Die for cutting off round steel

A technology of round steel and cutting knife, which is applied in the field of round steel cutting molds, and can solve problems such as differences in structure, function, and operation mode of cutting dies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

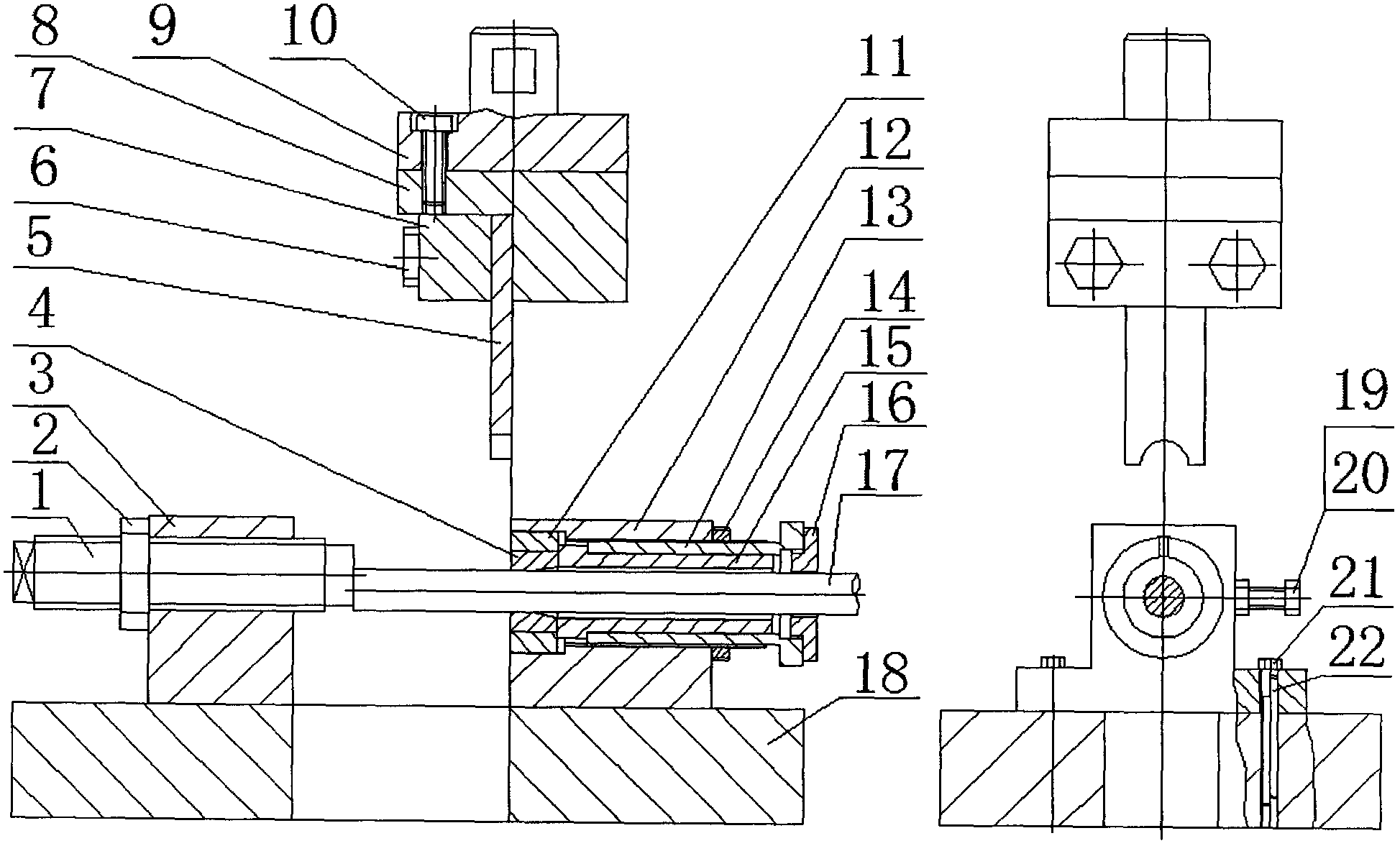

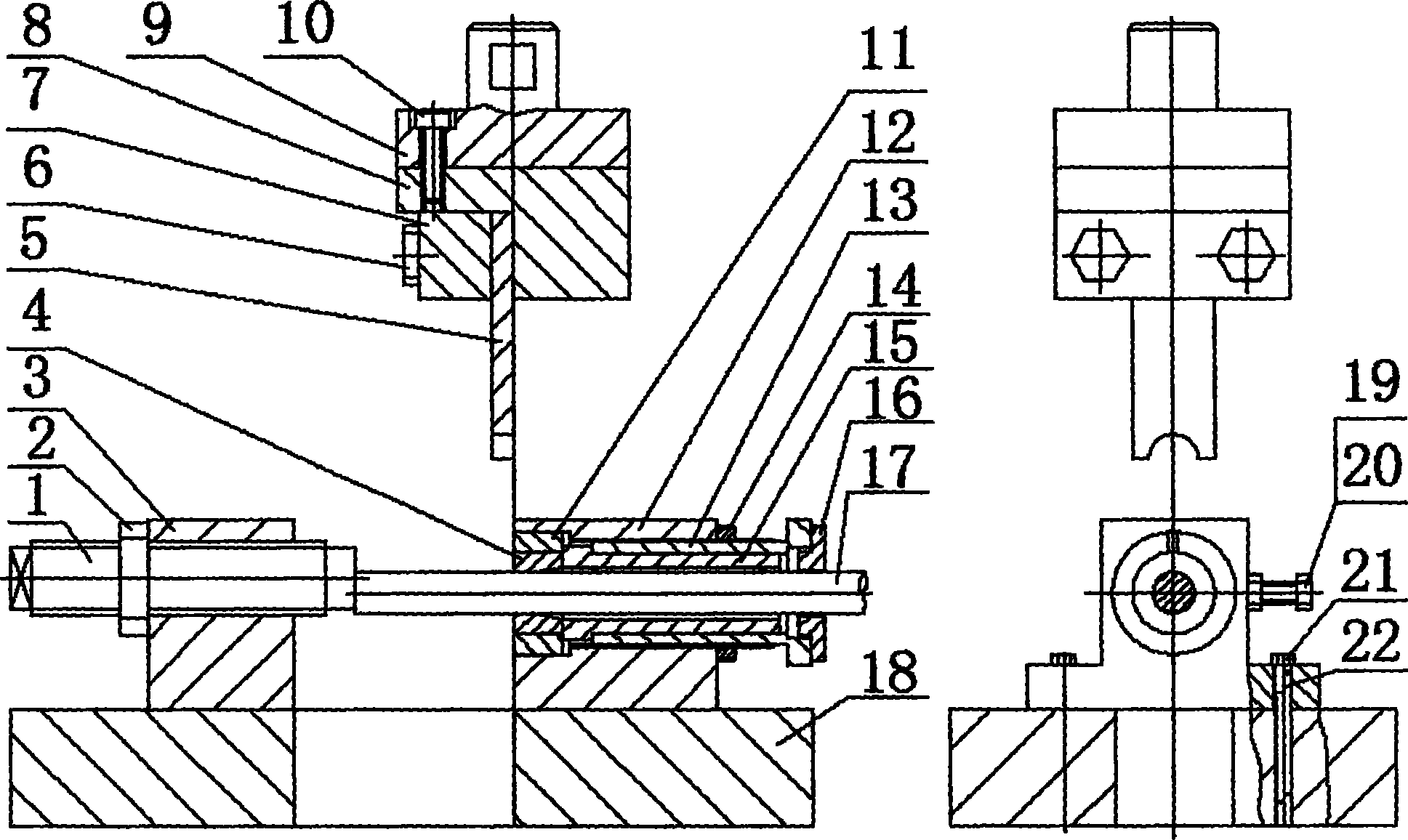

[0005] As shown in the figure, the round steel cutting die of the present invention includes two parts, an upper die and a lower die, and is suitable for a universal crank press. The unique working mechanism part of the mold includes an upper mold consisting of a cutting knife 5, a cutting knife pressing plate 7, a knife seat 8, a mold handle 9, etc., which are connected by screws 6 and 10 as shown in the figure to form a whole upper mold. Adjusting screw rod 1, locking nut 2, and adjusting seat 3 form the cutting length adjustment mechanism of the lower mold, which is connected with the lower mold seat plate 18 by the illustrated screw 21 and pin 22. The die 4 cooperates with the die support 12 through the opening clamping sleeve 11 in the radial direction, and is adjusted and tightened radially through the locking screw 19 and the locking nut 20 . The axial positioning of the die 4 is fixed by the axial sleeve 15 and the screw sleeve 13 and the die support 12 threaded pairs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com