Patents

Literature

39results about How to "Automatic and efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

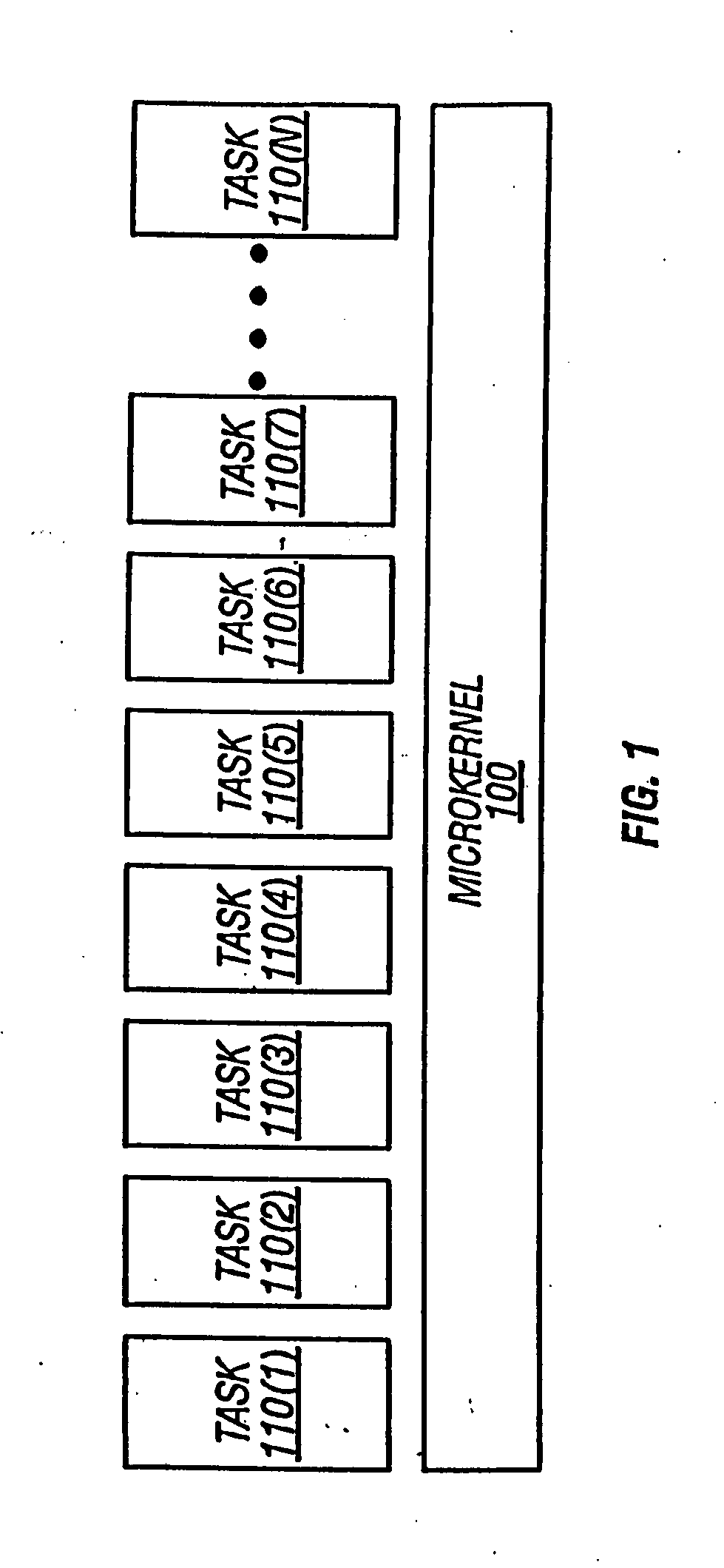

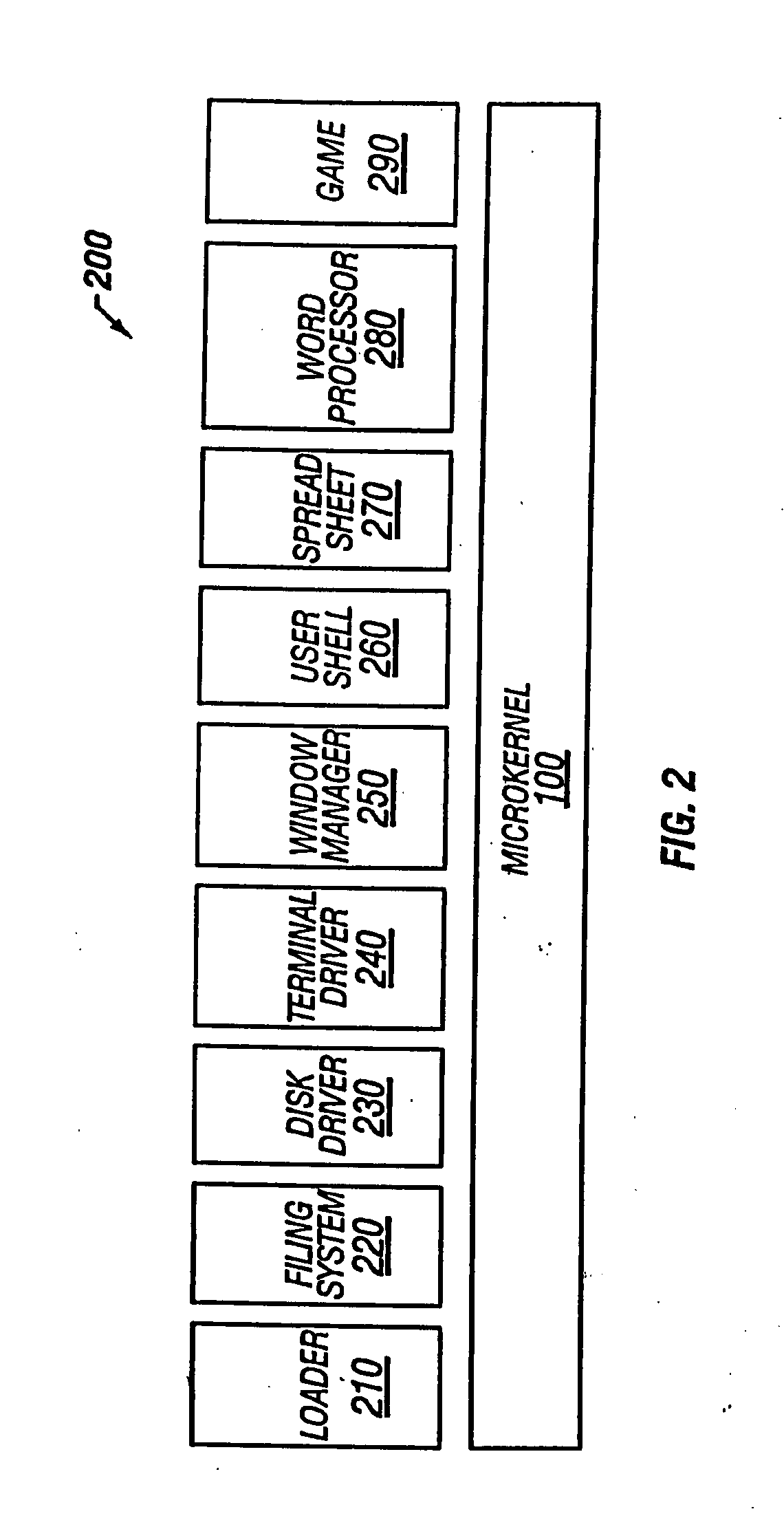

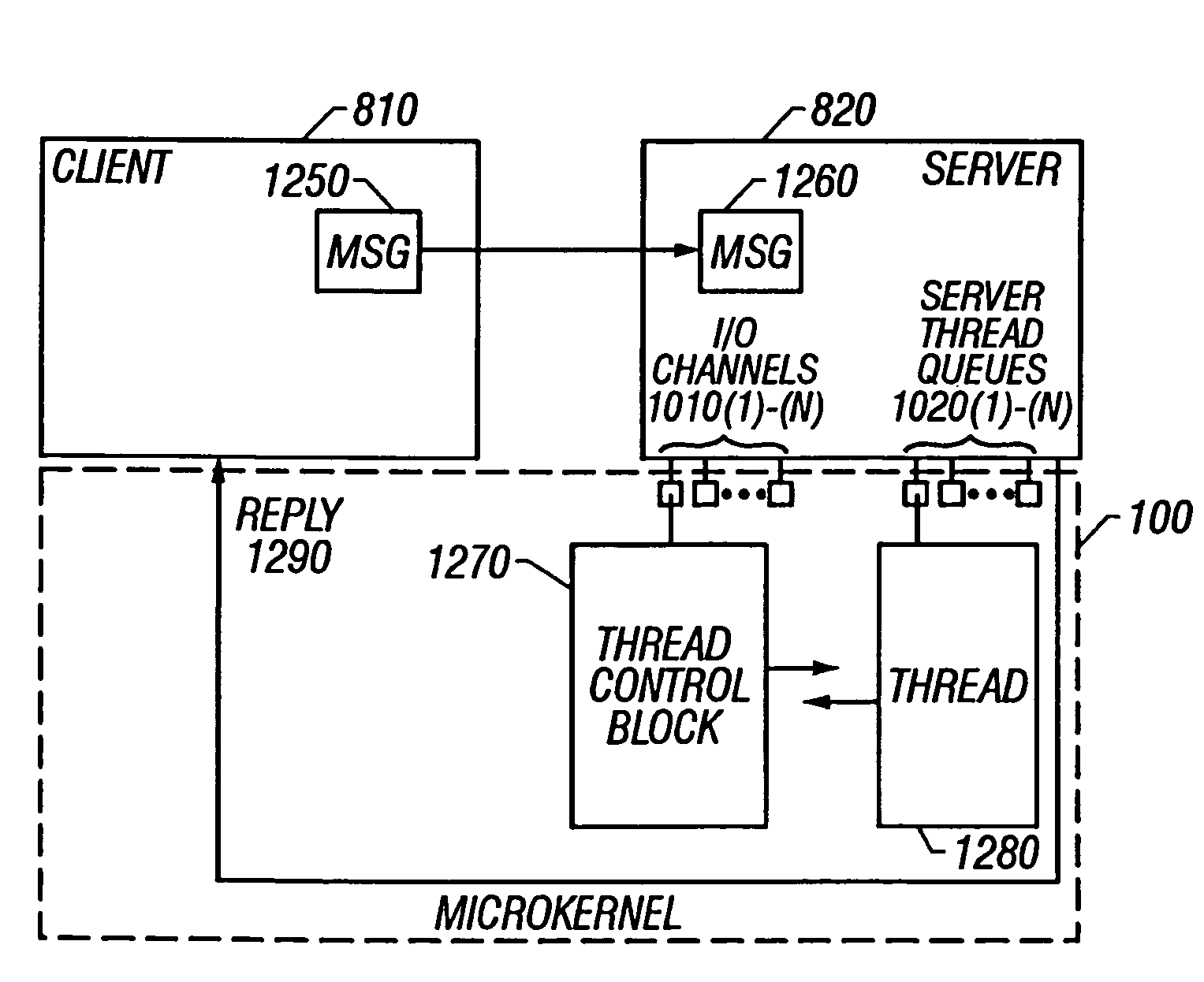

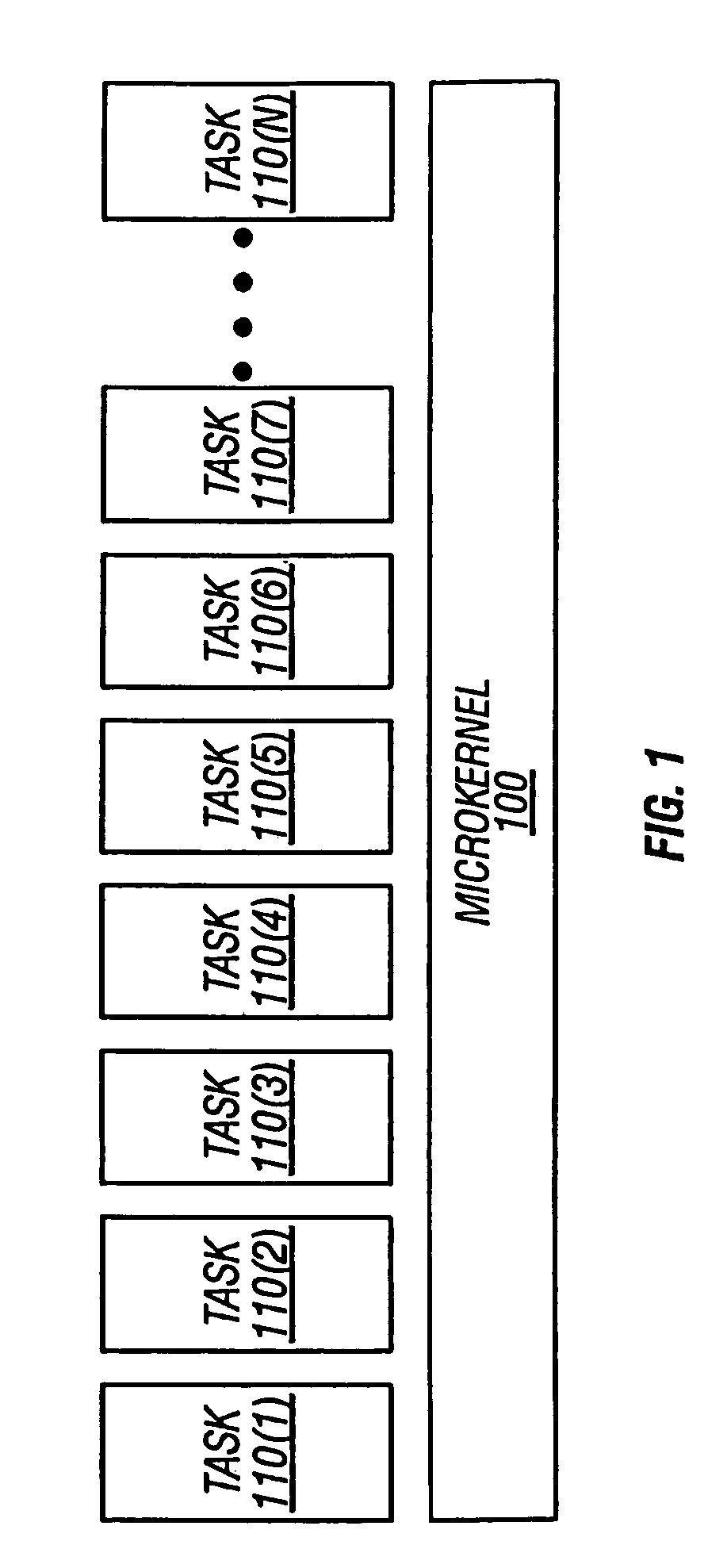

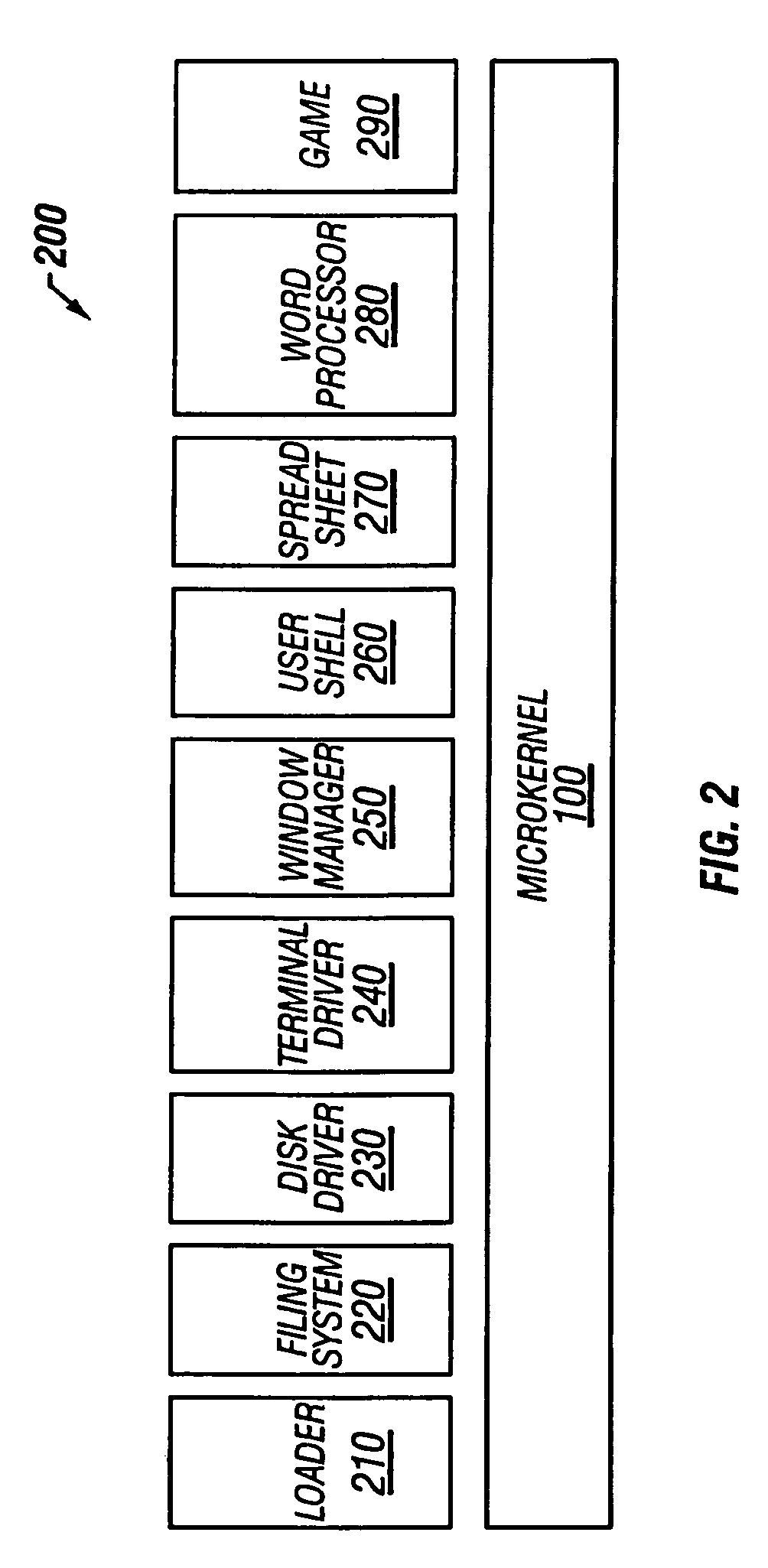

Data structure describing logical data spaces

InactiveUS20070156729A1Automatic and efficientAvoid disadvantagesData processing applicationsDigital data information retrievalData storingData store

