Patents

Literature

175results about How to "Small weight error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weighing module

ActiveCN101078649ADoes not affect accuracyHigh precisionWeighing apparatus detailsAgricultural engineeringNeck parts

Owner:METTLER TOLEDO CHANGZHOU PRECISION INSTR +2

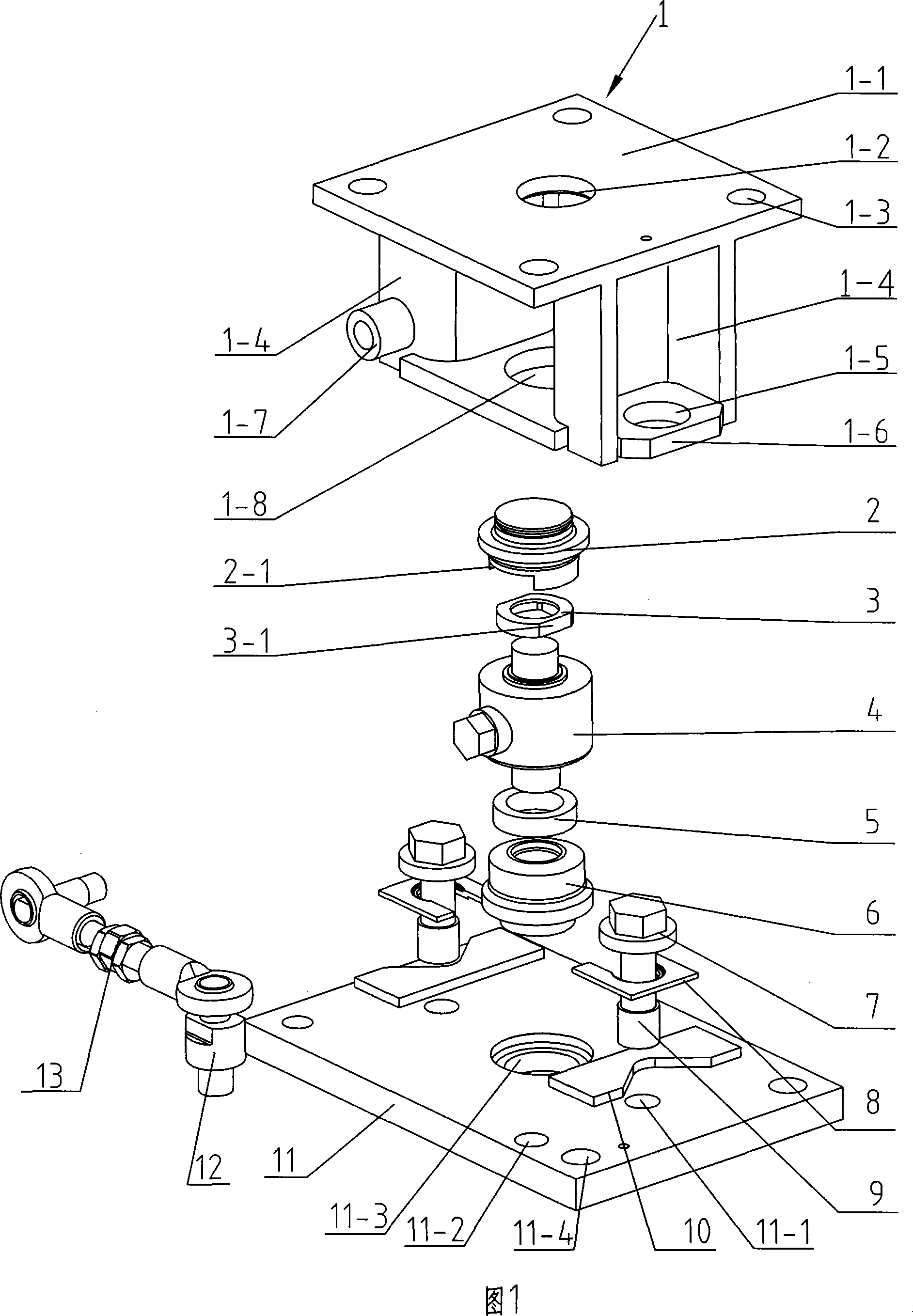

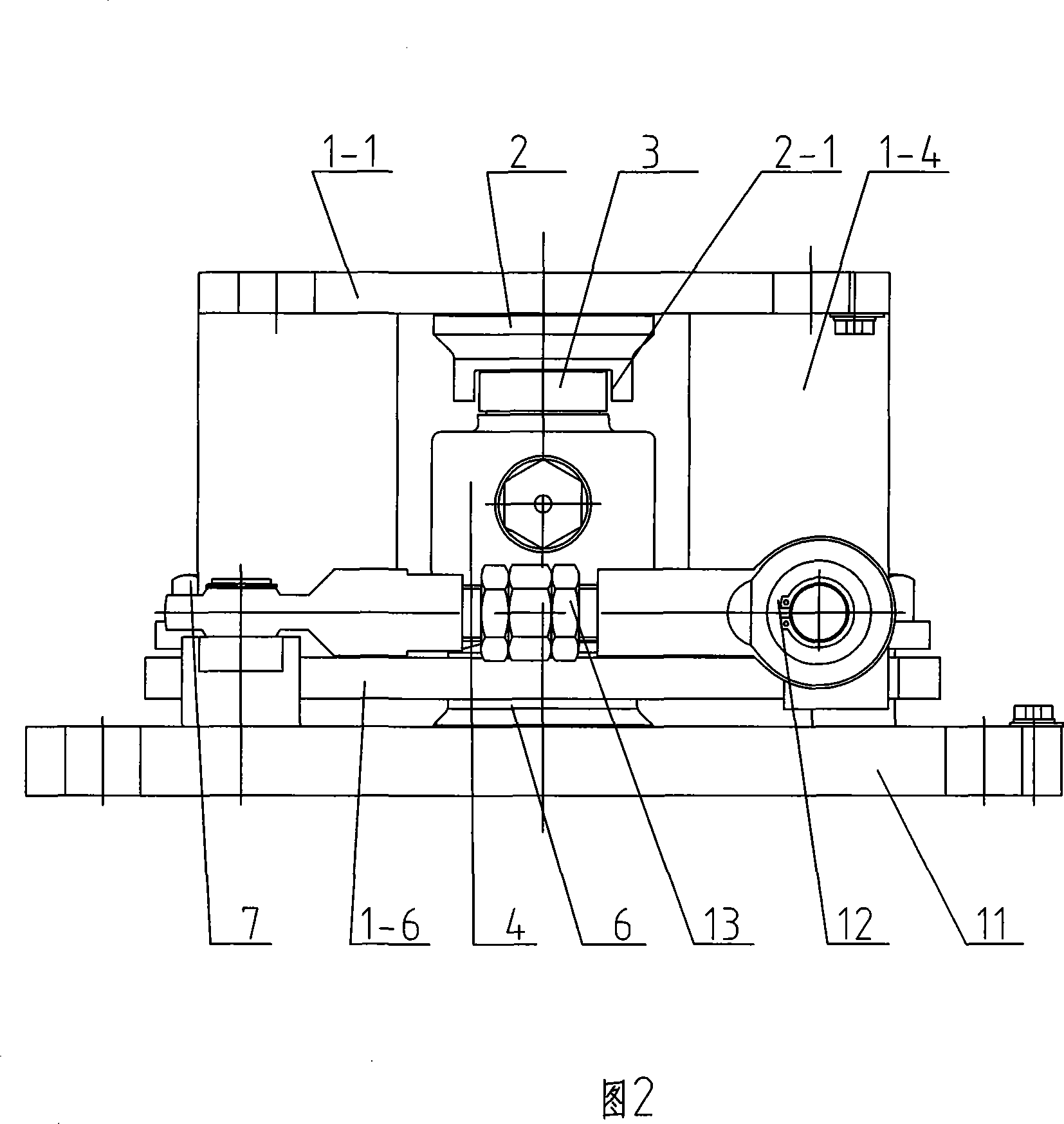

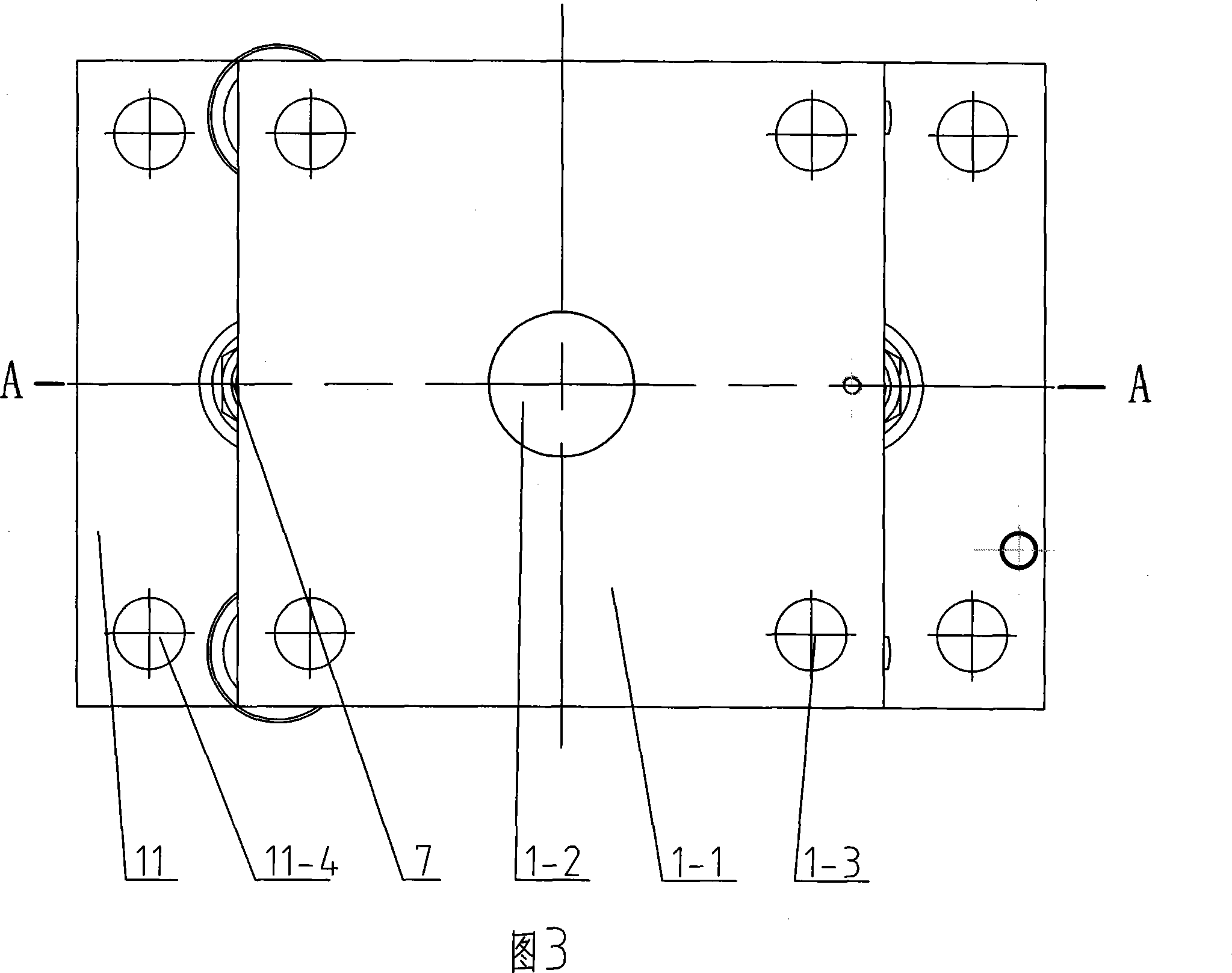

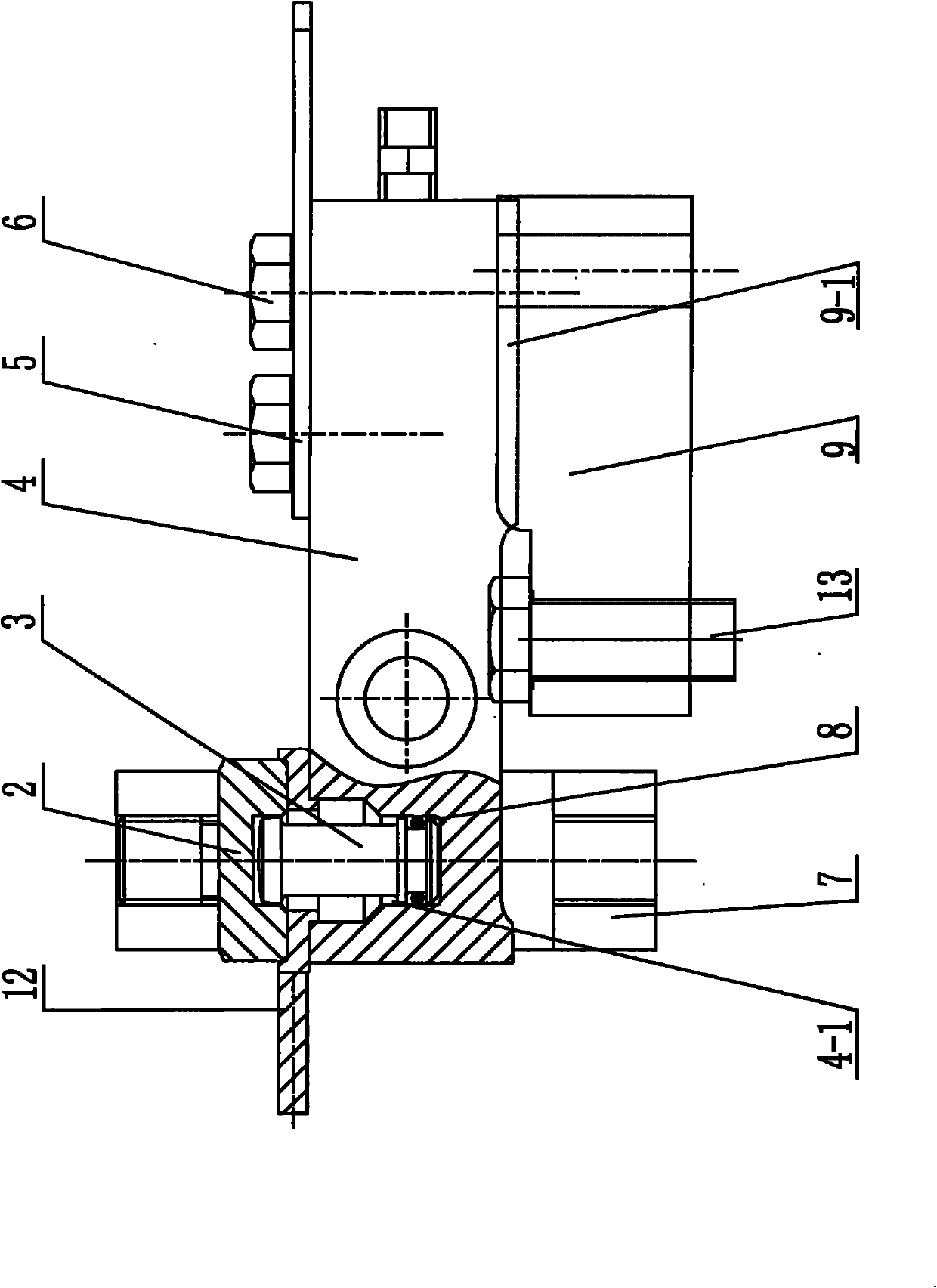

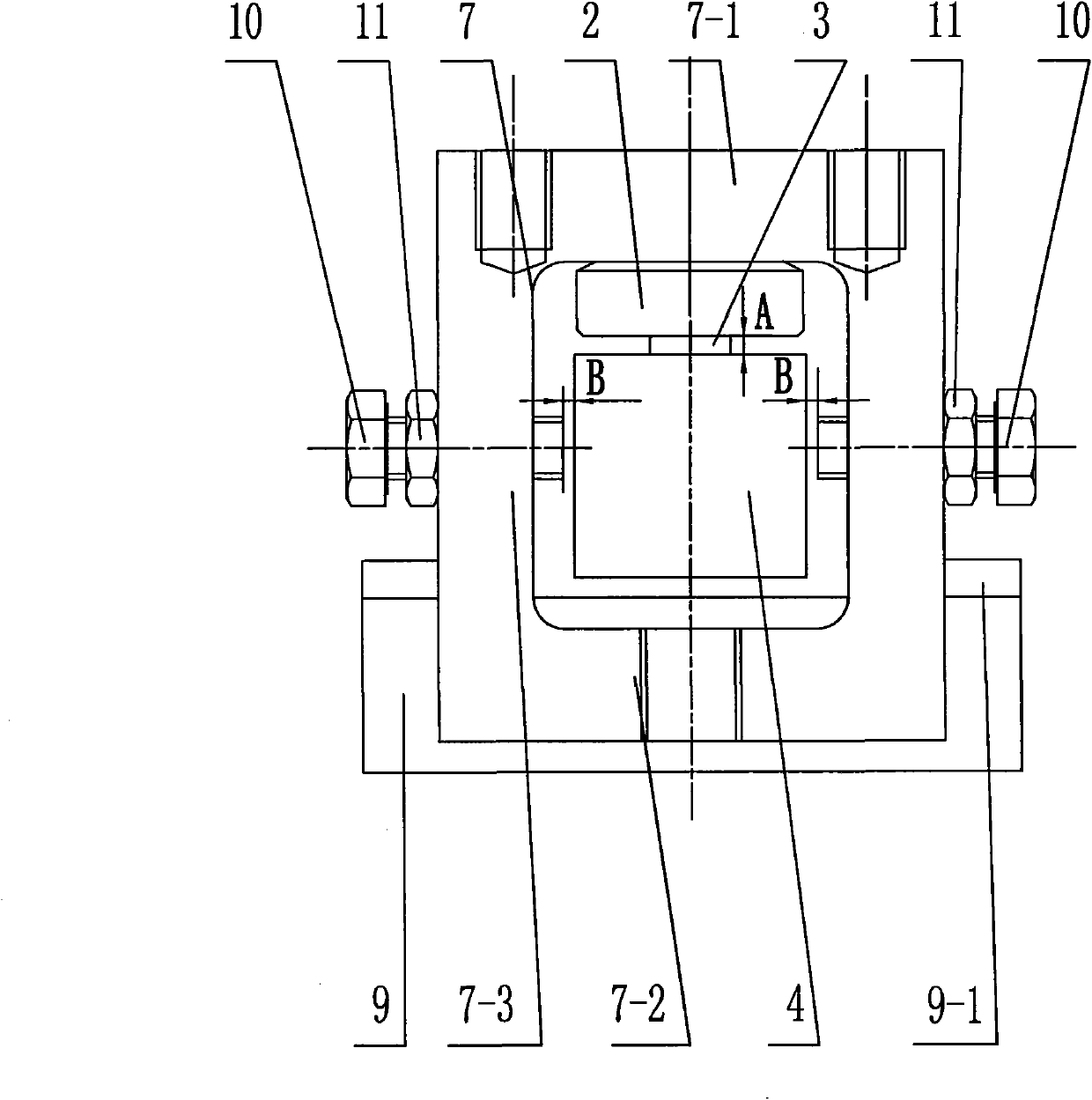

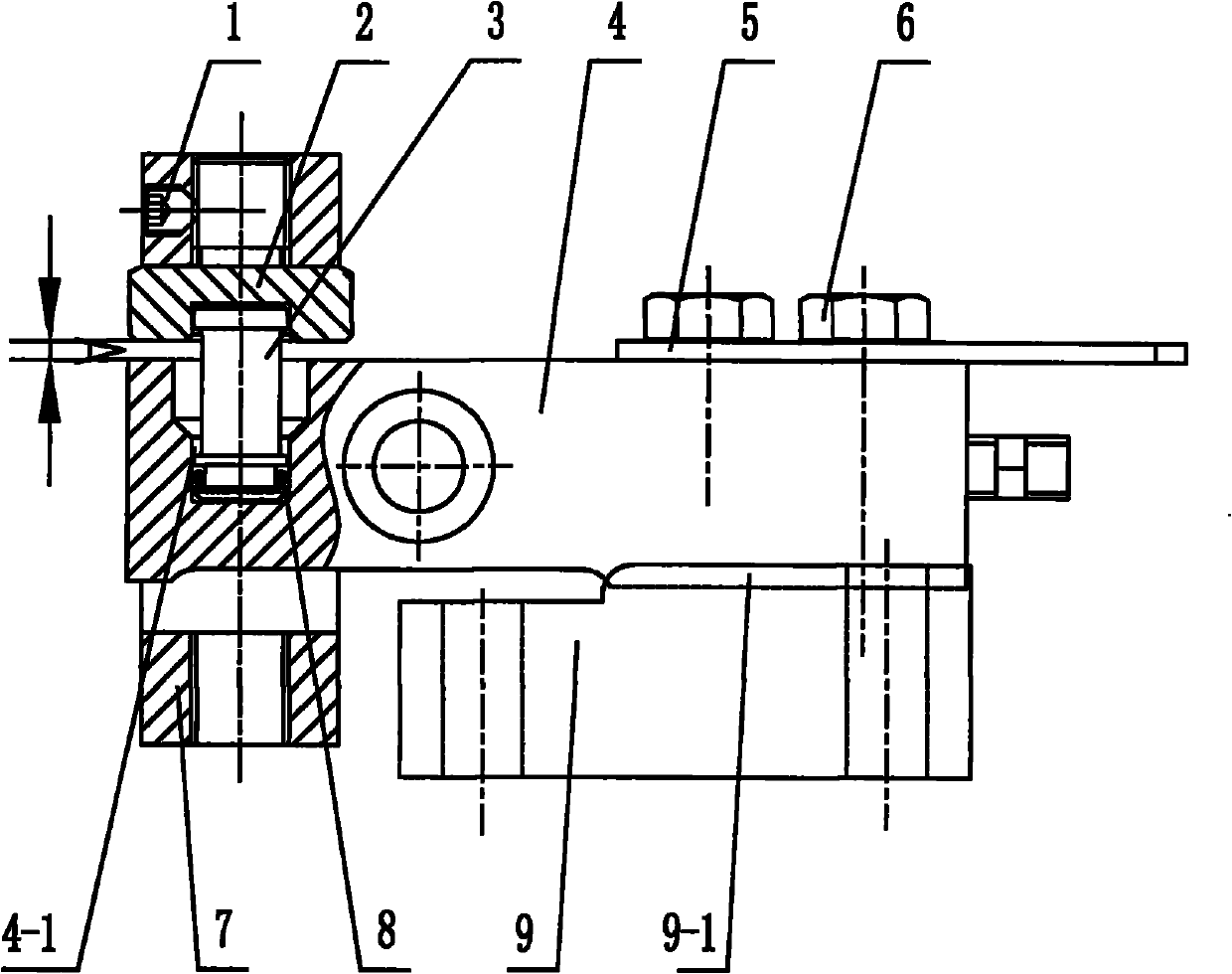

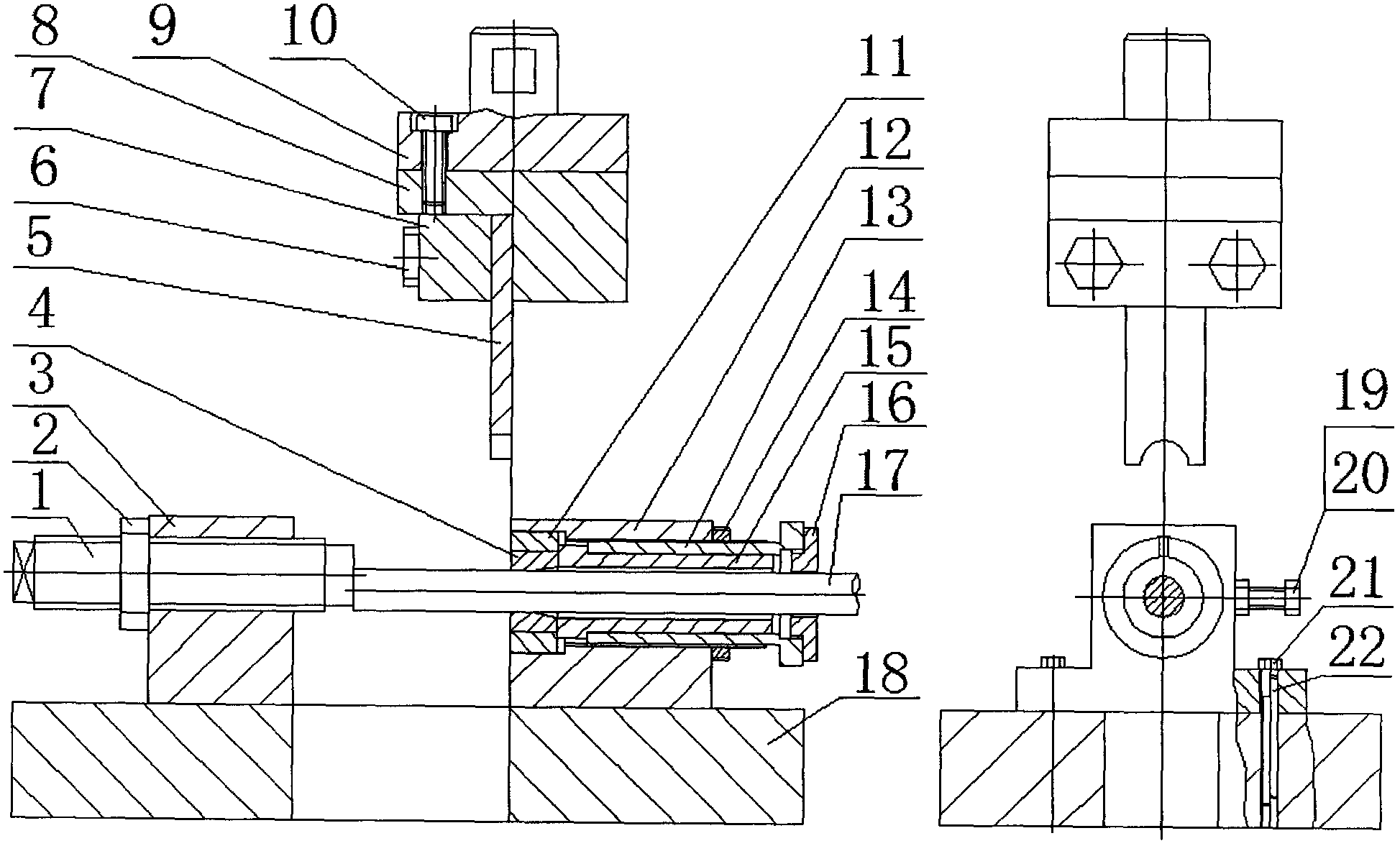

Weighing module

InactiveCN101949730AGuaranteed vertical forceEasy to adjustWeighing apparatus detailsSpecial purpose weighing apparatusComputer moduleLoad cell

The invention relates to a weighing module which comprises a base and a weighing sensor, wherein the connecting side of the weighing sensor is installed on the base by a fastener; the base is provided with more than two installation holes; both side faces of the weighing sensor are connected with the wall of a spacing groove; the bearing side of the weighing sensor is provided with blind holes in a vertical direction; a top board or / and a bottom board of a frame-shaped rack is provided with installation holes; a bearing piece with spacing holes at the bottom is screwed on the top board of the frame-shaped rack and is fixed with the top board by a fastening bolt; both end surfaces of a rocking column respectively come into contact with the bottom surfaces of the blind holes and the top surfaces of the spacing holes; protective space A is arranged between the upper end surface of the weighing sensor and the bottom surface of the bearing piece; two horizontal spacing bolts are respectively installed on two side boards and positioned on both sides of the weighing sensor; and protective space B is arranged between the end surfaces of the horizontal spacing bolts and both side faces of the weighing sensor. The weighing module has the characteristics of high weighing precision, safety, reliability, convenient installation and maintenance, stable operation, low manufacturing cost and wide application range.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

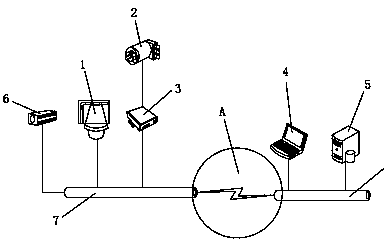

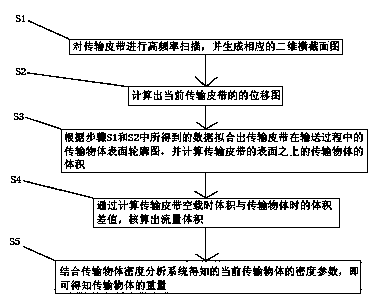

Laser weighing system for belt conveying and weighing method thereof

InactiveCN104006869ASmall weight errorWeighing apparatus for continuous material flowScannerDatabase server

