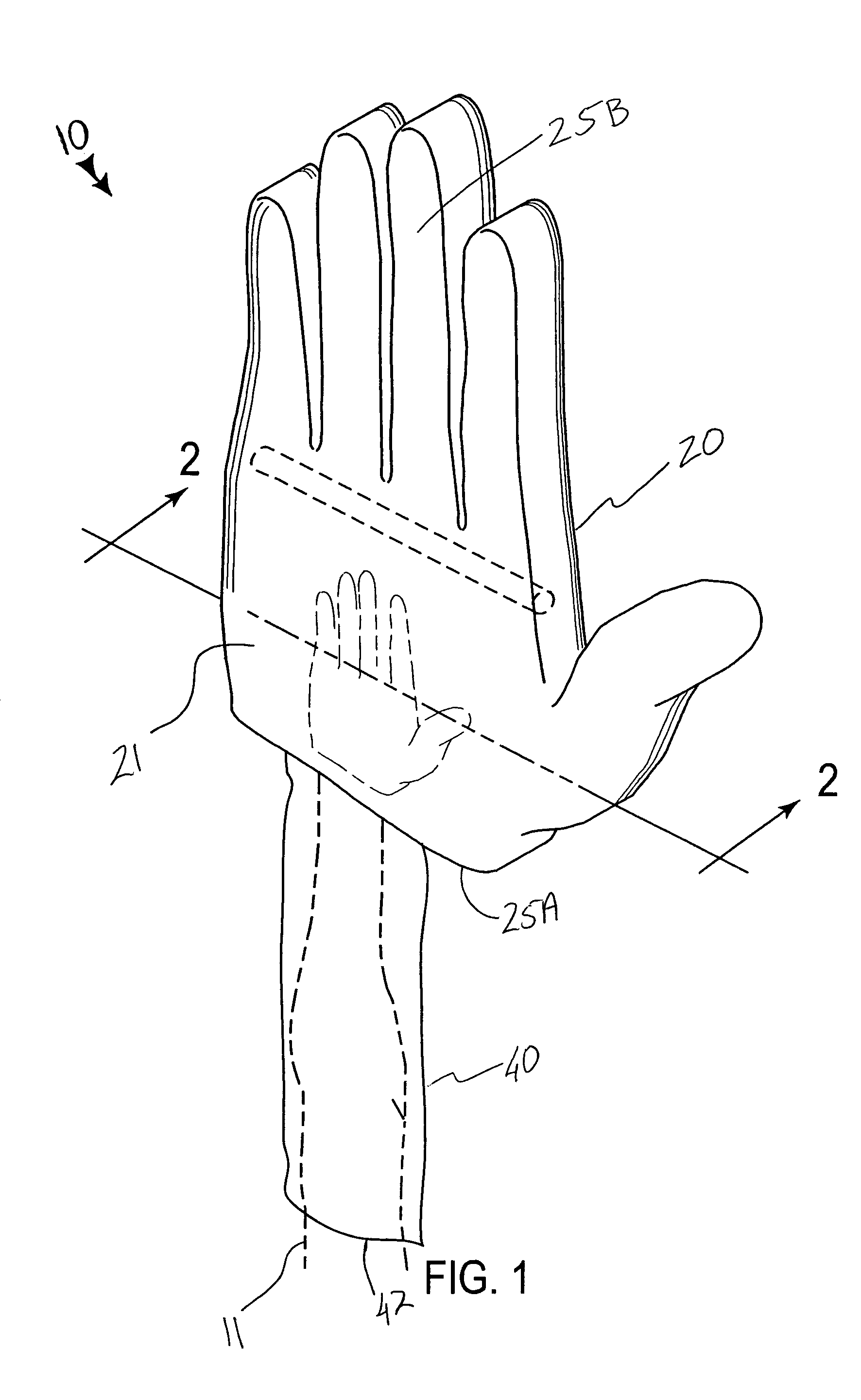

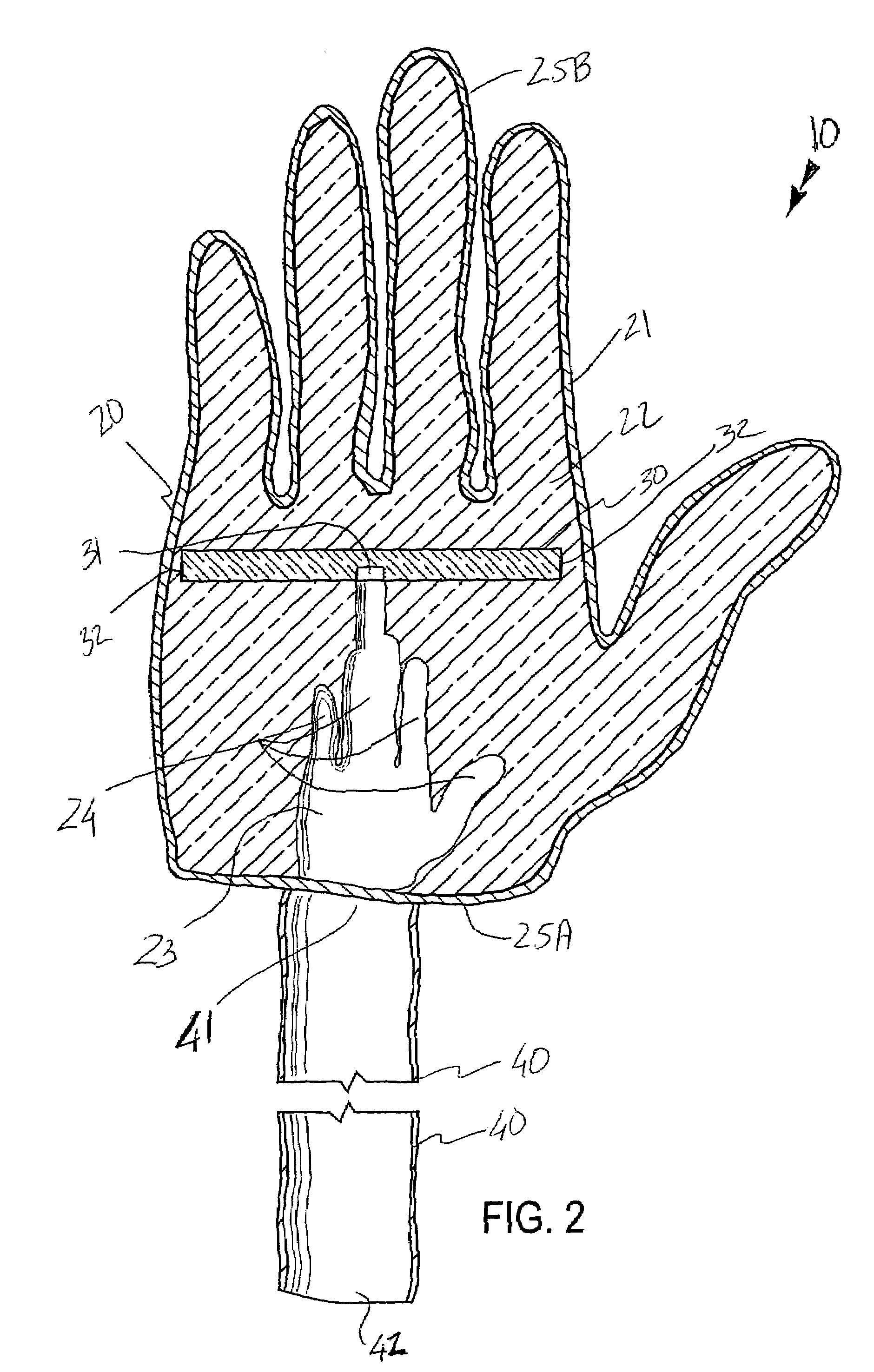

An apparatus includes a body shaped as a large open-faced hand made from deformably resilient material. The body has a water-impermeable outer surface and a solid core monolithically formed therewith. The solid core has a cavity that has flanges for receiving a user's metacarpals therein. A rectilinear stabilizing bar traverses longitudinally across the body, is statically seated within the solid core, is intercalated between the outer layers, and has a threaded aperture formed at a midpoint thereof. A mechanism is included for covering an arm of the user such that the user's arm is protected from undesirable air-traveling particulates during clapping conditions. The arm is invisible from an exterior of the arm covering mechanism. The arm covering mechanism is formed from flexible and water-impermeable material for prohibiting the user's arm from becoming soaked during inclement weather conditions.

Owner:WIMBERLY GREG E

Cooled rotor blade with vibration damping device

ActiveUS20050169754A1Evenly dispersedReduce chanceEngine manufactureOther chemical processesEngineeringBearing surface

A rotor blade for a rotor assembly is provided that includes a root, an airfoil, and a damper. The airfoil has a length, a base, a tip, a first side wall, a second side wall, and at least one cavity. The length extends the base and the tip. The at least one cavity is disposed between the side walls, and the channel is defined by a first wall portion and a second wall portion. The damper, which is selectively received within the channel, includes a first bearing surface, a second bearing surface, a forward surface, and an aft surface, all of which extend lengthwise. At least one of the surfaces is shaped to form a lengthwise extending passage within the channel. The passage has a flow direction oriented along the length of the at least one surface to permit cooling air travel along the at least one surface in a lengthwise direction. According to one aspect of the present invention, the damper has an arcuate lengthwise extending centerline.

Owner:RAYTHEON TECH CORP

Air feeding apparatus

An air feeding apparatus includes an air supplying chamber disposed in a housing, and cold producing plates in the chamber, which are connected to a switching circuit controllable for changing a working mode of the plates from a cold producing one to a heat producing one. A conduit is connected to an outlet of the air supplying chamber, and sticks outside the housing. Air is forced to travel through the air supplying chamber by means of an air pump, and is guided to outside by means of the conduit; thus, the air traveling through the chamber can have temperature changed by the cold producing plates, and can be conveyed to desired locations or into other objects for use.

