Patents

Literature

95 results about "Discharge procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Procedure for discharge. Discharge is planned and coordinated with the patient, family and all relevant agencies. As the date for discharge approaches, all patients will be assessed weekly, as opposed to monthly, to evaluate their progress.

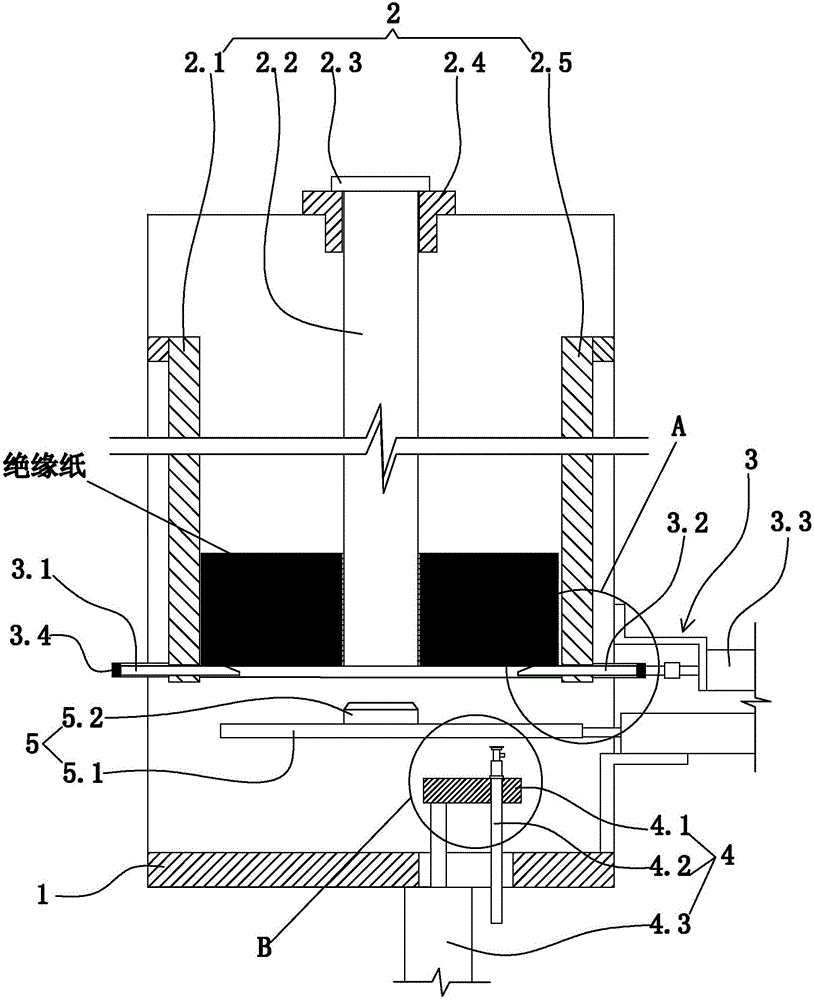

Temperature controlling system and method used during lithium ion power battery pack charging or discharging procedure

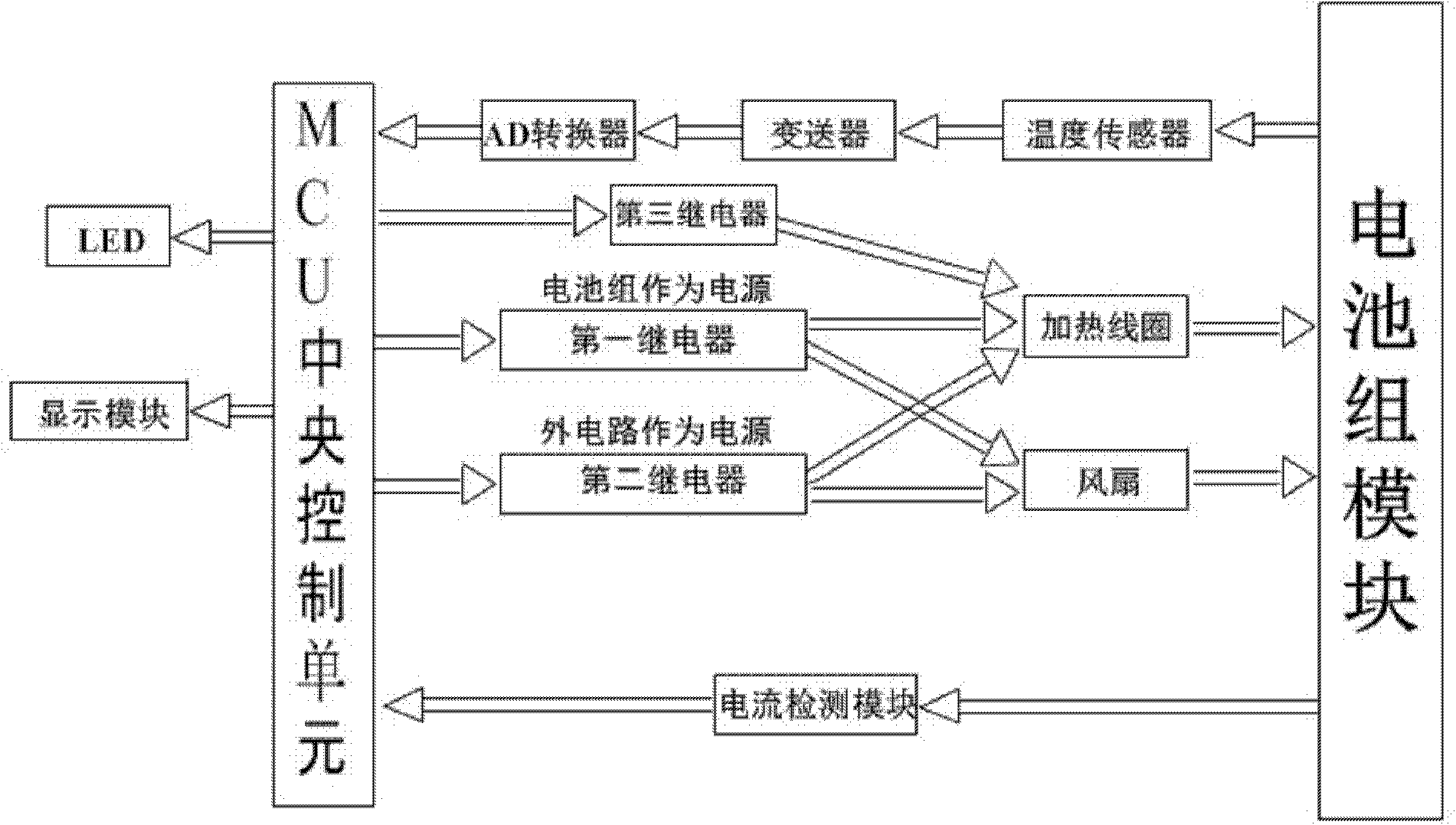

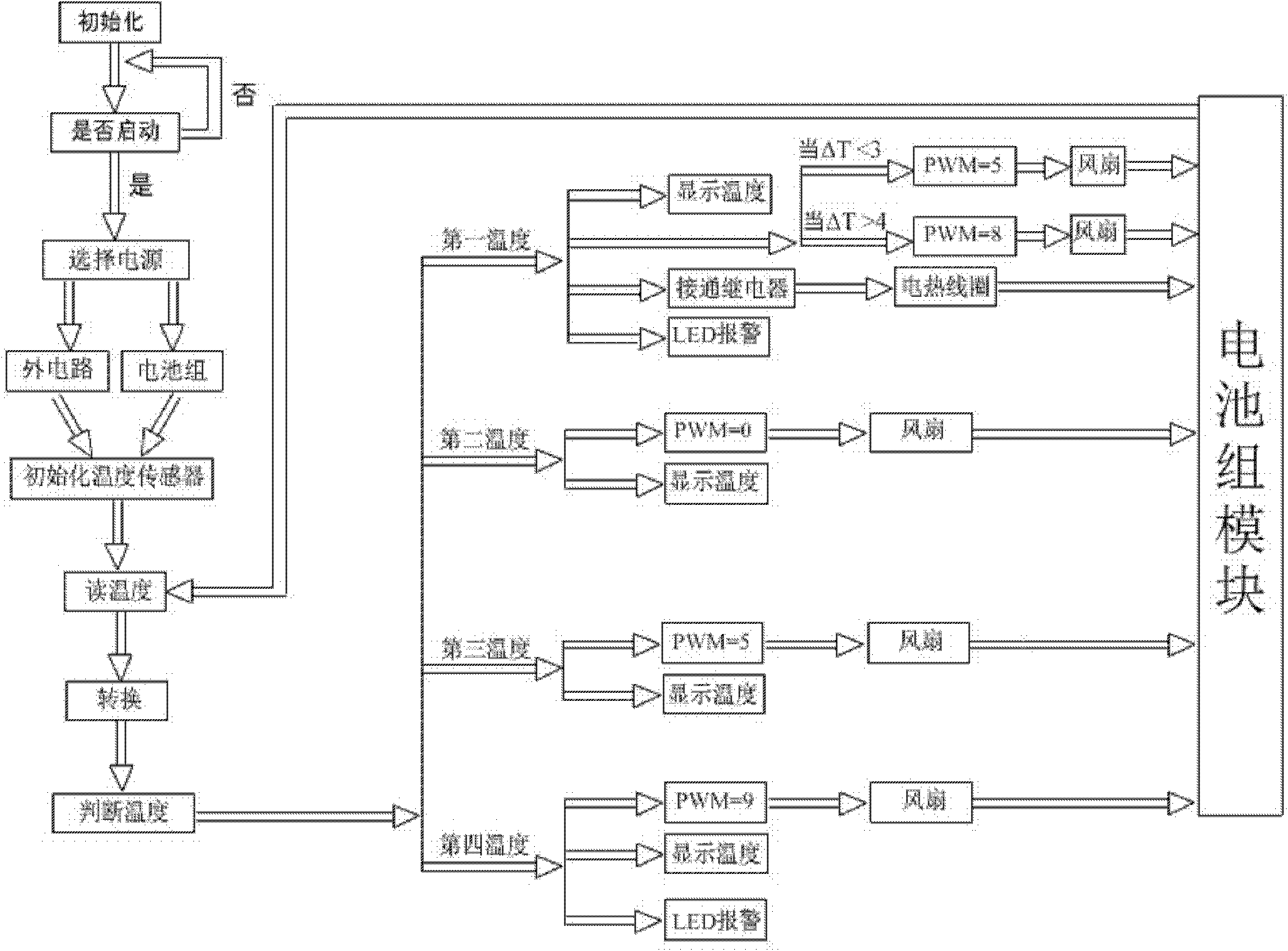

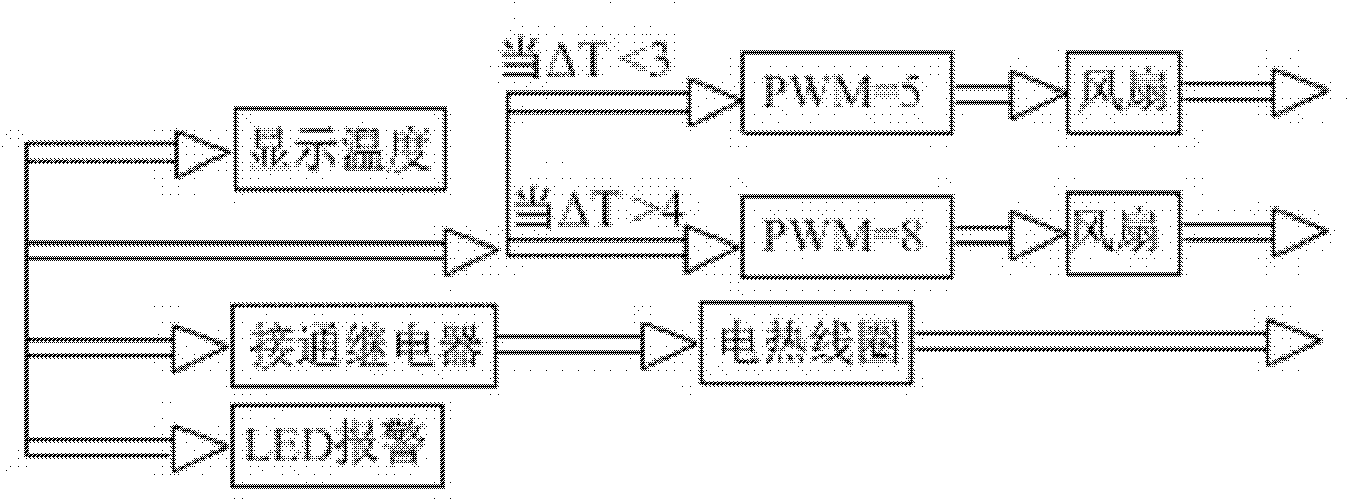

The invention relates to a temperature controlling system and a temperature controlling method used during a lithium ion power battery pack charging or discharging procedure. The system comprises a battery pack module, a temperature detecting unit, a temperature regulating unit, a controlling circuit, and a current detecting module used for detecting the current direction of the battery pack. The controlling circuit comprises a central controlling unit and a relay which are connected to each other. The battery pack module, the temperature detecting unit, and the central controlling unit are orderly connected. The current detecting module is arranged between the central controlling unit and the battery pack module. The temperature of the battery pack is regulated by the temperature regulating unit. Through the relay, the central controlling unit turns on or shuts off the temperature regulating unit according to the battery pack current direction detected by the current detecting module and the battery temperature detected by the temperature detecting unit. According to the invention, the output current can be regulated according to the temperature of the battery pack. An additional circuit or the battery pack is selected for providing currents for the temperature regulating unit according to charging or discharging conditions. With the system and the method provided by the invention, purposes of security ensuring, energy saving, and battery energy utilization rate improving are achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

