Urea-coated composite emulsion and preparation method and application thereof

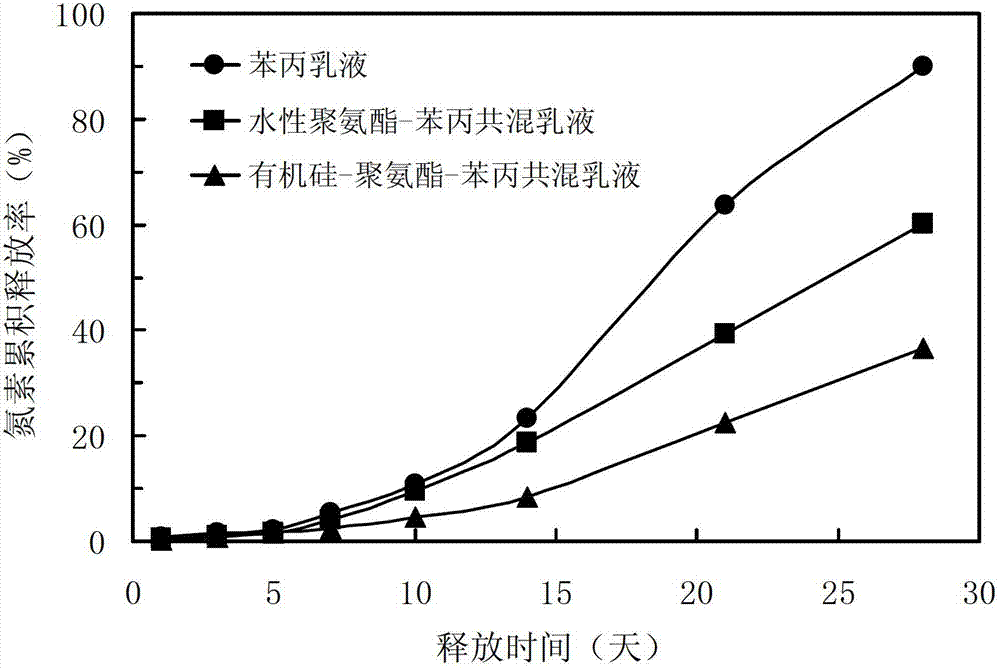

A technology of urea coating and compound emulsion, applied in application, fertilizer mixture, fertilization device, etc., can solve the problem of polymer coating controlled release fertilizer with short nutrient release period, cold brittleness and hot stickiness, and unsatisfactory water resistance and structural stability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

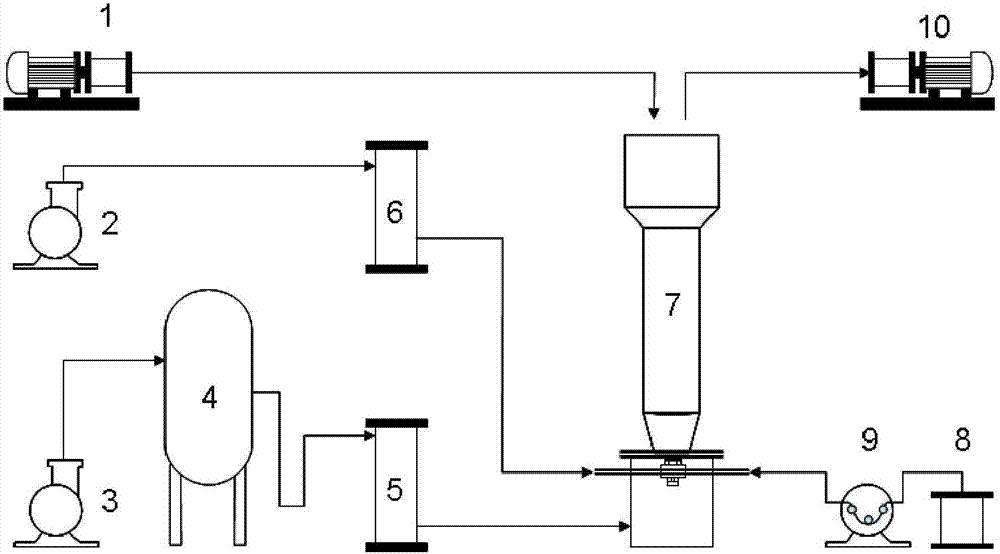

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: Preparation of urea-coated composite emulsion of the present invention

[0079] The implementation steps of this embodiment are as follows:

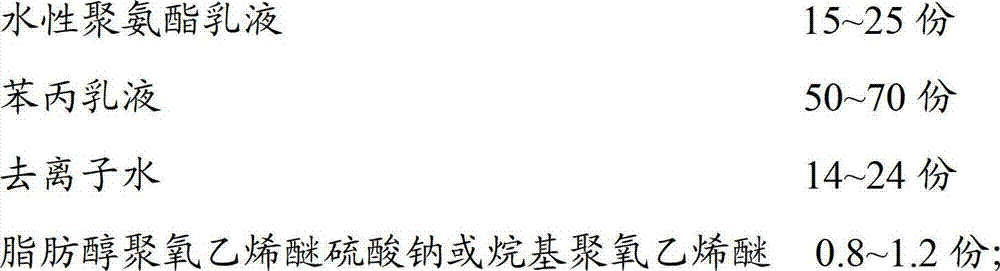

[0080] First put 14 parts by weight of deionized water into the container, and adjust its pH value to 7.8 with concentrated ammonia water; Under the condition of 480rpm, 50 parts by weight of styrene-acrylic emulsion sold by Rohm and Haas under the trade name AS-2010 were sequentially added, with a solid content of 49% by weight and a glass transition temperature of 21°C; Fatty alcohol polyoxyethylene ether sodium sulfate; 15 parts by weight of the aqueous polyurethane emulsion sold by Bayer under the trade name Dispercoll U54, its solid content is 50% by weight, viscosity 40-400mPa.s, activation temperature 45-55 ℃; Stirring for 8 minutes under the condition of 15000 rpm, thus obtaining the urea-coated composite emulsion.

Embodiment 2

[0081] Embodiment 2: Preparation of urea-coated composite emulsion of the present invention

[0082] The implementation steps of this embodiment are as follows:

[0083] Carry out according to the same embodiment as Example 1, just put 24 parts by weight deionized water in the container at first, adjust its pH value to 8.2 with concentrated ammonia water; Under the condition of 520rpm, add 70 parts by weight of the described styrene-acrylic emulsion sequentially respectively; 1.2 parts by weight of the described alkyl polyoxyethylene ether; 25 parts by weight of the described water-based polyurethane emulsion; then stir for 10min under the condition of rotating speed 20000rpm , so as to obtain the described urea-coated composite emulsion.

Embodiment 3

[0084] Embodiment 3: Preparation of urea-coated composite emulsion of the present invention

[0085] The implementation steps of this embodiment are as follows:

[0086] Carry out according to the same embodiment as Example 1, just put 18 parts by weight of deionized water into the container at first, adjust its pH value to 8.0 with concentrated ammonia water; Under the condition of 500rpm, add the styrene-acrylic emulsion described in 56 parts by weight sequentially respectively; The fatty alcohol polyoxyethylene ether sodium sulfate described in 0.9 parts by weight; The water-based polyurethane emulsion described in 18 parts by weight; Under the condition of stirring for 8-10910min, the urea-coated composite emulsion is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com