Gas discharging connector

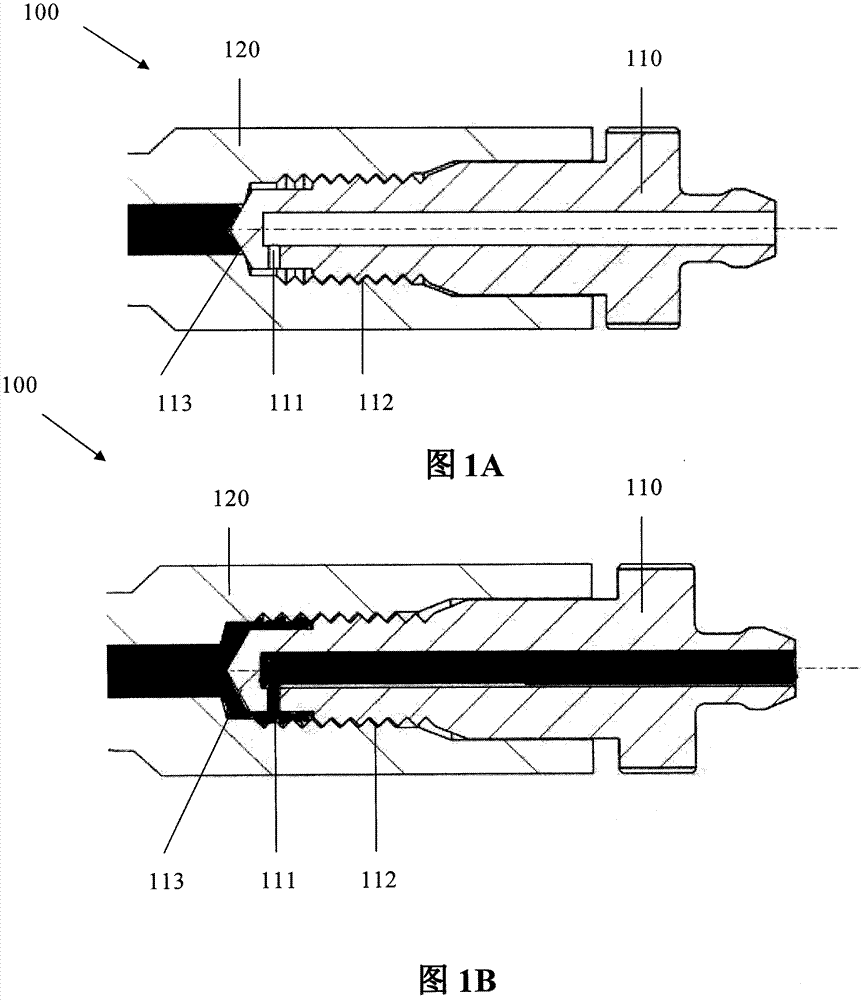

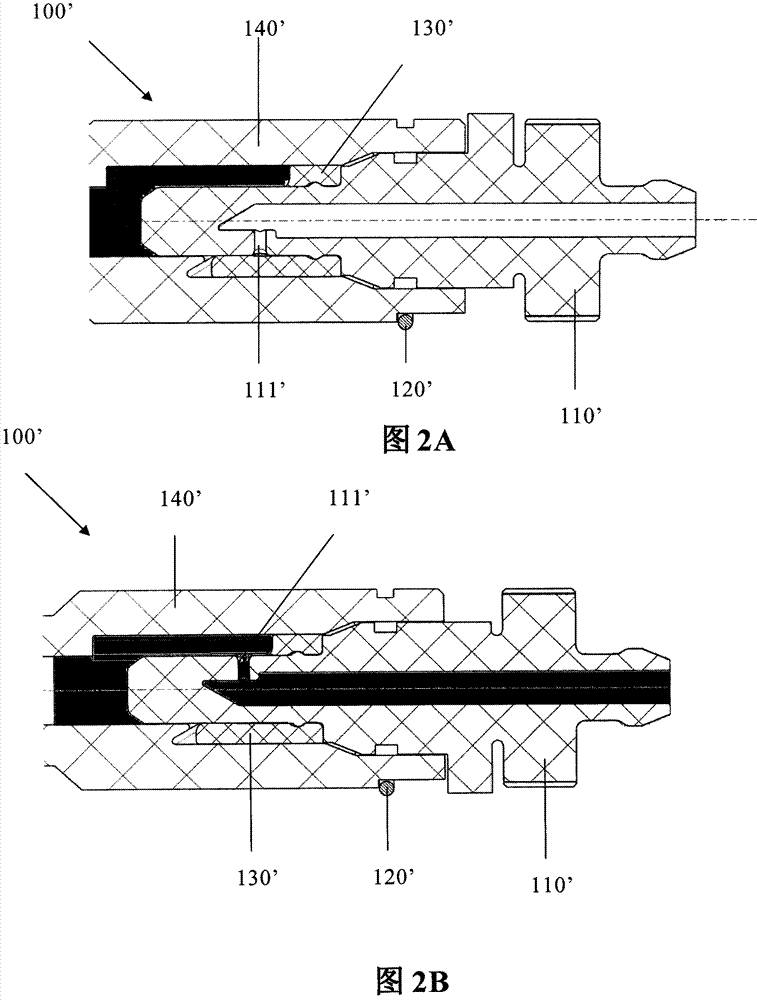

A technology for deflation joints and deflation valves, which is applied in the direction of non-mechanical drive clutches, fluid drive clutches, clutches, etc., can solve problems such as leakage of the deflation valve body and joint housing, and reduce the degree of correlation and leakage risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below with reference to FIGS. 3-5 .

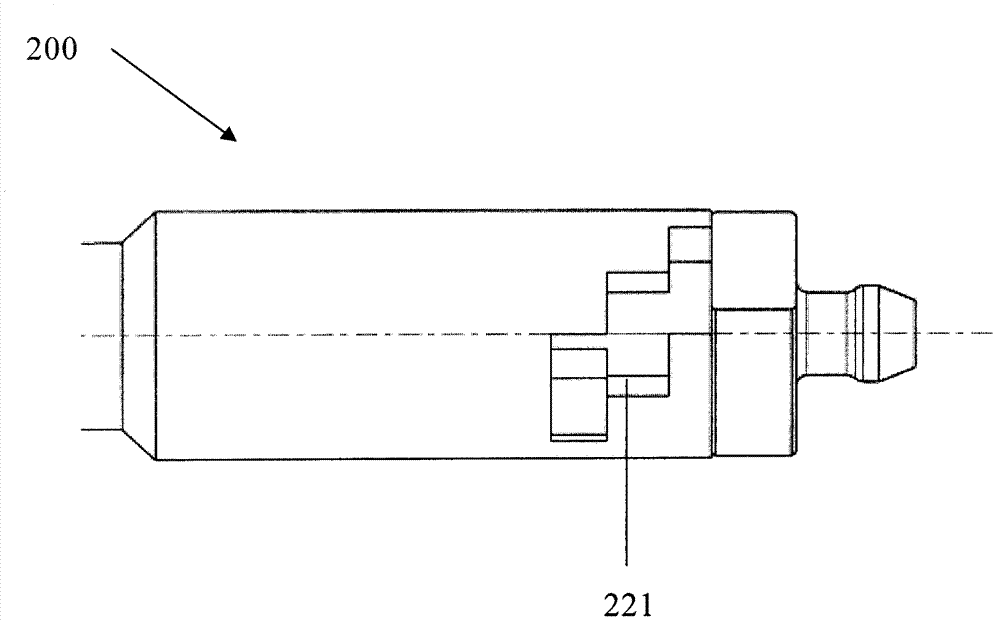

[0022] Figure 3A -B and Figure 4A -B shows the bleed joint 200 of the present invention for the vehicle hydraulic clutch separation system, which includes a bleed valve body 210 and a joint housing 220, the bleed valve body 210 is assembled in the joint housing 220, and can be opposite to the joint The housing 220 rotates, a main seal 230 is installed between the deflation valve body 210 and the joint housing 220, and the deflation valve body 210 has a hole 211 on its outer periphery, and the hole 211 can be main sealed The member 230 is closed and can be opened after being rotated 180 degrees for discharge. The joint 200 also has an auxiliary seal 240 installed between the deflation valve body 210 and the joint housing 220 behind the hole 211 in the discharge direction.

[0023] In an embodiment, the purge valve body 210 includes a large diameter portion and a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com