The invention discloses a laser weighing system for belt conveying and a weighing method thereof. The laser weighing system comprises a transmission belt, a laser scanner, a displacement encoder, a data transmitter, a data processing computer, a database server, an Ethernet and a camera. The weighing method includes the steps that a corresponding two-dimensional cross section diagram is generated, a displacement diagram of the current transmission belt is calculated, a transmitted object surface skeleton diagram in the transmission process of the transmission belt is fitted, the size of a transmitted object is calculated, the flow volume is calculated out, and the weight of the transmitted object is finally obtained. By means of the method and the system, a model is set up for the transmitted object, the accurate numerical value of the position of a current material is fed back to a corresponding mechanical device, so that real-time checking is achieved, the size and the weight of a cargo on the current transmission belt are checked and measured, and finally the purpose of reducing weighing errors is achieved.

Owner:SHANGHAI RUOSUN INFORMATION TECH

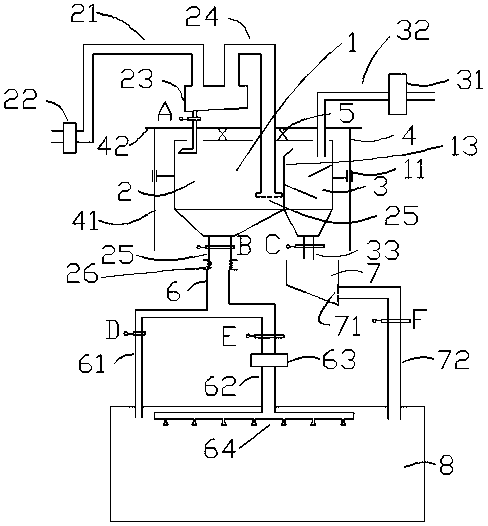

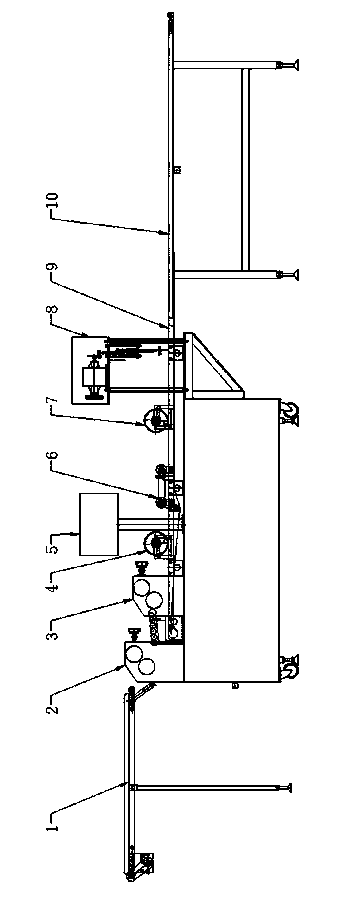

Environment-friendly type concrete mixing plant

ActiveCN109808068AImprove the weighing accuracy of water supplyQuality improvementLiquid ingredients supply apparatusMixing operation plantWastewaterEngineering

The invention discloses an environment-friendly type concrete mixing plant which can recycle wastewater generated in production as mixing water for producing concrete. A precise weighing water inlet tube is arranged in a high-precision water supply weighing device, so that water can be supplied to a water tank through the precise weighing water inlet tube at the tail stage of water supply weighing; a coarse weighing water inlet tube extends into the bottom of the water tank, a buffer hole plate is arranged at a water outlet of the coarse weighing water inlet tube; the water outlet of the precise weighing water inlet tube is horizontally formed, so that impact, on the water tank, of inlet water can be reduced; and two weighing sensors, a guide column and a guide sleeve are arranged on a beam, so that water tank swing and shake further can be reduced; and a buckled-weighing leakage tube is further arranged, so that precise buckled-weighing is realized. The environment-friendly type concrete mixing plant can improve water supply precision, and improves concrete quality.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY +2

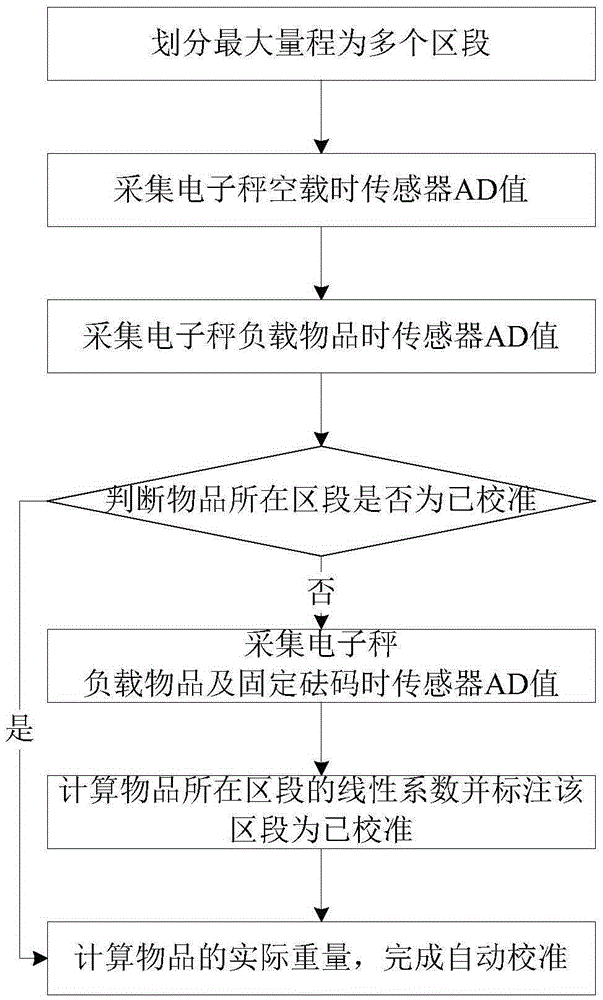

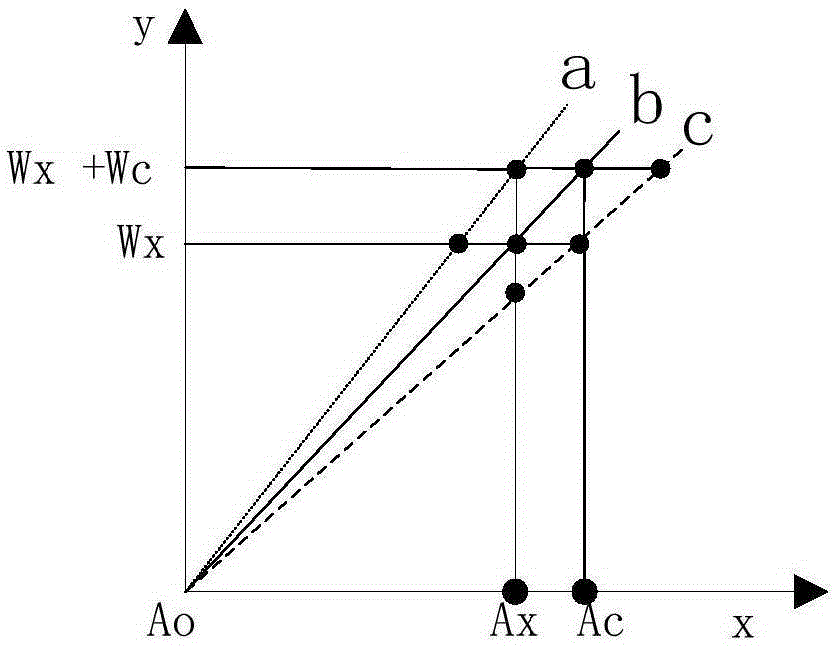

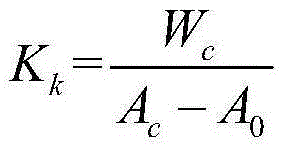

Automatic calibration method of electronic scale

ActiveCN105258779ARealize automatic calibrationSmall weight errorWeighing apparatus testing/calibrationLinearityComputer science