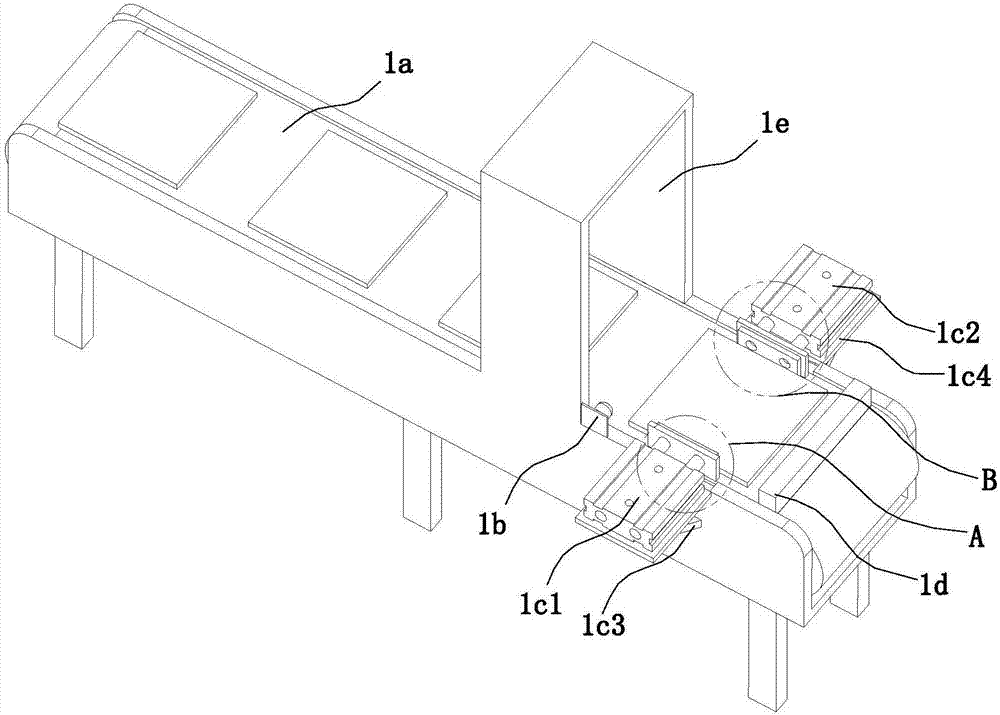

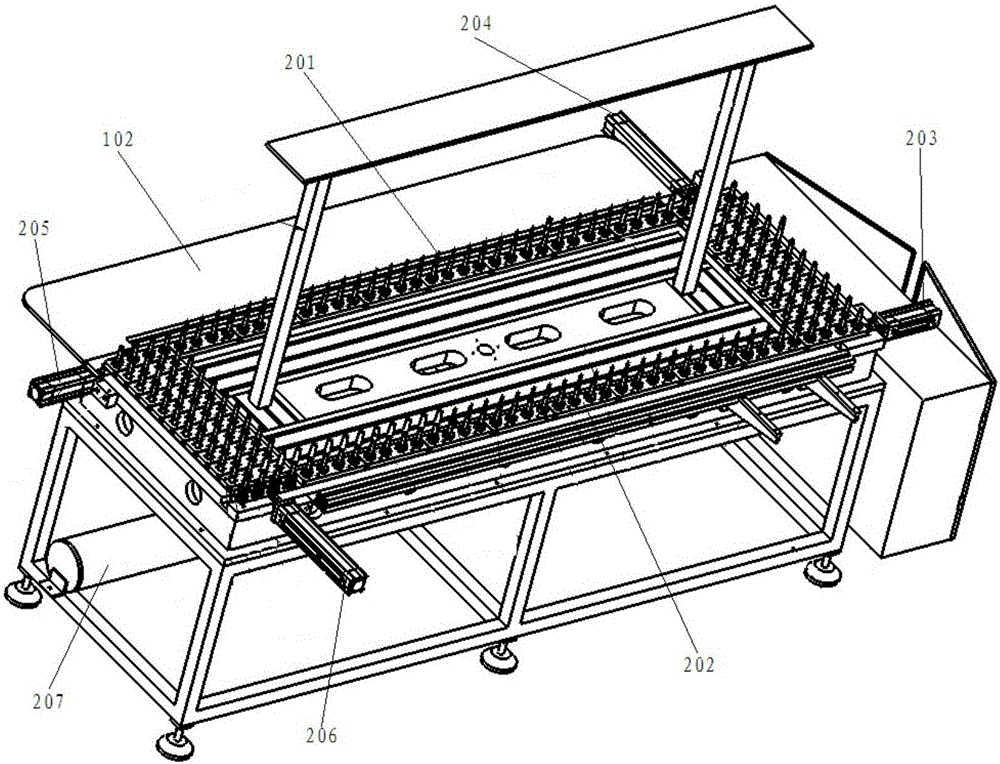

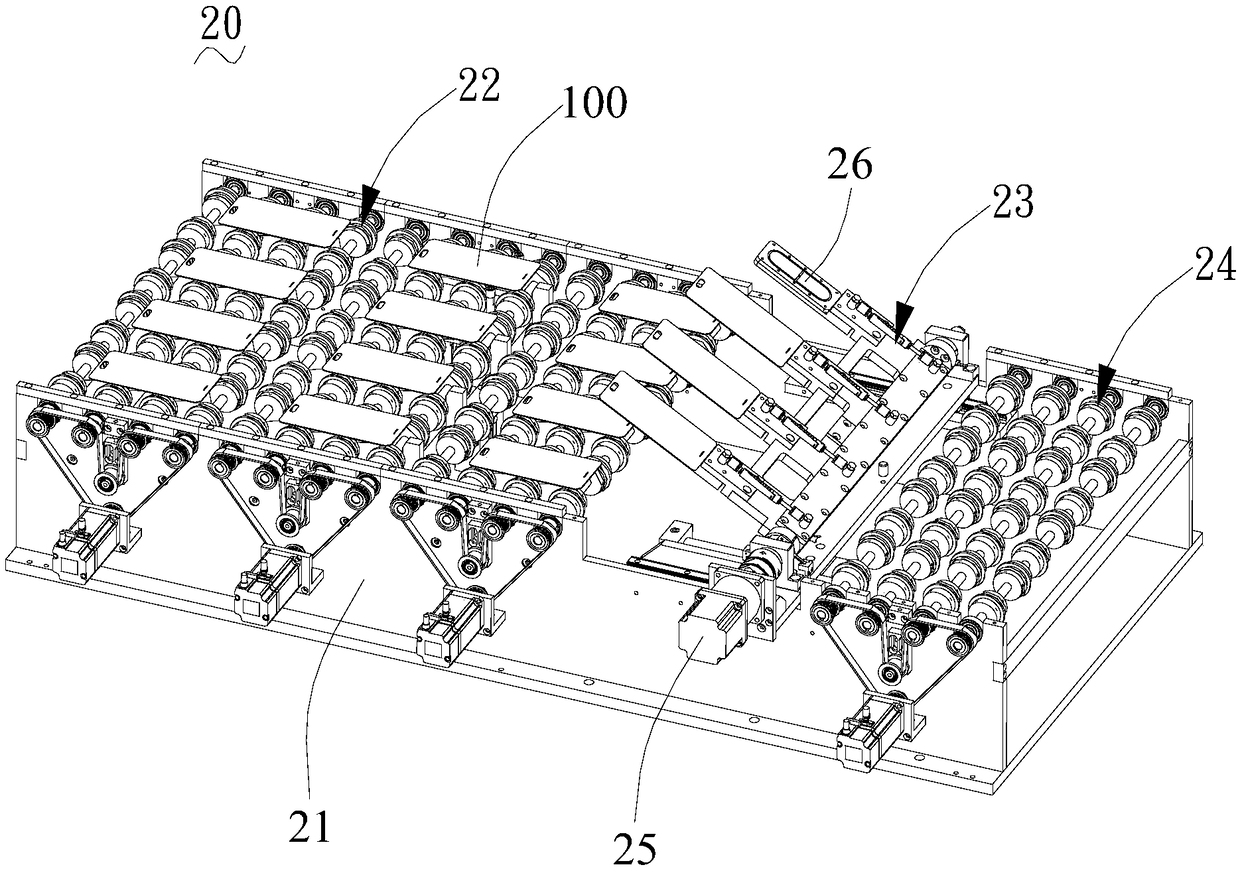

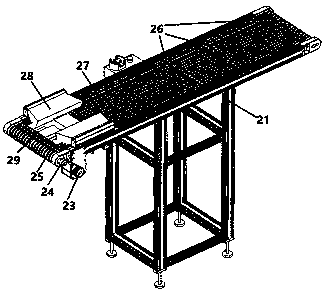

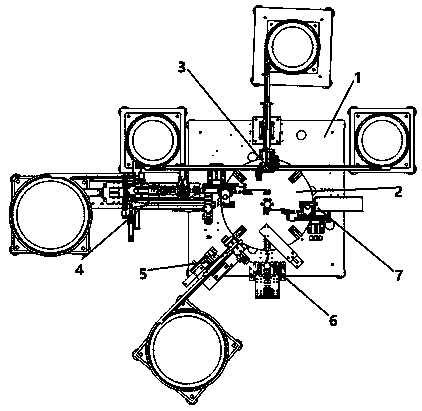

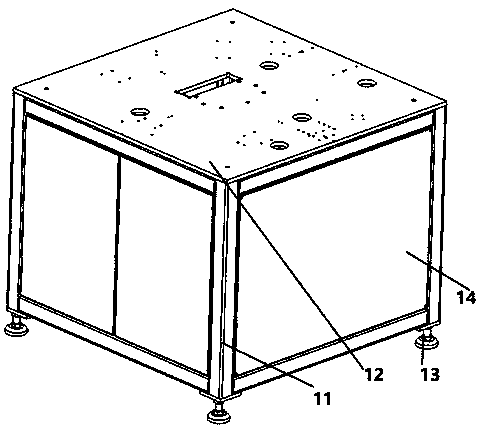

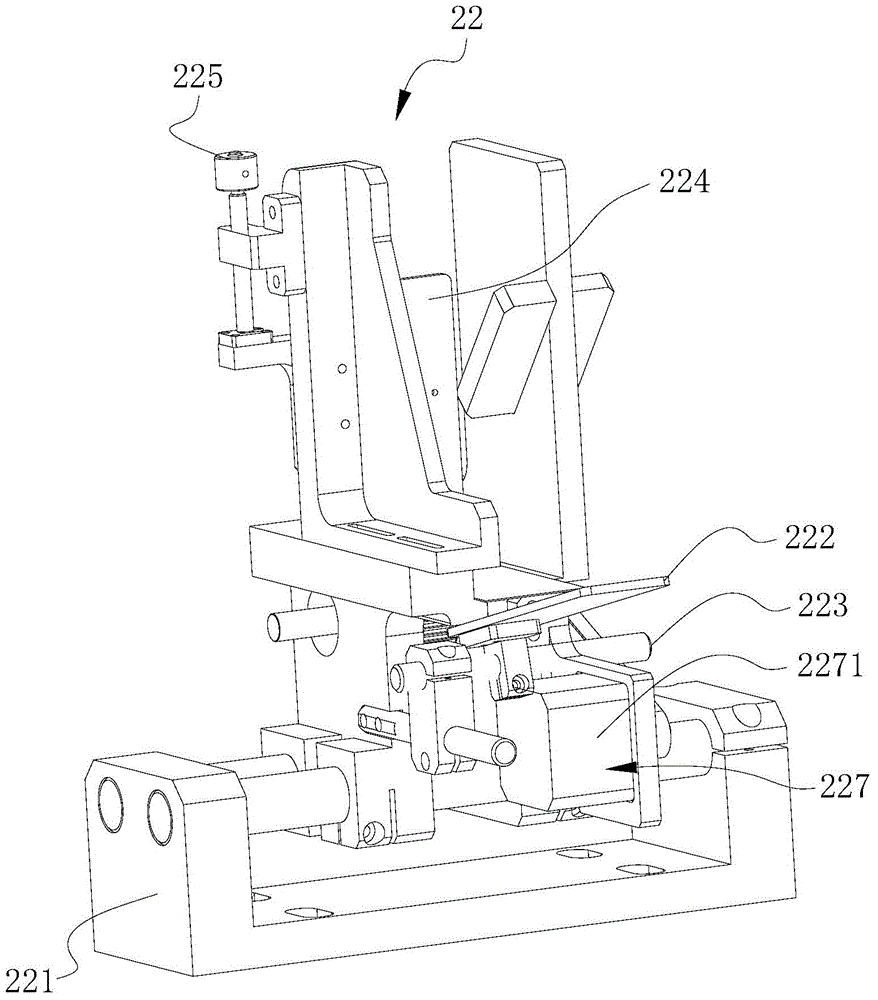

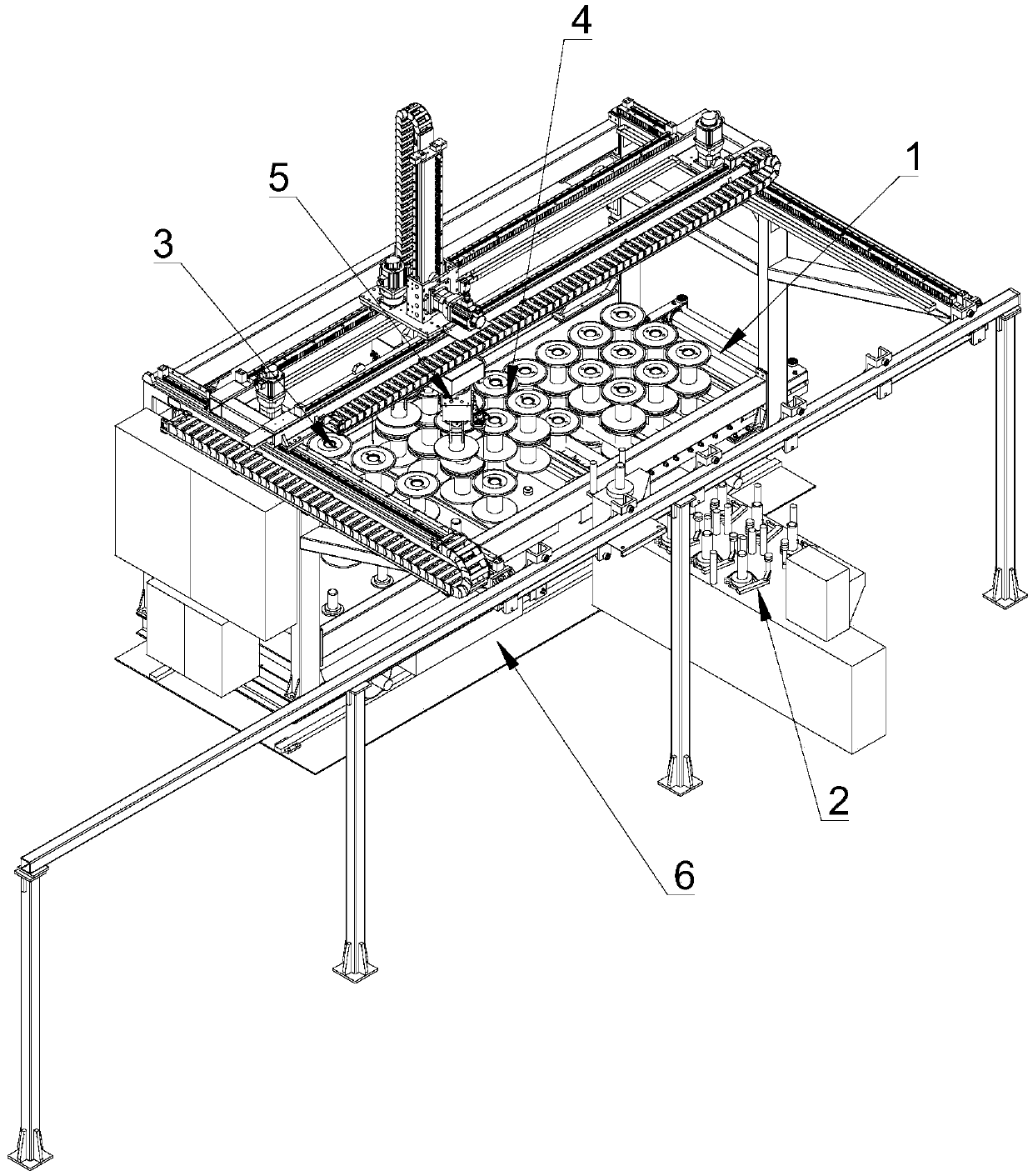

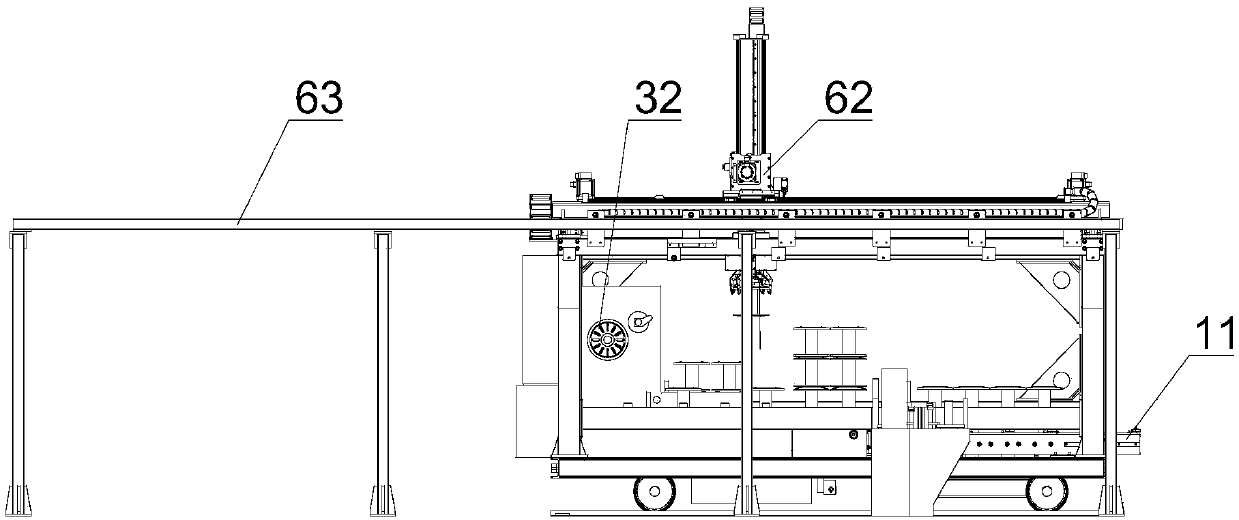

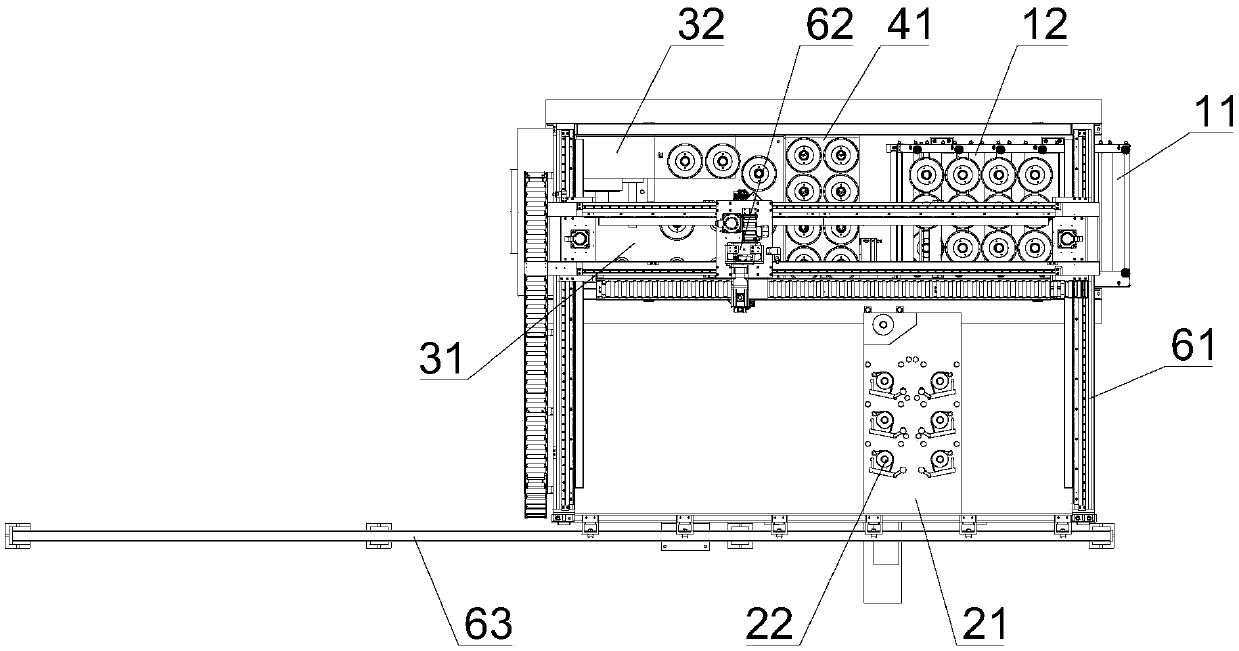

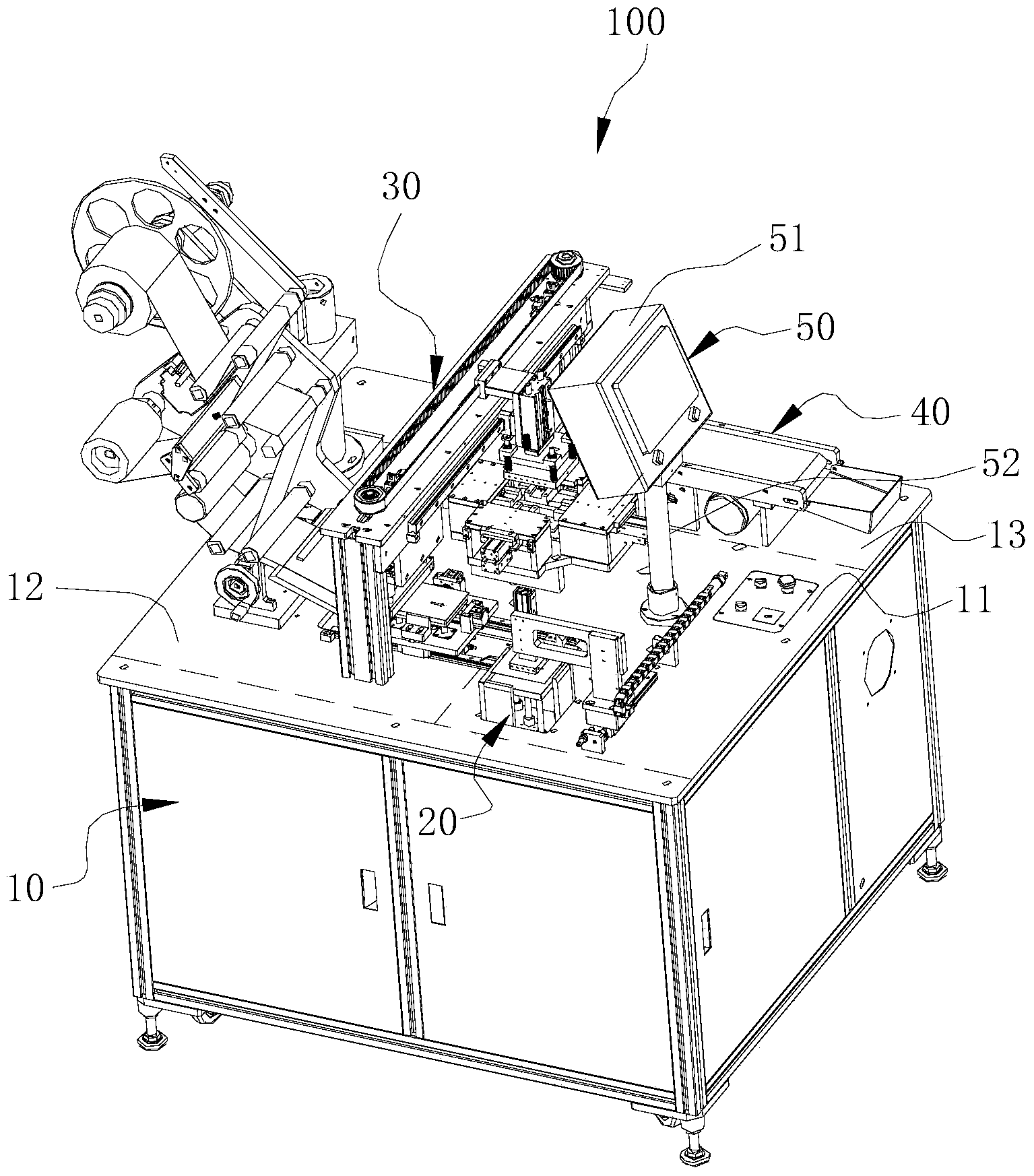

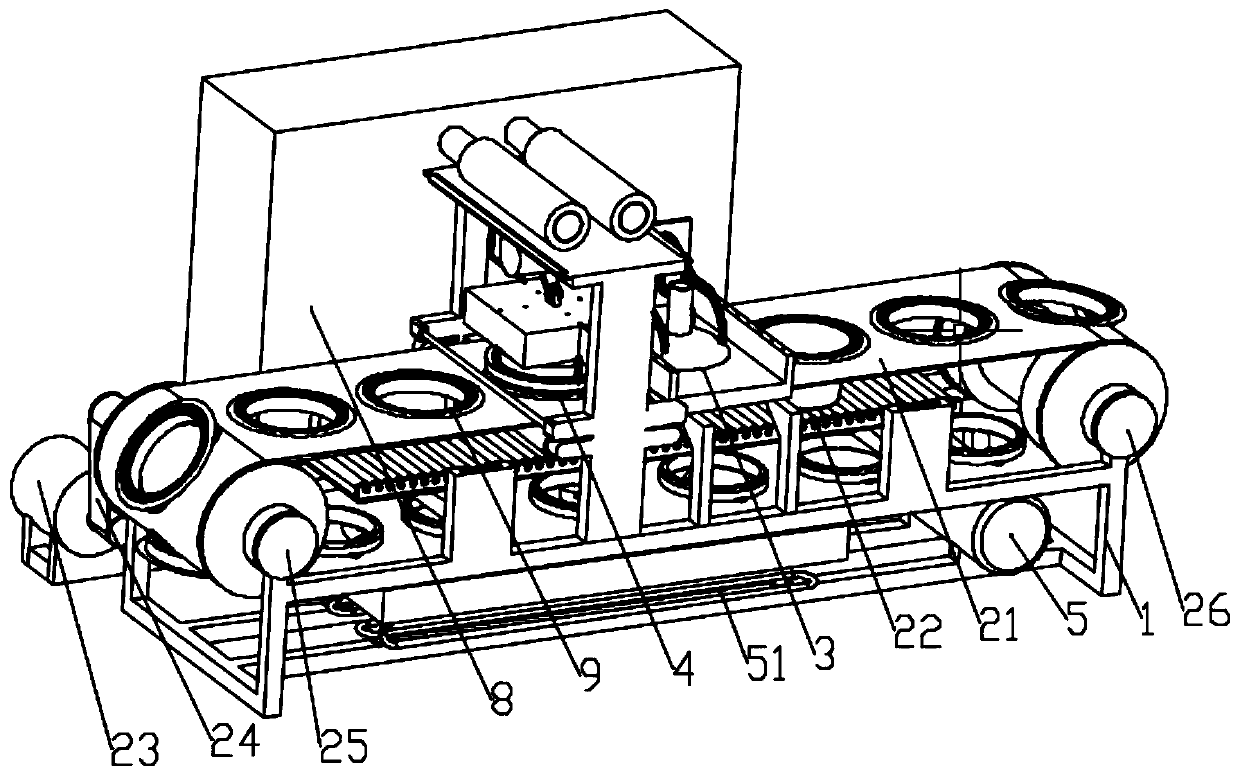

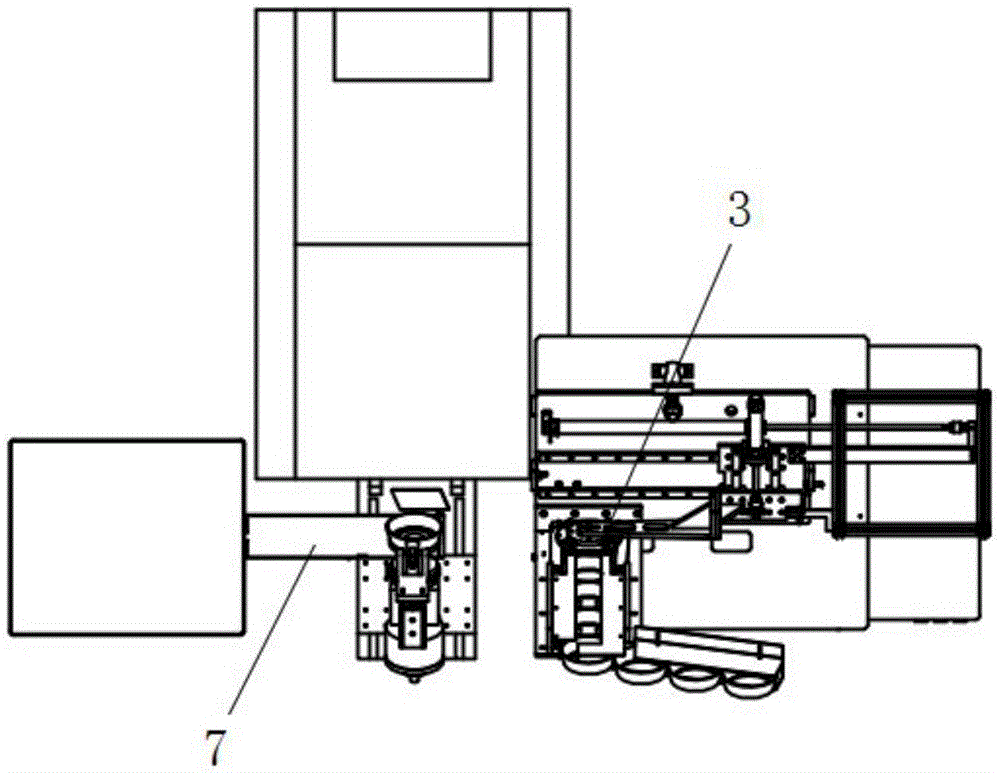

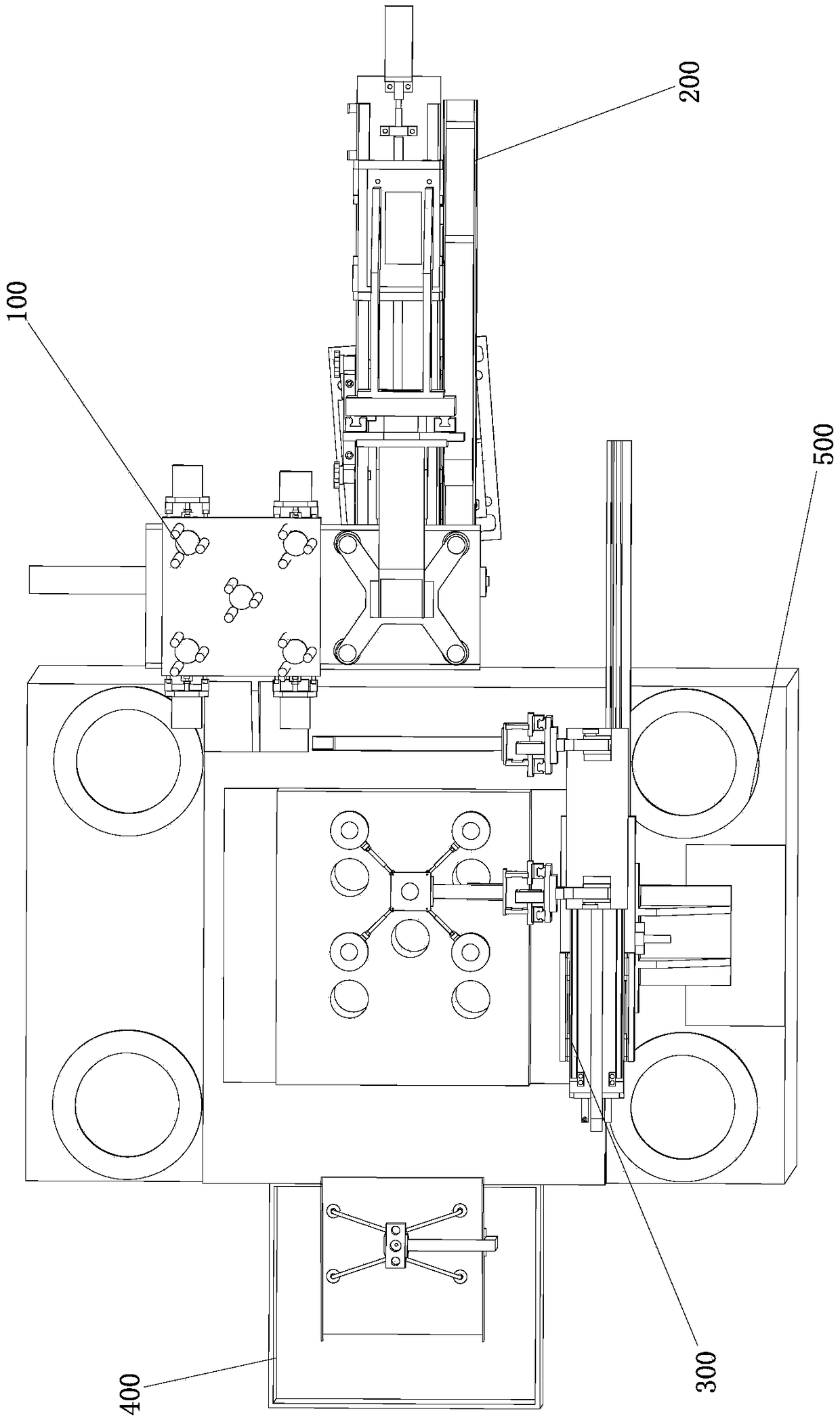

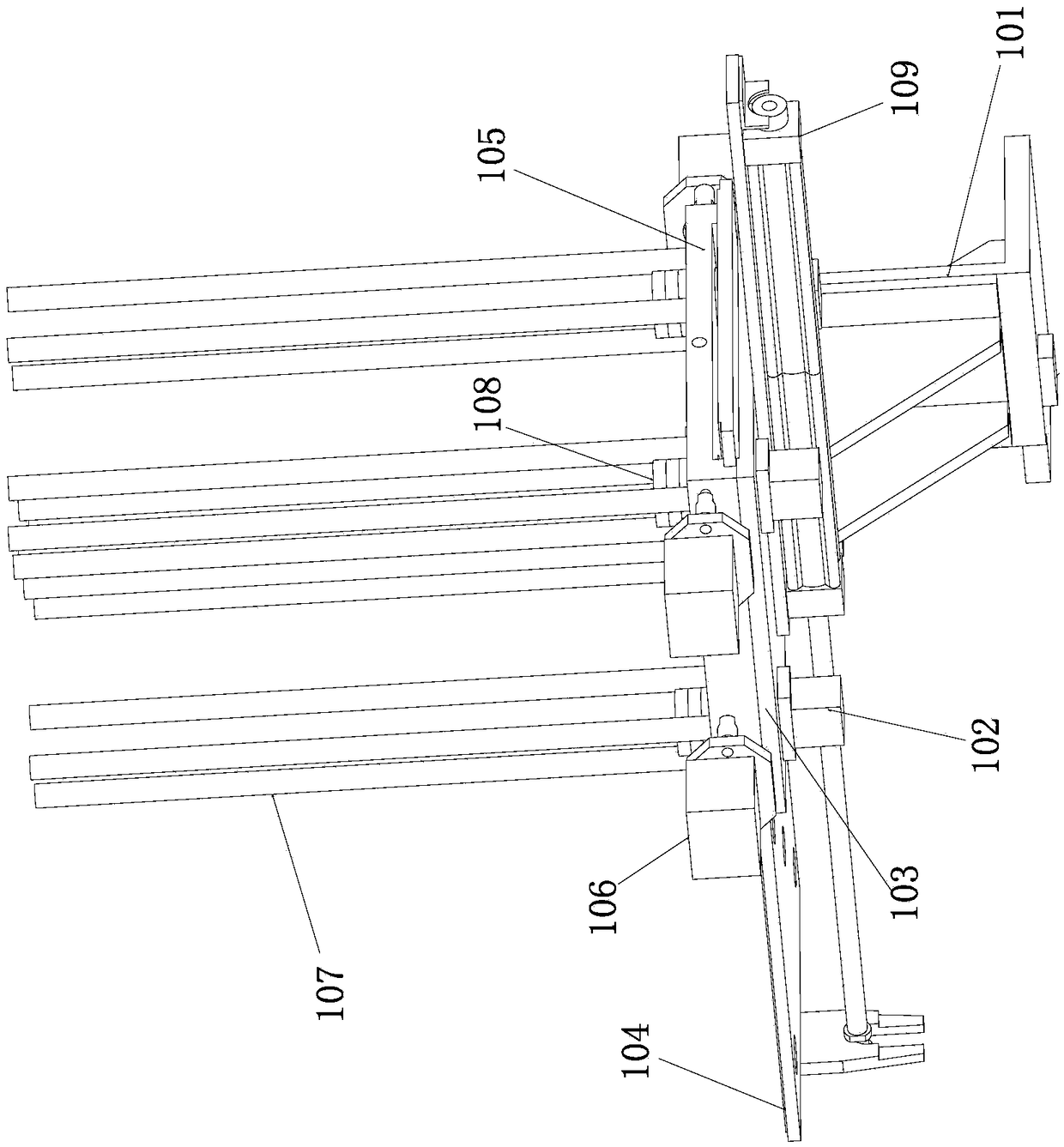

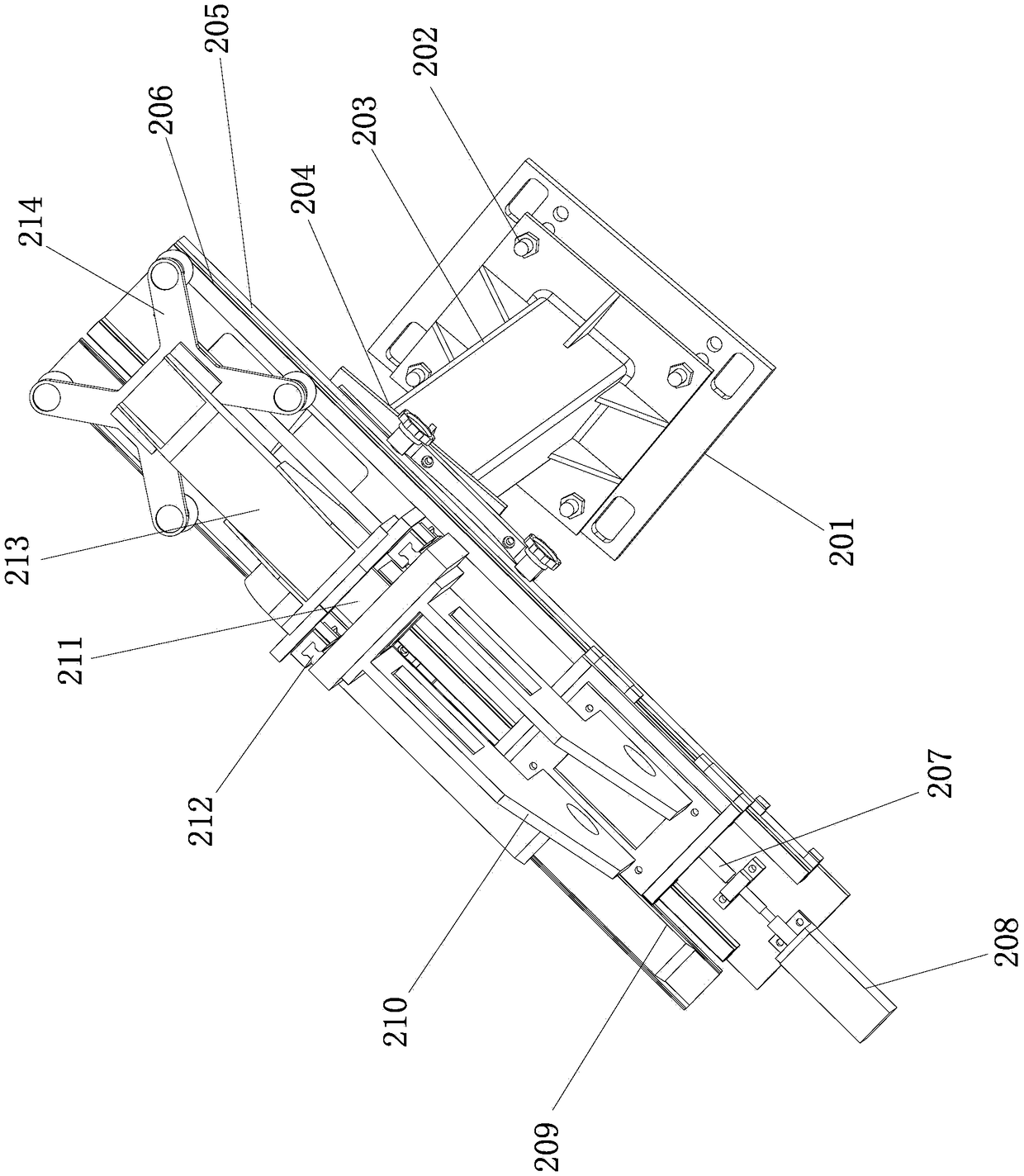

Automatic feeding and discharging device for glass edge grinding machine

PendingCN107511754AImproved edging processAvoid affecting subsequent processing operationsEdge grinding machinesGrinding feedersEngineeringTransfer mechanism

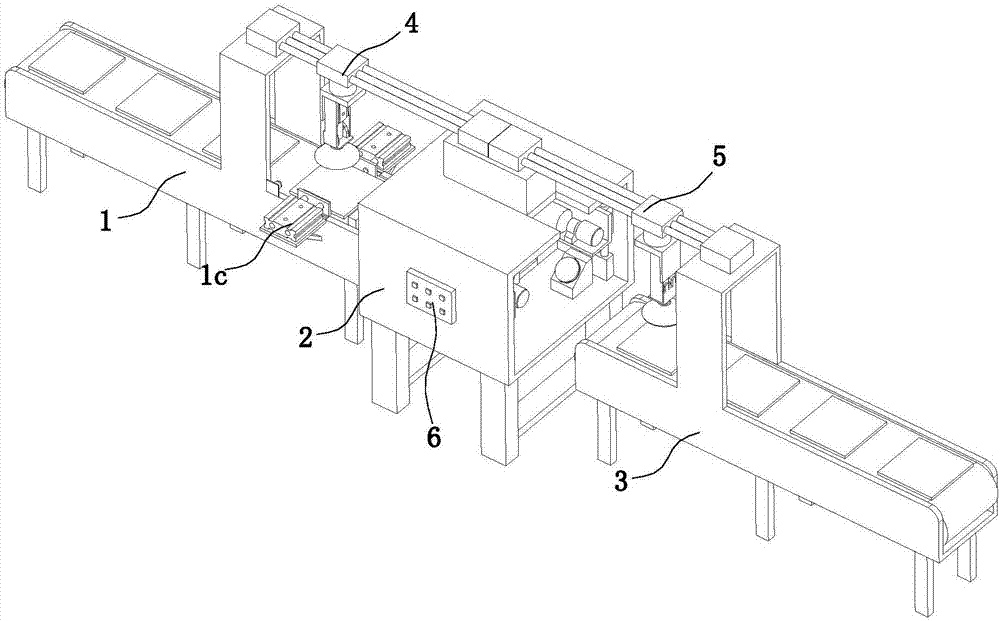

The invention relates to the field of edge grinding equipment, in particular to an automatic feeding and discharging device for a glass edge grinding machine. The automatic feeding and discharging device for the glass edge grinding machine comprises a feeding device, a machining device and a discharging device which are sequentially arranged along the glass machining procedure; a first transferring mechanism is arranged between the feeding device and the machining device; a second transferring mechanism is arranged between the machining device and the discharging device; the feeding device comprises a first conveying belt, an induction sensor and an auxiliary correcting mechanism; the induction sensor and the auxiliary correcting mechanism are arranged in the conveying direction of a first conveying belt; the position of the discharging end of the first conveying belt is provided with a limiting plate with the width same as that of the first conveying belt; and the first conveying belt is provided with a first portal frame used for supporting one end of the first transferring mechanism. According to the automatic feeding and discharging device for the glass edge grinding machine, the automatic feeding and discharging procedure of the edge grinding machine is completed through the first transferring mechanism and the second transferring mechanism. The automatic feeding and discharging device for the glass edge grinding machine is simple in structure, high in automation degree and capable of reducing the manual work and improving the whole edge grinding procedure on glass.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

