Uniform-sized konjak gulcomannan microspheres and preparation method thereof

A technology of konjac glucomannan and average particle size, which is applied in the field of small particle size konjac glucomannan microspheres and its preparation, and can solve problems such as difficulty in droplet shedding, wide particle size distribution, and increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

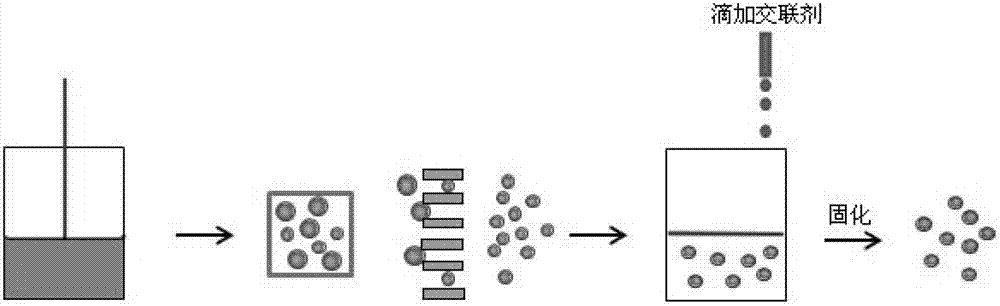

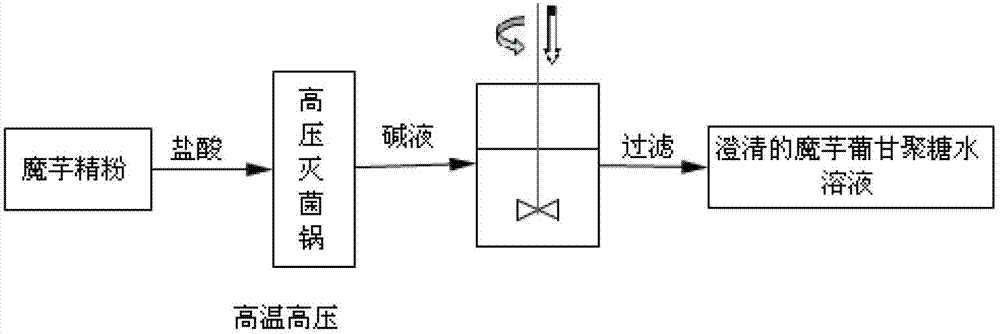

[0069] Embodiment 1: the preparation of konjac glucomannan aqueous solution (such as figure 2 )

[0070] In a 500ml reactor, mix 20ml of 0.5M HCl and 120g of deionized water evenly, pour 20.0g of konjac glucomannan into the mixture, stir evenly, and swell for 5 minutes to form jelly. Cover the reactor with parafilm or a watch glass, put it in an autoclave, and degrade it at 115°C for 30 minutes. After the degradation is complete, take out the reactor and place it at room temperature. Add 40g of 40% NaOH solution, stir to dissolve the slurry, and filter impurities to obtain a clear aqueous solution of 10% konjac glucomannan. The same method can prepare konjac glucomannan aqueous solution with solid content of 0.1%, 4%, 15%, 20%, 40% and so on for future use.

