An anti-jamming wire winding device

A wire winding and anti-jamming technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low pass rate, low degree of automation, affecting the production process, etc., to avoid wire jams, high product pass rate, The effect of small length error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the technical solution of the present invention will be described in detail through specific examples.

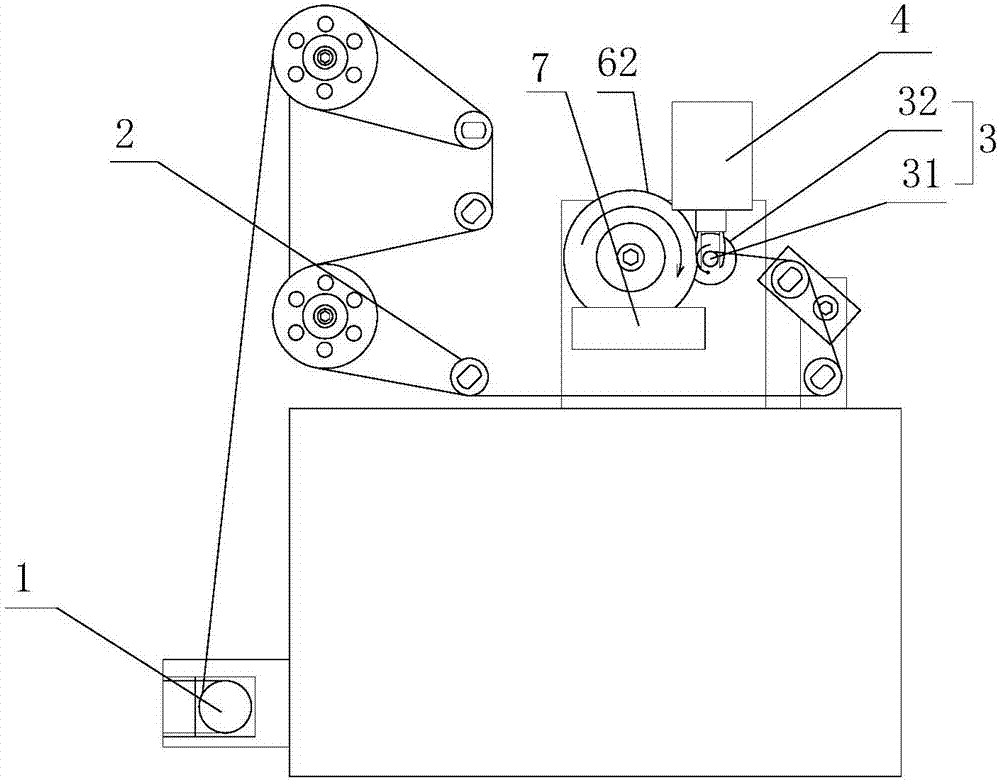

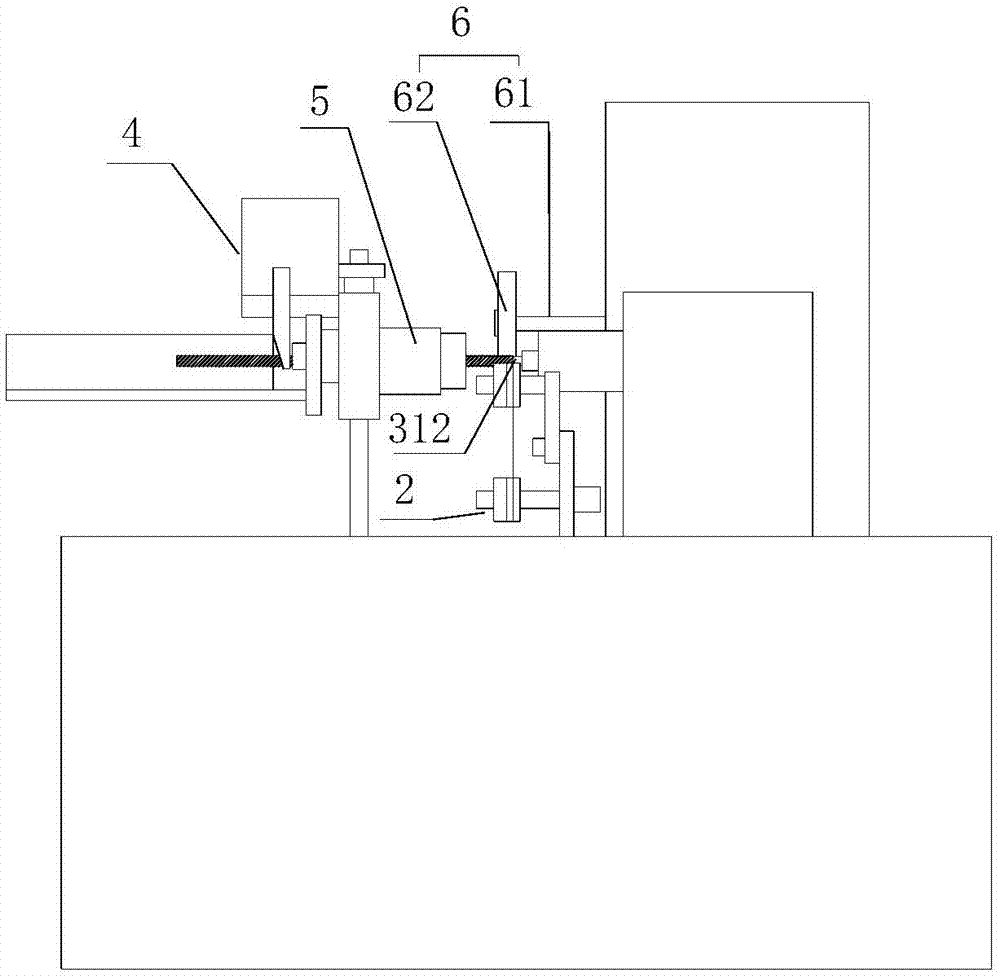

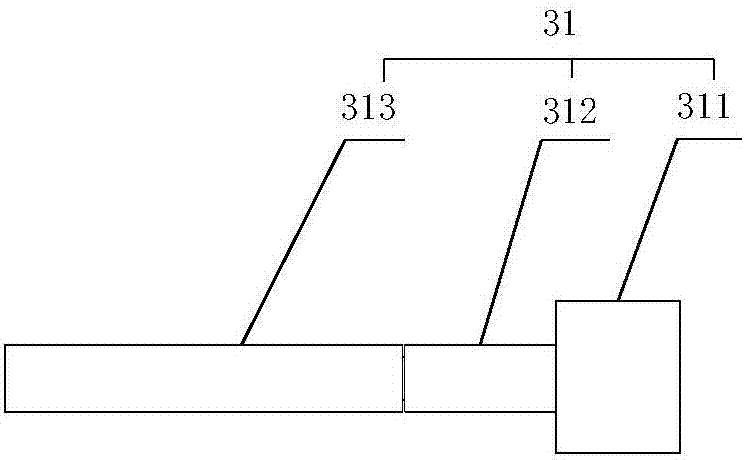

[0024] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of an anti-jamming wire winding device proposed by the present invention; figure 2 It is a side view of an anti-jamming wire winding device proposed by the present invention; image 3 It is a structural schematic diagram of the mandrel in an anti-jamming wire winding device proposed by the present invention.

[0025] refer to Figure 1-3 , an anti-jamming wire winding device proposed in an embodiment of the present invention, comprising: a wire releasing device 1, a wire device 2, a wire winding device 3 and a cutting device 4, wherein:

[0026] Pay-off device 1 is used for carrying out the wire-releasing action; Lead device 2 is positioned at the output end of pay-off device 1, and lead device 2 comprises the rotating shaft of rotating installation and the conductor pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com