Full-automatic test tube cap removing device

A fully automated test tube capping technology, which is applied in packaging, transportation and packaging, and the type of packaged items, can solve the problems of time-consuming, labor-intensive, unguaranteed, and inability to ensure that the test tube cap is corrected, and achieve the effect of saving the time of opening the cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

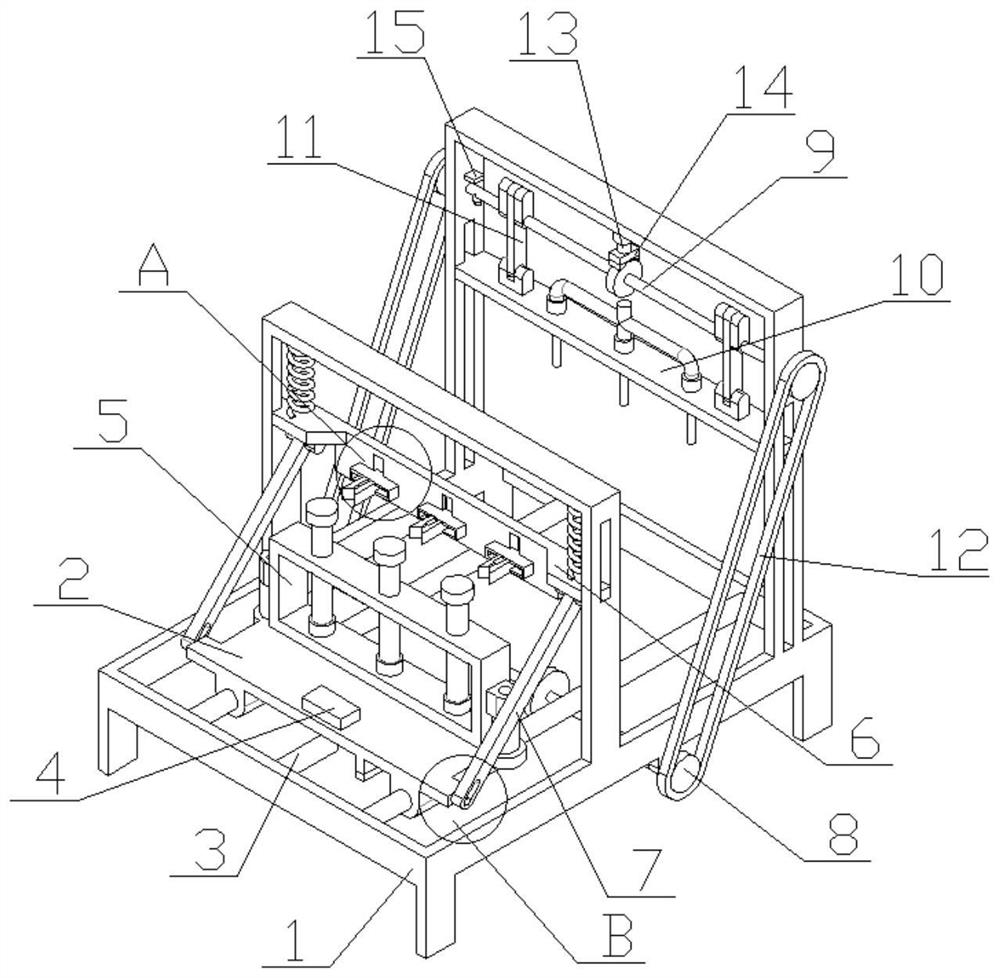

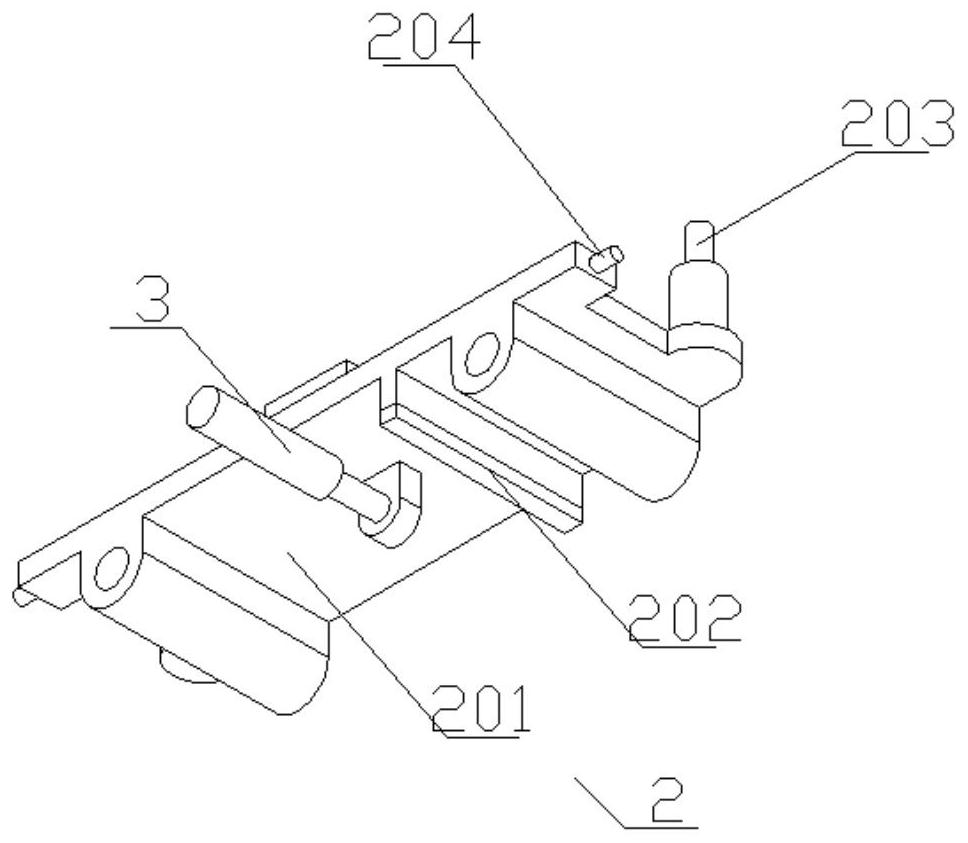

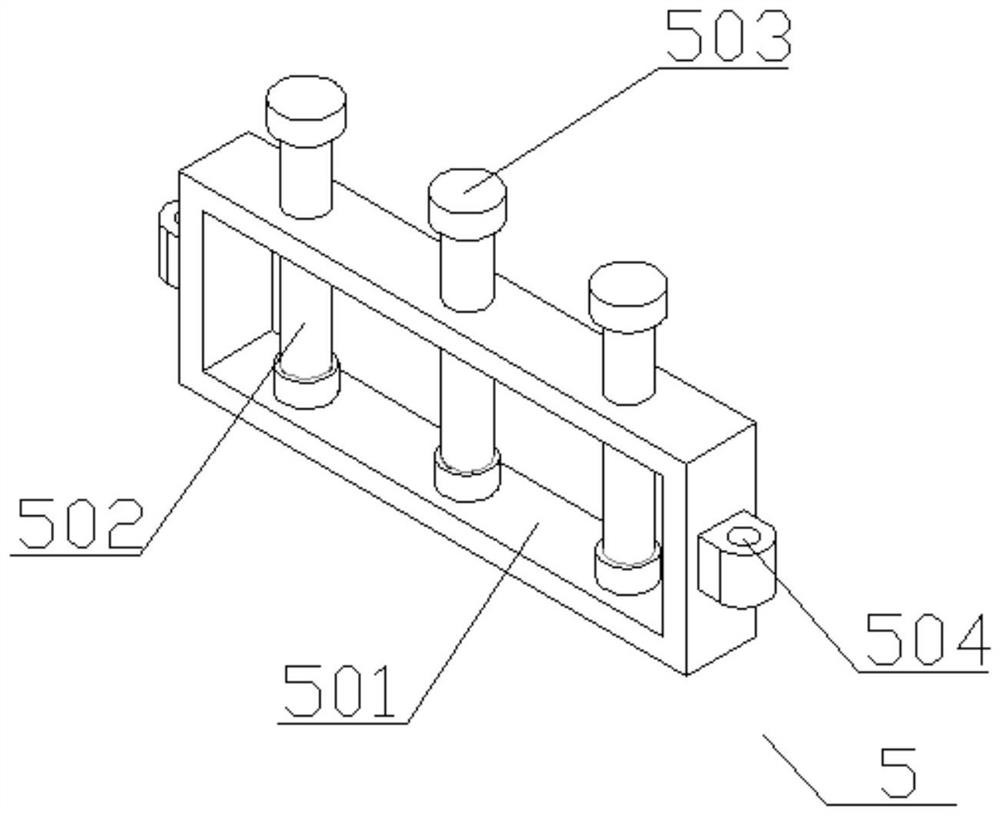

[0030] Combine below Figure 1-9 Describe the specific embodiment of the present invention, a fully automatic test tube cap removal device, including a support mechanism 1, a slide mechanism 2 horizontally slidably connected to the support mechanism 1, and a gripper vertically slidably connected to the support mechanism 1 Mechanism 6 and liquid filling mechanism 10, power storage mechanism 8 connected to the bottom of said support mechanism 1, and transmission mechanism 9 located on the upper side of said liquid filling mechanism 10 and connected to support mechanism 1 in rotation, mounted on said sliding mechanism 2 There is a fixing mechanism 5, the sliding mechanism 2 and the gripping mechanism 6 are connected through a first connecting rod 7, a spring is arranged between the gripping mechanism 6 and the supporting mechanism 1, and the power storage mechanism 8 is connected to the transmission mechanism 9 through a belt 12, the sliding mechanism 2 is meshed with the power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com