Owner:SUN MICROSYSTEMS INC

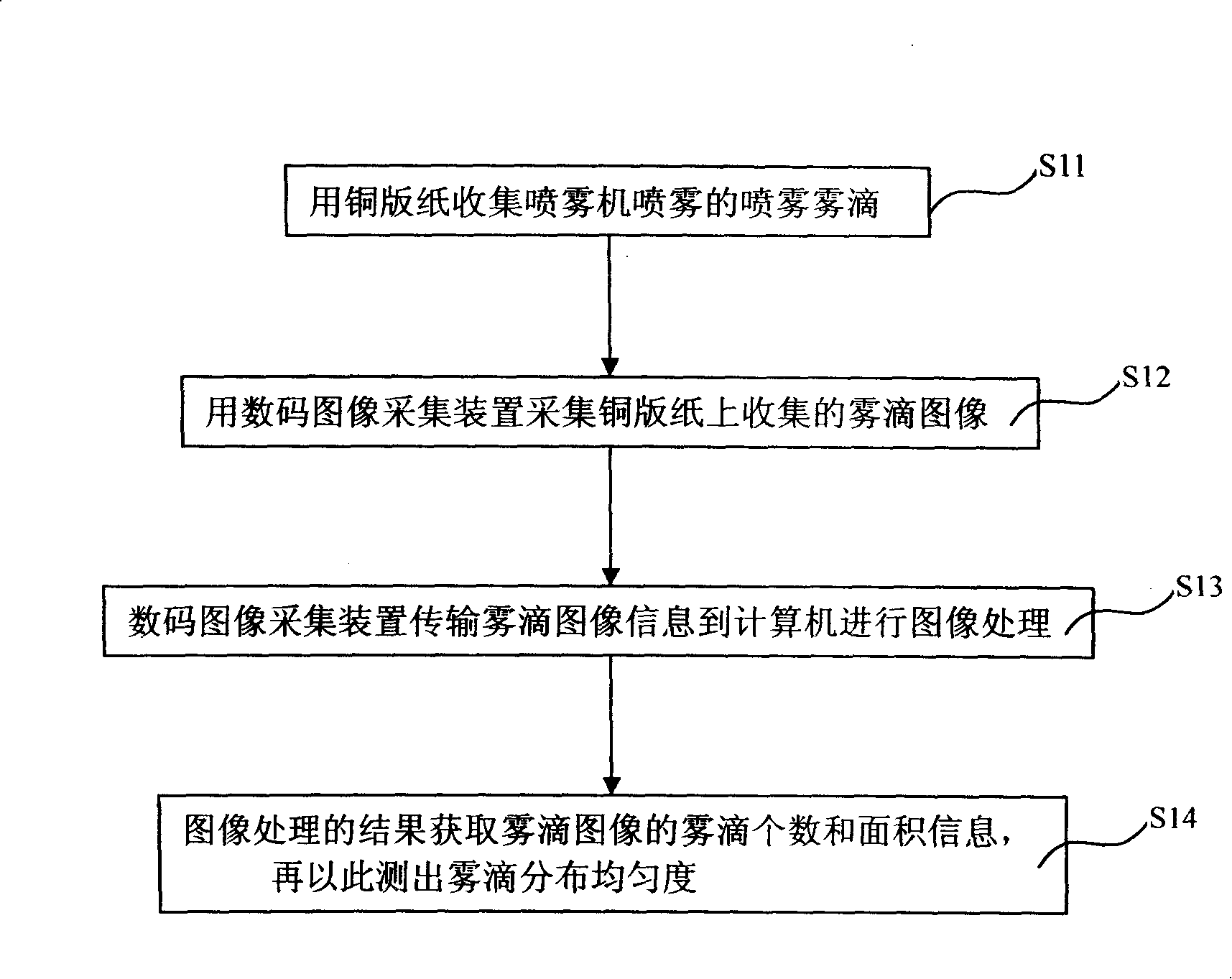

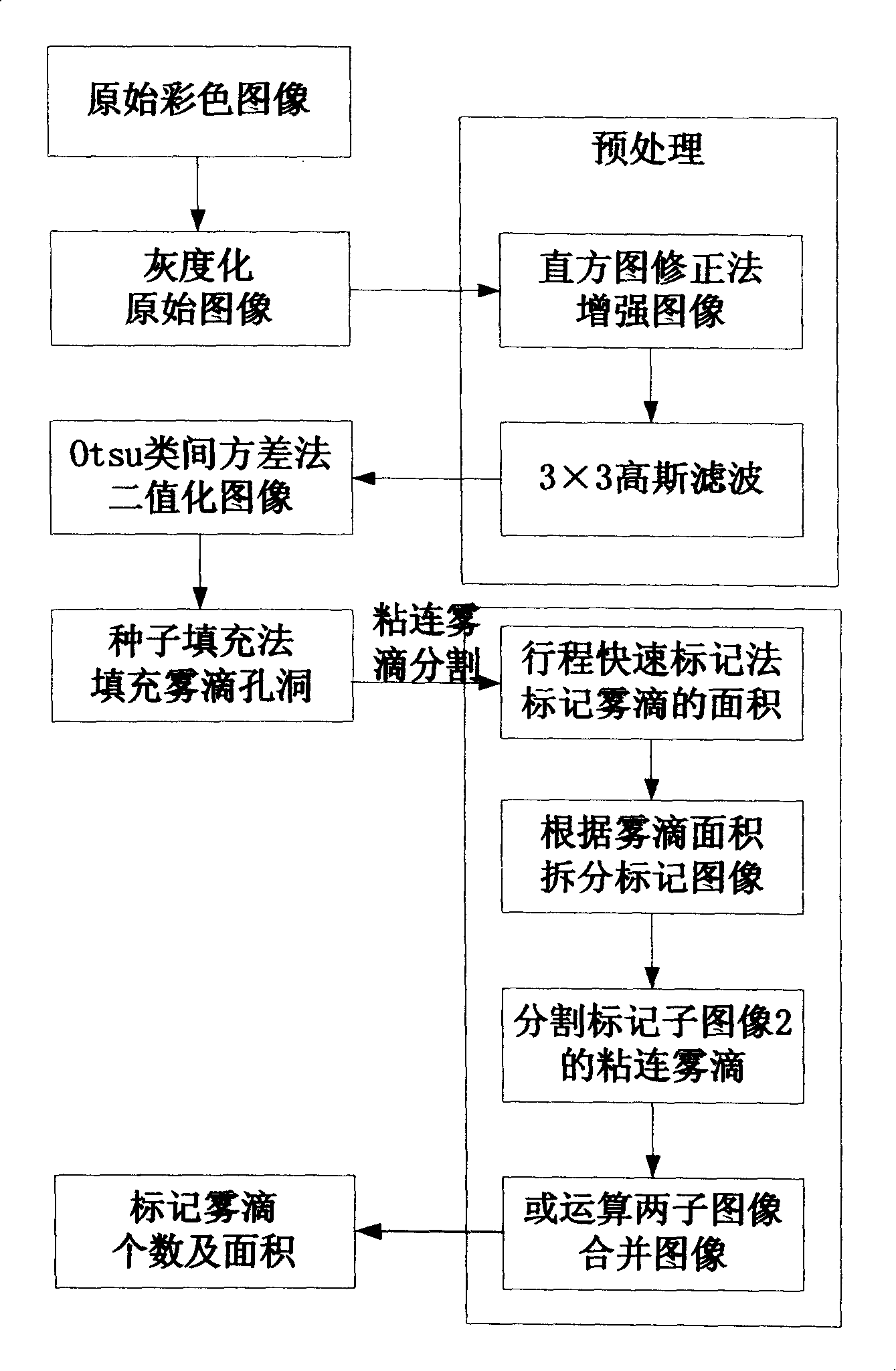

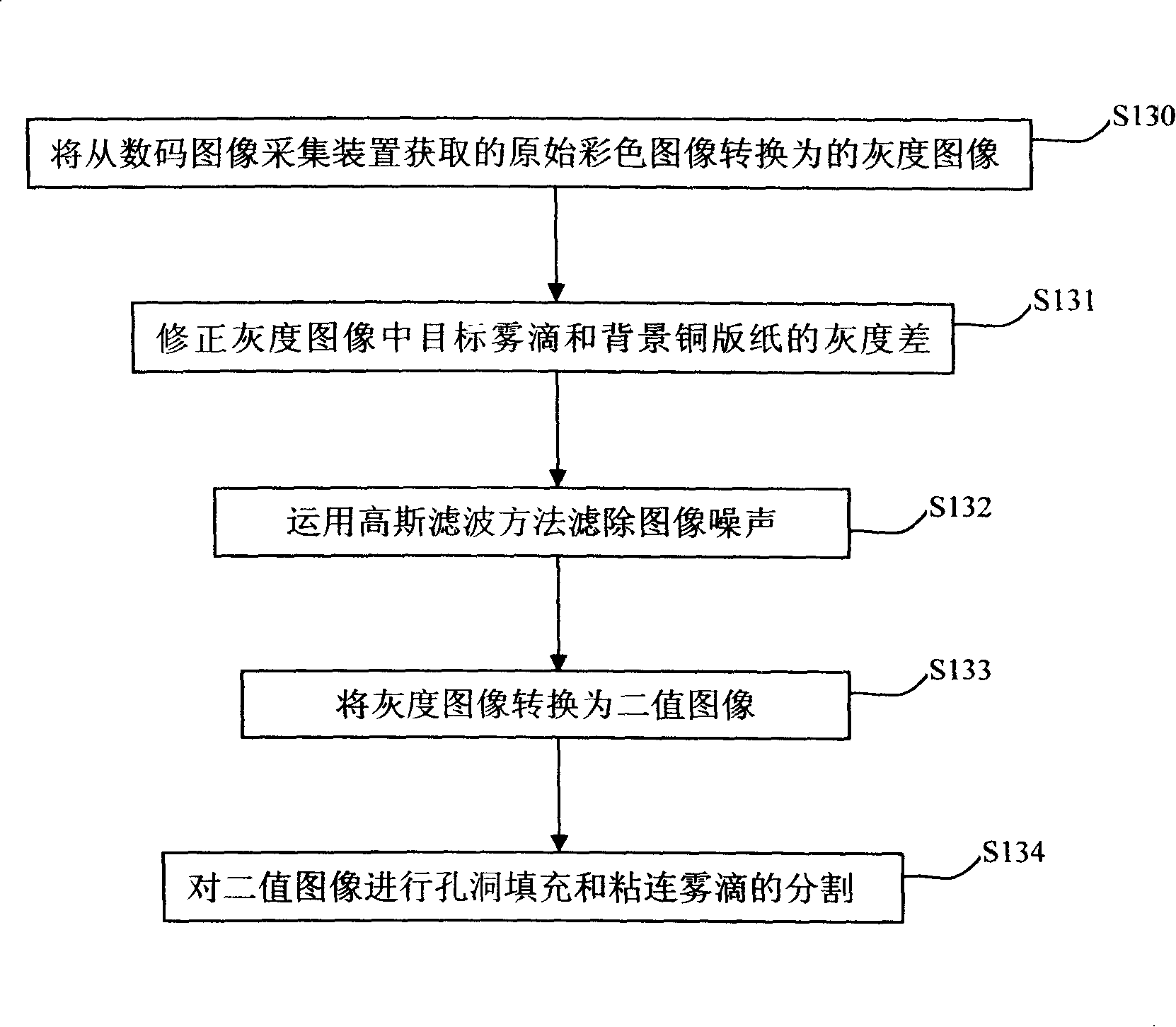

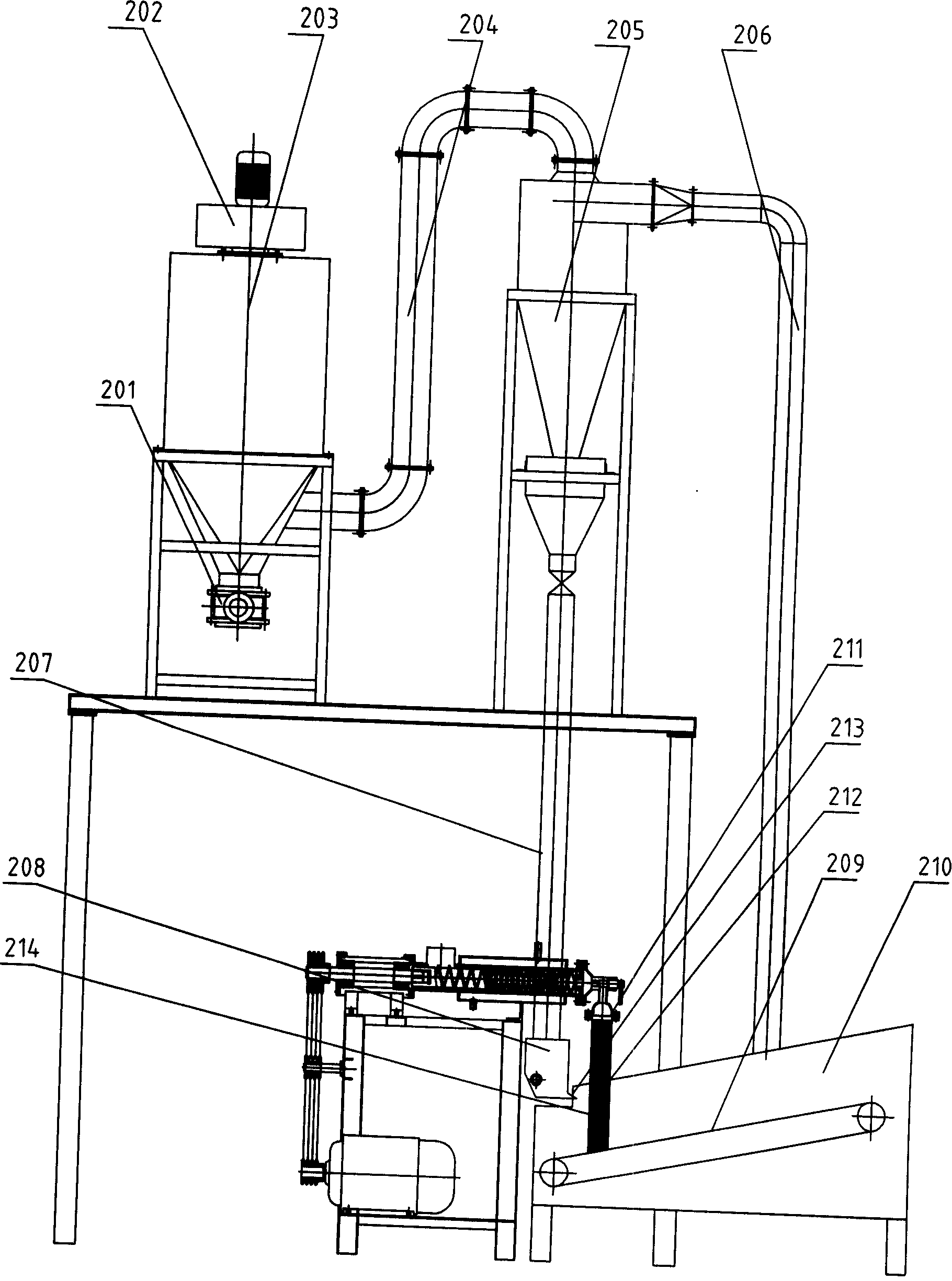

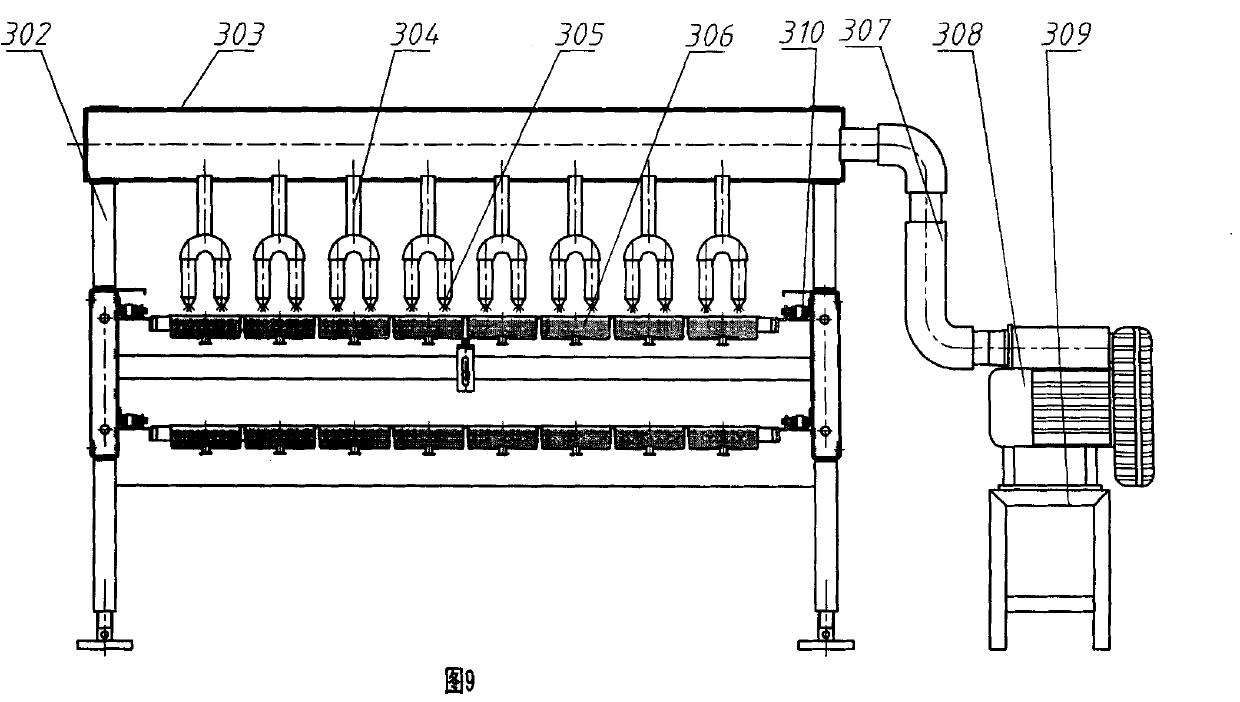

Method for testing droplet distribution consistency degree

ActiveCN101226108AEfficient detectionAutomatic and efficientSurface/boundary effectMaterial analysis by optical meansImaging processingSprayer

The invention discloses a detect method of droplet distribution uniformity, which can detect the droplet uniformity in the spray test of sprayer. The inventive method comprises a spray droplet collecting step for collecting the sprayed droplets of a sprayer, a droplet picture pick-up step for using a digit picture pick-up device to pick up the picture of the collected sprayed droplets, a computer droplet picture information obtaining-processing step that the digit picture pick-up device transmits the droplet picture information to the computer for image processing, and a droplet distribution uniformity information obtaining step for obtaining the droplet number and area information according to the result of the image processing to obtain the droplet distribution uniformity information.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

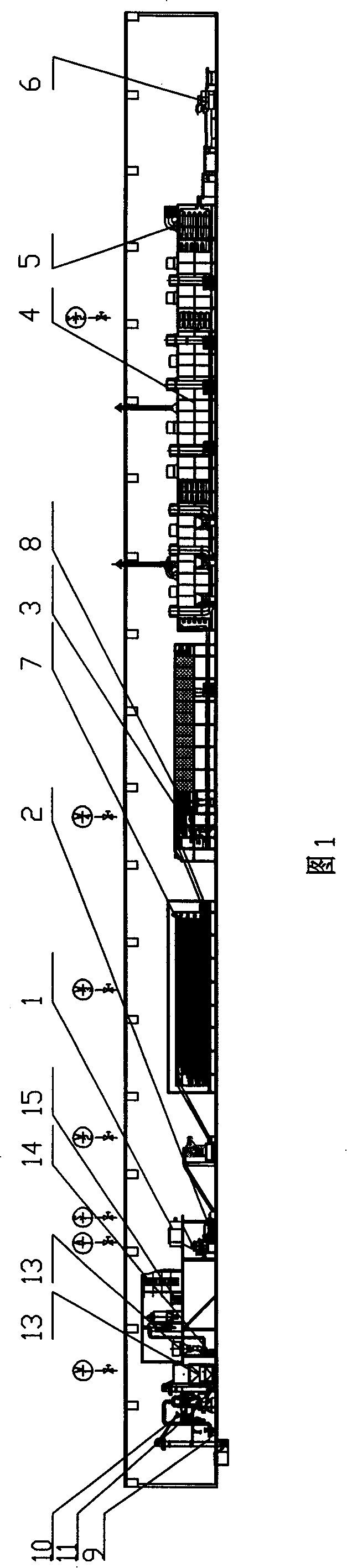

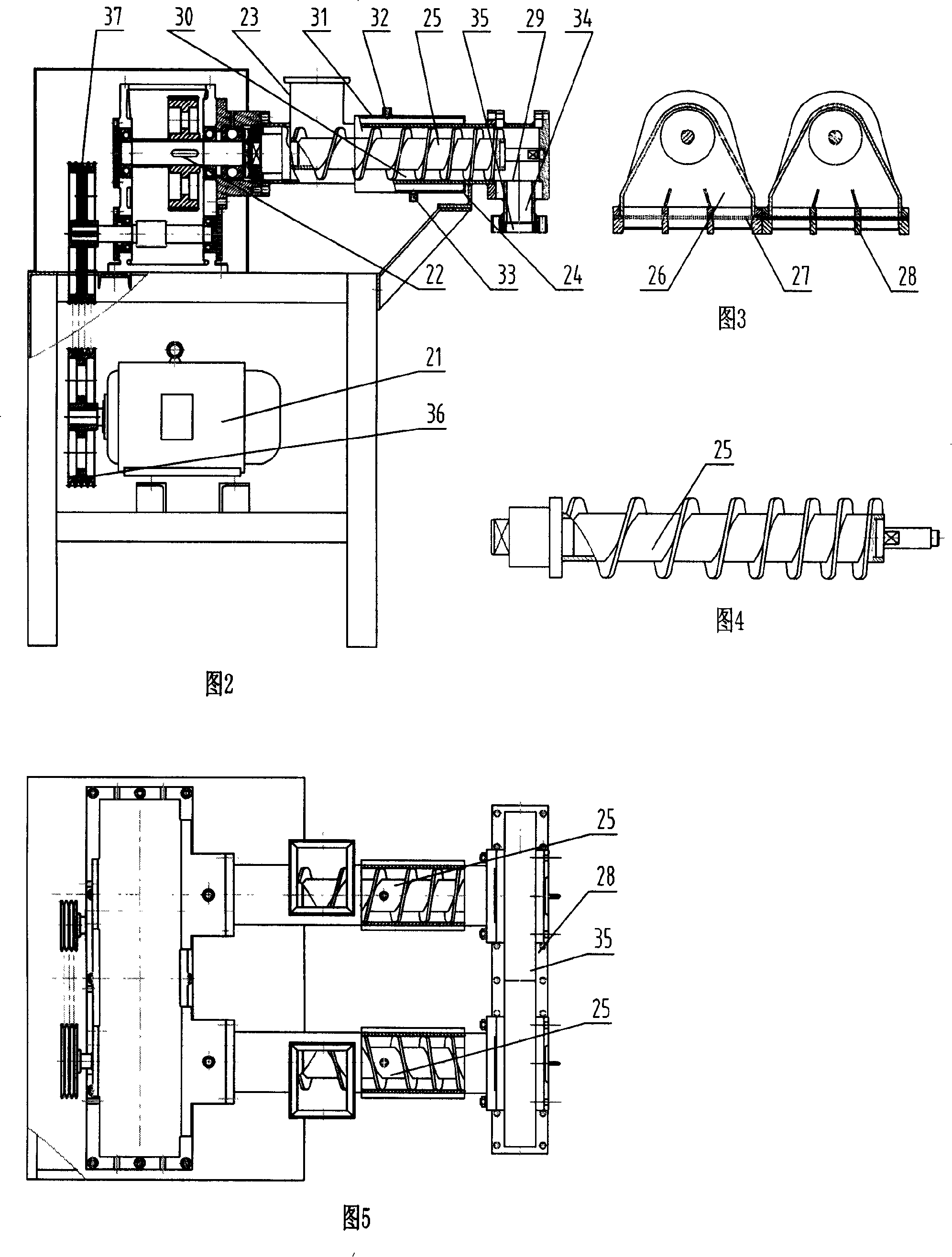

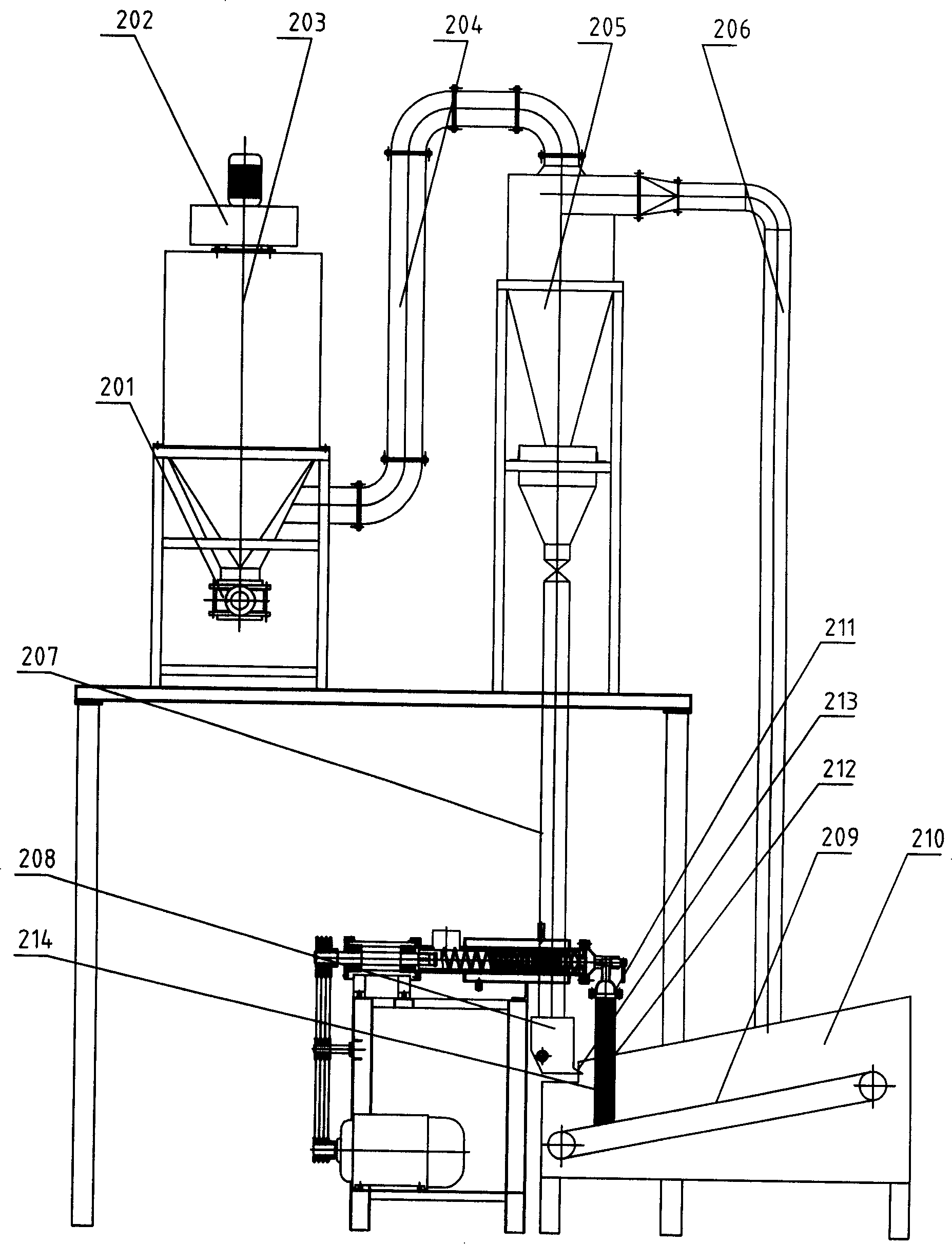

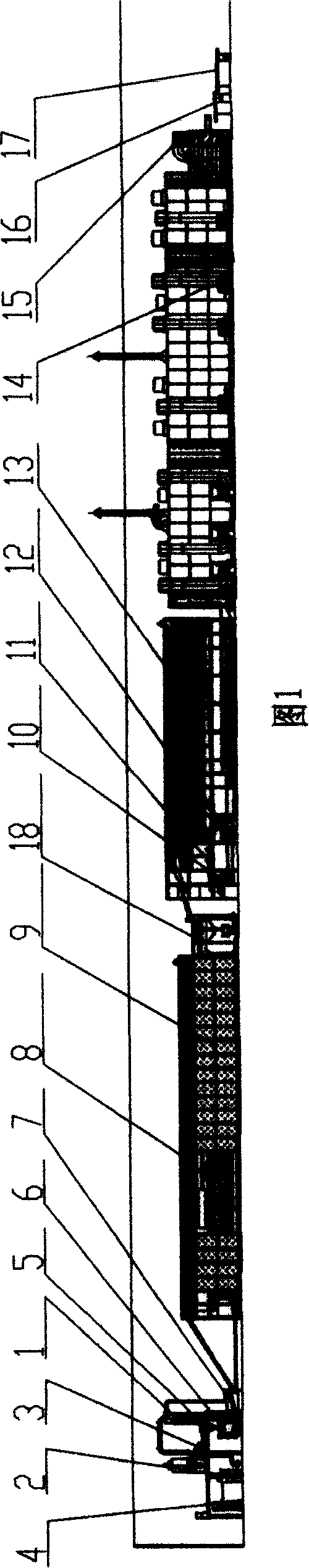

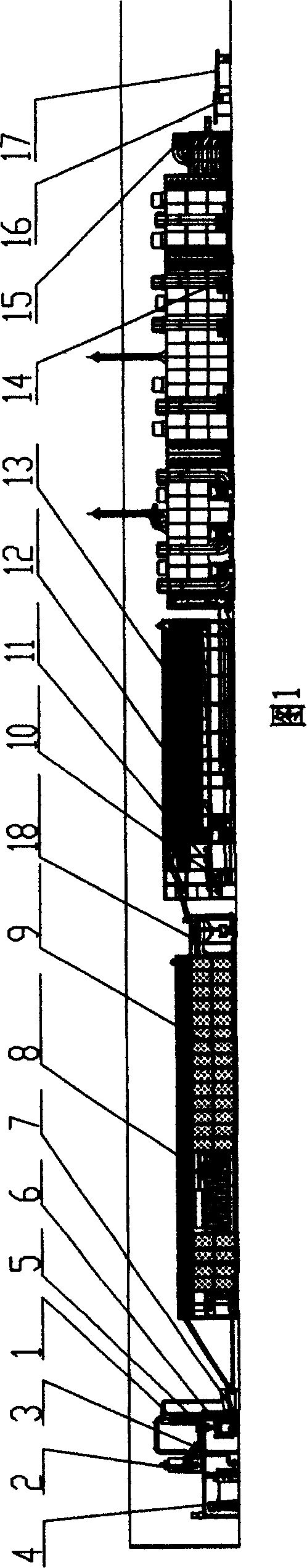

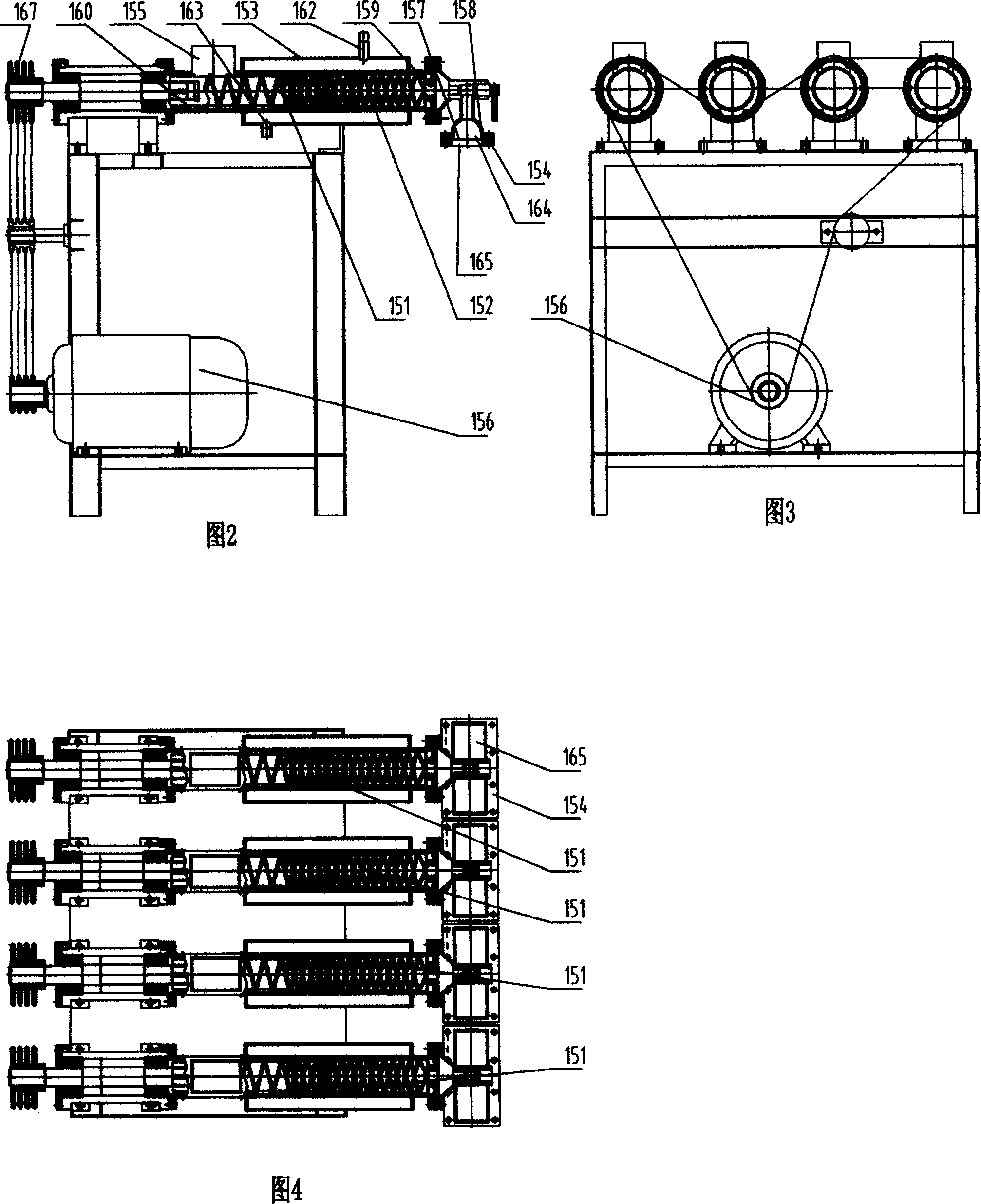

Fully-automatic convenient instant rice flour noodle production line and production technology thereof

InactiveCN101167541AQuality productionGreat tasteSeed preservation by freezing/coolingFood shapingEngineeringFully automatic

The invention relates to a production line of convenient instant rice flour and process technology, wherein the production line of the convenient instant rice flour comprises a rice treatment device, a cooking flour-mixing machine, a self-mature wire-extruding device, an aging device, a quantitative disconnecting device, a boxing shaping device, a powder block drying device, a powder block cooling device, and a packaging conveying device, which are orderly arranged according to the transfer direction of materials. The aging device comprises a rice vermicelli refrigerator, an aging machine and a continuous fluffer. The invention has the advantages of excellent product quality, wide adaptability, high performance, automaticity, low consumption, energy saving, high yield, health and environmental protection.

Owner:广州尧先机械有限公司

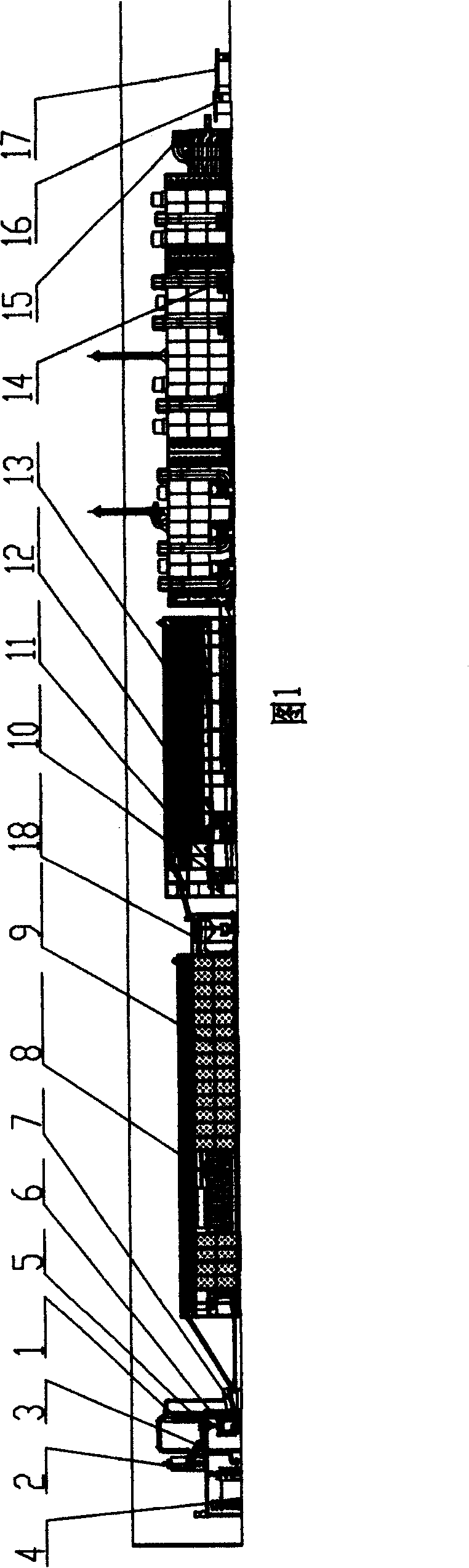

Full automatic production line of convenient and instant rice-flour and production technology thereof

InactiveCN101518311AIncrease production capacitySimple processFood preparationProduction lineMaterial transfer

The invention discloses a production line of convenient and instant rice-flour and a production technology thereof. The production line comprises a rice processing device, a stewing mill, a self-ripe scrooping device, an aging device, a quantitative disconnecting device, an entry-box shaping device, a powder block drying device, a powder block cooling device and a package conveying device which are arranged in sequence in accordance with material transferring direction. The aging device comprises a ricevermicelli refrigerator, an aging machine and a continuous fluffer. The production line and the production technology have the advantages of good product quality, broad suitability, high efficiency and automation, lower energy consumption, high yield, hygiene and environment protection.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

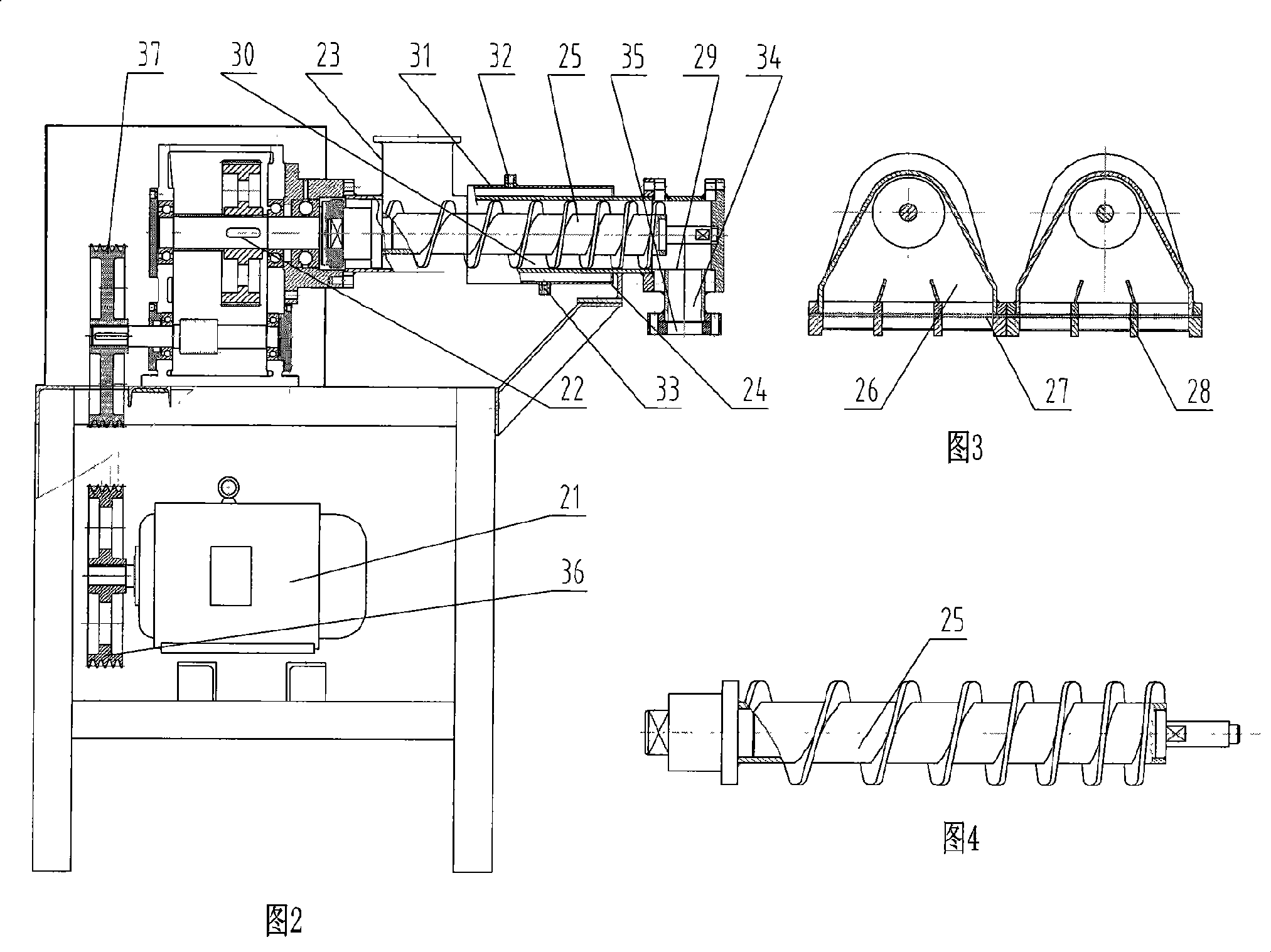

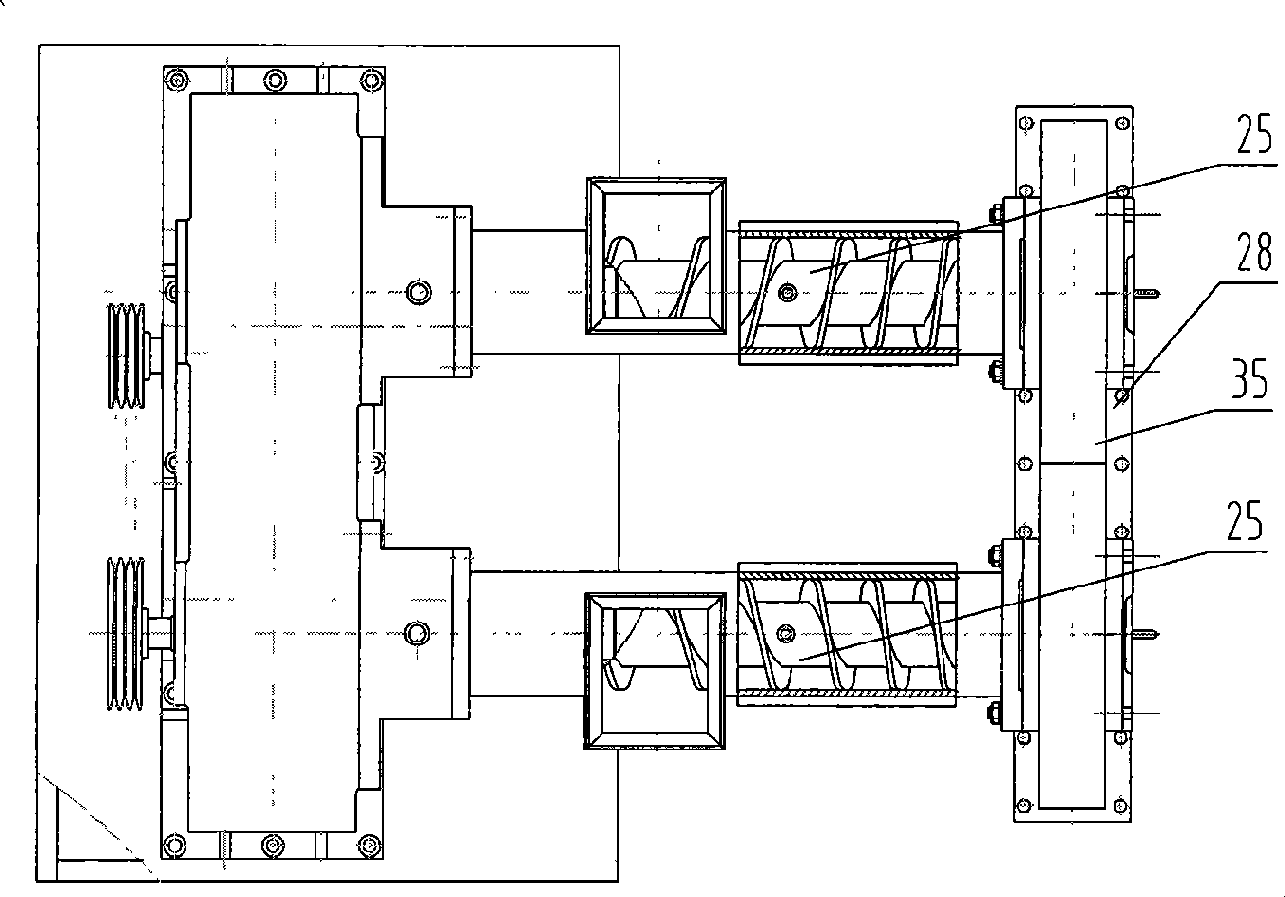

Fully automatic convenient vermicelli production line and its producing technology