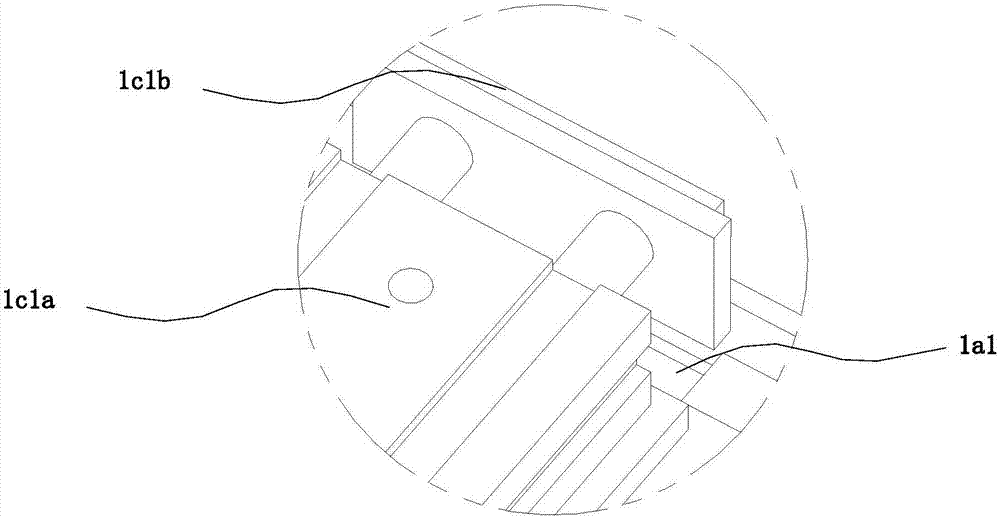

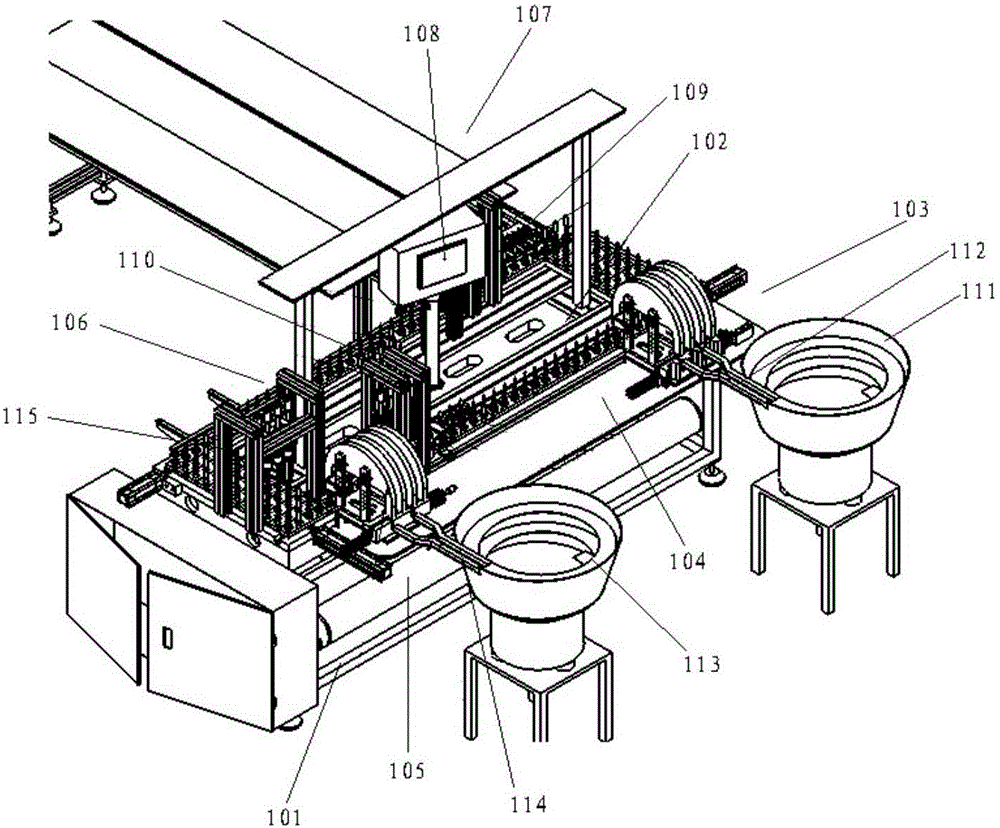

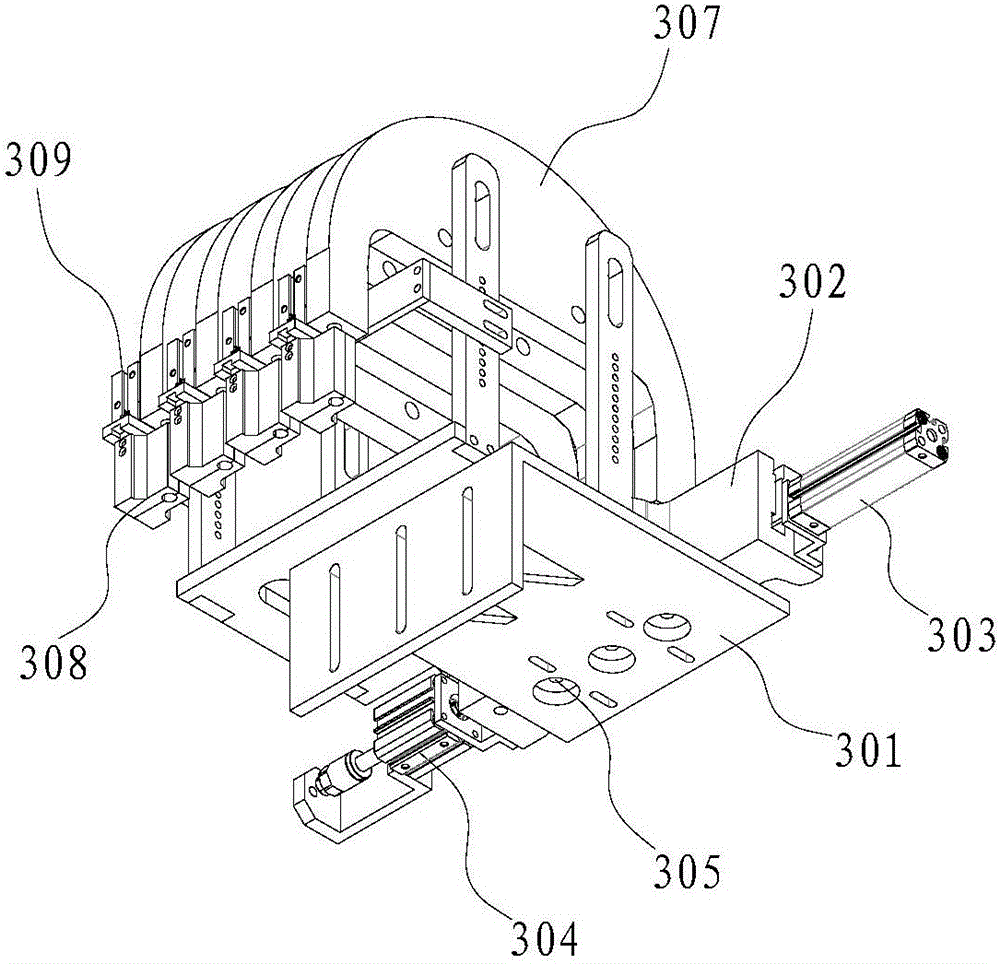

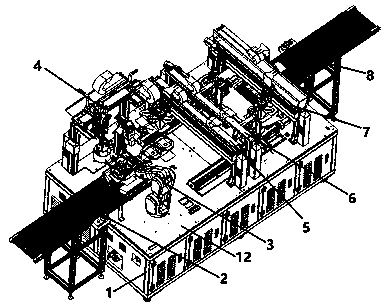

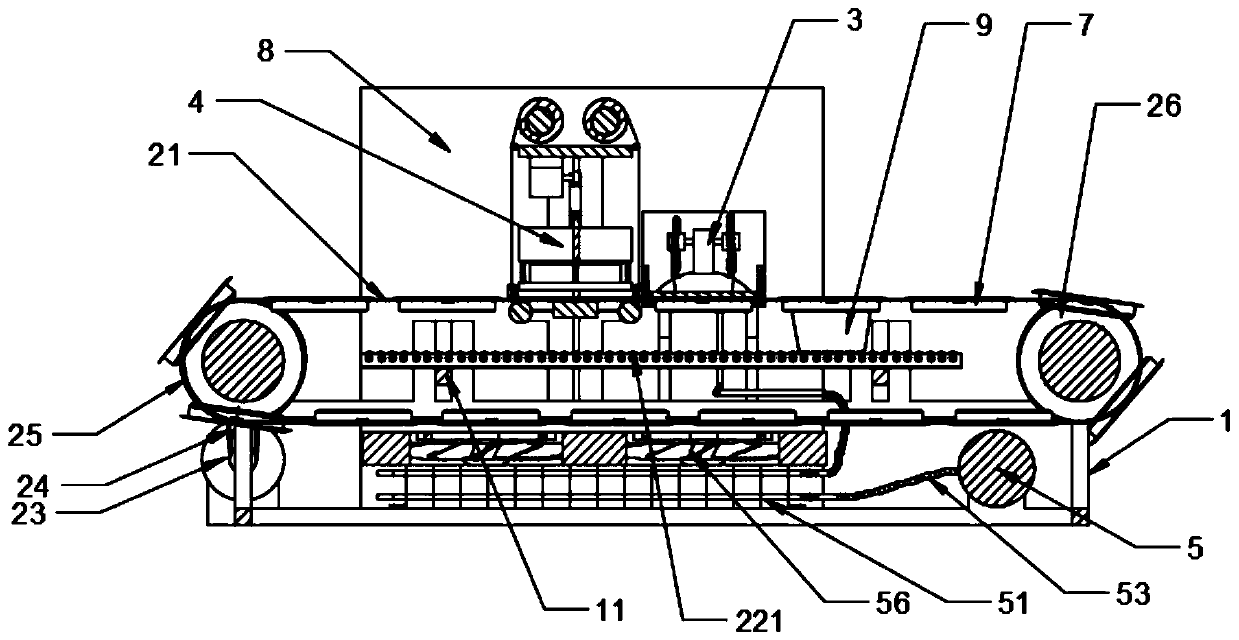

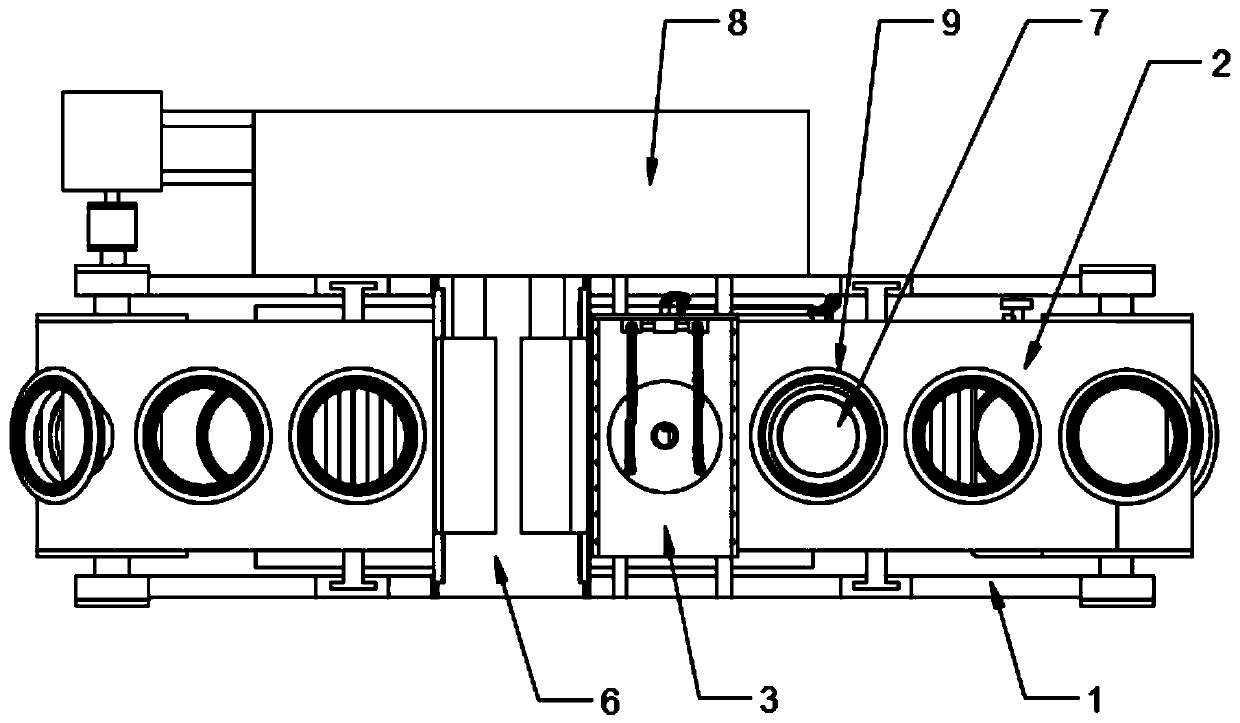

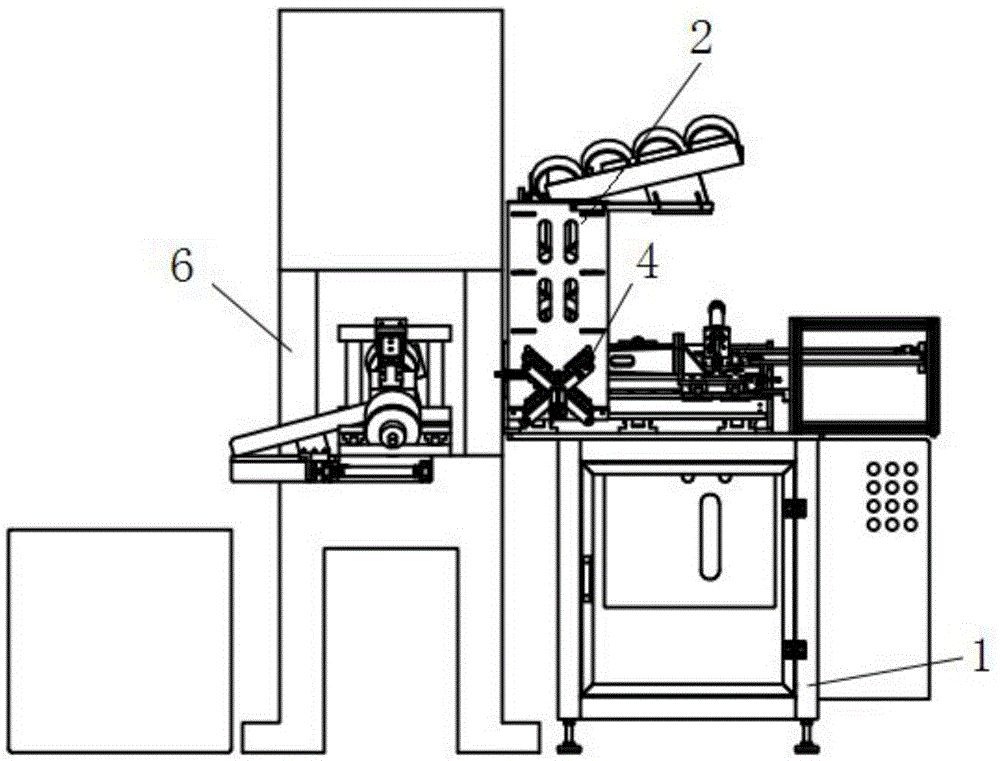

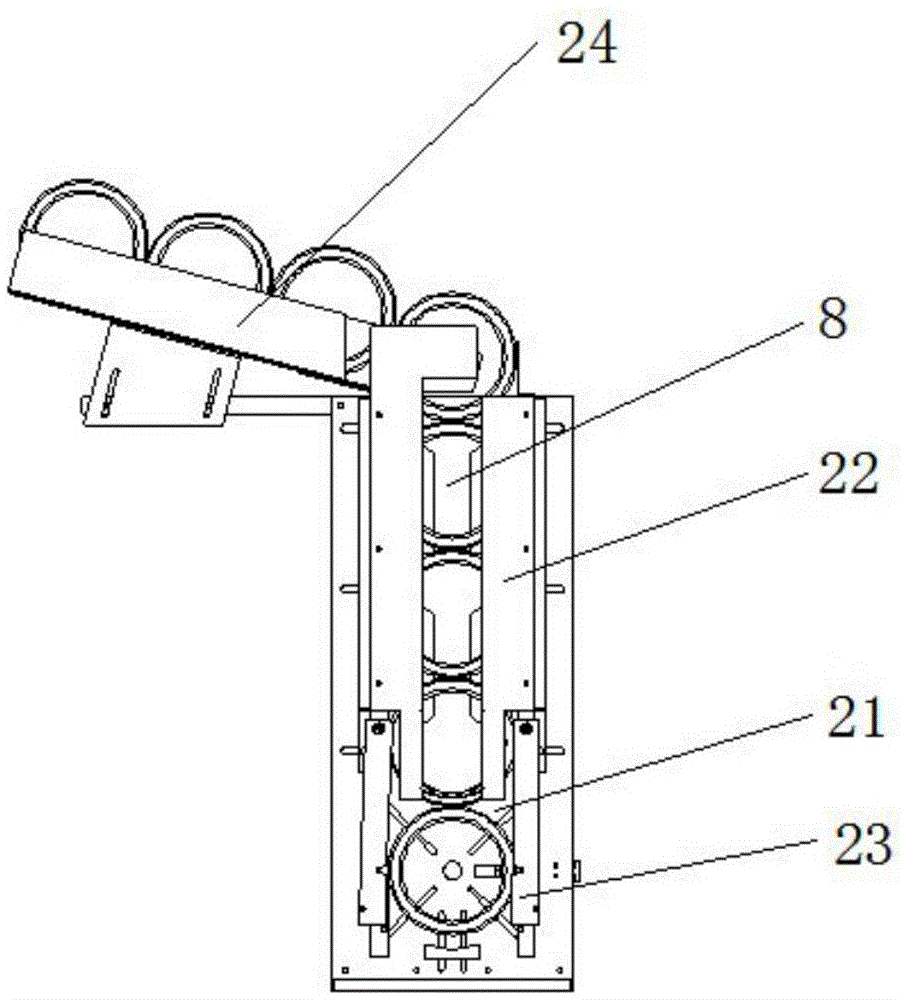

Full automatic dismantling equipment and method for power battery

PendingCN106684488AHigh degree of automationImprove dismantling efficiencyWaste accumulators reclaimingBattery recyclingPower batteryInternal noise

The invention discloses full automatic dismantling equipment and method for a power battery. The equipment comprises a rack, a feeding mechanism, a battery three-surface annular cutting mechanism, a battery dismantling mechanism, a battery conveying mechanism, a feeding cabin and a discharging cabin, wherein the feeding mechanism is used for clamping the power battery from the feeding cabin and conveying the power battery to the battery three-surface annular cutting mechanism; the battery three-surface annular cutting mechanism is used for performing joint cutting on the bottom, the upper and lower side surfaces of the battery and cutting on the head of the battery; then the battery dismantling mechanism competes separation of a battery shell and a cell; and finally, a discharging procedure is completed by the discharging cabin. A series of automatic technological processes of automatic feeding, joint cutting, cutting, separating, conveying, discharging and the like of the power battery are realized; meanwhile, the equipment is equipped with a dust removal apparatus and a purifying apparatus to realize dust removal and waste gas collection in the whole technological process; and in addition, the equipment is covered with a full-closed type protective outer cover, so that internal noise and dust of the equipment can be effectively isolated, and safety of an operator and the equipment can be protected.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

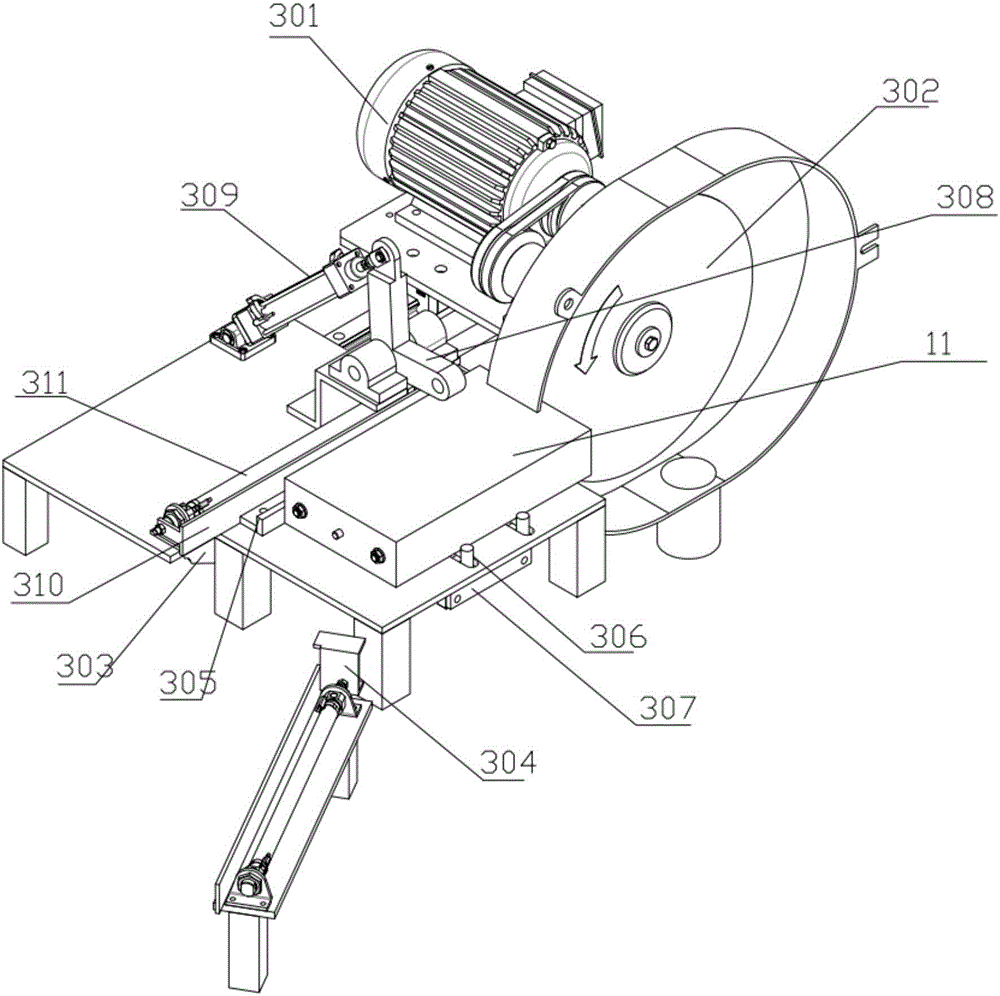

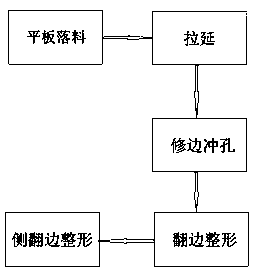

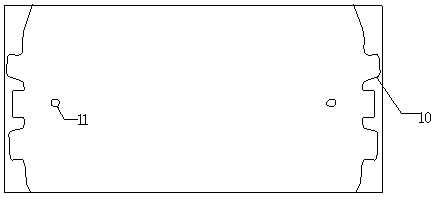

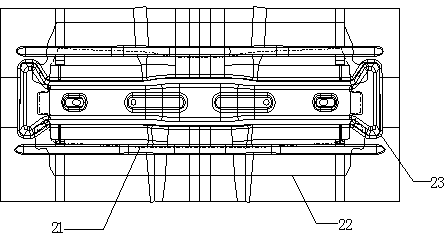

Automobile part production method

InactiveCN105363897AReduce manufacturing difficultyReduce manufacturing costPunchingMotor vehicle part

The invention discloses an automobile part production method. Before a traditional drawing procedure, the flat plate discharging procedure is added, procedures are optimized, only five procedures including flat plate discharging, drawing, trimming punching, edge turning shaping and side edge turning shaping are needed, and automobile part production can be finished. Compared with a traditional method in which six procedures including drawing, trimming punching, side trimming punching, edge turning shaping, secondary side trimming and side edge turning shaping are adopted, one procedure is omitted, and therefore the production procedures are simplified, and the manufacturing difficulty and production cost of a production die are reduced.