Owner:CHIU KUANG HSING

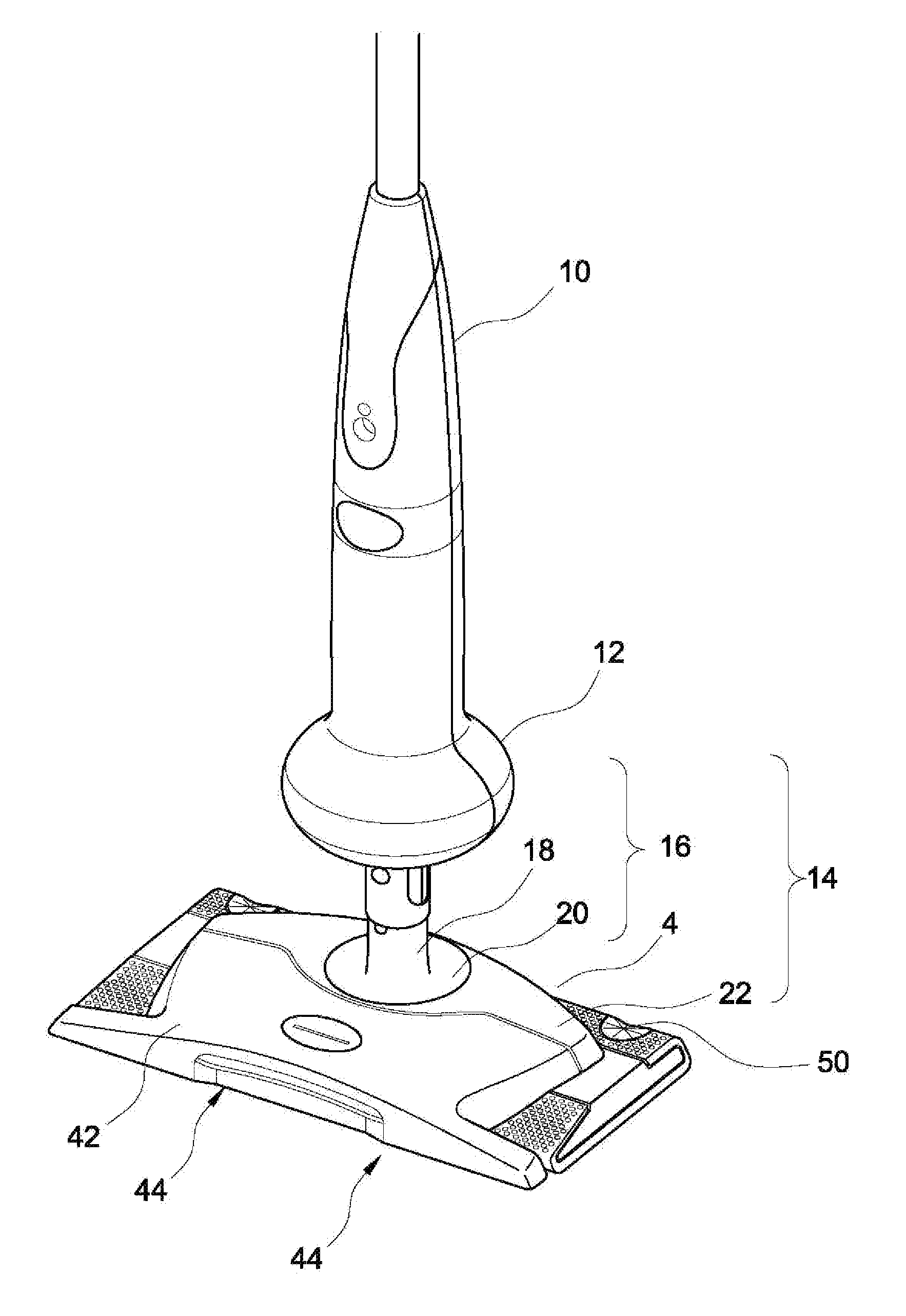

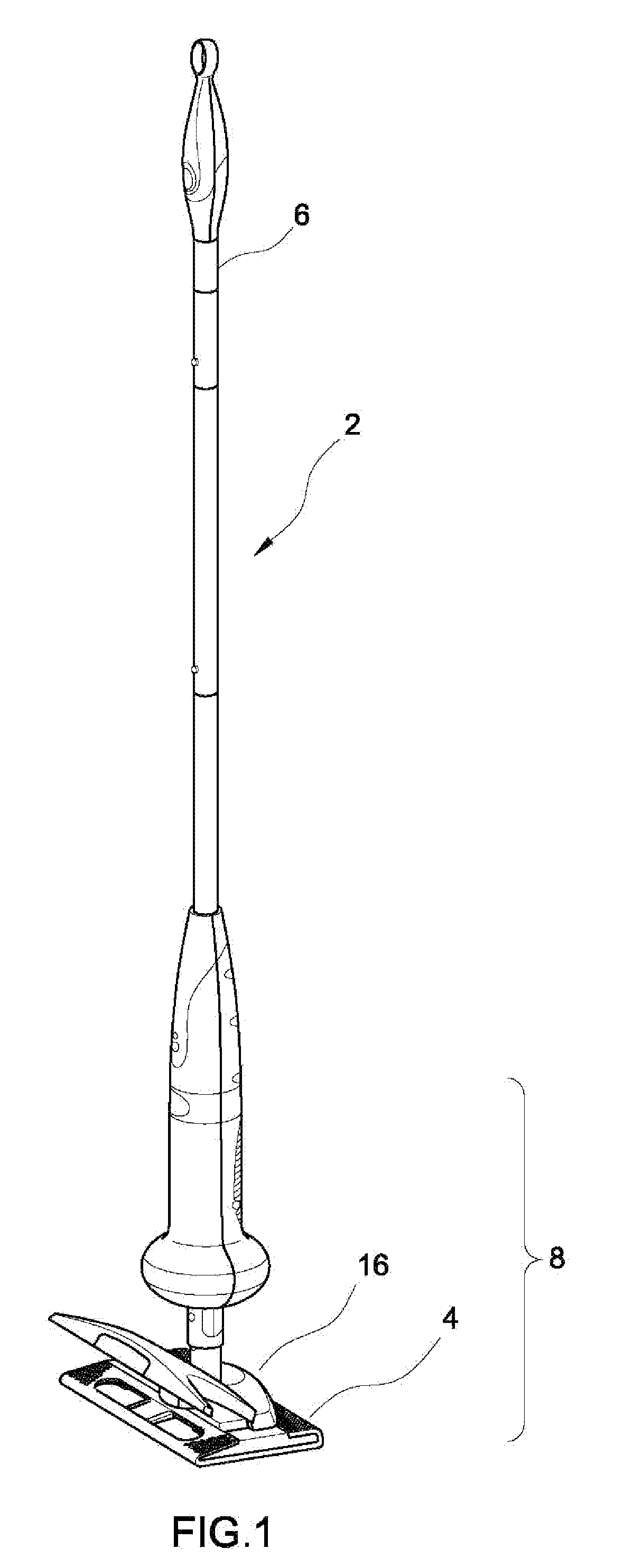

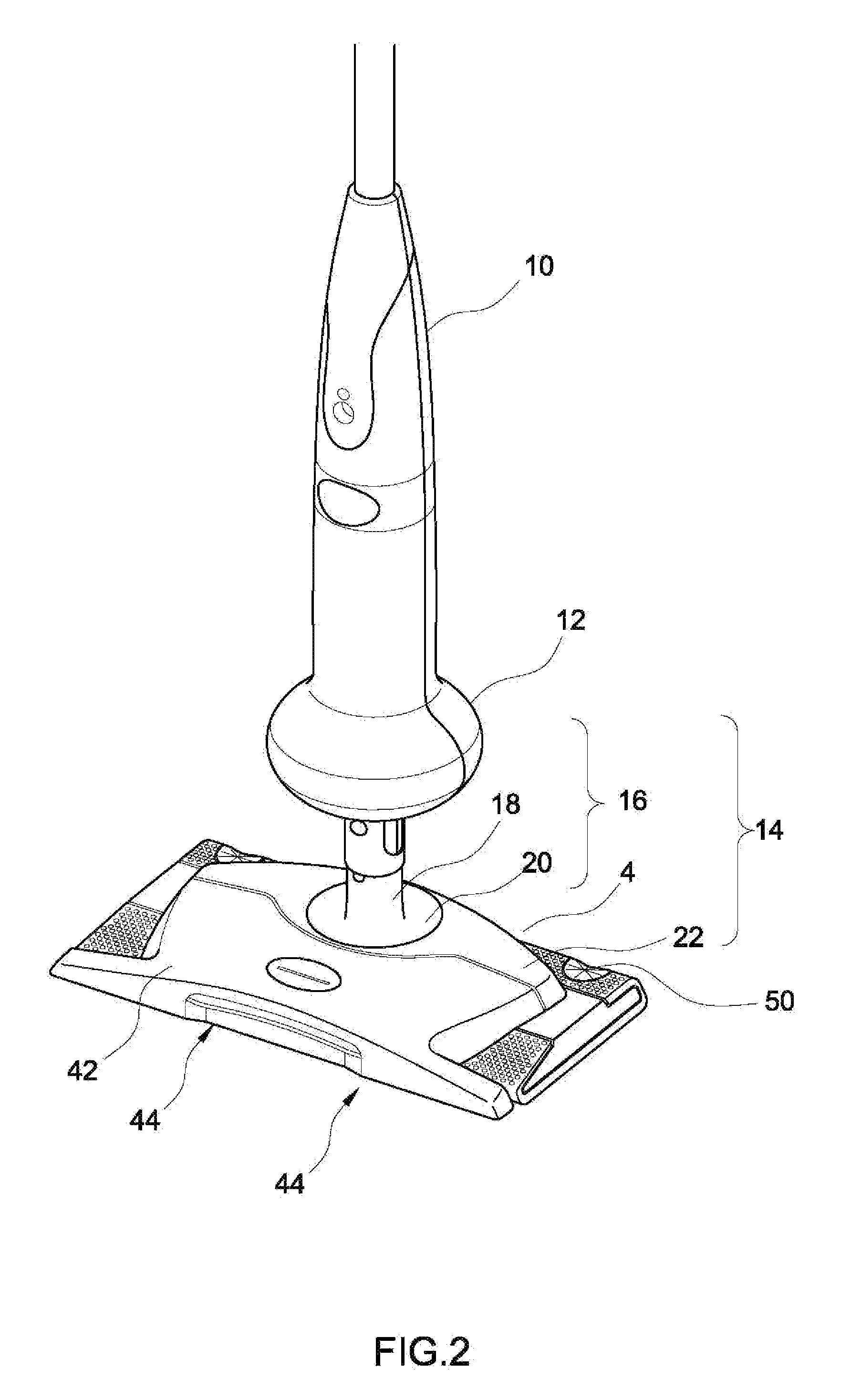

Floor Cleaning Apparatus

There is provided a floor cleaning apparatus assembly comprising a base portion for engaging a floor during cleaning, means for creating suction whereby air is drawn from the surrounding of the base portion through the base portion via an opening provided at a front end of the base portion, a cleaning sheet provided with a first area for collecting finer dirt particles and a second area for collecting larger dirt particles, means for securing the cleaning sheet to the base portion but exposing the first area of the cleaning sheet, and a channel provided within the floor cleaning apparatus through which suctioned air travels, the channel beginning with the opening at the front end of the base portion, followed by passing through the second area of the cleaning sheet whereby larger dirt particles carried in the air are trapped thereat, and ending at an exit.

