A brick yarding device that can automatically leave forklift holes

A forklift hole, automatic technology, applied in the field of sintered brick stacking, can solve the problems of inability to forklift unloading, stacking, low efficiency, brick stacking transfer, stacking, and unloading complex, etc., and achieve the overall maintenance workload. Small, meet the effect of automatic safety production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in combination with specific embodiments.

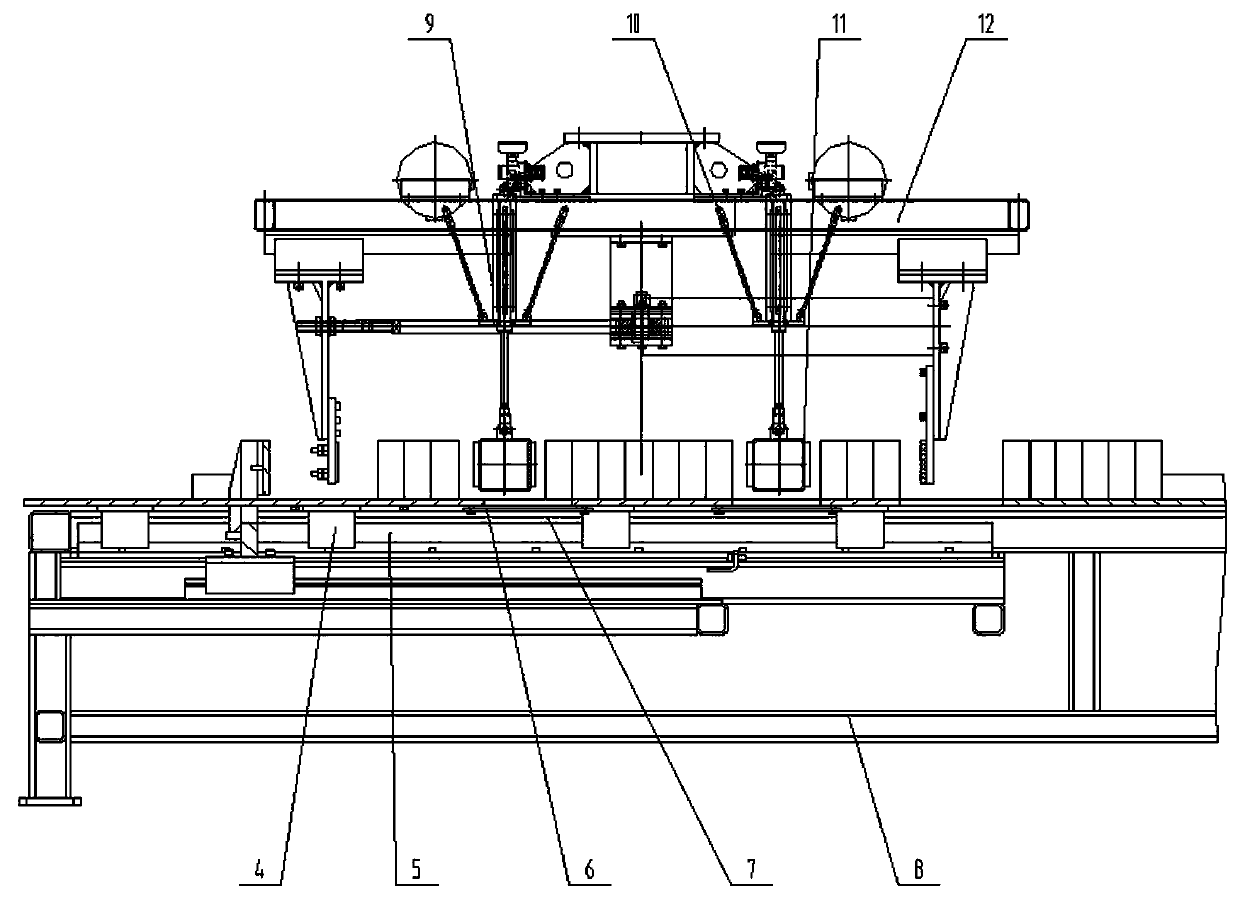

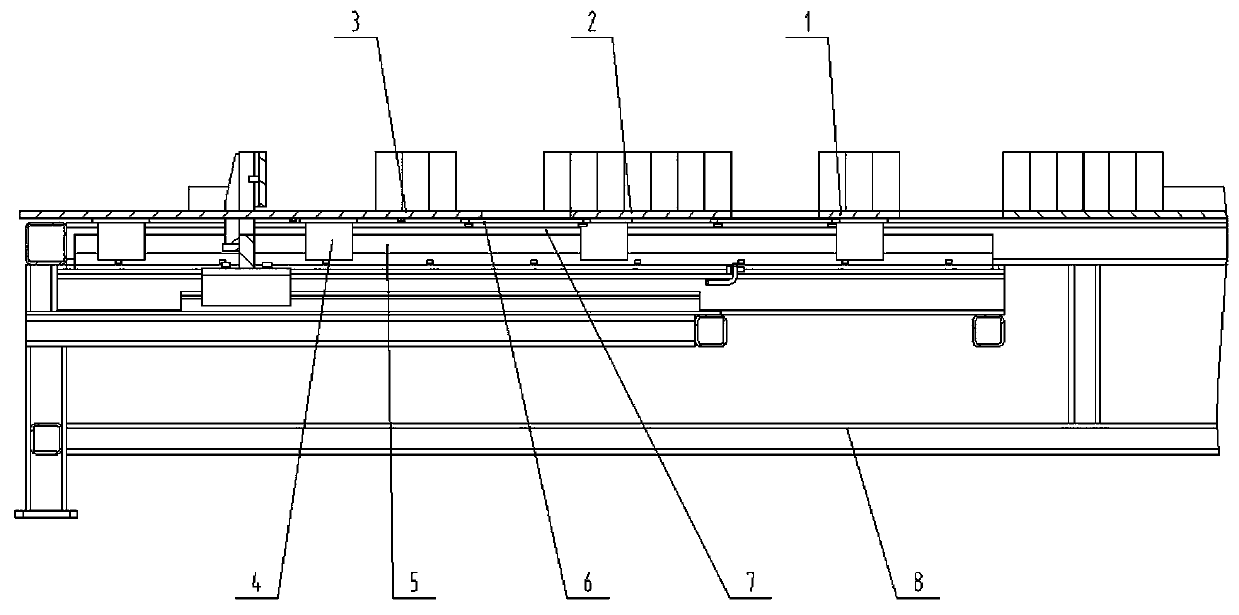

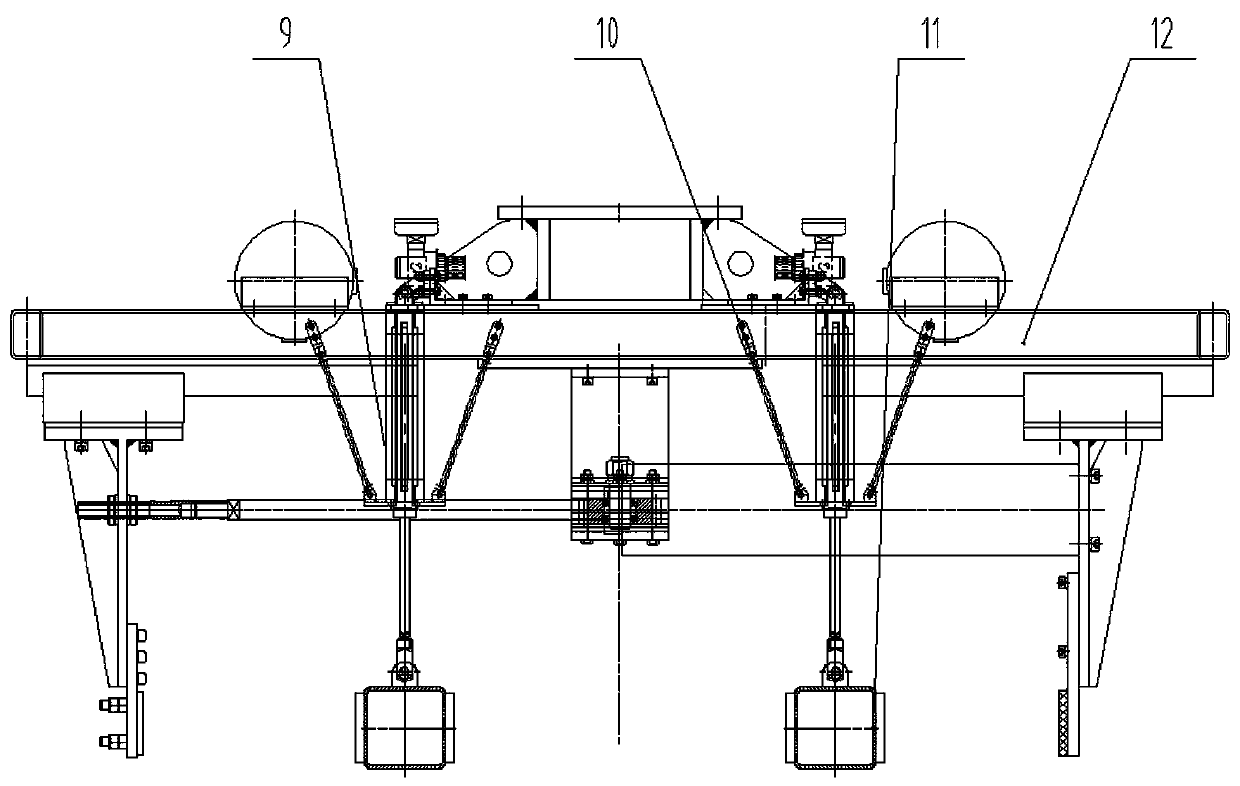

[0025] As shown in the figure: a palletizing device that can automatically leave holes for forklifts, including a brick collection platform 8 and a palletizer 12, the brick collection platform 8 is provided with a joint mechanism, and the palletizer 12 is provided with a brick joint Filling mechanism; the seam dividing mechanism includes three movable panels arranged on a plane, a guide mechanism, a limit mechanism and a cylinder I7, the guide mechanism is arranged at the bottom of the movable panel, and multiple movable panels can be placed on the cylinder Under the control of Ⅰ7, it moves along the guide mechanism, and the joints are realized between two adjacent movable panels, and there is a limit mechanism between the adjacent two movable panels; the brick joint filling mechanism includes cylinder Ⅱ9 and brick joint filling Object 11, the brick joint filler 11 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com