inventionBattery fixture for a large car battery swap substation

A technology for battery fixture and power station, applied in vehicle maintenance, vehicle components, electric power devices, etc., can solve the problem of increasing difficulty in the use and promotion of pure electric vehicles, increasing costs for battery maintenance and recycling, and reducing battery service life, etc. problem, to achieve the effect of strong practicability, reasonable structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

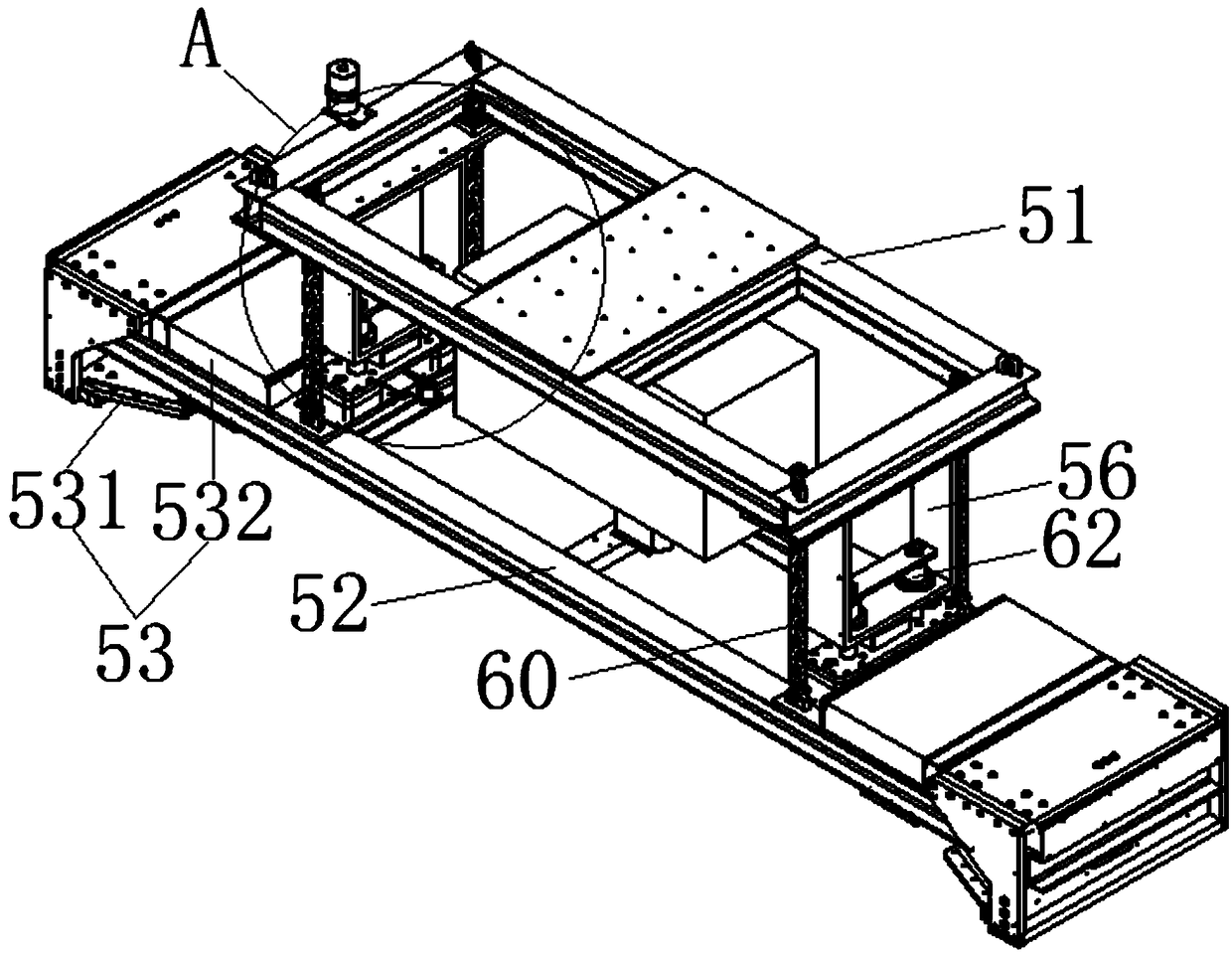

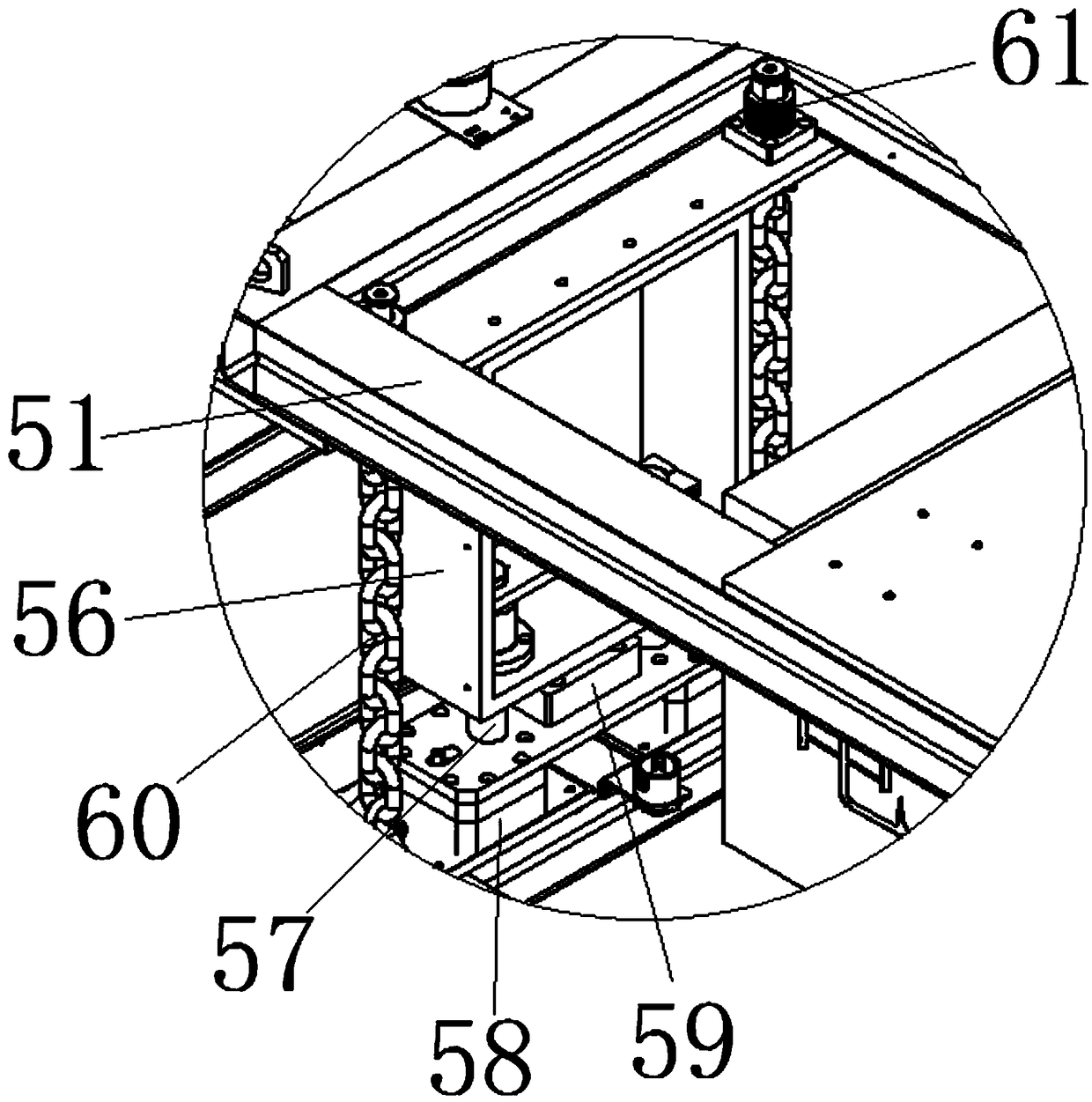

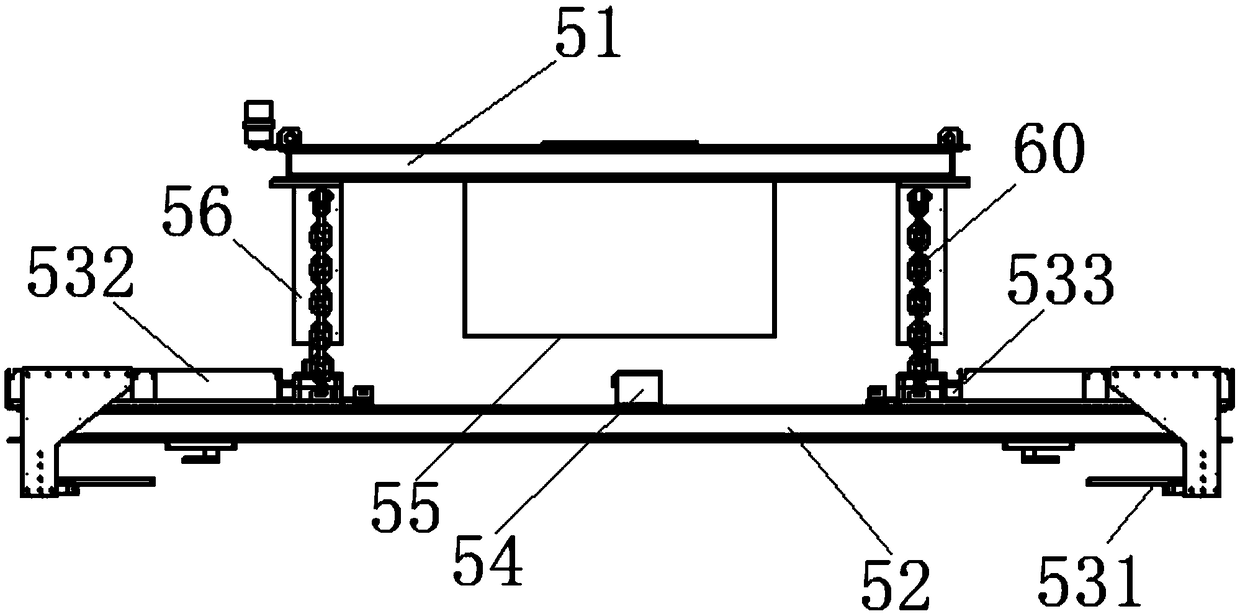

[0018] Embodiment: A battery clamp for a large-scale vehicle exchange station, including a fixed bracket 51, a floating bracket 52, a gripper mechanism 53, a camera mechanism 54, and an electric control part 55; fixed frames 56 are arranged on both sides of the fixed bracket 51; The fixed frame 56 is provided with a lifting rod 57; the lower part of the lifting rod 57 is provided with a floating frame 52; an electromagnetic absorber 58 and a magnetic block 59 are arranged between the floating frame 52 and the fixed frame 56; the floating frame 52 and the fixed bracket 56 are also provided with a chain suspension structure 60; when the magnetic block 59 is separated from the fixed frame 56, the chain suspension structure 60 carries the floating frame 52 and is in a stressed state; the top of the chain suspension structure 60 is set There is a disc spring floating device 61; the two ends of the floating frame 52 are provided with gripper mechanisms 53; the camera mechanism 54 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com