Automatic carrying device of material rolling spool

A technology of handling device and I-shaped wheel, which is used in transportation and packaging, thin material handling, and transportation of filamentous materials, etc., can solve the problems of high noise in the production workshop, low production efficiency, time-consuming and laborious material handling, etc., and achieve high efficiency. Production, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

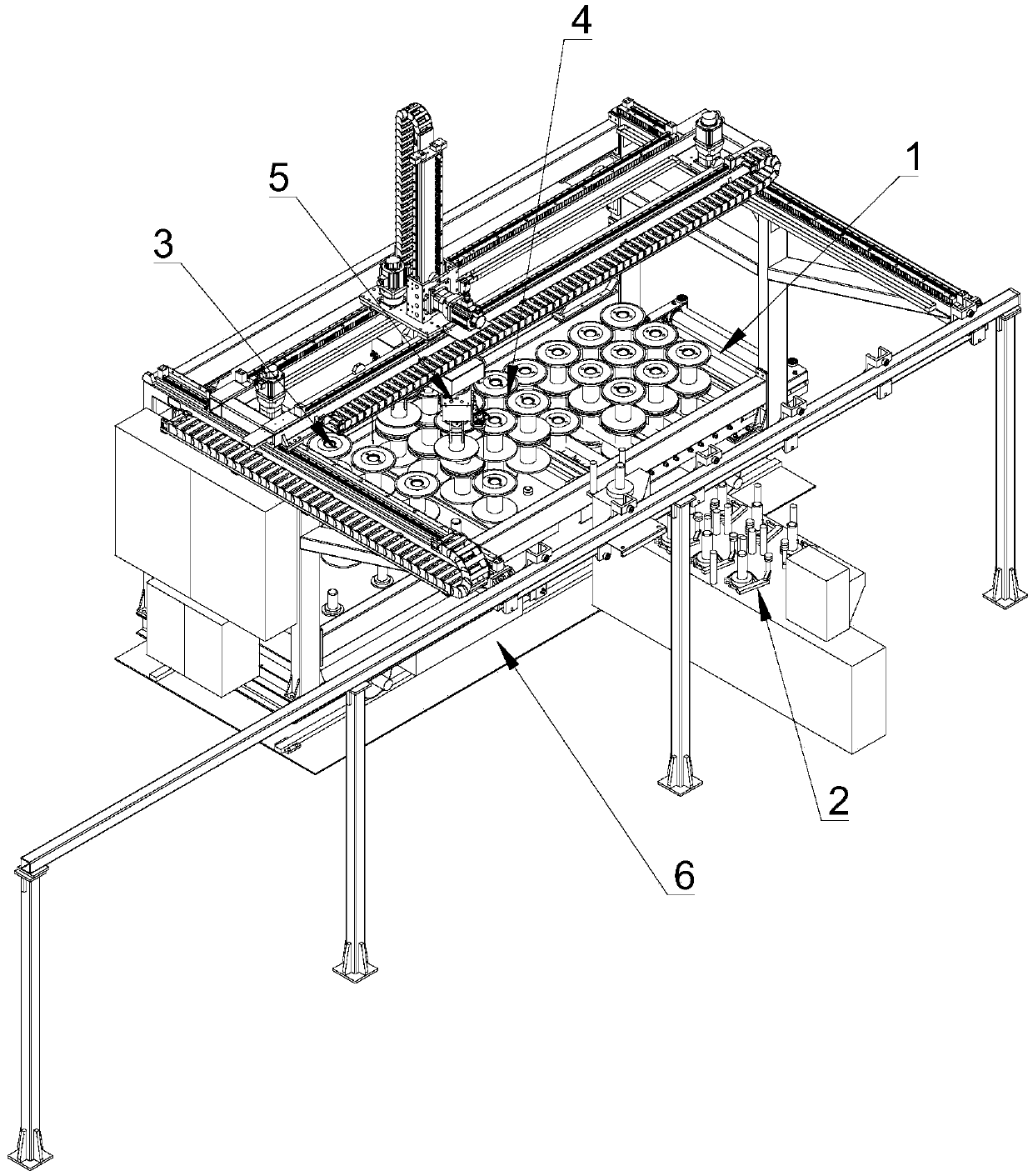

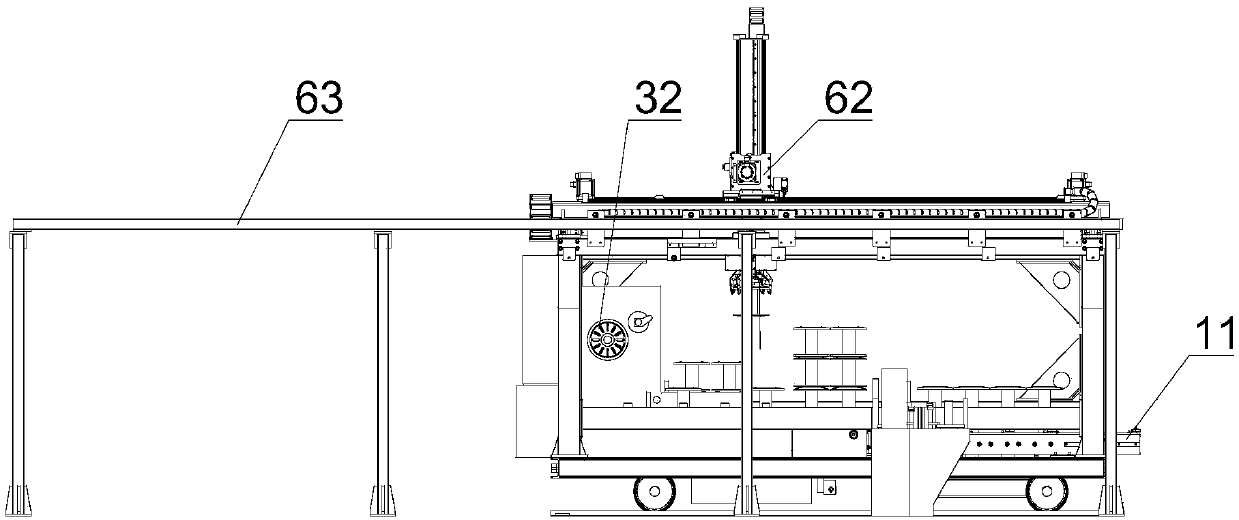

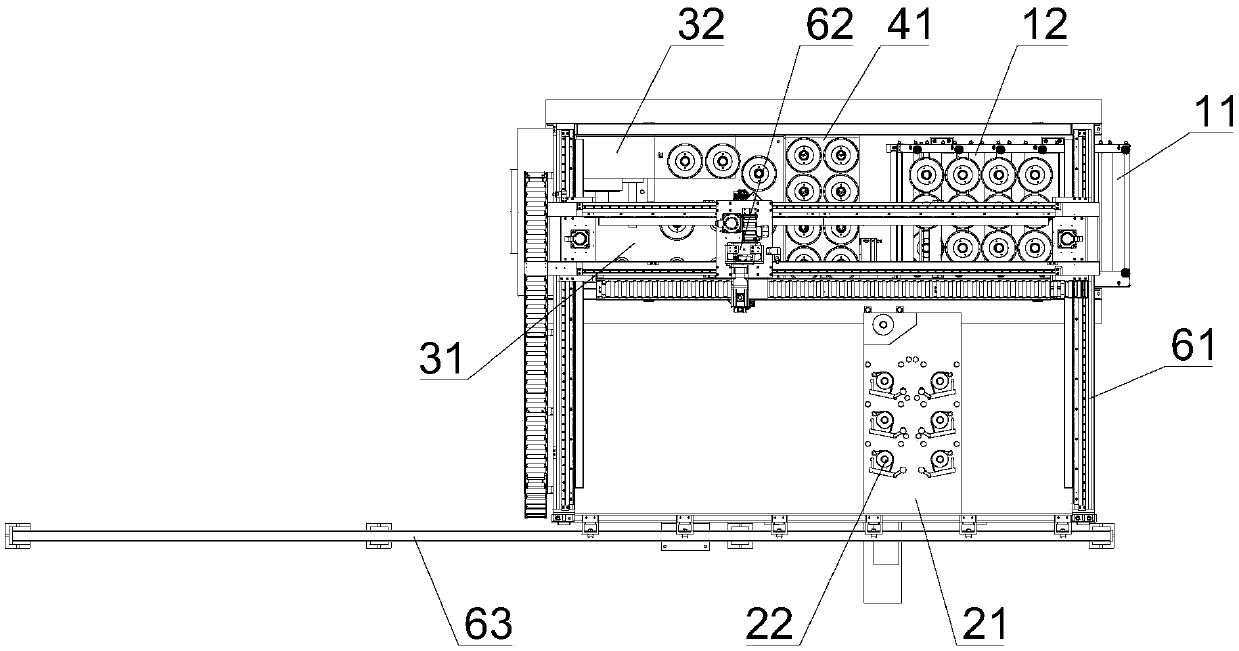

[0029] see Figures 1 to 7 As shown, the present embodiment provides an automatic transfer device for coiled I-shaped wheels, which is mainly used for automatic loading and unloading and handling of I-shaped wheels in the production of steel wire products. Metal wire raw materials for production are wound on the I-shaped wheels. It mainly includes the material area 1 for providing full rolls and recycling empty rolls, the pay-off area for taking the metal wire on the rolls 2, and the wire passing area for removing residual waste wires on the rolls Area 3 and the buffer area 4 for storing the empty I-shaped wheel after removing waste silk, as well as the separation area for abnormal parts, etc., are not subdivided here.

[0030] The conventional production process is, firstly, transfer the fully rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com