Petal-shaped tungsten sulfide nano-sphere, preparation method and application of nano-sphere

A technology of tungsten sulfide and nanospheres, applied in the field of nanomaterials, can solve problems such as scarcity restricting large-scale application, and achieve the effects of abundant raw materials, improved performance, and good electrocatalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

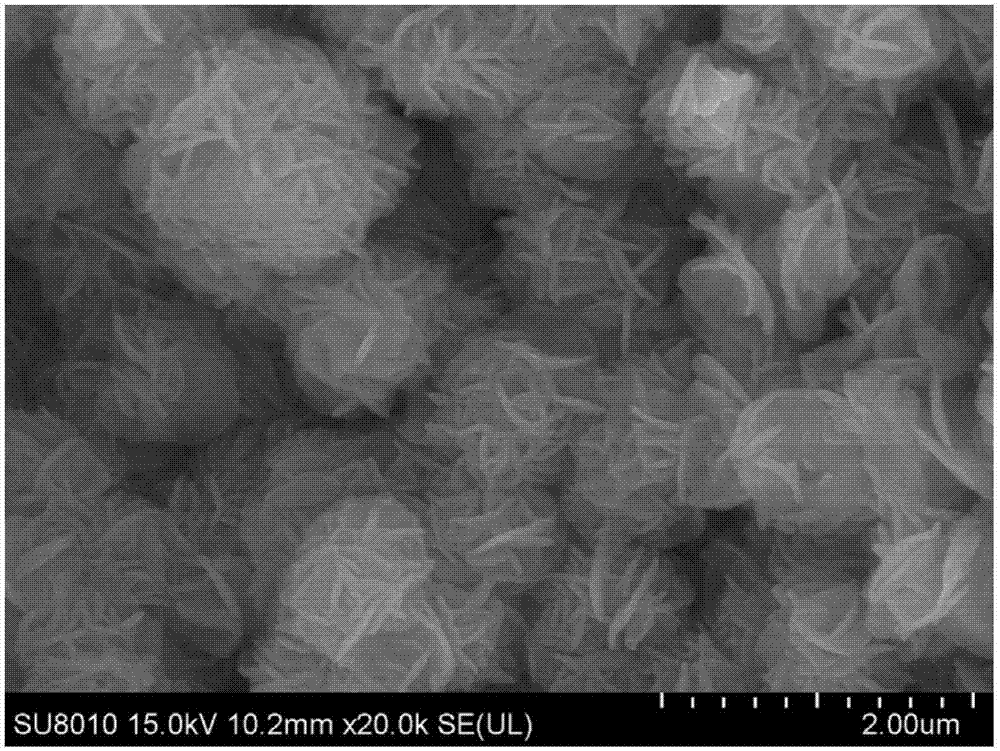

[0027] The preparation method of petal-shaped tungsten sulfide nanospheres of the present invention comprises the following steps: (a) dissolving tungstate and thiourea in water to form a mixed solution; the mass ratio of tungstate and thiourea is 4.2:1.3~ 5.3; (b) Put the mixed solution in an autoclave, conduct hydrothermal reaction at 220~250°C, centrifuge, wash with water, and dry. Using sodium tungstate and thiourea as raw materials, the preparation process is simple, the required equipment is conventional, the raw materials are abundant, and the price is cheap, realizing the low-cost synthesis of petal-shaped tungsten sulfide nano-electrocatalysts.

[0028] In step (b), after the hydrothermal reaction, naturally cool to room temperature, take out the autoclave, pour off the upper layer of transparent liquid and take out the black precipitate; add alcohol to the black precipitate for centrifugal cleaning; the time of the hydrothermal reaction is 18-24 hours; the drying met...

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of petal-shaped tungsten sulfide nanosphere, and it comprises the following steps:

[0032] (a) Add 4.2g of sodium tungstate and 1.3g of thiourea into 50ml of deionized water, and stir ultrasonically for 30 minutes to form a mixed solution;