Owner:HUNAN TONGXIN MOLD MFG

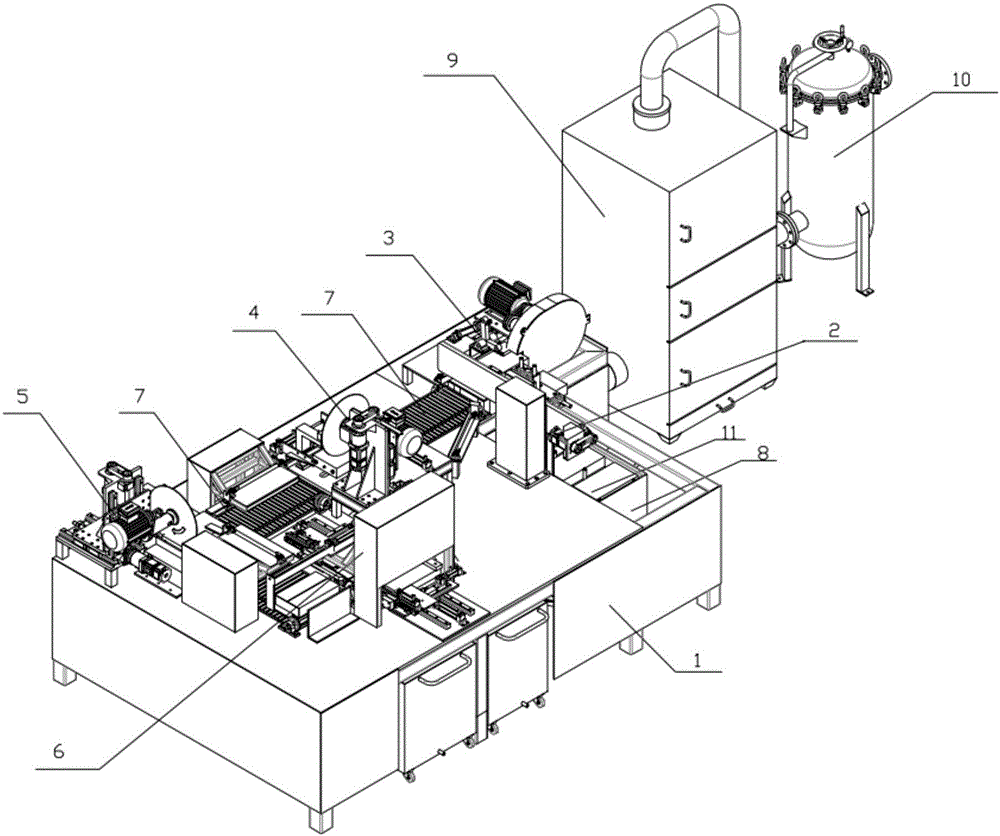

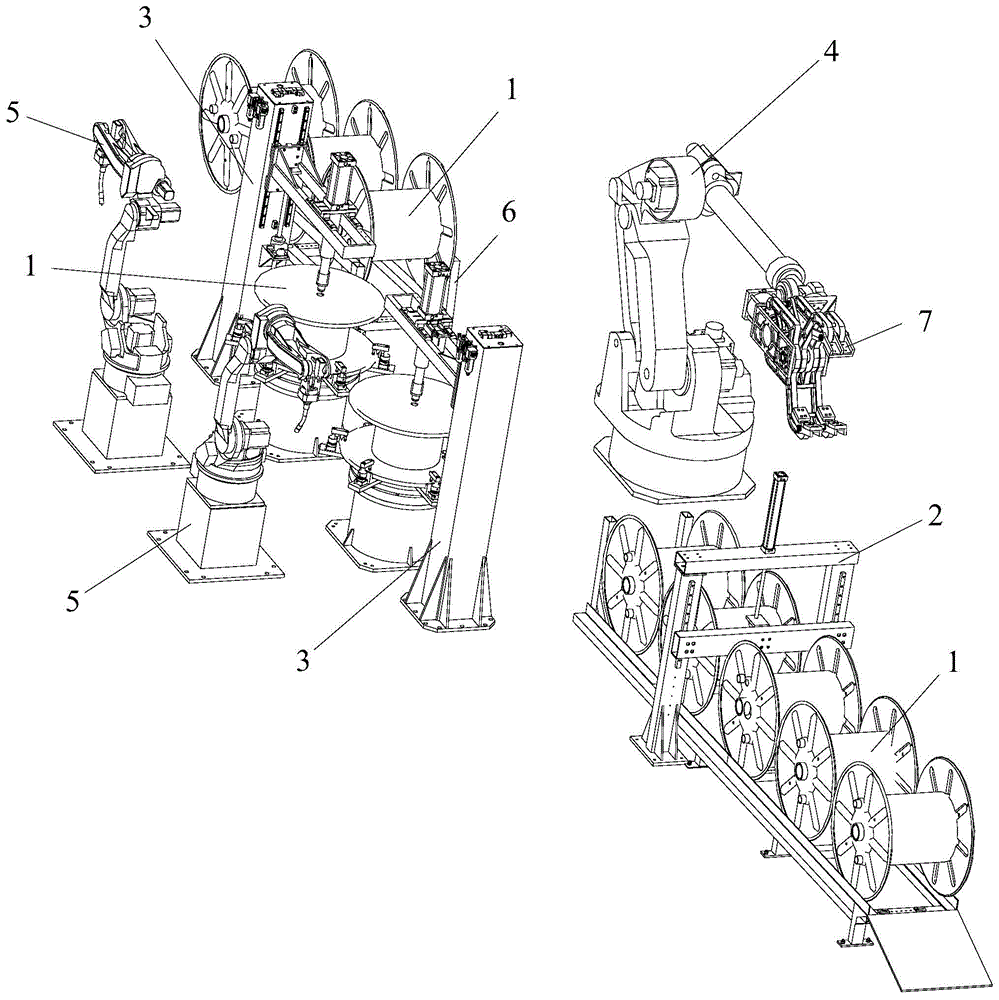

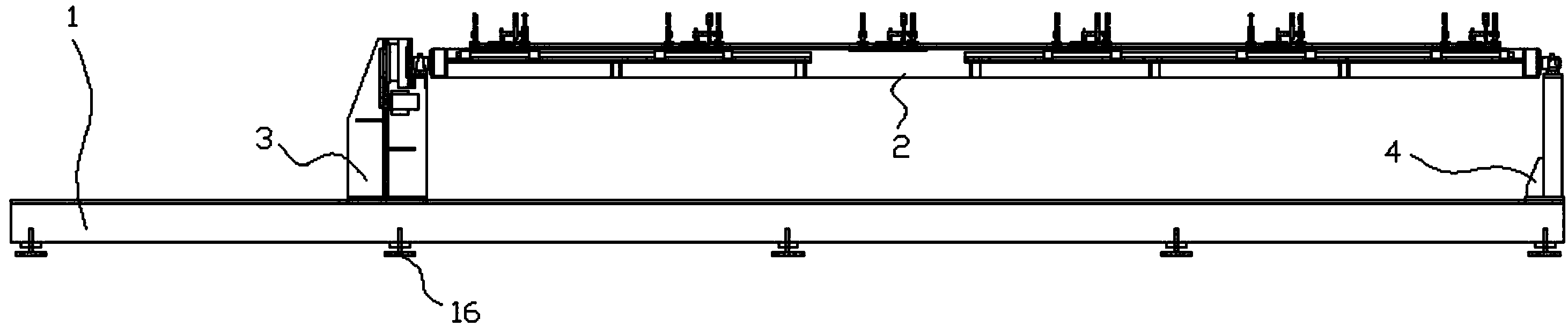

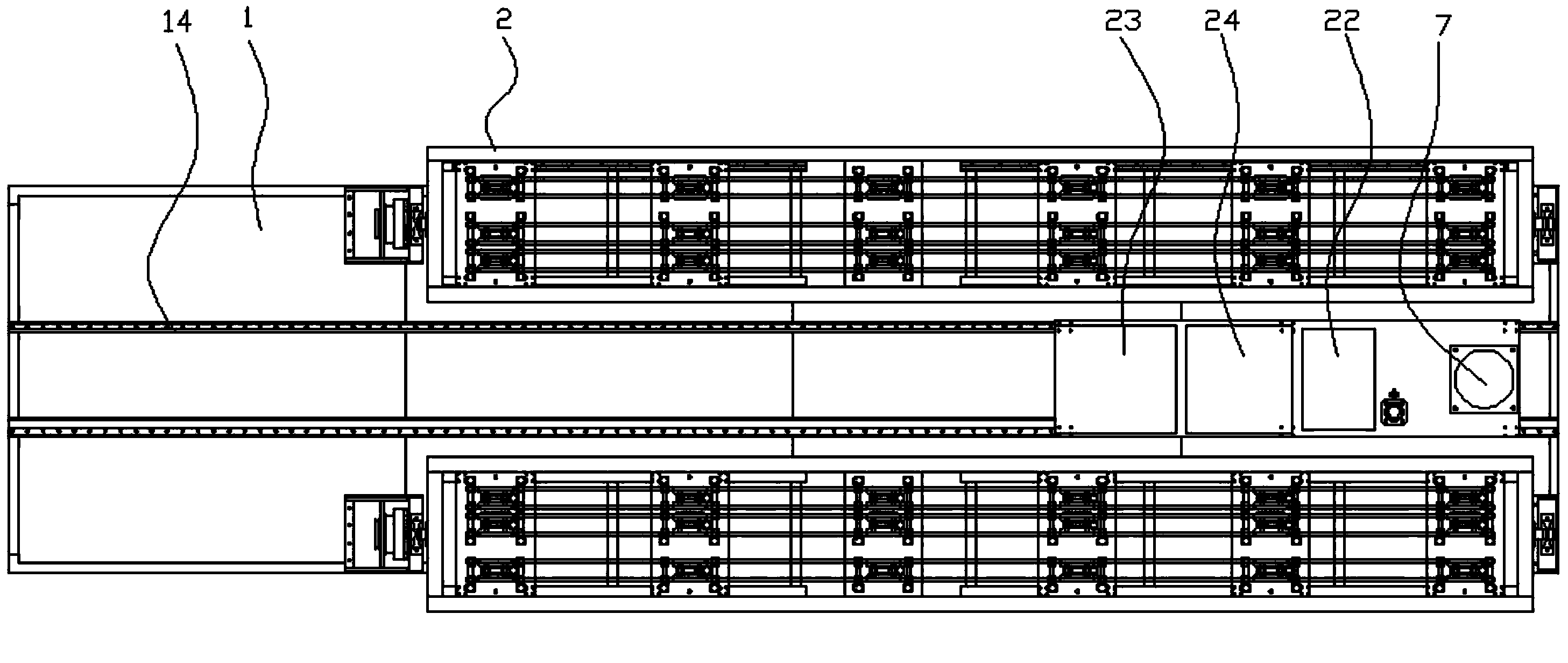

Automatic welding production line and automatic welding method for wire coils

ActiveCN104625454AHigh precisionHigh speedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

Automatic lipstick tube assembling device

The invention discloses an automatic lipstick tube assembling device which comprises a rack. An annular guide rail groove is formed in a table top of the rack. A cyclically-circulating jig board is assembled in the guide rail groove. A bead feeding work station, a middle bundle inserting station, a screw feeding work station, a bottom feeding work station and a discharging work station are sequentially arranged on the table top along the guide rail groove. The above five work stations are all internally provided with corresponding function mechanisms to finish a bead assembling procedure, a middle bundle inserting procedure, a screw placing procedure, a bottom sleeve installing procedure and a finished product discharging procedure, and lipstick tubes are automatically arranged. By the adoption of the automatic lipstick tube assembling device, the occupied area is relatively small, the overall manufacturing cost is relatively low, and the locating accuracy is high; and the production efficiency can be improved to a great extent, the manual cost is reduced, man-made product defects are avoided, and the product assembling efficiency is improved.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

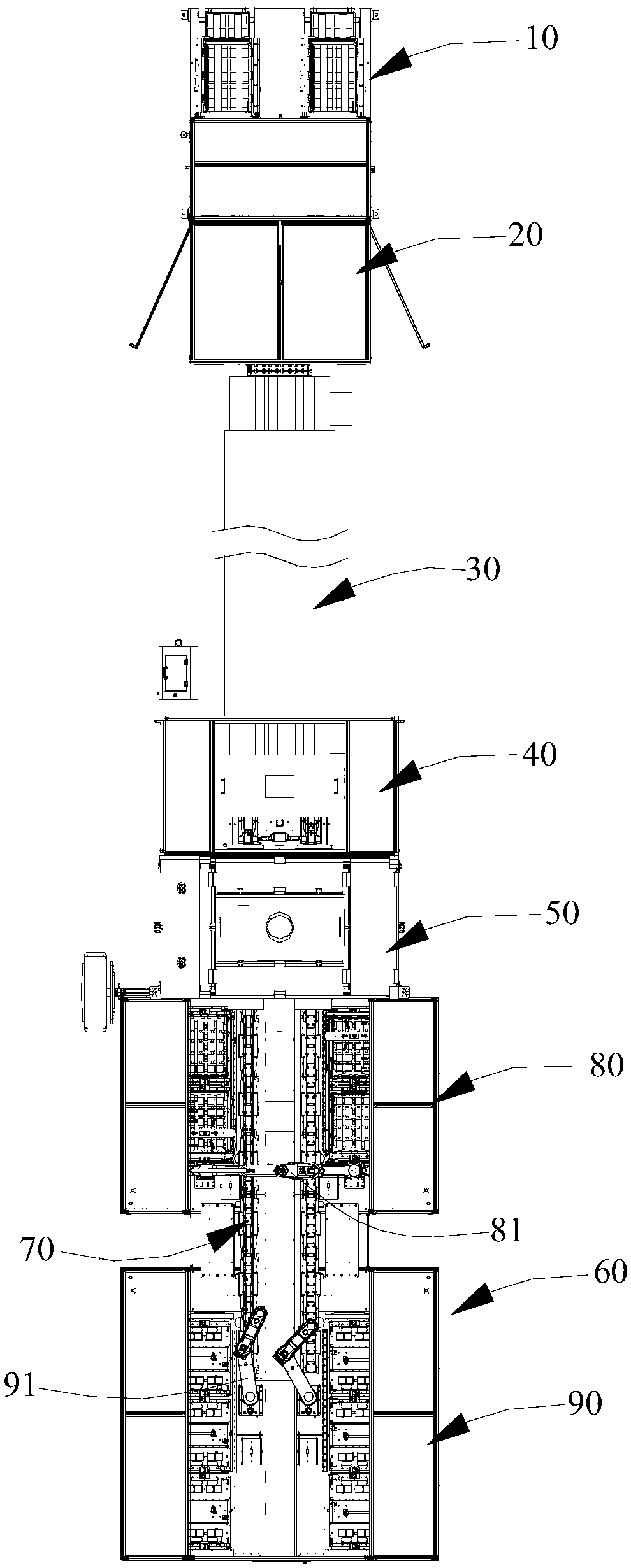

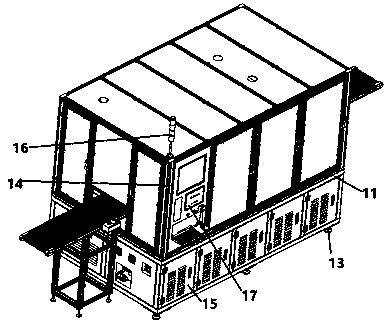

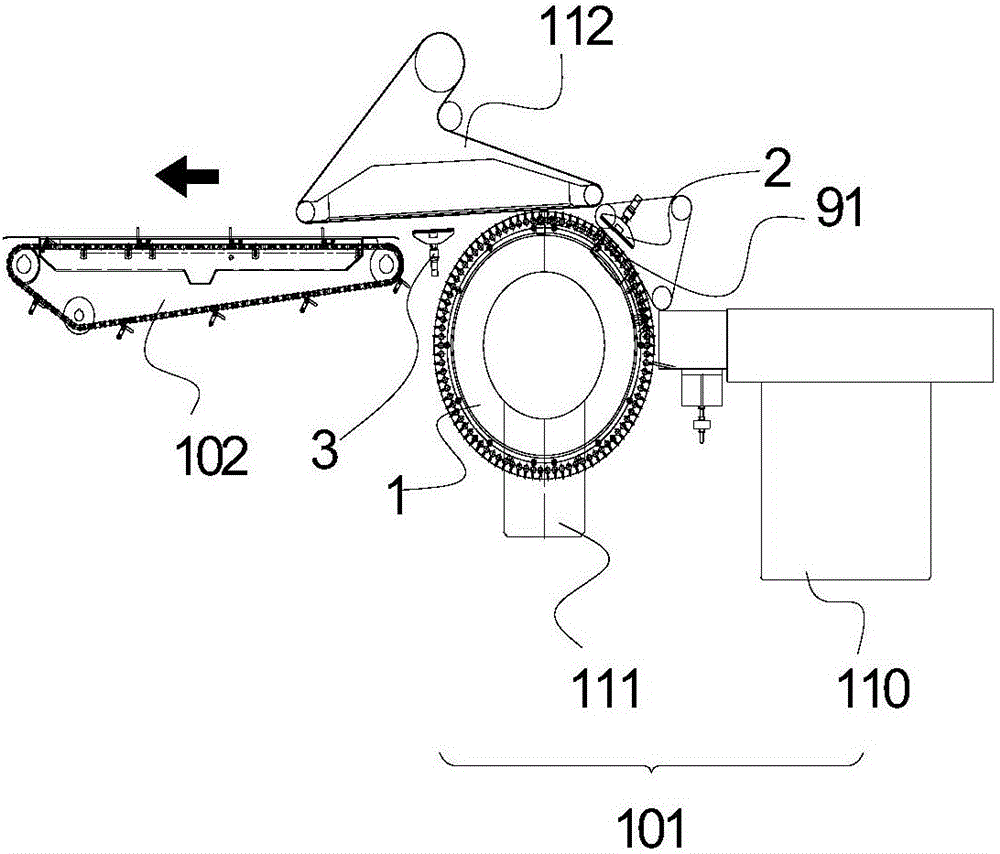

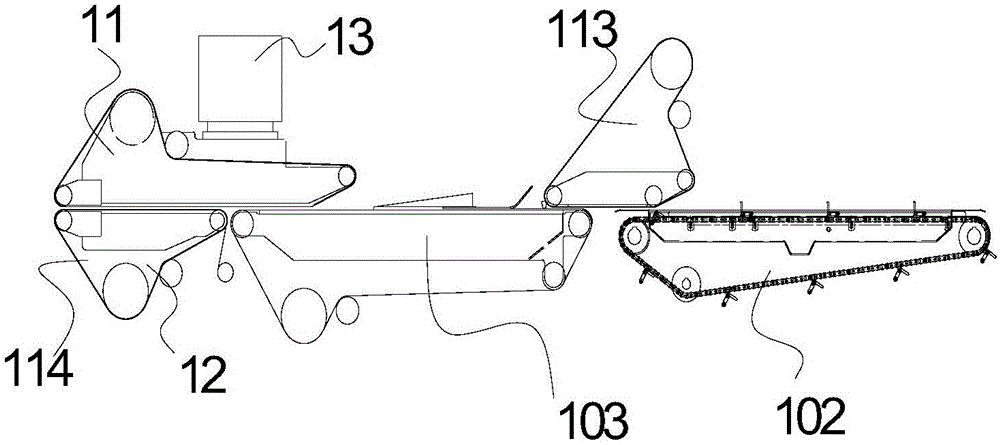

Glass cleaning and sorting integrated system

ActiveCN108380625AReduce wearImprove qualityFlexible article cleaningSortingIntegrated operationsEngineering

The invention relates to a glass cleaning and sorting integrated system. The g lass cleaning and sorting integrated system comprises a feeding machine, a conveying-overturning machine, a cleaning machine, a detecting machine and a receiving machine which are sequentially arranged along the motion direction of glass, wherein the conveying-overturning device is used for overturning the glass conveyed from the feeding mechanism by 180 degrees; the cleaning machine is used for cleaning the glass conveyed from the conveying-overturning device; the detecting machine is used for detecting the qualityof the cleaned glass; and the receiving machine is used for classifying and loading the glass conveyed from the detecting machine. The above glass cleaning and sorting integrated system has the beneficial effects that through the feeding machine, the conveying-overturning machine, the cleaning machine, the detecting machine and the receiving machine, the automated integrated operation of the glass feeding, cleaning, detecting, as well as classifying and discharging procedures is achieved; the occupied area is reduced, the manual intervention is reduced, the production cost is reduced, and theworking efficiency is greatly improved; and meanwhile, the abrasion to the glass is reduced and the improvement of the glass quality is facilitated.

Owner:GUANGDONG TOPSTAR TECH

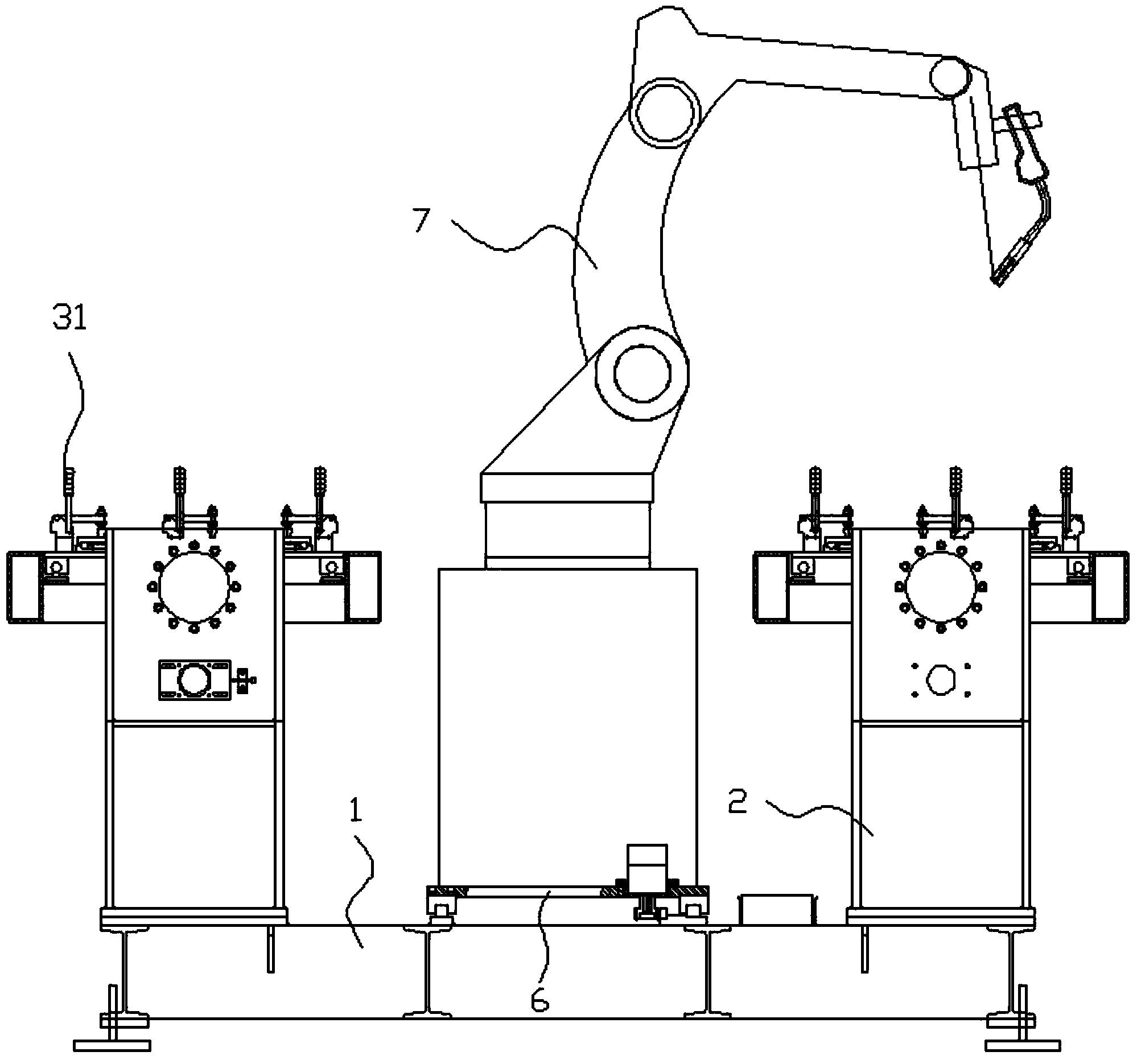

Special robot welding machine for joist

ActiveCN104014900AImprove welding efficiencySimple inputWelding/cutting auxillary devicesAuxillary welding devicesJoistReducer

The invention relates to joist welding, and discloses a special robot welding machine for a joist. The special robot welding machine comprises a main engine base, a rotating frame and a moving trolley, a main support and an auxiliary support are arranged on the main engine base, the two ends of the rotating frame are arranged on the main support and the auxiliary support through bearings respectively, and a welding robot is arranged on the moving trolley; a controller is further arranged on the main engine base, a harmonic speed reducer is arranged on the main support, a first servo motor is arranged below the harmonic speed reducer and synchronously connected with the harmonic speed reducer, and one end of the rotating frame is connected with the harmonic speed reducer. The moving trolley and the servo motor on the main support are controlled through the PLC, and the welding robot is taught to simulate a welding track, so that full automation is achieved, labor is liberated completely, only feeding and discharging procedures need to be finished manually, other procedures are automatic, labor intensity of workers is greatly reduced, welding efficiency is improved, and welding is even.

