Method for preparing carbon quantum dot modified lithium-sulfur battery positive electrode materials

A technology of carbon quantum dots and positive electrode materials is applied in the field of preparation of positive electrode materials of carbon quantum dots modified lithium-sulfur batteries to achieve the effects of good charge and discharge performance, improved capacity and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

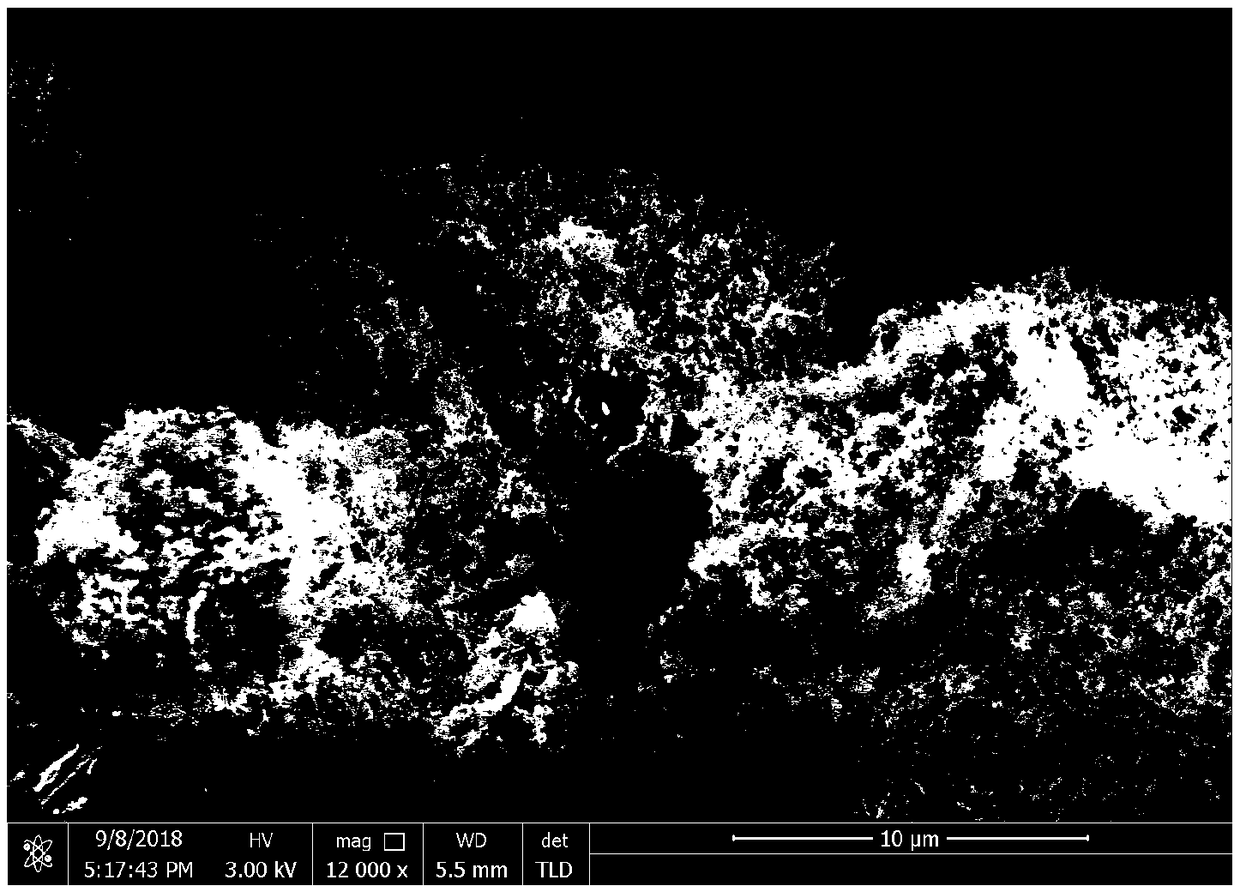

Image

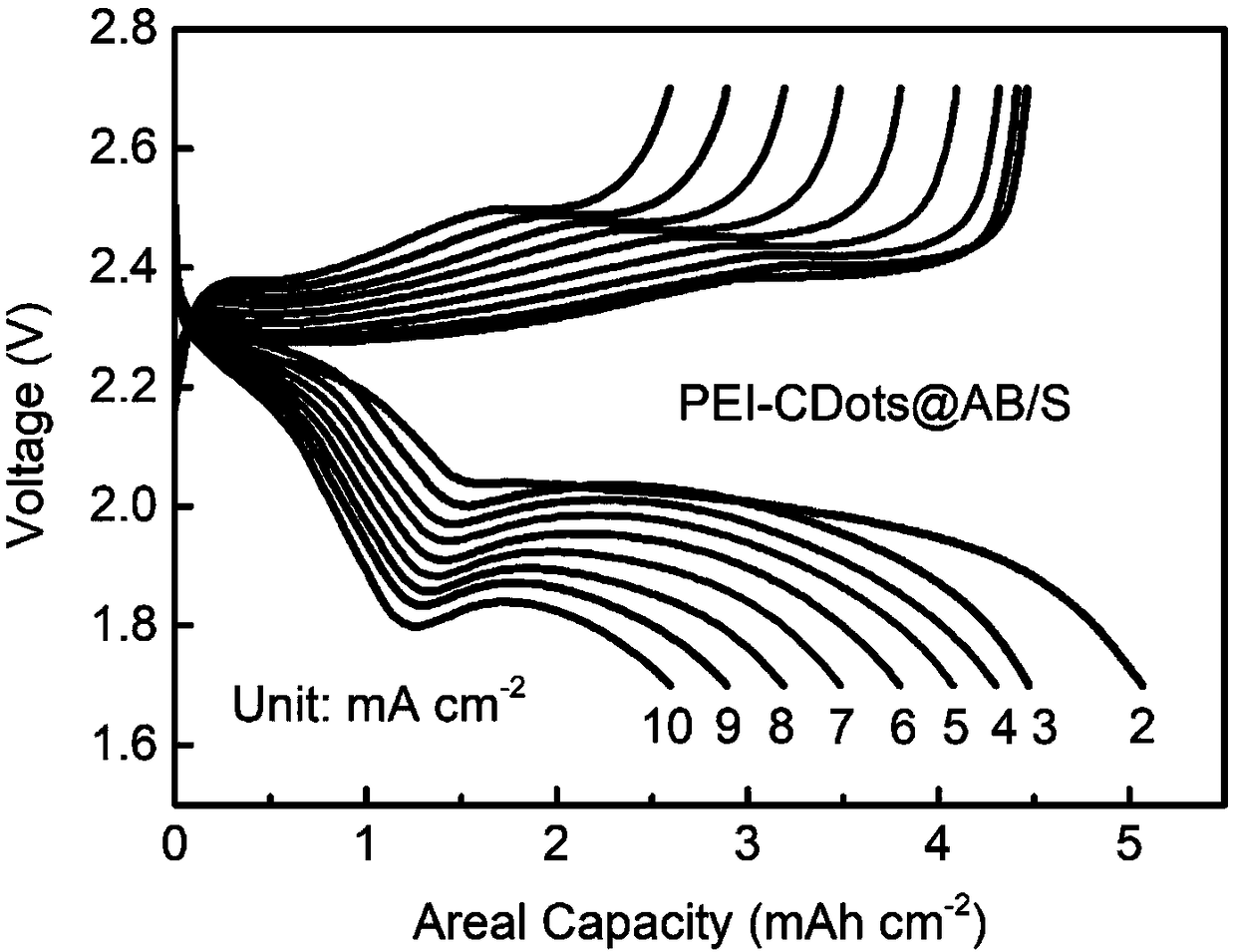

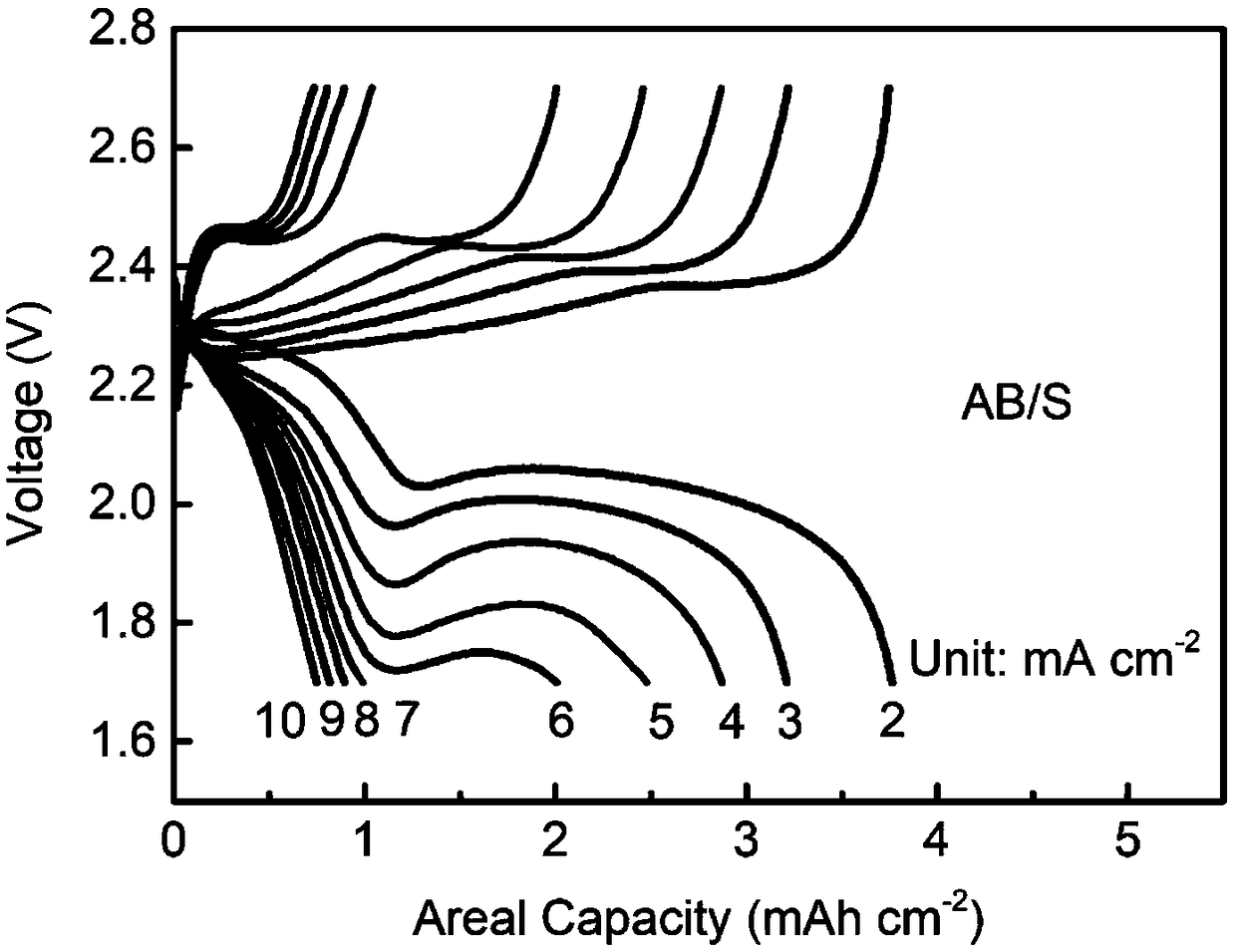

Examples

Embodiment 1

[0025] Step 1: preparing carbon quantum dots functionalized on the surface of polyethyleneimine, the specific steps are:

[0026] Place polyethyleneimine in a glass sample vial and place it on a heating platform at 400°C for 50 minutes of carbonization