The invention discloses an automatic calibration method of an electronic scale. The automatic calibration method comprises steps of dividing the maximum measurement scale into multiple sections; acquiring the AD value of a sensor during the zero load of the electronic scale; acquiring the AD value of the sensor when the electronic scale carries an object; judging whether the section where the object is arranged have been calibrated or not; acquiring the sensor AD value when the electronic scale carries the object and a fixed weight; calculating the linear coefficient of the section and marking that the section has been calibrated; and calculating the actual weight of the object so as to finish the automatic calibration of the electronic scale. According to the invention, the sensor is divided into multiple sections with smaller linearity according to the linear characteristics of the sensor, the fixed weight with known weight is used as the reference substance, and the AD value of the sensor, which is acquired in real time, is used for calibrating the linear coefficient of each of the sections, thereby achieving the automatic calibration of the actual weight of the object.

Owner:CHENGDU JIUZHOU ELECTRONIC INFORMATION SYSTEM CO LTD

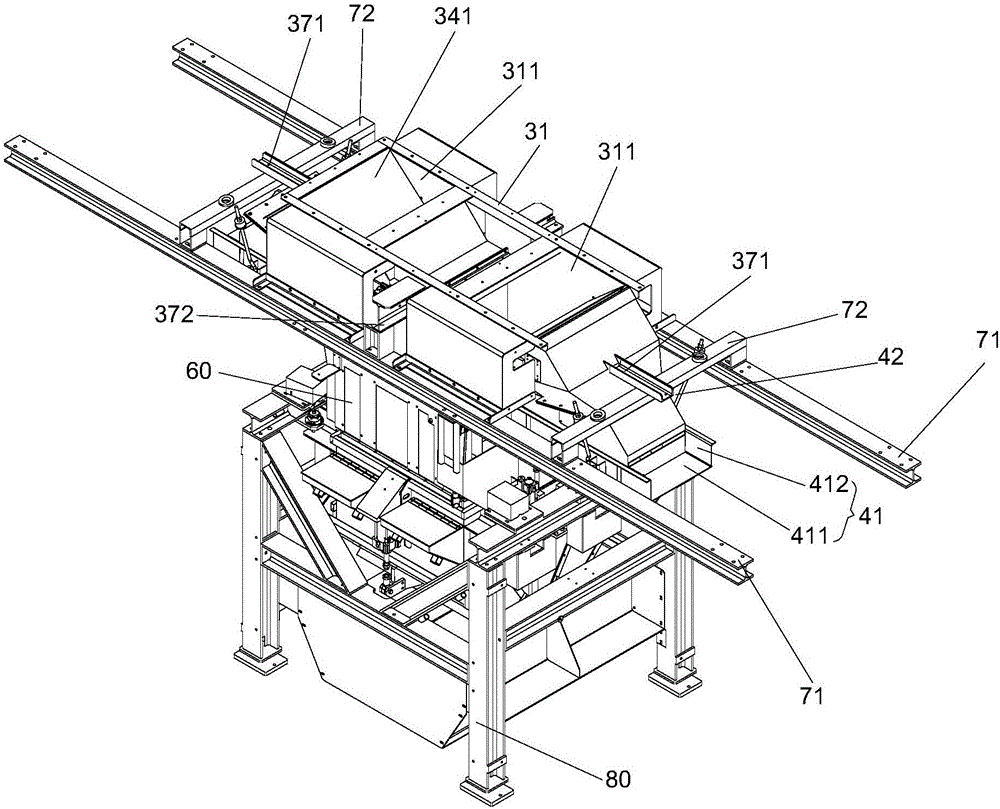

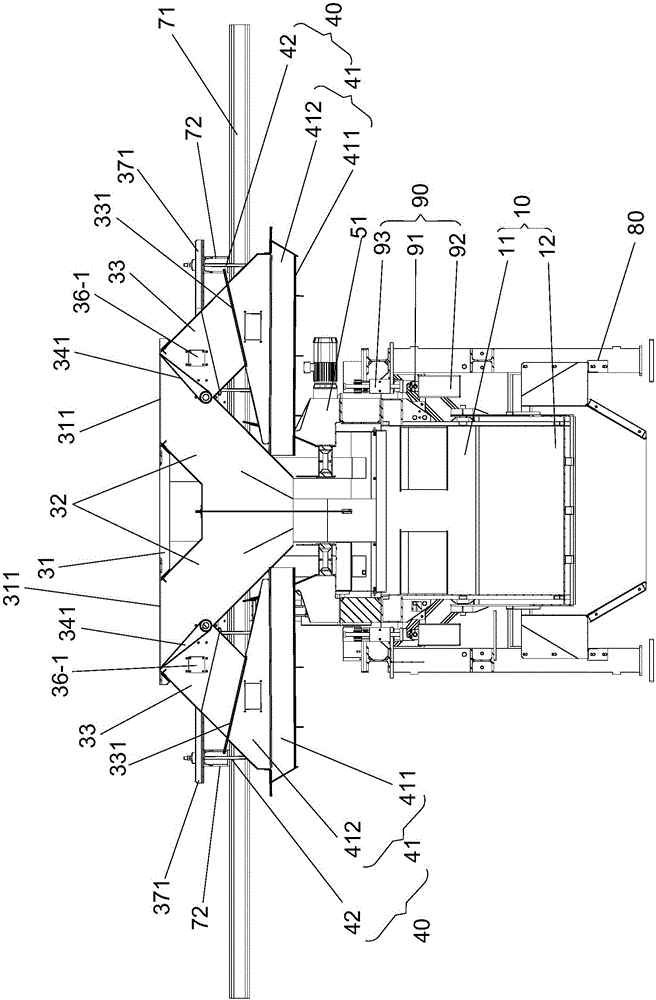

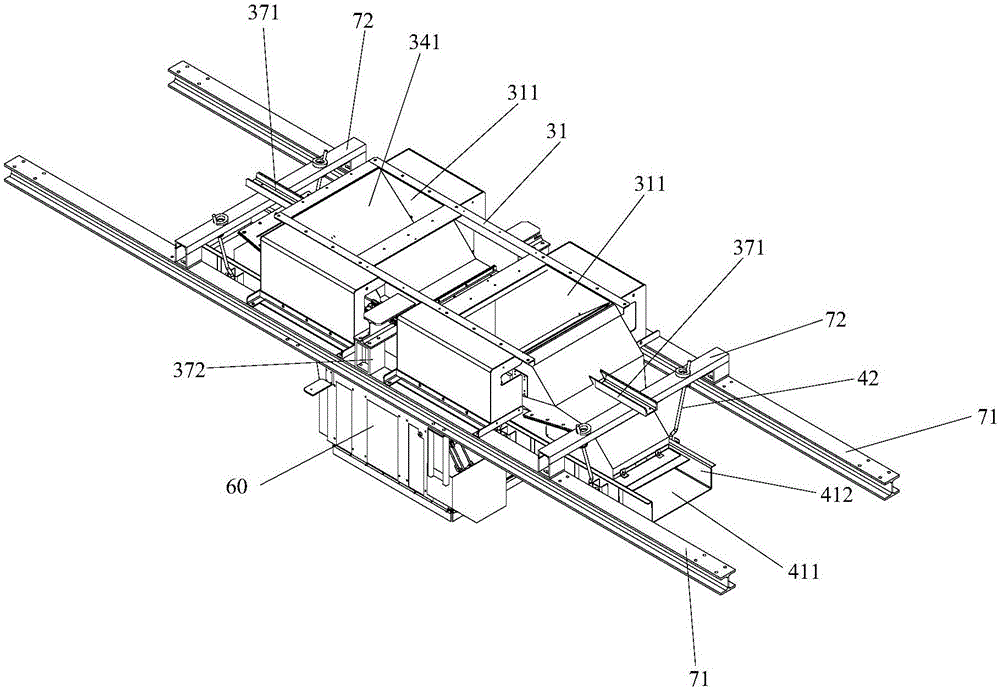

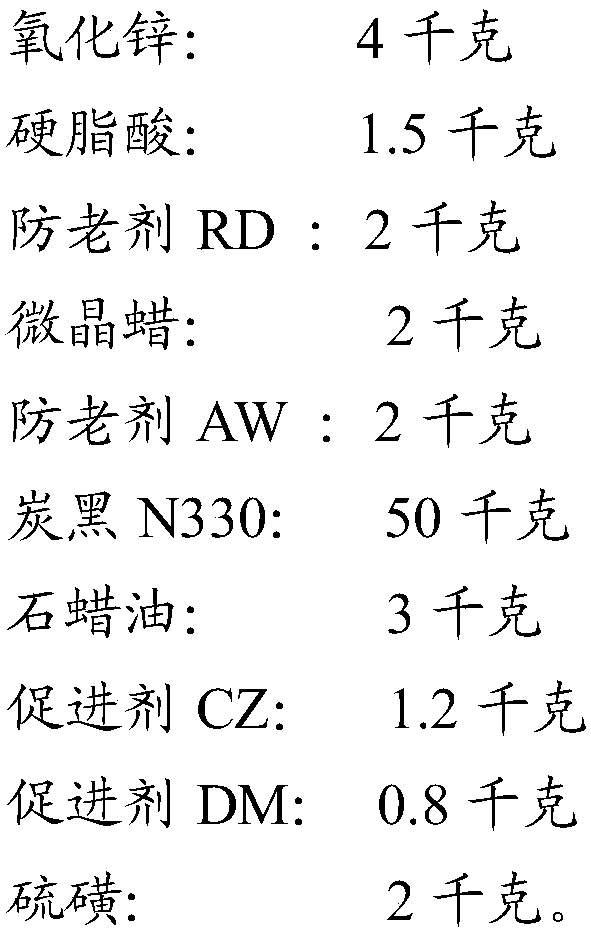

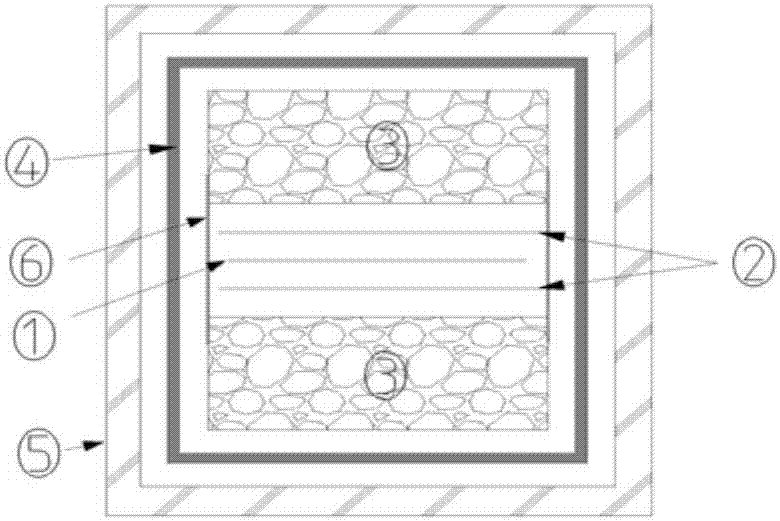

Material balance and internal mixer system with material balance

ActiveCN106393467AHigh precisionSmall weight errorWeighing apparatus for materials with special property/formWeighing apparatus with automatic feed/dischargeMaterials preparationMaterial balance

The invention provides a material balance and an internal mixer system with the material balance. The material balance comprises a material preparation hopper (10), a weighing assembly and a feeding mechanism, wherein the material preparation hopper (10) is used for accommodating to-be-weighed materials; the weighing assembly cooperates with the material preparation hopper (10) to weigh the to-be-weighed materials; the feeding mechanism and the material preparation hopper (10) are independently arranged; the feeding mechanism comprises a material divider (30) and accurate feeding devices (40); the material divider (30) comprises coarse feeding channels (32) and accurate feeding channels (33); coarse feeding outlets (321) of the coarse feeding channels (32) are above the material preparation hopper (10); accurate feeding outlets (331) of the accurate feeding channels (33) are above the accurate feeding devices (40); and the accurate feeding devices (40) are above the material preparation hopper (10). According to the technical scheme, the problem that in the prior art, the weighing error of a belt conveyer electronic platform scale is relatively large can be effectively solved.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG

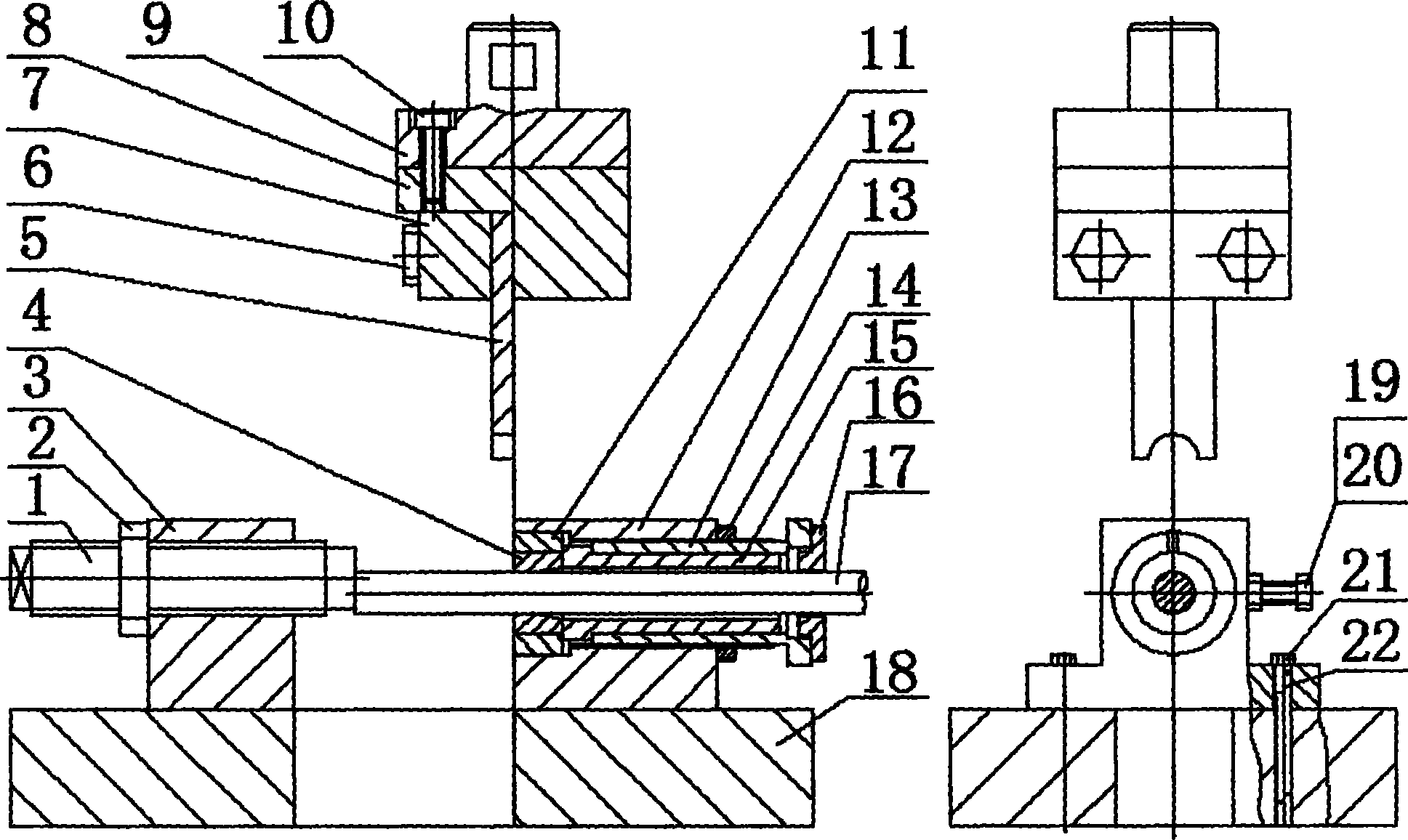

Die for cutting off round steel

Owner:WENZHOU POLYTECHNIC

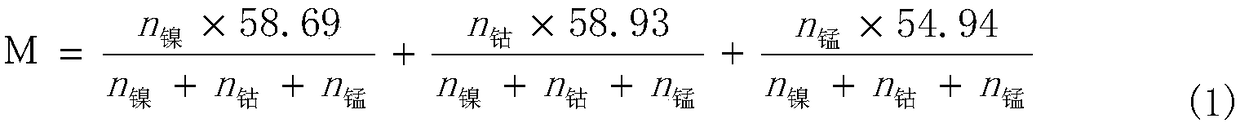

Method for determining total amount of nickel, cobalt and manganese in NCM material through complexometric titration method