InactiveCN101167599AIncrease production capacitySimple processFood shapingFood preparationFlavorProduction line

The invention relates to a full-automatic instant vermicelli production line, and comprises a starch agitating device, a self-curing scroop machine which can produce instant vermicelli only by one time curing, a time-effect aging device, a washing fluffer device, a quantitative cutting device, a powder agglomate drying device, a powder agglomate cooling device, and a package conveying device which are all sequentially arranged along the direction of transmitting materials. The time-effect aging device comprises a first natural time-effect aging machine, a vermicelli refrigerating machine, a washing fluffer machine, and a washing bean jelly machine for the secondary natural time-effect aging. The producing process sequentially comprises the starch agitating, the self-curing scroop, the time-effect aging, the quantitative cutting, the powder agglomate drying, the powder agglomate cooling, and the package conveying, and also comprises the merely primary self-curing scroop. The time-effect aging comprises the first natural time-effect aging, the vermicelli refrigerating, the washing fluffer, and the secondary natural time-effect aging which can lead the self-curing scroop machine which can produce instant vermicelli only by one time curing to extrude the vermicelli, and the vermicelli is not adhesive. The instant vermicelli cannot become burnt when the instant vermicelli is placed in the boiled water, and the flavor is good.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

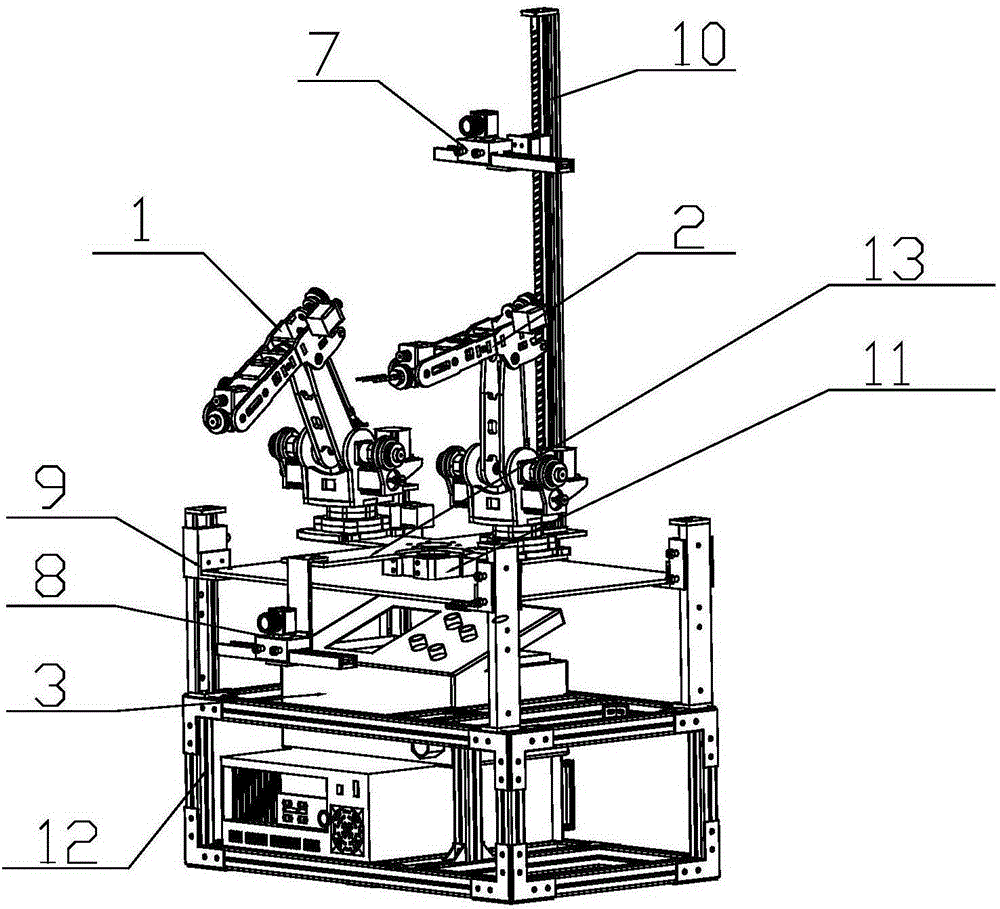

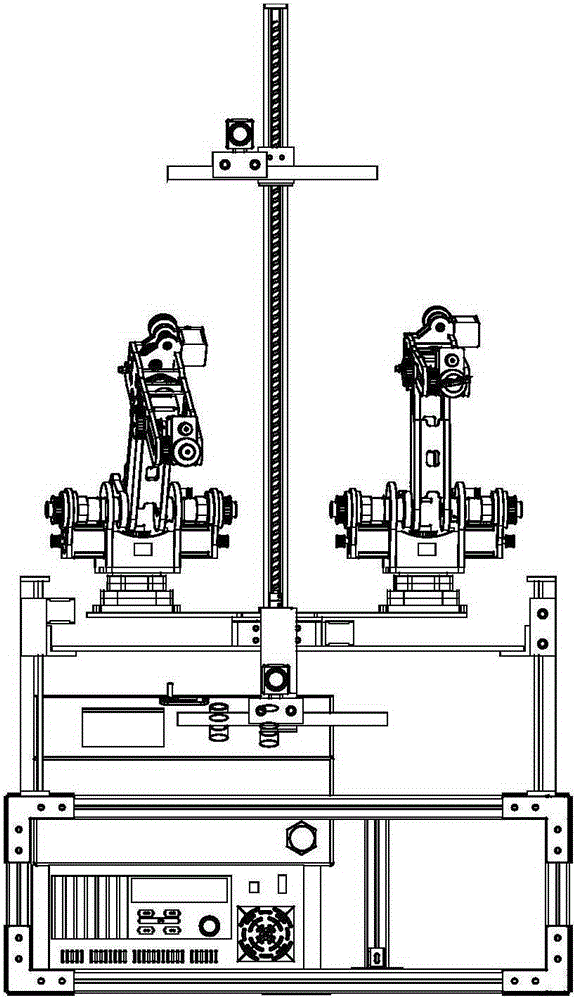

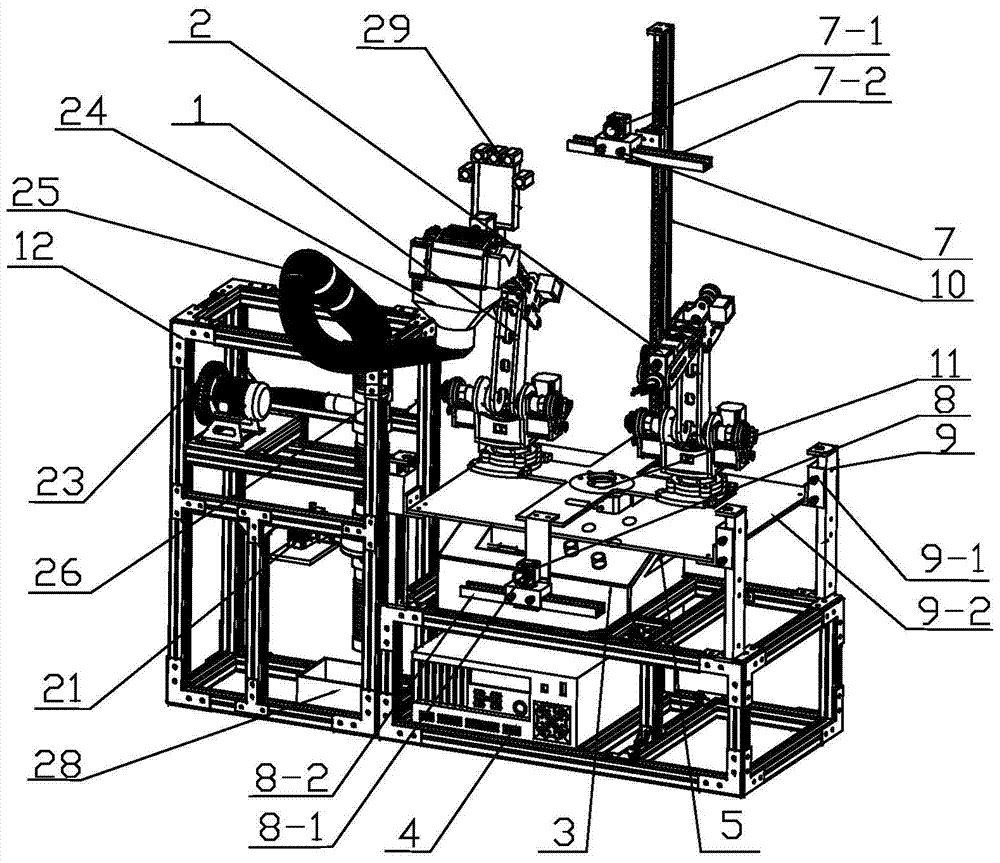

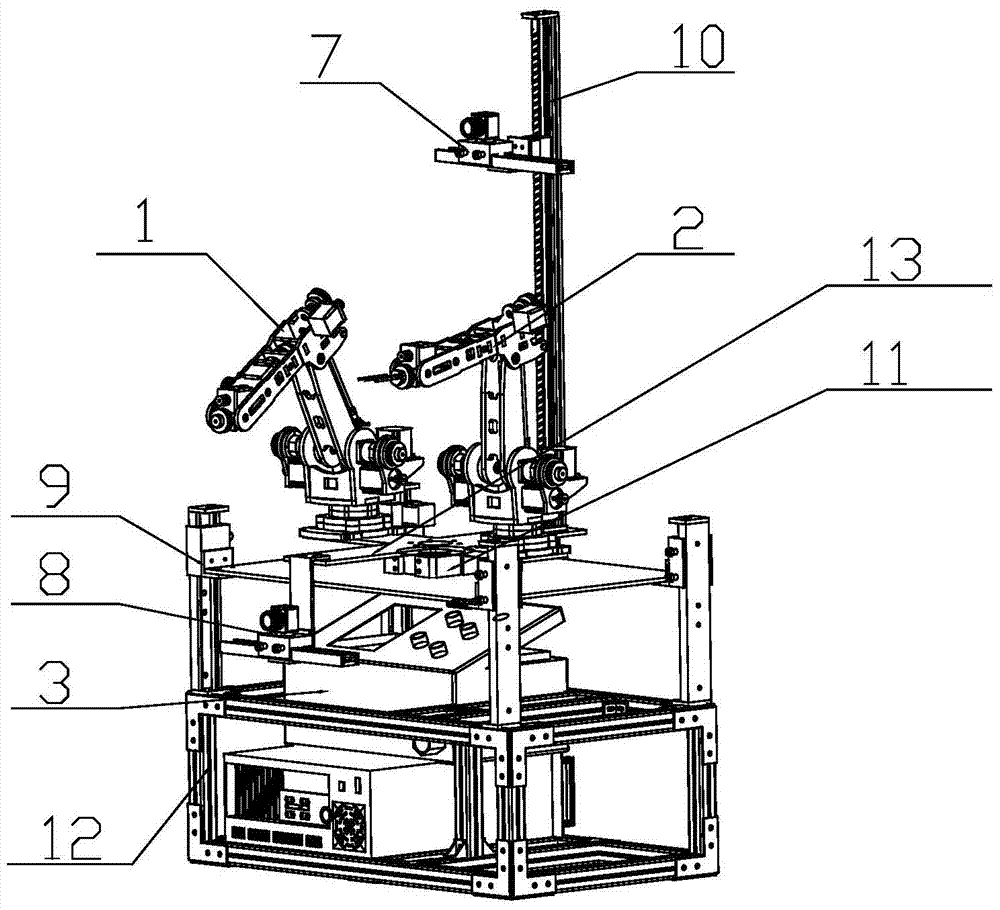

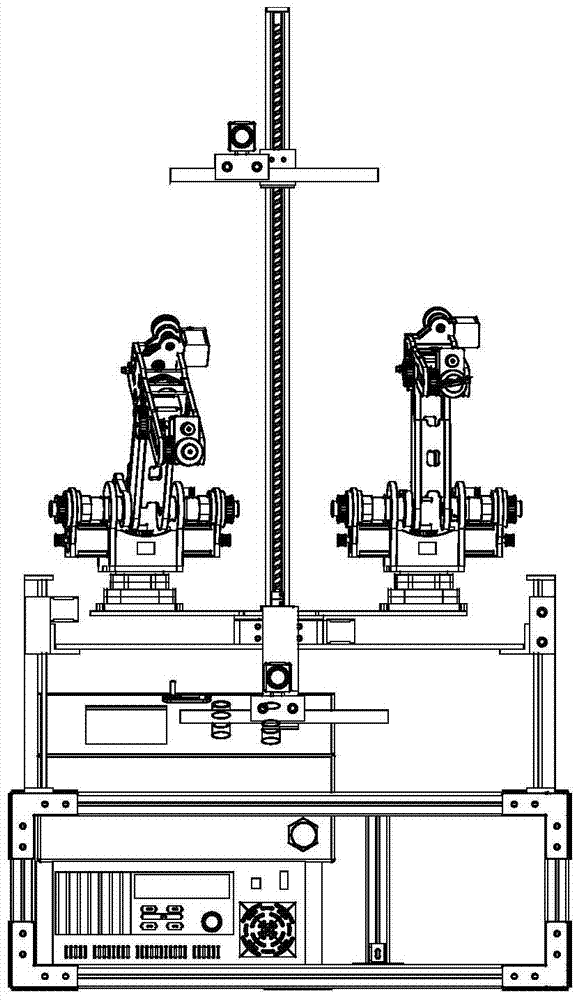

Intelligent recognition medlar picking device

InactiveCN105309131AGuaranteed timely harvestQuality assurancePicking devicesControl systemManipulator

The invention provides an intelligent recognition medlar picking device provided with a distributed machine vision system for solving the problems existing in the prior art. The medlar picking device comprises a rack, a power source system, a control system, a driving system, the machine vision system, a medlar picking mechanical hand, a branch positioning mechanical hand, a medlar picking head and a fruit collecting device, wherein the power source system, the control system, the driving system, the machine vision system, the medlar picking mechanical hand, the branch positioning mechanical hand, the medlar picking head and the fruit collecting device are arranged on the rack. The control system is connected with the machine vision system, the medlar picking mechanical hand, the branch positioning mechanical hand, the medlar picking head and the fruit collecting device through the driving system. The invention further provides a medlar picking method based on the intelligent recognition medlar picking device. The medlar picking device automatically and efficiently collects medlar fruits, solves the problems that the medlar fruits are prone to breakage in the harvesting process, and the picking device is prone to be blocked by leaves, greatly reduces production cost and has good practical application prospects.