Owner:江苏沃达电子科技有限公司

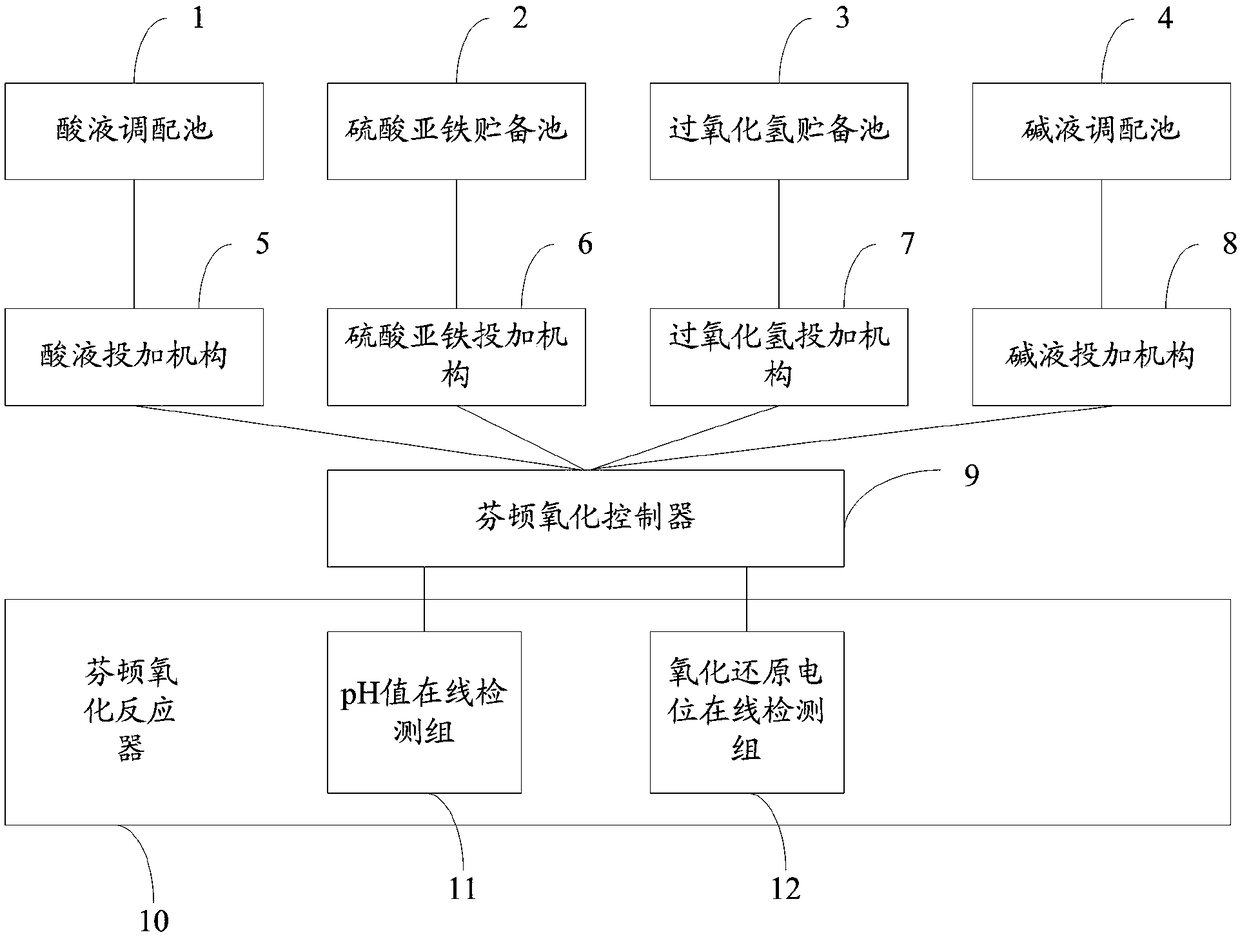

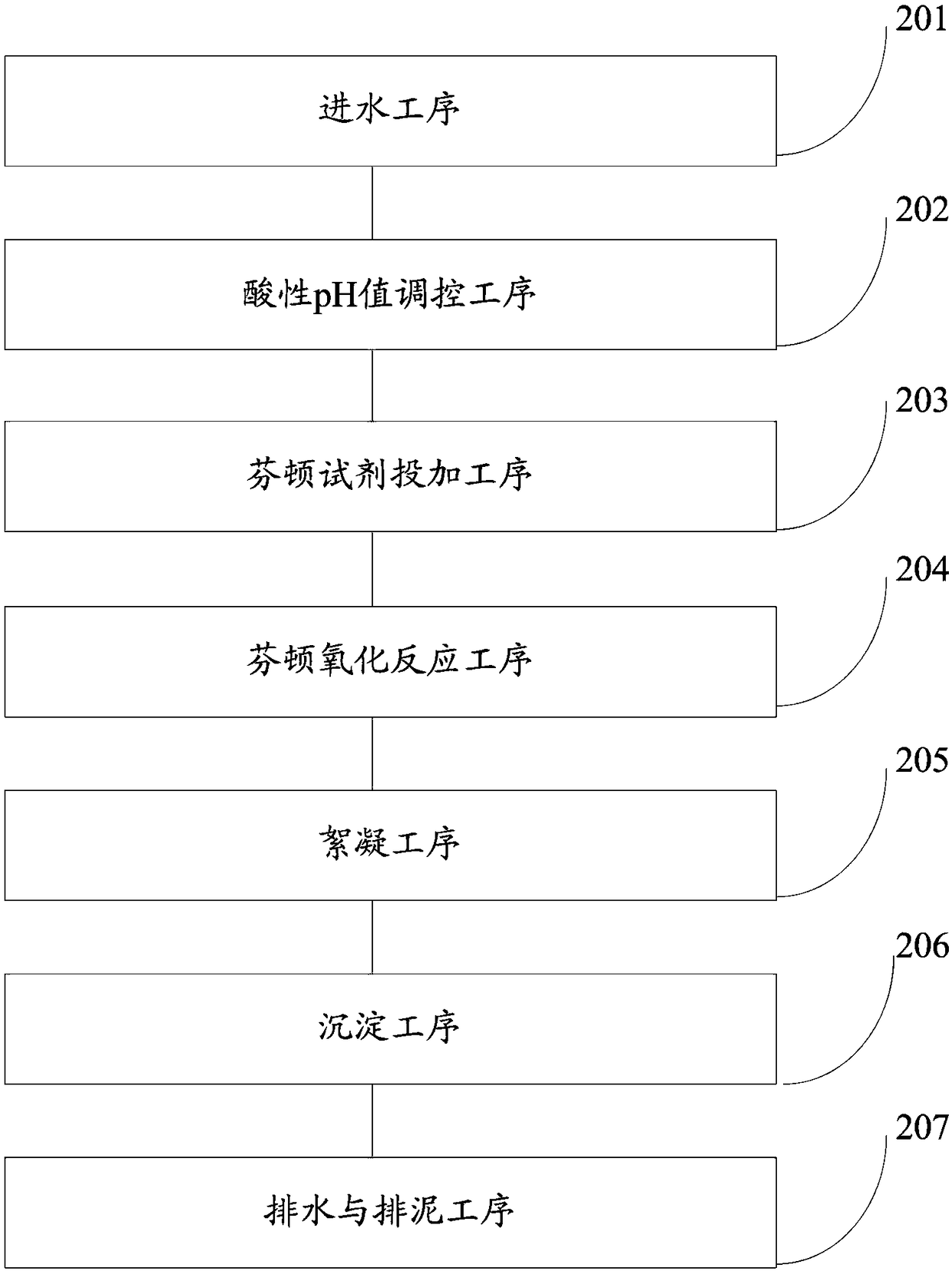

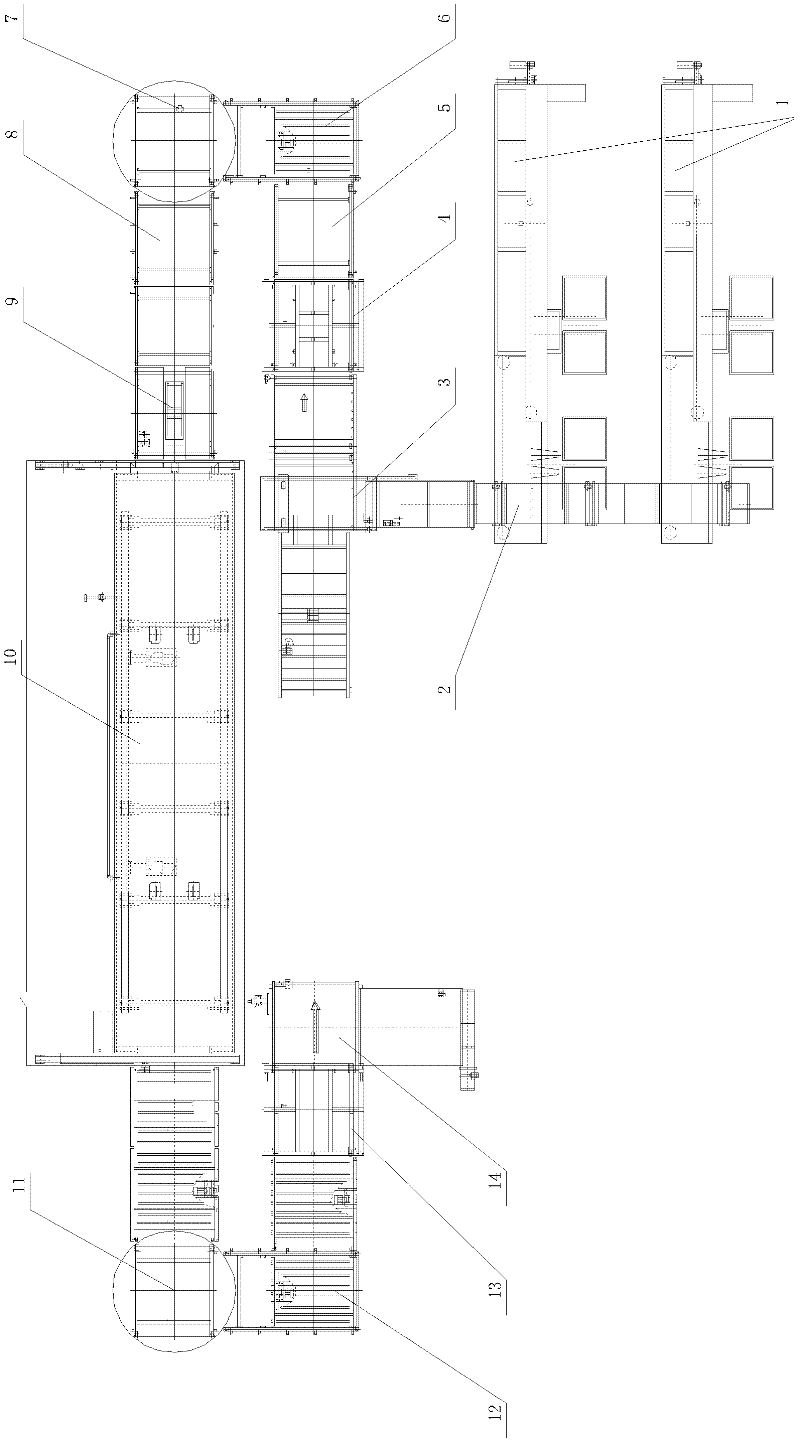

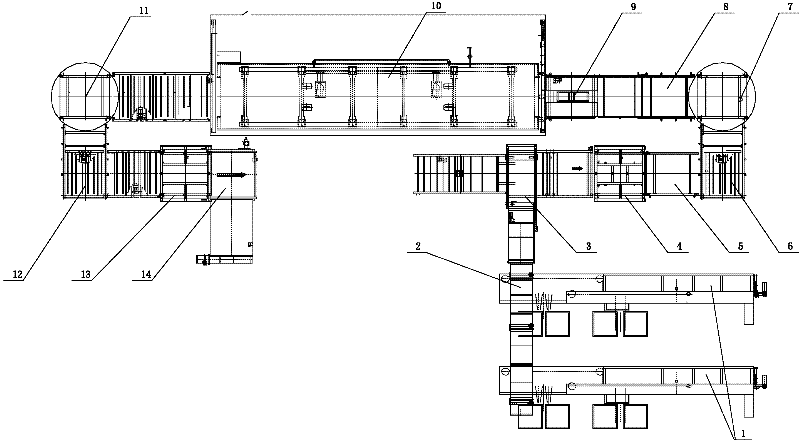

Automatic control device and method for Fenton oxidation reactor for treating lignite upgrading wastewater

InactiveCN108178281AImprove processing efficiencyAutomatic pH controlWater treatment parameter controlWater treatment compoundsAutomatic controlSludge

The invention discloses an automatic control device and method for a Fenton oxidation reactor for treating lignite upgrading wastewater. The method comprises a water feeding procedure, an acidic pH value regulation and control procedure, a Fenton reagent feeding procedure, a Fenton oxidation reaction procedure, a flocculation procedure, a settling procedure and water and sludge discharging procedures which are performed in sequence. In the acidic pH value regulation and control procedure, acidic liquid feeding is automatically controlled by adopting a feedback control algorithm; in the Fentonreagent feeding procedure, feeding amounts of a ferrous sulfate solution and a hydrogen peroxide solution are automatically controlled by adopting a set redox potential threshold value control strategy; in the Fenton oxidation reaction procedure, alkaline liquid feeding is automatically controlled by adopting a control strategy that a first-order derivative of a redox potential to a time period isin plateau; in the flocculation procedure, the alkalinity of a solution in the Fenton oxidation reactor is automatically controlled by adopting the feedback control algorithm. Therefore, the device and the method which are provided by the invention can automatically regulate and control a pH value, the generation amount of .OH and a Fenton oxidation reaction process, so that the lignite upgradingwastewater treatment efficiency is improved.

Owner:JILIN JIANZHU UNIVERSITY

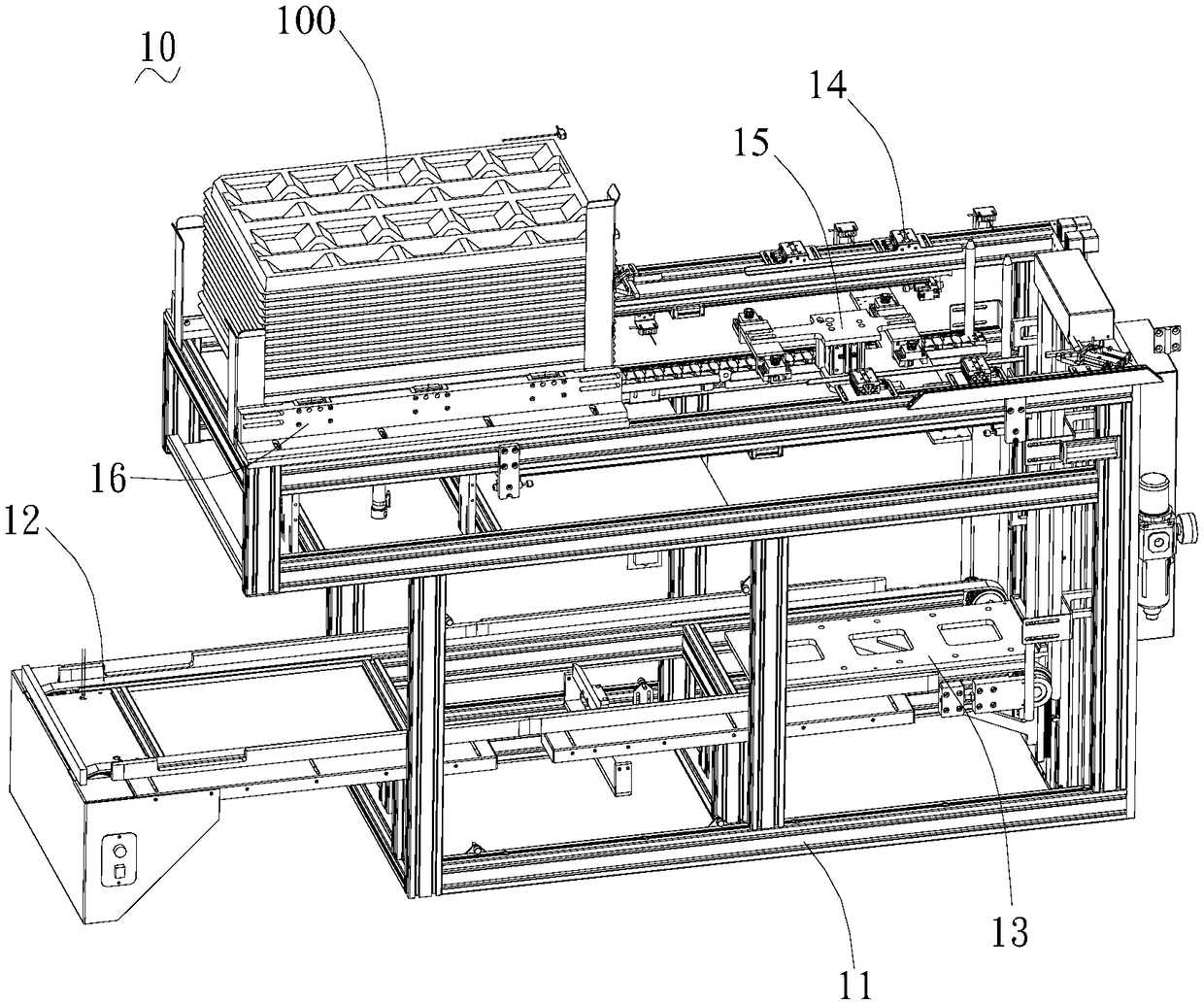

Full-automatic logistics system for soft bags

ActiveCN102431805AReduce labor intensityIncrease productivityCharge manipulationConveyor partsLogistics managementMechanical equipment

The invention relates to a full-automatic logistics system for soft bags, which belongs to the technical field of mechanical equipment and is characterized in that the logistics system comprises a soft bag thread, a bag sorting system, a telescopic automatic tray filler, a first full-automatic tray folding machine, a pushing unit in front of a cabinet, a high-temperature sterilizer, a second full-automatic tray folding machine and a full-automatic tray discharging machine which are sequentially connected. The full-automatic logistics system for the soft bags realizes the full-automatic tray filling, tray folding, conveying, sterilizing and discharging procedures of the soft bags, the production personnel in the workshop are greatly reduced, the labor intensity is reduced, and the production efficiency is improved.

Owner:SHINVA MEDICAL INSTR CO LTD

Fully-automatic intelligent mobile phone screen dispensing equipment and dispensing method

ActiveCN110038768AReduce waiting timeIncrease productivityLiquid surface applicatorsSpraying apparatusAgricultural engineeringSpray nozzle

The invention discloses fully-automatic intelligent mobile phone screen dispensing equipment and a dispensing method. The fully-automatic intelligent mobile phone screen dispensing equipment comprisesa base, a feeding device, a carrying mechanical arm, a UV glue dispensing device, a translation device, a blue mask dispensing device, a discharging mechanical arm and a discharging device, wherein the feeding device, the carrying mechanical arm, the UV glue dispensing device, the translation device, the blue mask dispensing device, the discharging mechanical arm and the discharging device are fixed on the base. The UV glue dispensing device is provided with a lifting glue spraying assembly, a pressure tank, a leakage-proof storage tank and a glue wiping mechanism, wherein the glue wiping mechanism is fixed on a workbench, the blue mask dispensing device is provided with a blue mask dispensing support, a first blue mask dispensing mechanism and a second blue mask dispensing mechanism, wherein the first blue mask dispensing mechanism and the second blue mask dispensing mechanism are fixed on the blue mask dispensing device. The full-automatic intelligent mobile phone screen dispensingmethod comprises a feeding procedure, a UV glue dispensing procedure, a material distributing procedure, a blue mask dispensing procedure and a discharging procedure. The equipment and method have thebeneficial effects that the glue wiping mechanism can automatically clean a nozzle of the UV glue dispensing device, the blue mask dispensing device can automatically carry out blue mask dispensing on the product, and the two blue mask dispensing mechanisms are arranged, so that the waiting time of sequential processing is reduced, and the production efficiency is high.

Owner:深圳市三力高科技有限公司

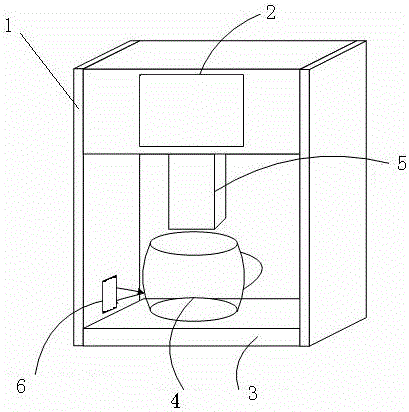

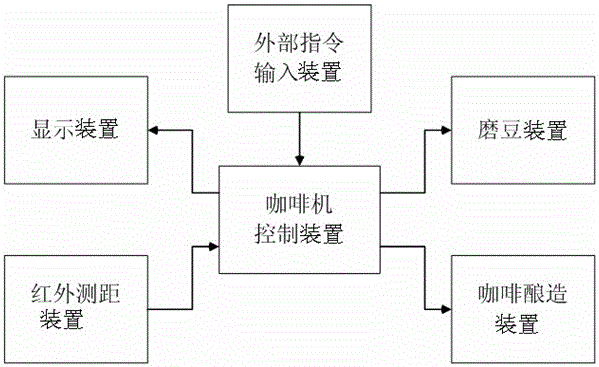

Full-automatic coffee machine with intelligent coffee cup sensing device and control device

The invention discloses a full-automatic coffee machine with an intelligent coffee cup sensing device. The full-automatic coffee machine comprises a framework, a display screen, a water storage plate, a coffee cup, a coffee outlet and an infrared distance measuring sensor. The display screen, the water storage plate, the coffee cup and the infrared distance measuring sensor are positioned inside the rectangular framework, the coffee outlet is formed inside the rectangular framework, the water storage plate is positioned at the bottom of the framework, and the coffee cup is positioned on the upper side of the water storage plate. Owing to the mode, the full-automatic coffee machine with the intelligent coffee cup sensing device has the advantages that work can be immediately suspended after users press beverage keys, beans are ground by the coffee machine and pushing is completely carried out by a brewing machine if the coffee cup below the coffee outlet is not detected by a coffee machine system, and beverage can immediately start to be made by the coffee machine system after the coffee cup is detected; the coffee machine can suspend discharging the beverage if the coffee cup is shifted by the users in beverage discharging procedures of the coffee machine, and beverage making completion is tacitly approved by the system after the waiting time is out.

Owner:SUZHOU DR COFFEE SYST TECH CO LTD

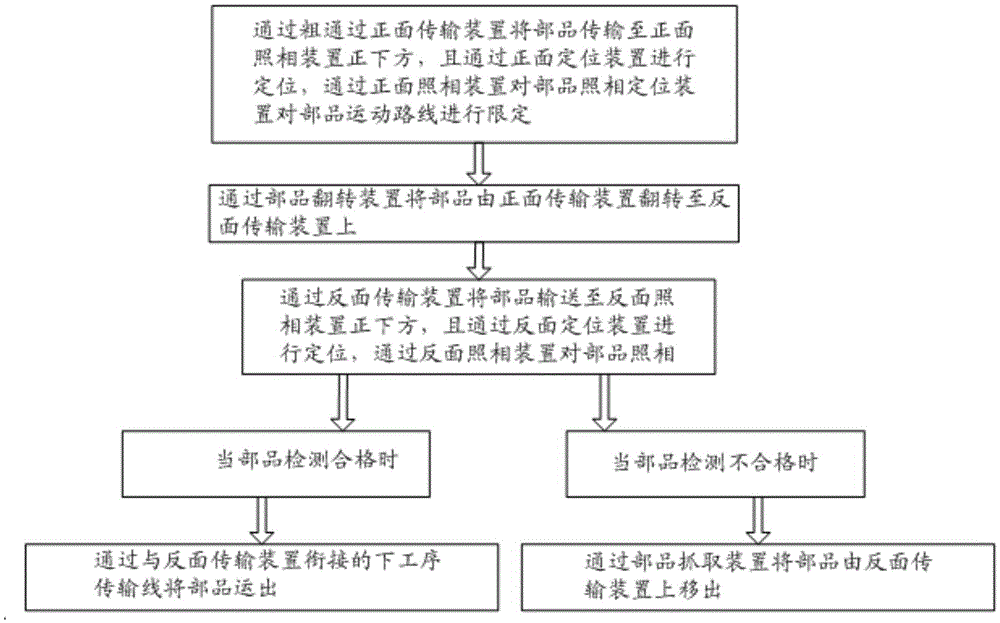

Detection method of CCD detection machine

InactiveCN105466859AReduce labor intensityMaterial analysis by optical meansEngineeringUltimate tensile strength

The invention discloses a detection method of a CCD detection machine. The detection method comprises the steps that firstly, a component is conveyed to the part under a front face photographing device through a front face conveying device, positioned through a front face positioning device, and photographed through the front face photographing device; secondly, the component is overturned to a reverse face conveying device from the front face conveying device through a component overturning device; thirdly, the component is conveyed to the part under a reverse face photographing device through the reverse face conveying device, is positioned through a reverse face positioning device, and photographed through the reverse face photographing device; fourthly, when the component is detected to be qualified, the fifth step is executed, and when the component is detected to be not qualified, the sixth step is executed; fifthly, the component is conveyed out through a discharging procedure conveying line linked with the reverse face conveying device; sixthly, the component is moved out of the reverse face conveying device through a component grabbing device. By means of the detection method of the CCD detection machine, the labor intensity of workers is effectively relieved.

Owner:DONGGUAN GOOD MARK NEW PRECISION TECH CO LTD

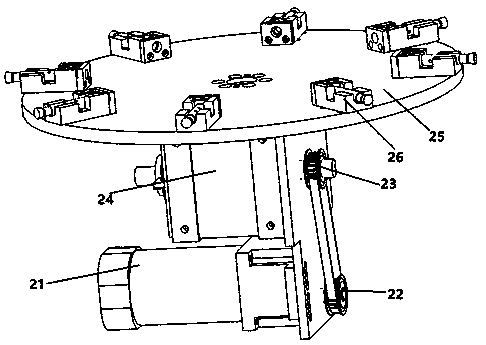

Full-automatic assembling and producing method for expansion screw

InactiveCN109128818ASuitable for mass assembly productionReduce the difficulty of screwingAssembly machinesEngineeringThreaded rod

The invention discloses a full-automatic assembling and producing method for an expansion screw. The indexing rotation procedure, the three-piece feeding procedure, the expansion pipe feeding procedure, the expansion threaded rod feeding procedure, the threaded rod and nut screwing procedure and the discharging procedure are included. In the three-piece feeding procedure, an elastic sheet, a nut and a gasket are arranged at the assigned position of a jig together; in the expansion pipe feeding procedure, an expansion pipe is placed at the assigned position of the jig; in the expansion threadedrod feeding procedure, an expansion threaded rod is conveyed to the jig and sequentially penetrates through the expansion pipe, the gasket and the elastic sheet to straightly abut against the nut; inthe threaded rod and nut screwing procedure, the expansion threaded rod and the nut are screwed; and in the discharging procedure, the assembled expansion screw is conveyed to the next procedure. Thefull-automatic assembling and producing method has the beneficial effects that an expansion bolt can be automatically assembled without manual work, the assembling efficiency is high, and the productqualification rate can be effectively increased; and according to the full-automatic assembling and producing method, positioning is accurate, the assembling precision is high, and the full-automaticassembling and producing method is suitable for large-batch expansion screw assembling and producing.

Owner:车敏

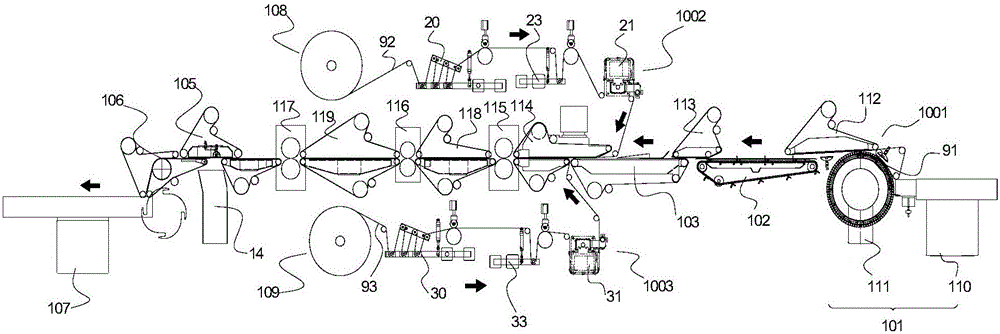

Single-piece packing device and method for disposable sanitary products

ActiveCN106428756ASolve the costSolve efficiency problemsWrapping material feeding apparatusWrappingManufacturing cost reductionEngineering

The invention discloses a single-piece packing method for disposable sanitary products. The method comprises a conveying procedure of conveying the sanitary products, a conveying procedure of respectively conveying upper and lower envelopes, a thermal sealing and cutting procedure, a waste absorption procedure and a product discharging procedure. The invention further discloses a single-piece packing device for the disposable sanitary products. The single-piece packing device is provided with a conveying unit for enabling a fore-and-aft clearance of the sanitary products to be consistent, a thermal sealing and cutting combination unit for performing periphery thermal sealing, embossing of easy-to-tear incisions and peripheral cutting in sequence on an upper envelope and a lower envelope on the upper and lower side of each sanitary product, a waste absorption unit for discharging waste edges generated by peripheral cutting, and a product discharging unit. Each sanitary product is clamped between the upper and lower envelopes, and then is subjected to the periphery thermal sealing, the embossing of the easy-to-tear incisions and the peripheral cutting to form a single-piece packed product; the surface of the product is free of folded edges, so that the product looks more beautiful and ingenious; and meanwhile, a gluing machine is eliminated, so that the manufacturing cost is reduced. The single-piece packing device solves the problems of high manufacturing cost, easiness in halt and low packing efficiency of the conventional device, and has the advantages of compact structure, steady operation and high operation rate.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

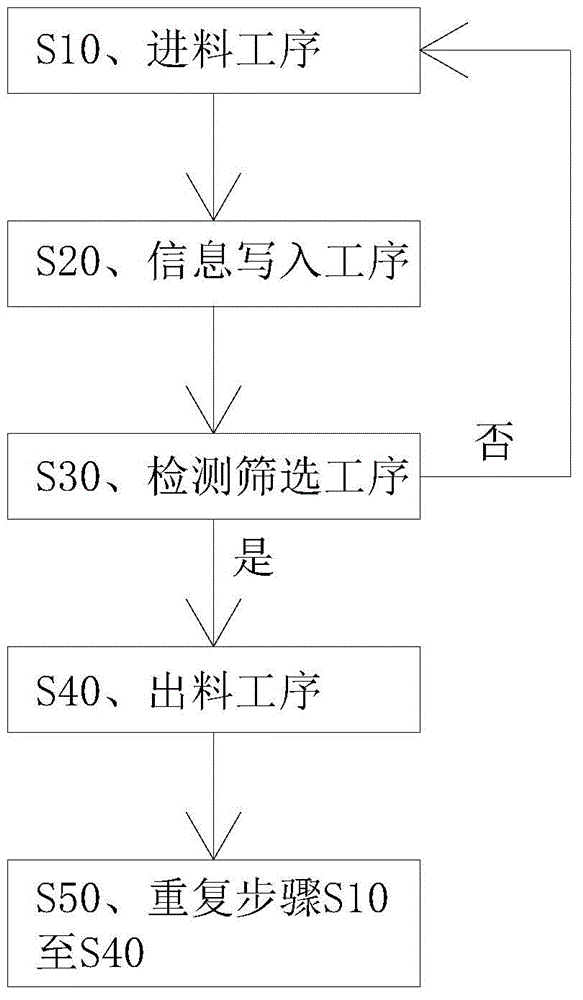

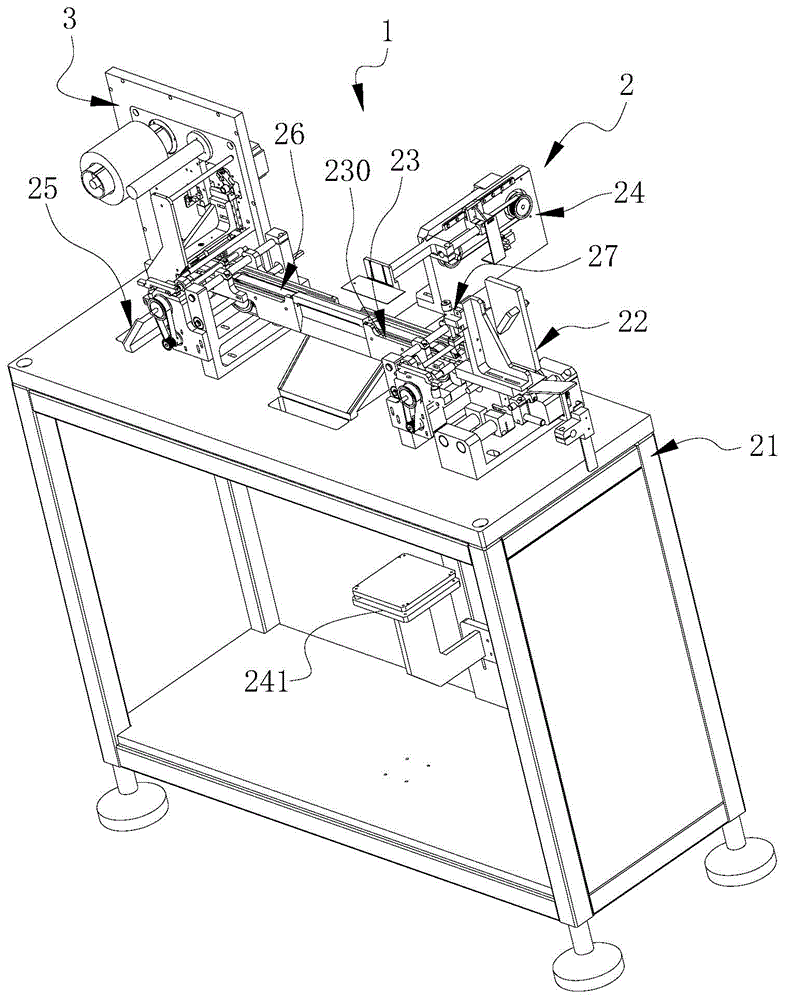

Method for detecting performance of RFID (radio frequency identification) labels

InactiveCN104899619ASolve efficiency problemsSolve labor intensityCo-operative working arrangementsScreening proceduresEmbedded system

The invention provides a method for detecting the performance of RFID (radio frequency identification) labels. The method comprises a feeding procedure, an information write-in procedure, a detection screening procedure and a discharge procedure. During detection, a plurality of RFID labels are stacked on a feeding unit and then conveyed to a conveying unit by the feeding unit, the conveying unit conveys the RFID labels to an information write-in unit to write information, then the conveying unit conveys the RFID labels to a detection screening unit to screen defective products, and the conveying unit conveys the qualified RFID labels to a discharge hatch. The whole process is automatic, so that the problems of low efficiency, high labor intensity and high cost in the manner of artificially detecting the performance of the RFID labels in the prior art are effectively solved.