InactiveCN108918752AThe end color changes obviouslyImprove stabilityChemical analysis using titrationSpecific testManganese

The invention discloses a method for determining the total amount of nickel, cobalt and manganese in a NCM material through a complexometric titration method. In the prior art, the rapid test of the total amount of nickel, cobalt and manganese is performed by using the EDTA complexometric titration method, and a lot of differences exist in the specific test operations. According to the present invention, the auxiliary reagent hydroxylamine hydrochloride is additionally used in the complexometric titration method, wherein the color change at the ending point is significant and the test result is stable and accurate by adding the reagent; during the titration test, the buffer solution and the murexide indicator are added at 1-2 ml position before the ending point, such that the test result is stable and accurate; with the method, the total amount of nickel, cobalt and manganese in the NCM material can be quickly, accurately and stably determined, wherein the test result is close to the real value by verifying the standard sample; and the method has characteristics of low requirements on operators, easy grasping, good reproducibility of test result and significantly-shortened test time, and can completely meet the requirements of large-scale and continuous production.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

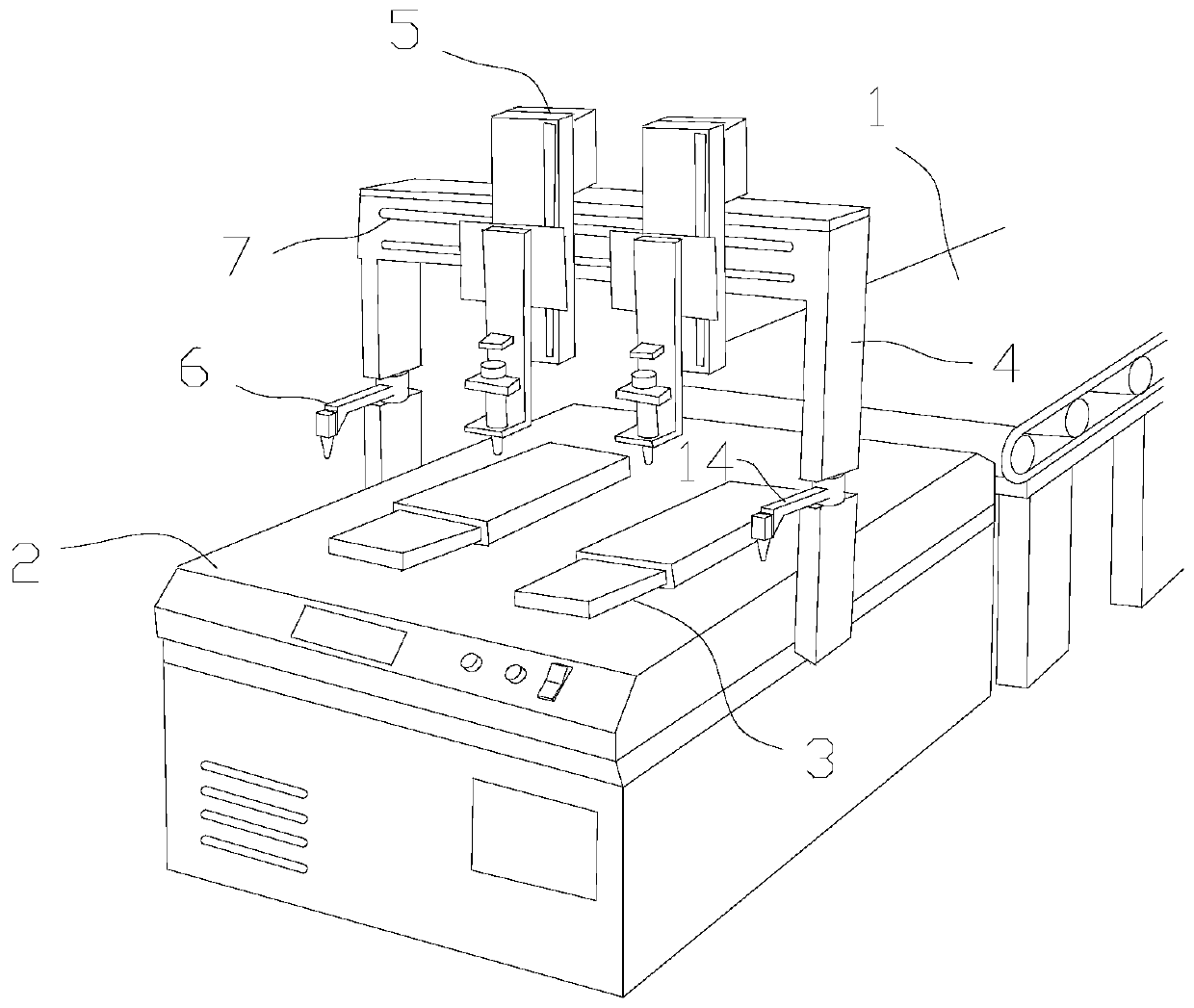

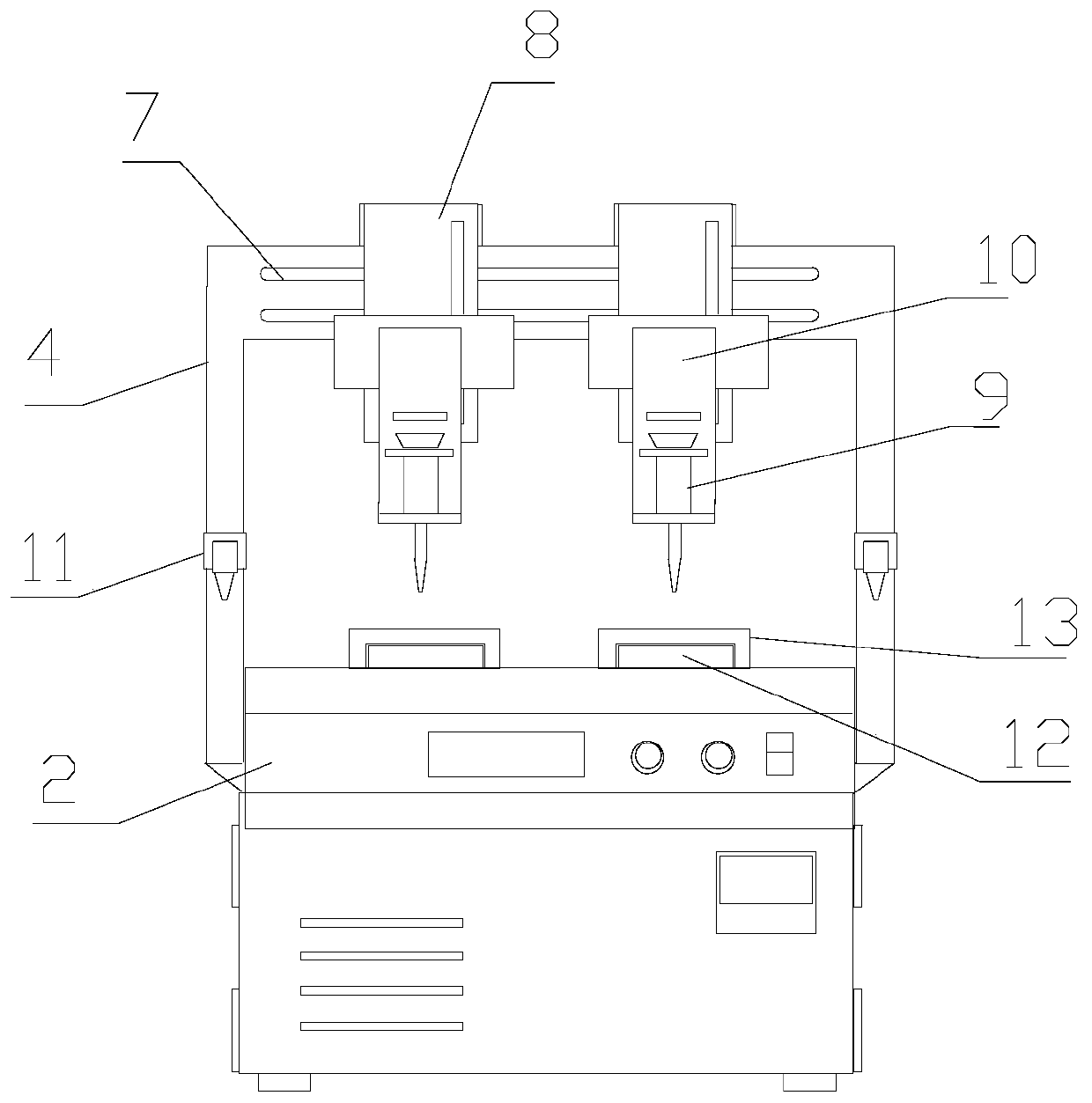

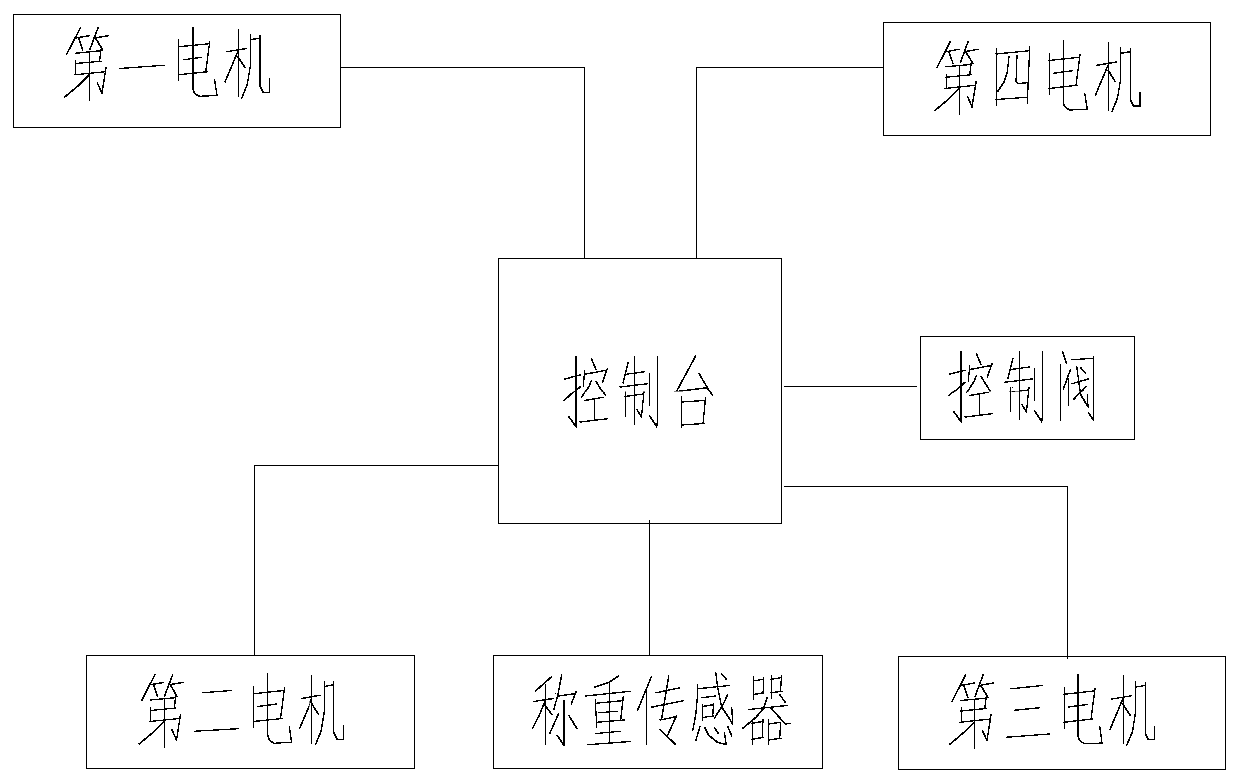

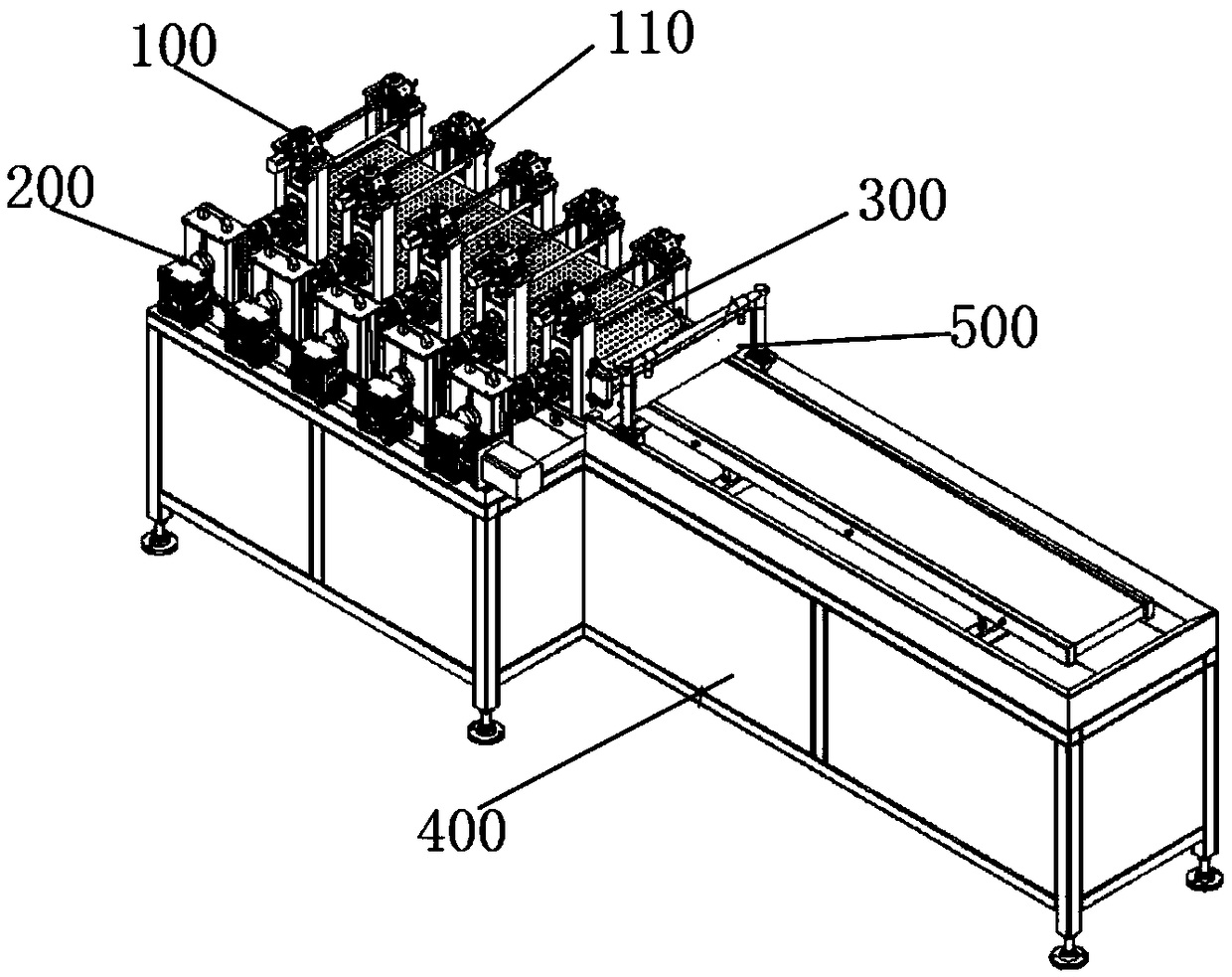

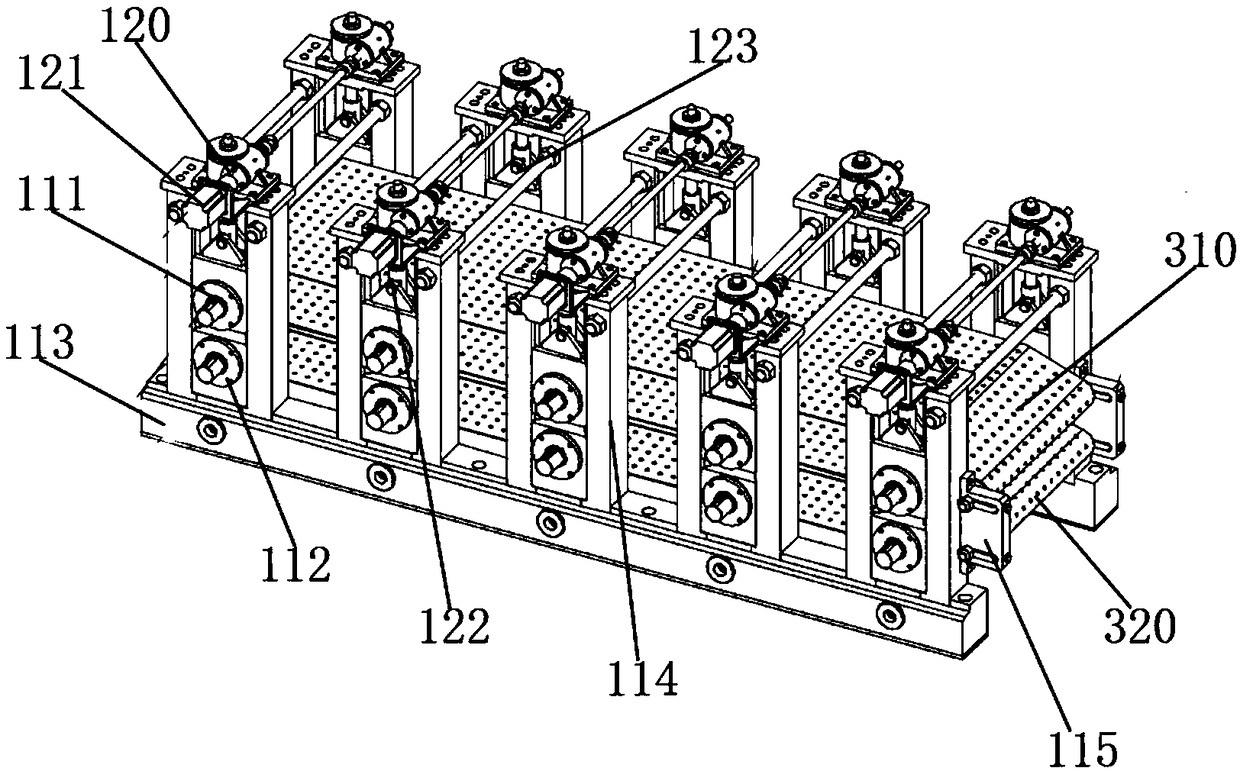

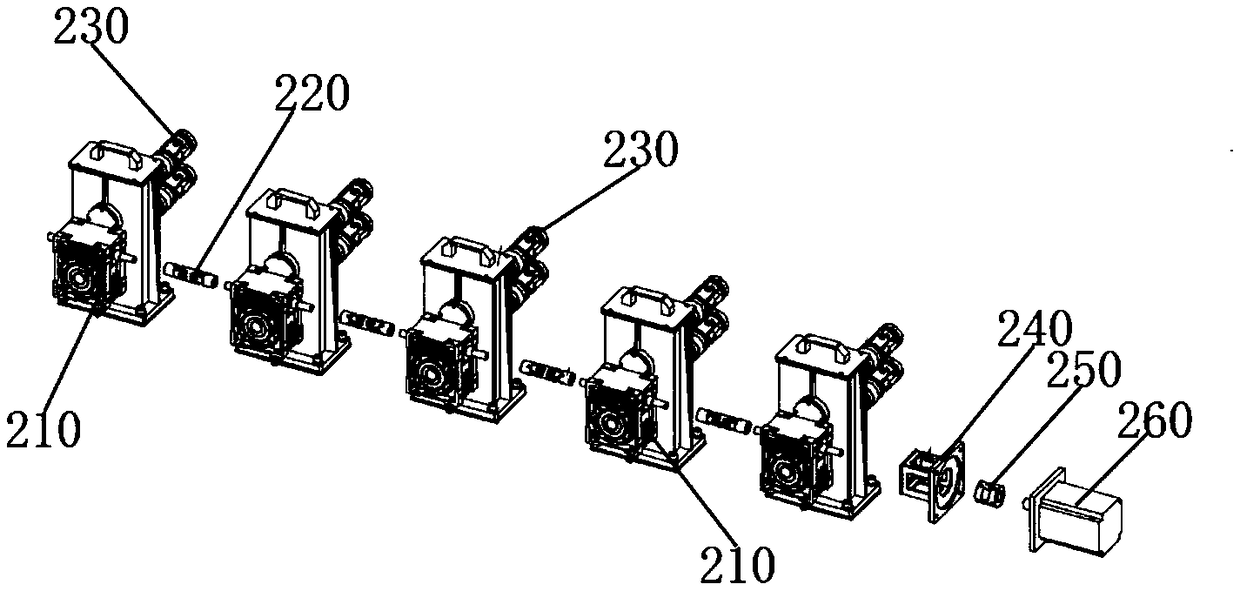

Double-station automatic gluing production line

InactiveCN110013946ASmall weight errorLow costLiquid surface applicatorsCoatingsProduction lineDelivery system

The invention relates to shoe processing equipment, in particular to a double-station automatic gluing production line. The double-station automatic gluing production line comprises a conveying system, and further comprises a control console, weighing devices, a glue supply pump, a connecting pipe, a supporting frame, first gluing devices and second gluing devices. The conveying system and the control console are arranged side by side, the output end of the conveying system faces to the control console, the weighing devices are arranged on the surface of the control console, the bottoms of theweighing devices are fixedly connected with the control console to be used for storing shoes to be glued, and the supporting frame is erected on the control console and connected with the two sides of the control console. The first gluing devices are arranged at the top of the supporting frame and driven by first motors to transversely slide along sliding rails. The second gluing devices are arranged on side arms of the supporting frame and driven by second motors to rotate horizontally. The double-station automatic gluing production line is improved on the basis of traditional gluing equipment. Compared with the traditional problem that the left and right shoe weight difference is big and left and right shoes need to be returned to the production line for adjustment, the weight error ofthe left and right shoes can be reduced, the enterprise cost can be reduced, the working efficiency can be improved, and the market benefit is high.

Owner:陈俊

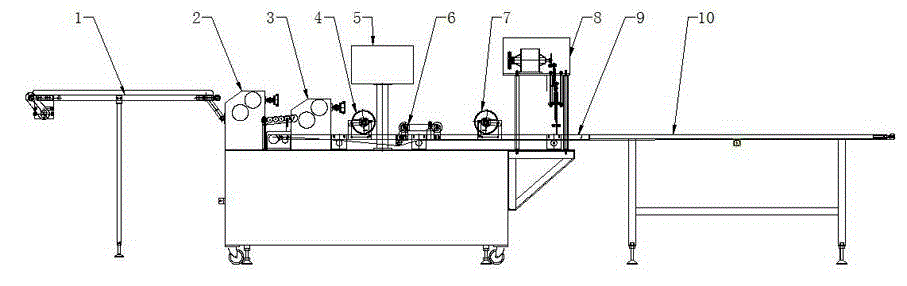

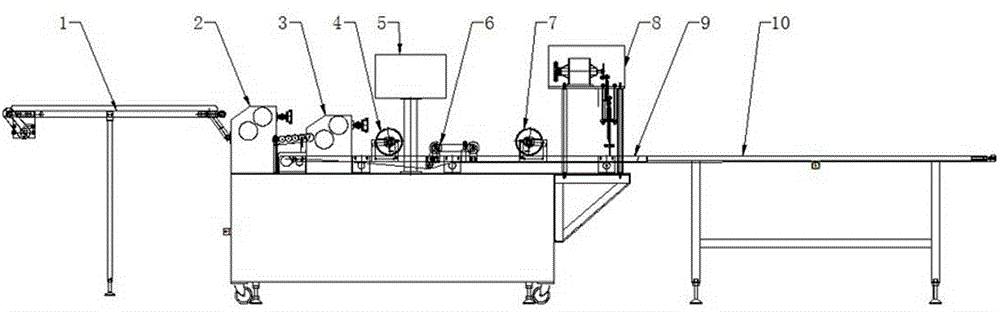

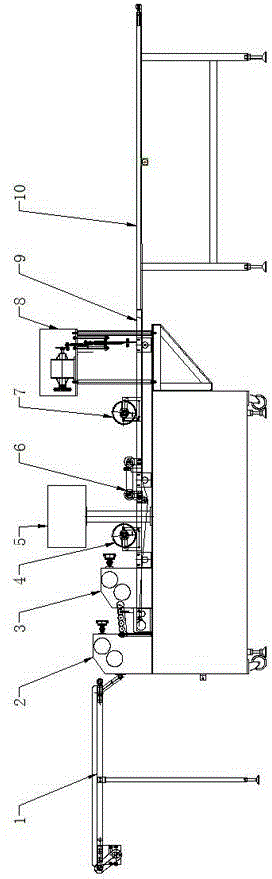

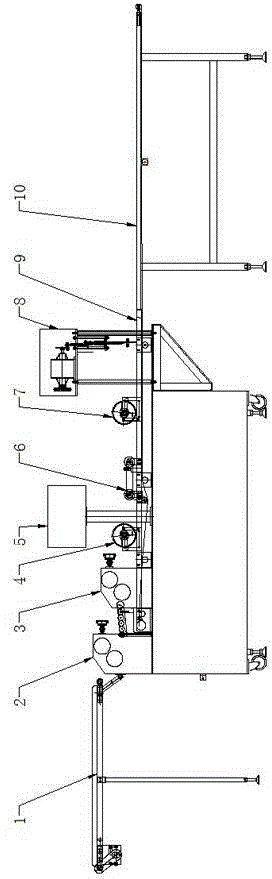

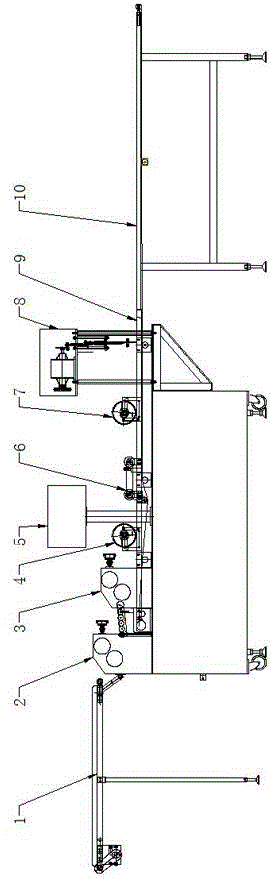

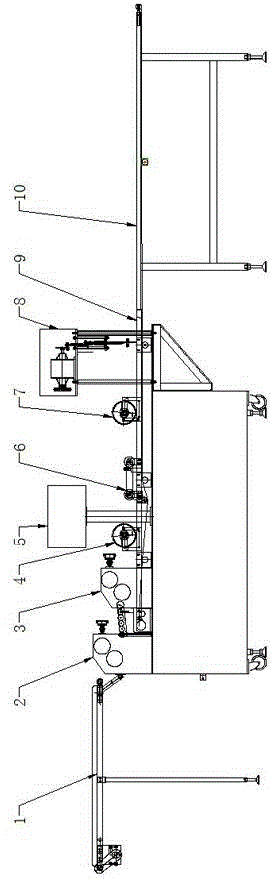

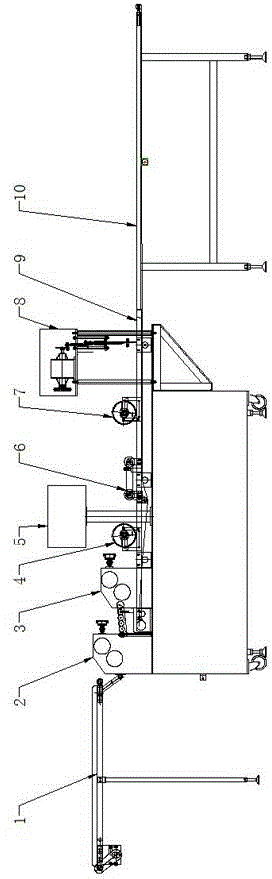

Automatic fried bread stick production line

InactiveCN105557800ASmall weight errorIncrease productivityDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationProduction lineEngineering

The invention provides an automatic fried bread stick production line and relates to the field of food processing machines. The automatic fried bread stick production line is characterized by being composed of a dough feeding and conveying assembly, a pre-pressing assembly, a thickness adjusting assembly, a partition cutter assembly, an operation box, a dough stacking assembly, a pressing groove assembly, a cutter assembly, a rear conveyor belt assembly and a manual picking-up table. The dough feeding and conveying assembly is connected with the pre-pressing assembly which is then connected with the rear conveyor belt assembly. The rear conveyor belt assembly is provided with the thickness adjusting assembly, the partition cutter assembly, the operation box, the dough stacking assembly, the pressing groove assembly and the cutter assembly. The manual picking-up table is connected to the rear of the rear conveyor belt assembly. Many original parts operated manually are omitted, production efficiency is improved, and weight errors among fried bread sticks are reduced.