Owner:QINGDAO AGRI UNIV +1

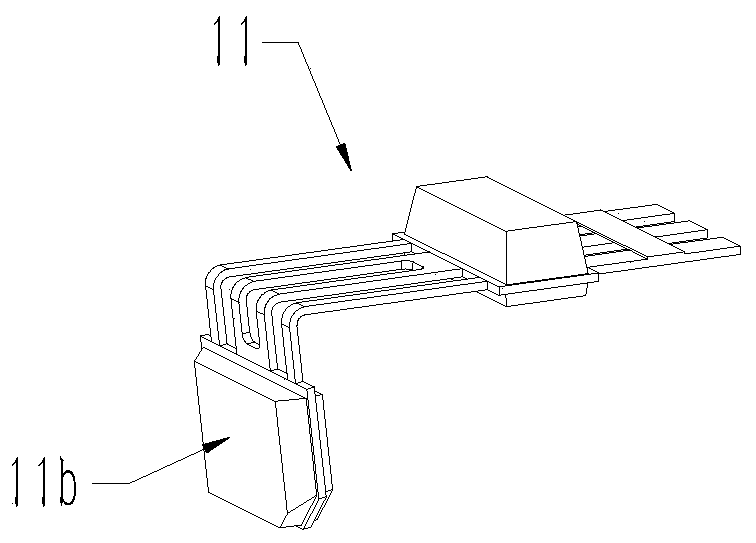

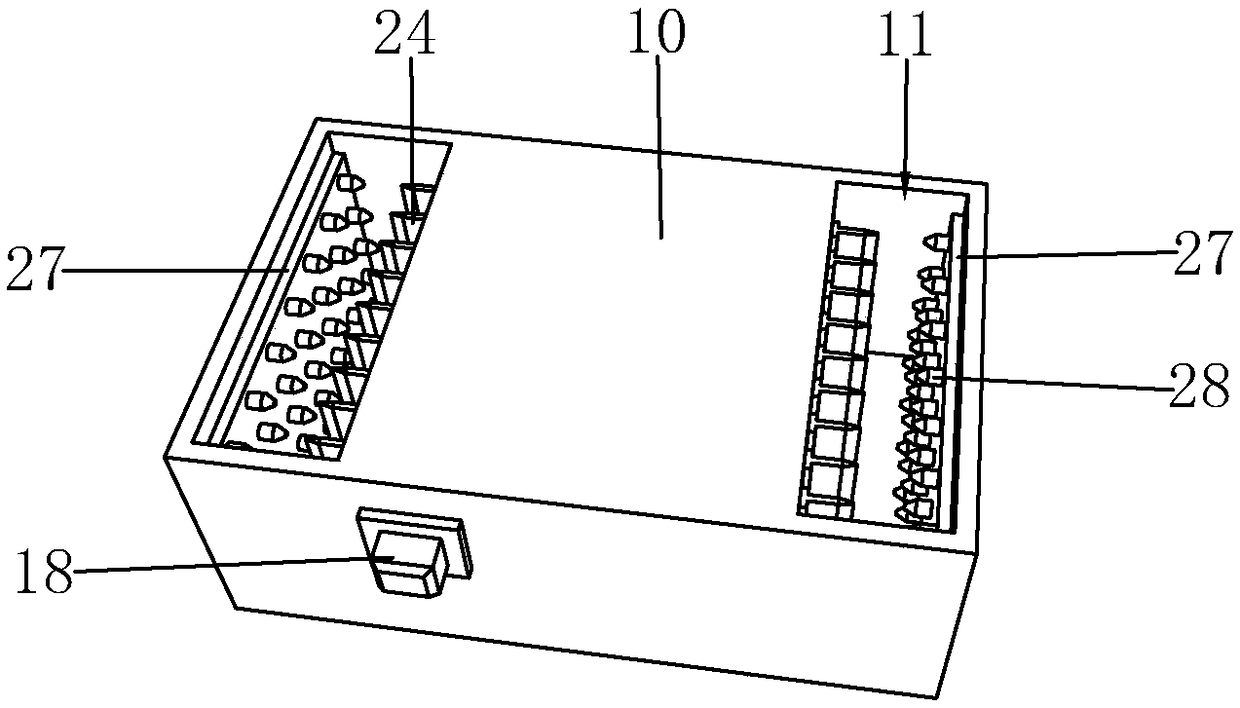

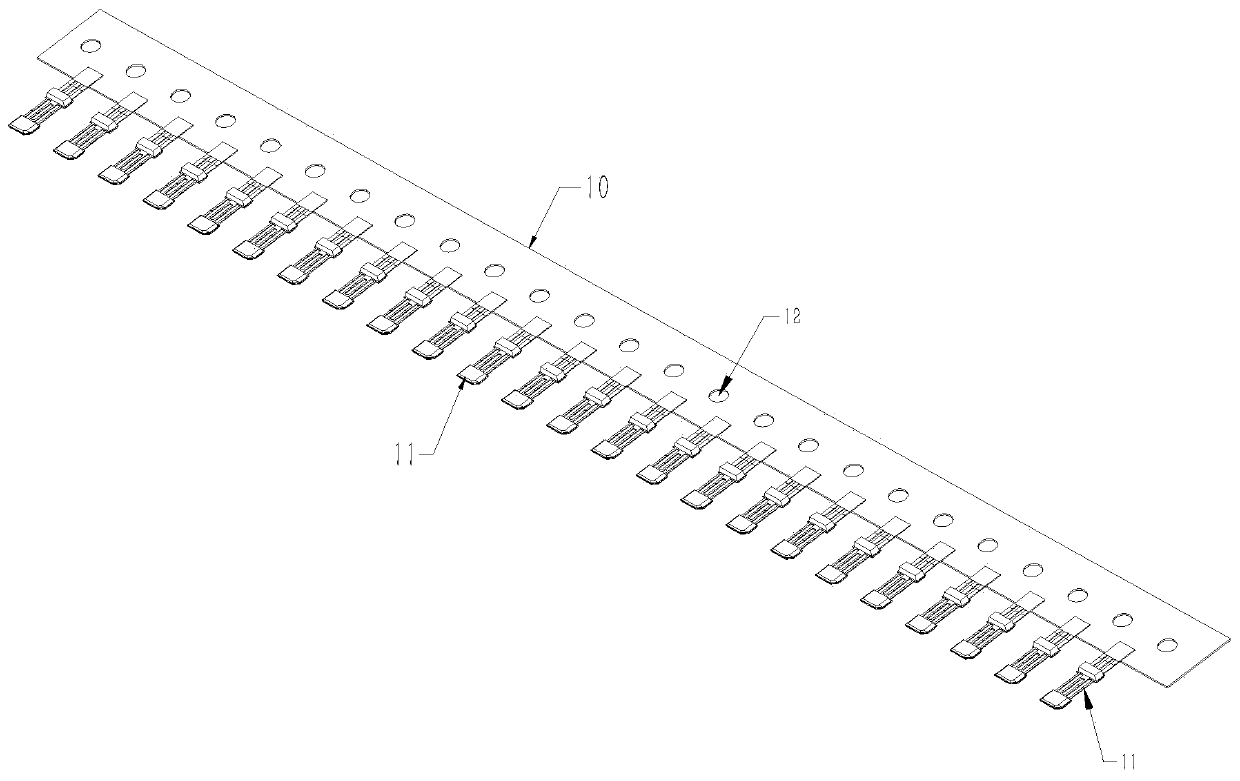

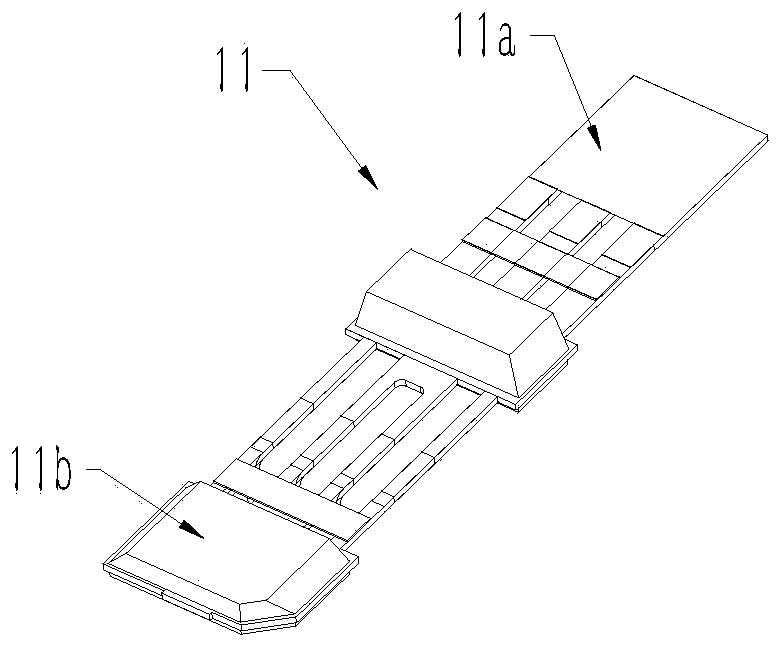

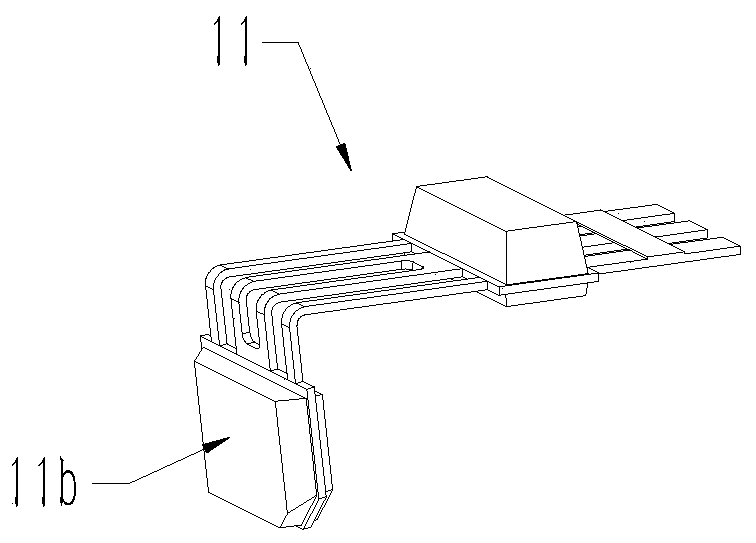

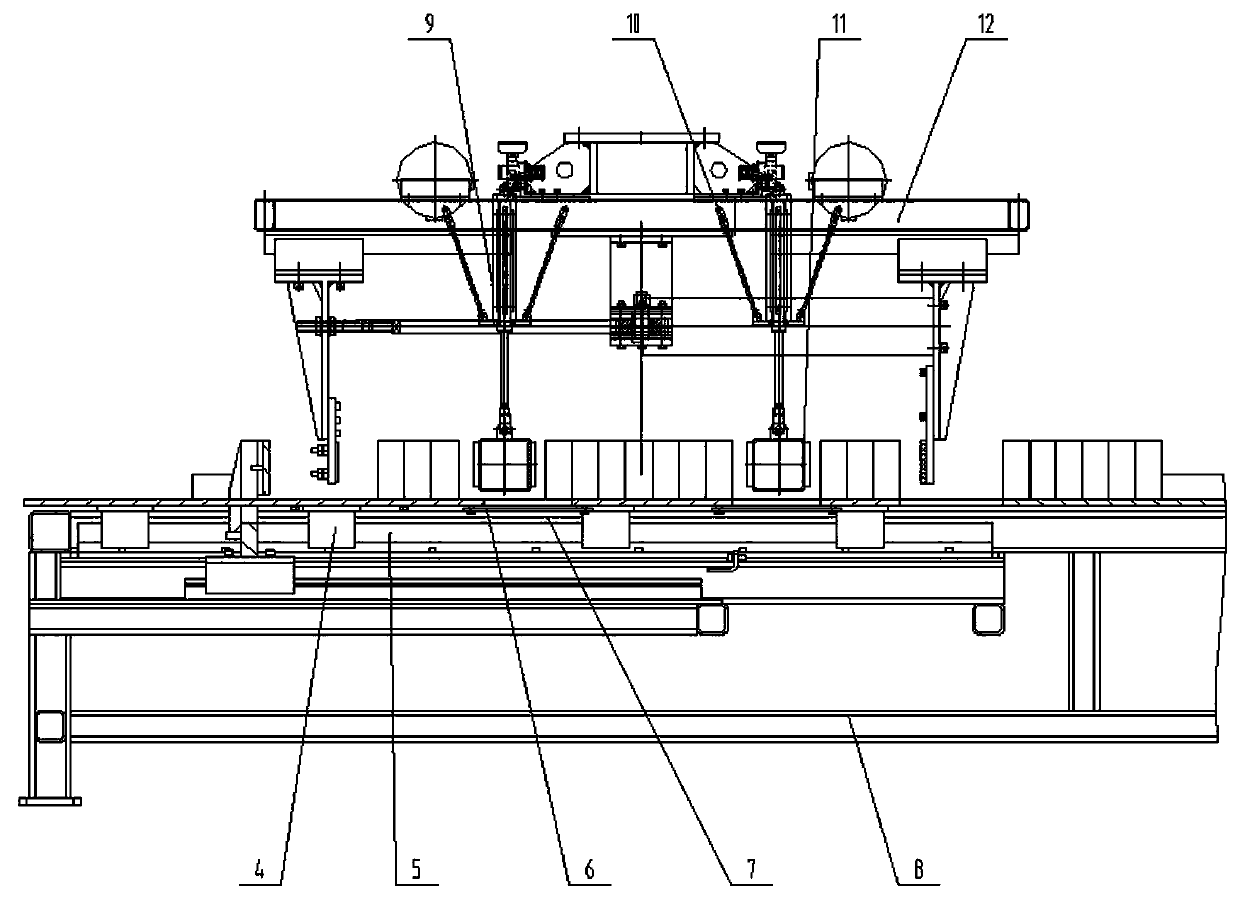

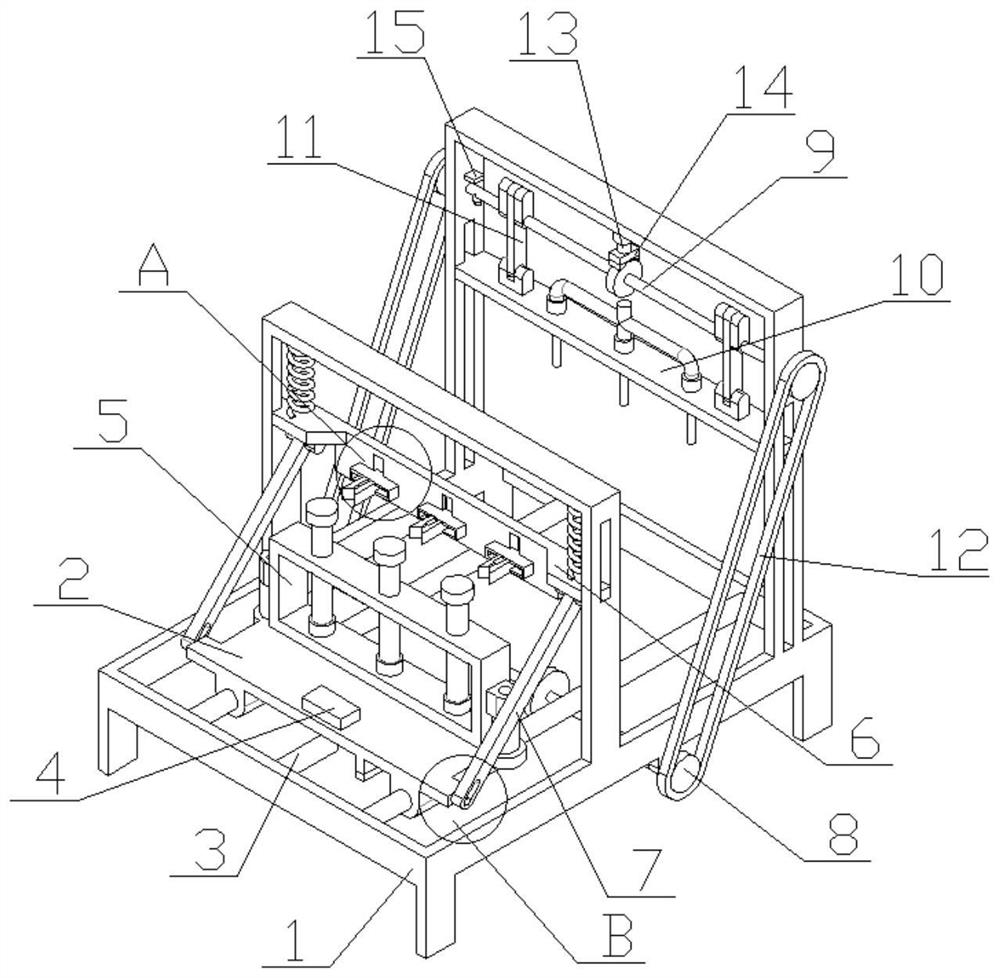

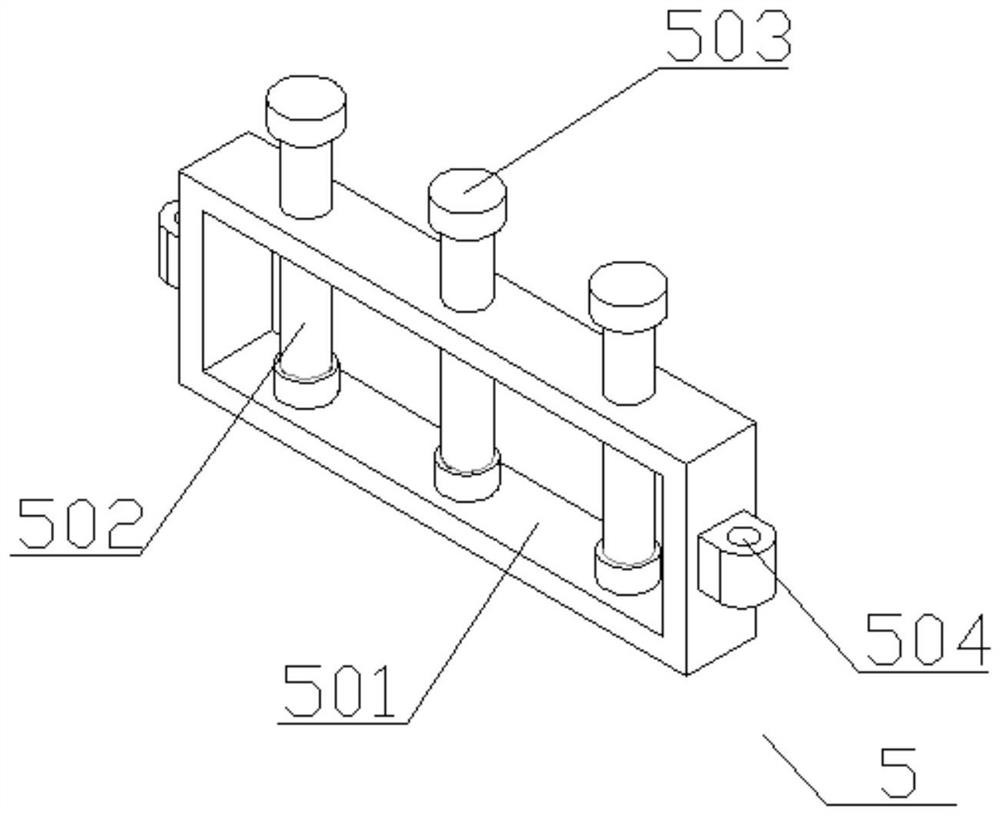

Automatic pin-shearing bending device

The invention discloses an automatic pin-shearing bending device. The automatic pin-shearing bending device includes a coil stock feeding platform arranged on a working table, a coil stock feeding power assembly, a single integrated circuit (IC) chip cutting assembly, a clamping jaw air cylinder assembly, a pin-shearing bending positioning assembly, a pin-shearing assembly and a bending assembly,the coil stock feeding power assembly and the single IC chip cutting assembly are both arranged on the upper part of the coil stock feeding platform, the coil stock feeding power assembly is used forallowing coil stocks to move towards a positioning platform, the single IC chip cutting assembly is used for cutting single IC chips on the coil stocks, the pin-shearing assembly and the bending assembly are arranged at the two ends above the positioning platform correspondingly, the clamping jaw air cylinder assembly is used for grabbing the cut single IC chips onto the positioning platform, thepin-shearing bending positioning assembly positions the cut single IC chips, and the pin-shearing assembly and the bending assembly shear and bend the two ends of the single IC chips correspondingly.The automatic pin-shearing bending device can realize the length of pins of the IC chips on a large scale quickly according to the actual use needs.

Owner:苏州英维特精密机械有限公司

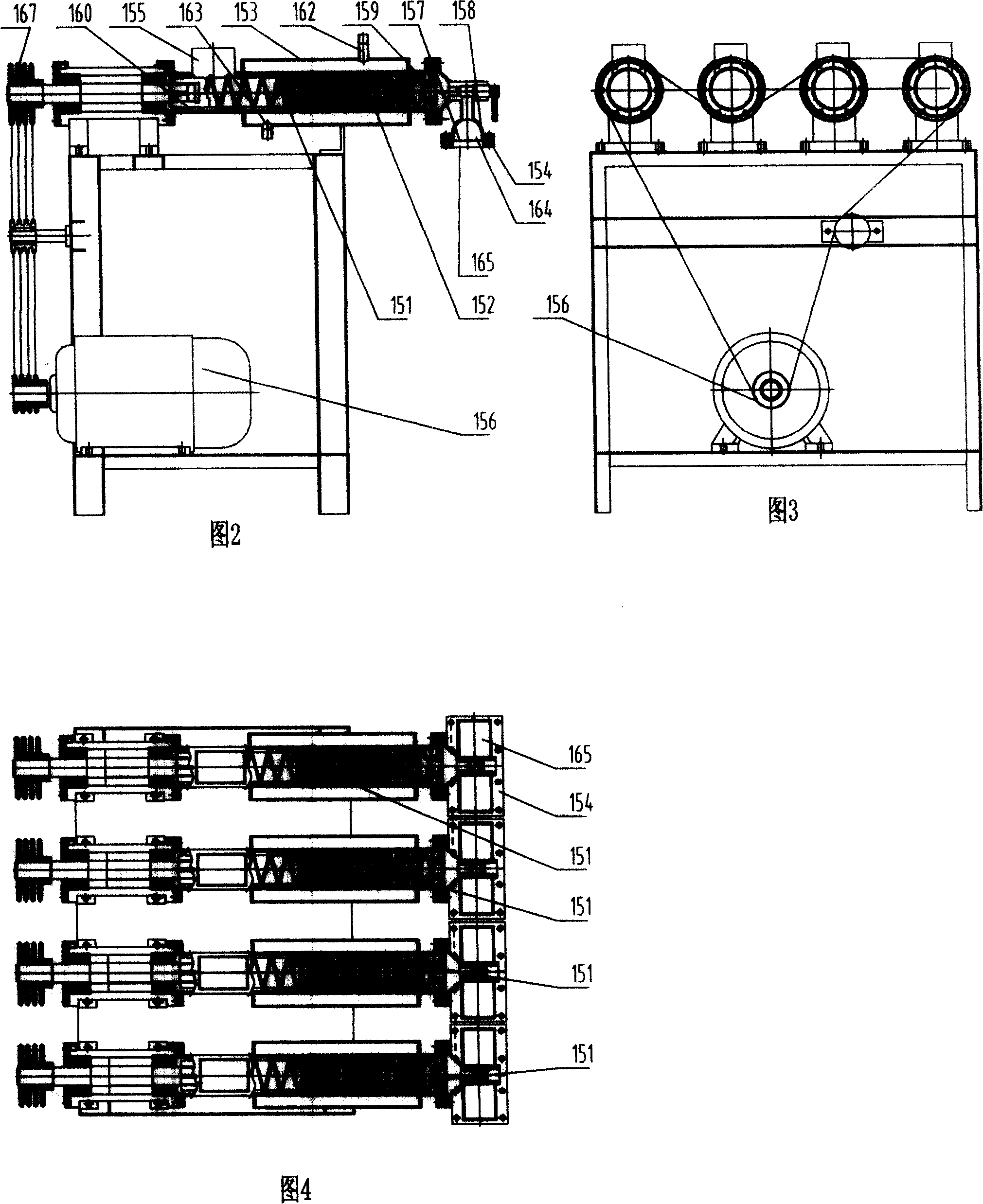

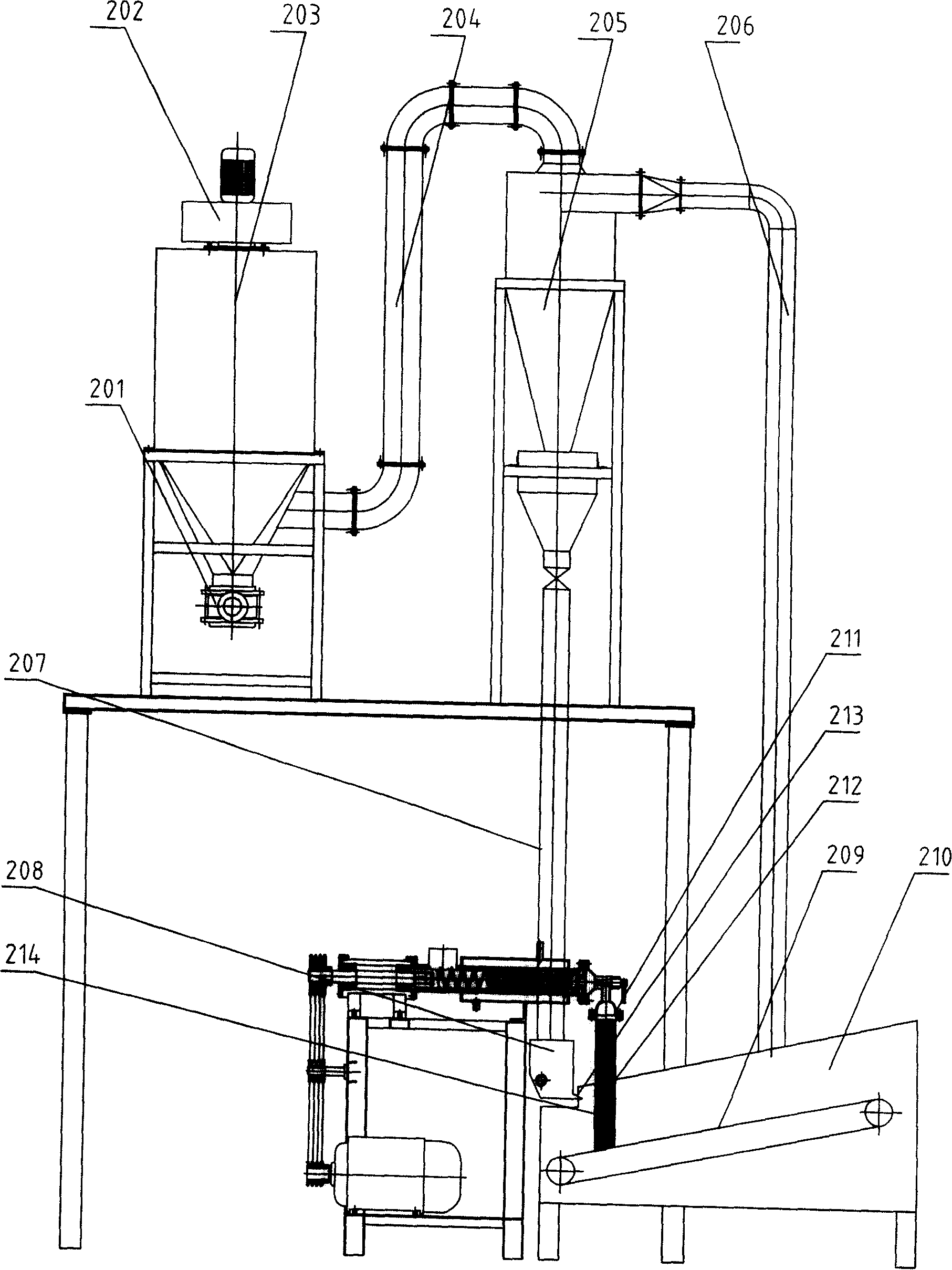

Fully-automatic convenient vermicelli production line and production technology

InactiveCN101167485AQuality productionGreat tasteDough mixing/kneading machinesDough extruding machinesFully automaticSelf curing

An instant bean vermicelli production line comprises a starch stirring device, a self-curing vermicelli extruding device, an ageing effect aging device, a water scrubbing vermicelli loosing device, a quantitative shearing device, a flour agglomerate drying device, a flour agglomerate cooling device and a packing transporting device which are sequentially arranged according to material conveying direction. An antisticking machine is further arranged between the self-curing vermicelli extruding device and a first natural ageing machine, comprising a flour applying chamber, a flour applying device, an air-supply arrangement and a flour retracting device. An instant bean vermicelli manufacturing technique sequentially comprises starch stirring, self-curing vermicelli extruding, ageing effect aging, quantitative shearing, flour agglomerate drying, flour agglomerate cooling and packing transporting. Bean vermicelli antisticking is carried through between the self-curing vermicelli extruding and the ageing effect aging, and the bean vermicelli antisticking process comprises the air-supply arrangement for supplying air to the flour spouting device which spouts flour to the bean vermicelli under the function of wind from the air-supply arrangement. The instant bean vermicelli production line of the invention has the advantages of great antisticking effect and capability of meeting antisticking requirement of bean vermicelli with different proportion.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

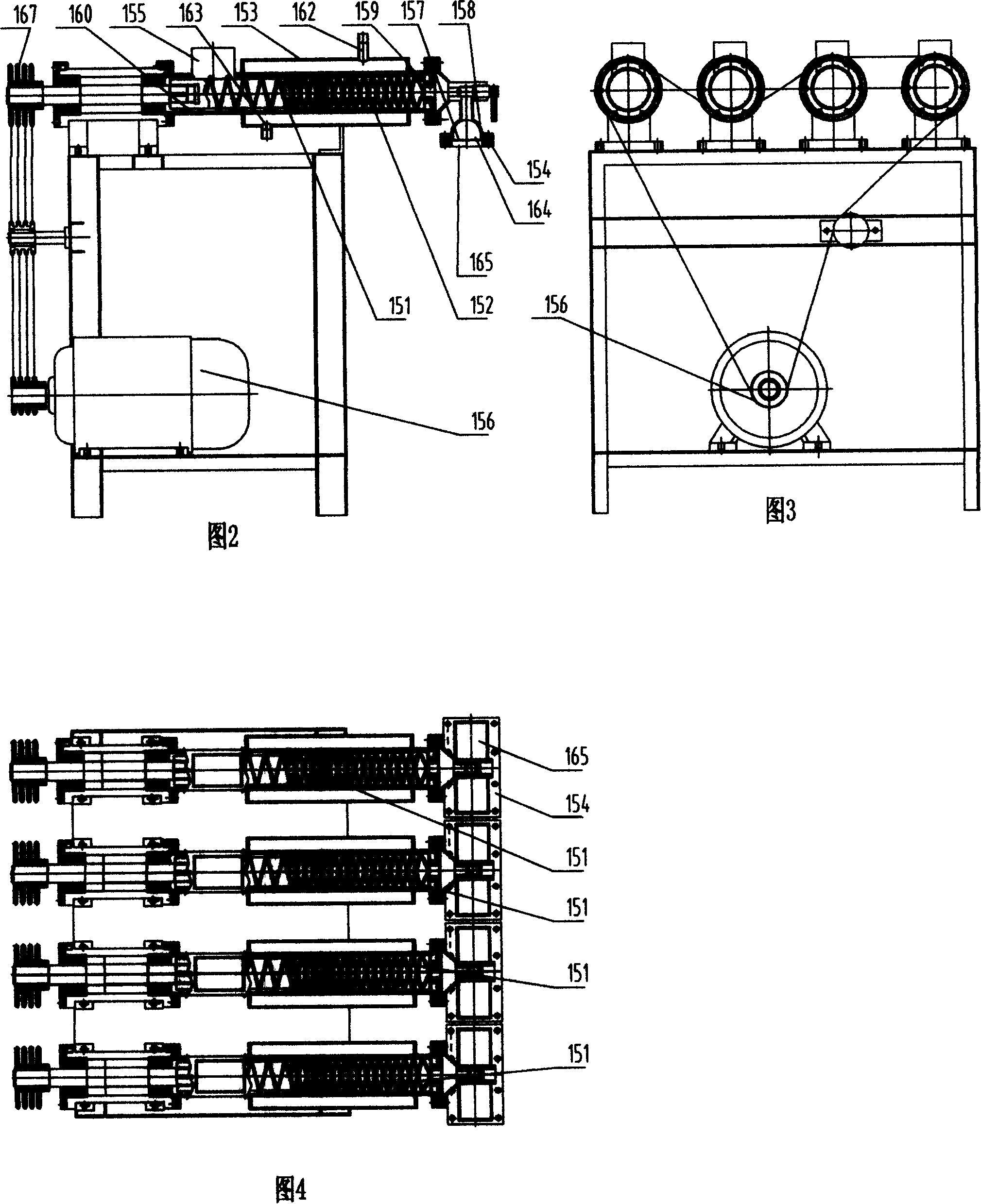

Convenient vermicelli production line and its producing technology

InactiveCN101167598AIncrease production capacitySimple processFood shapingFood preparationProduction lineEngineering

The invention relates to an instant vermicelli production line, and comprises a starch agitating device, a self-curing scroop device, a time-effect aging device, a quantitative cutting device, a powder agglomate drying device, a powder agglomate cooling device, and a package-conveying device which are all sequentially arranged along the direction of transmitting materials. A reshaping dehumidifier is further arranged between a quantitative cutting machine and a drying machine, and comprises a reshaping dehydration device which comprises one row or more than one rows of air ducts, the number of the air ducts at each row is corresponding to the number of powder boxes at each row of a drying box, blowing ports of the air ducts are correspondingly dead against the powder boxes along the vertical direction, the dehumidification method of the producing process comprises the powder box or a face box on a band carrier to be conveyed to the position just below the air duct, the air duct is arranged just above the corresponding powder box or the face box for blowing, water films and powder agglomates between the powder box and an eyelet of the face box or the water films on the face blocks are blown, the water on the surface of the powder agglomates or the face blocks is discharged from the eyelet of the power box or face box. The invention can save plenty of energy sources and time.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

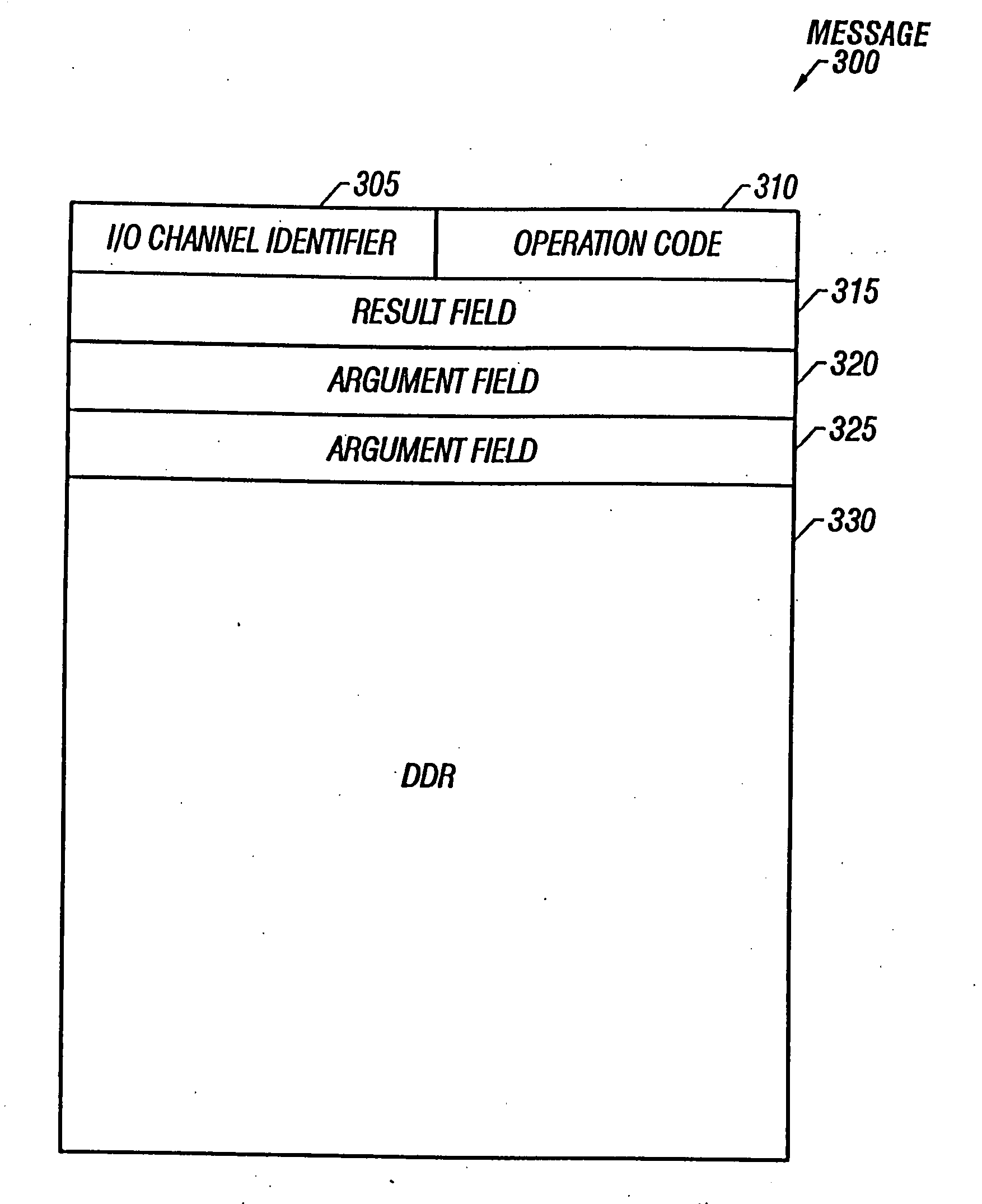

Method of re-formatting data

InactiveUS7194569B1Avoid disadvantagesAutomatic and efficientData processing applicationsDigital data information retrievalArray data structureData storing

A data structure is disclosed. The data structure includes a data descriptor record. In turn, the data descriptor record includes a type field, a base address field, an offset field, wherein the, and a length field. The type field may be configured, for example, to indicate a data structure type. The data structure type may be configured to assume a values indicating one of a contiguous buffer, a scatter-gather list and a linked list structure, among other such data structures. The base address field may be configured, for example, to store a base address, with the base address being a starting address of a secondary data structure associated with the data descriptor record. The offset field may be configured, for example, to indicate a starting address of data within a secondary data structure pointed to by a base address stored in the base address field. The length field is configured to indicate a length of data stored in a secondary data structure pointed to by a base address stored in the base address field.

Owner:SUN MICROSYSTEMS INC

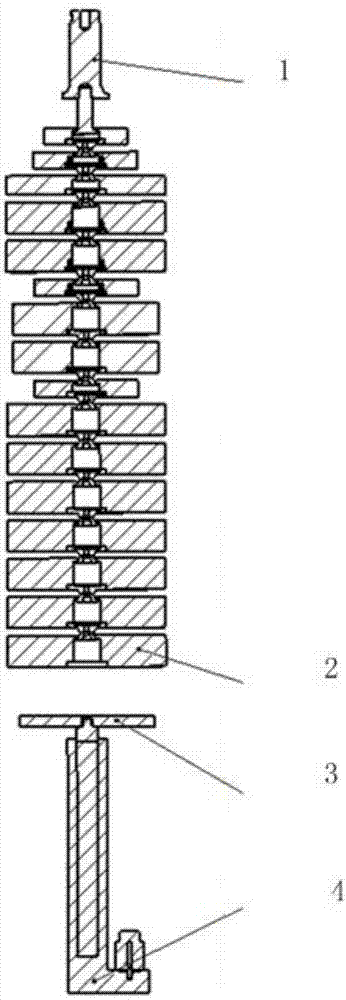

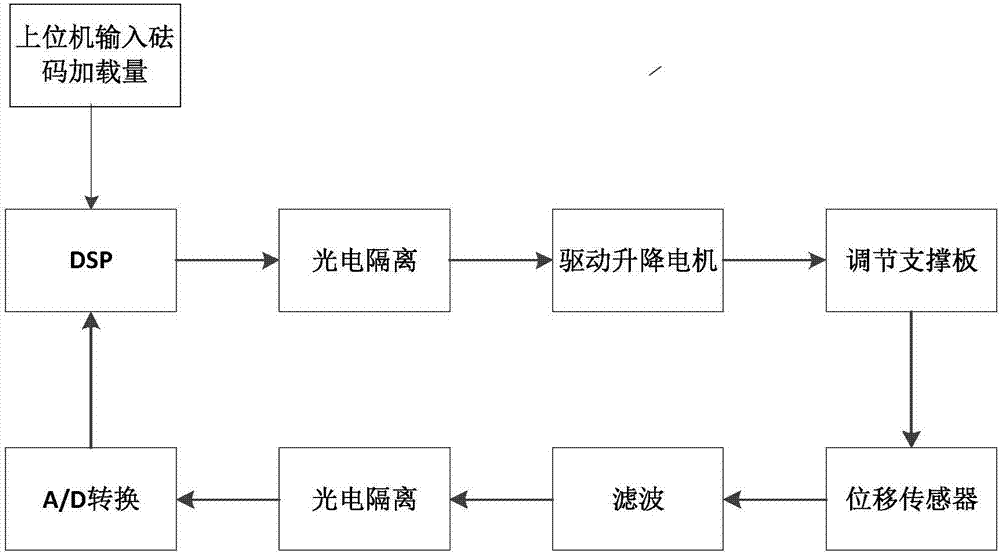

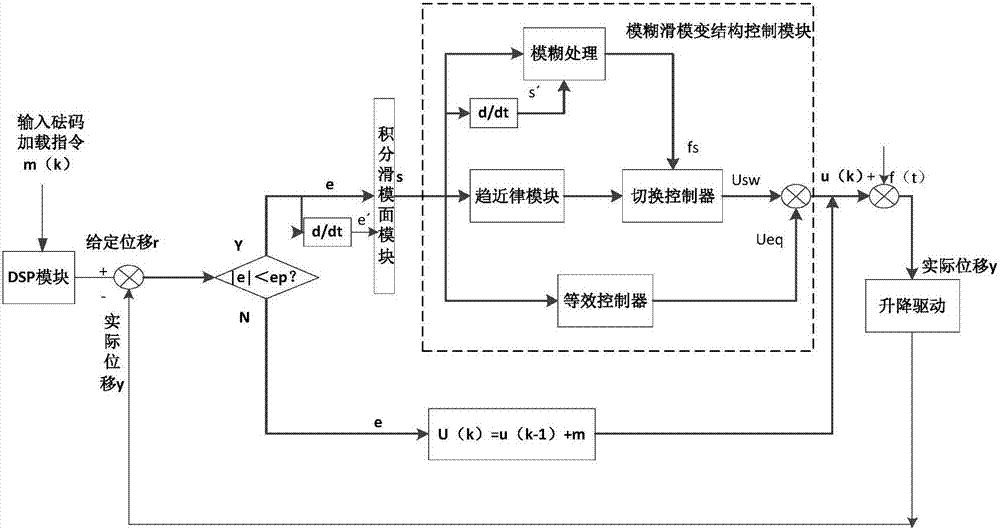

Automatic counterweight loading control device for electronic steelyard detector

PendingCN107884057AAutomatic and efficientAutomatic loading is efficientWeighing apparatus testing/calibrationDigital signal processingControl signal

The invention discloses an automatic counterweight loading control device for an electronic steelyard detector. The control device comprises a host computer module, a digital signal processing module,a fuzzy sliding mode variable structure operation module, a shoe plate elevation driving module and a displacement sensor; the host computer module is used to obtain the loading weight of a target counterweight; according to a counterweight loading instruction m(k) input by the host computer, the digital signal processing module outputs a position instruction r(k) of the displacement sensor in next time; the displacement sensor detects and outputs a position signal x(k) of a shoe plate at present, a control signal output by the fuzzy sliding mode variable structure operation module is obtained via operation of the module, and a shoe plate elevation controller is driven. Thus, the counterweight can be loaded automatically and accurately in high efficiency.