Owner:HAYCO MFG

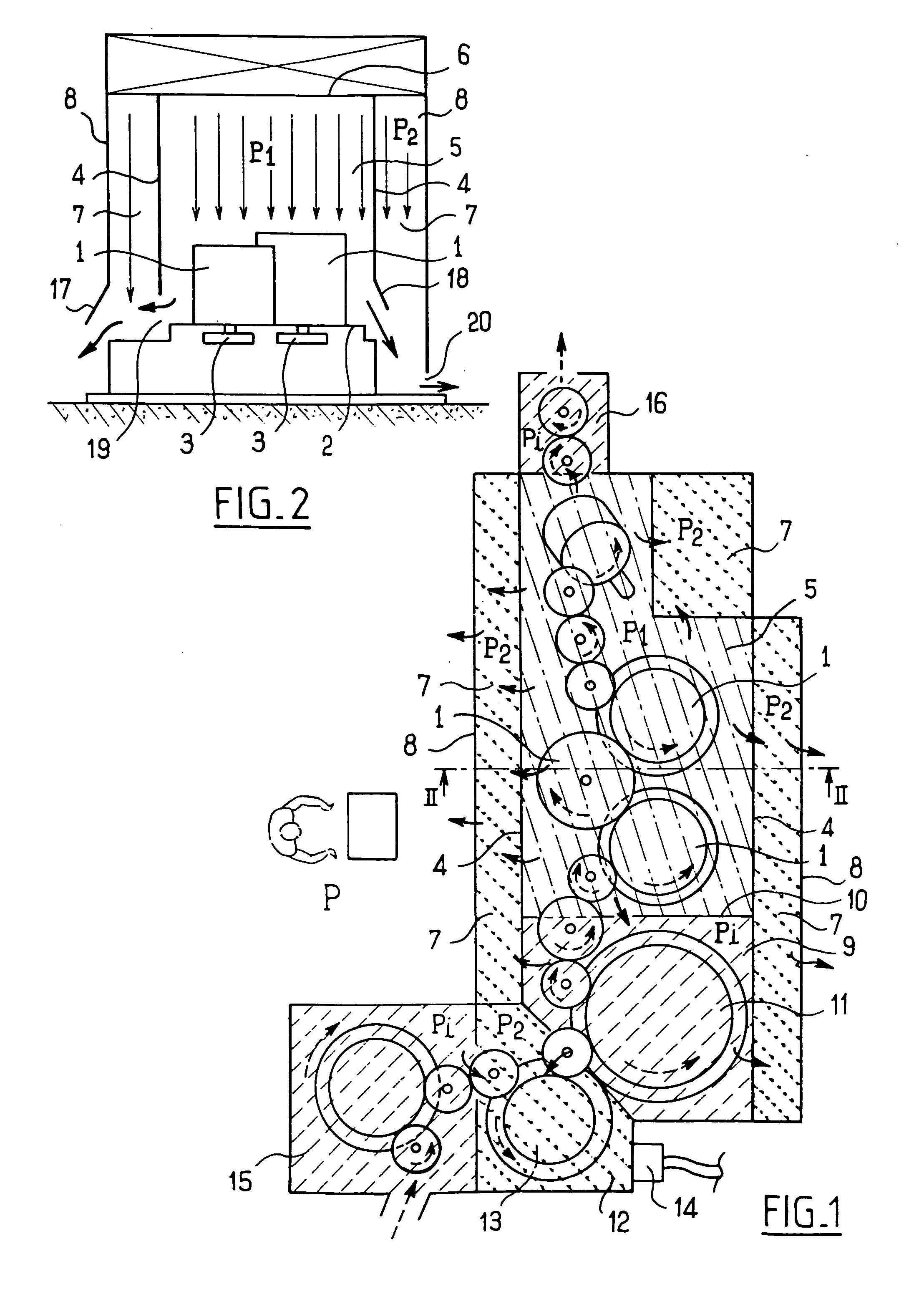

Premixed combustion burner for gas turbine

ActiveUS20100263381A1Uniform concentrationAvoid problemsContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEngineering

A premixed combustion burner for a gas turbine is provided that can efficiently premix fuel and air to produce fuel gas having a uniform concentration, while reliably achieving prevention of flash back by making the flow rate of fuel gas substantially uniform. The premixed combustion burner for a gas turbine has: a fuel nozzle; a burner cylinder arranged so as to surround the fuel nozzle and form an air passageway between itself and the fuel nozzle; and swirler vanes that are arranged along an axial direction of the fuel nozzle in a plurality of positions around the circumferential direction of an outer circumference surface of the fuel nozzle and that gradually curve from an upstream side to a downstream side to spin the air traveling within the air passageway from the upstream side to the downstream side. A cutaway section is provided in a rear edge section on an inner circumference side of the swirler vane.

