Anti-blocking isolation plug for wolfberry collection device

The technology of isolation plug and wolfberry is applied in the field of collection device and anti-blocking isolation collection device, which can solve the problems of unfavorable automation and intelligence of wolfberry, small fruit collection box, shaking of wolfberry fruit, etc., and achieves good practical application prospect and continuous collection. and packing, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

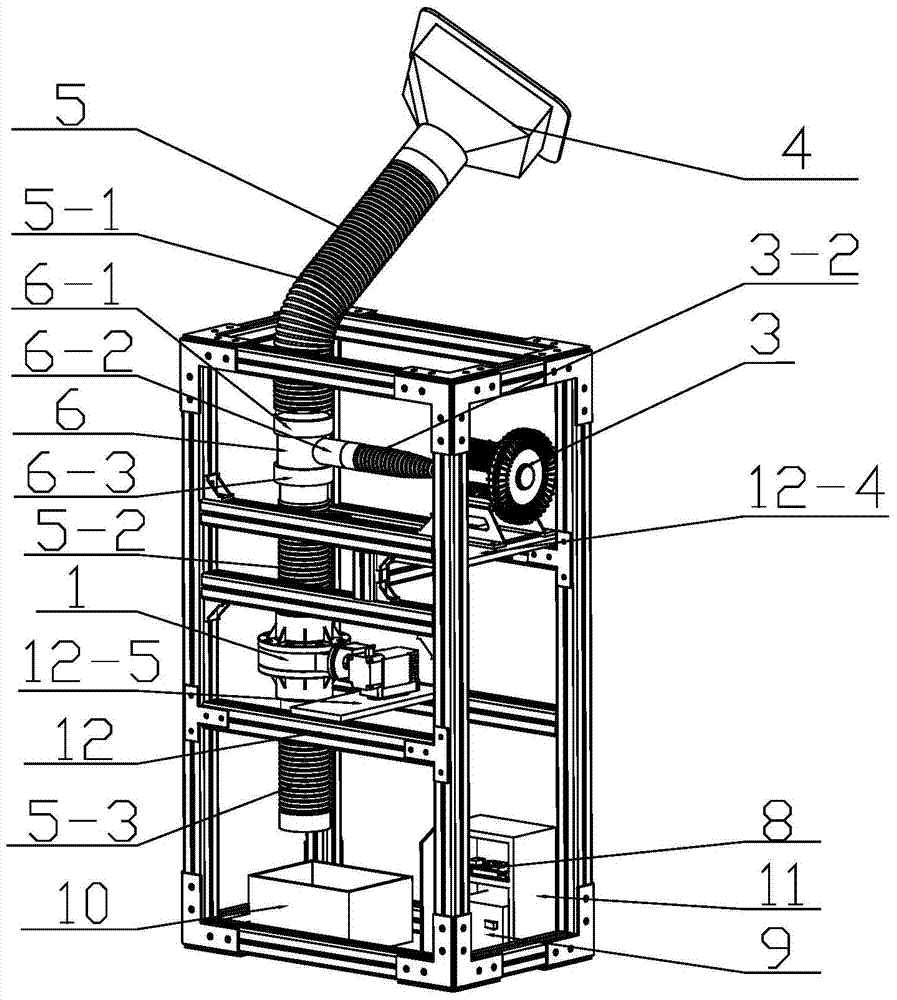

[0029] The anti-blocking isolation type wolfberry automatic collection device includes a frame 12 and a collection device, a power device and a storage device arranged on the frame 12; the power device is connected with the collection device, and then connected with the storage device. The power device includes a power supply 9, a control device 8 and a fan 3, and the storage device is a fruit collection box 10; The control device of the anti-blocking isolation type wolfberry automatic collection device is a control cabinet 11, and a controller 8 and a power supply 9 are arranged in the control cabinet 11; the control device is connected with the blower fan 3 and the anti-blocking type electric valve 1 respectively. The fan 3 is placed on the frame 12 through the fan backing plate 12-4.

[0030] The collection device includes a collection funnel 4 and a collection hose 5 , and the collection hose 5 is provided with a three-way interface 6 and an anti-blocking electric valve 1 . ...

Embodiment 2

[0033] Different from Embodiment 1, the second end interface 6-2 of the tee interface 6 is provided with an anti-blocking isolation bolt inside, and the anti-blocking isolation bolt is a cylindrical structure that penetrates up and down inside, including an isolation bolt shell The body 2-1 and the roller 2-2 and the wind deflector 2-4 arranged inside the spacer housing 2-1. The rollers 2-2 are evenly arranged at one end of the anti-blocking isolation bolt, and the wind deflector 2-4 is arranged at the other end of the anti-blocking isolation bolt. The gap between the adjacent rollers 2-2 is smaller than the diameter of the fruit, and the rollers 2-2 and the wind deflectors 2-4 are arranged in parallel. The roller 2-2 is provided with a rotating shaft inside, and the roller 2-2 is connected to the rotating shaft in rotation; the roller 2-2 is connected to the bearing 2-5 through the rotating shaft, and then connected to the isolation bolt housing 2-1 . Two fan wheels 2-3 are...

