Method and apparatus for feeding tubes to the winding stations of a textile machine, and textile machine

A technology for textile machines and sleeves, applied in the field of winding stations, can solve problems such as undescribed solutions for efficiently supplying winding stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following detailed description, identical and / or at least equivalent features in different drawings use the same reference numerals. Individual features, their configuration and / or mode of operation are usually only detailed when they are first mentioned. If the individual features are not specified again, their configuration and / or mode of operation correspond to those of equivalent or similar features already described.

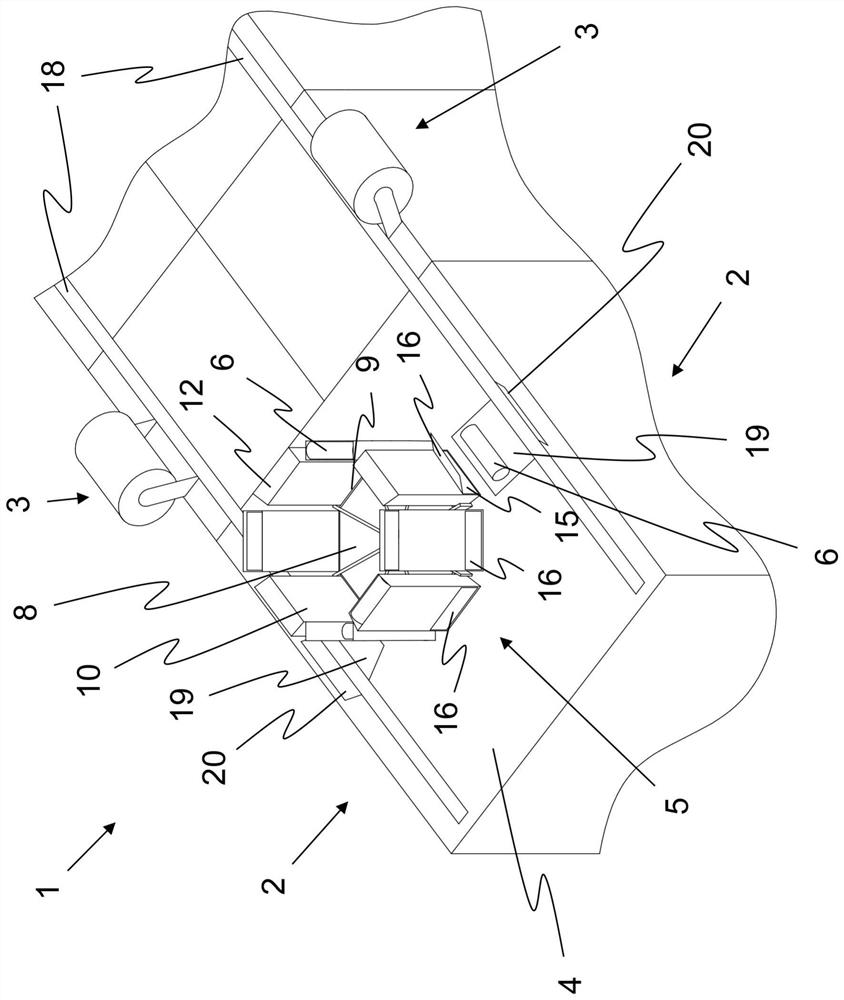

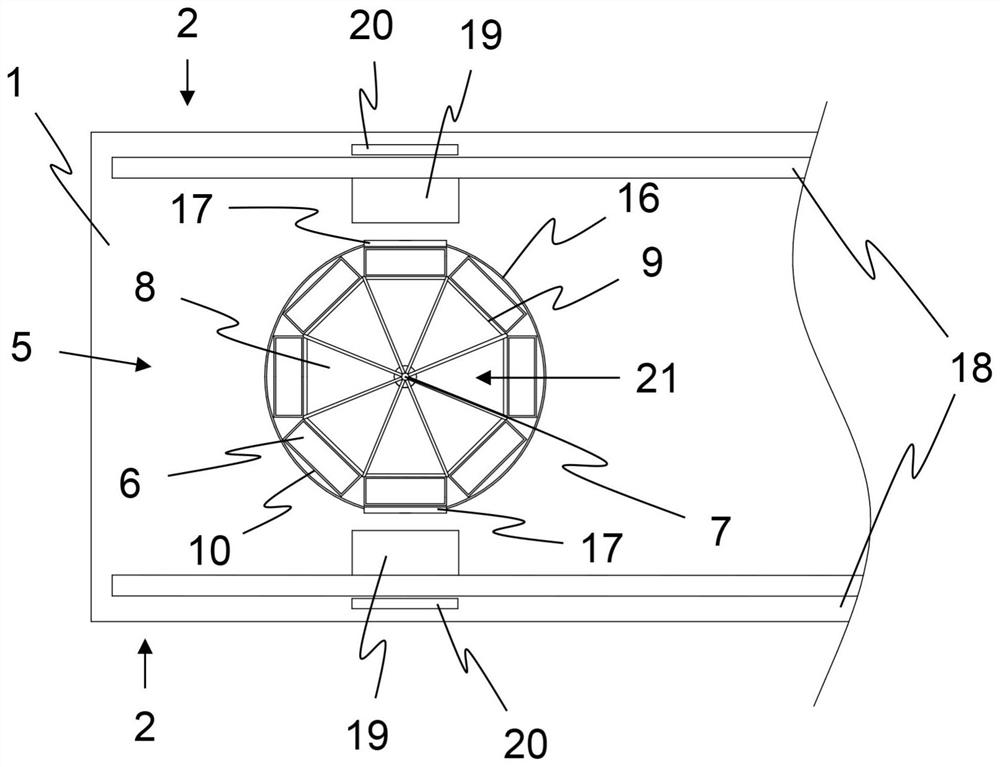

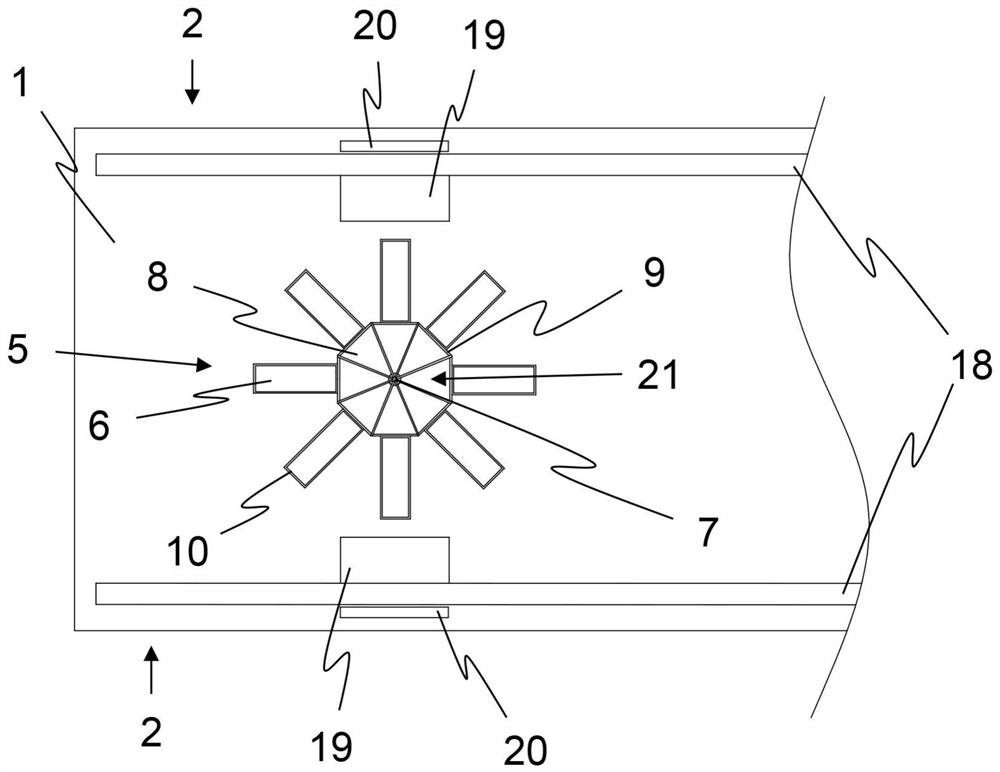

[0037] figure 1 A textile machine 1 is shown with winding stations 3 arranged on two machine sides 2 . Arranged on the top side 4 of the textile machine 1 is a device 5 according to the invention for feeding a sleeve 6 to a winding station 3 . Centrally arranged between the machine sides 2 is a frame 8 mounted rotatably around a vertical axis 7 (see figure 2 ). On the outer periphery 9 of the frame 8 are again arranged a plurality of casing magazines 10 comprising casing casings 6 with longitudinal axes 11 arranged substantially horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com