Owner:SHENZHEN JIA WEN HONG TECH

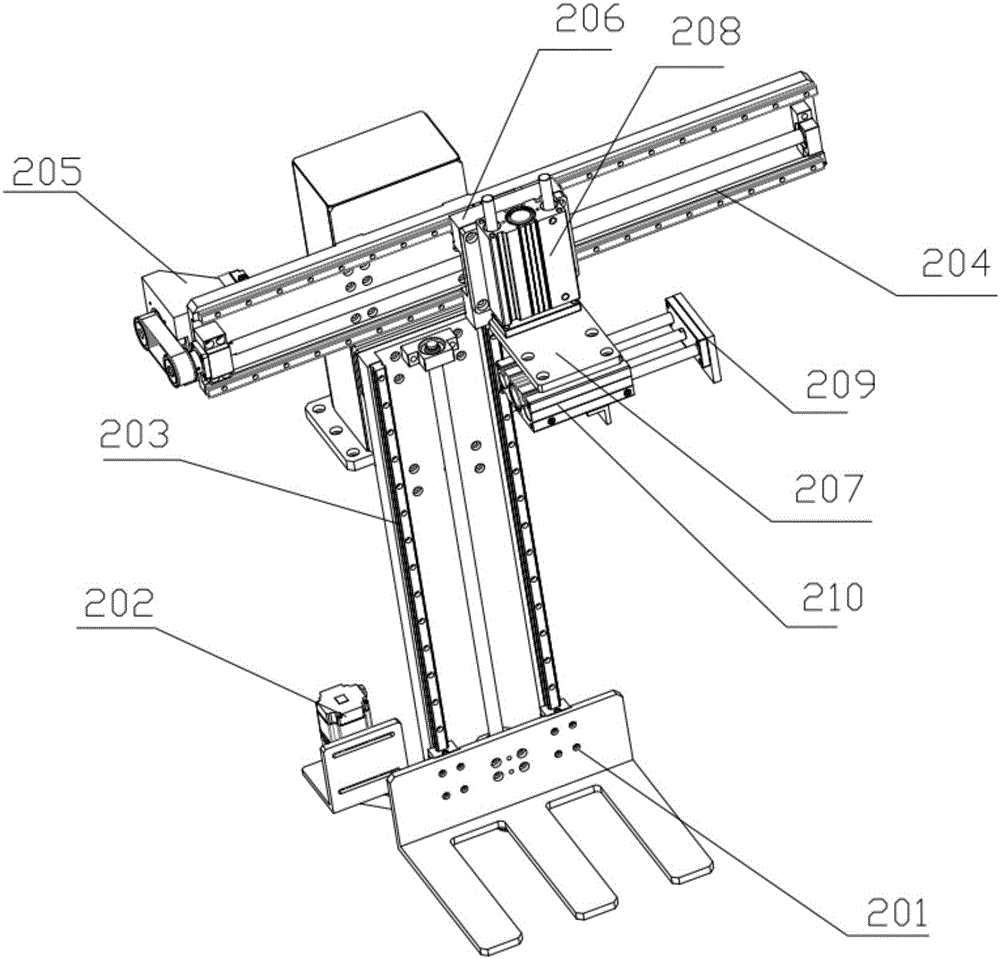

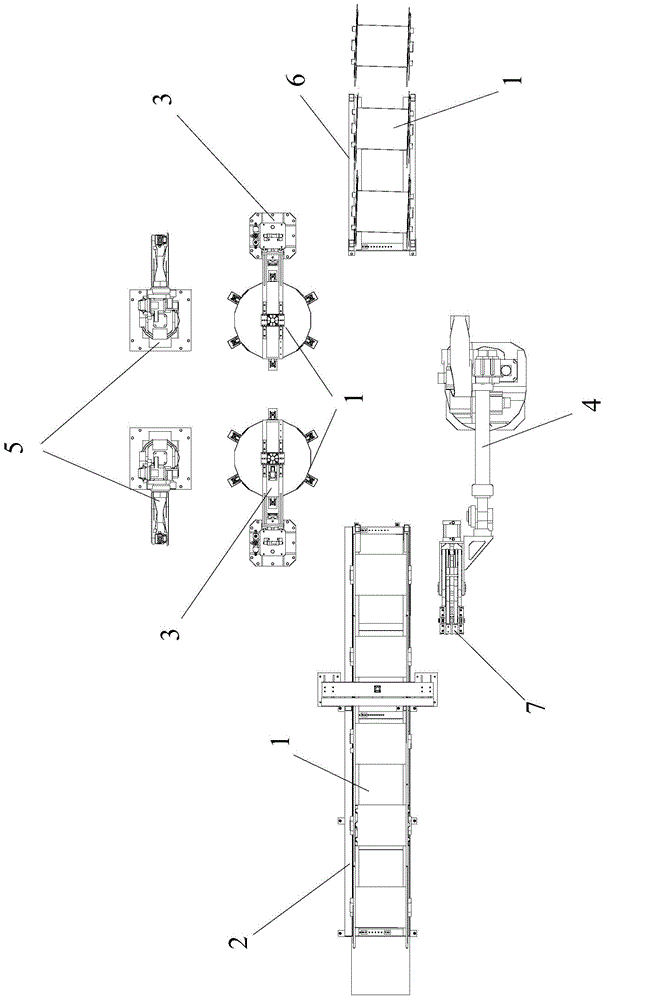

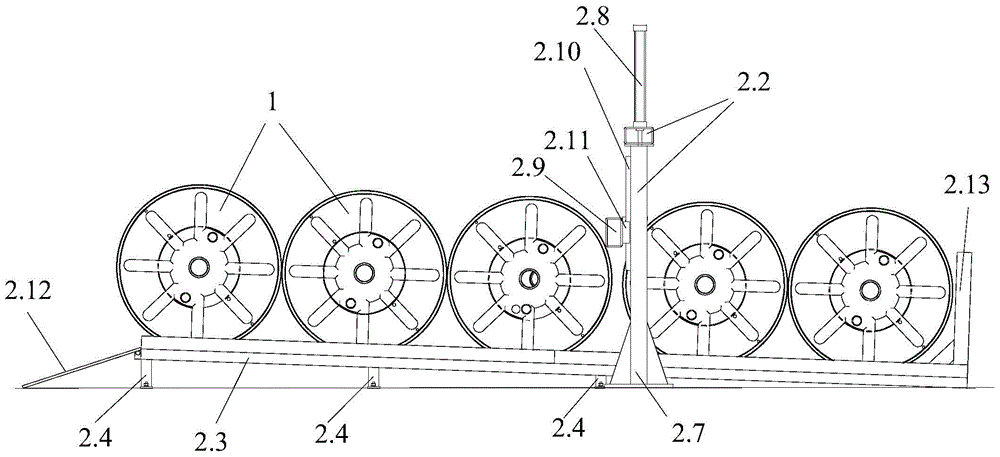

Automatic carrying device of material rolling spool

PendingCN109534100AIncrease productivityAutomatic safetyFilament handlingStacking articlesDischarge procedureTemporary storage

The invention discloses an automatic carrying device of a material rolling spool. The device comprises a material area, a paying-off area, a wire rolling area, a temporary storage area, and a dual-clamping-claw mechanism. The material area is used for providing a full-roll spool and recycling an empty-roll spool, the paying-off area is used for taking a metal wire on the spool, the wire rolling area is used for removing residual waste wires on the spool, the temporary storage area is used for storing the empty-roll spool with the waste wires removed, the dual-clamping-claw mechanism comprisestwo clamping claw assemblies which are arranged in a central symmetry manner and can rotate around the center axis, and are used for clamping the full-roll spool and / or the empty-roll spool, the dual-clamping-claw mechanism can move in a circular path formed among the material area, the paying-off area, the wire rolling area, the temporary storage area and the material area. The manner of a rail car is adopted in the device, according to the loading, paying off, wire rolling and discharging procedures, the material area, the paying-off area, the wire rolling area and the temporary storage areaare formed, in cooperation with the dual-clamping-claw mechanism, automatic supplementing of the full-roll spool and recycling of the empty-roll spool can be achieved, production efficiency is greatly improved, and safe, automatic and efficient production is achieved.

Owner:无锡华工大光电智能科技有限公司

Production method of photo with protection structure

ActiveCN103935104ASuitable for hemming operationsReduce labor cost expensesLamination ancillary operationsLaminationEngineeringPlastic adhesive tape

The invention provides a production method of a photo with a protection structure. The photo comprises a photo body; the production method comprises a laminating procedure, a gluing procedure, a cutting procedure, an edge covering procedure and a discharging procedure. According to the production method, the photo body is simply and conveniently adhered with a substrate and coated with a plastic adhesive tape, meanwhile, the whole production process is automatically carried out, and few operators are required, so that the labor and the time are saved, the expenditure on labor cost can be reduced, and the production method is suitable for the batch edge covering operation of the photos.

Owner:深圳市思博克科技有限公司

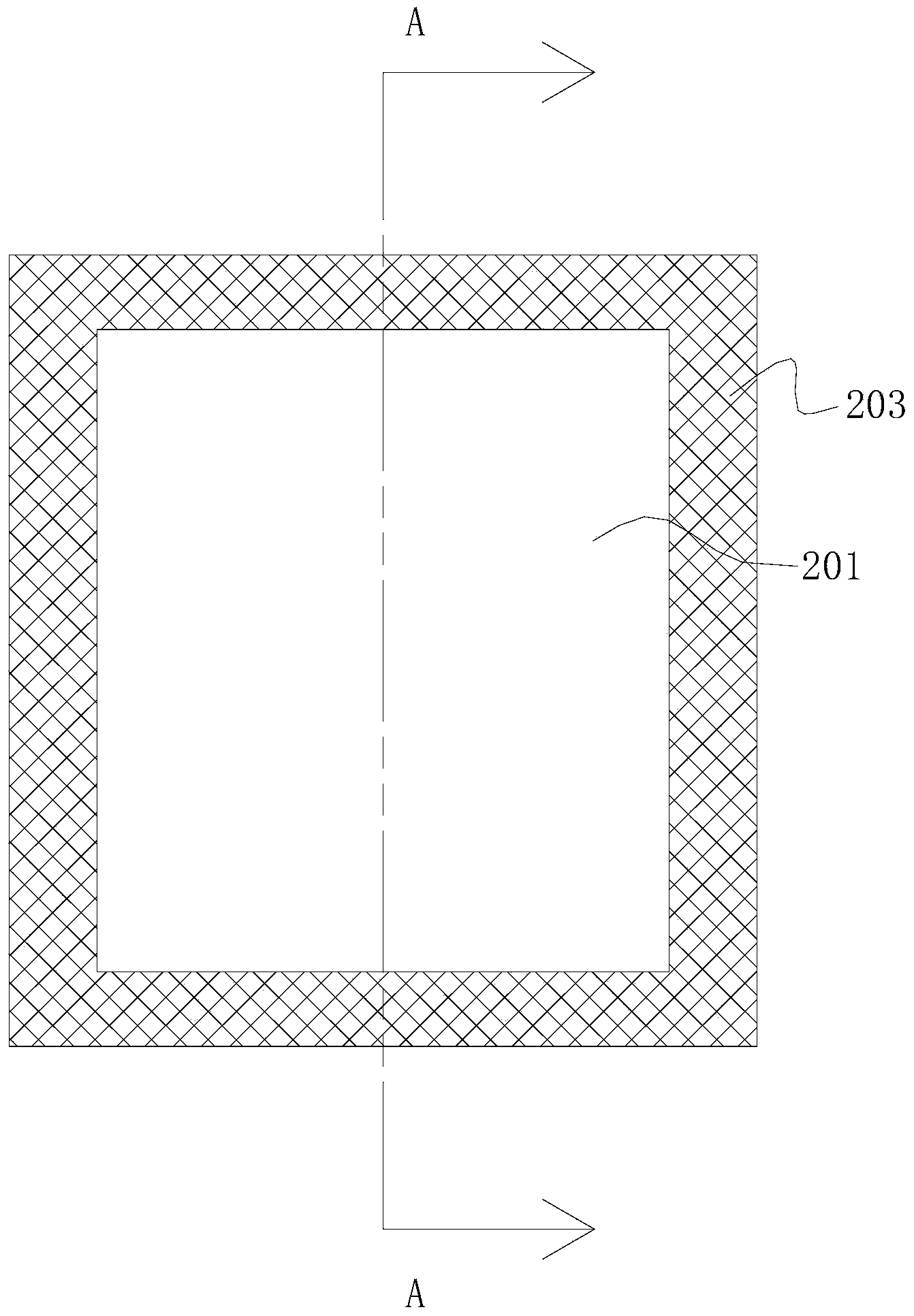

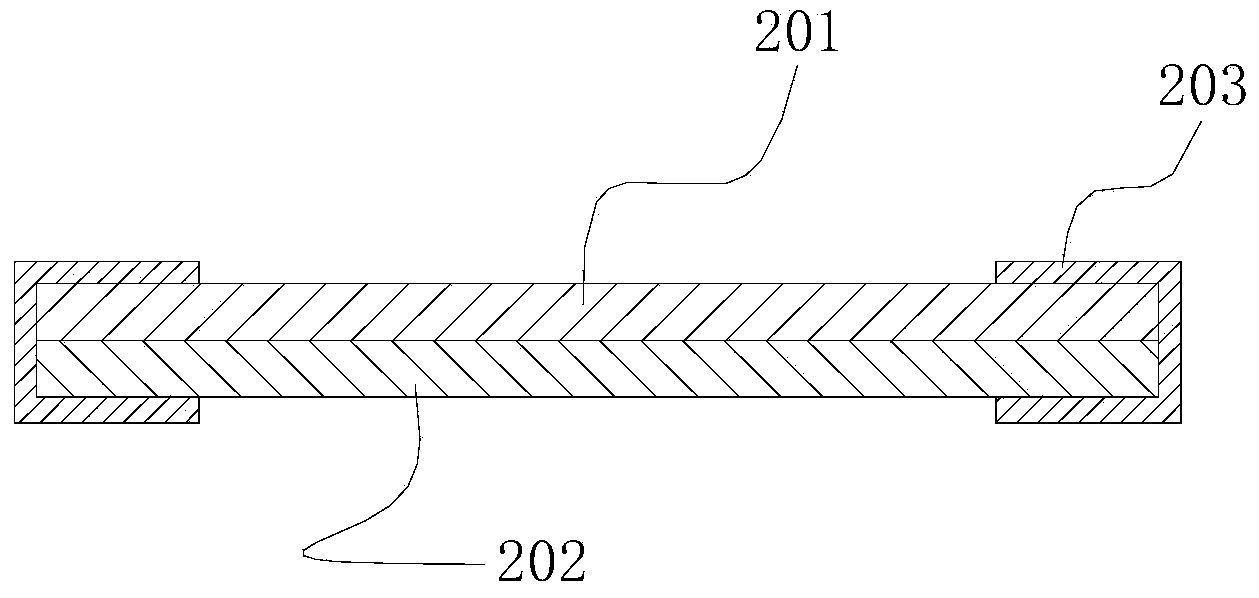

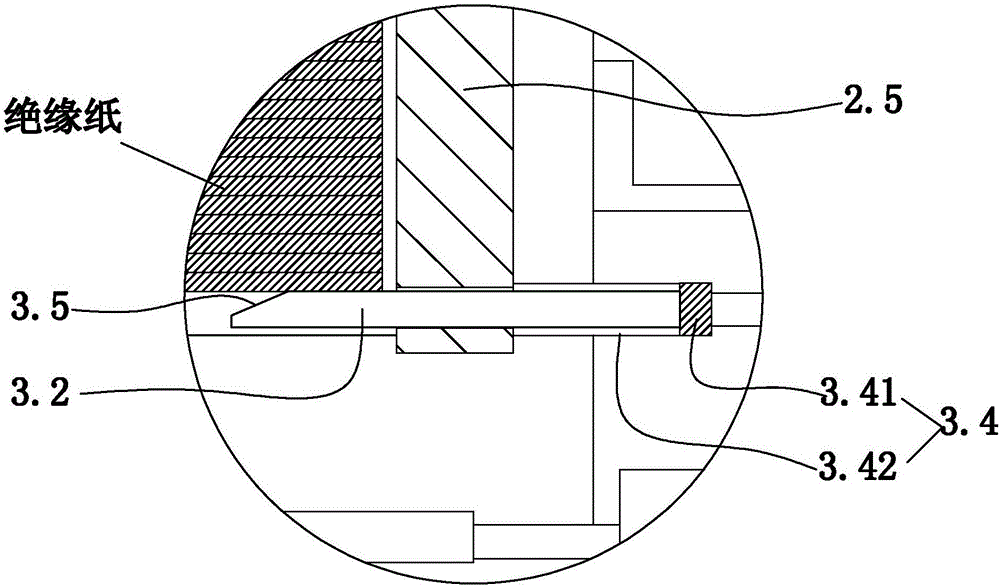

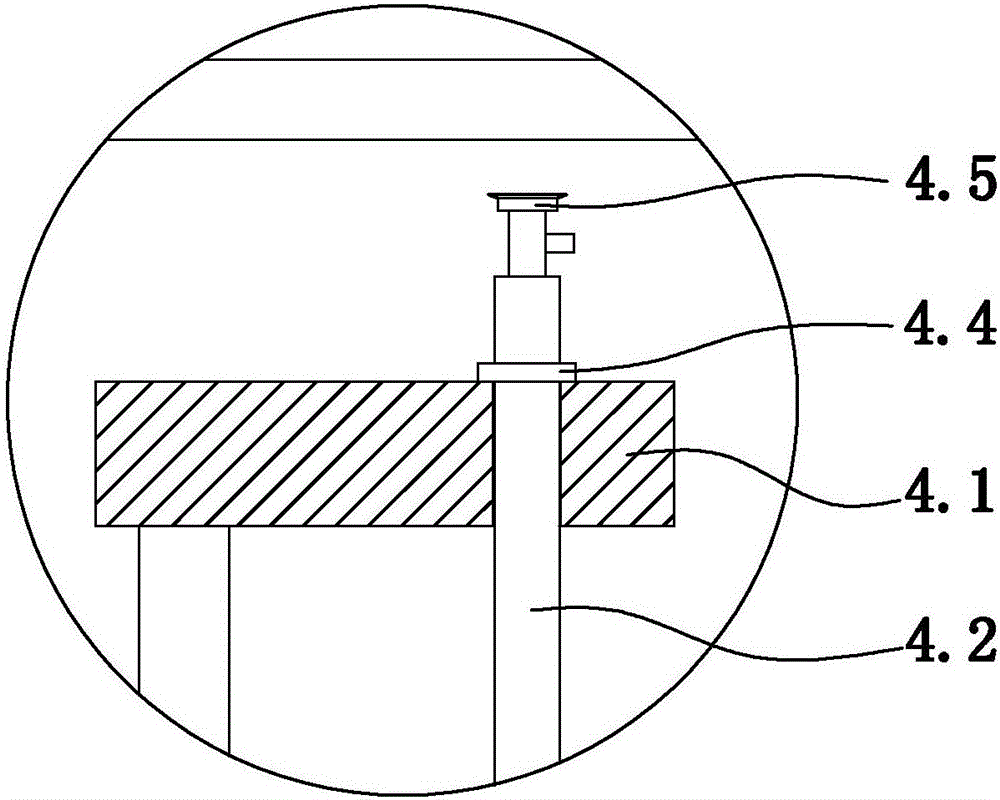

Insulating paper distributing mechanism

ActiveCN106829563ARealize cutting one by oneAddressing the risk of being damagedArticle separationPulp and paper industryDischarge procedure

