Automatic counterweight loading control device for electronic steelyard detector

A detection device and technology of electronic crane scale, applied in the field of measurement and detection, can solve the problem of difficulty in loading weights and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

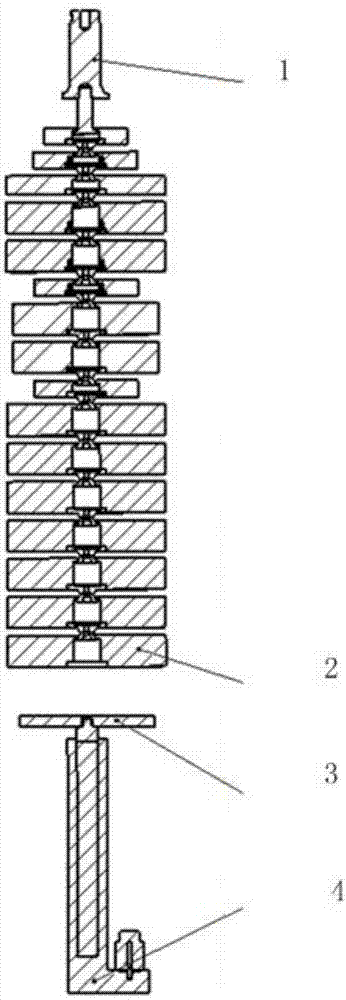

[0032] Such as figure 1 As shown, the present invention provides an electronic crane scale detection device, including an automatic weight loading control device for the electronic crane scale detection device, and also includes a hanging mechanism 1, a standard weight group 2, a support plate 3 and a support plate lift motor 4,

[0033] The standard weights are interlocked layer by layer through buckles, and the electronic crane scale to be tested is connected to the standard weight group 2 through the hanging mechanism 1;

[0034] The standard weight group 2 is arranged above the support plate 3;

[0035] The support plate 3 moves up and down under the drive of the support plate lifting motor 4;

[0036] The support plate lift drive module 500 is used to send a driving signal to drive the support plate lift motor 4 .

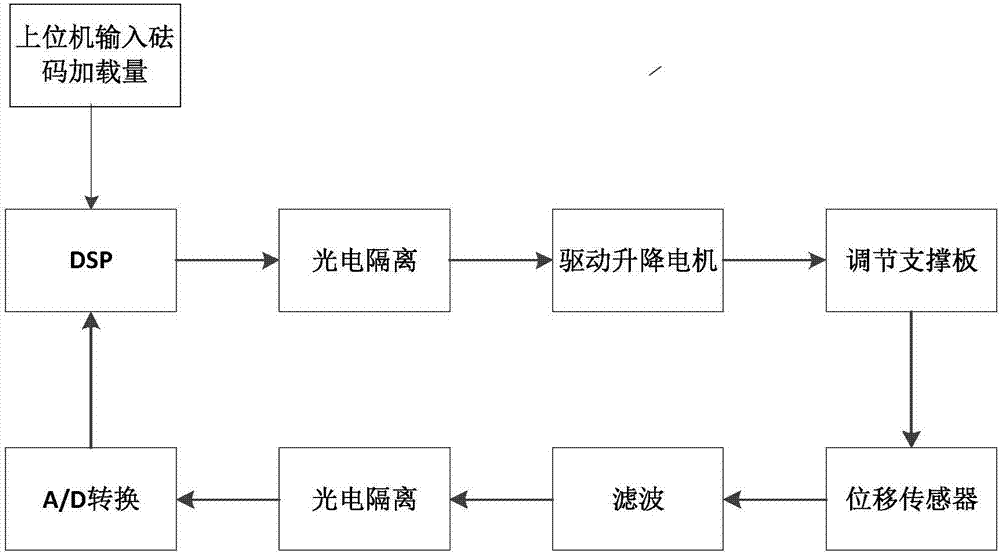

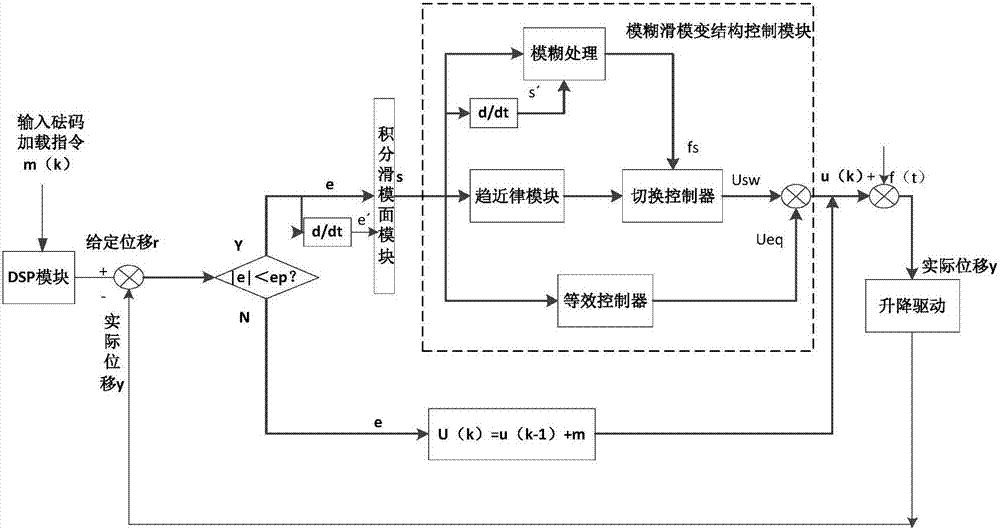

[0037] figure 2 It is a weight loading and unloading control block diagram, by converting the preset weight loading signal into a support plate displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com