Owner:ANHUI HEFEI WANMEI FOOD TRADING CO LTD

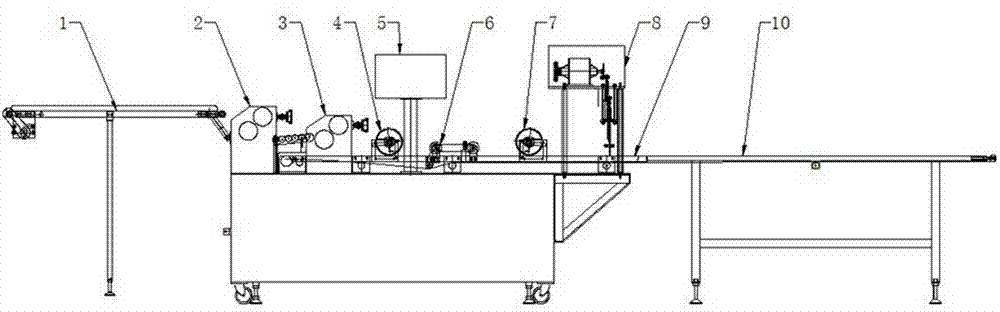

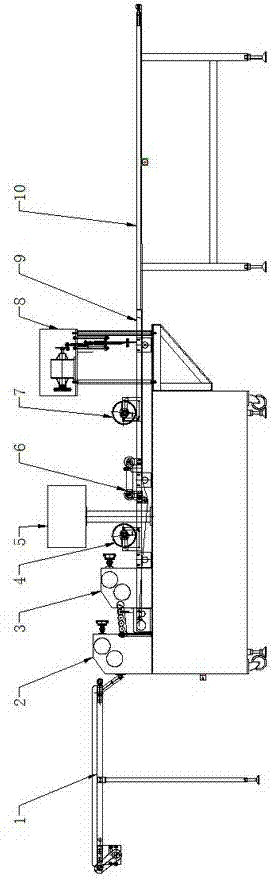

Automatic deep-fried dough stick production line

InactiveCN104814075AIncrease productivitySmall weight errorDough shaping and cutting apparatusDough processingEngineeringFood processing

The invention provides an automatic deep-fried dough stick production line, relating to the field of food processing machinery. The automatic deep-fried dough stick production line is characterized by comprising an incoming dough conveying assembly, a prepressing assembly, a thickness adjusting assembly, a dividing cutter assembly, an operation box, a dough superposing assembly, a pressing groove assembly, a cutter assembly, a rear conveyor belt assembly and a manual pickup platform, wherein the incoming dough conveying assembly is connected with the prepressing assembly; the prepressing assembly is connected with the rear conveyor belt assembly; the thickness adjusting assembly, the dividing cutter assembly, the operation box, the dough superposing assembly, the pressing groove assembly and the cutter assembly are arranged on the rear conveyor belt assembly; the manual pickup platform is also connected behind the rear conveyor belt assembly. The automatic deep-fried dough stick production line omits plenty of parts needing manual operation, thus improving the production efficiency and reducing the weight errors between deep-fried dough sticks.

Owner:合肥市开平食品贸易有限责任公司

Automatic deep-fried dough stick production line

InactiveCN105557853ASmall weight errorIncrease productivityDough shaping and cutting apparatusDough processingEngineeringMechanical engineering

The invention discloses an automatic deep-fried dough stick production line, and relates to the field of food processing machinery. The automatic deep-fried dough stick production line is characterized by consisting of a dough charging and conveying assembly, a pre-pressing assembly, a thickness adjusting assembly, a dividing knife assembly, an operation box, a dough laminating assembly, a groove pressing assembly, a cutting knife assembly, a rear conveying belt assembly and a manual picking table; the dough charging and conveying assembly is connected with the pre-pressing assembly, and the pre-pressing assembly is then connected with the rear conveying belt assembly; the thickness adjusting assembly, the dividing knife assembly, the operation box, the dough laminating assembly, the groove pressing assembly and the cutting knife assembly are arranged on the rear conveying belt assembly; and the manual picking table is further connected behind the rear conveying belt assembly. According to the automatic deep-fried dough stick production line, a large number of original manual operations are avoided, the production efficiency is increased, and the weight error among deep-fried dough sticks is reduced.

Owner:HEFEI HUAJUN FOOD CO LTD

Novel fried bread stick production line

InactiveCN104839270ASmall weight errorIncrease productivityDough shaping and cutting apparatusDough processingEngineeringManufacturing line

The invention provides a novel fried bread stick production line and relates to the field of food processing machines. The novel fried bread stick production line is characterized by comprising a flour feeding conveying assembly, a prepressing assembly, a thickness adjusting assembly, a partitioning cutter assembly, an operation box, a flour overlaying assembly, a pressure tank assembly, a cutter assembly, a rear conveying belt assembly and a manual picking-up platform, wherein the flour feeding conveying assembly is connected with the prepressing assembly, the prepressing assembly is then connected with the rear conveying belt assembly, the thickness adjusting assembly, the partitioning cutter assembly, the operation box, the flour overlaying assembly, the pressure tank assembly and the cutter assembly are arranged on the rear conveying belt assembly, and the manual picking-up platform is also connected behind the rear conveying belt assembly. The novel fried bread stick production line has the advantages that the original manual operations are greatly reduced, production efficiency is improved, and weight error between fried bread sticks is reduced.

