Spring energy storage hydraulic operation mechanism and energy storage spring unit

A technology of hydraulic operation and energy storage spring, applied in electrical components, high-voltage air circuit breakers, high-voltage/high-current switches, etc., can solve problems such as difficult installation, low output characteristics of combined disc springs, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

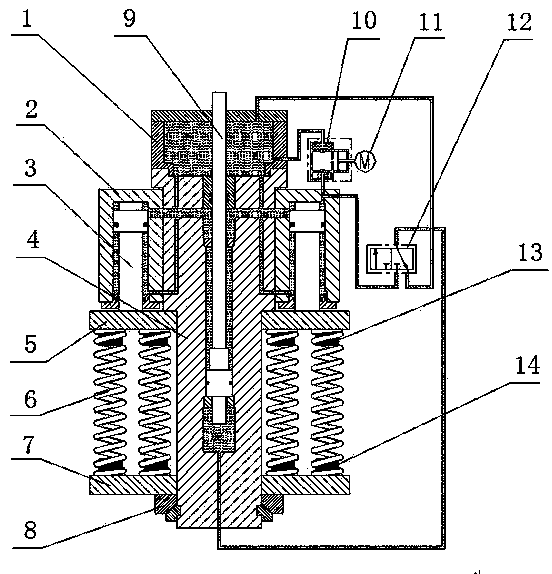

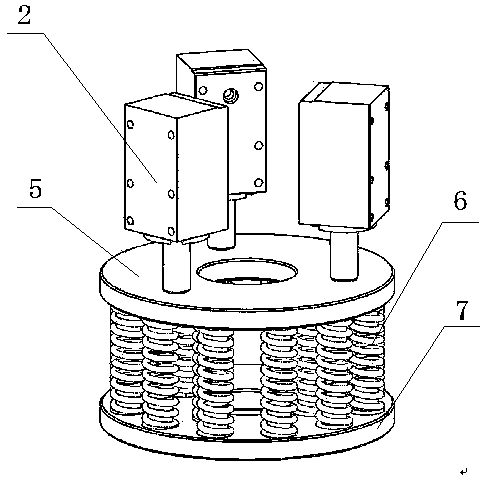

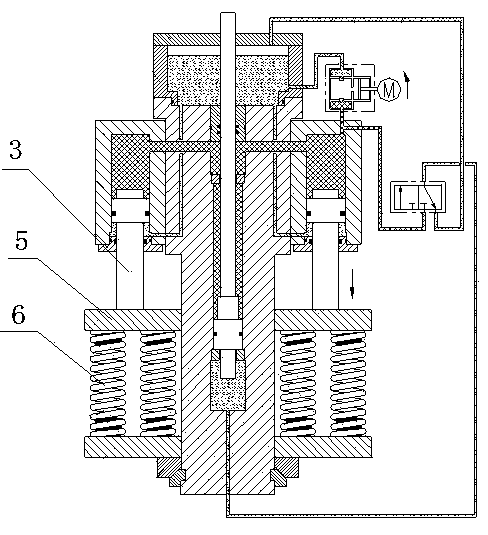

[0019] Embodiments of the spring energy storage hydraulic operating mechanism of the present invention: as Figure 1-3 As shown, it mainly includes a working cylinder 4 and an energy storage assembly, wherein the working cylinder 4 is a hydraulic cylinder, and the working cylinder piston rod 9 extends upwards from the working cylinder body as the power output shaft of the operating mechanism. The energy storage assembly is composed of an energy storage power unit and an energy storage spring unit, and the energy storage assembly stores energy when the energy storage power unit pushes the energy storage spring unit to compress. The energy storage power unit is composed of three energy storage cylinders 2, the energy storage cylinders 2 are hydraulic cylinders, and the three energy storage cylinders 2 are fixedly attached to the outer peripheral surface of the working cylinder body and evenly distributed along the circumferential direction of the working cylinder body , the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com