Automatic fried bread stick production line

A fritter production line, automatic technology, applied in the directions of dough sheeter/roller/rolling pin, baking, dough forming and slitting combination, etc., can solve the problem of low production efficiency, unsanitary, increased labor burden of workers, etc problem, to achieve the effect of reducing weight error and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

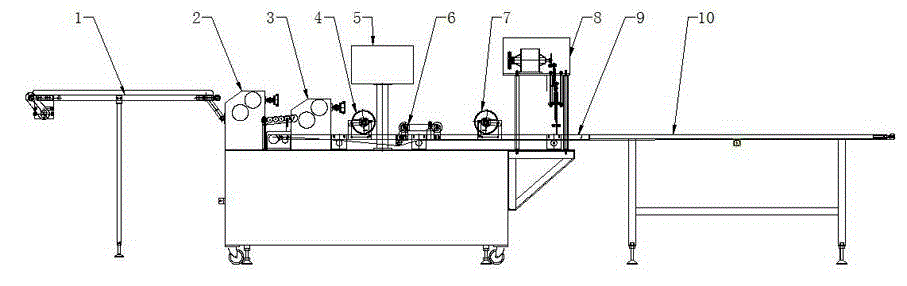

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: it consists of a face feeding assembly 1, a pre-pressing assembly 2, a thickness adjustment assembly 3, a splitting knife assembly 4, an operation box 5, a stacking assembly 6, a pressure groove assembly 7, and a cutter assembly 8. The rear conveyor belt assembly 9 is composed of a manual pick-up platform 10. The surface feeding assembly 1 is connected to the pre-pressing assembly 2, and the pre-pressing assembly 2 is connected to the rear conveyor belt assembly 10. The rear conveyor belt assembly 10 is provided with Thickness adjustment assembly 3, splitting knife assembly 4, operation box 5, stacking surface assembly 6, pressure groove assembly 7, cutting knife assembly 8, also is connected with manual pick-up table 9 behind the rear conveyor belt assembly 10.

[0009] When this specific embodiment works normally, put the noodle sheet pressed by the noodle press on the noodle conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com