Owner:苏州市计量测试研究所

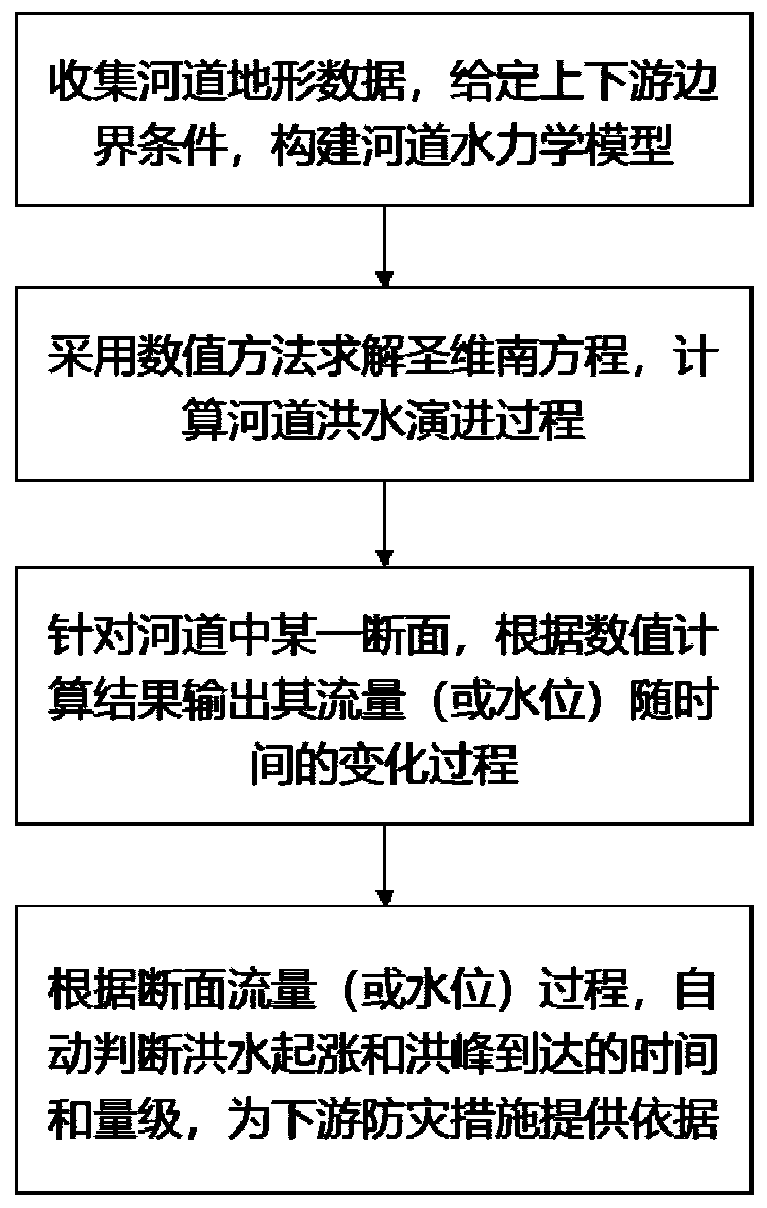

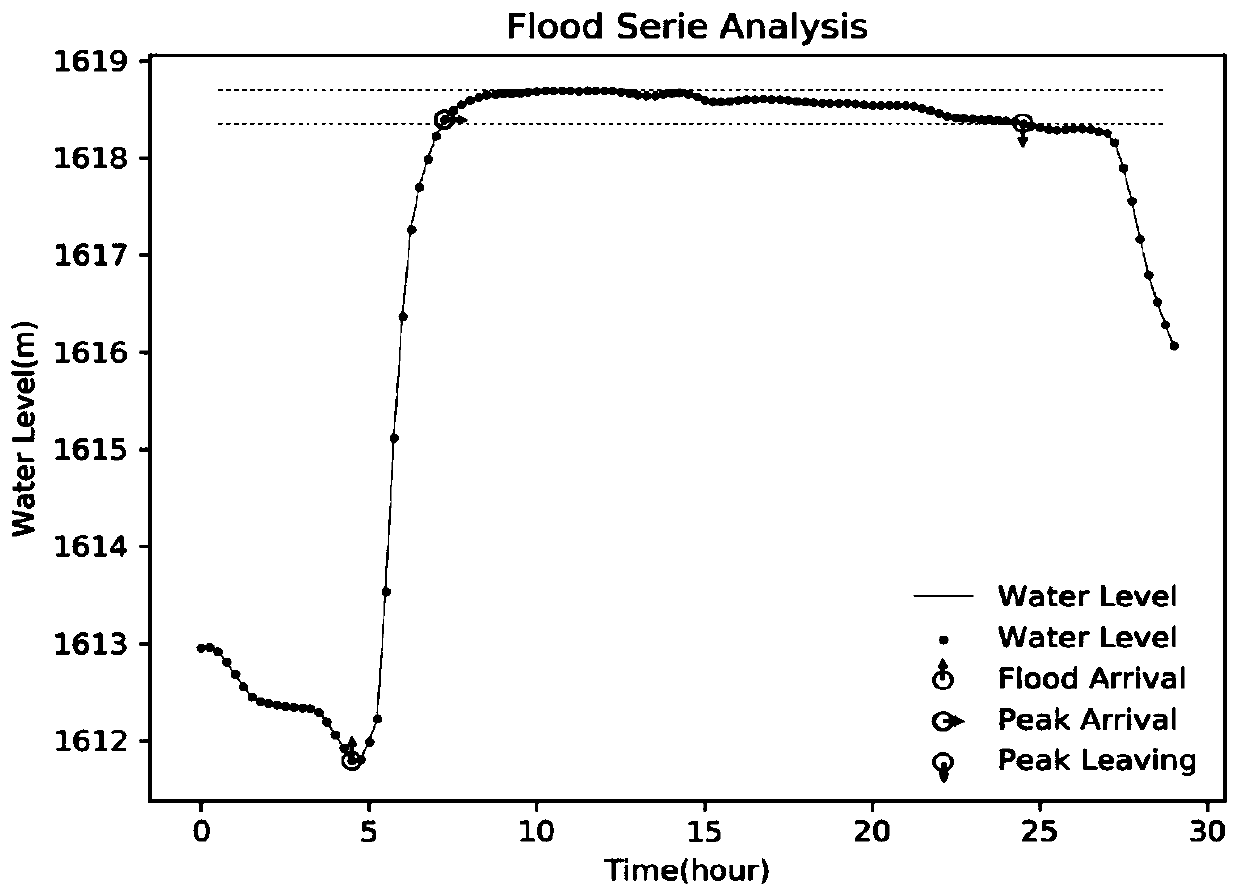

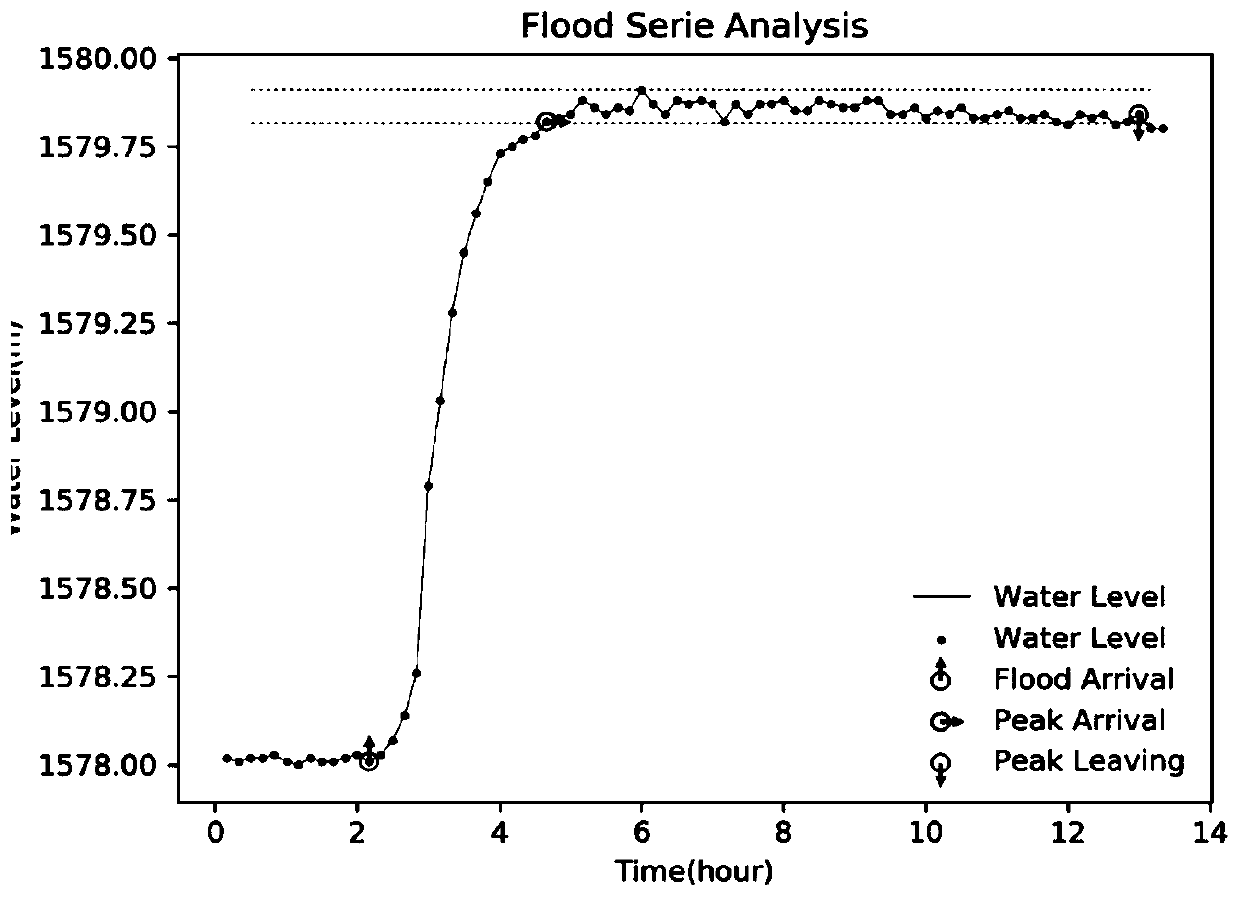

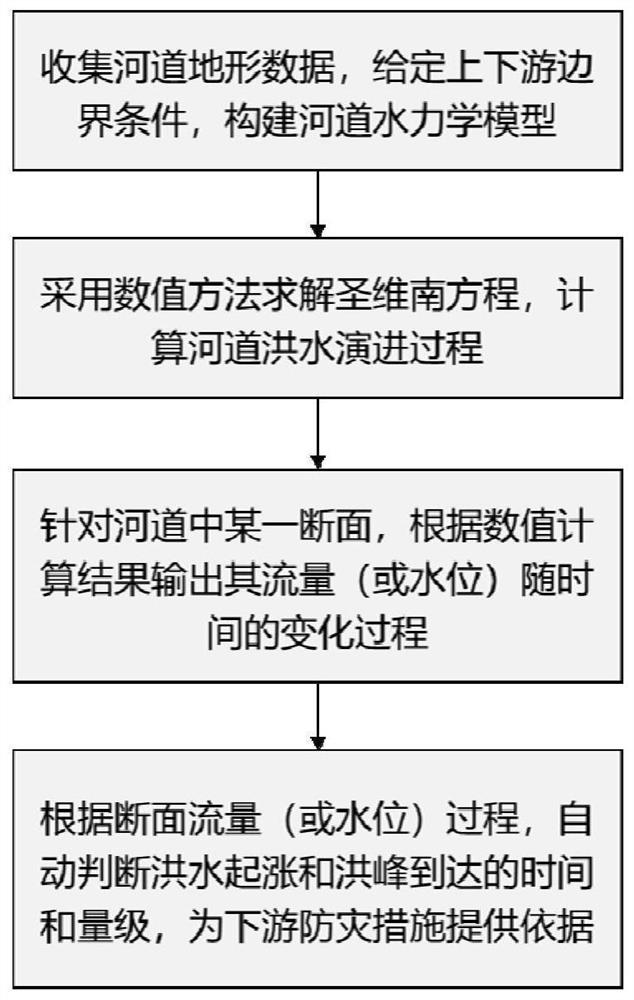

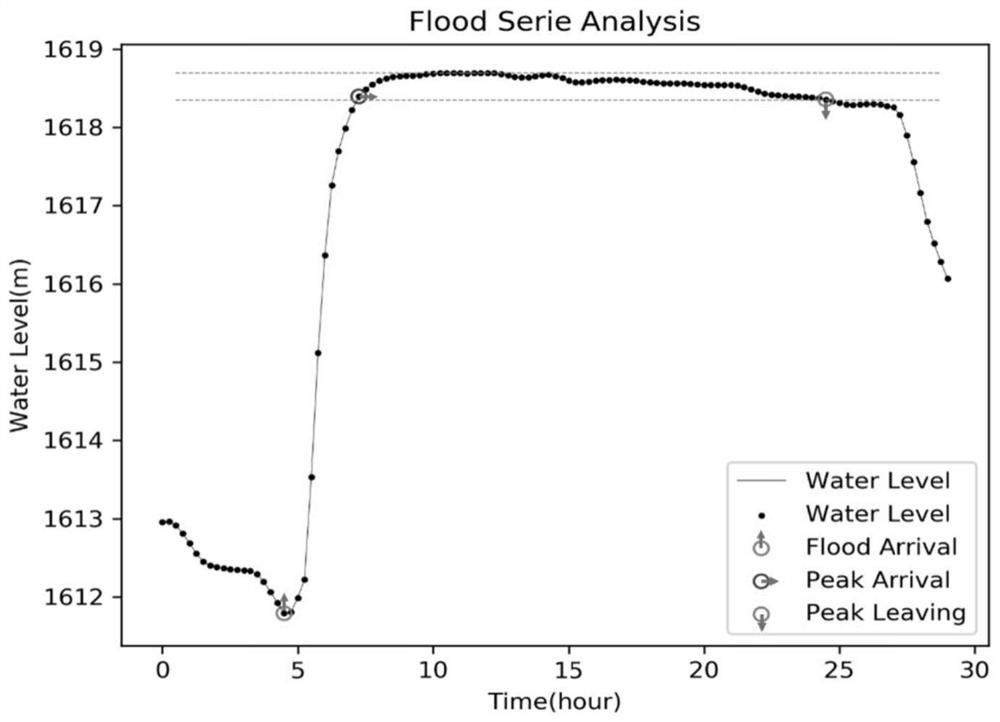

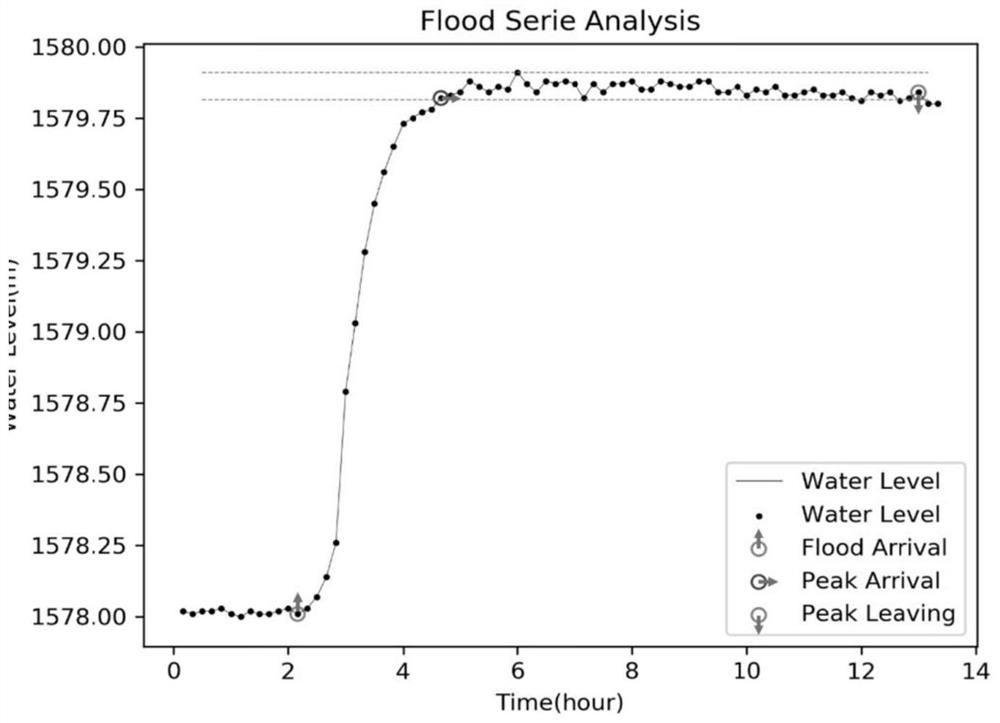

River channel flood discharge early warning method based on hydraulic simulation

ActiveCN110847112ADetermine the result of the judgmentAvoid chanceHydraulic modelsHydrometryRiver routing

The invention discloses a river channel flood discharge early warning method based on hydraulic simulation, and relates to the field of river channel flood routing and early warning. As reservoir flood discharge and river channel natural flow processes have obvious difference, on the basis of constructing a one-dimensional hydraulic model for a river channel, each obtained fracture surface water level sequence is simulated according to the model, and the flood rising time, flood peak reaching time and corresponding rising water level and peak value water level due to reservoir flood dischargeare automatically identified and extracted. The method is suitable for hydraulic simulation of the river channel, flood propagation time and magnitude prediction, has universality, is simple and easyto operate, can calculate flood propagation process according to a drainage plan of a hydraulic building or hydrological prediction of a natural river channel, and provides early warning information for disaster prevention and reduction of a downstream area.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Intelligent identification wolfberry picking device

InactiveCN105309131BGuaranteed timely harvestQuality assurancePicking devicesControl systemEngineering

Aiming at the problems existing in the prior art, the present invention provides an intelligent identification wolfberry picking device equipped with a distributed machine vision system. The device includes a frame and a power supply system arranged on the frame, a control system, a drive system, a machine vision system, a wolfberry picking manipulator, a branch positioning manipulator, a wolfberry picking head and a fruit collecting device; The vision system, wolfberry picking manipulator, branch positioning manipulator, wolfberry picking head and fruit collecting device are connected respectively. The invention also proposes a method for picking wolfberry based on the above-mentioned image recognition wolfberry picking machine. The wolfberry picking device realizes the automatic and efficient collection of wolfberry fruit, solves the problems that the fruit is easily broken and the leaves are easy to block during the harvest of wolfberry fruit, greatly reduces the production cost, and has a good practical application prospect.

Owner:QINGDAO AGRI UNIV +1

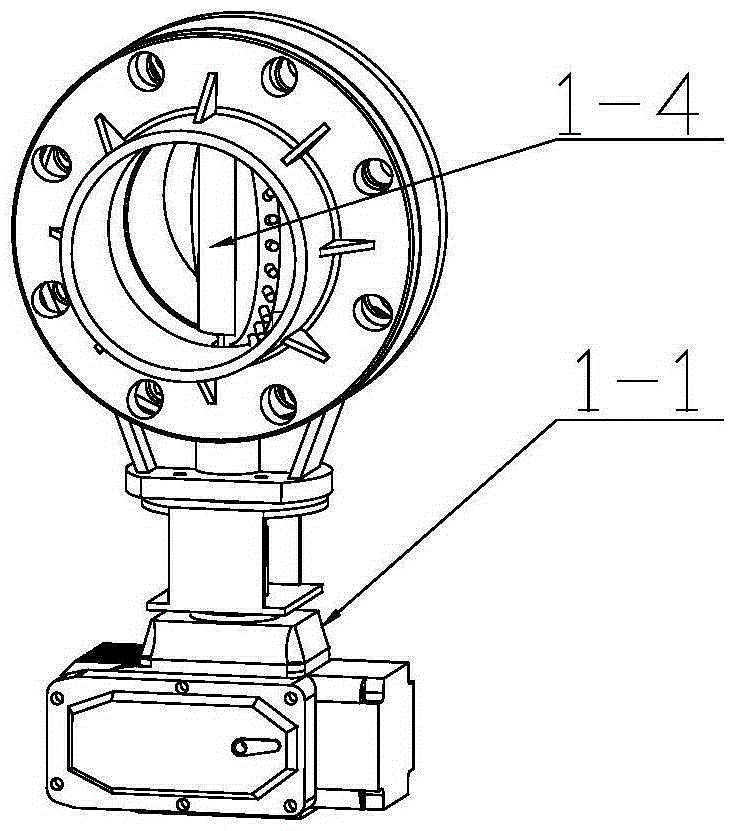

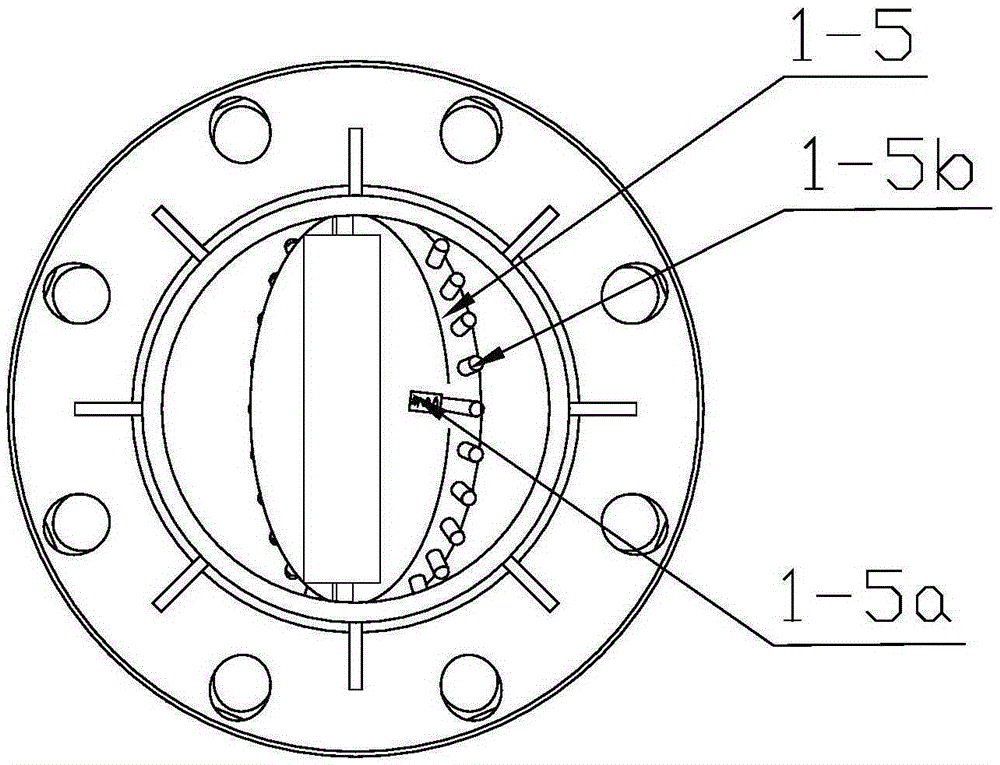

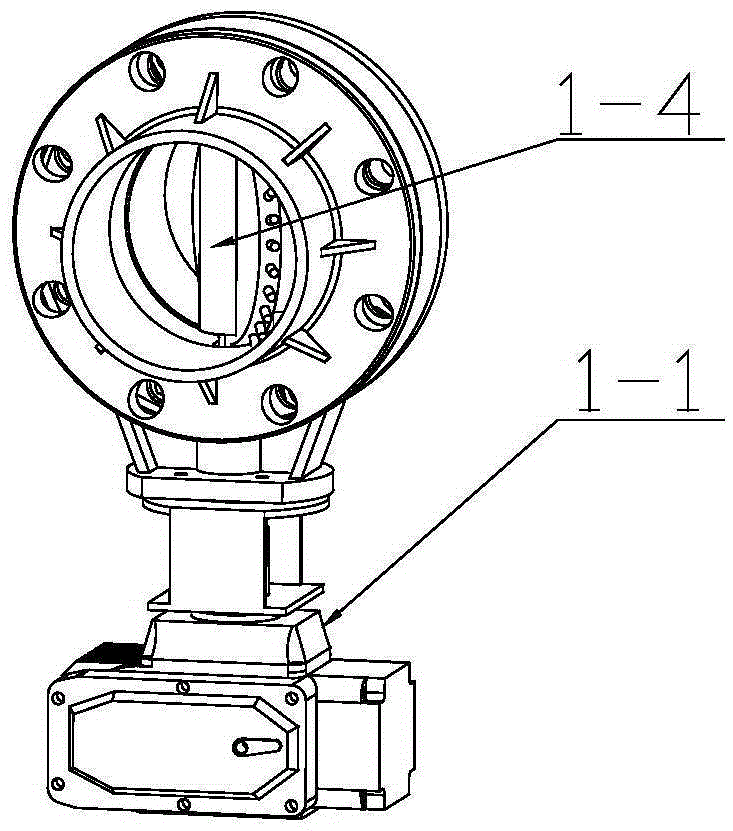

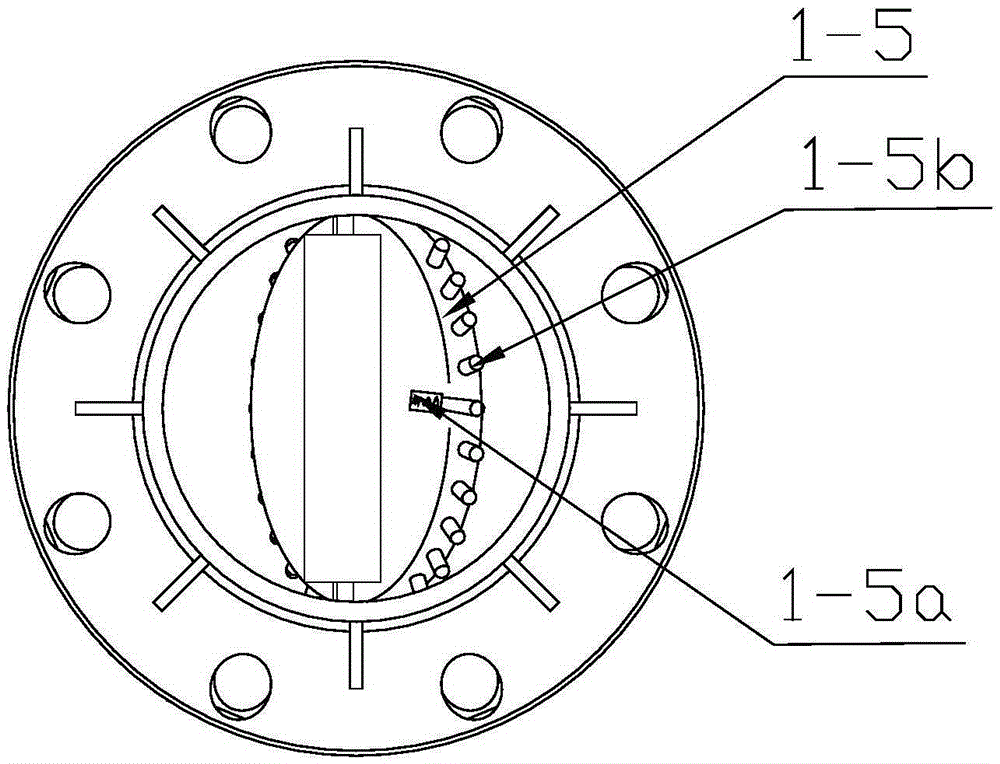

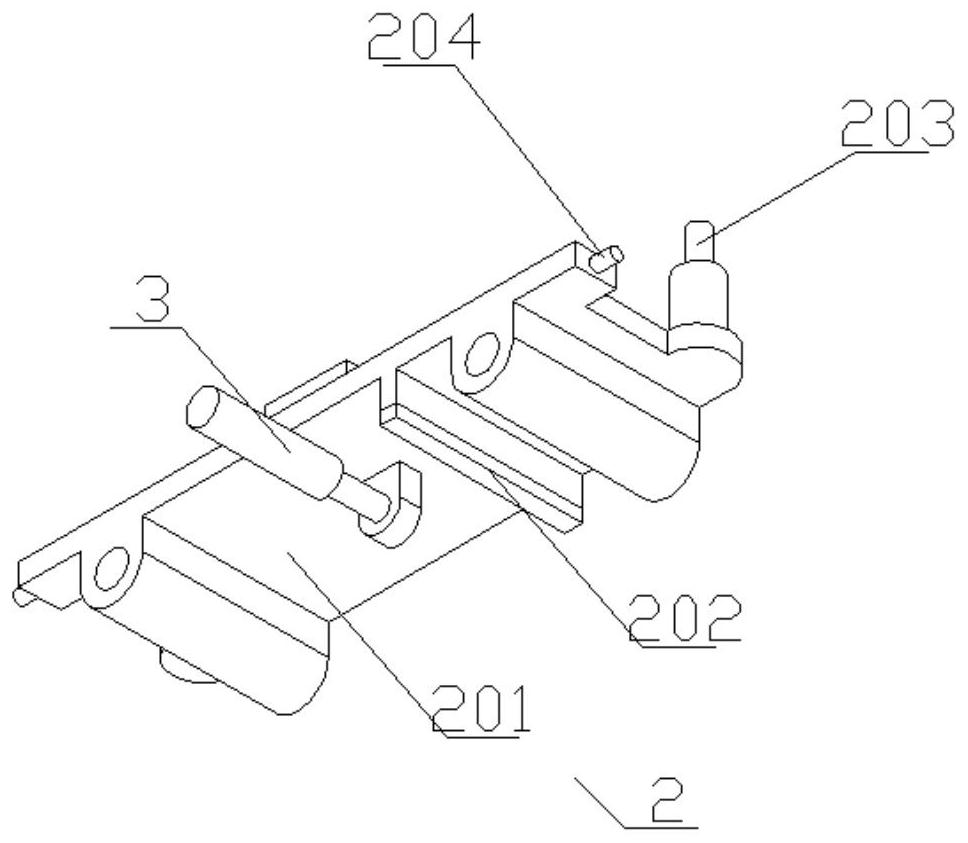

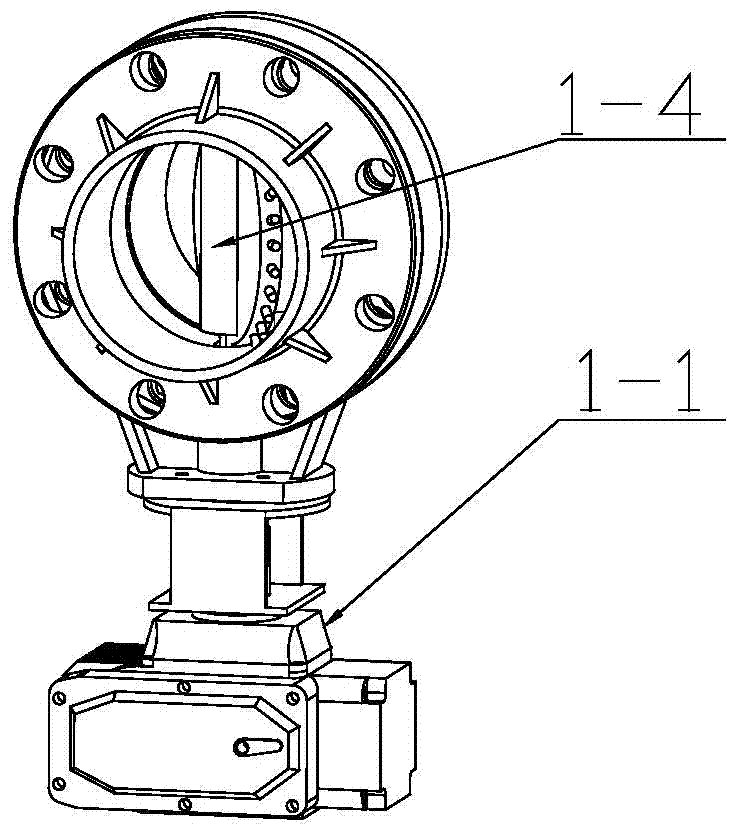

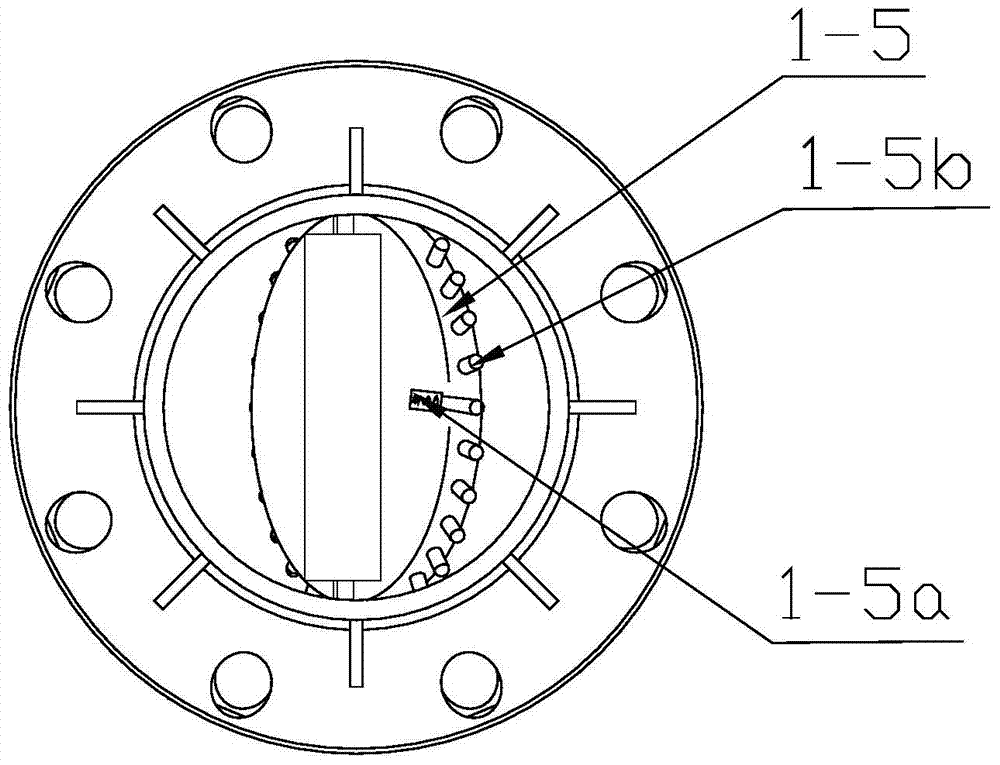

Anti-blocking type electric valve used for Chinese wolfberry collecting device

ActiveCN105333200AAutomatic and efficientAutomatic collection and efficientOperating means/releasing devices for valvesLift valveMechanical engineering