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

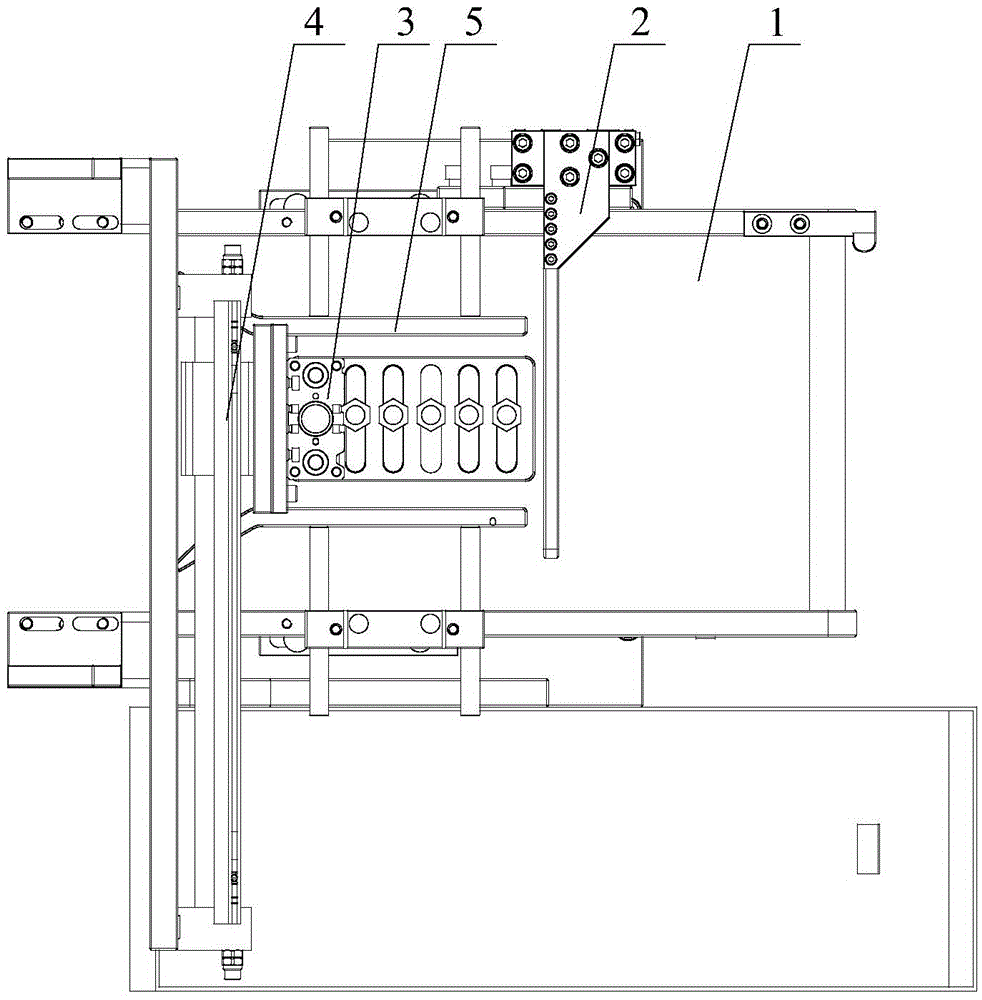

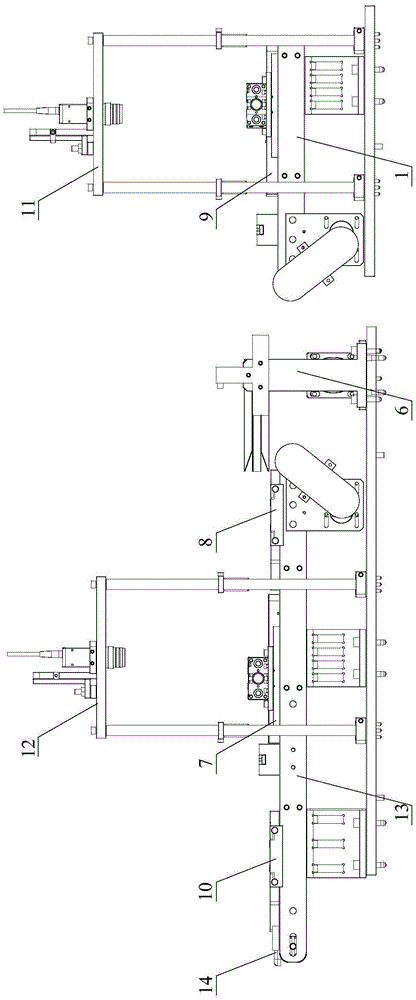

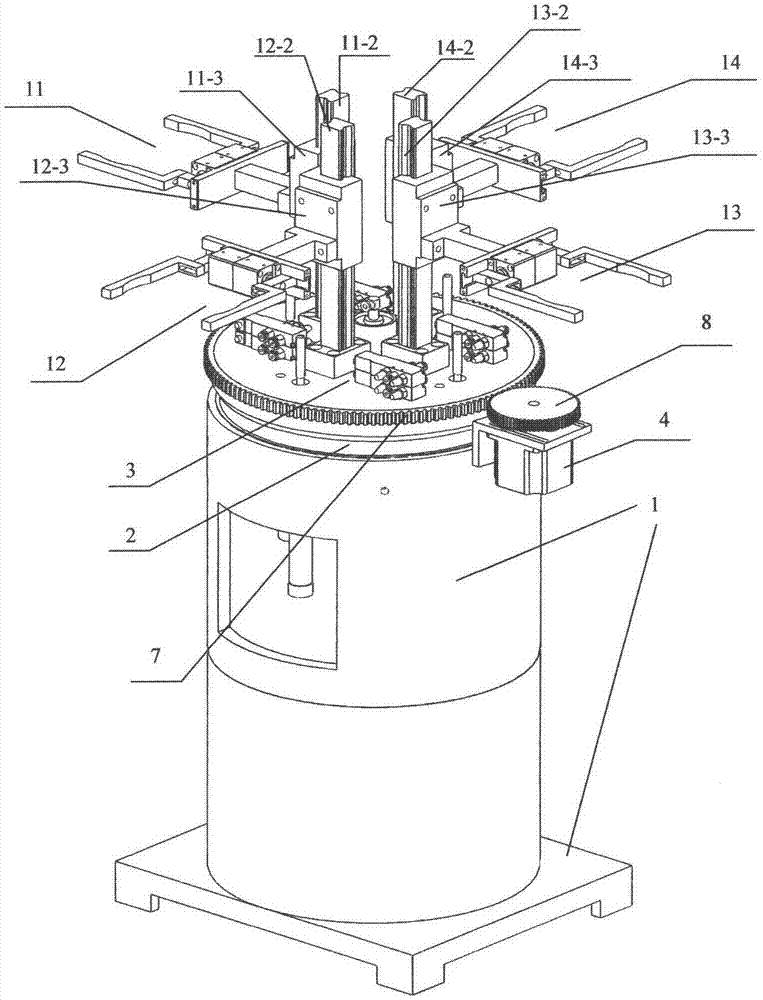

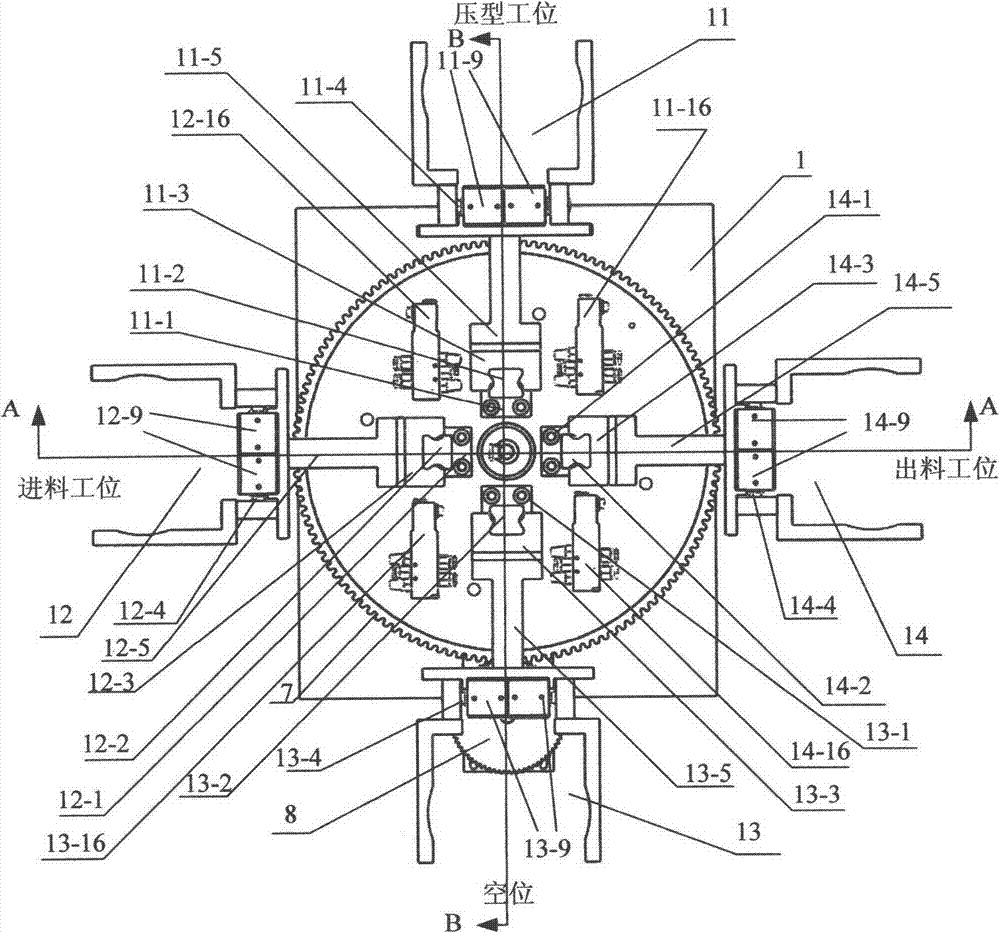

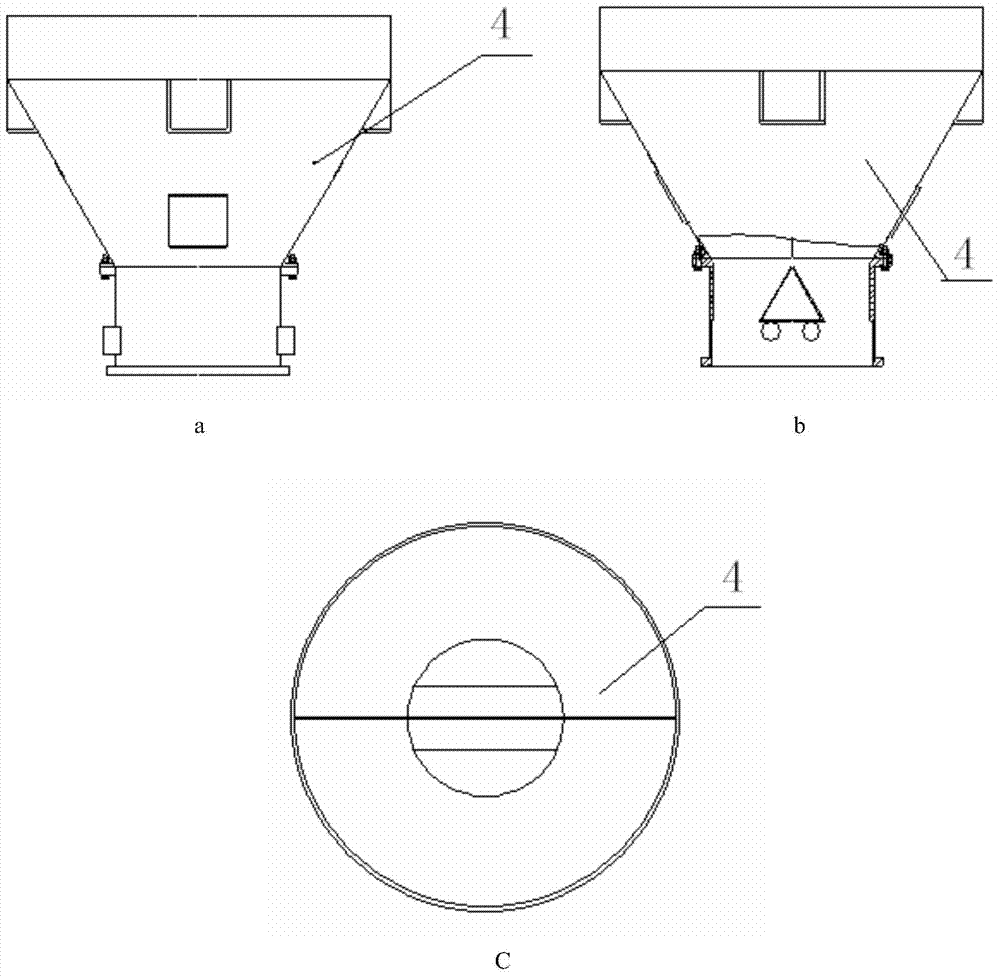

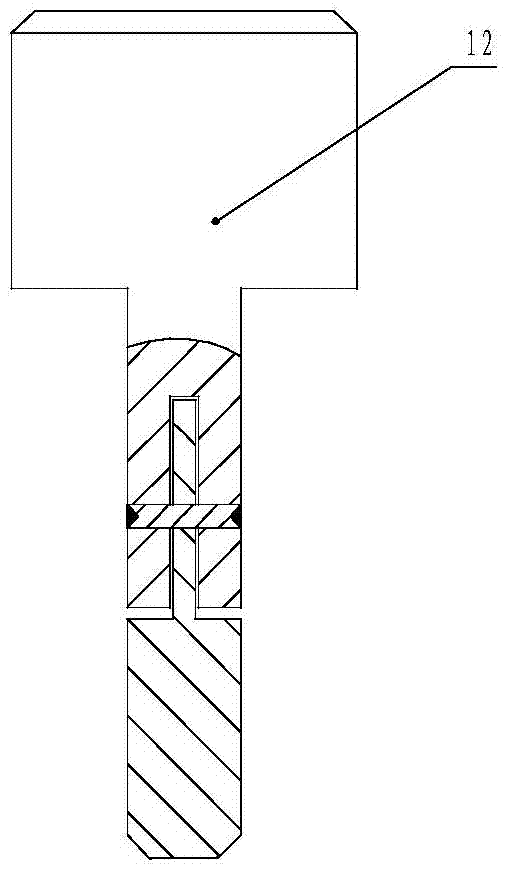

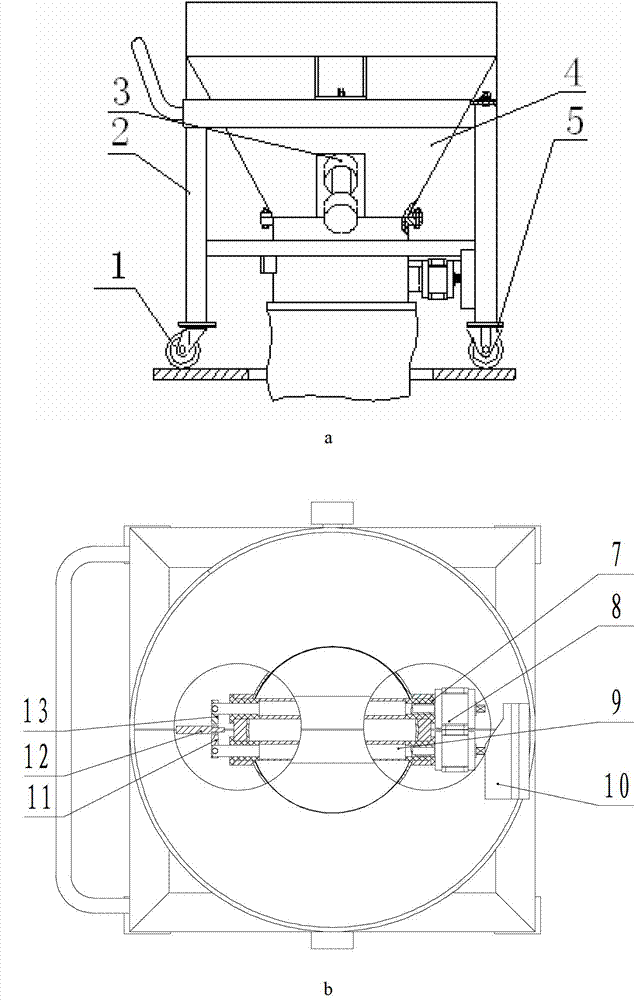

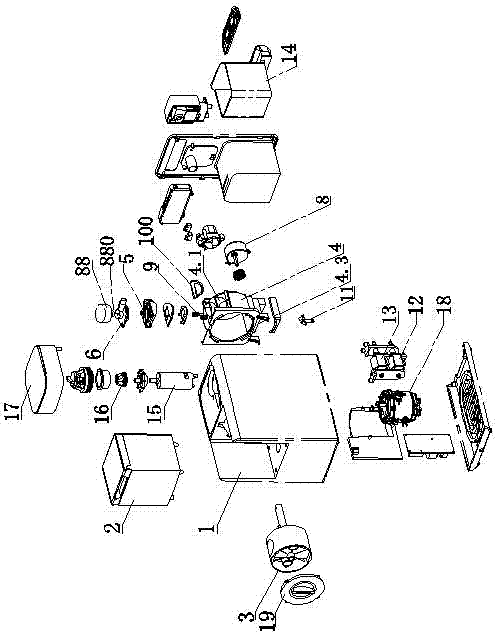

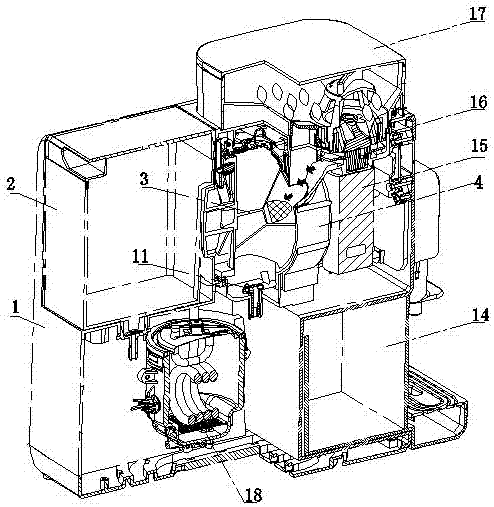

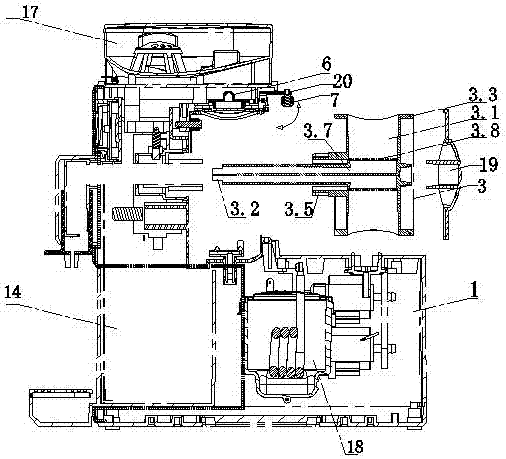

Mechanical arm device

InactiveCN103496033AReduce labor intensityEnsure safetyAuxillary shaping apparatusCeramic moldingGear wheel

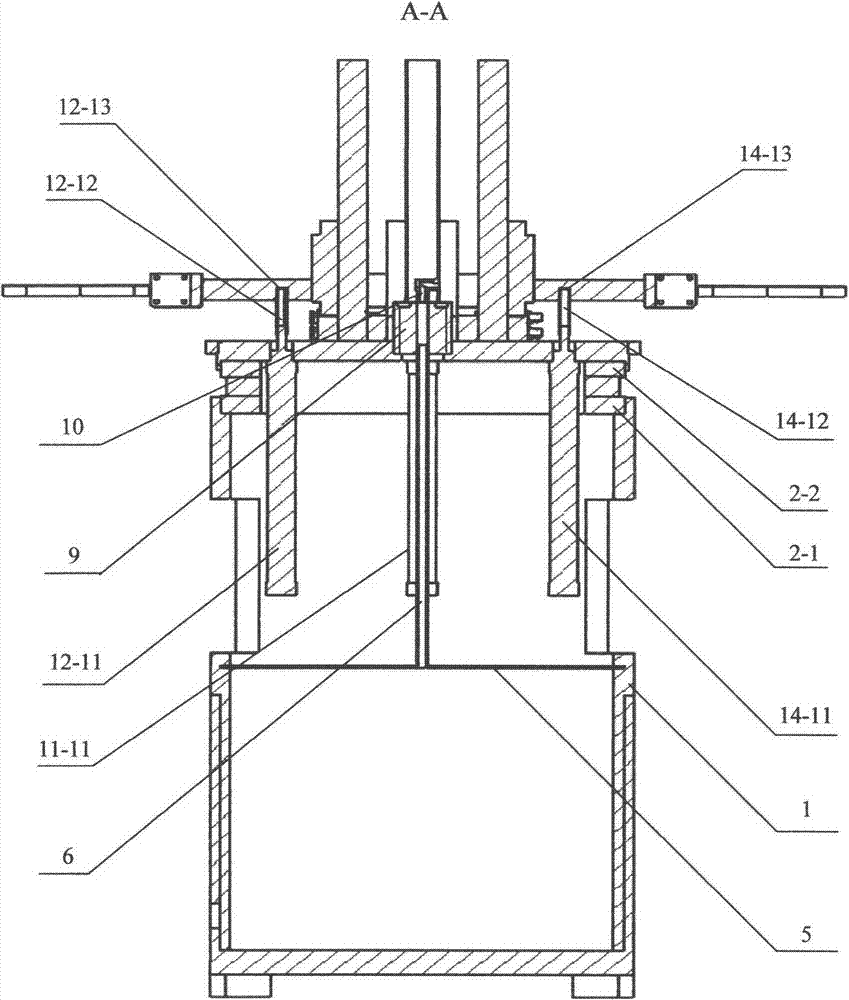

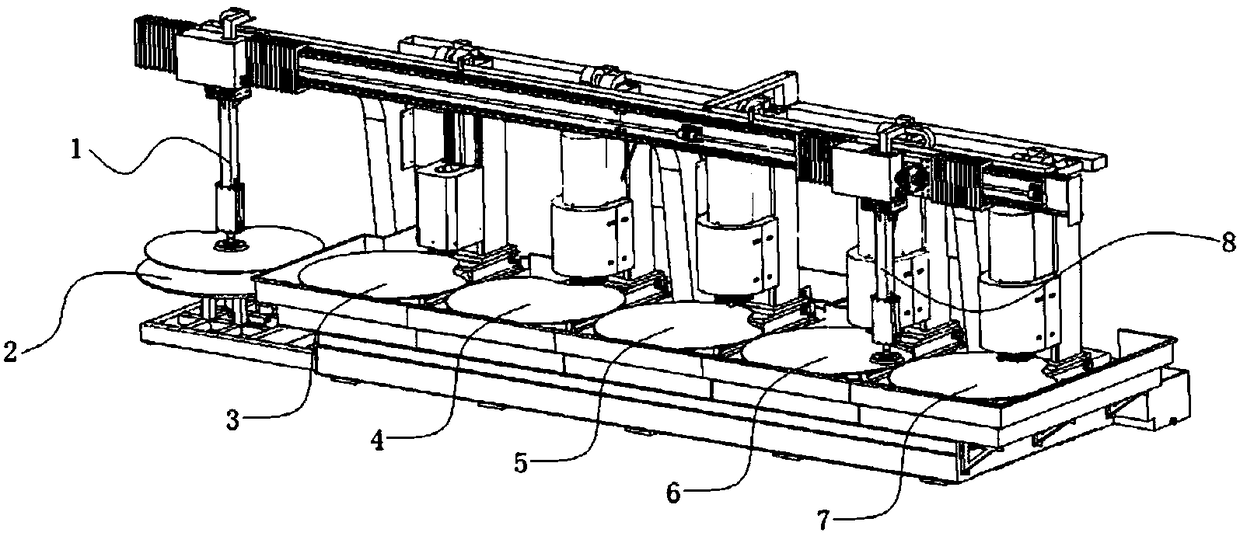

The invention relates to a mechanical arm device, in particular to a multi-mechanical-arm circulation working device which is used for feeding and discharging procedures of a ceramic molding press. According to the technical scheme, the multi-mechanical-arm working device comprises a chassis 1, a bearing 2, a rotating platform 3, a motor 4 and mechanic arms 11,12,13,14. The bearing 2 is installed between the chassis 1 and the rotating platform 3 to ensure that the rotating platform 3 can rotate relative to the chassis 1; the mechanical arm 11,12,13,14 are fixedly connected with sliding blocks 11-3, 12-3, 13-3, 14-3 respectively to achieve sliding of guide rails 11-2,12-2,13-2,14-2. Lifting air cylinders are installed below the mechanical arms respectively and can achieve rise and descent of the mechanical arms, and each mechanical arm is provided with two clamping air cylinders and can achieve clamping and opening of mechanical arm clamping pieces; rotating of the rotating platform 3 is driven by the motor 4 through a gear transmission device.

Owner:邓刚锋

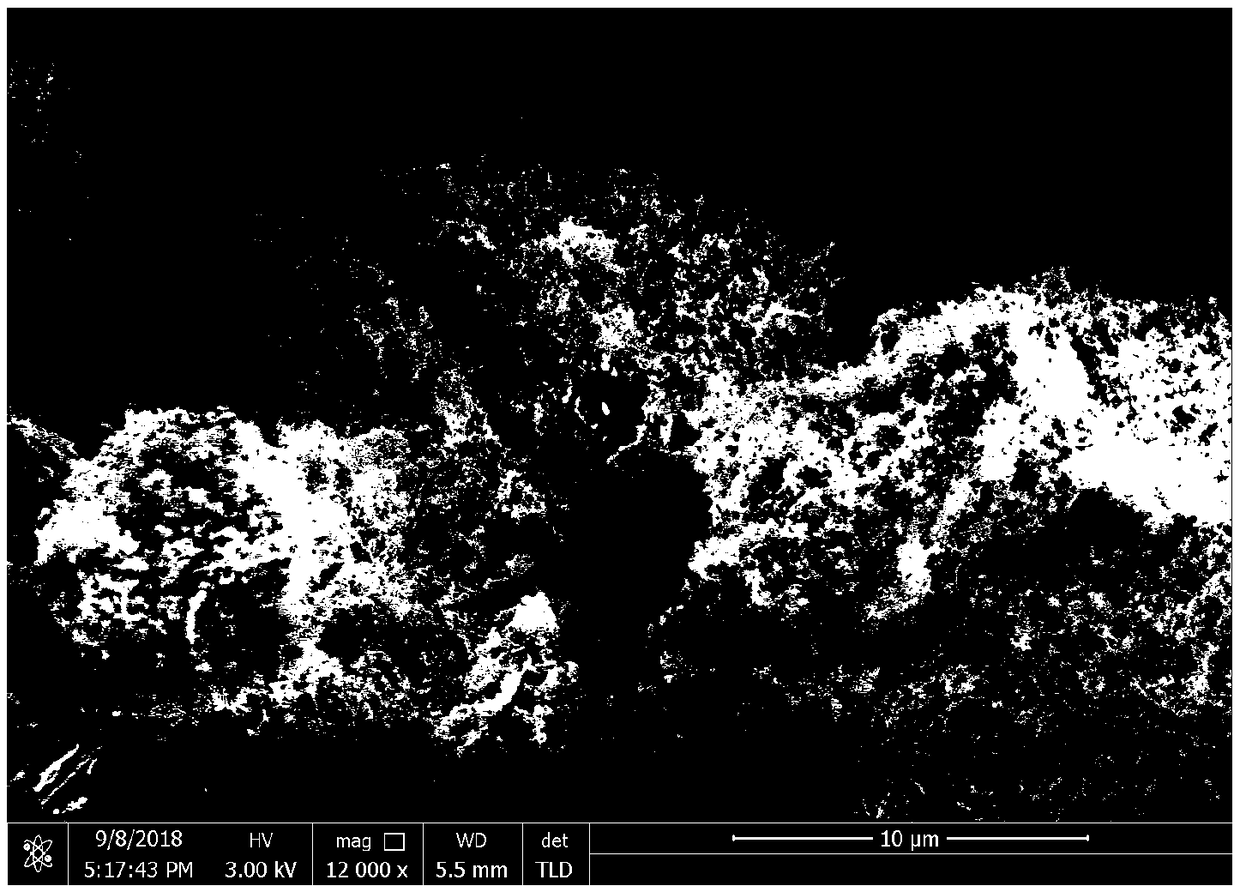

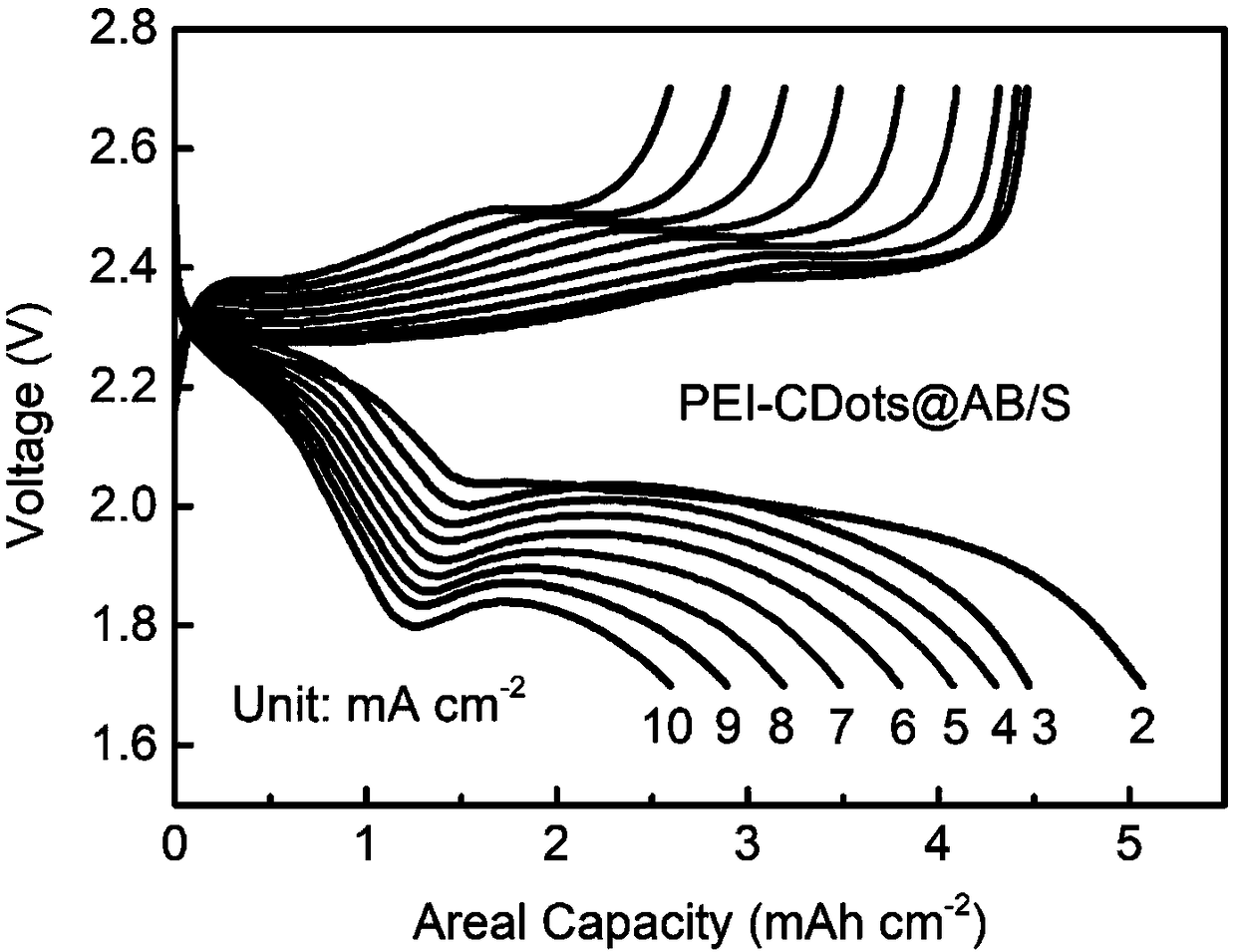

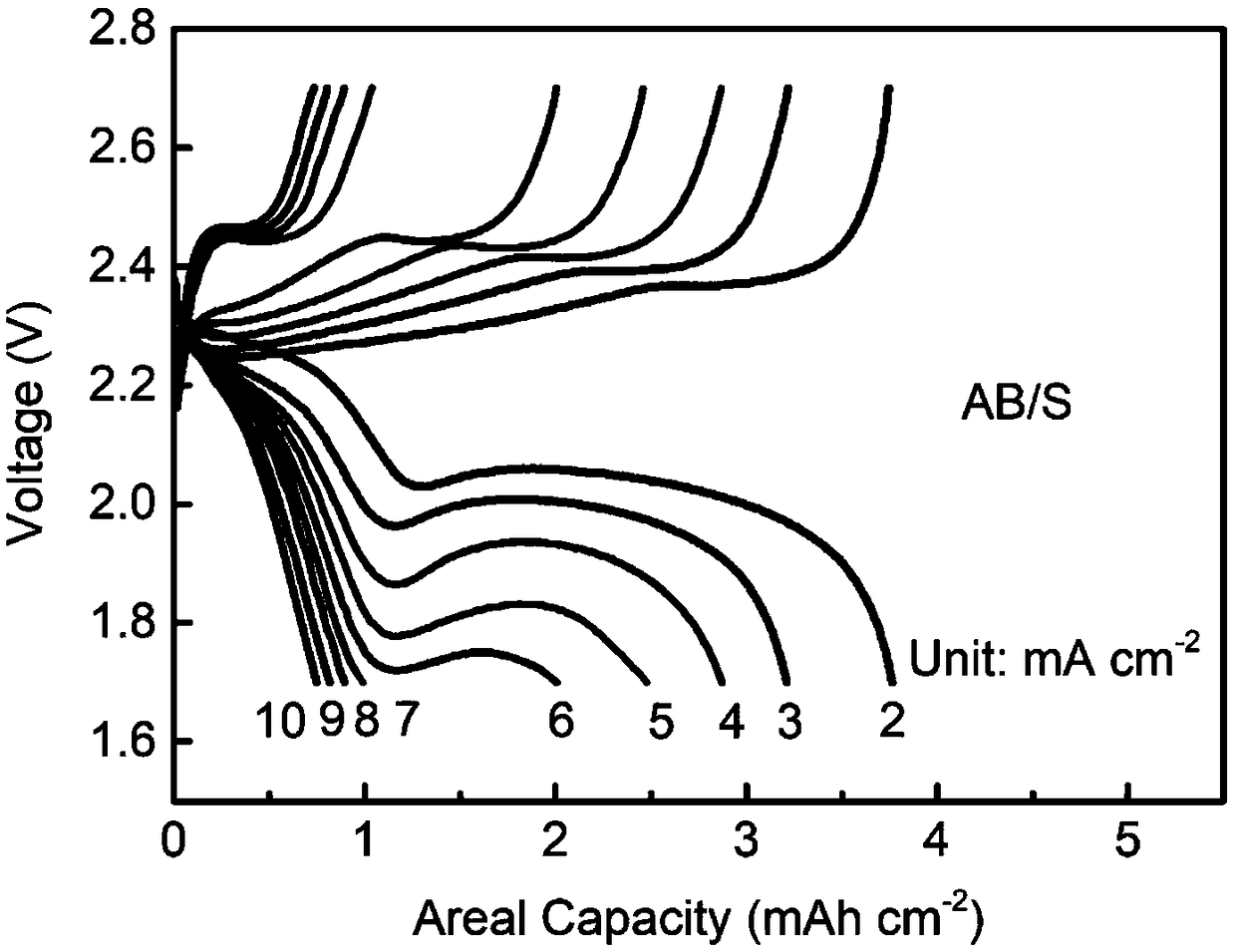

Method for preparing carbon quantum dot modified lithium-sulfur battery positive electrode materials

ActiveCN109494346AIncrease capacityHigh magnificationElectrode carriers/collectorsElectrode collector coatingHigh current densityBattery charge

The invention provides a method for preparing carbon quantum dot modified lithium-sulfur battery positive electrode materials, and belongs to the field of preparation of lithium-sulfur battery positive electrode materials. The method has the advantages that carbon quantum dots with functionalized polyethyleneimine surfaces are used for preparing lithium-sulfur battery positive electrodes, shuttling effects in battery charge and discharge procedures can be inhibited under polysulfide adsorption effects of polyethyleneimine, and accordingly the long cycle performance of lithium-sulfur batteriescan be guaranteed; the method for preparing the carbon quantum dot modified lithium-sulfur battery positive electrode materials includes simple and convenient processes, the capacity, the rates and the cycle performance of the lithium-sulfur batteries under working conditions of high load and high current density can be obviously improved, and accordingly the method has a potential application value in the field of lithium-sulfur batteries.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

