Automatic welding production line and automatic welding method for wire coils

An automatic welding and production line technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency and low degree of automation, improve production efficiency and degree of automation, reduce production costs, and increase clamping The effect of holding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

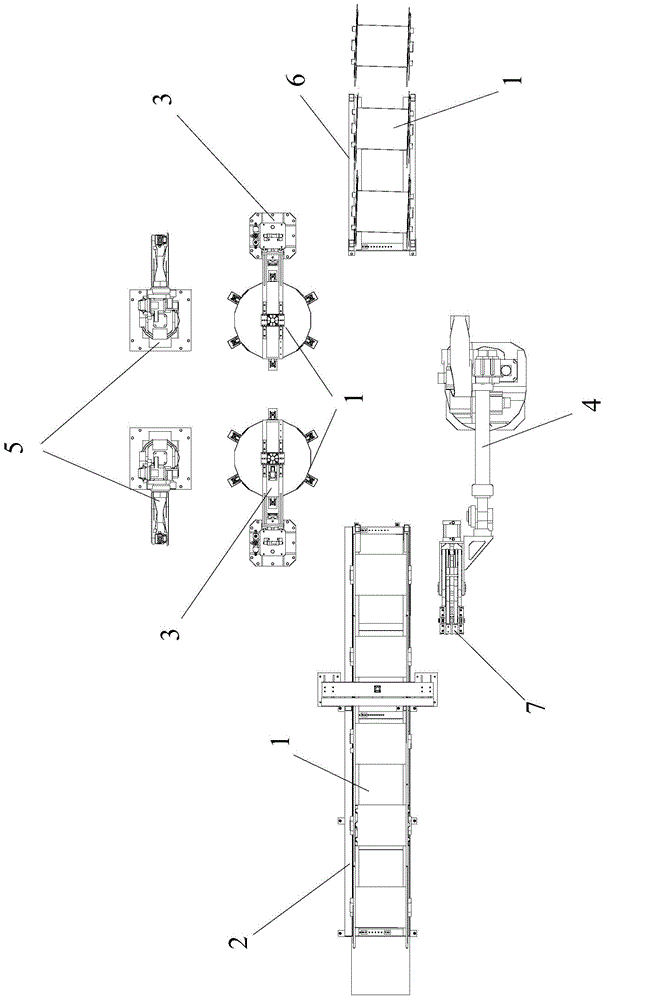

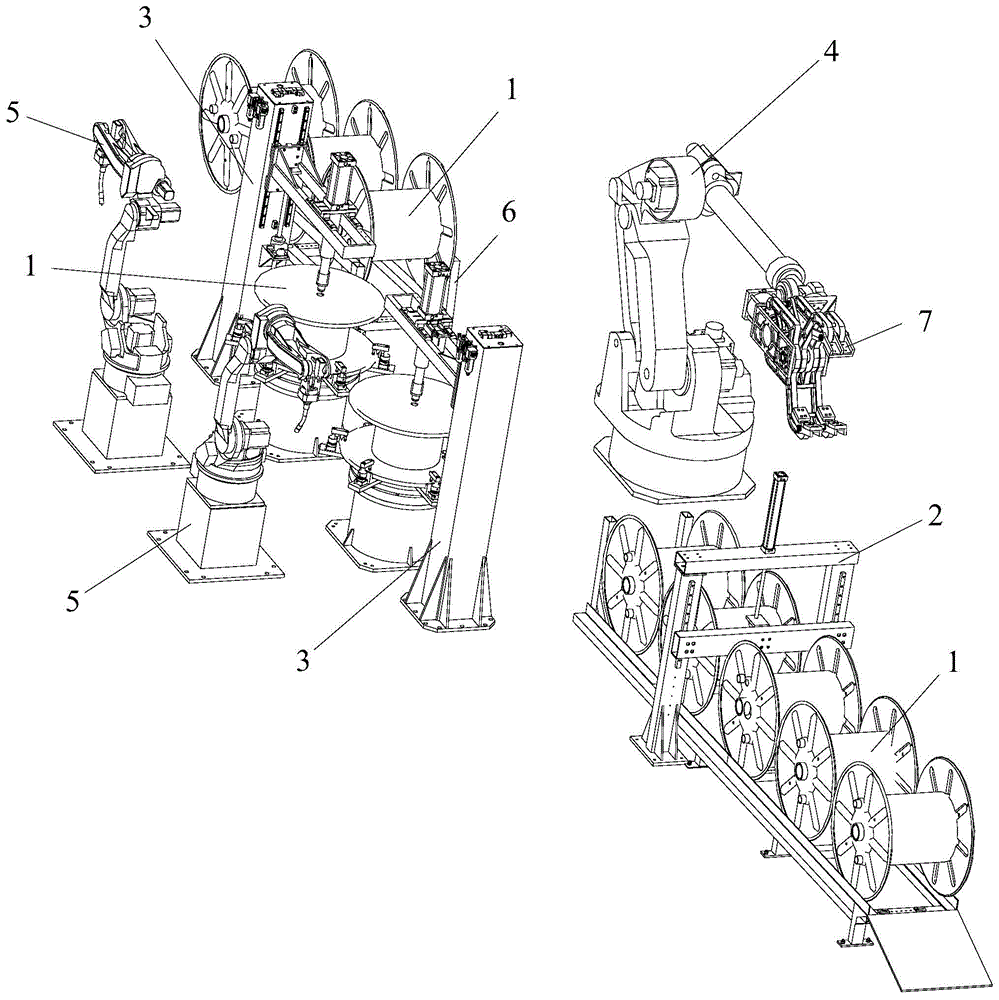

[0054] Such as Figure 1 to Figure 9 As shown, the wire reel automatic welding production line of the present invention is used for welding the wire reel 1, which includes a feed conveying mechanism 2 for separating and conveying the wire reel 1; for positioning and rotating the wire reel 1 The compression positioning mechanism 3; is used to grab the wire reel 1 from the feed conveying mechanism 2, and the wire reel 1 is transported and placed on the compression positioning mechanism 3 for welding. The handling manipulator 4; The welding manipulator 5 for welding the wire reel 1 on the 3; the discharge conveying mechanism 6 for transferring the wire reel 1; Control mechanism for signal connection.