Embodiment 2

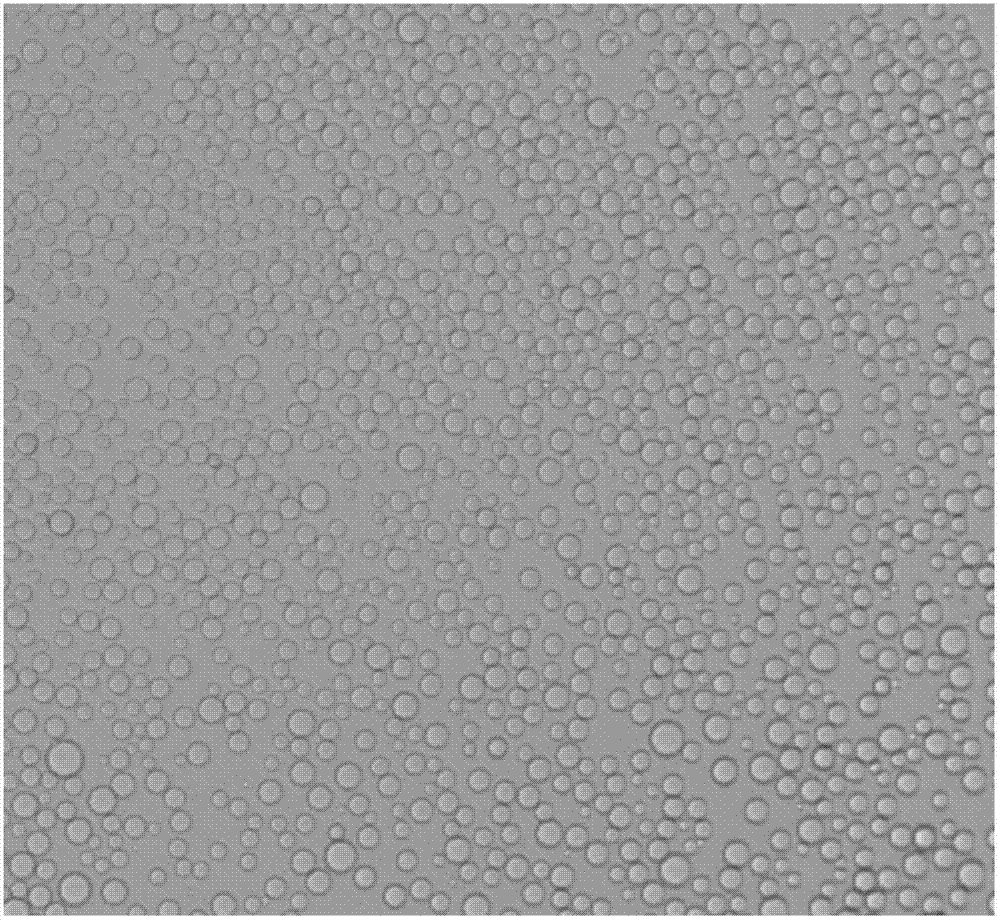

[0072] Put a membrane with a pore size of 9.2 μm in a lipophilic substance for infiltration, add 37.5g of oil-soluble emulsifier Span 80 to 750g of a mixture of liquid paraffin and petroleum ether (mass ratio 11:1), and stir until completely dissolved And heated to 60°C as an oil phase. Quickly mix 100g of the water phase (the concentration of konjac glucomannan is 5%) with the oil phase and emulsify at 5000rpm for 30 seconds with homogeneous emulsification. kgf / cm 2 Quickly pass through a microporous membrane with uniform pore size under pressure to obtain a W / O emulsion with relatively uniform particle size, and use the obtained emulsion as a primary emulsion at 0.5kgf / cm 2 The pressure passes through the microporous membrane again and repeats the emulsification three times; after the emulsification is completed, slowly add 50 g of the cross-linking agent epichlorohydrin into the emulsion for about 0.5 hours. After the dropwise addition, the cross-linking reaction was carr...

Embodiment 3

[0074] Place a membrane with a pore size of 10.2 μm in a lipophilic substance for infiltration, add 8015 g of oil-soluble emulsifier Span to 500 g of a mixture of liquid paraffin and petroleum ether (mass ratio 7:5), stir until completely dissolved and heat to 50°C as the oil phase. Quickly mix 100g of the water phase (the concentration of konjac glucomannan is 12%) with the oil phase and emulsify at 5000rpm for 30 seconds with homogeneous emulsification. kgf / cm 2 Rapidly pass through a microporous membrane with uniform pore size under pressure to obtain a W / O emulsion with relatively uniform particle size, and use the obtained emulsion as a primary emulsion at 0.7kgf / cm 2 The pressure passes through the microporous membrane again and repeats the emulsification three times; after the emulsification is completed, slowly add 50 g of the cross-linking agent epichlorohydrin into the emulsion for about 0.5 hours. After the dropwise addition was completed, the crosslinking reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com