In order to solve the problems in the prior art, the invention provides an anti-blocking electric valve used for a Chinese wolfberry anti-blocking and isolating type collecting device. The anti-blocking type electric valve comprises an electric valve body, a fruit inlet, a fruit outlet and a valve plate, wherein the valve plate is arranged on a pipeline between the fruit inlet and the fruit outlet. The valve plate is a circular plate matched with the pipeline. A circular valve plate frame is arranged at the peripheral outer side of the valve plate, and a plurality of circular holes are formed in the valve plate frame. The anti-blocking type electric valve further comprises a shrinkage connecting rod which penetrates through the circular holes; one end, facing towards the valve plate, of the shrinkage connecting rod is connected with the valve plate through a valve plate spring, so that length regulation, changing along with the pipeline aperture, of the shrinkage connecting rod is realized. By virtue of the anti-blocking type electric valve, continuous collecting and encasing of fruits is realized, and damages which are possibly caused to the fruits in the collecting process are avoided.

Owner:QINGDAO AGRI UNIV +1

Device for recovering discarded packaging paperboard

ActiveCN109201224AGood transmission effectPlay a guiding roleGrain treatmentsKnife bladesEngineering

The invention discloses a device for recovering a discarded packaging paperboard. The device comprises a supporting bottom plate, wherein supporting frames are symmetrically distributed on the supporting bottom plate; a crushing box is arranged between the supporting frames; the bottom of the crushing box is sleeved with a material receiving tank; the supporting bottom plate is provided with a supporting component; the supporting component is used for supporting the material receiving tank; a crushing roller is arranged in the crushing box; the crushing box is provided with a pretreatment box;the pretreatment box is provided with a material feed hopper; a driving rod is movably connected into the pretreatment box; one end of the driving rod is connected with a drive rod; one end of the drive rod is connected with a swinging rod; the swinging rod is connected with the pretreatment box through a rotating shaft; a fixing bracket is arranged in the pretreatment box; the fixing bracket isconnected with a driving shaft in a sliding manner; two ends of the driving shaft are both provided with mounting plates; crushing knife blades are uniformly distributed on the mounting plates; the driving shaft is provided with a drive plate; and spring rods are arranged between the drive plate and the fixing bracket. The device is novel in structure, automatic, high-efficiency and high in economic benefit; the recovery rate of the discarded paperboard is improved; and the waste is changed into the valuable.

Owner:南阳统包包装股份有限公司

A method for early warning of river flood discharge based on hydraulic simulation

ActiveCN110847112BDetermine the result of the judgmentAvoid chanceHydraulic modelsHydrometryRiver routing

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

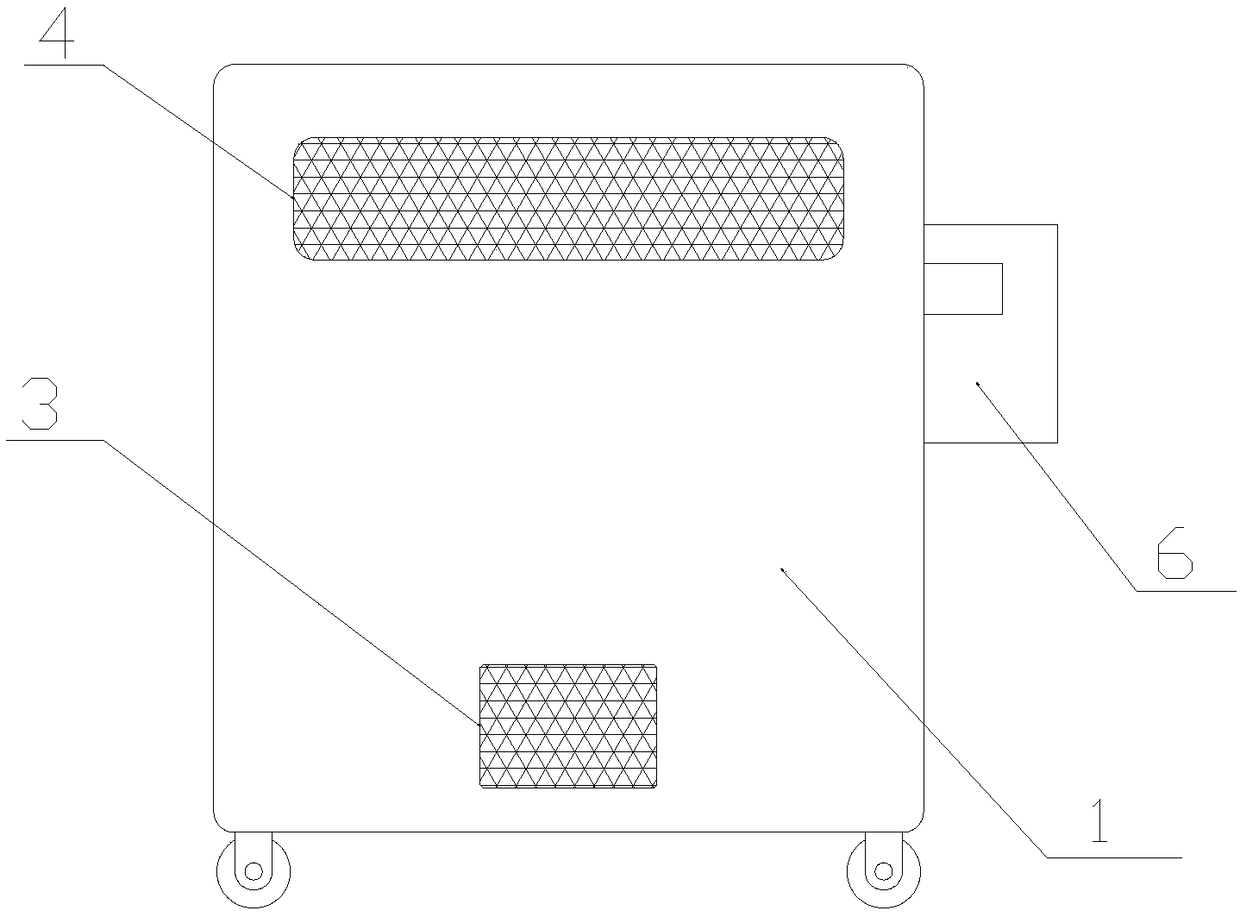

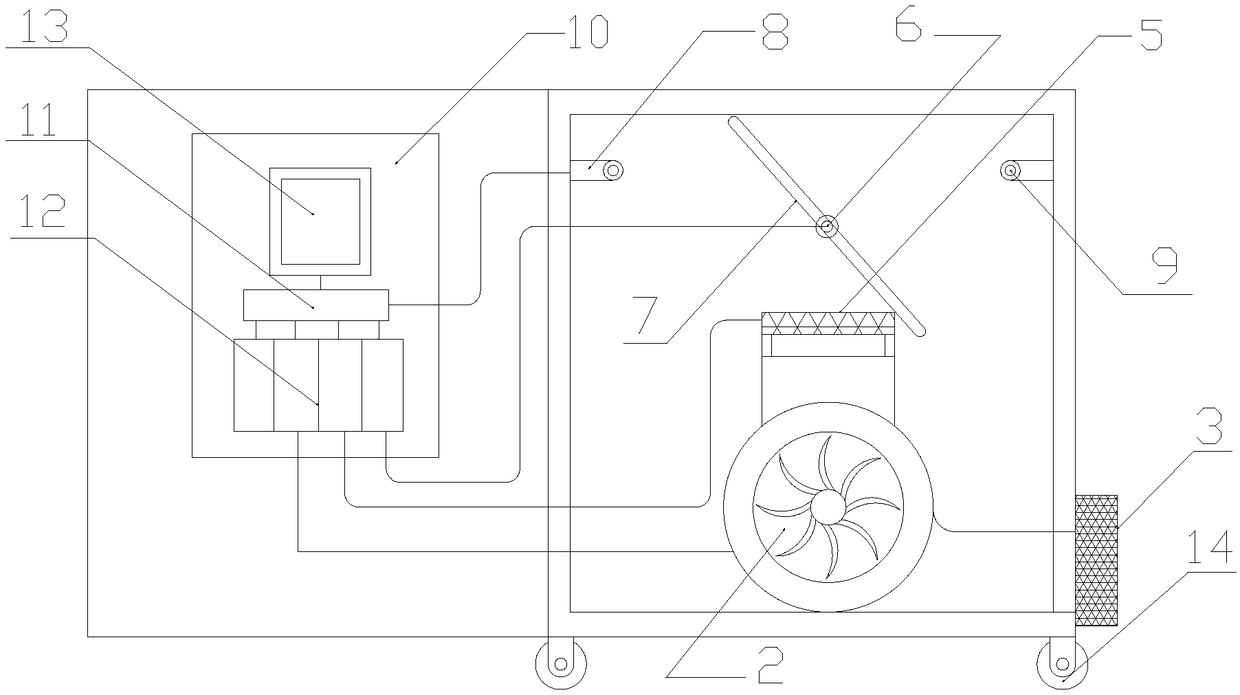

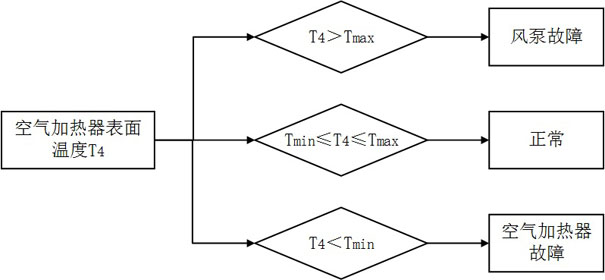

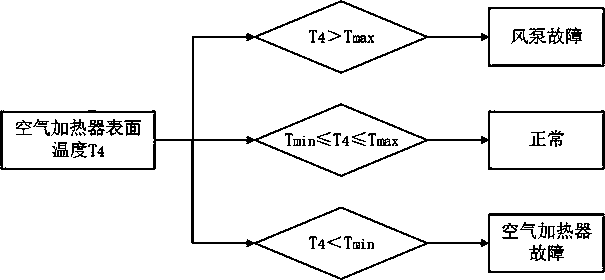

Intelligent energy-saving dehumidifier

InactiveCN108800356AAddressing functional deficienciesConvenience to workLighting and heating apparatusAir conditioning systemsEngineeringEnergy Saving Module

The invention discloses an intelligent energy-saving dehumidifier. According to the intelligent energy-saving dehumidifier, a rectangular box body is arranged as a dehumidifier cabinet body, a compressor is arranged at the bottom end of the dehumidifier cabinet body, the bottom end of the compressor is connected with an air inlet, moreover, an electric heating wire is installed at the top end of the compressor, wing plates are installed at the top end of the dehumidifier cabinet body through an automatic rotating shaft, the automatic rotating shaft drives the wing plates to overturn to adjustthe direction and the size of dehumidifying air, meanwhile, electronic thermometers are installed to detect temperature signals and an electronic humidity meters are installed to detect humidity signals, moreover, an energy-saving module is installed on a panel of the dehumidifier cabinet body, the electronic thermometers and the electronic humidity meters transmit the temperature detection signals and the humidity detection signals to the energy-saving module, the energy-saving module is used for adjusting the power of the compressor and the electric heating wire through executive electric appliances after analyzing the signals so that the dehumidification can be carried out automatically and efficiently, then better services can be brought to the work and life of people, the problem thatthe functionality of a dehumidifier in the prior art is insufficient is solved, and the good practical value is achieved.

Owner:朗瀚智能装备(江苏)有限公司

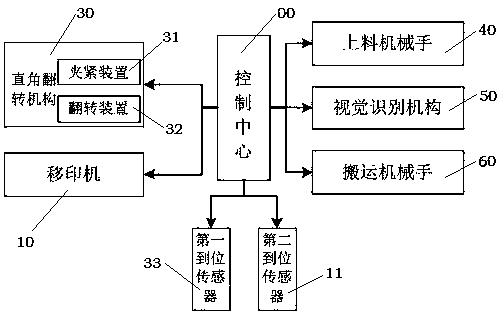

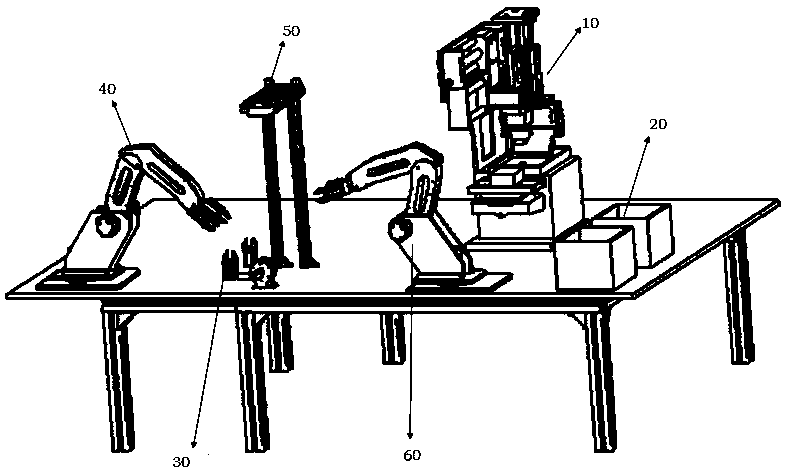

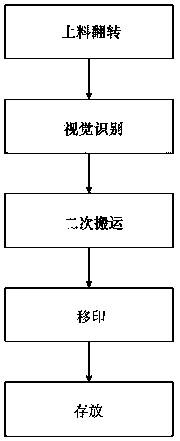

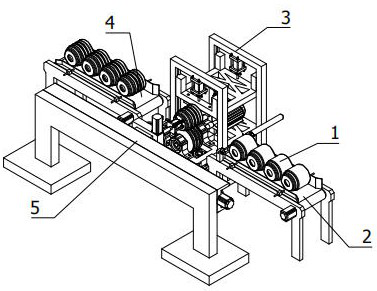

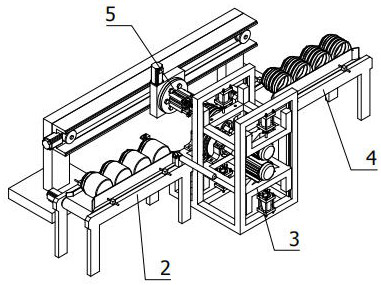

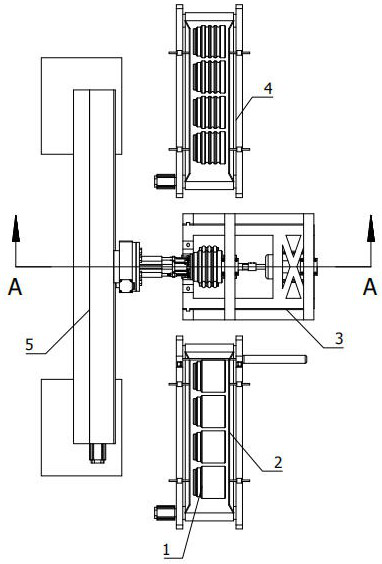

Slipper strap automatic pad printing system and method

PendingCN109924611AMeet pad printing requirementsSafe automaticShoemaking devicesTemplate matchingPad printing

The invention discloses a slipper strap automatic pad printing system and method. The system comprises a pad printing machine and a storage box, wherein the pad printing machine is connected with a control center; the control center is further connected with a right-angle turnover mechanism, a feeding manipulator, a visual recognition mechanism and a carrying manipulator; the right-angle turnovermechanism is used for turning a slipper strap to a horizontal state; the feeding manipulator is used for grabbing the to-be-printed slipper strap and carrying the slipper strap to the right-angle turnover mechanism; the visual recognition mechanism is used for shooting images of the overturned slipper strap and processing and identifying the images; the carrying manipulator is used for carrying the slipper strap matched with a template to the pad printing machine, and carrying the slipper strap obtained after pad printing to the storage box. According to the system and method, safe and efficient automatic pad printing of the slipper strap in the pad printing link can be realized, so that the problem of labor shortage is solved. According to the technology, on the premise that the requirement for pad printing of the slipper strap is met, the working efficiency is improved, the working risk coefficient is reduced, and the utilization rate of labor is improved while the development trendof contemporary science and technology is met.

Owner:FUJIAN UNIV OF TECH

A brake drum rolling type processing equipment

The invention relates to the field of auto parts processing equipment, in particular to a brake drum rolling processing equipment, including a rolling machine; a feeding mechanism and a discharging mechanism, and the feeding mechanism and the discharging mechanism are along the transmission direction of the brake drum Distributed on both sides of the roll forming machine; industrial robots are installed beside the feeding mechanism, rolling machine, and discharging mechanism, and are used to move the brake drum at the discharge end of the feeding mechanism to the working end of the rolling machine and The feeding end of the discharging mechanism; the controller, the feeding mechanism, the rolling machine, the discharging mechanism, and the industrial robot are all electrically connected to the controller; the equipment can automatically roll the brake drum with high efficiency.

