Double-station automatic gluing production line

A double-station, production line technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as unreasonable structure of urine cups, achieve the effects of improving work efficiency, reducing enterprise costs, and high market benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

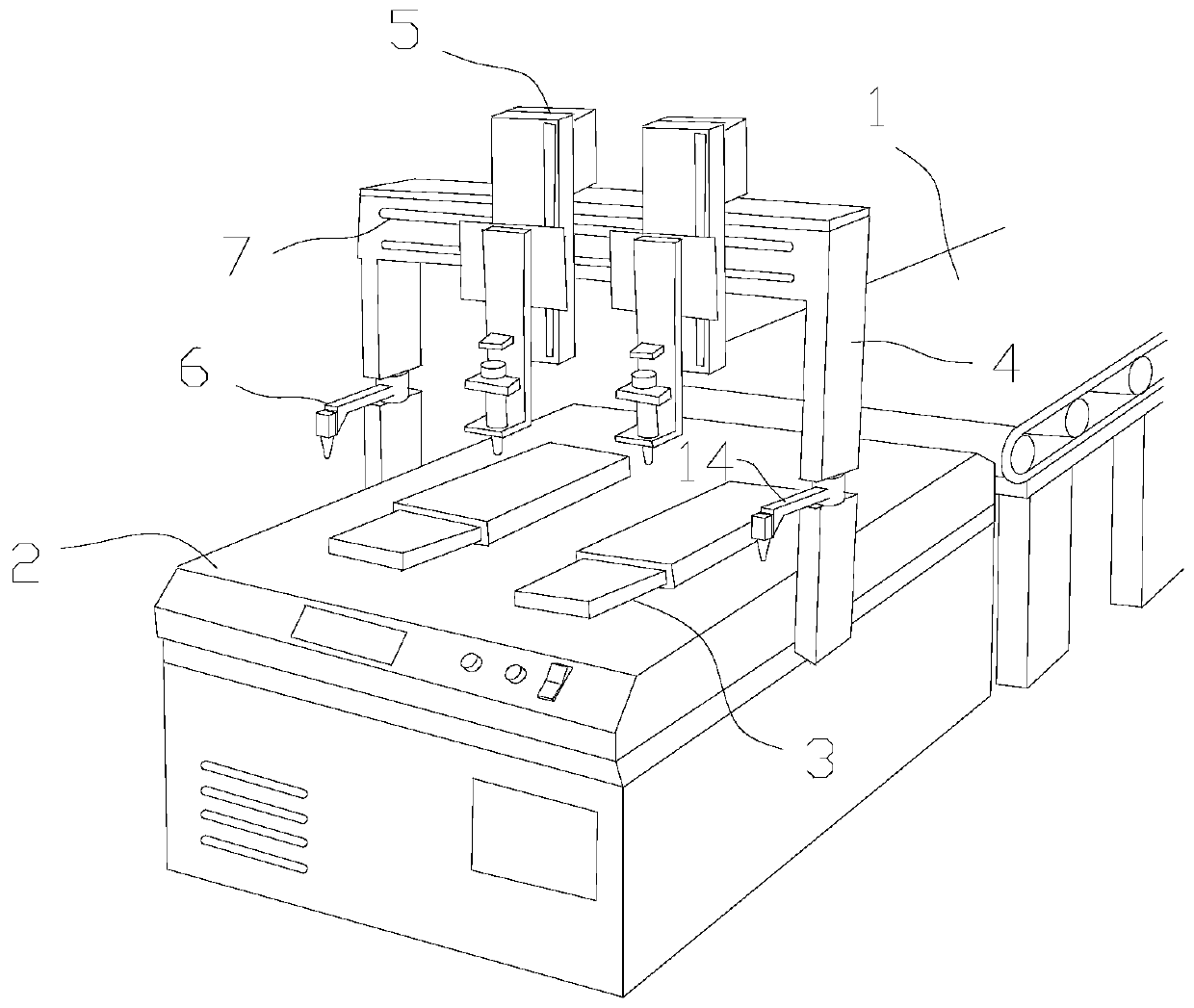

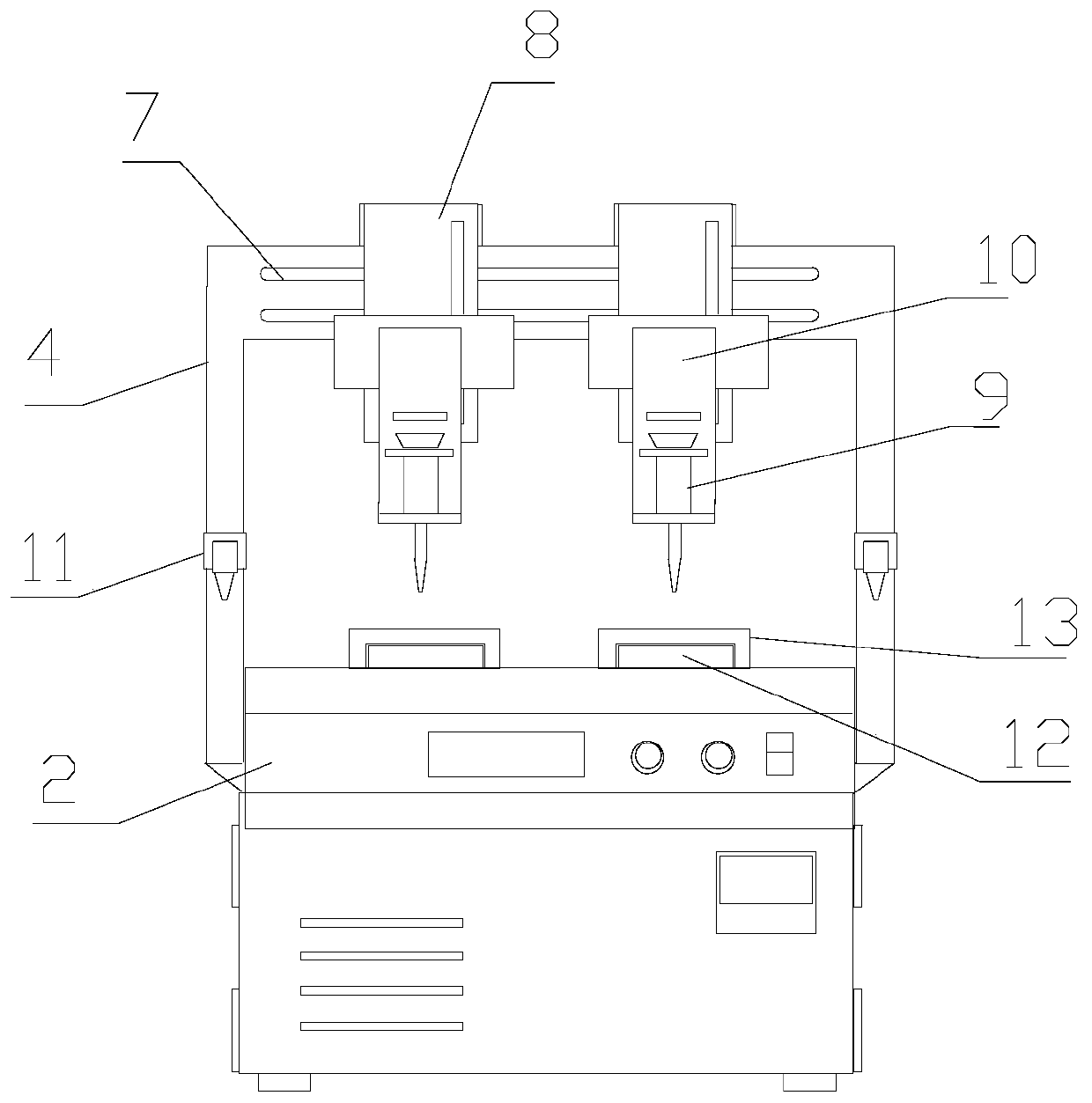

[0018] Attached below Figure 1-3 The present invention is further described with embodiment:

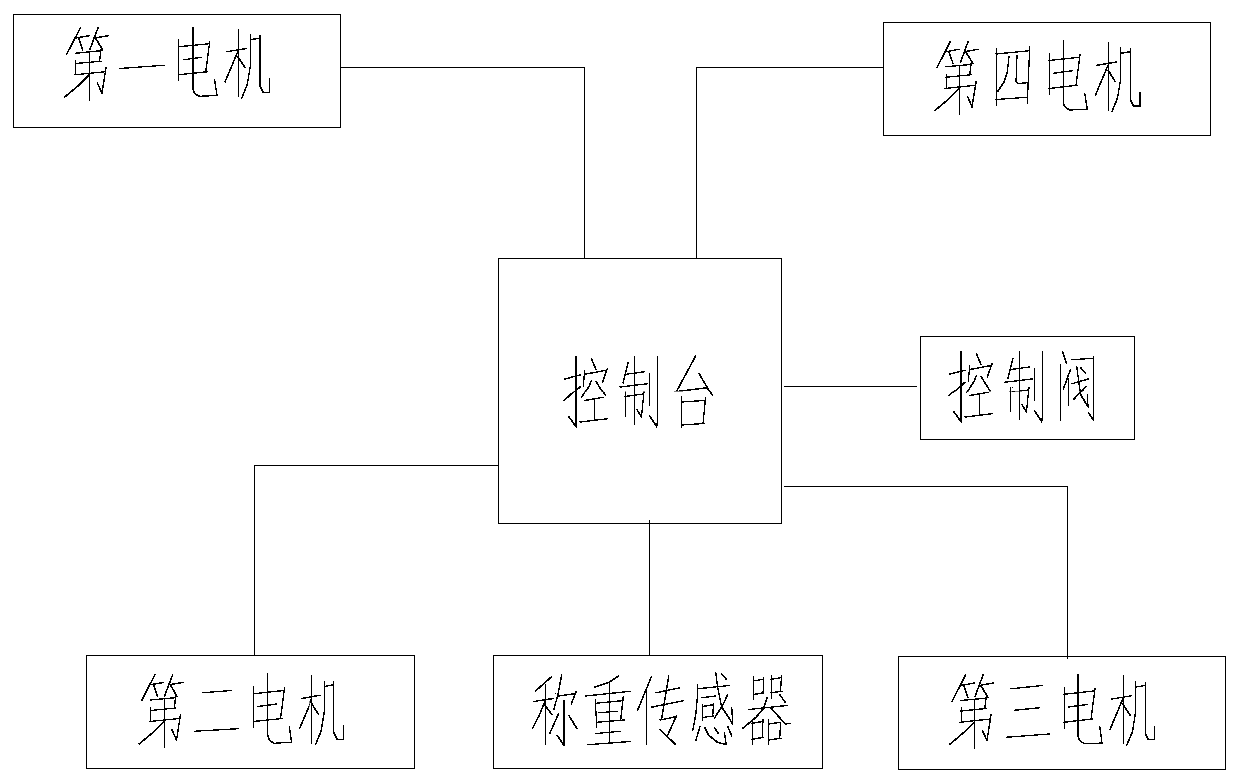

[0019] like Figure 1-2 Shown is a double-station automatic gluing production line, including a conveying system 1, and also includes: console 2, weighing device 3, glue supply pump, connecting pipe, support frame 4, first gluing device 5 and second gluing device Device 6, the conveying system 1 is arranged side by side with the console 2 and the output end faces the console 2, the weighing device 3 is arranged on the surface of the console 2 and the bottom is fixedly connected to it for placing the shoe body to be glued, The support frame 4 is erected on the console 2 and connected to both sides of the console 2, the support frame 4 is provided with slide rails 7, and the first gluing device 5 is arranged on the top of the support frame 4 and is formed by the first The motor drives to slide laterally along the slide rail 4, the second gluing device 6 is arranged on the side arm o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com