Embodiment 3

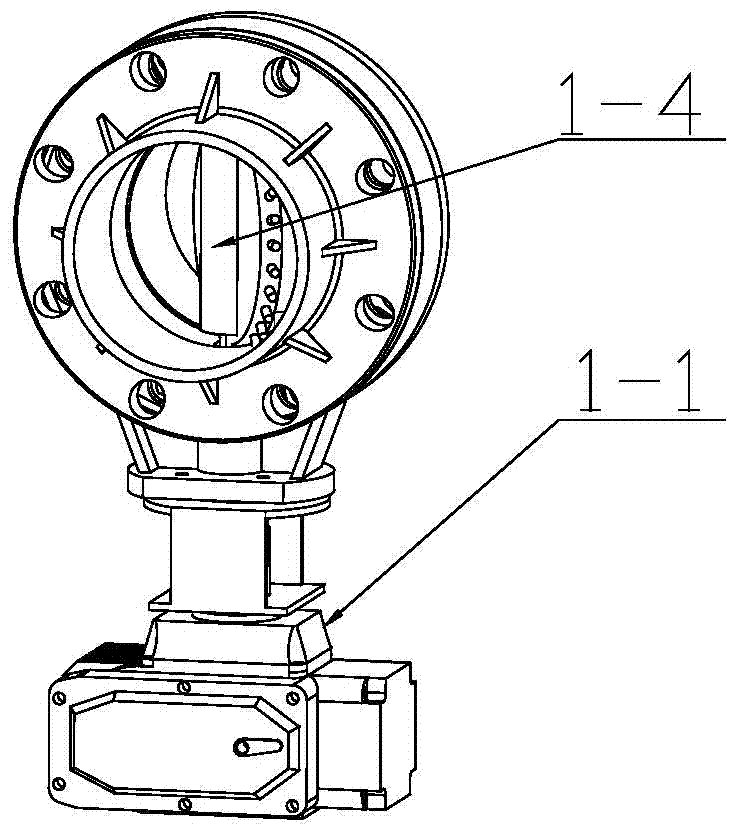

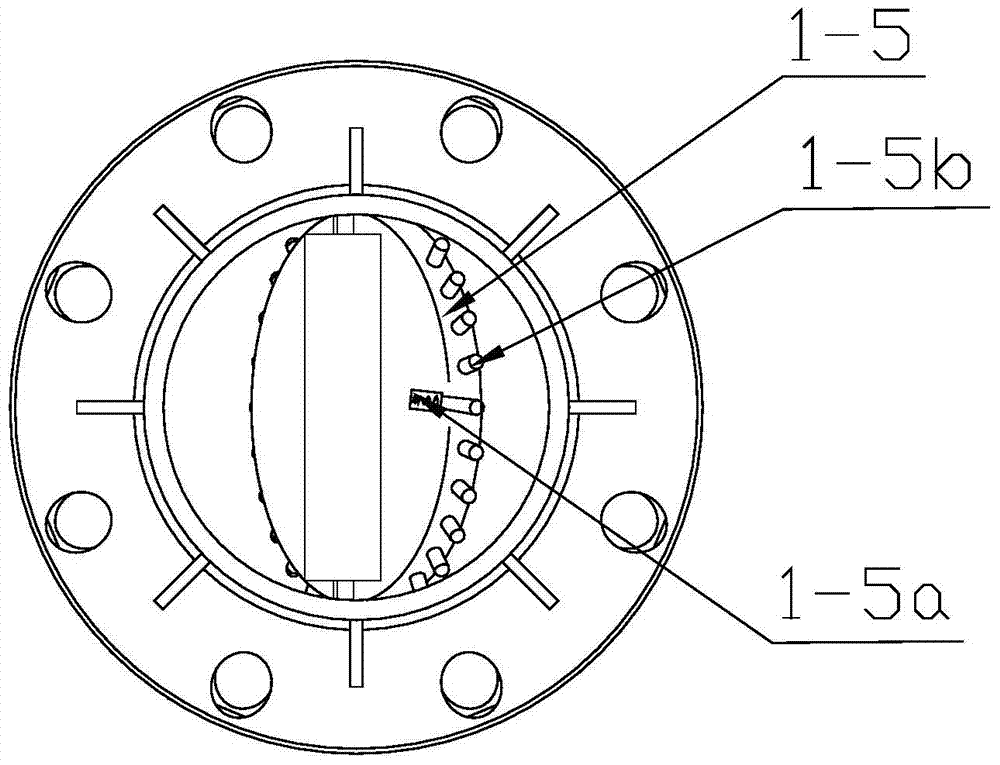

[0035] Different from embodiment 1, the valve plates 1-4 are mesh plates, and the aperture of the mesh is smaller than the size of wolfberry fruit. The interior of the collection hose 5 is provided with a buffer device, and the buffer device includes a plurality of sponge damping strips 7-1 fixed on the inner wall of the collection hose 5, and the sponge damping strips 7-1 are arranged along the collection hose 5. The lengthwise direction is set on the inner wall of the collecting hose 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com