Owner:莱州双力机械有限公司

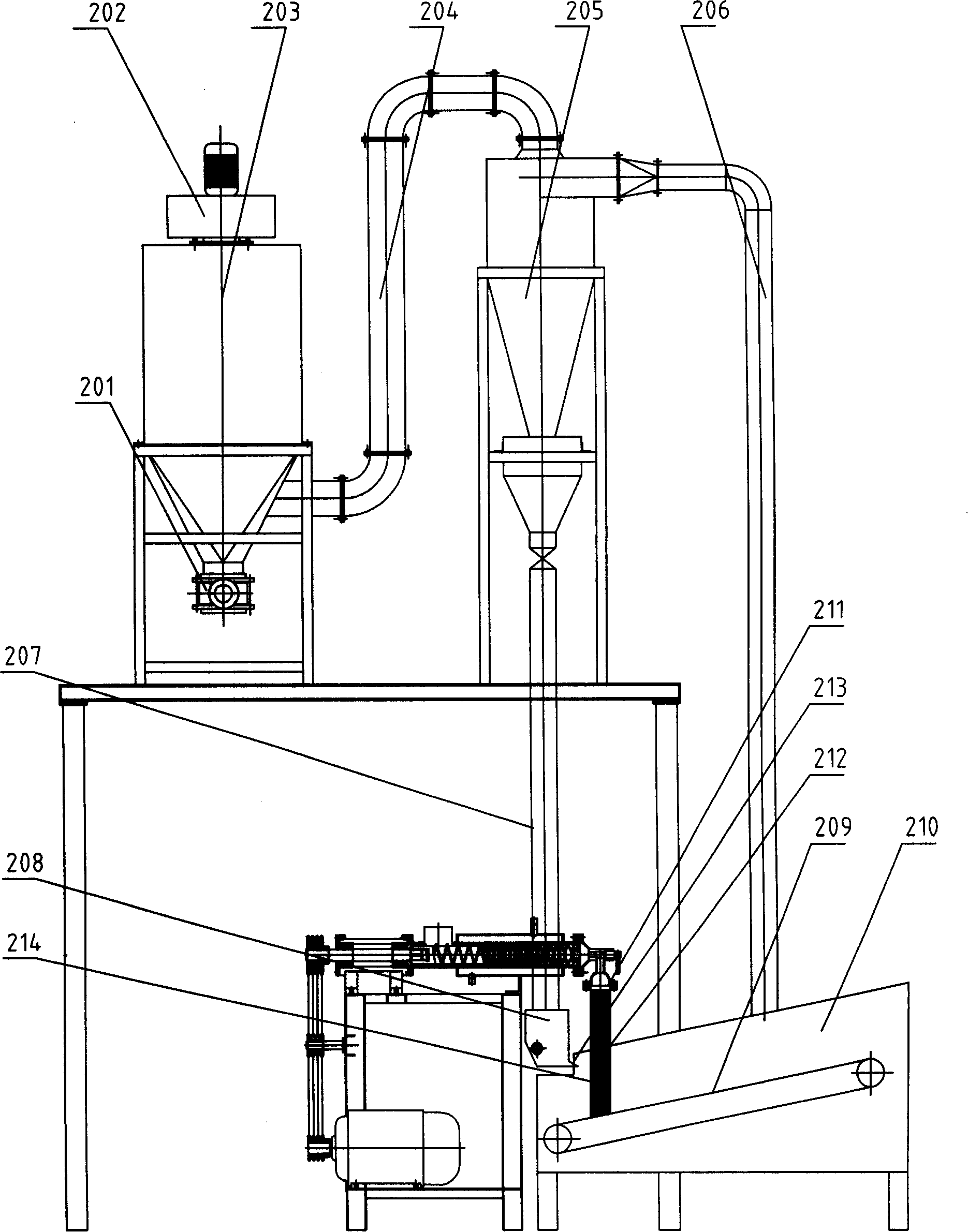

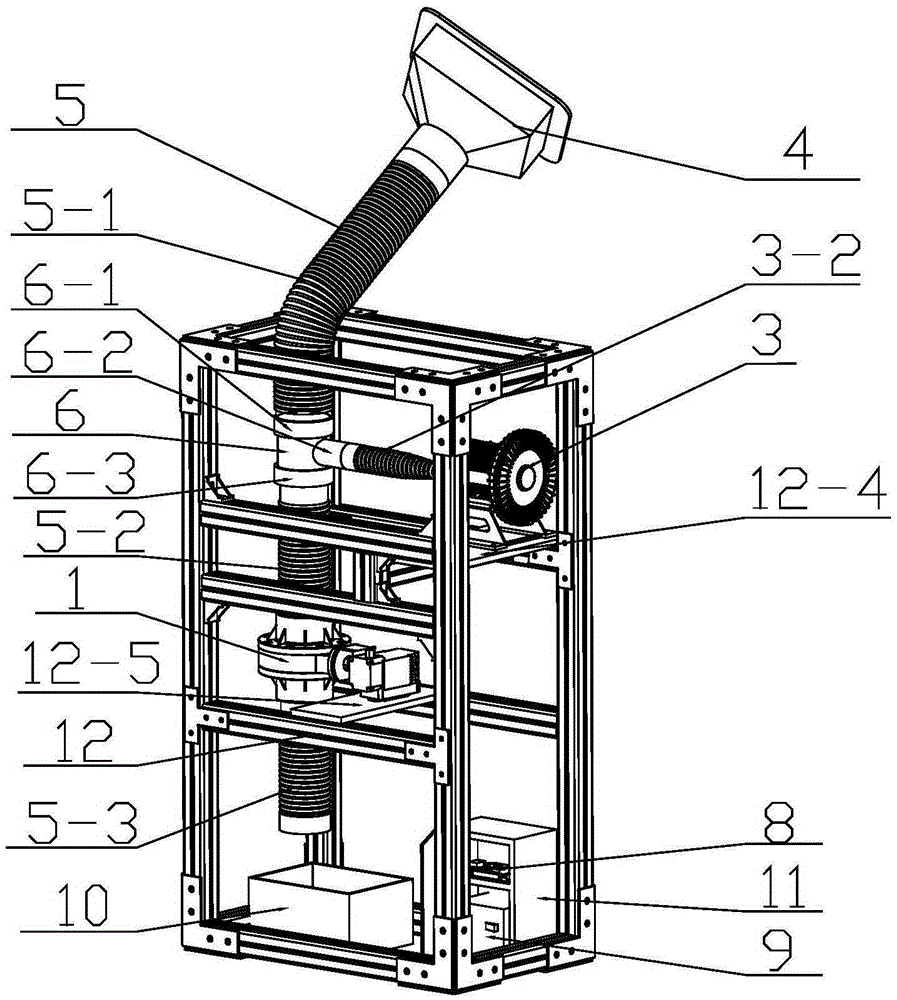

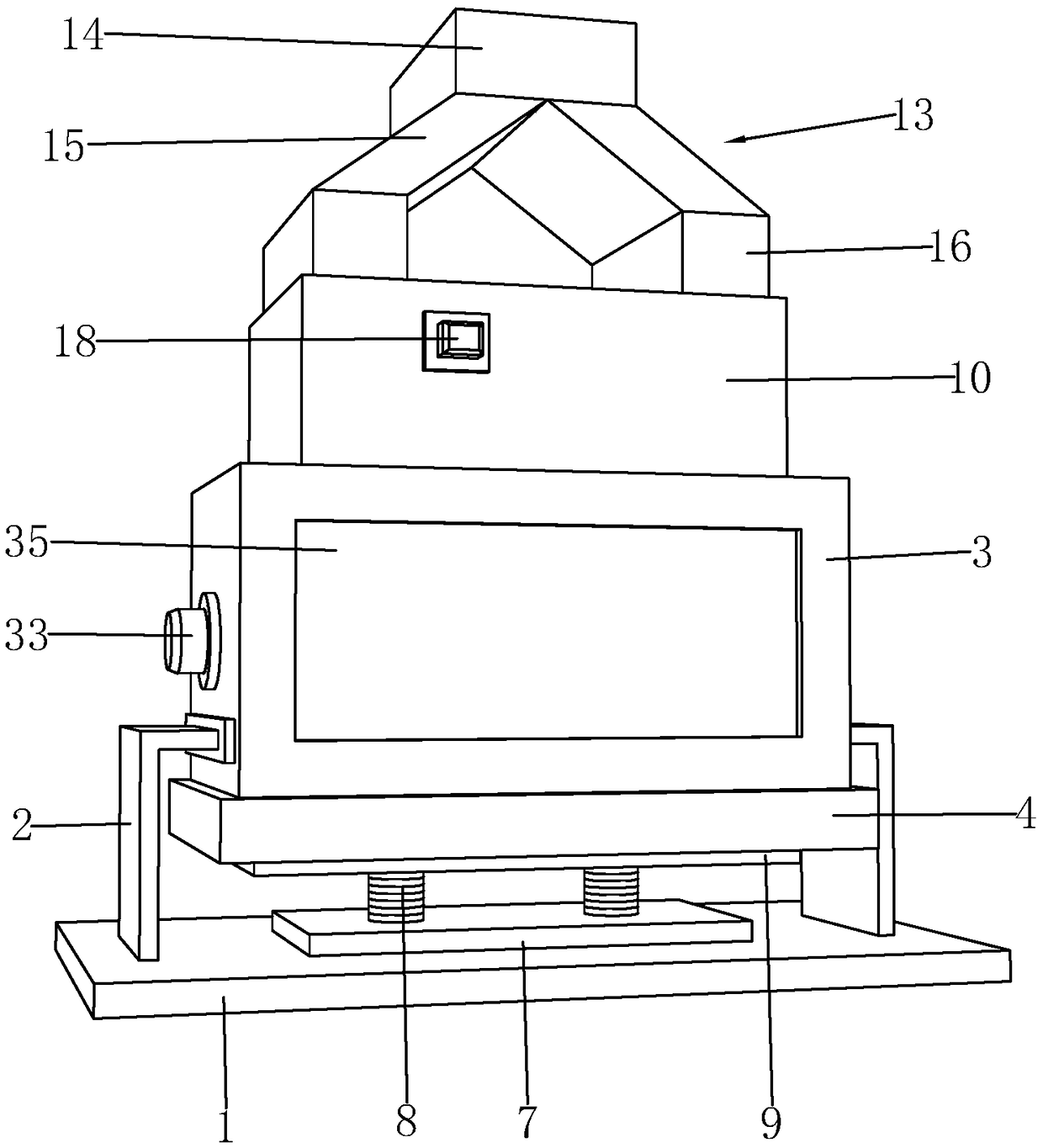

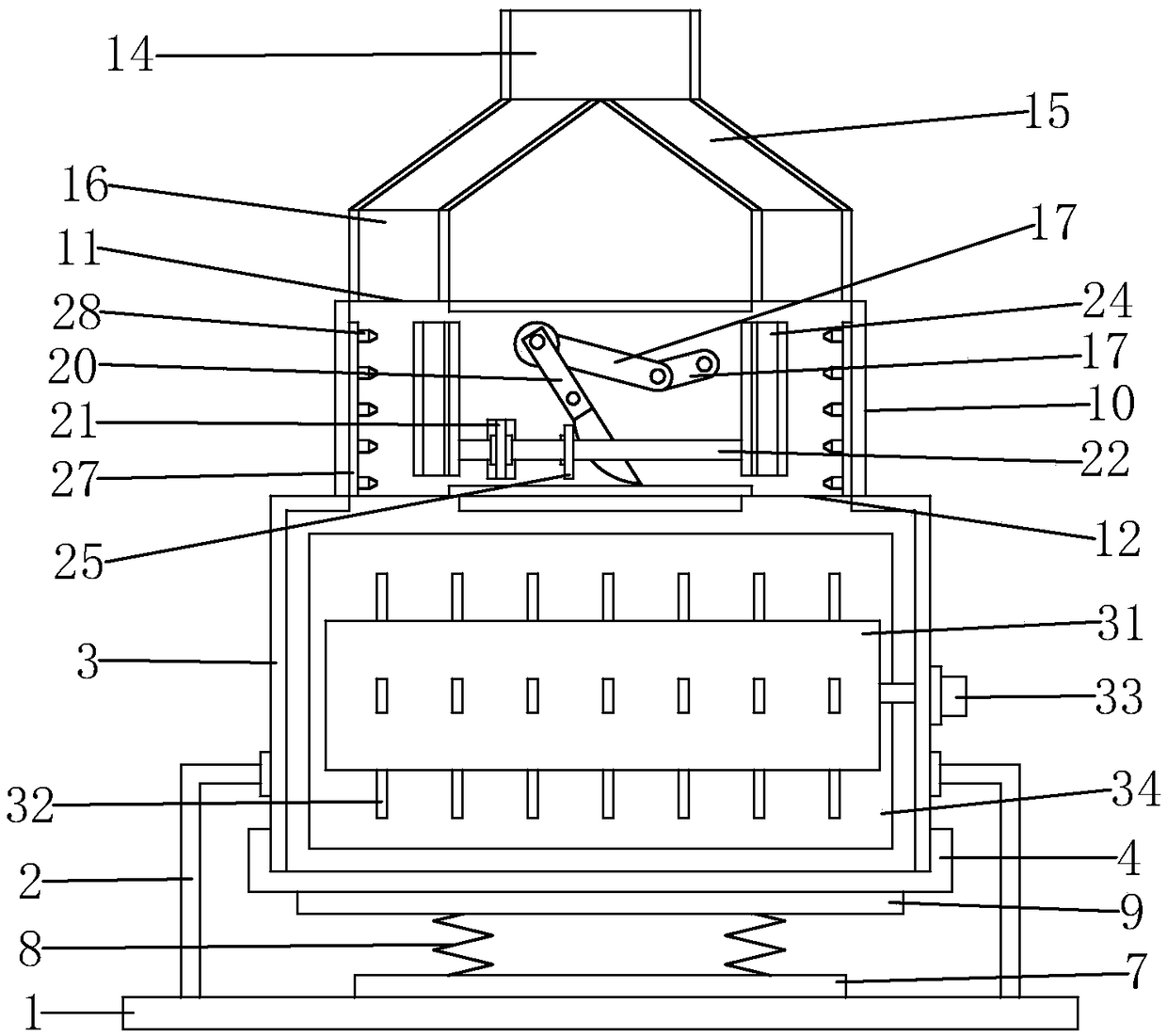

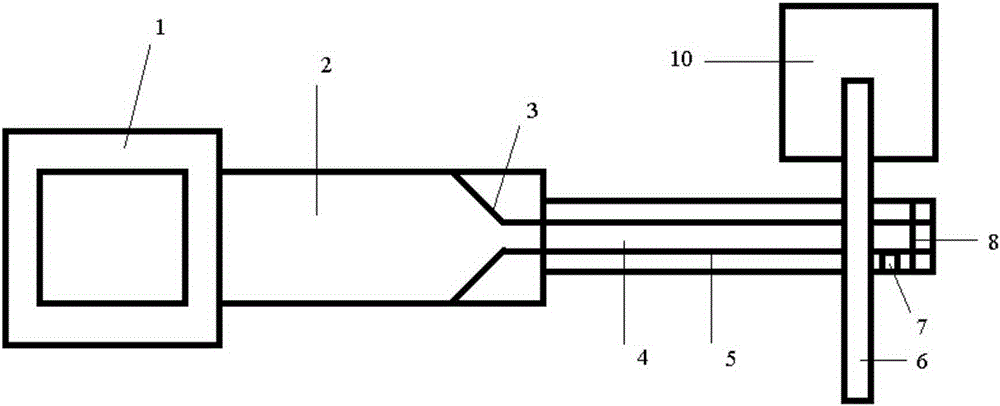

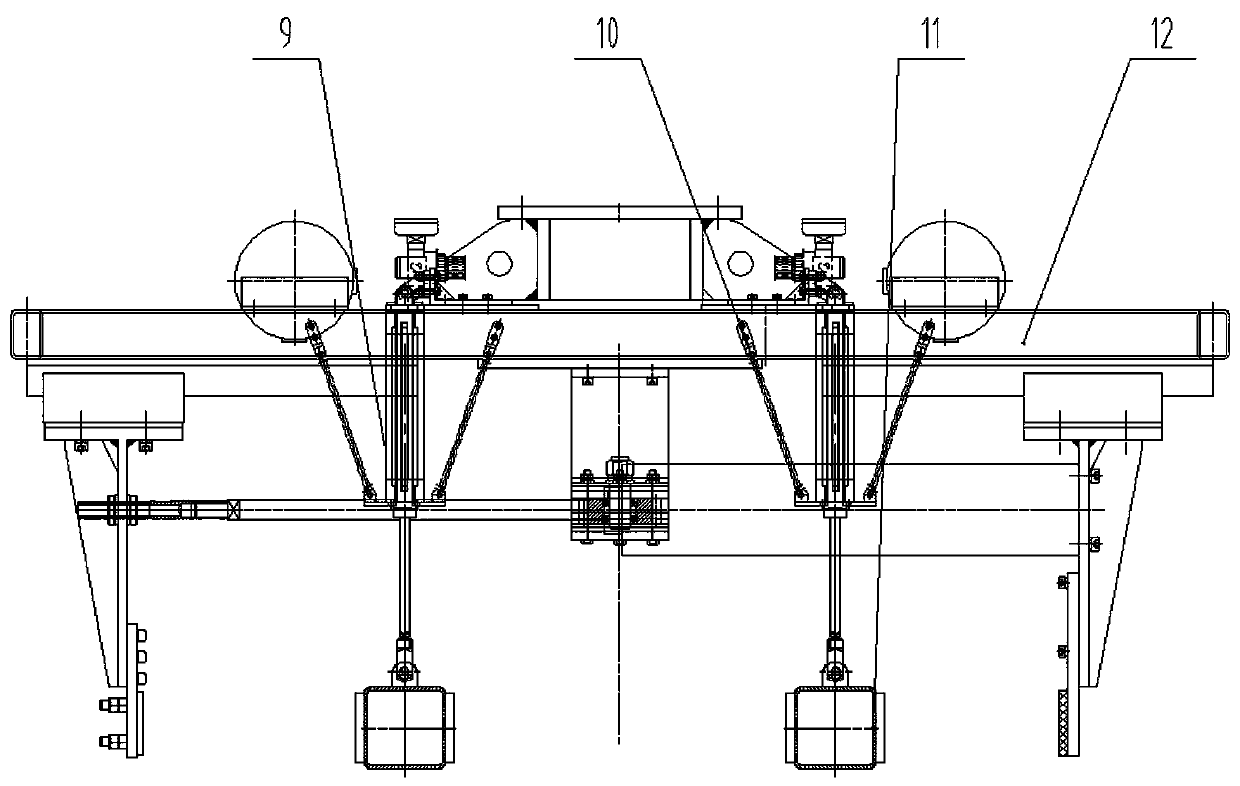

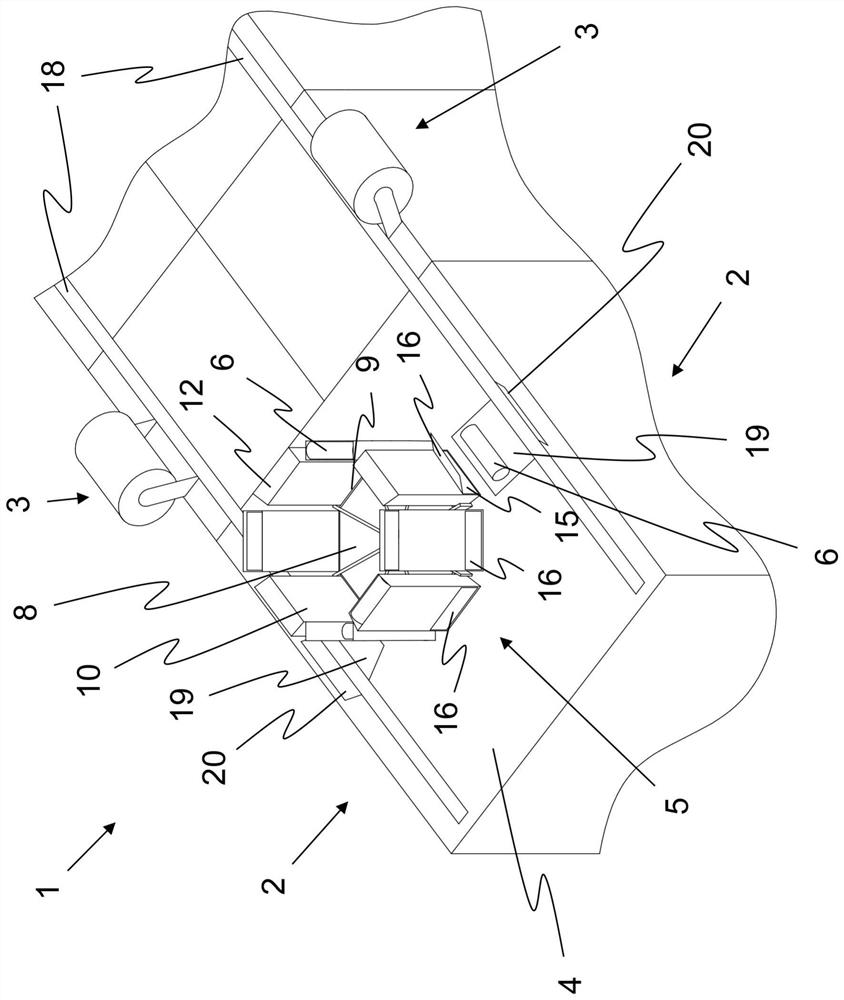

Anti-blocking isolation type Chinese wolfberry automatic collection device

InactiveCN105265097AAutomatic and efficientAutomatic collection and efficientPicking devicesLycium barbarum fruitEngineering

The invention provides an anti-blocking isolation type Chinese wolfberry automatic collection device so as to solve the problems in the prior art. The collection device comprises a rack as well as a collection unit, a power unit and a storage unit which are arranged on the rack. The power unit is connected with the collection unit and further connected with the storage unit; the connection unit comprises a collection funnel and a connection flexible pipe. A tee interface and an anti-blocking electric valve are arranged on the collection flexible pipe, and the collection flexible pipe comprises an upper part collection flexible pipe, a middle collection flexible pipe and a lower part collection flexible pipe. When a Chinese wolfberry picking machine works, a controller controls a fan to work, and the anti-blocking electric valve is in a closed state; Chinese wolfberries picked by the Chinese wolfberry picking machine enter the upper collection flexible pipe through the collection funnel and are gathered at a first end interface of the tee interface; when the Chinese wolfberries are enough, the controller controls the anti-blocking electric valve to be opened, and the Chinese wolfberries enter a fruit collection box through the lower connection flexible pipe by a third interface of the tee interface.