Owner:MITSUBISHI POWER LTD

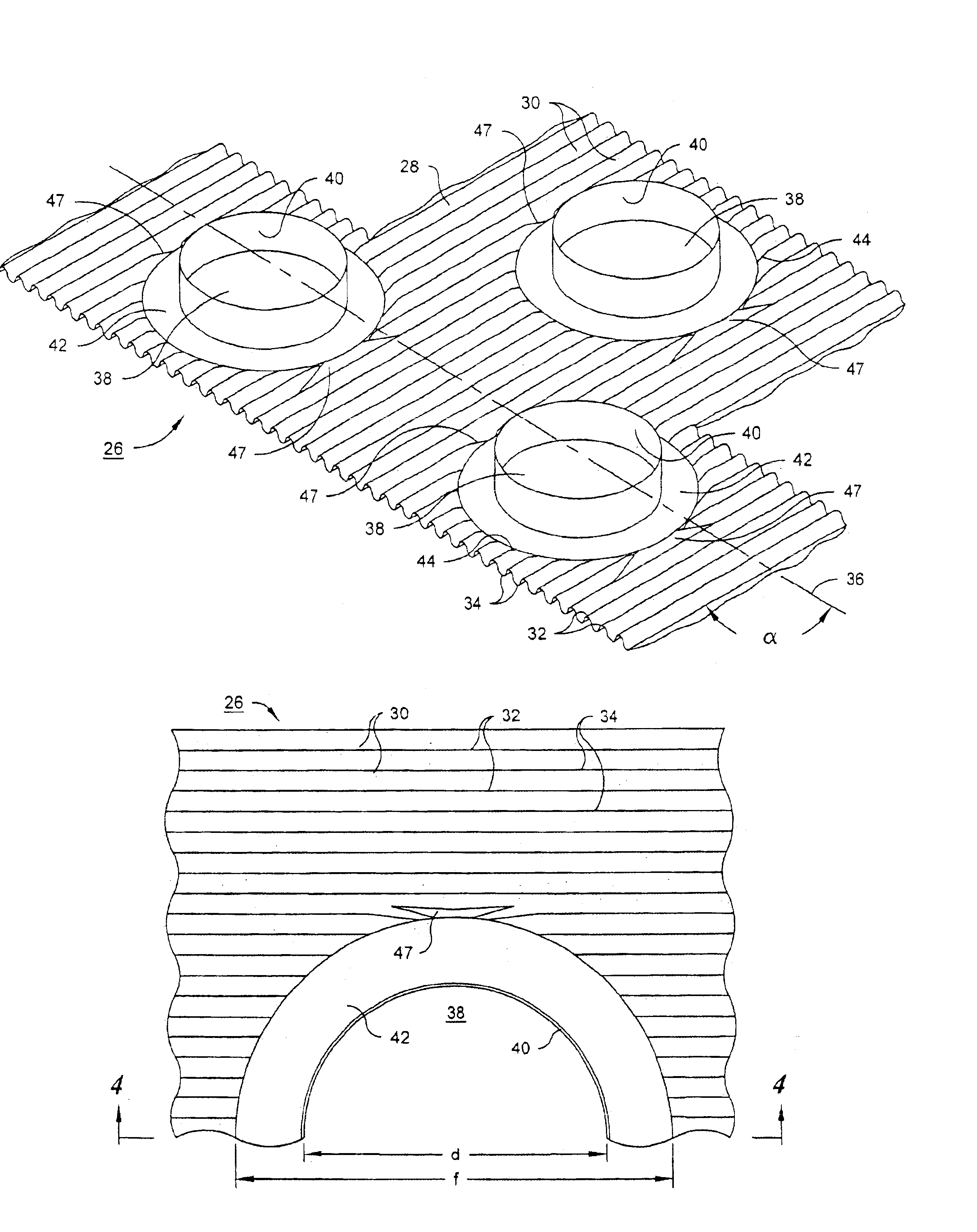

Fin for heat exchanger coil assembly

A fin is disclosed for use in a heat exchanger coils including tube segments extending through the fin. The fin includes a corrugated sheet of material having a plurality of major corrugations, about 8 to about 24 corrugations per inch (2.54 cm), each major corrugation being a peak or a valley with an amplitude “h” at the peaks or the valleys perpendicular to a reference major plane equally bisecting the major corrugations, and a width “w”; a plurality of orifices; a collar perpendicular to the reference major plane and extending from the sheet around each of the orifices; and a generally flat area that is generally parallel to or generally coextensive with the reference major plane and that surrounds each collar. The major corrugations have angled walls extending from at least one of the peaks and valleys to the generally flat areas adapted to create a vortex when air travels over the fin. A ratio of “h” to “w” is about 0.32 to about 0.7.

Owner:EVAPCO

Aseptic packaging installation with aseptic buffer zones

InactiveUS20060185321A1Risk minimizationAvoid pollutionLiquid fillingLavatory sanitoryEngineeringBuffer zone