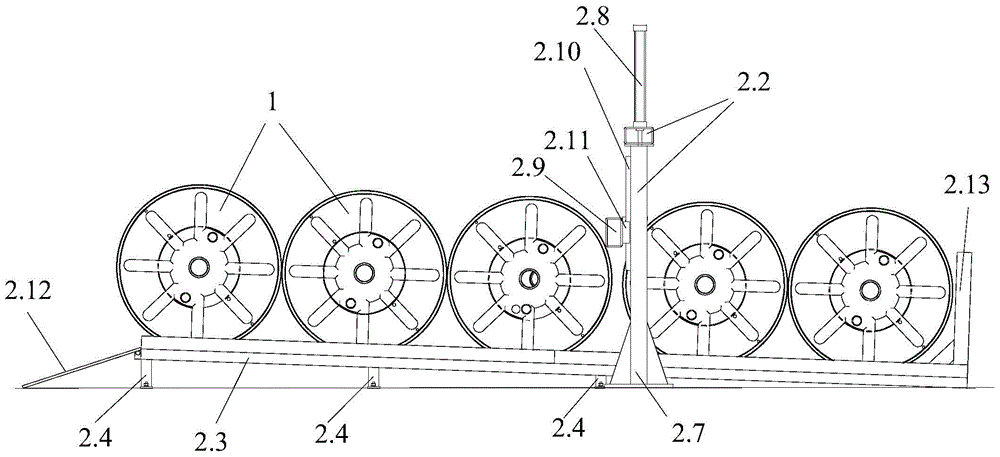

[0055] Such as image 3 and Figure 4 As shown, wherein, the feeding conveying mechanism 2 includes a transmission line and a separation device 2.2 for separating the transmission between the wire reels 1 so as to facilitate the subsequent operation of a single wire reel 1, wher...

Embodiment 2

[0082] The only difference between this embodiment and Embodiment 1 is that the two clamping arms can be set to a single-layer structure, a three-layer structure or a structure with more than three layers, and in the clamping arms with a three-layer structure or a structure with more than three layers , each structure is connected by connecting rods. The design of the multi-layer structure of the clamping arm can increase the contact area between the clamping arm and the workpiece, thereby further improving the clamping force of the clamping device.

[0083] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com