treatment. After the treatment, remove the glass sample vial from the heating platform, let it cool down to room temperature naturally, and then place it on the treated glass sample Add deionized water into the bottle, and perform ultrasonic treatment for 30 minutes to disperse the carbon quantum dots in the deionized water to form carbon quantum dot dispersion, put the carbon quantum dot dispersion into a dialysis bag for dialysis, and remove the unreacted polyethylene sub Amine, the carbon quantum dots with polyethylenimine surface functionalization can be obtained by freeze-drying the carbon quantum dot dispersion after the dialysis treatment;

[0027] Step 2: Mix the carbon quantum dots, sulfur powder, acetylene black and po...

Embodiment 2

[0032] Prepare a lithium-sulfur battery according to the steps in Example 1, only adjust the coating amount of sulfur on the surface of the carbon paper current collector in step 3 to 5.2mg / cm 2 , other steps remain unchanged. The lithium-sulfur battery that embodiment 2 obtains is in 6mA / cm 2 The long-term cycle capacity and Coulombic efficiency performance diagram of constant current charge and discharge under current density Image 6 shown.

Embodiment 3

[0034] Prepare a lithium-sulfur battery according to the steps in Example 1, only adjust the coating amount of sulfur on the surface of the carbon paper current collector in step 3 to 4 mg / cm 2 , other steps remain unchanged. The lithium-sulfur battery that embodiment 3 obtains at 6mA / cm 2 The attenuation rate of 400 cycles of long-cycle constant current charge and discharge under the current density is 0.02% per cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com