TiFe hydrogen storage alloy containing Co and Y and preparation method thereof

A hydrogen storage alloy and alloy technology, applied in the field of hydrogen storage materials, can solve the problems of easy oxidation, difficult activation of TiFe alloys, unsatisfactory hydrogen storage capacity, etc. The effect of improving hydrogen release time and solving activation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

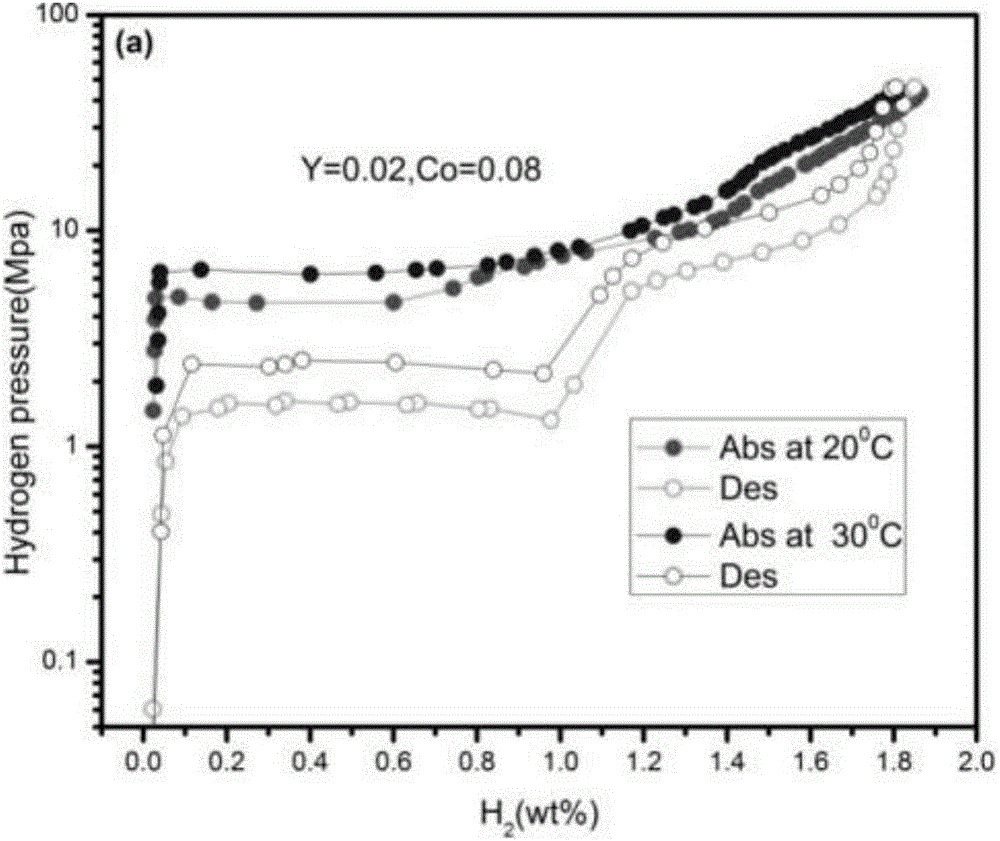

[0021] In this example, a TiFe hydrogen storage alloy with Co and Y added, its chemical formula is TiFe 0.86 mn 0.1 co 0.08 Y 0.02 .

[0022] In this embodiment, the preparation method of TiFe hydrogen storage alloy comprises the following steps:

[0023] a. According to TiFe 0.86 mn 0.1 co 0.08 Y 0.02 The molar ratio of the elements is respectively weighed Ti, Fe, Mn, Co and Y elemental metal materials with a purity of 99.9%, and the Ti, Fe, Mn, Co and Y elemental elements are used as raw materials;

[0024] b. Using the magnetic levitation smelting process, first put all the raw materials weighed in the step a into the crucible, feed the smelting crucible with high-purity argon gas with a purity of 99.9%, and wash the furnace 5 times, each time Fill the furnace with high-purity argon to make the atmosphere pressure in the furnace 0.6atm; in the magnetic levitation melting process, control the melting power up to 15KW, and slowly increase the melting power at a rate o...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