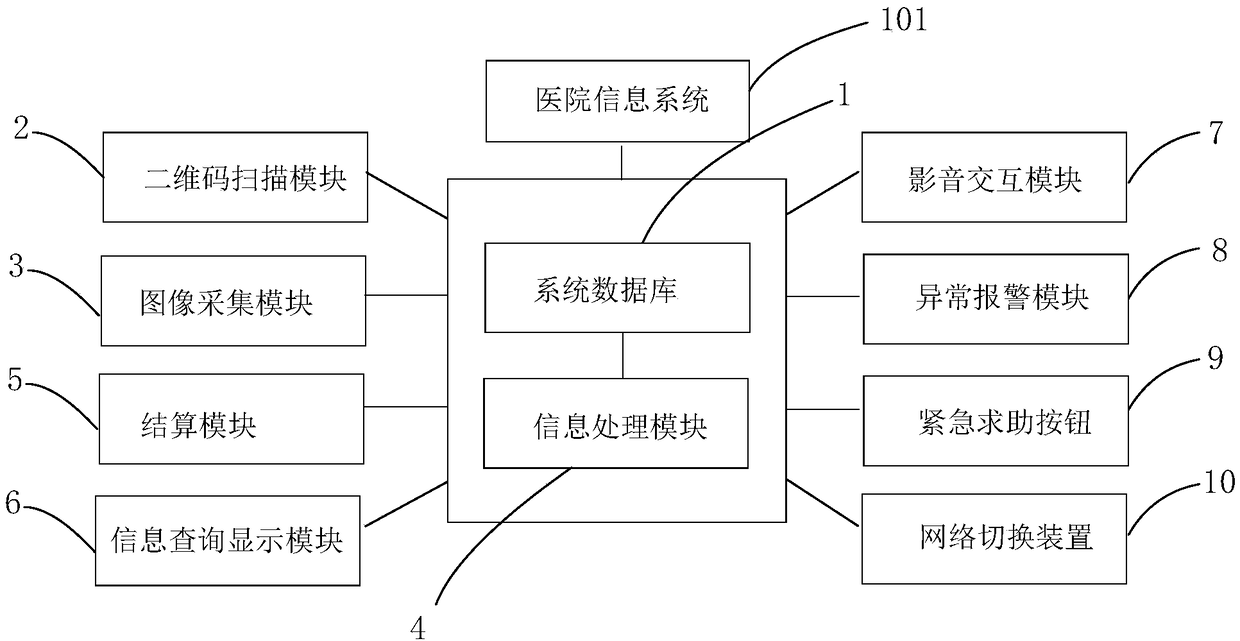

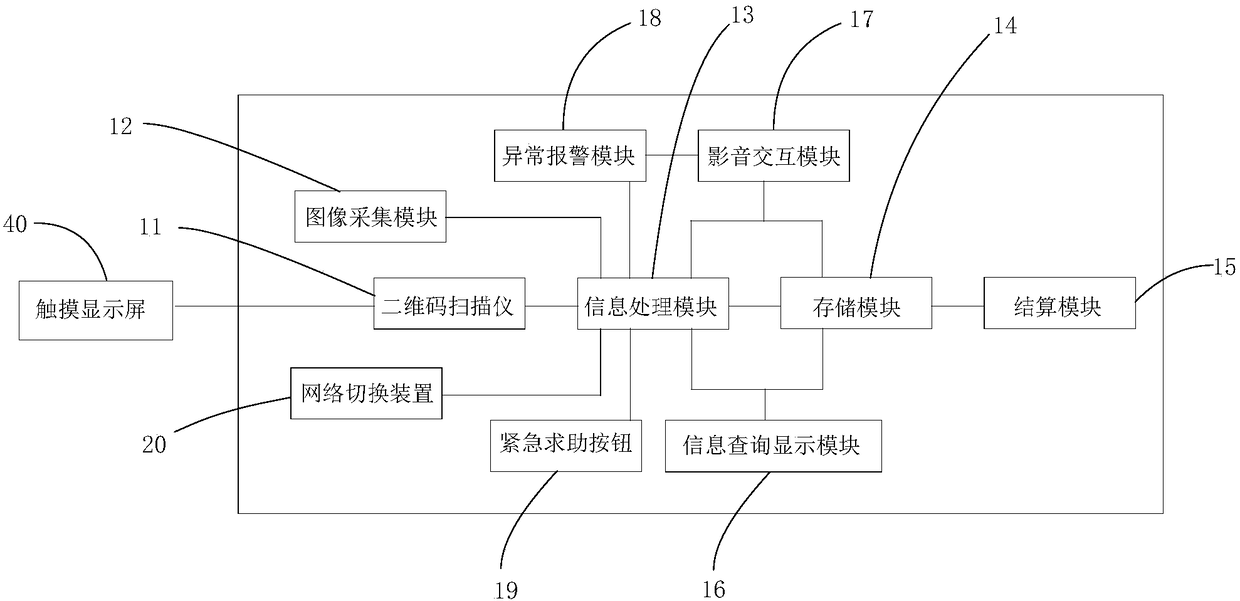

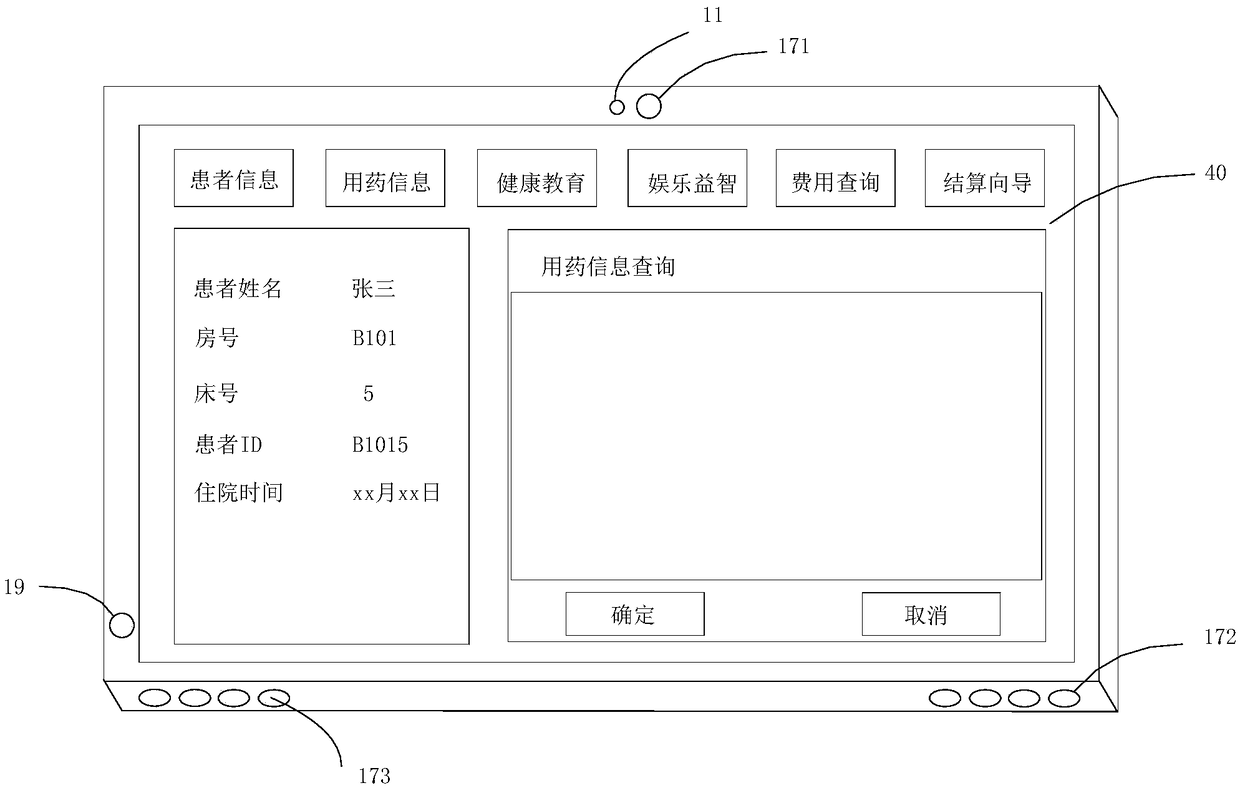

Bedside informatization interaction system

InactiveCN108091374AEasy accessGuaranteed to workMedical communicationCo-operative working arrangementsInformatizationInformation processing

The invention relates to a bedside informatization interaction system, which comprises a system database, a two-dimensional code scanning module, an image acquisition module, an information processingmodule and a settlement module, wherein the system database is connected with a hospital information system which is used for establishing hospitalization file information for patients in a wired orwireless manner; the two-dimensional code scanning module is connected with the system database and used for acquiring and verifying hospitalization file information and medication information of thepatients; the image acquisition module is connected with the system database and used for acquiring patient certificate information and the medication information; the information processing module isconnected with the two-dimensional code scanning module, the image acquisition module and the system database separately, and is used for combining the acquired information to output digital files and storing the digital files in the system database; and the settlement module is connected with the system database and the information processing module and used for generating a settlement expense list. The bedside informatization interaction system can realize the self-service completion of discharge procedures, reduces hospital service costs and improves efficiency.

Owner:SINO MEDICAL DEVICE TECH

Continuous modified atmosphere fresh-keeping packaging machine and packaging method thereof

PendingCN110525720AFully automatedImprove work efficiencyPackaging by pressurising/gasifyingModified atmosphereEngineering

The invention discloses a continuous modified atmosphere fresh-keeping packaging machine and a packaging method thereof. The packaging machine comprises a conveying mechanism, an atmosphere modification mechanism and a sealing and cutting mechanism which are arranged on a rack; at least four stations are arranged on a containing opening conveying belt and synchronously conduct feeding, atmospheremodification, sealing and cutting and discharging procedures respectively; packaging containers are placed in the containing opening stations, and a containing opening bearing mechanism is borne at the lower ends of the containing opening packaging containers. The containing opening atmosphere modification mechanism comprises an atmosphere modification chamber main body; the containing opening atmosphere modification chamber main body and the conveying face of the containing opening conveying belt are elastically sealed, a dynamic sealing space is formed above the conveying belt, the atmosphere modification chamber main body is connected with an inflation mechanism, the inflation mechanism sprays nitrogen to the containing opening packaging containers, an exhaust channel is formed in the atmosphere modification chamber main body, and an oxygen sensor for monitoring the oxygen concentration is installed on the inner wall of the containing opening exhaust channel. The dynamic sealing space can effectively prevent space gaps caused by station transfer from influencing air tightness, and the oxygen sensor monitors the oxygen content in exhausted gas to prevent a large amount of oxygenfrom remaining in the packaging container.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Fine material weighing hopper device

InactiveCN103587844ARealize automatic weighingAccurate and reliable closing actionLarge containersEngineeringMechanical engineering

The invention discloses a fine material weighing hopper device. The fine material weighing hopper device is characterized in that an electric positioner drives two vane oscillating cylinders to rotate, two turning plates are further driven to rotate to reach horizontal positions to so as block fine materials, and the fine materials flow through lower middle through holes and can be automatically weighed by explosion-proof on-ground electronic scales; the turning plates are opened by certain angles after the fine materials are weighed, so that the fine materials can be discharged into a fine material conveying hopper, the discharging speed can be increased under the impact effect of an air hammer in a discharging procedure, and then the fine material conveying hopper is transported to the position corresponding to a next working procedure. The fine material weighing hopper device has the advantages that the turning plates are accurate and reliable in opening and closing actions, weighing errors are few, and the fine material weighing hopper device can be applied to weighing and feeding operation on similarly powdery materials; the fine materials can be automatically weighed and can be automatically fed into the fine material conveying hopper, so that the shortcoming of troublesome labor required by manual carrying and feeding can be overcome, an intermediate link for loading fine materials into cloth bags can be omitted, and a phenomenon of inaccuracy in weighing due to the fact that the fine materials are attached to the cloth bags can be completely eradicated.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

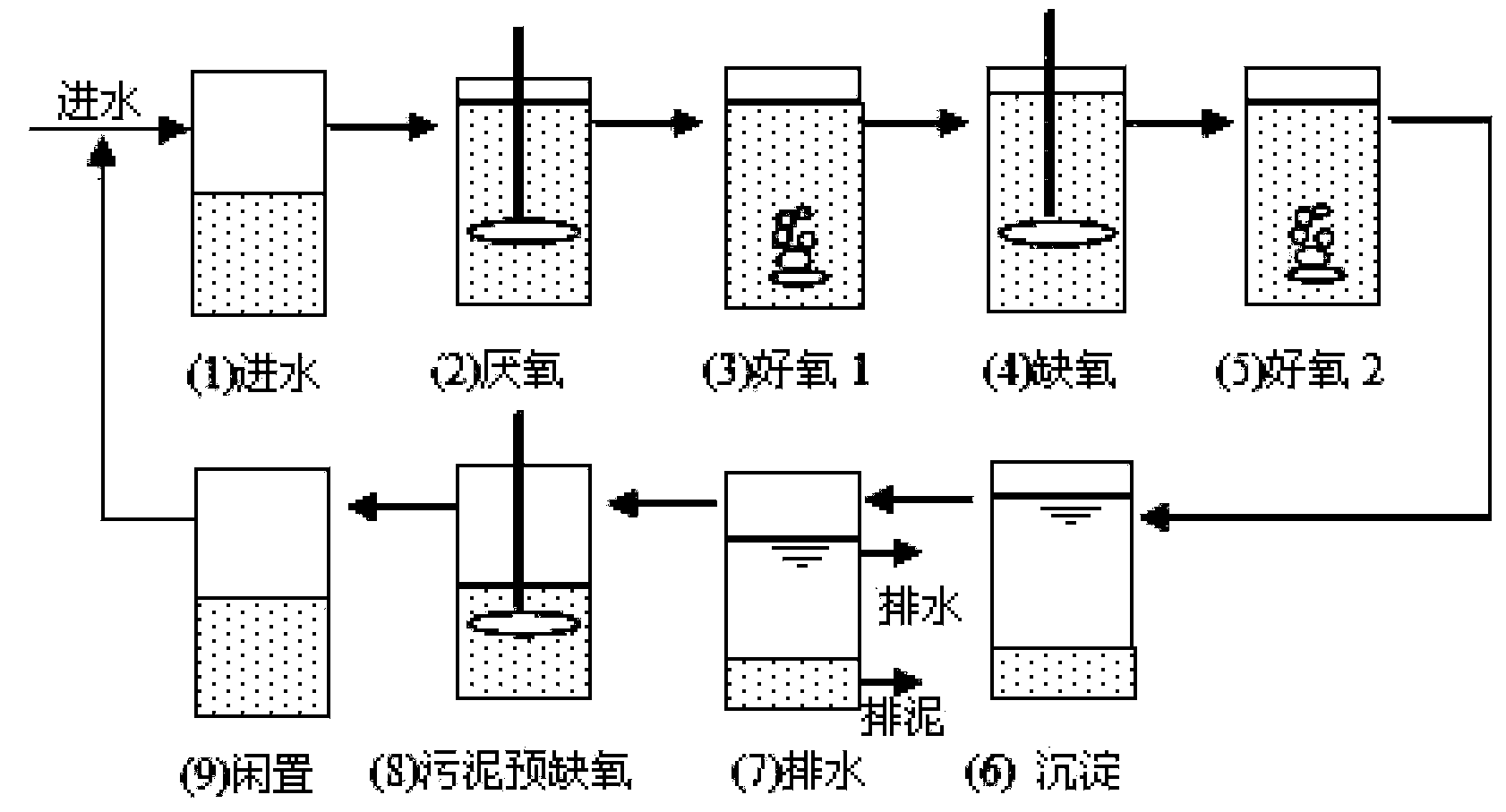

Nitrogen and phosphorus removal technological method for sewage treatment with capabilities of endogenesis strengthening and postposition denitrification

InactiveCN104386820AAchieve transferAchieve removalTreatment with aerobic and anaerobic processesHypoxic preconditioningNitrogen removal

The invention discloses a nitrogen and phosphorus removal technological method for sewage treatment with the capabilities of endogenesis strengthening and postposition denitrification. The nitrogen and phosphorus removal technological method is a sequencing batch type nitrogen and phosphorus removal process and comprises the following eight steps: water intake procedure, anaerobic procedure, primary aerobic procedure, hypoxic procedure, secondary aerobic procedure, precipitation procedure, water and sludge discharge procedure, sludge hypoxic preconditioning procedure. According to the nitrogen and phosphorus removal technological method disclosed by the invention, endogenesis denitrification process of a system is strengthened by virtue of the hypoxic procedure and the sludge hypoxic preconditioning procedure, so that the nitrogen removal effect of the system is improved; meanwhile, by virtue of the endogenesis denitrification process in the sludge hypoxic preconditioning procedure, the nitrate concentration in returned sludge is effectively lowered, so that the nitrate problem in synchronous nitrogen and phosphorus removal process is effectively relieved, and good foundation of anaerobic phosphorus release is laid. With the adoption of the nitrogen and phosphorus removal technological method, the contradiction of biological nitrogen removal and biological phosphorus removal can be relieved, the efficiencies of nitrogen and phosphorus removal are both high, and the system is small in sludge yield, is simply controlled, is easy in production and implementation and has potential and wide application prospect.

Owner:HUNAN UNIV OF SCI & TECH

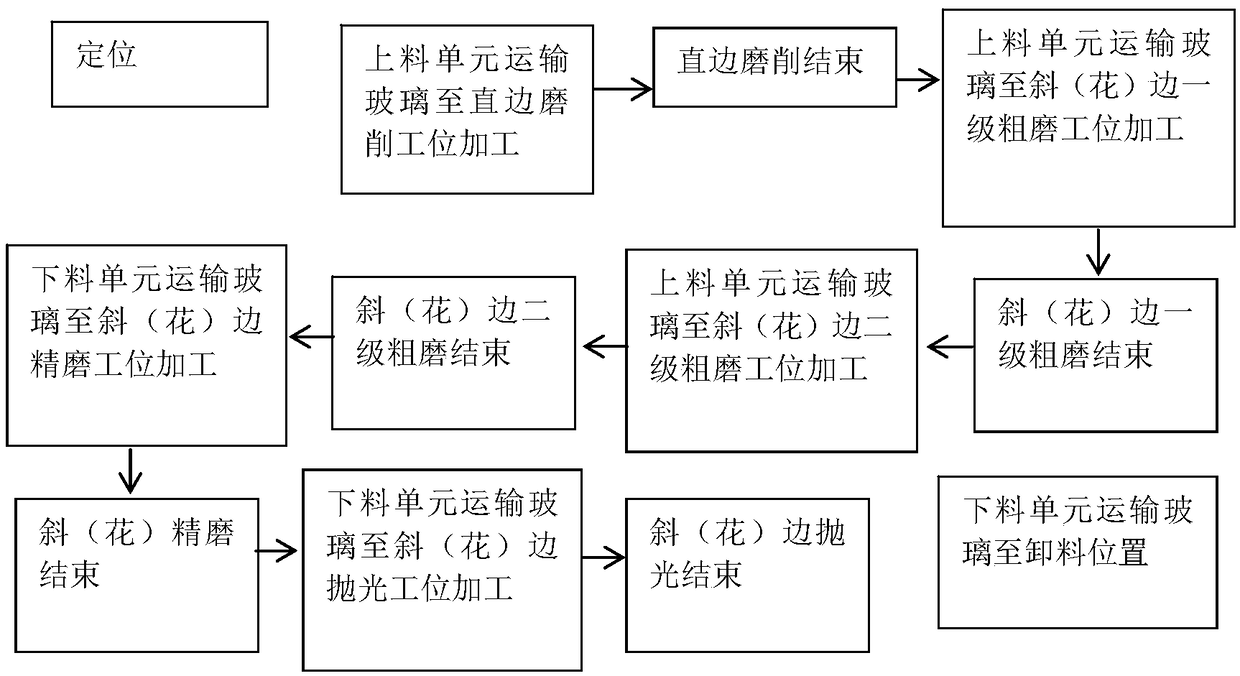

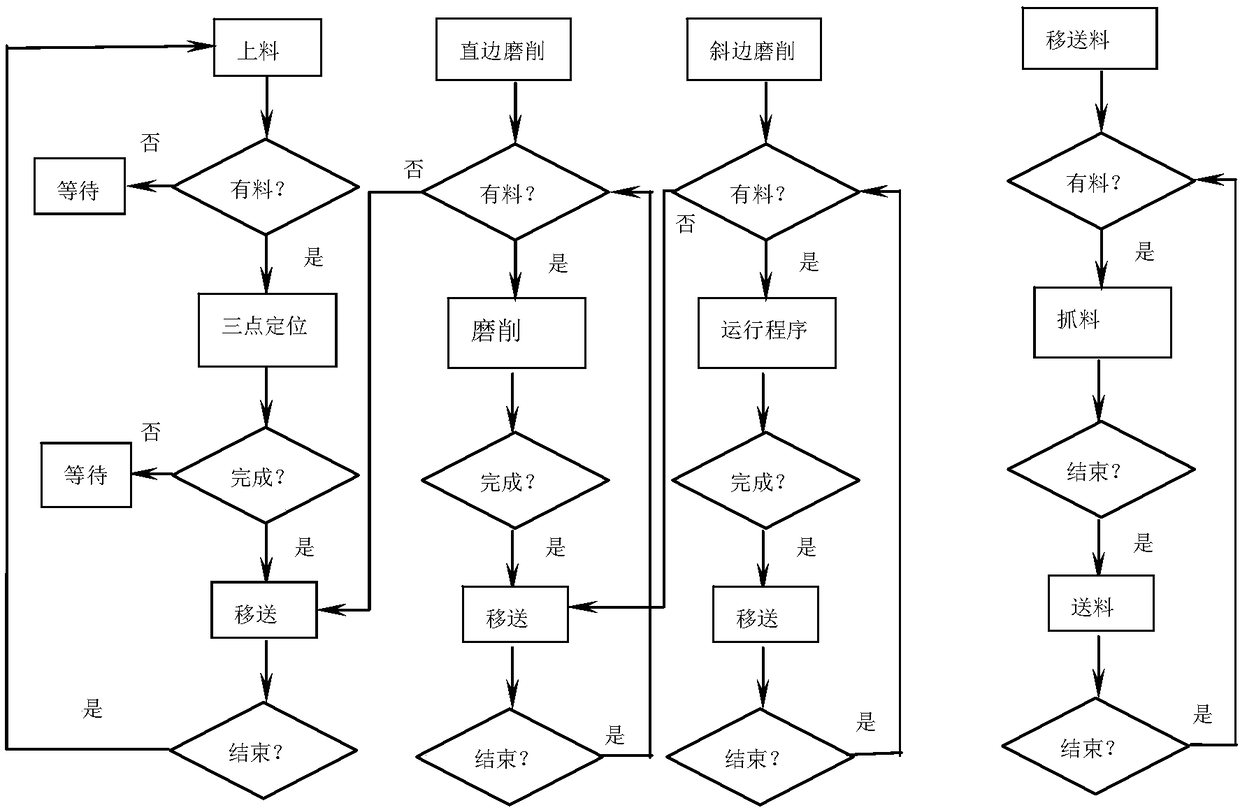

Glass edge continuous grinding method

InactiveCN108067971AReduce labor intensityShorten production timeEdge grinding machinesGrinding feedersMetallurgyMachining time

The invention provides a glass edge continuous grinding method, relates to the technical field of glass grinding and relates to a glass edge continuous grinding method. The glass edge continuous grinding method is designed for solving the problems that when the same glass needs straight edge and hypotenuse (or lace) grinding, automatic transfer of the glass in different procedures cannot be achieved, after machining devices are switched, multiple times of locating and tool setting are needed, consequently labor intensity is high, machining time is long, and production efficiency is low. The glass edge continuous grinding method comprises a feeding procedure, multiple grinding procedures and a discharging procedure. The feeding procedure comprises a locating procedure. All the grinding procedures are arranged sequentially and are performed at least once. A feeding unit is used for transferring to-be-machined glass to the prior one or multiple grinding procedures. A discharging unit is used for transferring to-be-machined glass to the later one or multiple grinding procedures. The machined glass is discharged through the discharging unit. Through the glass edge continuous grinding method, automatic transfer of the glass at different stations can be achieved.

Owner:ZHEJIANG SCI-TECH UNIV +1

Automatic vacuum stirring device capable of realizing cleaning

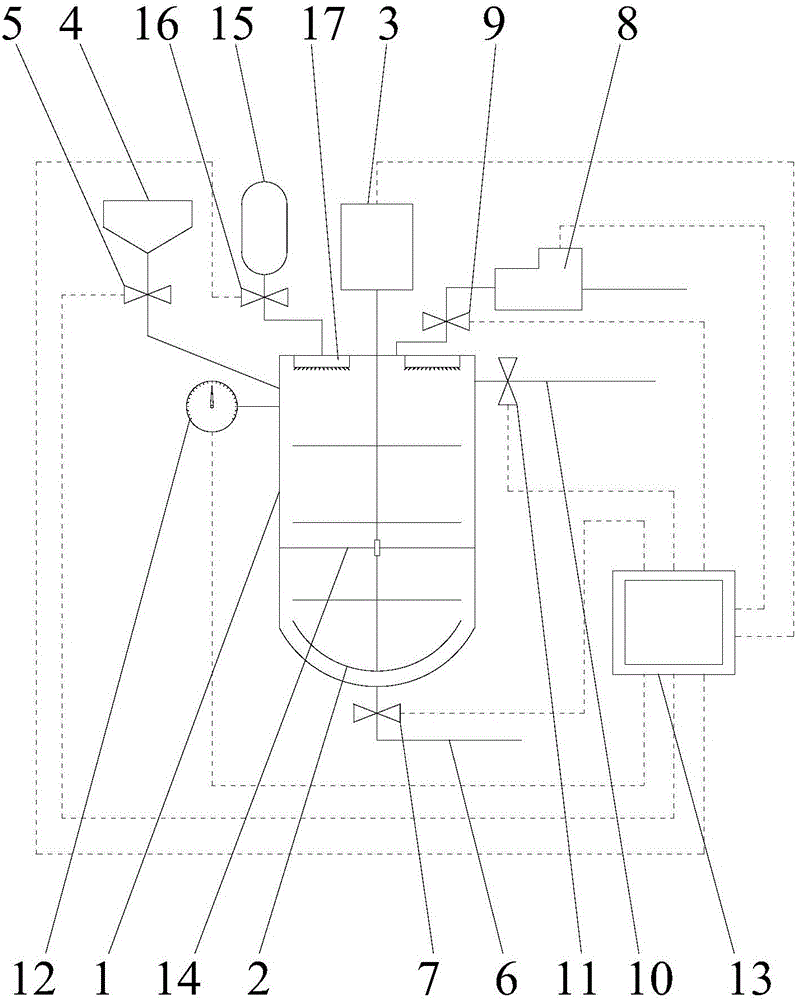

InactiveCN105056805AReduce labor costsImprove securityRotary stirring mixersMixer accessoriesVacuum pumpingControl system

An automatic vacuum stirring device capable of realizing cleaning comprises a stirring kettle, a stirring paddle, a stirring motor, charging hoppers, charging flow control valves, a discharging pipe, a discharging switch, an air pump, a vent valve, an air pressure balancing pipe, an air pressure balancing switch, a barometer, cleaning nozzles, a cleaning switch, a cleaning fluid storage tank and a control system, wherein an anti-shaking fixing rod is also arranged in the stirring kettle. The automatic vacuum stirring device capable of realizing cleaning can automatically perform vacuum pumping stirring and pressurized discharging procedures to replace manual operation, time and labor are saved, the labor cost is reduced, the production safety is improved, accurate charging control is realized, the stirring quality is guaranteed, the automation degree is high, the production requirement can be met, and the inside of the stirring kettle can be cleaned automatically, conveniently and quickly after stirring is finished.

Owner:WUJIANG JIA BILLION ELECTRONICS TECH

Automatic feeding and discharging device for window punching of tapered roller bearing retainers

ActiveCN105665567AEnsure safetySimple structureMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses an automatic feeding and discharging device for window punching of tapered roller bearing retainers. The automatic feeding and discharging device comprises a machine frame. A material way, a grabbing mechanism, a material ejecting mechanism, a material taking mechanism, a punching mechanism and a discharging mechanism are arranged on the machine frame. The automatic feeding and discharging device is simple in structure and easy and convenient to operate, in the feeding and discharging procedures for window punching of tapered roller bearing retainers, manual feeding conducted by workers can be replaced, safety of operation of the workers is ensured, and the production efficiency is improved; and meanwhile, the automatic feeding and discharging device can be compatible with various types of tapered roller bearing retainers, and has the beneficial effects of being wide in application range and low in production cost.

Owner:HEFEI JUNGJIN AUTOMATION CO LTD

Grinding coffee maker with function of automatic water injection

InactiveCN107397439AFully automatic requirementsImprove work efficiencyBeverage vesselsEngineeringBrewing

A coffee machine capable of automatically feeding water and grinding beans, including a water tank, a body, a water supply assembly, a grinding assembly and a brewing assembly; the body is provided with at least a brewing chamber and a grinding chamber, and the brewing assembly and the grinding assembly are respectively placed in the brewing chamber. The brewing chamber and the grinding chamber; the brewing assembly includes a rotatable rotating member, at least one brewing chamber is arranged in the rotating member, and the opening of the brewing chamber rotates in a circular track; the brewing assembly is at least provided with a brewing chamber The opening of the brewing head and the outlet, the water outlet of the water supply assembly and the powder outlet of the grinding assembly respectively pass through the opening of the brewing head and the opening of the brewing chamber connected to the outlet of the barrel; the opening of the brewing chamber rotates with the rotating part, The circulation makes it communicate with the discharge port and the opening of the brewing head in turn; there is a pressure-generating flow-limiting hole between the opening of the brewing chamber and the liquid discharge hole, and the water supply pump supplies water to the sealed brewing chamber quickly and limitedly. The slow interaction of the orifices and the water discharge creates a brewing chamber for pressure discharge. The present invention rotates and arranges the rotary member, so that the feeding, brewing and discharging procedures of the coffee machine can be carried out automatically and continuously and in a cycle, thereby realizing the full-automatic requirement.

Owner:周林斌 +1

Automatic feeding and discharging device of punch machine

ActiveCN109482764ANovel structureFully automatedMetal-working feeding devicesCleaning using toolsElectric machineryEngineering

The invention provides an automatic feeding and discharging device of a punch machine, and belongs to the technical field of material molding engineering equipment. The automatic feeding and discharging device is structurally composed of a stock bin, a feeding mechanism, a double speed manipulator and a discharging mechanism, and workpieces are conveyed for the feeding mechanism by a feed tray through a first cylinder; a sucker mechanism on the feeding mechanism is vertically moved through a second cylinder, and used for conveying the workpieces to the double speed manipulator through a motoron the feeding mechanism and a ball screw horizontally; the workpieces are cleaned through a brush, and a discharging bowl group is used for storing the workpieces conveyed by the sucker mechanism; finished products are stored and waste materials are filtered upon completion of machining by the machine body; and the discharging bowl group is used for conveying the materials to the discharging mechanism through a belt transmission device horizontally, and the workpieces conveyed by the double speed manipulator are sucked through the sucker mechanism on a material pushing mechanism. The automatic feeding and discharging device is novel in structure, and the working principles are clear; the shortcomings of low working efficiency of traditional feeding and discharging procedures, poor fluencyof part supply, high labor cost and the like are overcome; and the production automation and intellectualization of products are achieved, and the labor cost is reduced.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com