Environment-friendly type concrete mixing plant

An environment-friendly concrete and mixing building technology, which is applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problems of inaccurate water supply weighing, low water supply weighing accuracy, swaying and shaking, etc., to improve water supply Accuracy, improve the accuracy of water supply weighing, improve the effect of concrete quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

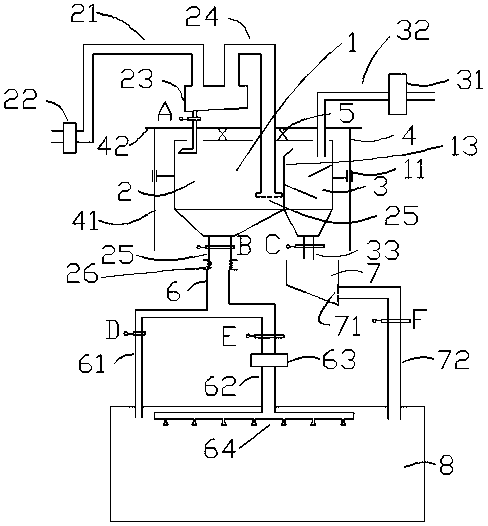

[0021] Such as figure 1 As shown, the environment-friendly concrete mixing building of the present invention includes a material storage system, a material conveying system, an aggregate weighing device, a powder weighing device, a high-precision water supply weighing device, a liquid admixture weighing device, and a concrete mixing host The high-precision water supply weighing device includes a water tank 1, and the water tank 1 includes a clean water chamber 2 and a recovery waste water chamber 3, and the clean water chamber 2 and the recovery waste water chamber 3 are separated by a partition 13, and the partition There is a gap between the upper end of 13 and the top wall of the water tank, and the gap forms a connecting channel connecting the clean water chamber 2 and the recycled waste water chamber 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com