Full-automatic logistics system for soft bags

A logistics system and fully automatic technology, applied in the field of medical devices, can solve the problems of workers working for a long time, hidden dangers of production safety, inconvenience of workers, and physical labor consumption of production personnel, so as to reduce production personnel, reduce labor intensity, and improve production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

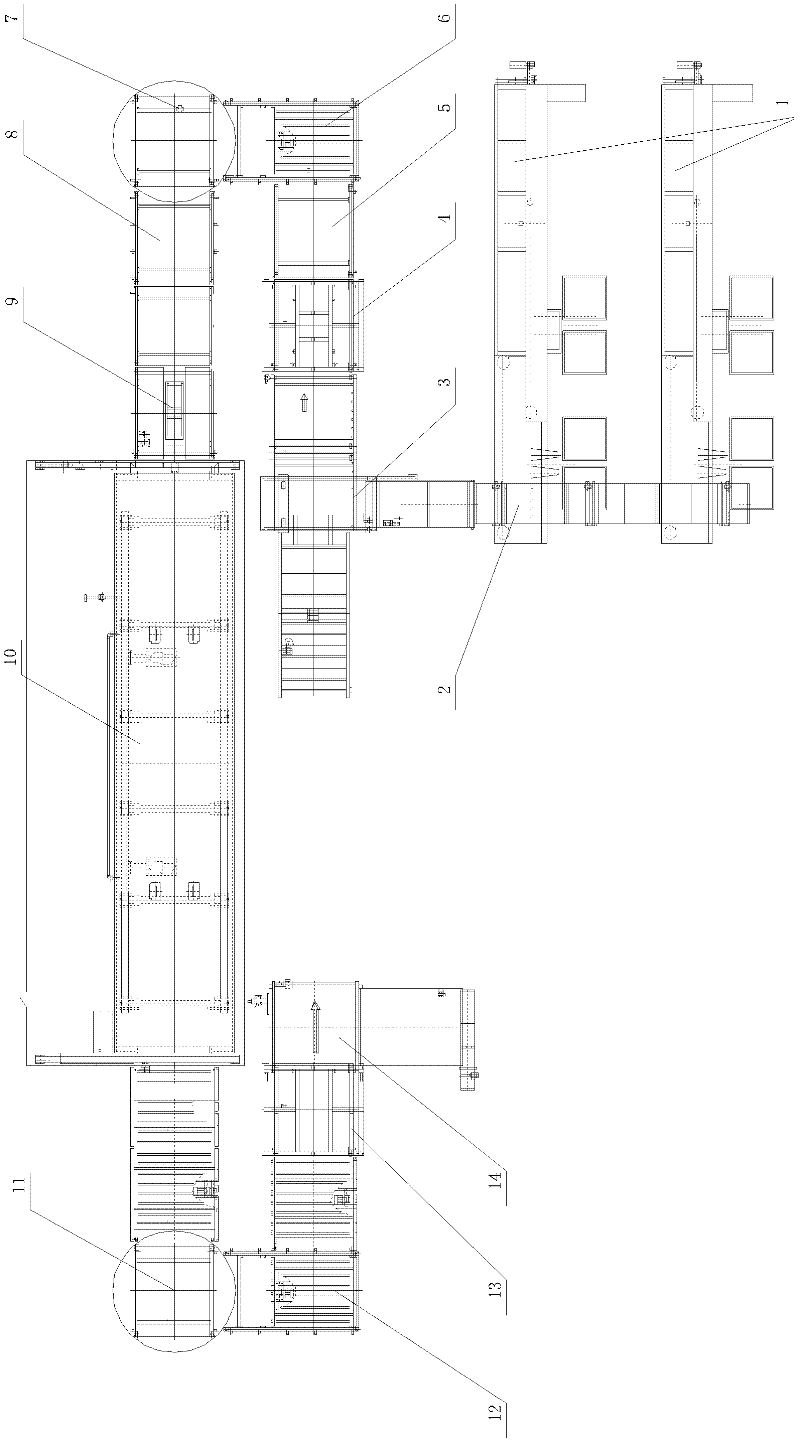

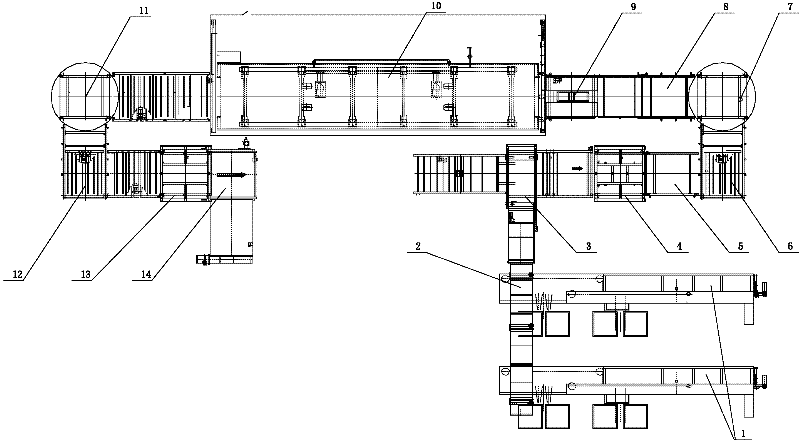

[0013] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0014] Such as figure 1 As shown, the soft bag automatic logistics system includes a soft bag line 1, a bag sorting system 2, a telescopic automatic tray loading machine 3, a first fully automatic tray unstacking machine 4, a first linear conveying unit 5, and a second A jacking and moving unit 6, a first 90° turning unit 7, a second linear conveying unit 8, a cabinet front propulsion unit 9, a high-temperature sterilizer 10, a second 90° turning unit 11, a second jacking and moving unit 12, The second fully automatic disc stacking machine 13 and the fully automatic disc unloading machine 14.

[0015] The soft bags produced by the soft bag line 1 go through the bag sorting system 2 to sort out the messy soft bags according to the requirements, and then transport them to the telescopic automatic tray loading machine 3, and then the telescopic automatic tray load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com