Owner:QINGDAO AGRI UNIV +1

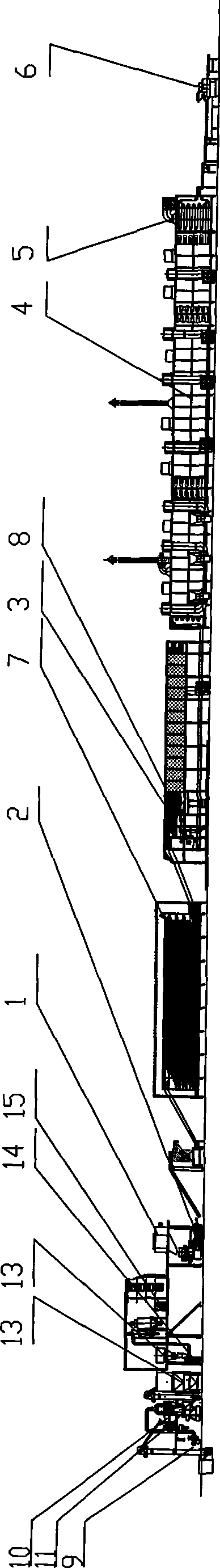

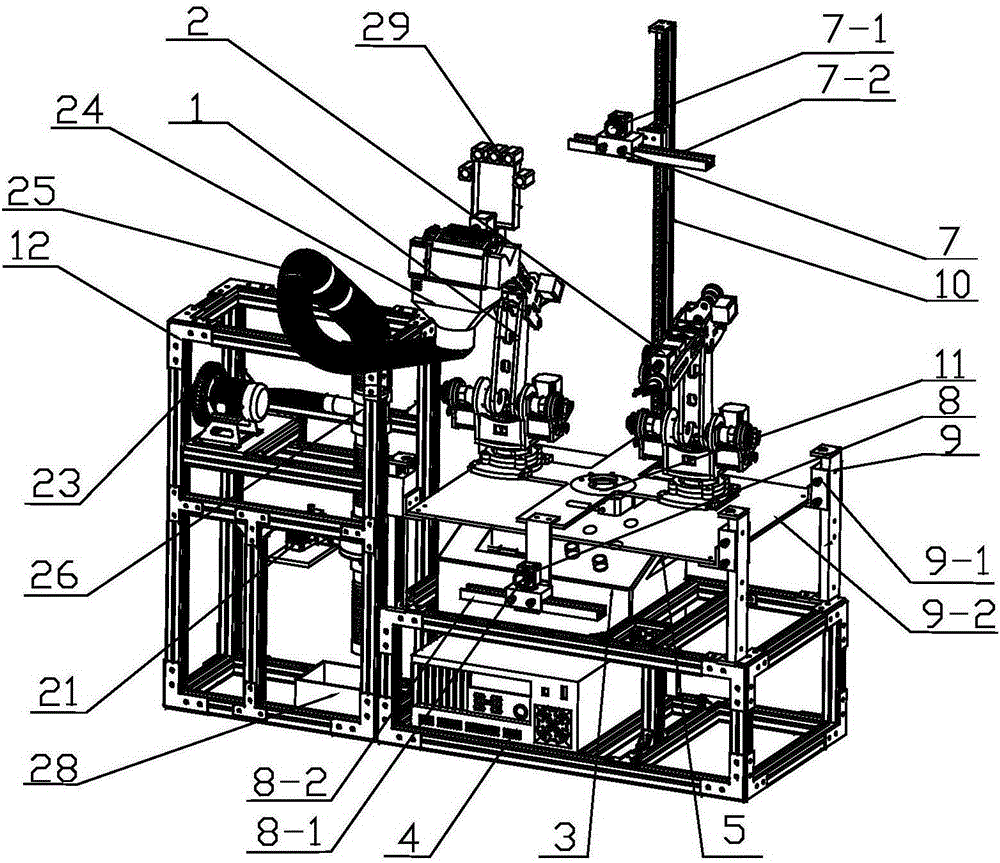

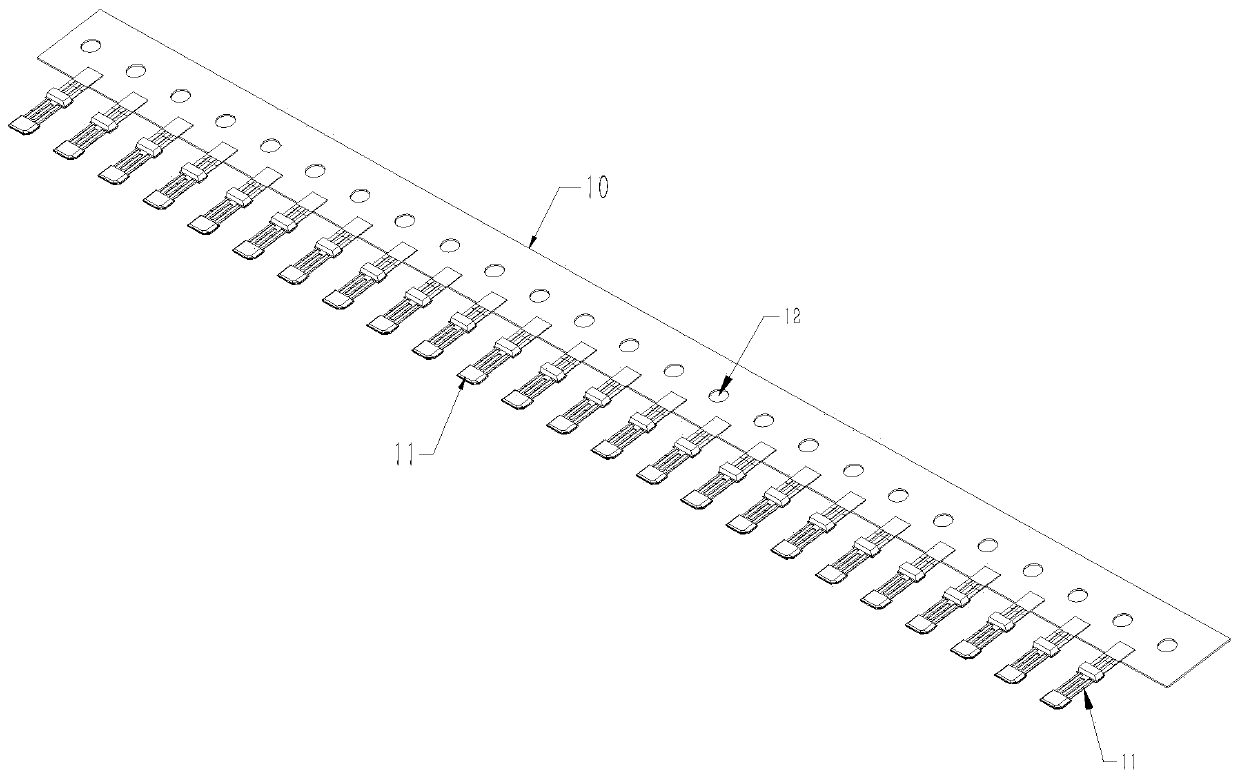

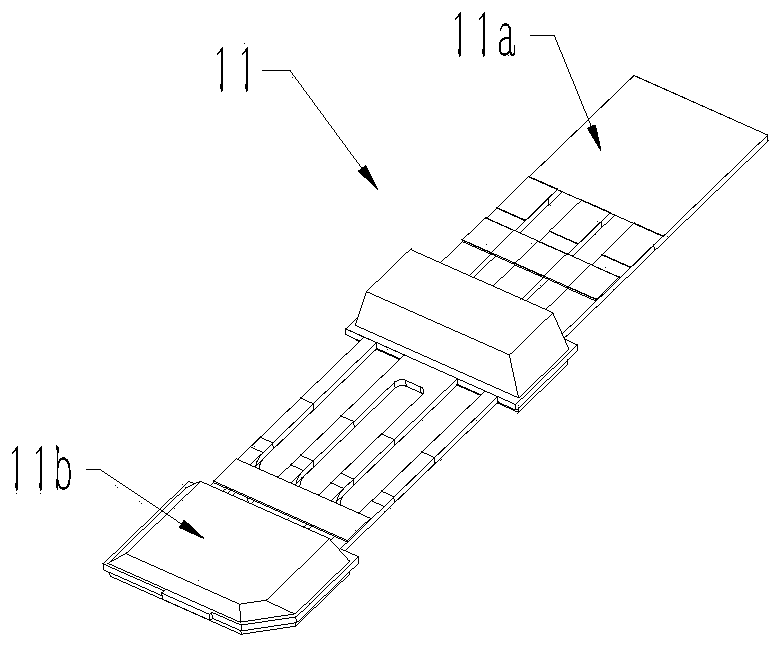

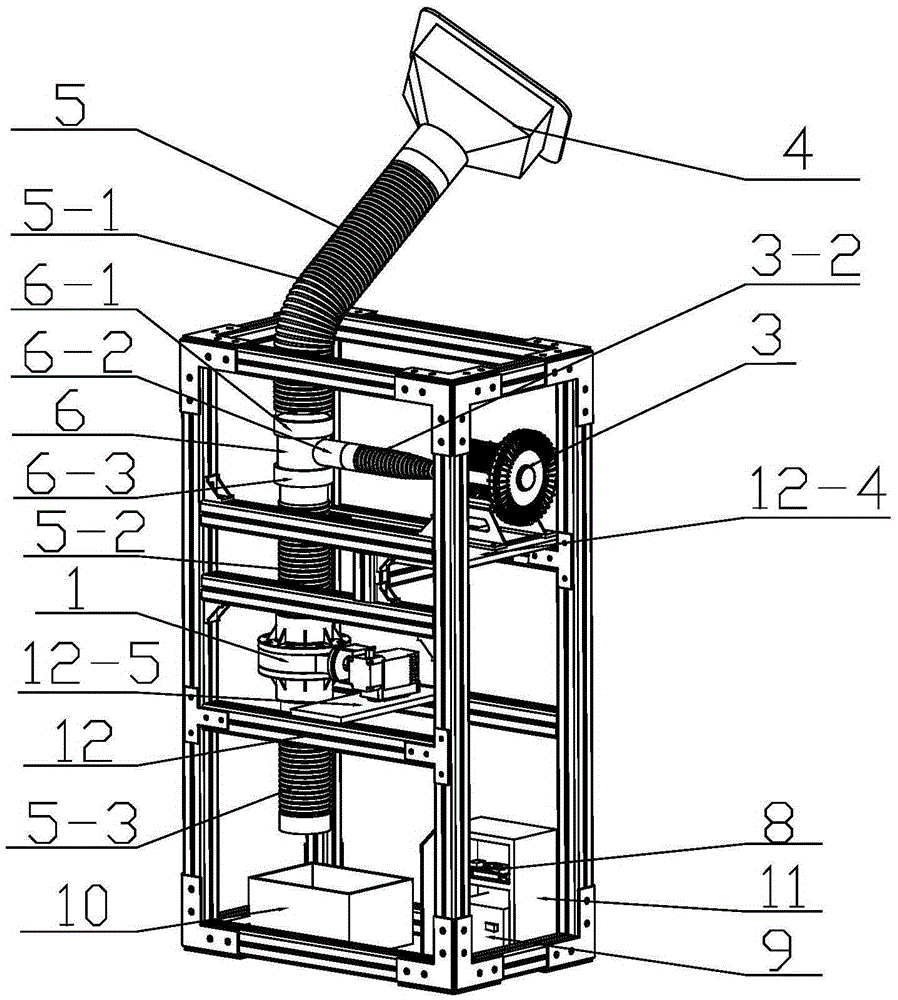

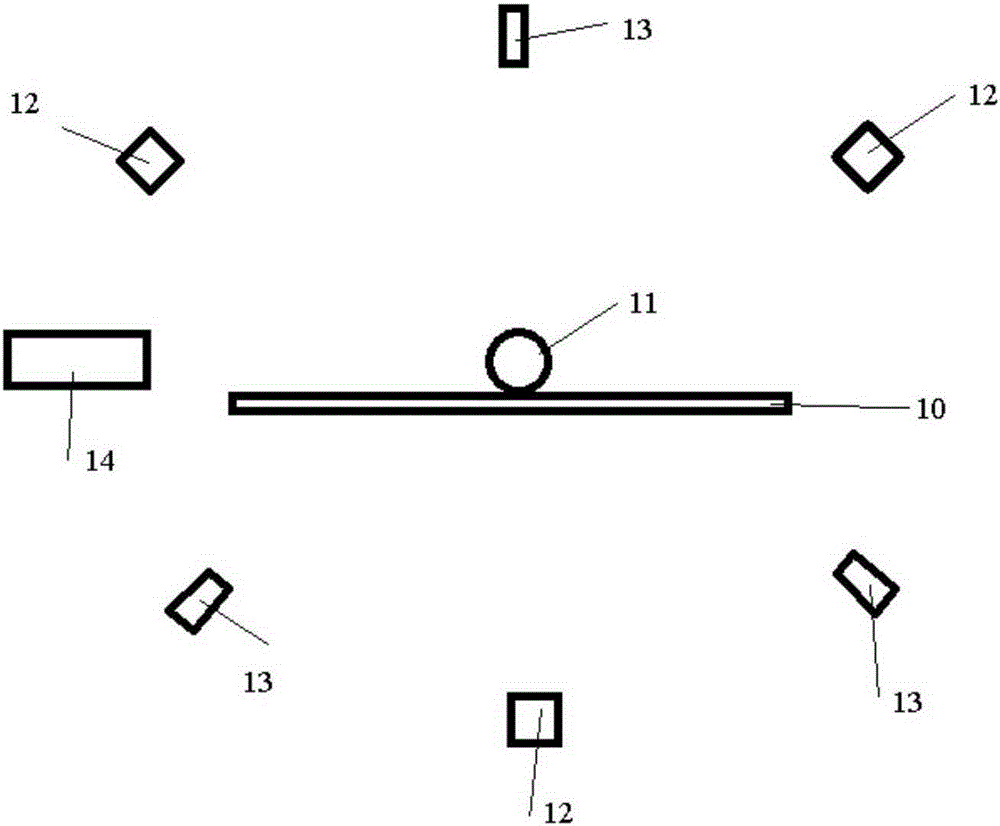

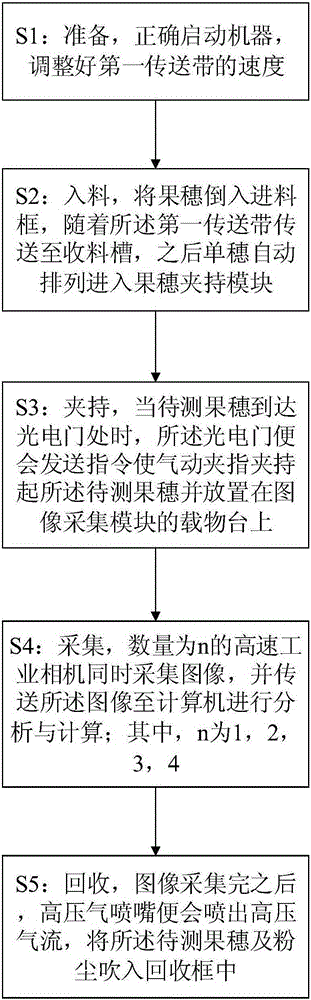

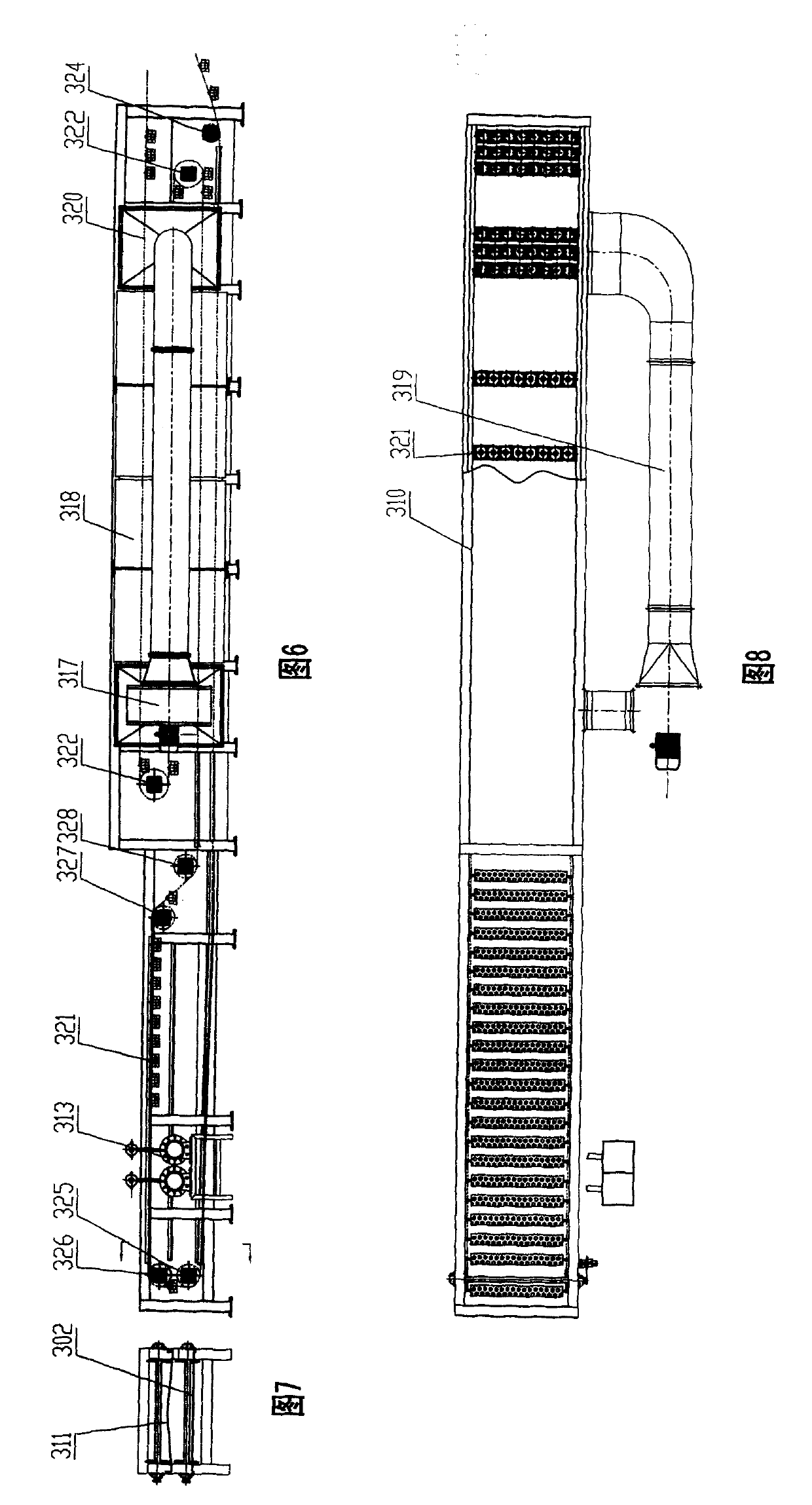

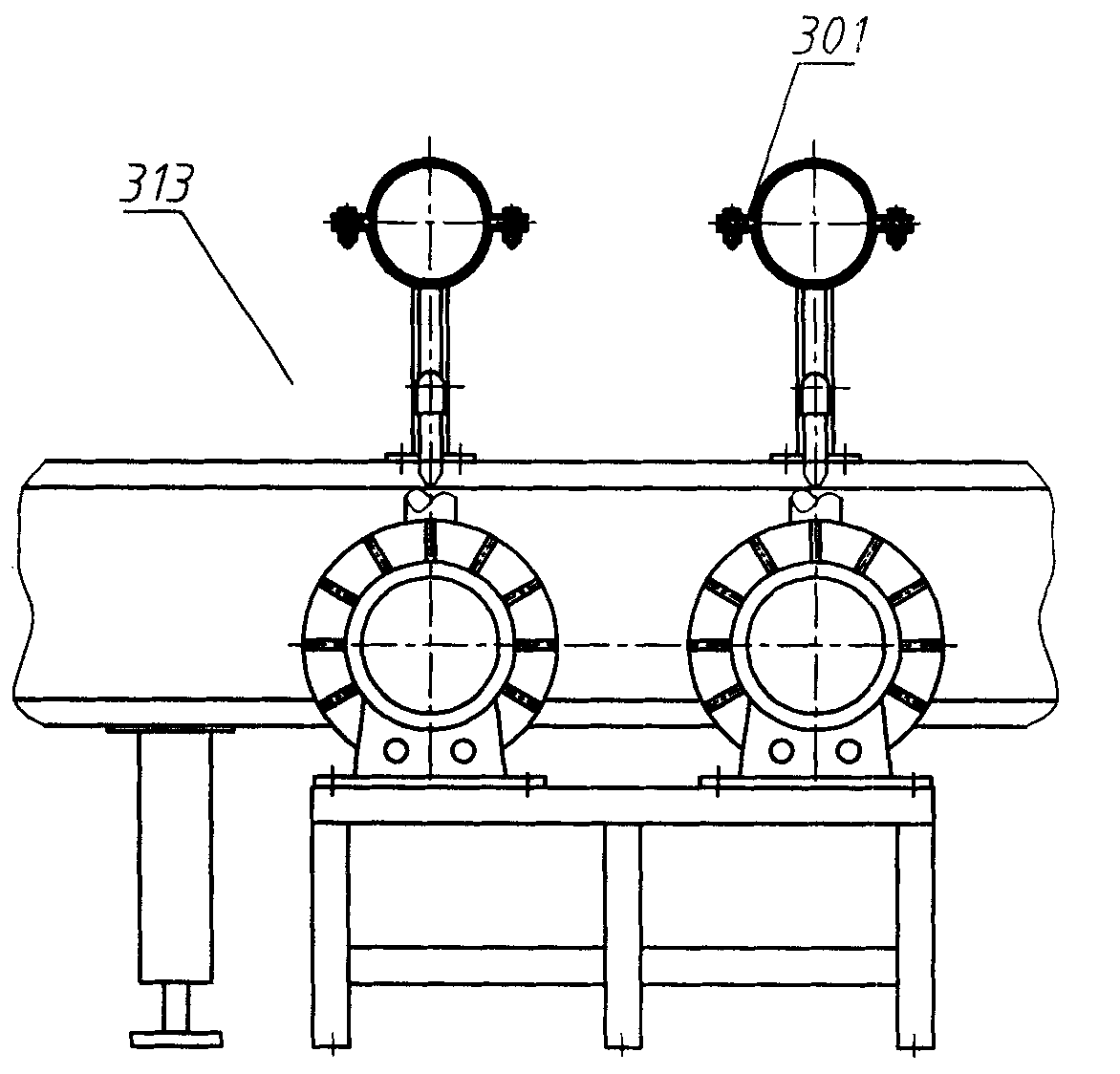

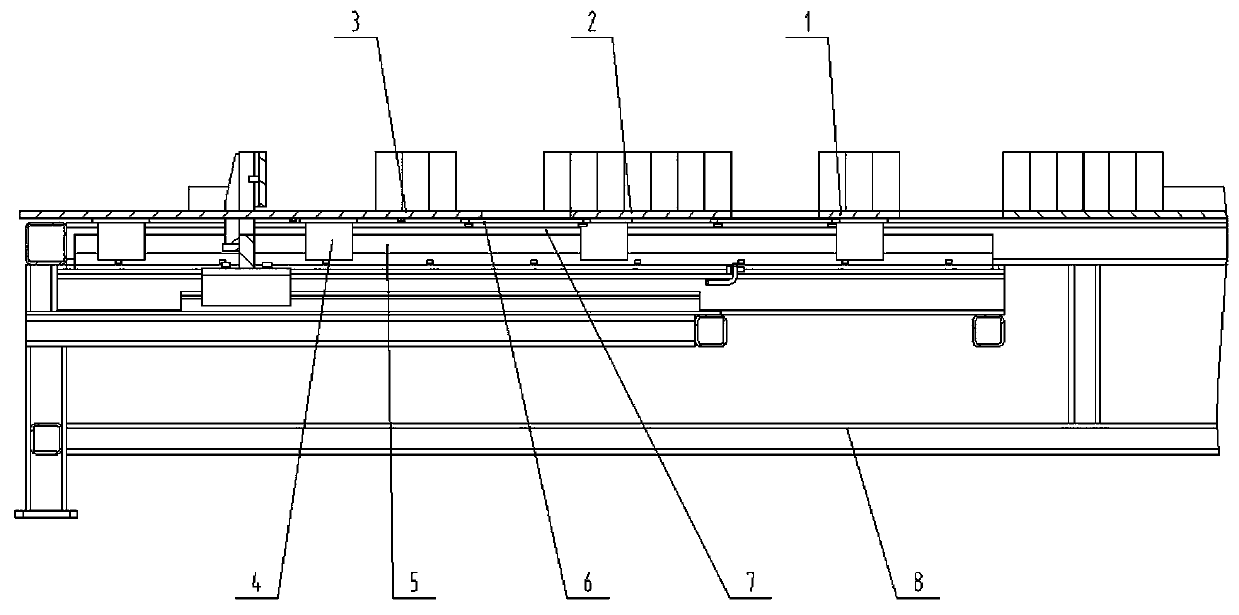

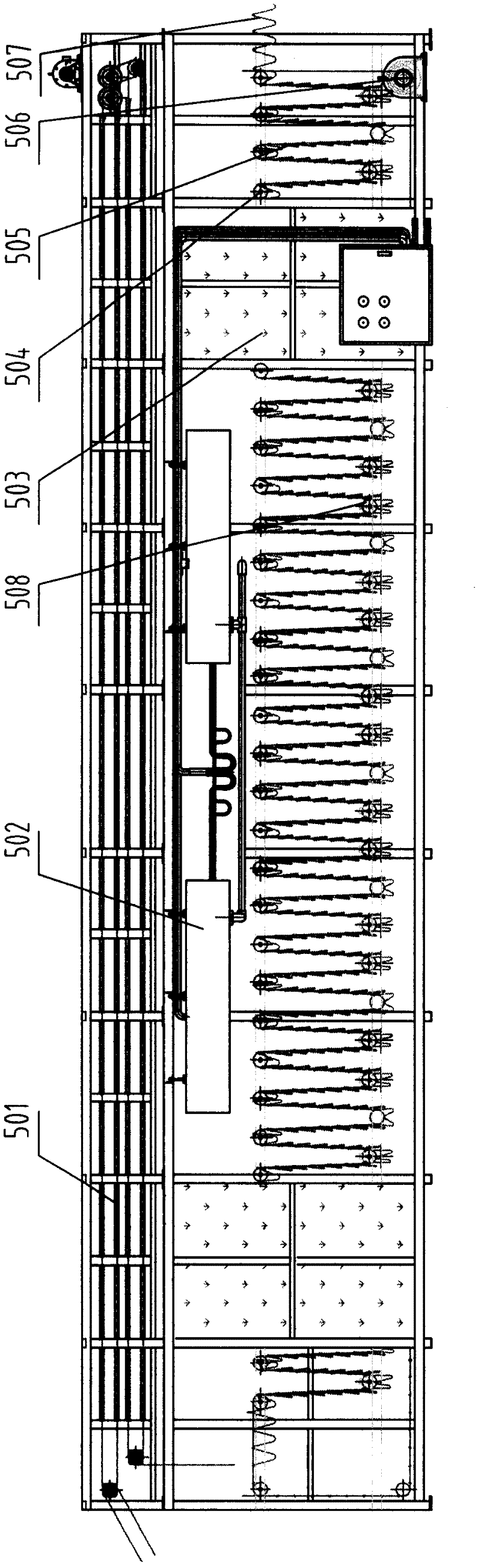

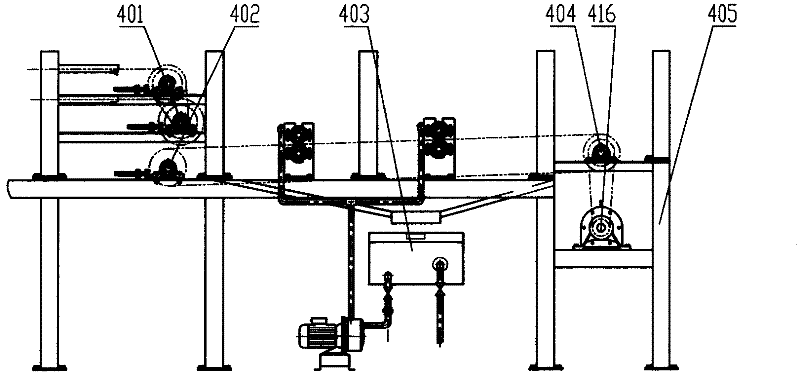

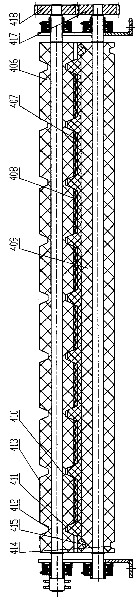

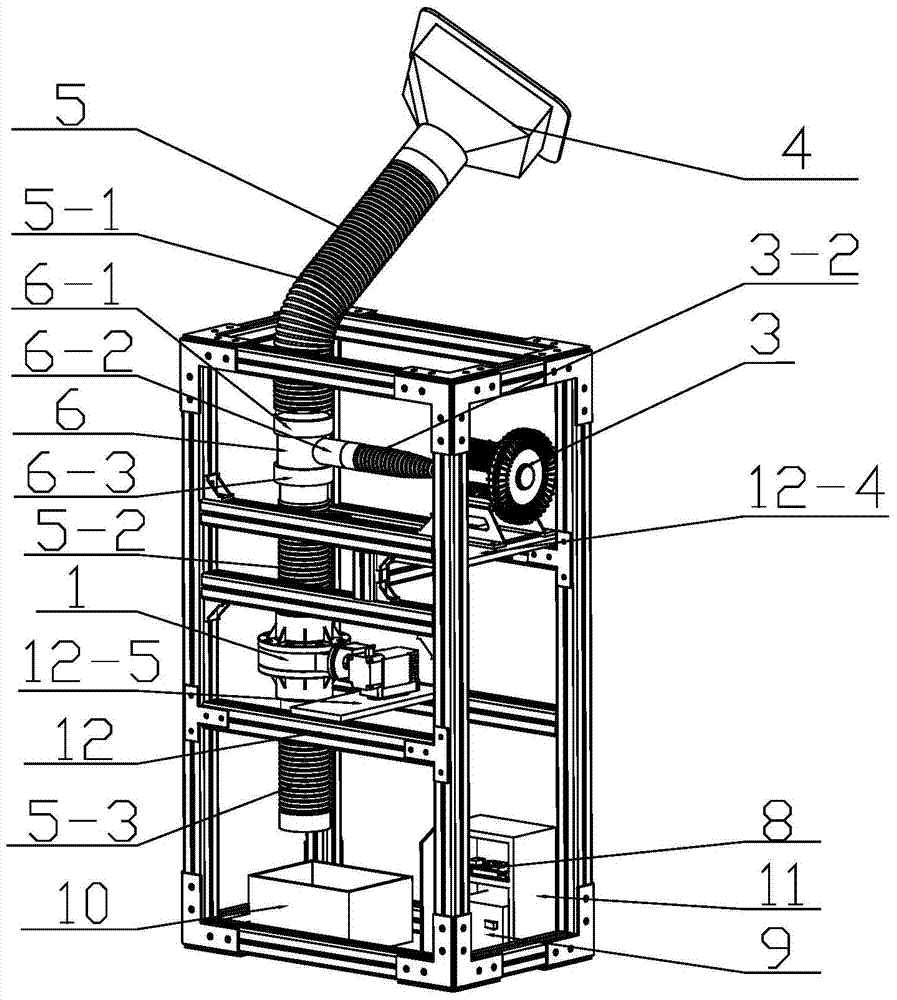

High-throughput corn ear testing assembly line device and method based on machine vision

ActiveCN104488405BAcquisition speed is fastAutomatic, objective and accurateSeed and root treatmentVisual technologyMeasurement device

The invention belongs to the technical field of machine vision and particularly relates to a machine vision based corn ear high-throughput pipelining measurement device and method. The machine vision based corn ear high-throughput pipelining measurement device comprises a feeding and transmitting module, a sensor module, an image acquiring module and a corn-ear clamping module, wherein the sensor module is connected with the feeding and transmitting module and is used for perceiving the corn ears which need to be measured and are transmitted to the sensor module by the feeding and transmitting module, the image acquiring module is used for acquiring the images of the corn ears to be measured, and the corn-ear clamping module is connected with the sensor module and is used for receiving the command of the sensor module, clamping the corn ears to be measured and releasing the corn ears to be measured to the image acquiring module. The machine vision based corn ear high-throughput pipelining measurement device can realize the full-automatic pipelining measurement of corn ears, can be used for acquiring the corn ears at a high speed and measuring the agronomic characters of corn ears accurately, objectively, non-destructively, automatically and efficiently and can well replace the manual labor to be applied to the agricultural field of corn variety breeding, producing and researching.

Owner:CHINA AGRI UNIV

Convenient vermicelli production line and its producing technology

InactiveCN101167598BIncrease production capacitySimple processFood shapingFood preparationProcess engineeringMechanical engineering

Owner:BUHLER GUANGZHOU FOOD MACHINERY

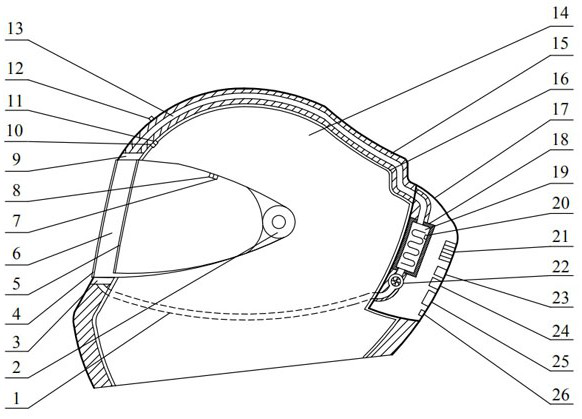

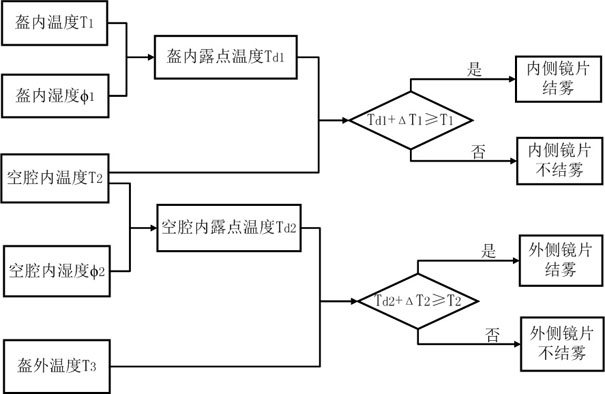

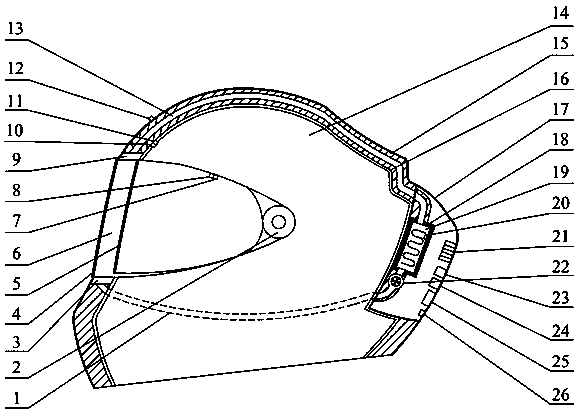

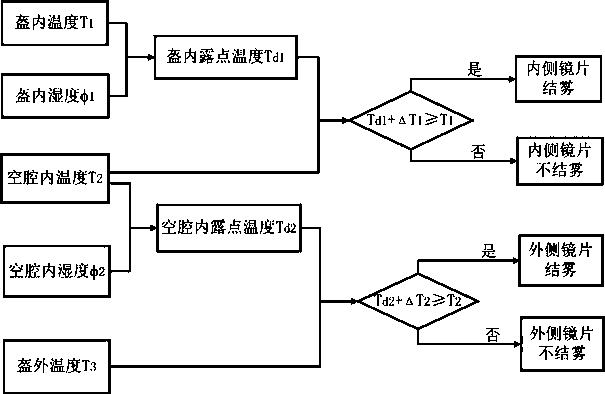

An automatic anti-fogging double-lens helmet and its use method

ActiveCN111000316BImprove securityAnti-fog and high efficiencyHelmetsHelmet coversAutomatic controlDriver/operator

The present invention proposes an automatic anti-fogging double-lens helmet and its use method. The double-lens helmet includes a helmet body, an outer lens and an inner lens are installed on the helmet body, and the inner lens is located inside the outer lens; the outer lens A cavity is provided between the inner lens and the cavity, the cavity is connected with the anti-fog mechanism, and the anti-fog mechanism is connected with the automatic control circuit. The invention has both anti-fog and anti-sunlight functions, not only realizes automatic, efficient and reliable anti-fog through the cooperation of anti-fog mechanism and automatic control circuit, and significantly improves the safety of helmet use; The cavity formed by the lens can achieve a significant reduction in energy consumption and a significant improvement in safety at the same time, thereby effectively solving the problem of fogging on the inside of the helmet lens when the driver wears the helmet in cold weather or rainy days, which seriously affects driving safety.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Automatic shearing and bending equipment

The invention discloses an automatic pin-shearing bending device. The automatic pin-shearing bending device includes a coil stock feeding platform arranged on a working table, a coil stock feeding power assembly, a single integrated circuit (IC) chip cutting assembly, a clamping jaw air cylinder assembly, a pin-shearing bending positioning assembly, a pin-shearing assembly and a bending assembly,the coil stock feeding power assembly and the single IC chip cutting assembly are both arranged on the upper part of the coil stock feeding platform, the coil stock feeding power assembly is used forallowing coil stocks to move towards a positioning platform, the single IC chip cutting assembly is used for cutting single IC chips on the coil stocks, the pin-shearing assembly and the bending assembly are arranged at the two ends above the positioning platform correspondingly, the clamping jaw air cylinder assembly is used for grabbing the cut single IC chips onto the positioning platform, thepin-shearing bending positioning assembly positions the cut single IC chips, and the pin-shearing assembly and the bending assembly shear and bend the two ends of the single IC chips correspondingly.The automatic pin-shearing bending device can realize the length of pins of the IC chips on a large scale quickly according to the actual use needs.

Owner:苏州英维特精密机械有限公司

A brick yarding device that can automatically leave forklift holes

ActiveCN106494901BSolve the problem that forklift holes cannot be leftAutomatic and reliableStacking articlesDe-stacking articlesBrickStack machine

The invention relates to a stacking device capable of automatically reserving a forklift hole. The stacking device comprises a brick collecting platform and a stacking machine; a joint dividing mechanism is arranged on the brick collecting platform; a brick joint filling mechanism is arranged on the stacking machine. The stacking device provided by the invention has the benefits that the problem that the forklift hole cannot be reserved is effectively solved; as the joint dividing mechanism is additionally arranged on the brick collecting platform, and the brick joint filling mechanism is additionally arranged on a stacking machine clamping hand, the stacking machine can reliably and efficiently reserve the forklift hole; the stacking device is automatic, efficient and stable to implement and low in overall maintenance workload, and can meet needs of automated safety production.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Full-automatic test tube cap removing device

InactiveCN113501174AAvoid pollutionQuick changeLiquid materialClassical mechanicsStructural engineering

The invention discloses a full-automatic test tube cap removing device. The device comprises a supporting mechanism, a sliding mechanism, a clamping mechanism, a liquid adding mechanism, a force storage mechanism and a transmission mechanism, wherein the sliding mechanism is horizontally and slidably connected to the supporting mechanism, the clamping mechanism and the liquid adding mechanism are vertically and slidably connected to the supporting mechanism, the force storage mechanism is connected to the bottom of the supporting mechanism, the transmission mechanism is located on the upper side of the liquid adding mechanism and is rotatably connected to the supporting mechanism, a fixing mechanism is arranged on the sliding mechanism, the sliding mechanism is connected with the clamping mechanism through a first connecting rod, the sliding mechanism is connected with the force storage mechanism in a meshed mode, and the transmission mechanism is connected with the liquid adding mechanism through a second connecting rod. Through mutual cooperation of all the mechanisms, the test tube cap is removed in the moving process, liquid adding is conducted through the liquid adding mechanism after the test tube cap is moved to the end point, the test tube cap can be covered in the process of returning to the original position, and automatic treatment of the whole process of test tube cap removing, liquid adding and cap covering is achieved.

Owner:长沙千麦医学检验实验室有限公司

Full automatic production line of convenient and instant rice-flour and production technology thereof

InactiveCN101518311BIncrease production capacitySimple processFood preparationDough processingProcess engineeringIndustrial engineering

The invention discloses a production line of convenient and instant rice-flour and a production technology thereof. The production line comprises a rice processing device, a stewing mill, a self-ripe The invention discloses a production line of convenient and instant rice-flour and a production technology thereof. The production line comprises a rice processing device, a stewing mill, a self-ripescrooping device, an aging device, a quantitative disconnecting device, an entry-box shaping device, a powder block drying device, a powder block cooling device and a package conveying device which arscrooping device, an aging device, a quantitative disconnecting device, an entry-box shaping device, a powder block drying device, a powder block cooling device and a package conveying device which are arranged in sequence in accordance with material transferring direction. The aging device comprises a ricevermicelli refrigerator, an aging machine and a continuous fluffer. The production line ande arranged in sequence in accordance with material transferring direction. The aging device comprises a ricevermicelli refrigerator, an aging machine and a continuous fluffer. The production line andthe production technology have the advantages of good product quality, broad suitability, high efficiency and automation, lower energy consumption, high yield, hygiene and environment protection.the production technology have the advantages of good product quality, broad suitability, high efficiency and automation, lower energy consumption, high yield, hygiene and environment protection.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Anti-blocking isolation plug for wolfberry collection device

InactiveCN105248044BAutomatic and efficientAutomatic collection and efficientPicking devicesLycium barbarum fruitEngineering

Owner:QINGDAO AGRI UNIV +1

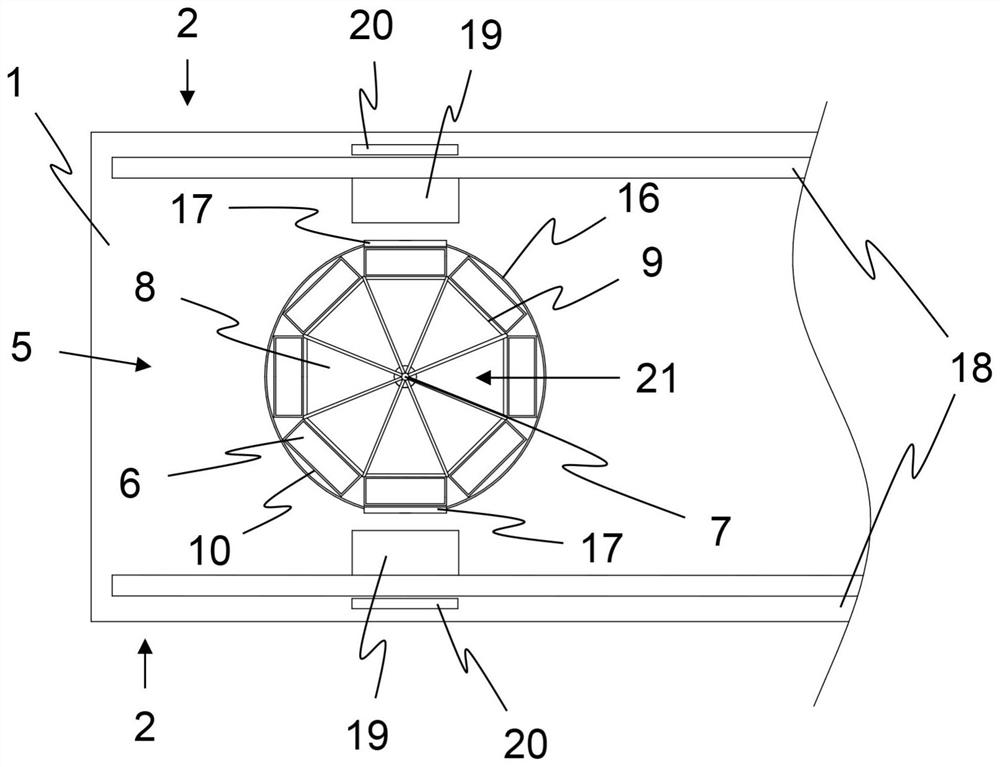

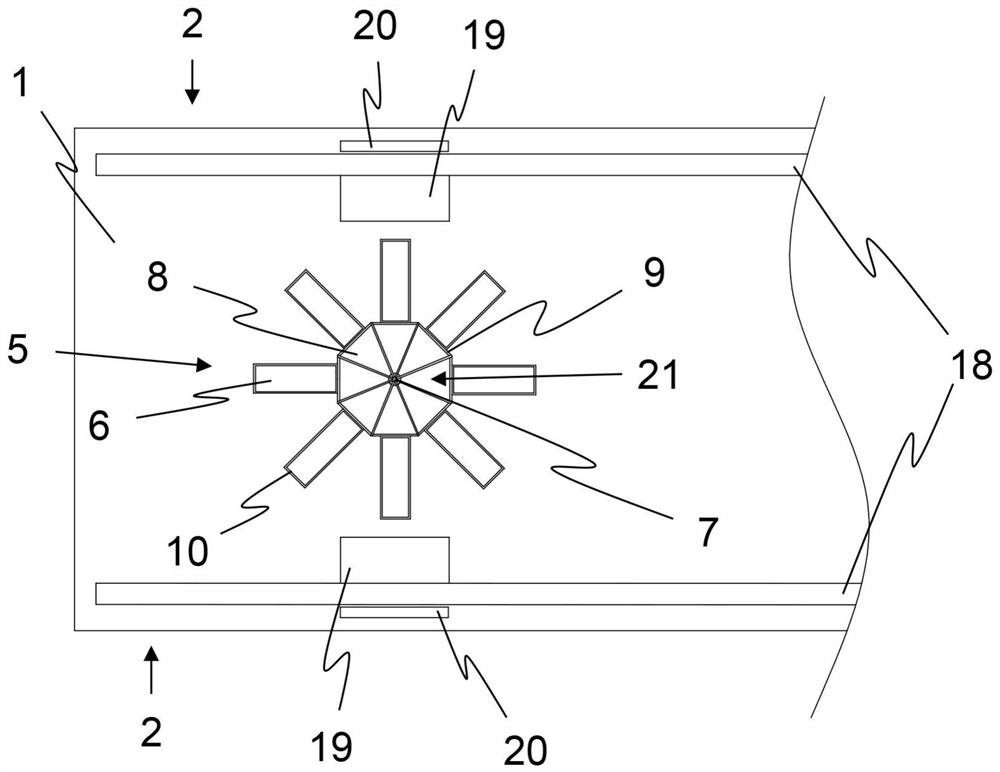

Method and apparatus for feeding tubes to the winding stations of a textile machine, and textile machine

PendingCN112805231AEfficient deliveryOptimize layoutFilament handlingStructural engineeringMechanical engineering

The present invention relates to a method for feeding tubes (6) to the winding stations (3) of a textile machine (1), wherein the tubes (6) are arranged in a rotatably mounted frame (8) and are fed to a transporting device (18), which transports the tubes (6) to the winding stations (3). In the method according to the invention, the tubes (6) are arranged with substantially horizontal longitudinal axes (11) in tube shafts (10) of a rotatably mounted frame (8). As a result of the rotation of the frame (8), the tubes (6) are assigned selectively to one machine side (2) of the textile machine (1). The present invention also relates to an apparatus (5) for feeding tubes (6) to the winding stations (3) of a textile machine (1) by means of the method according to the invention. The invention also relates to a textile machine (1) having an apparatus (5) according to the invention.

Owner:MASCHINENFABRIK RIETER AG

Automatic anti-fogging double-lens helmet and using method

ActiveCN111000316AImprove securityAnti-fog and high efficiencyHelmetsHelmet coversAutomatic controlDriver/operator

The invention provides an automatic anti-fogging double-lens helmet and a using method thereof. The double-lens helmet comprises a helmet body, an outer side lens and an inner side lens are installedon the helmet body, and the inner side lens is located on the inner side of the outer side lens; a cavity is arranged between the outer side lens and the inner side lens, the cavity is connected withan anti-fogging mechanism, and the anti-fogging mechanism is connected with an automatic control circuit. The anti-fogging helmet has the anti-fogging function and the direct sunlight prevention function, automatic, efficient and reliable anti-fogging is achieved through cooperation of the anti-fogging mechanism and the automatic control circuit, and the use safety of the helmet is remarkably improved; moreover, the cavity formed by the two lenses can achieve the remarkable reduction of energy consumption and the remarkable improvement of safety at the same time, thereby effectively solving aproblem that the driving safety is severely affected because the inner sides of the lenses of the helmet are fogged when a driver wears the helmet in cold weather and rainy days.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com