Owner:合肥市开平食品贸易有限责任公司

Deep-fried dough stick production machine

InactiveCN104839280ASmall weight errorIncrease productivityDough shaping and cutting apparatusDough extruding machinesEngineeringMechanical engineering

The invention discloses a deep-fried dough stick production machine and relates to the field of food processing machinery. The deep-fried dough stick production machine is characterized by consisting of a dough charging and conveying assembly, a pre-pressing assembly, a thickness adjusting assembly, a dividing knife assembly, an operation box, a dough laminating assembly, a groove pressing assembly, a cutting knife assembly, a rear conveying belt assembly and a manual picking table, wherein the dough charging and conveying assembly is connected with the pre-pressing assembly, the pre-pressing assembly is then connected with the rear conveying belt assembly, the thickness adjusting assembly, the dividing knife assembly, the operation box, the dough laminating assembly, the groove pressing assembly and the cutting knife assembly are arranged on the rear conveying belt assembly, and the manual picking table is further connected behind the rear conveying belt assembly. According to the deep-fried dough stick production machine, a large number of original manual operations are avoided, the production efficiency is increased, and the weight error among deep-fried dough sticks is reduced.

Owner:合肥市三强调味品厂

Novel fried bread stick production line

InactiveCN105557857ASmall weight errorIncrease productivityDough shaping and cutting apparatusProduction lineEngineering

The invention provides a novel fried bread stick production line and relates to the field of foodstuff processing machinery. The novel fried bread stick production line is characterized by consisting of a feeding face conveying assembly, a pre-pressing assembly, a thickness adjusting assembly, a dividing cutter assembly, an operating box, a face folding assembly, a press groove assembly, a cutter assembly, a rear conveying belt assembly and a manual pickup table, wherein the feeding face conveying assembly is connected with the pre-pressing assembly, the pre-pressing assembly is then connected with the rear conveying belt assembly, the thickness adjusting assembly, the dividing cutter assembly, the operating box, the face folding assembly, the press groove assembly and the cutter assembly are arranged on the rear conveying belt assembly, and the manual pickup table is further connected behind the rear conveying belt assembly. A large amount of original manual operations is omitted, the production efficiency is improved, and weigh errors of fried bread sticks are decreased.

Owner:ANHUI HEFEI WANMEI FOOD TRADING CO LTD

Automatic deep-fried dough stick production line

InactiveCN105557847ASmall weight errorIncrease productivityDough shaping and cutting apparatusEngineeringManufacturing line

The invention provides an automatic deep-fried dough stick production line, and relates to the field of food processing machinery. The automatic deep-fried dough stick production line is characterized by comprising a dough feeding conveying assembly, a pre-pressing assembly, a thickness adjustment assembly, a dividing cutter assembly, an operation box, a dough stacking assembly, a pressing tank assembly, a cutter assembly, a rear conveying belt assembly and an artificial picking table, wherein the dough feeding conveying assembly is connected to the pre-pressing assembly, the pre-pressing assembly is connected to the rear conveying belt assembly, the rear conveying belt assembly is provided with the thickness adjustment assembly, the dividing cutter assembly, the operation box, the dough stacking assembly, the pressing tank assembly and the cutter assembly, and the rear of the rear conveying belt assembly is provided with the artificial picking table. According to the present invention, with the automatic deep-fried dough stick production line, a lot of the original manual operation is saved, the production efficiency is improved, and the weight error between the deep-fried dough sticks is reduced.

Owner:HEFEI LAONAINAI FOOD CO LTD

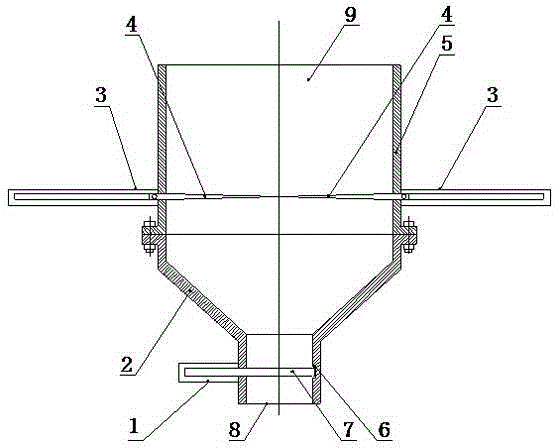

Loose particle bagging measuring hopper

The invention discloses a loose particle bagging measuring hopper and relates to the field of automatic bagging equipment. The loose particle bagging measuring hopper comprises a hopper body and a measuring shell. The hopper body is in a cuboid shape. A feeding opening is formed in the upper portion of the hopper body. The measuring shell is fixedly arranged on the lower portion of the hopper body. Gates I are arranged on the hopper body and divide the internal space of the hopper body into two parts. A discharging opening is formed in the lower portion of the measuring shell, and a gate II is arranged at the position of the discharging opening. According to the loose particle bagging measuring hopper, the volume between the two gates is used for limiting the weight of materials of each bag, it can be ensured that the weight error of the bags fluctuates within a very small range, and the loose particle bagging measuring hopper has the beneficial effects of being simple in structure and high in reliability.

Owner:成都经纬机械制造有限公司

Deep-fried dough stick machine

InactiveCN105557848ASmall weight errorIncrease productivityDough shaping and cutting apparatusDough processingEngineeringMechanical engineering

The invention provides a deep-fried dough stick machine, and relates to the field of food processing machinery. The deep-fried dough stick machine is characterized by comprising a dough feeding conveying assembly, a pre-pressing assembly, a thickness adjustment assembly, a dividing cutter assembly, an operation box, a dough stacking assembly, a pressing tank assembly, a cutter assembly, a rear conveying belt assembly and an artificial picking table, wherein the dough feeding conveying assembly is connected to the pre-pressing assembly, the pre-pressing assembly is connected to the rear conveying belt assembly, the rear conveying belt assembly is provided with the thickness adjustment assembly, the dividing cutter assembly, the operation box, the dough stacking assembly, the pressing tank assembly and the cutter assembly, and the rear of the rear conveying belt assembly is connected to the artificial picking table. According to the present invention, with the deep-fried dough stick machine, a lot of the original manual operation is saved, the production efficiency is improved, and the weight error between the deep-fried dough sticks is reduced.

Owner:HEFEI LAONAINAI FOOD CO LTD

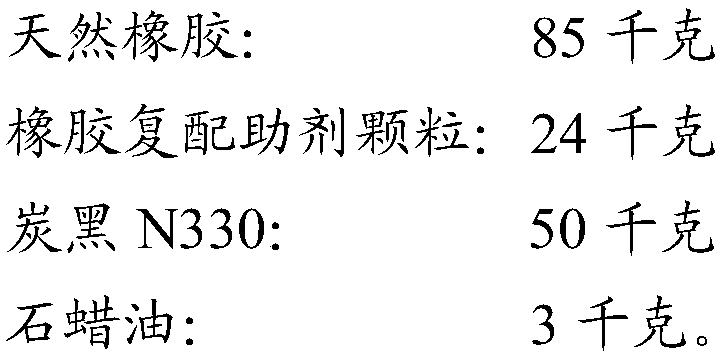

Rubber compound additive particle, preparation method thereof and application of particle

The invention provides a rubber compound additive particle, and belongs to the technical field of rubber. The rubber compound additive particle comprises, by weight, 20-30 parts of rubber, 5-8 parts of zinc oxide, 3-5 parts of stearic acid, 4-6 parts of anti-aging agents, 0.5-1 part of scorch retarders, 3-5 parts of accelerators and 2-4 parts of vulcanizing agents. The particle is cylindrical, thediameter of the particle is 2-5mm, and the height of the particle is 5-10mm. The rubber compound additive particle has functions of activating agents, the anti-aging agents, the accelerators, the vulcanizing agents and the scorch retarders, a small number of additives are used, the same effects can be achieved as compared with a traditional production process, the multifunctional rubber compoundadditive particle is a colloidal particle, on one hand, dispersion effects of various rubber additives in rubber can be effectively improved, on the other hand, matching is facilitated, weighing errors are reduced, environmental pollution caused by dust in production is decreased, and physical health of operators is facilitated.

Owner:河北省同创交通工程配套产品产业技术研究院

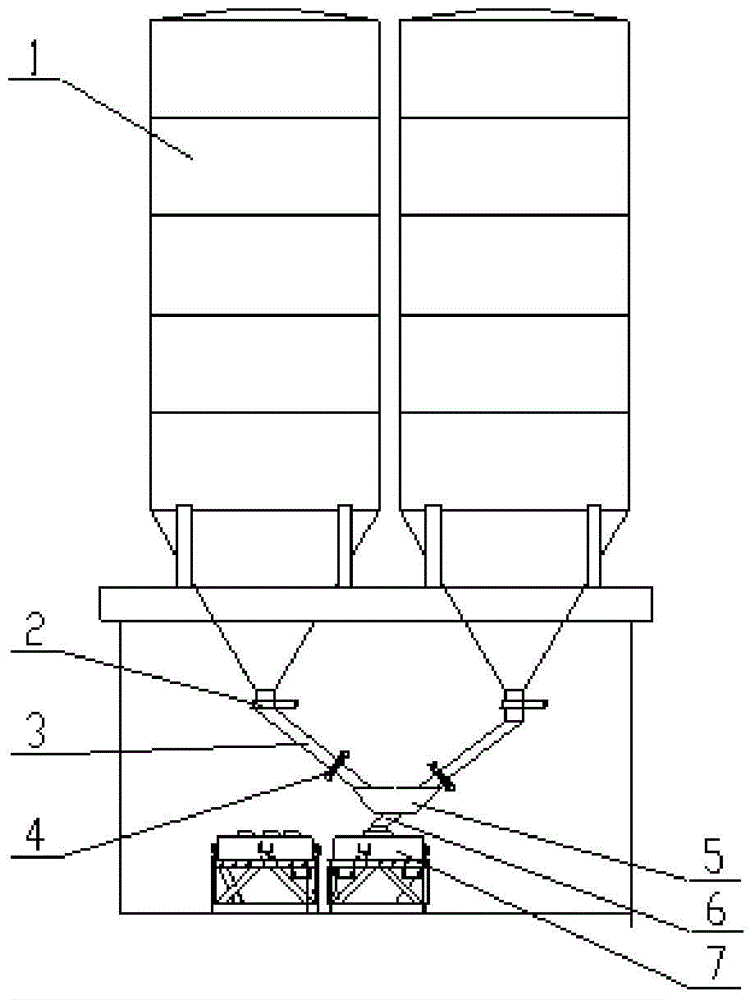

Dry-mixed mortar stirring station weighing system and dry-mixed mortar stirring station

ActiveCN103552157AAvoid shockWon't shakeSold ingredients supply apparatusSpecial purpose weighing apparatusDry sandMaterials science

The invention discloses a dry-mixed mortar stirring station weighing system and a dry-mixed mortar stirring station, relates to the technical field of engineering machinery, and aims to solve the problem of metering errors caused by easy shaking of dry sand weighing hoppers in the prior art. The dry-mixed mortar stirring station weighing system comprises at least two dry sand discharging bins, first slide pipes, a temporary storage bin, a second slide pipe and the dry sand weighing hoppers, wherein the bottoms of different dry sand discharging bins are communicated with the upper part of the temporary storage bin through different first slide pipes; the lower part of the temporary storage bin is communicated with one end of the second slide pipe; the other end of the second slide pipe is communicated with the dry sand weighing hoppers. According to the technical scheme, impact on the dry sand weighing hoppers during discharging in different directions is avoided, and the dry sand weighing hoppers cannot shake, so that weighing errors caused by shaking of the dry sand weighing hoppers can be reduced.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

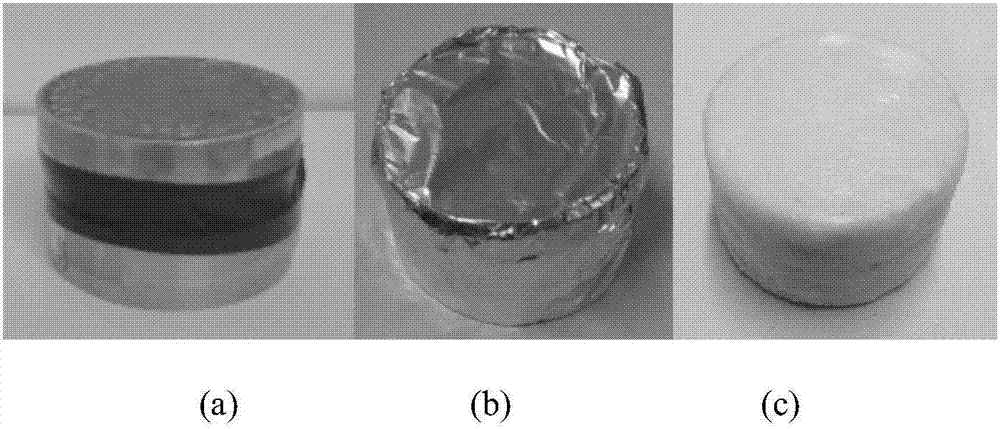

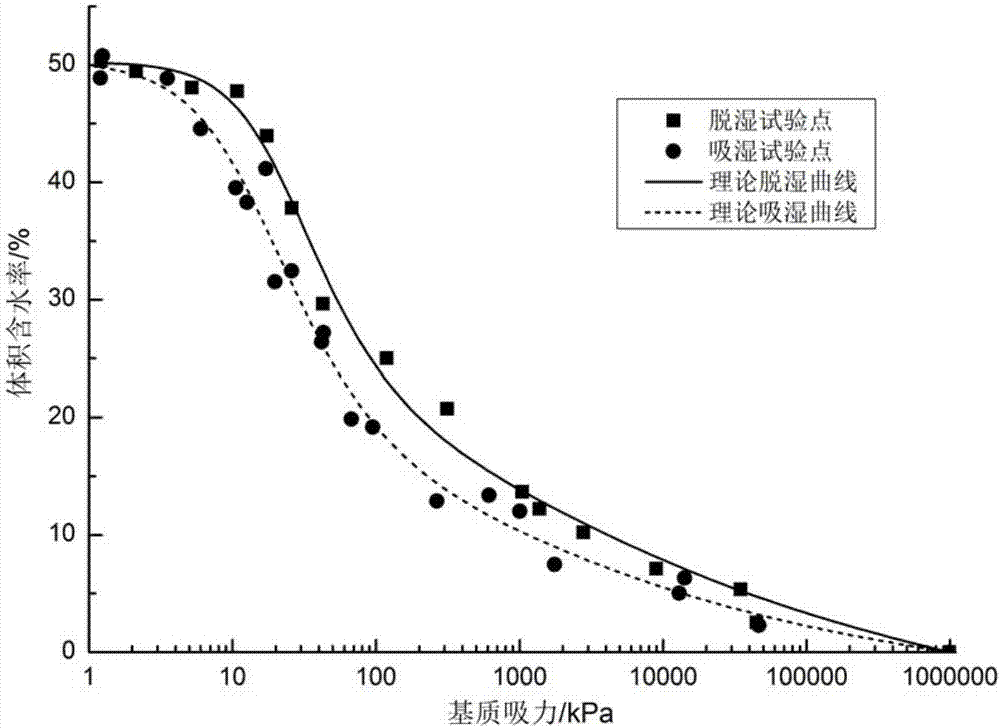

Unsaturated soil matrix suction filter paper method measurement device and method

The invention discloses an unsaturated soil matrix suction filter paper method measurement device and method. The unsaturated soil matrix suction filter paper method measurement device and method is an improvement on the basis of ASTM (American Society for Testing Material) by taking unsaturated loess for example from the four aspects of sealing conditions, weighing manners, weighing speed and balance time. The unsaturated soil matrix suction filter paper method measurement device and method overcomes the shortcomings of the sealing conditions of original filter paper methods during experiments and provides a new experimental sealing device, namely, changes a sealing tank into a sealing experimental environment with tinfoil wrapping and wax sealing. Besides, the unsaturated soil matrix suction filter paper method measurement device and method achieves improvement of aspects of the weighing manners, the balance time and the like, verifies the weighing speed and provides a complete set of testing scheme. The unsaturated soil matrix suction filter paper method measurement device is reasonable in structural design, capable of meeting requirements on experimental principles and precision, rapid in experimental operation, small in errors, high in reliability and working efficiency, convenient to popularize and apply and applicable to providing a solid foundation for conveniently testing the soil-moisture characteristic curve of unsaturated soil.

Owner:CHANGAN UNIV

Deep-fried dough stick machine

InactiveCN105557850ASmall weight errorIncrease productivityDough shaping and cutting apparatusDough processingMechanical engineeringFood processing

The invention discloses a deep-fried dough stick machine, and relates to the field of food processing machinery. The deep-fried dough stick machine is characterized by consisting of a dough charging and conveying assembly, a pre-pressing assembly, a thickness adjusting assembly, a dividing knife assembly, an operation box, a dough laminating assembly, a groove pressing assembly, a cutting knife assembly, a rear conveying belt assembly and a manual picking table; the dough charging and conveying assembly is connected with the pre-pressing assembly, and the pre-pressing assembly is then connected with the rear conveying belt assembly; the thickness adjusting assembly, the dividing knife assembly, the operation box, the dough laminating assembly, the groove pressing assembly and the cutting knife assembly are arranged on the rear conveying belt assembly; and the manual picking table is further connected behind the rear conveying belt assembly. According to the deep-fried dough stick machine, a large number of original manual operations are avoided, the production efficiency is increased, and the weight error among deep-fried dough sticks is reduced.

