Facial mask pressing system capable of digitally adjusting thickness of finished-product facial masks

A technology for laminating and masking, which is applied to cosmetics, cosmetic preparations, medical preparations containing active ingredients, etc., can solve the problems of low production efficiency, low efficiency, unstable film thickness control, etc. The effect of small weight measurement error and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

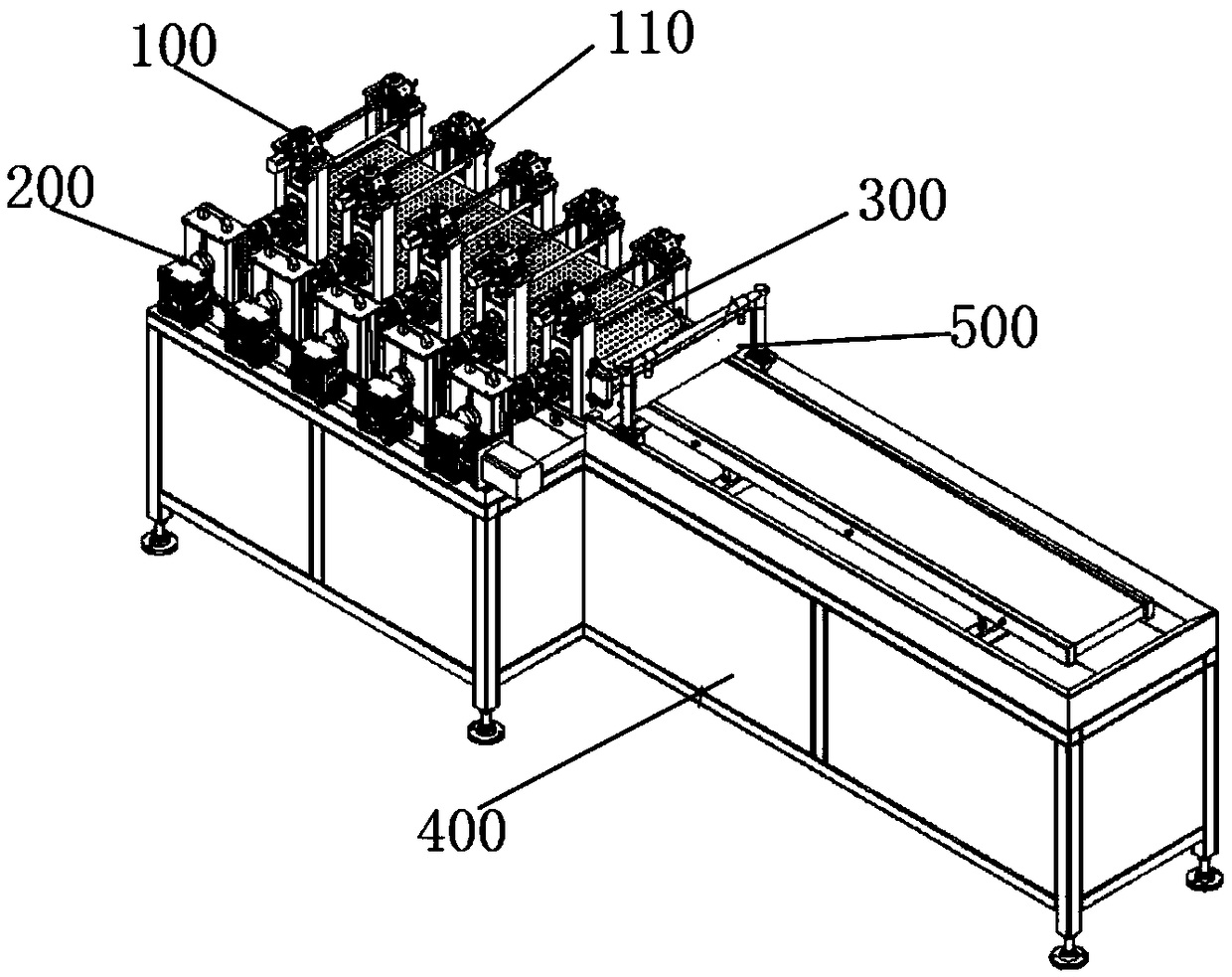

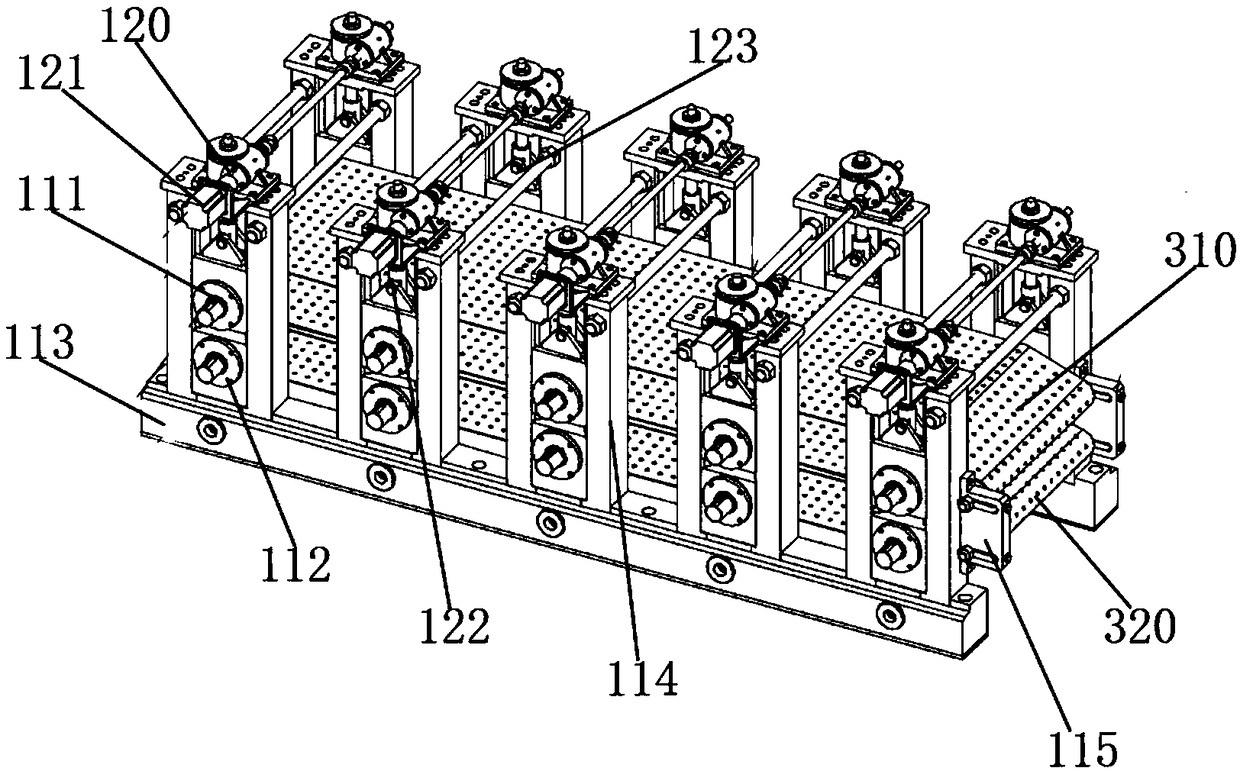

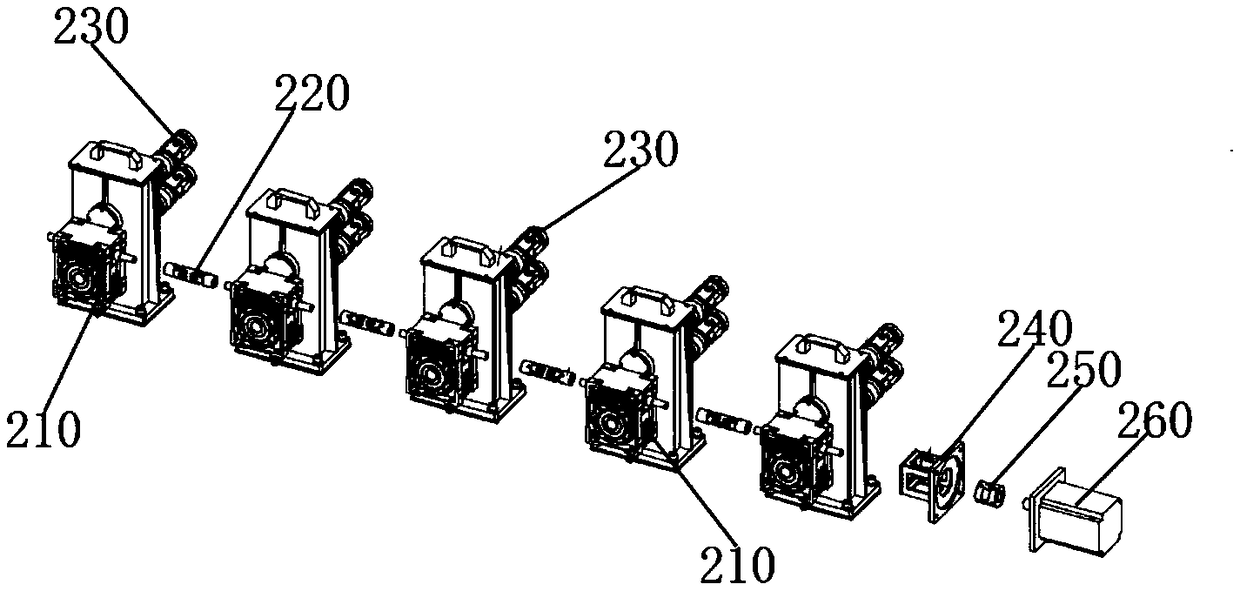

[0029] Such as figure 1 and figure 2 As shown, the lamination system of digitally adjusting the thickness of the finished film of the present invention includes a controller, a belt conveying device 300, a pressing roller device 100 and a driving device 200 for driving the pressing roller device, wherein the pressing roller device 100 includes a base 113, Multiple sets of fixed columns 114, pressure rollers 111 and pressure roller adjustment mechanism 120 arranged on the fixed columns, multiple sets of fixed columns 114 are fixed on the base 113, each set of fixed columns 114 is equipped with a lower pressure roller 112 and an upper pressure roller 111 , the upper pressure roller 111 is connected with the pressure roller adjustment mechanism 120, so that the upper pressure roller 111 moves up and down under the effect of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com