Loose particle bagging measuring hopper

A technology for measuring hoppers and granules, which is applied in packaging and other directions, and can solve problems such as complex structures, response time, inaccurate bagging accuracy, and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

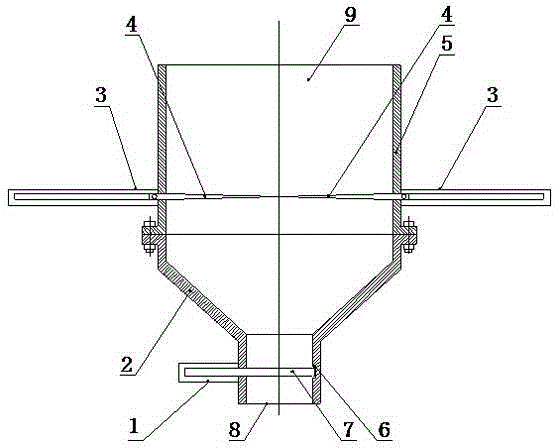

[0012] figure 1 Shown is a kind of bagging metering hopper for bulk particles provided by the present invention, bucket body 5, quantitative shell 2, bucket body 5 is cuboid in shape, the top of bucket body 5 is provided with feed inlet 9, and quantitative shell 2 is fixedly arranged on The lower part of the bucket body 5 is provided with a gate I3, which divides the inner space of the bucket body 5 into two parts. The lower part of the quantitative shell 2 is provided with a discharge port 8, and the position of the discharge port 8 is provided with a gate II1.

[0013] In this embodiment, there are two gates I3, which are symmetrically arranged on both sides of the bucket body 5. The gate I3 includes a gate I4, and the two gates I4 are arranged on the same plane, so that when both gates I4 are closed The inner space of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com