Owner:HEFEI HUAJUN FOOD CO LTD

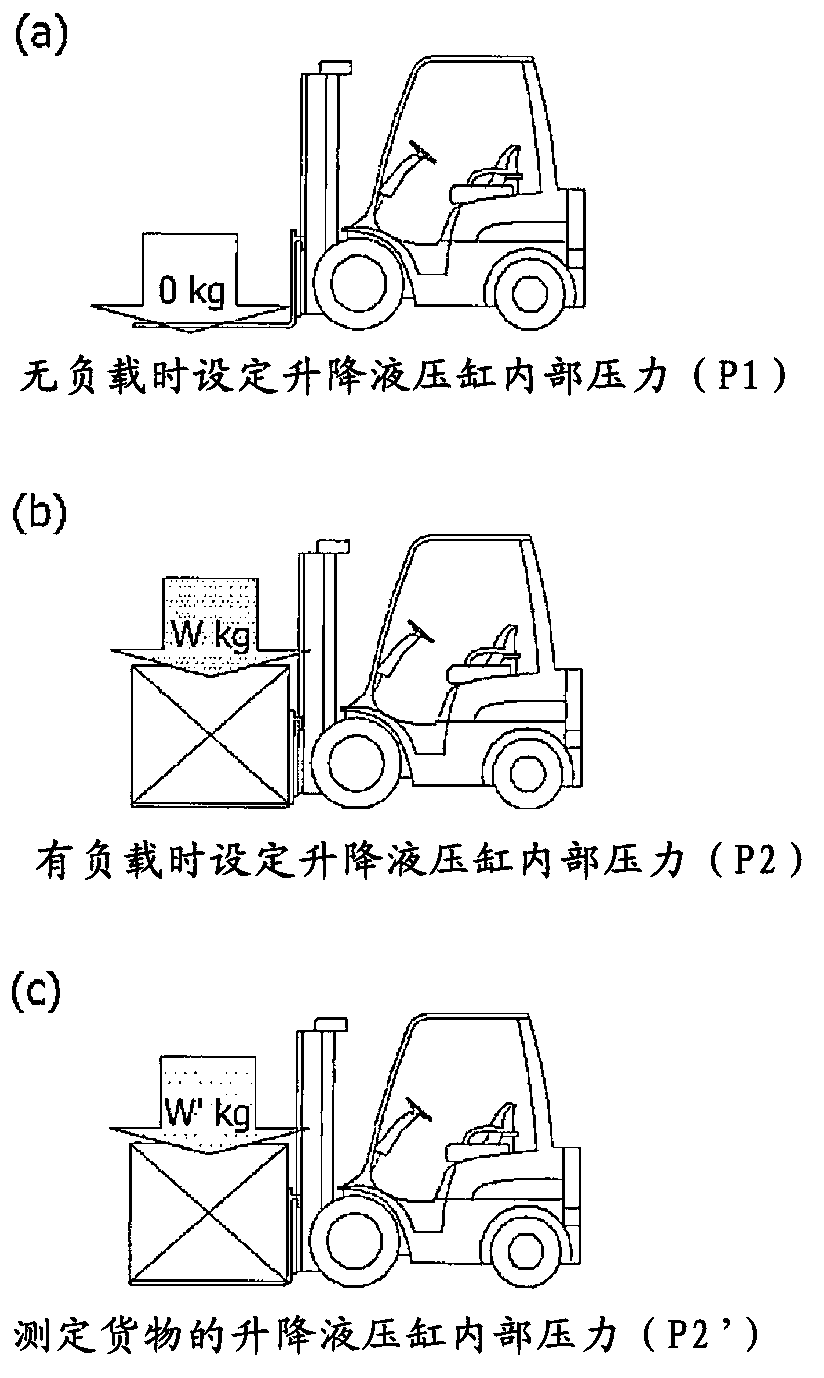

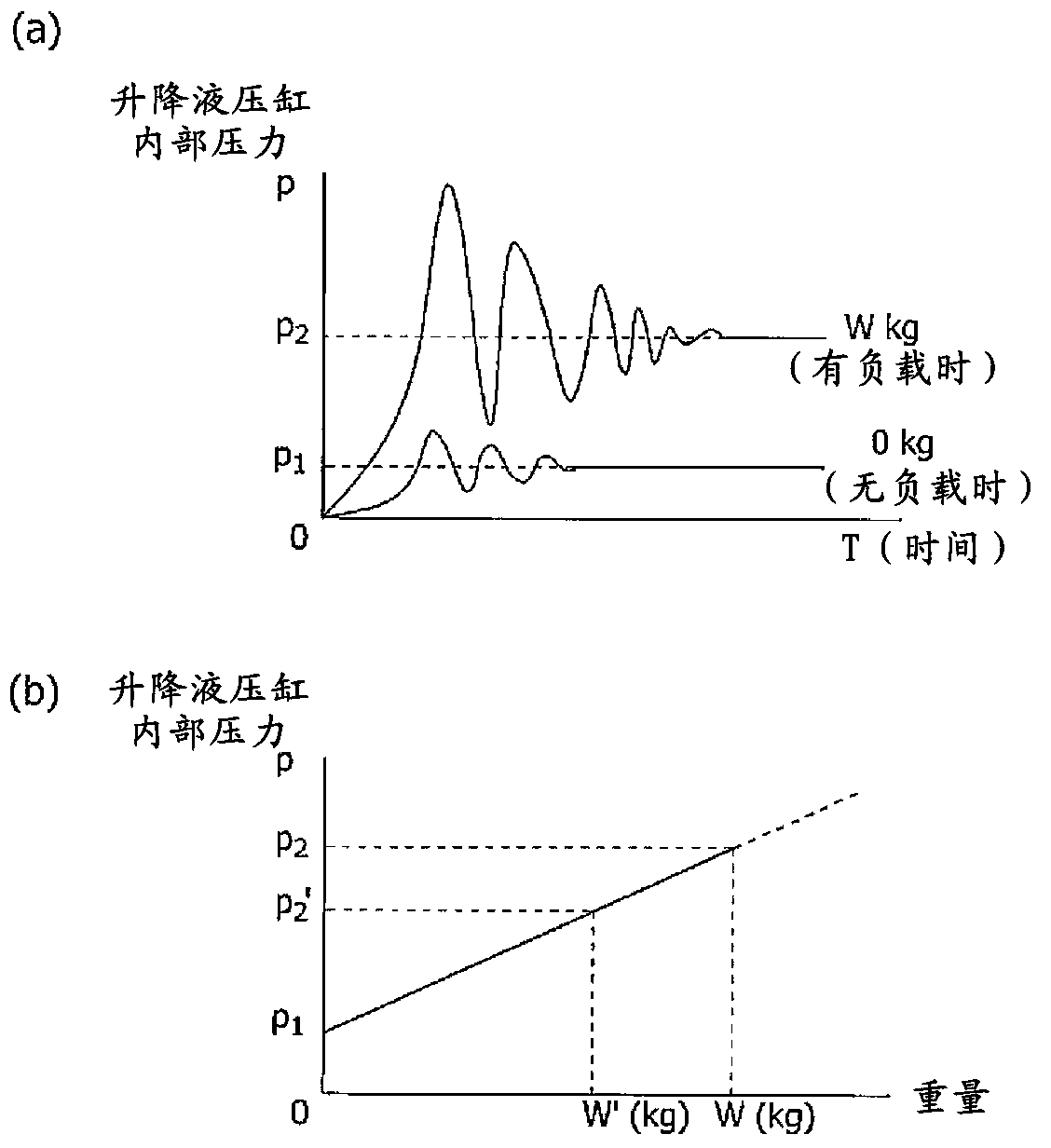

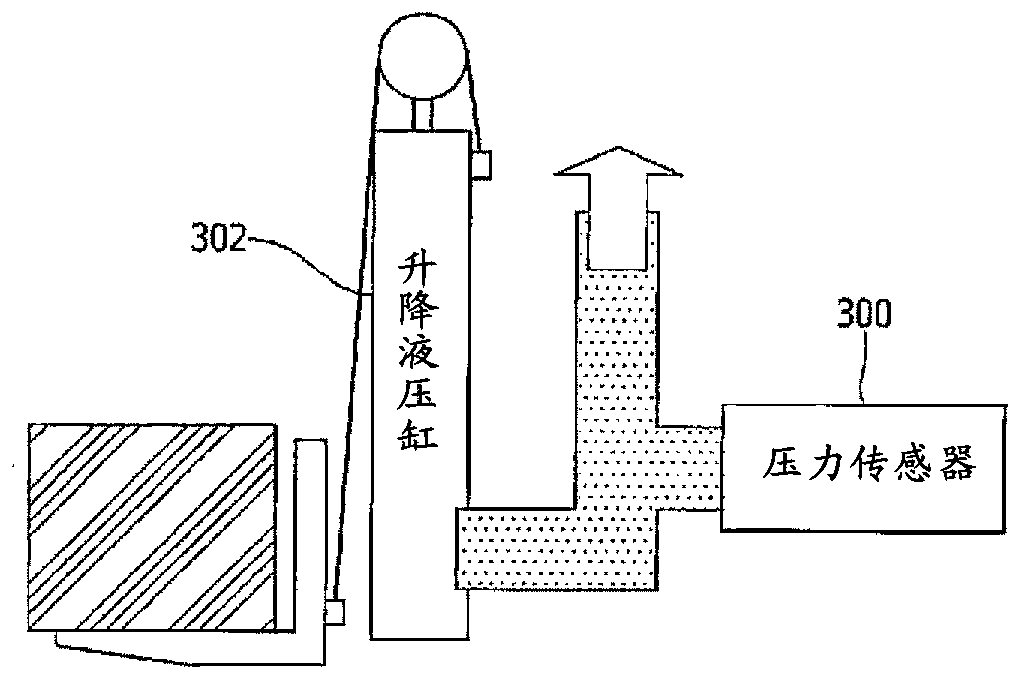

Freight weight measurement apparatus and method using compensation pressure in accordance with temperature change of hydraulic fluid

ActiveCN102770741ASmall weight errorHigh measurement accuracyWeighing apparatus using fluid action balancingWeighing temperature-compensating arrangementsEngineeringHydraulic fluid

The present invention relates to a freight weight measurement apparatus and method using compensation pressure in accordance with a temperature change of a hydraulic fluid. To this end, the freight weight measurement apparatus of the present invention comprises: a lift cylinder; a pressure sensor which is mounted in a lift cylinder line, and measures the inside pressure of the lift cylinder; a temperature sensor which is mounted inside the lift cylinder, and senses the temperature of the hydraulic fluid of the lift cylinder; ; and a controller which compensates a pressure value in case of no load and a pressure value in case of the maximum load as preset pressure compensation values according to a change of the temperature of the hydraulic fluid sensed by the temperature sensor, sets the pressure values to change the pressure values, and measures the weight of freight by using the set pressure values.

Owner:DOOSAN IND VEHICLE

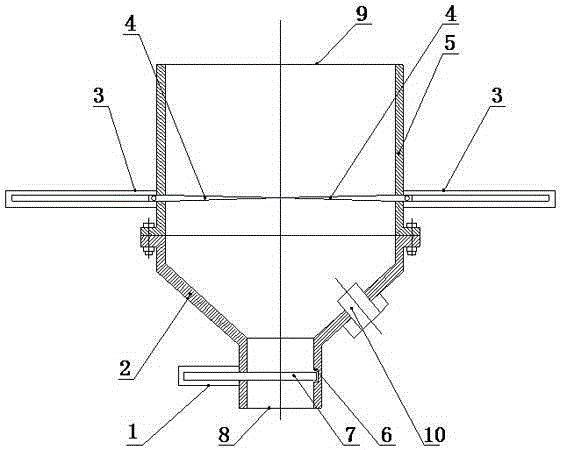

High-accuracy bulk particle bagging measuring hopper

InactiveCN105329468ASmall weight errorImprove reliabilitySolid materialEngineeringMechanical engineering

The invention discloses a high-accuracy bulk particle bagging measuring hopper and relates to the field of automatic bagging equipment. The high-accuracy bulk particle bagging measuring hopper comprises a hopper body and a quantifying shell; the hopper body is cuboid; a feeding inlet is formed in the upper portion of the hopper body; the quantifying shell is fixedly disposed on the lower portion of the hopper body; a gate I is disposed on the hopper body and divides the inner space of the hopper body into two parts; a discharging outlet is formed in the lower portion of the quantifying shell; a gate II is disposed at the discharging outlet; an adjusting screw is disposed on the side wall of the quantifying shell. Material weight of each bag is limited through volume between the two gates; it is guaranteed that the weight error among bags changes within a very small range, and advantages of high bagging accuracy, simple structure and high reliability are achieved.

Owner:成都经纬机械制造有限公司

Novel fried bread stick production line

InactiveCN105475407ASmall weight errorIncrease productivityDough shaping and cutting apparatusDough processingEngineeringManufacturing line

The invention provides a novel fried bread stick production line and relates to the field of food processing machines. The novel fried bread stick production line is characterized by comprising a flour feeding conveying assembly, a prepressing assembly, a thickness adjusting assembly, a partitioning cutter assembly, an operation box, a flour overlaying assembly, a pressure tank assembly, a cutter assembly, a rear conveying belt assembly and a manual picking-up platform, wherein the flour feeding conveying assembly is connected with the prepressing assembly, the prepressing assembly is then connected with the rear conveying belt assembly, the thickness adjusting assembly, the partitioning cutter assembly, the operation box, the flour overlaying assembly, the pressure tank assembly and the cutter assembly are arranged on the rear conveying belt assembly, and the manual picking-up platform is also connected behind the rear conveying belt assembly. The novel fried bread stick production line has the advantages that the original manual operations are greatly reduced, production efficiency is improved, and weight error between fried bread sticks is reduced.

Owner:HEFEI LAONAINAI FOOD CO LTD

Method for detecting quality characteristics of fired coal raw material

InactiveCN108801841AIncrease costEasy to operateWeighing by removing componentMaterial heat developmentEngineeringOxygen

The invention relates to a method for detecting quality characteristics of fired coal raw material. The method comprises the following steps of 1, using a coal stack as a sampling unit, and obtaininga coal sample with granularity smaller than 13mm; 2, putting the coal sample with granularity smaller than 13mm into an air drying box with temperature not higher than 40 DEG C to dry, and measuring the external moisture; crushing the coal sample until the granularity is smaller than 3mm, putting into the air drying box with temperature of 105 to 110 DEG C to dry, and measuring the internal moisture, so as to obtain the total moisture of the fired coal; 3, crushing the coal sample until the granularity is smaller than 0.15mm, drying for 0.5h in an oven with temperature of 50 DEG C, putting into the drying box with temperature of 105 to 110 DEG C to dry, and measuring the air dry base moisture; 4, putting the coal sample with granularity smaller than 13mm into an oxygen bomb with pressure of 2.8 to 3 MPa, measuring by a constant-temperature type oxygen bomb calorimeter, and measuring the air dry base low-grade heat value; 5, according to the total moisture of the fired coal, the air drybase moisture and the air dry base low-grade heat, judging whether the quality requirement standard of the coal is met or not. The method has the advantage that the actual moisture content and minimum heat value of the fired coal can be precisely measured, so as to more comprehensively and accurately judge the quality of the fired coal.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +1