Owner:SERAC GROUP

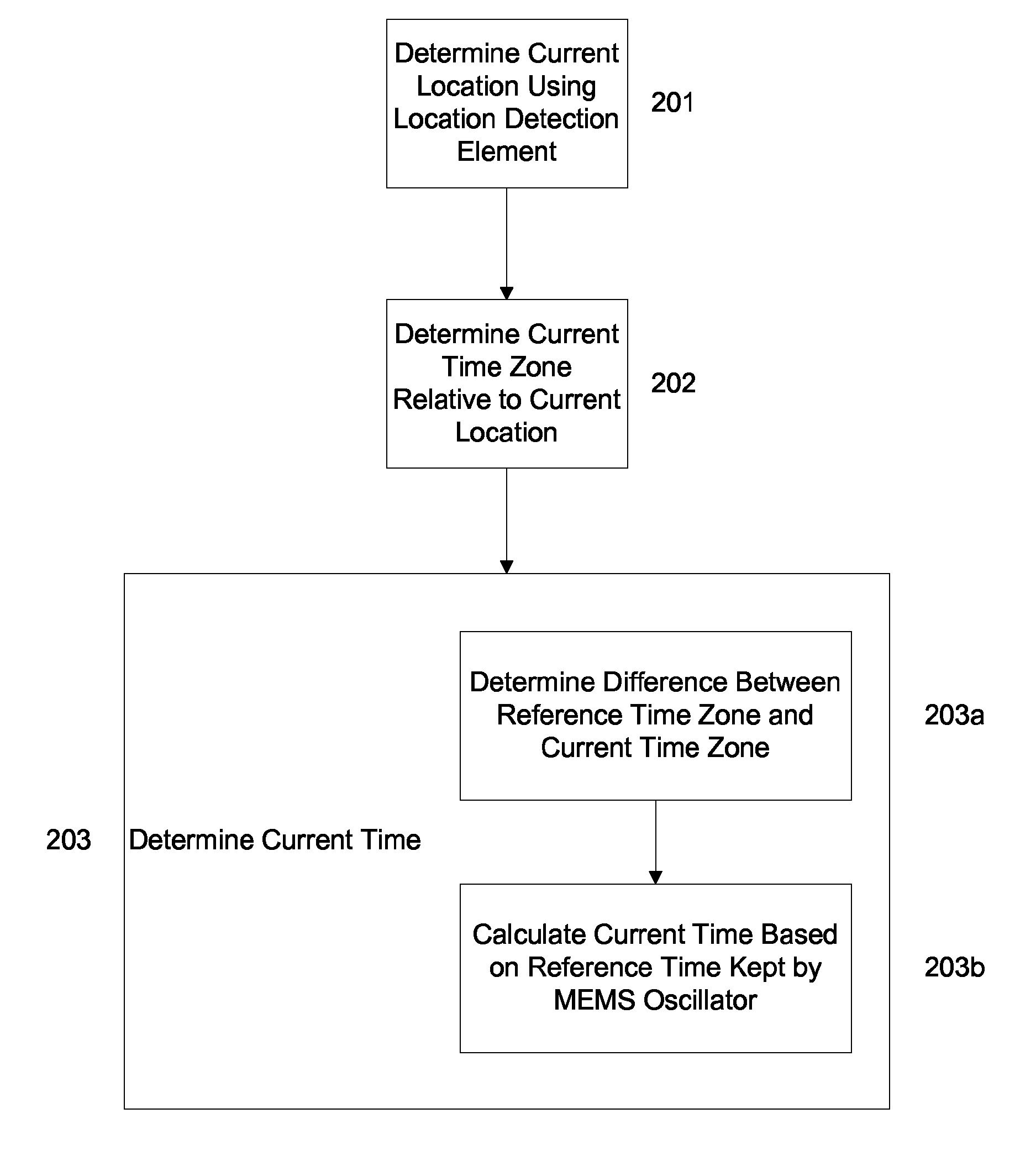

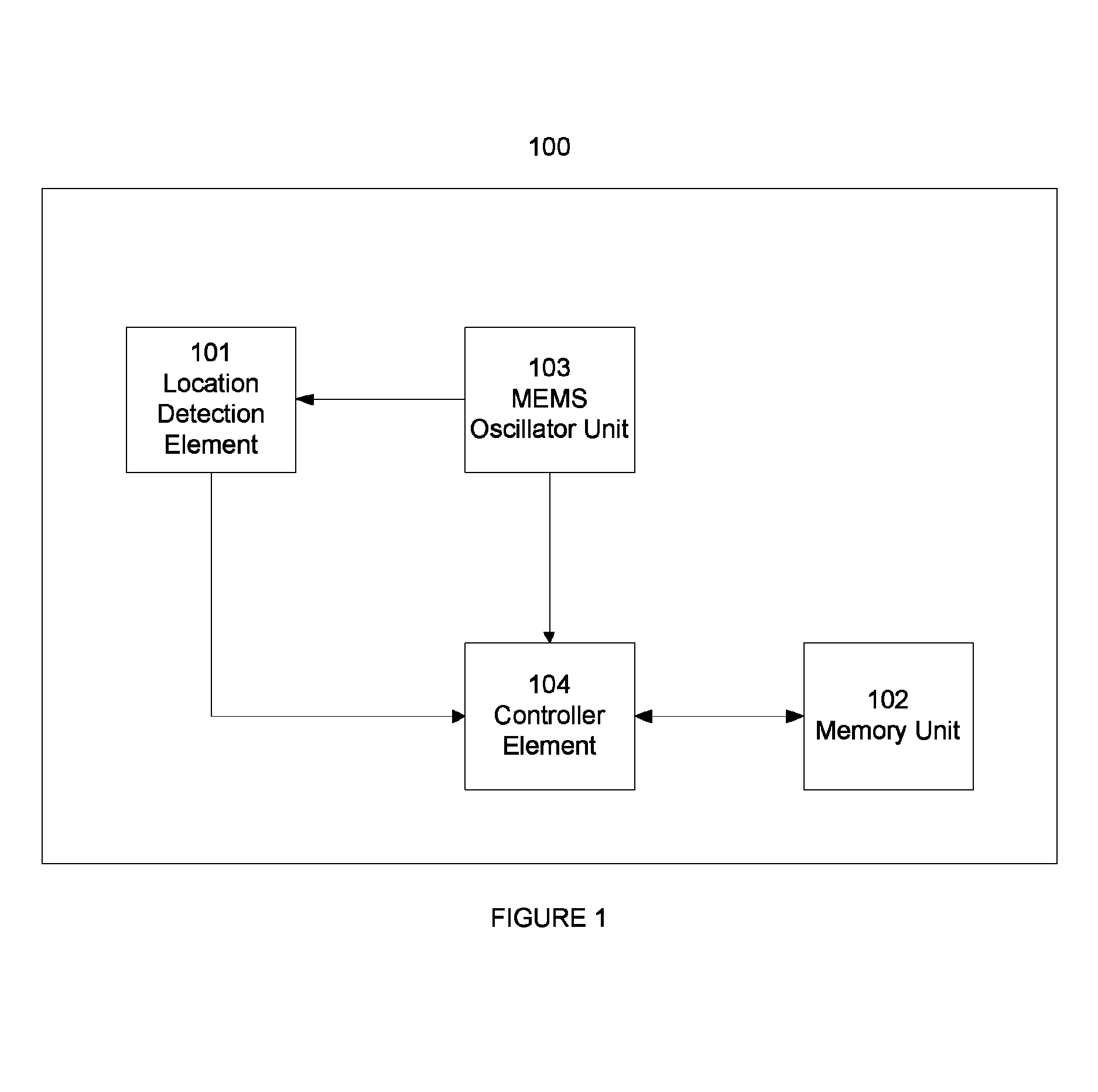

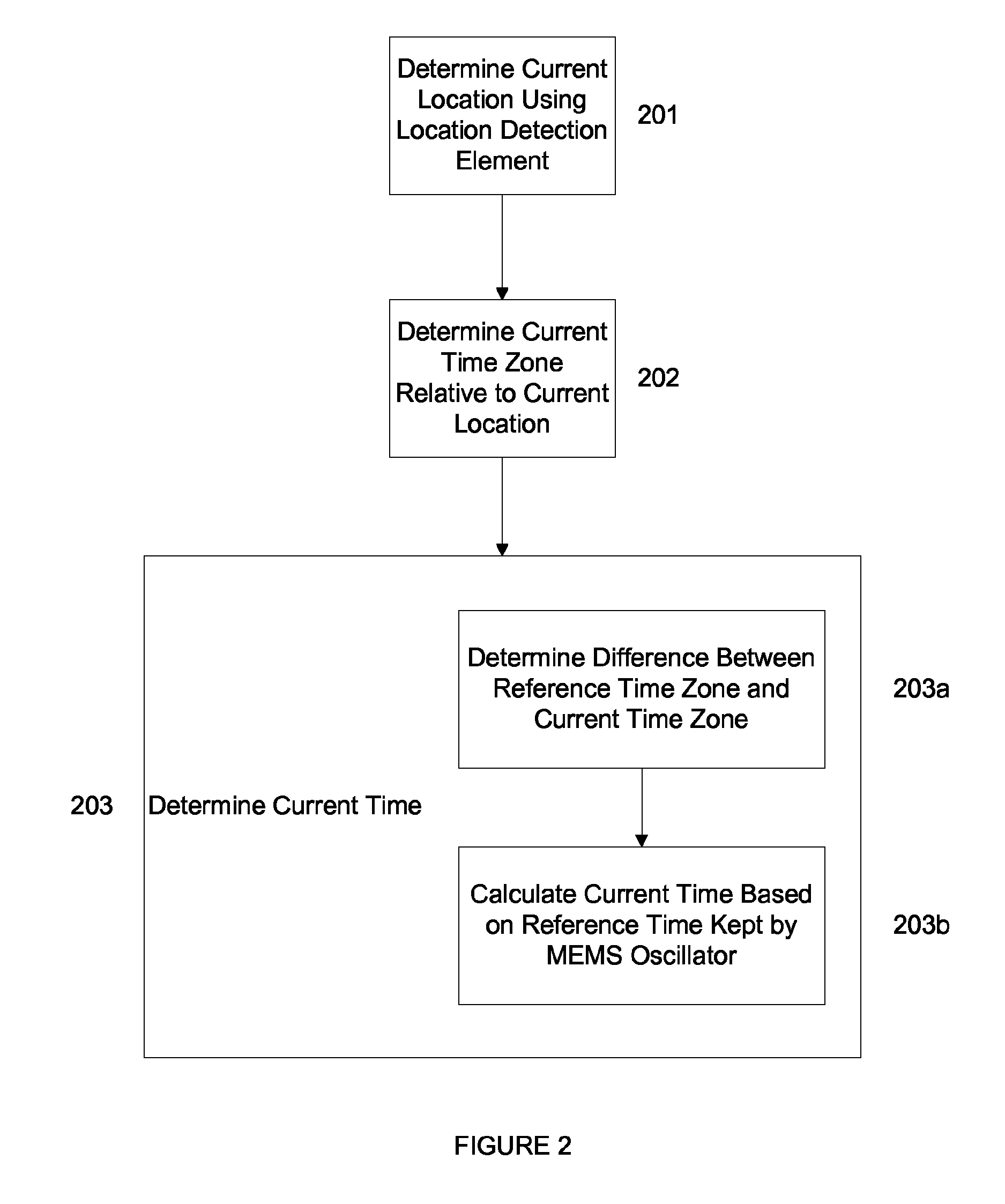

Portable device using location determination and MEMS timekeeping to update and keep time

ActiveUS7852711B1Reduce in quantityImprove accuracyVisual indicationVisual indicationsLocation detectionChipset

Devices and methods for determining a current location using a location detection element, determining a local time zone based on the current location using a memory unit, keeping time using a micro-electro-mechanical-system (MEMS) oscillator unit co-fabricated on a common substrate with the location detection element, and determining a local time based on the local time zone using a controller element. Optional embodiments comprise a MEMS oscillator unit that is fabricated underneath, next to, or on top of the location detection element. Additional embodiments comprise a GPS chip optionally assisted by a cell phone chipset or FM receiver to enhance location and time determination. Optional embodiments may additionally enter a power conservation mode after the current location has been determined, or may detect air travel to disable the location detection element and enable the location detection element upon detected landing.