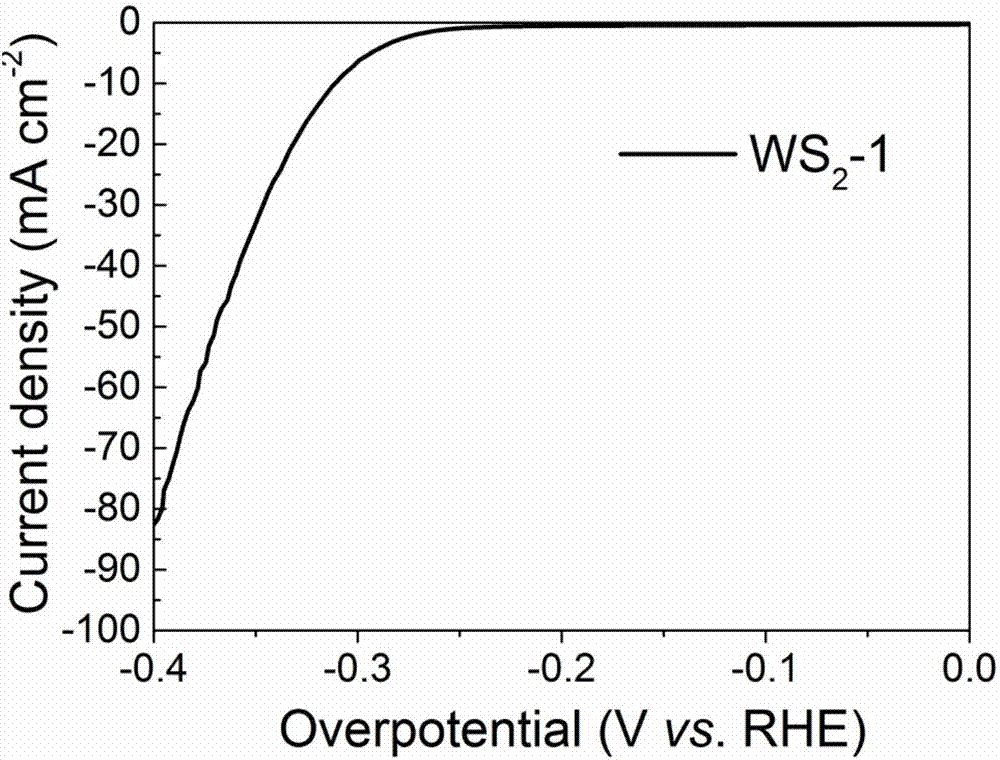

[0033] (b) Transfer the mixed solution to an autoclave, heat it up to 220°C, and keep it for 24 hours; then cool it down to room temperature and take it out, pour the upper transparent liquid into the waste liquid bucket, and take out the black precipitate; add alcohol, and centrifuge for 3 Then add deionized water, centrifuge and wash 3 times; the product obtained after centrifugation can be freeze-dried by freeze-drying, and the obtained tungsten sulfide nanospheres are named WS 2 -1.

Embodiment 2

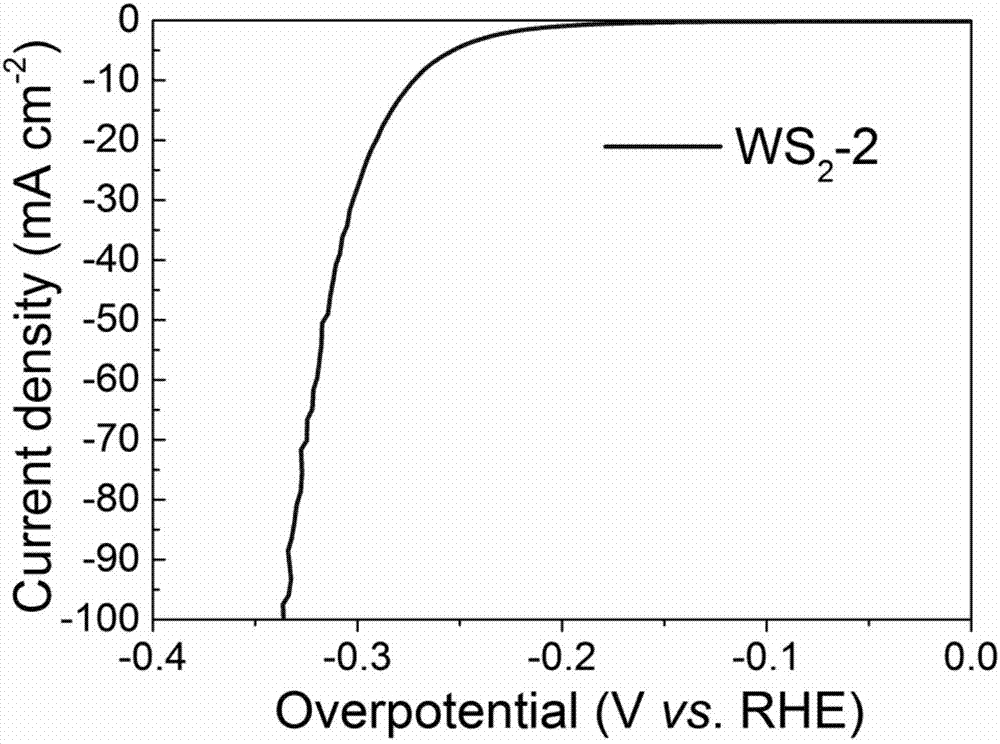

[0035] This embodiment provides a preparation method of petal-shaped tungsten sulfide nanospheres, the preparation steps of which are basically the same as in Example 1, the difference is that 2.6 g of thiourea is added, and the obtained tungsten sulfide nanospheres are named WS 2 -2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com