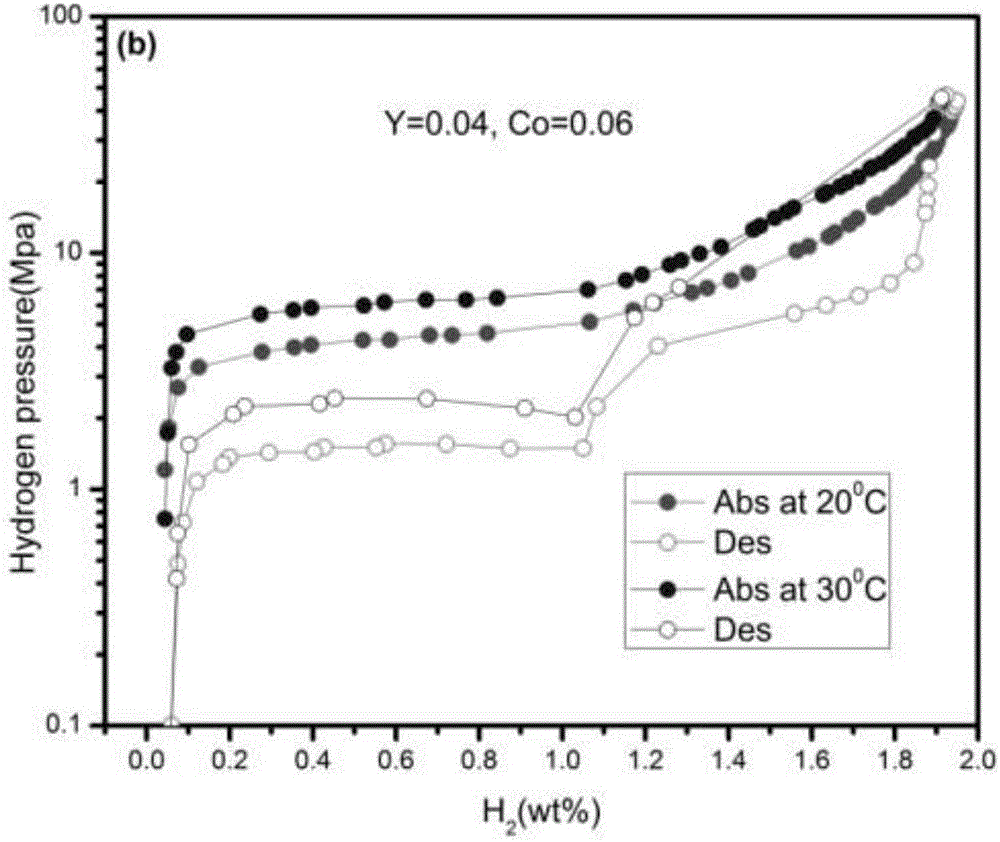

[0030] In this example, a TiFe hydrogen storage alloy with Co and Y added, its chemical formula is TiFe 0.86 mn 0.1 co 0.06 Y 0.04 .

[0031] In this embodiment, the preparation method of TiFe hydrogen storage alloy comprises the following steps:

[0032] a. According to TiFe 0.86 mn 0.1 co 0.06 Y 0.04 The molar ratio of the elements is respectively weighed Ti, Fe, Mn, Co and Y elemental metal materials with a purity of 99.9%, and the Ti, Fe, Mn, Co and Y elemental elements are used as raw materials;

[0033] b. Using the magnetic levitation smelting process, first put all the raw materials weighed in the step a into the crucible, feed the smelting crucible with high-purity argon gas with a purity of 99.9%, and wash the furnace 5 times, each time Fill the furnace with high-purity argon gas so that the atmosphere pressure in the furnace is 0.6atm; in the magnetic levitation melting proc...

Embodiment 3

[0038] This embodiment is basically the same as the previous embodiment, and the special features are:

[0039] In this example, a TiFe hydrogen storage alloy with Co and Y added, its chemical formula is TiFe 0.86 mn 0.1 co 0.08 Y 0.02 .

[0040] In this embodiment, the preparation method of TiFe hydrogen storage alloy comprises the following steps:

[0041] a. Use Ti-Fe-Mn as the master alloy, and use TiFe hydrogen storage alloy TiFe according to the target 0.86 mn 0.1 co 0.08 Y 0.02 Add Co material and Y material to Ti-Fe-Mn master alloy in molar ratio of element components as raw materials;

[0042] b. This step is the same as in Embodiment 1.

[0043] Experimental test analysis:

[0044] Grind the TiFe hydrogen storage alloy ingot prepared in Example 3 with sandpaper to remove the surface oxide layer, then mechanically grind and pulverize the alloy through a 200-mesh sieve to obtain hydrogen storage alloy powder and reserve it for later use. The density of the hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com