Fine material weighing hopper device

A hopper device and fine material technology, applied in the direction of packaging, transportation, packaging, containers, etc., can solve the problems of inaccurate weighing, high labor intensity, backward technology, etc., achieve accurate and reliable closing action, overcome tedious labor, and weigh small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

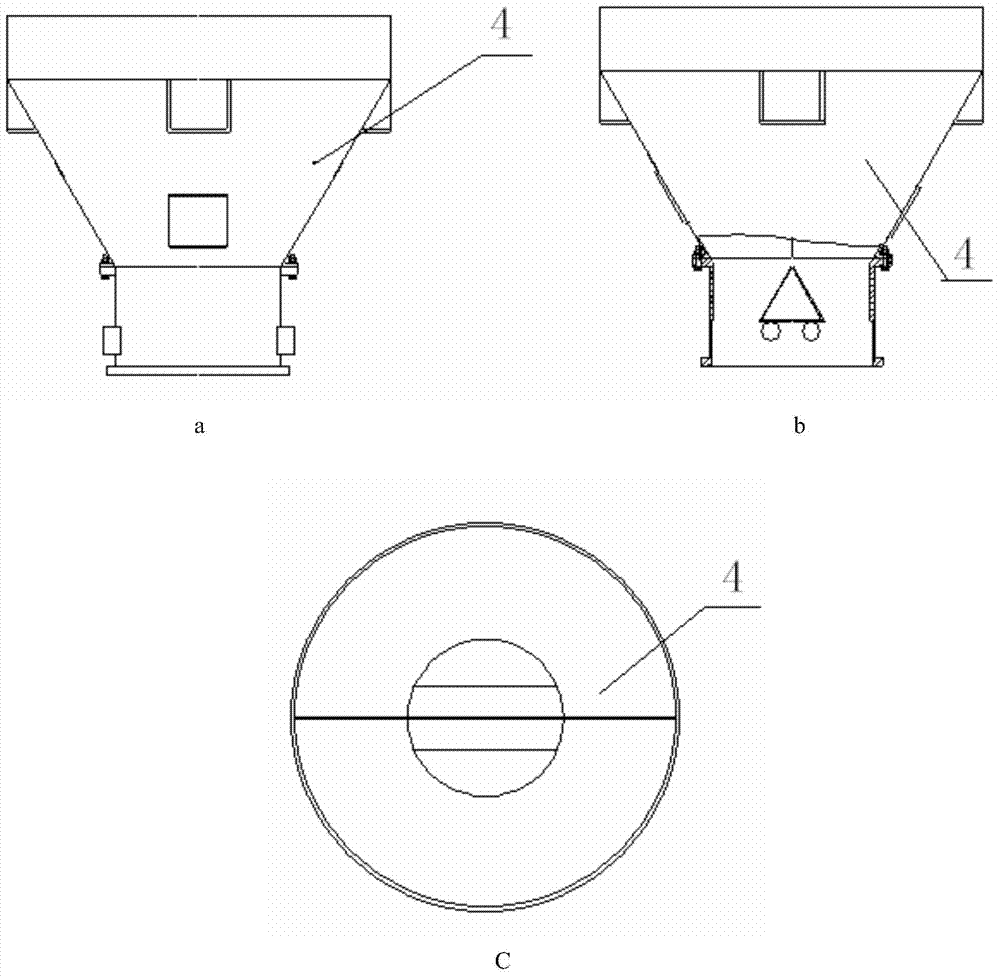

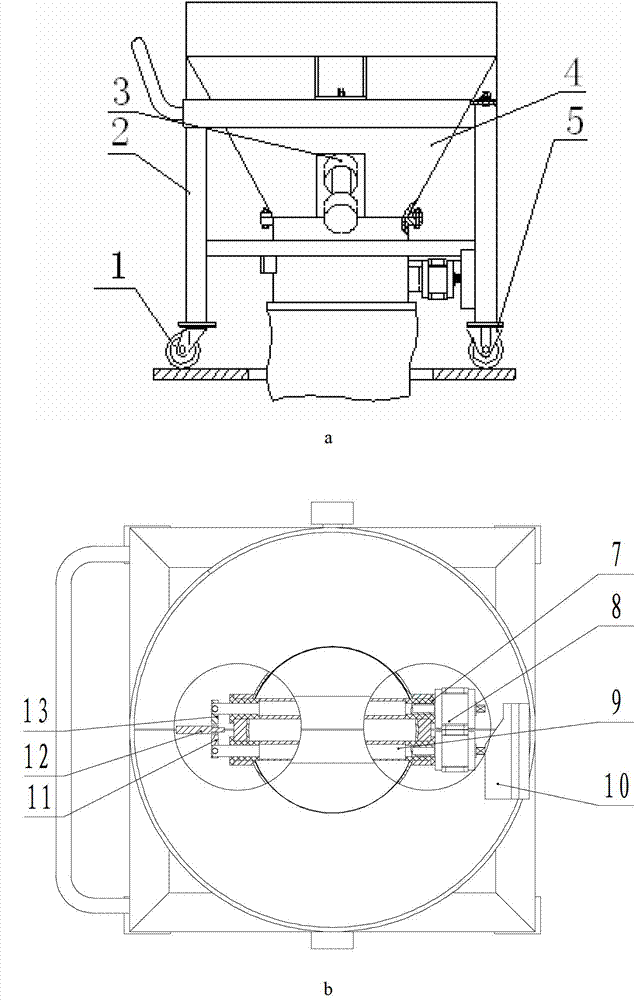

[0026] This embodiment is a weighing hopper device for fine materials, including a vehicle frame 2 , a hopper 4 , a flap 6 , and a blade-type swing cylinder 8 .

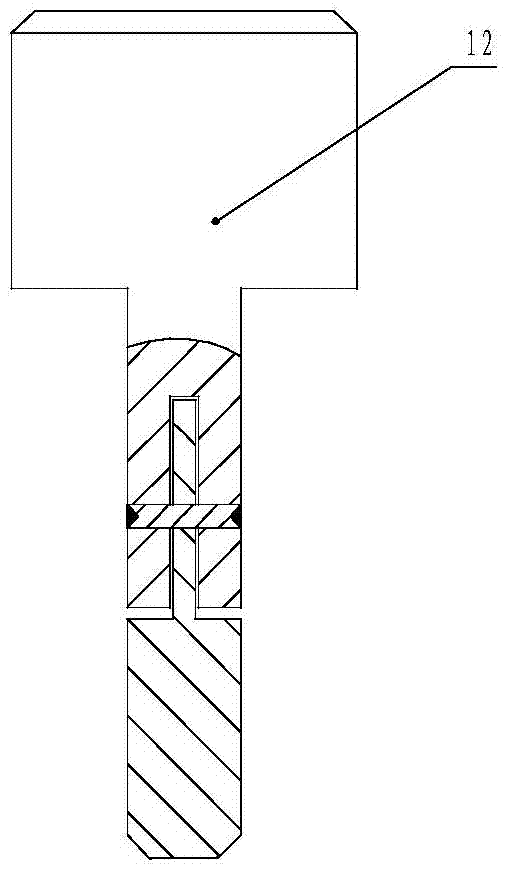

[0027] Such as figure 1 As shown, the vehicle frame 2 is a carrier, and the hopper 4 is located on the vehicle frame 2 and fastened with bolts. The air hammer 3 is installed symmetrically on the outer peripheral surface of the small diameter end of the cone section of the hopper 4 . The small-diameter end of the hopper 4 and the straight section are connected together by bolts through flanges. The two ends of the two rotating shafts 9 are respectively installed in two symmetrical through holes on the barrel of the straight barrel section of the hopper 4 through the bushings 7 . The two flaps in the flap valve 6 are located in the cylindrical body of the straight section of the cylindrical body 4, and are respectively sleeved on the rotating shaft 9. The centerlines of the two rotating shafts are parallel to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com