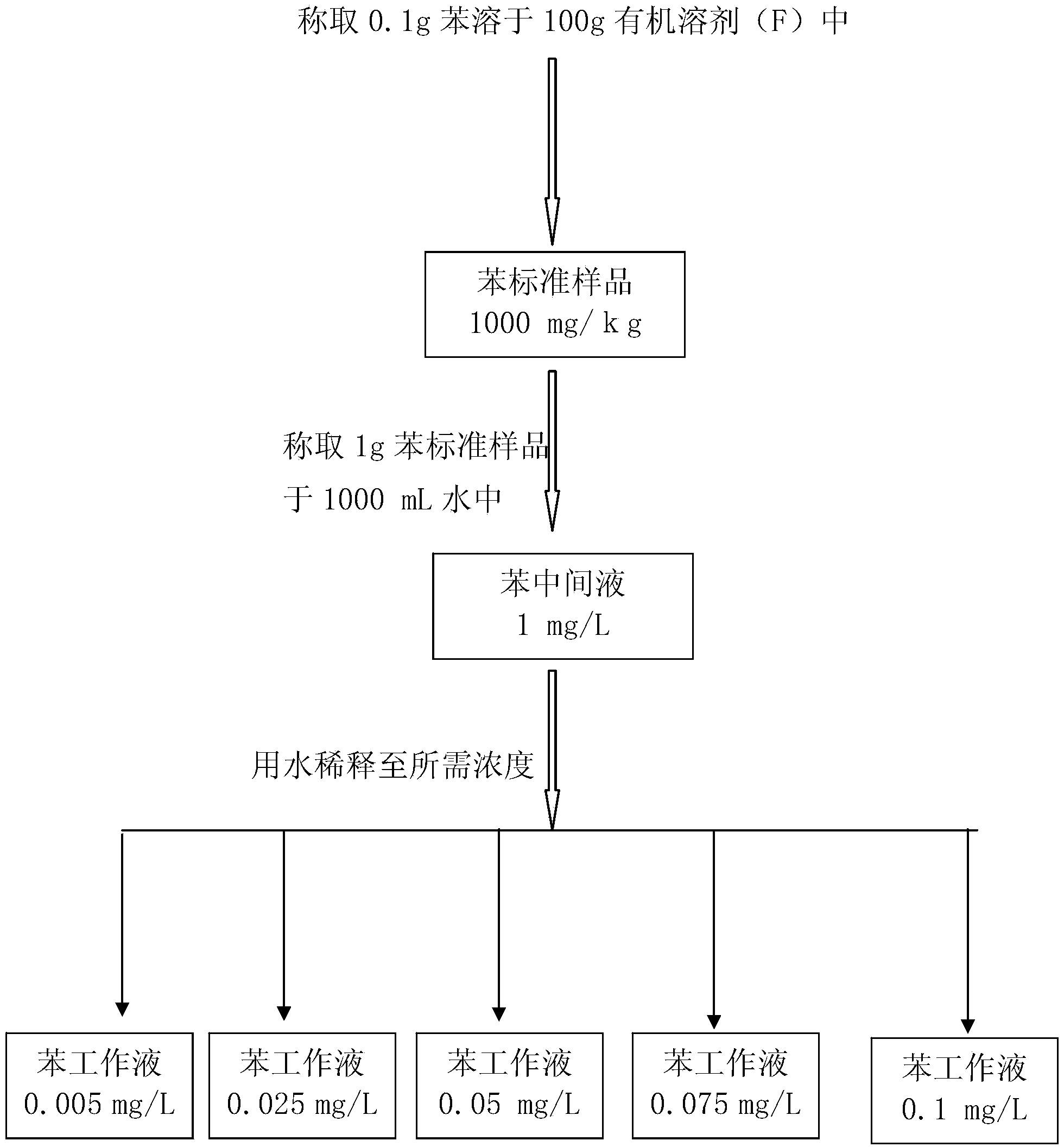

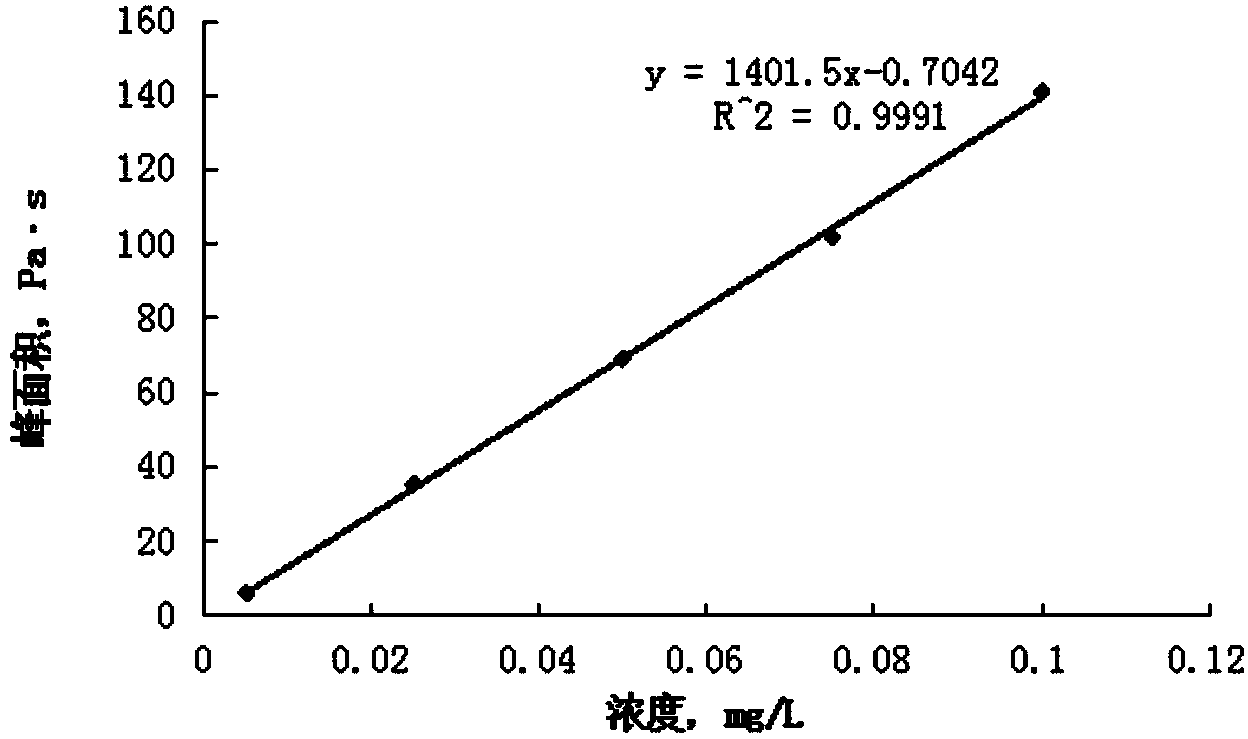

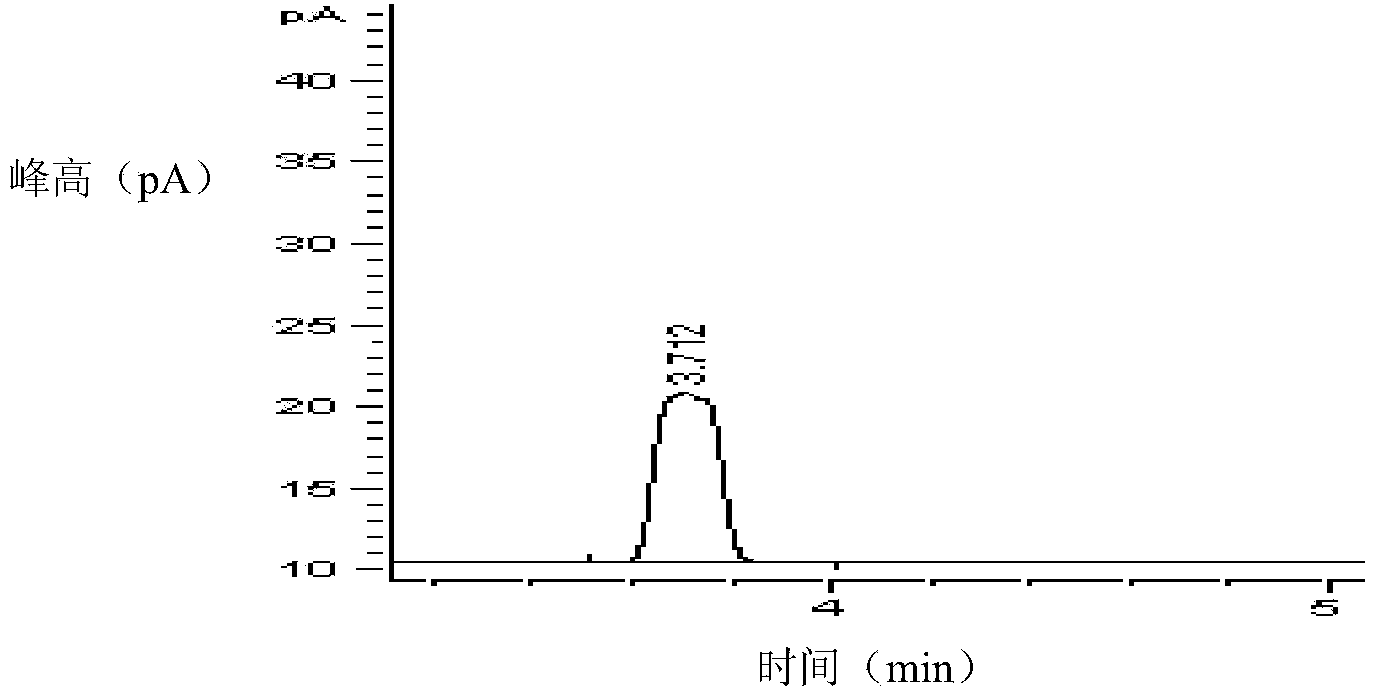

Standard sample used for headspace analysis of trace quantity benzene in water and method for measuring trace quantity benzene in water by using method thereof

ActiveCN104345104AIncrease concentrationIncrease the weighing amountComponent separationOrganic solventMutual solubility

The invention provides a standard sample used for headspace analysis of trace quantity benzene in water and a method for measuring trace quantity benzene in water by using the method thereof. The method comprises the following step of dissolving a benzene solution in a polarity sulfone organic solvent with high boiling point and capable of dissolving with water and benzene to obtain the standard sample. When in use, the standard sample is diluted by water to the required concentration; wherein the mass ratio of benzene to polarity sulfone organic solvent is 1: 100-1: 1000. According to the invention, benzene concentration in the standard sample can be increased, expiry data of the standard sample is prolonged to more than 1 year; benzene sampling weight is increased, weighing error is reduced, and the weighing relative error is reduced from 10% to 1%. The invention also provides a method for measuring trace quantity benzene in water by using the standard sample, and the standard sample does not influence the benzene measurement in headspace analysis.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

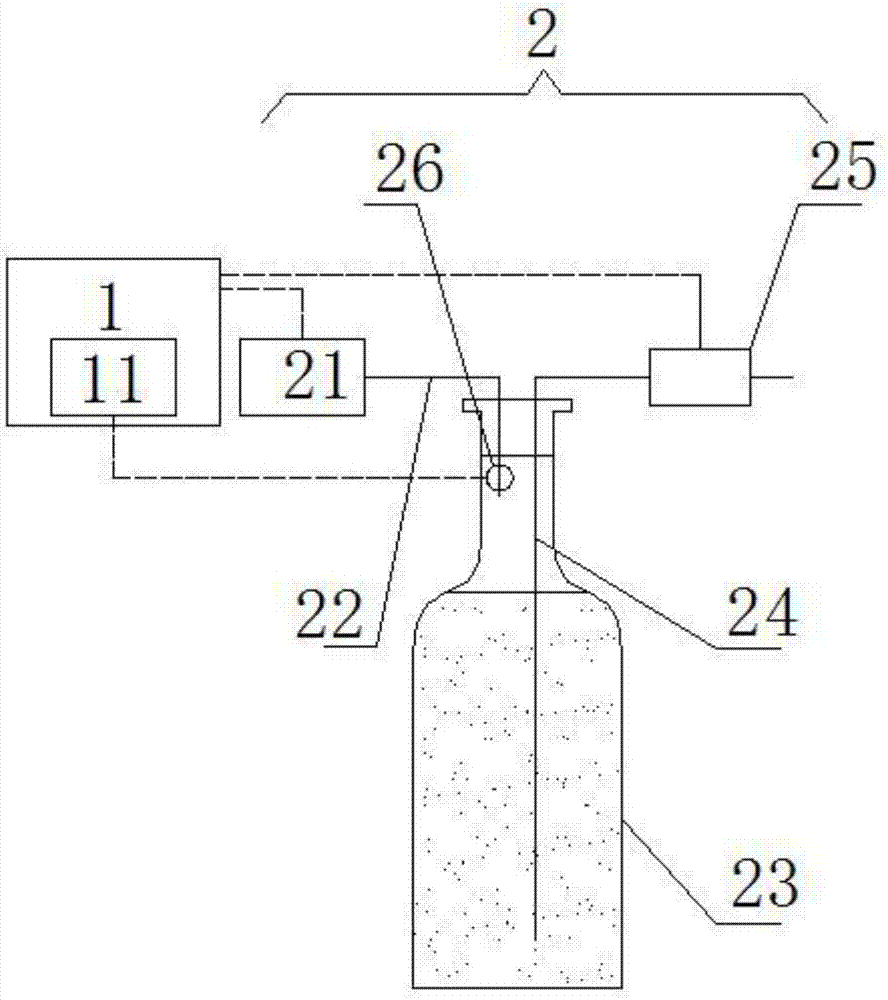

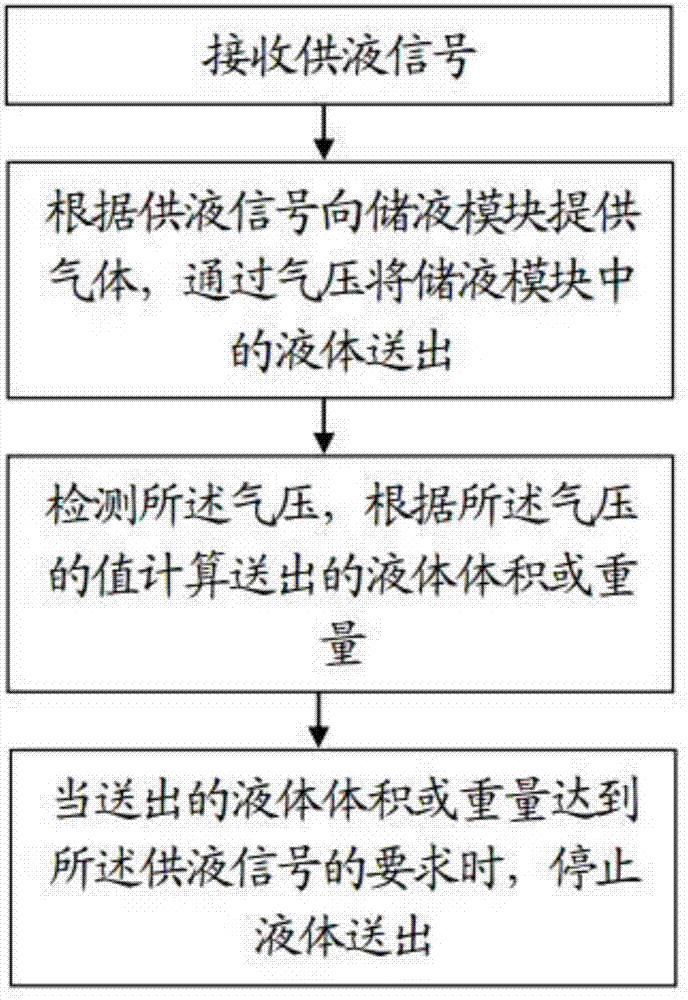

Liquid flow metering system and method

InactiveCN107507345AOverall small sizeSmall weight errorApparatus for dispensing fluids/granular materialsControl systemEngineering

The invention discloses a liquid flow metering system. The liquid flow metering system comprises a control system, a liquid taking module and a detection module, and the control system is used for receiving a liquid supply signal and controls the liquid taking module according to the liquid supply signal; the liquid taking module is used for providing gas and delivering liquid in a liquid storage module through gas pressure; the detection module is used for detecting gas pressure and calculating the volume or the weight of the liquid delivered according to the pressure intensity; when the volume or the weight of the delivered liquid reaches the requirement of the liquid supply signal, the control system is further used for stopping the liquid taking module from delivering the liquid. The invention further discloses a metering method based on the liquid flow metering system. The volume or the weight of the delivered liquid is obtained by measuring the pressure intensity, the volume or the weight of the delivered liquid is integrated in a pipeline where pumped gas flows liquid through the pressure intensity, a weighing sensor does not need to be additionally arranged, and the liquid flow metering system has the advantages of being compact in structure, precise to measure and simple in operating method and saving the cost.

Owner:康兆君

Detection method of chlorine content in 2-ethylanthraquinone

InactiveCN108982750AImprove weighing accuracyDetection speedChemical analysis using titrationWorkstationData stability

The invention discloses a detection method of the chlorine content in 2-ethylanthraquinone. The detection method comprises the following steps of 1) preparing an organic chlorine standard solution; 2)preparing a sample, and weighing about 4 micrograms of sample in a sample weighing cup with an analysis scale; 3) putting the sample on a micro-coulometry sulfur-chlorine determinator for detection,wherein integration resistance of a data workstation of the micro-coulometry sulfur-chlorine determinator is equal to 1 K, and the amplification factor is equal to 2000; 4) calculating an average conversion rate; and 5) sending the sample into the micro-coulometry titrator for determination by using a solid sample feeding boat. In the detection method, as the feeding quantity required for detection is small and is less than 4 micrograms, the detection cost can be reduced, and the detection speed is increased. The practical application discovers that the detection method is short in detection time, good in data stability and simpler in operation compared with the prior art and can lower the labor intensity of detecting personnel.

Owner:HUZHOU JICHANG CHEM

Facial mask pressing system capable of digitally adjusting thickness of finished-product facial masks

InactiveCN109077936AStable controlEasy to adjust the thicknessCosmetic preparationsToilet preparationsEngineeringBelt conveyor

The invention discloses a facial mask pressing system capable of digitally adjusting the thickness of finished-product facial masks. The facial mask pressing system comprises a controller, a belt conveyor, pressing roller devices and drive devices for driving the pressing roller devices, wherein each pressing roller device comprises a base, multiple groups of fixing standing columns, pressing rollers and pressing roller adjusting mechanisms arranged on the fixing standing columns, the fixing standing columns are fixed to the base, the upper pressing roller and the lower pressing roller are arranged between each group of fixing standing columns, and the upper pressing roller is connected with the pressing roller adjusting mechanisms to allow the upper pressing roller to move vertically under the effect of the pressing roller adjusting mechanisms. The facial mask pressing system is stable in facial mask thickness control, small in weighing errors after extrusion molding, high in controlprecision, convenient to adjust the thickness of input base film and the output facial mask, capable of evidently increasing facial mask quality and production efficiency and especially good in pressing effect on facial masks satisfying the thickness requirements of different users.

Owner:WUHAN SHEN AN M & E ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com