Owner:PILLAR

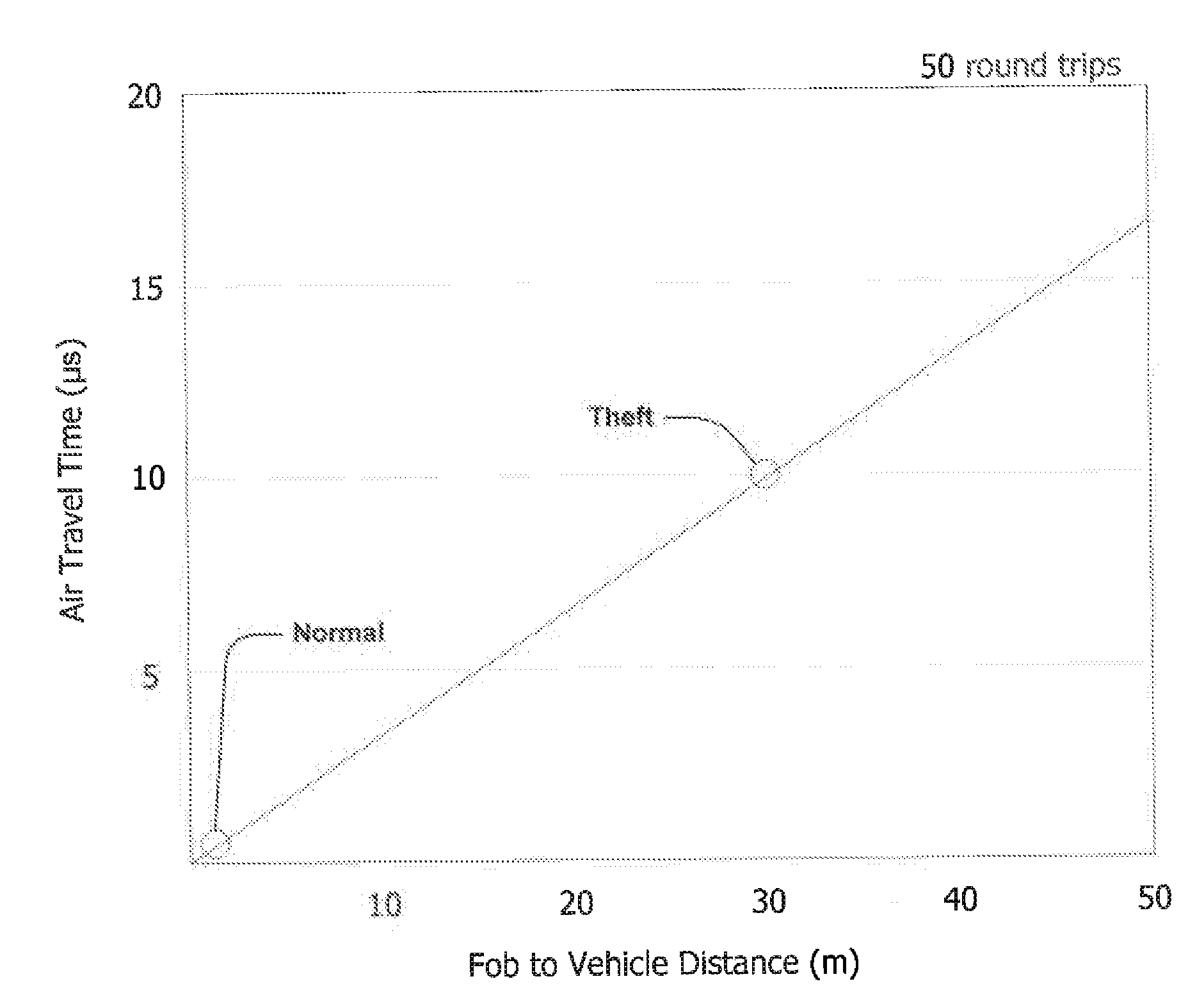

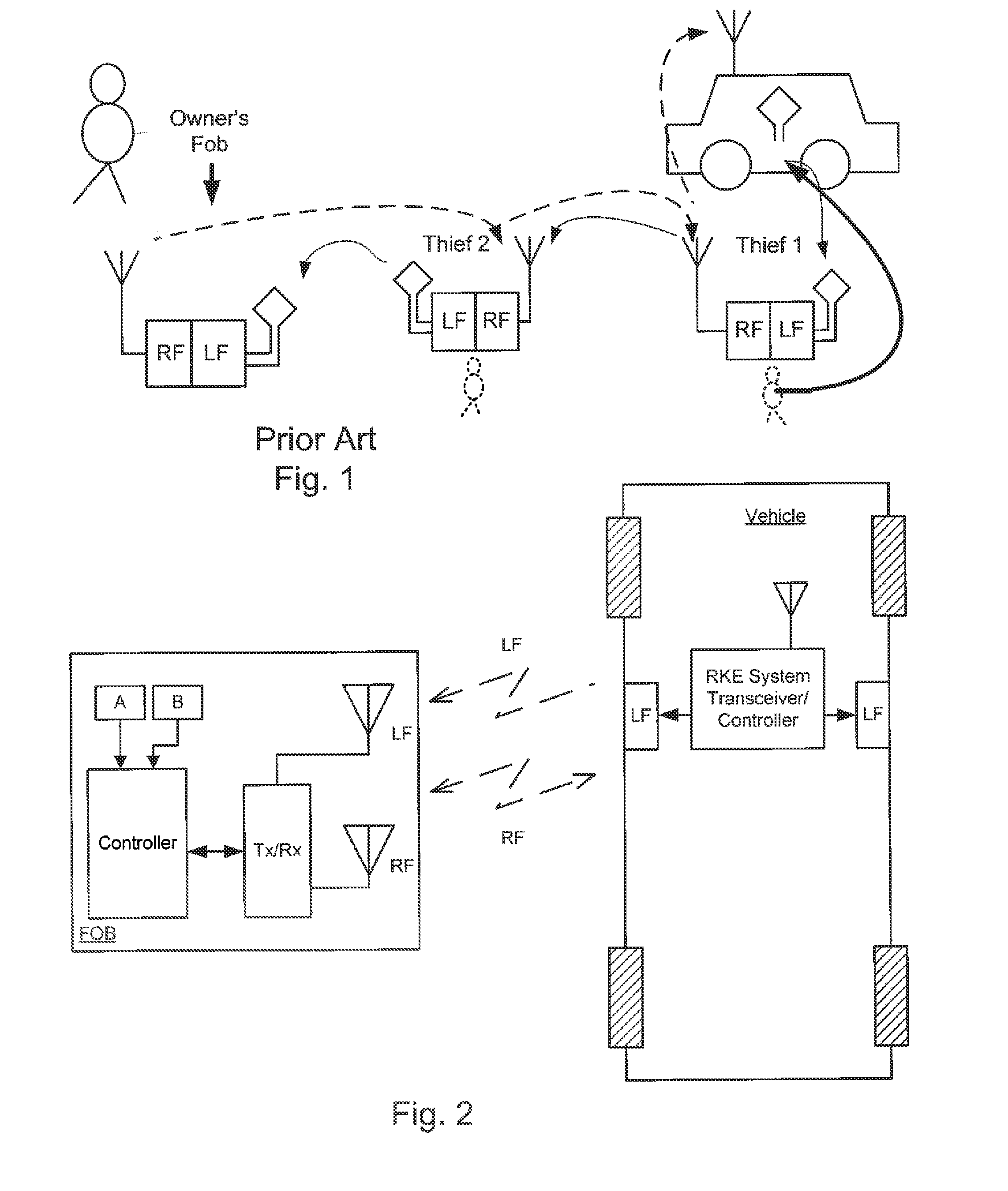

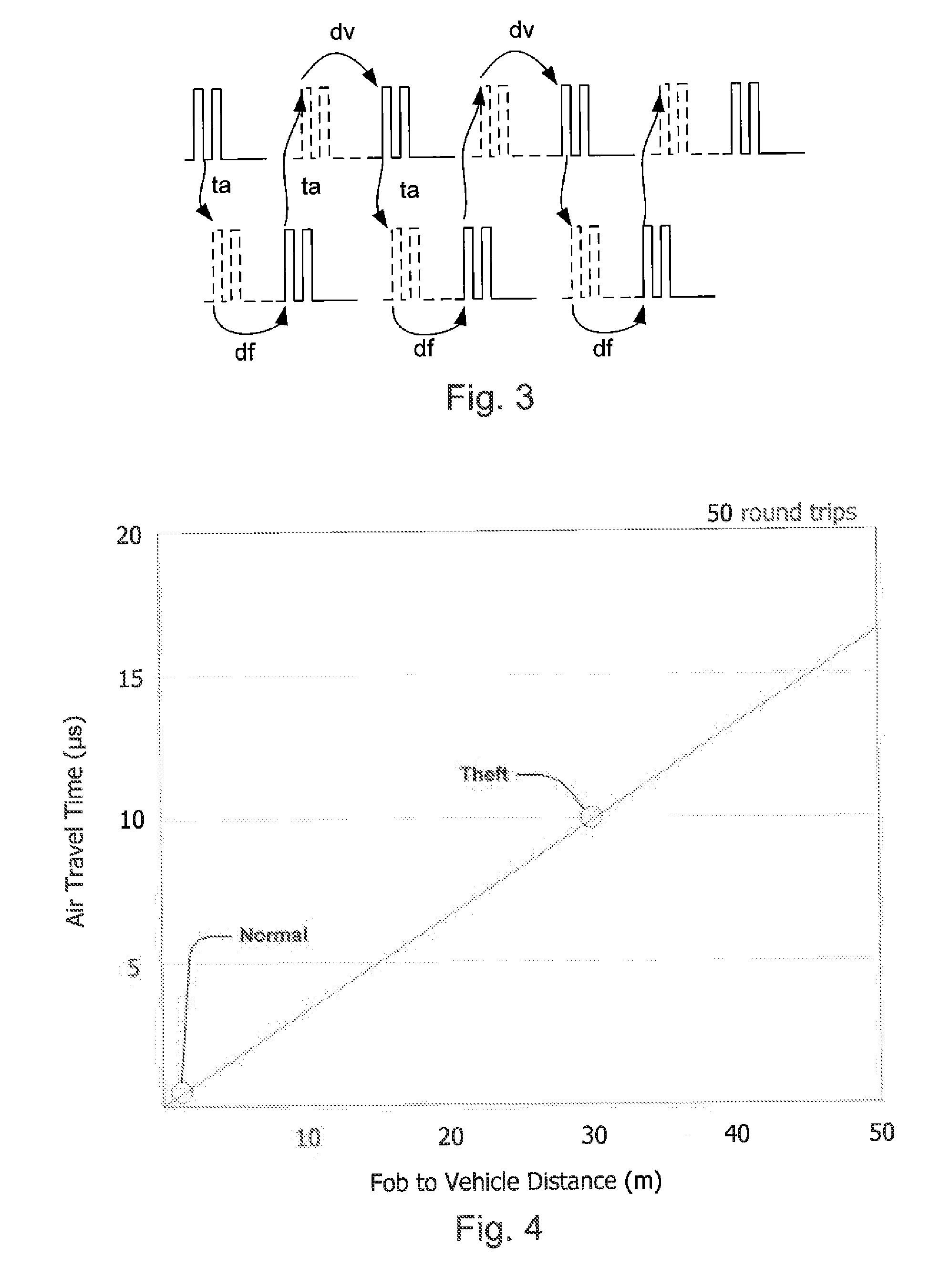

Passive remote keyless entry system with time-based Anti-theft feature

Method for preventing security breaches via the two-thief method of attack of passive remote keyless entry systems for vehicles. The method involves the measurement of air travel time of the RF messages between the RKE fob and the vehicle. Multiple round trips between the fob and the vehicle are employed to magnify the distance covered by the messages and thereby allow accurate measurement of the air travel time.

Owner:TRW AUTOMOTIVE US LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com