Detection method of CCD detection machine

A detection method and detection machine technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of poor positioning accuracy of parts and high labor intensity of staff, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The core of the invention is to provide a detection method of a CCD detection machine to reduce the labor intensity of staff.

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

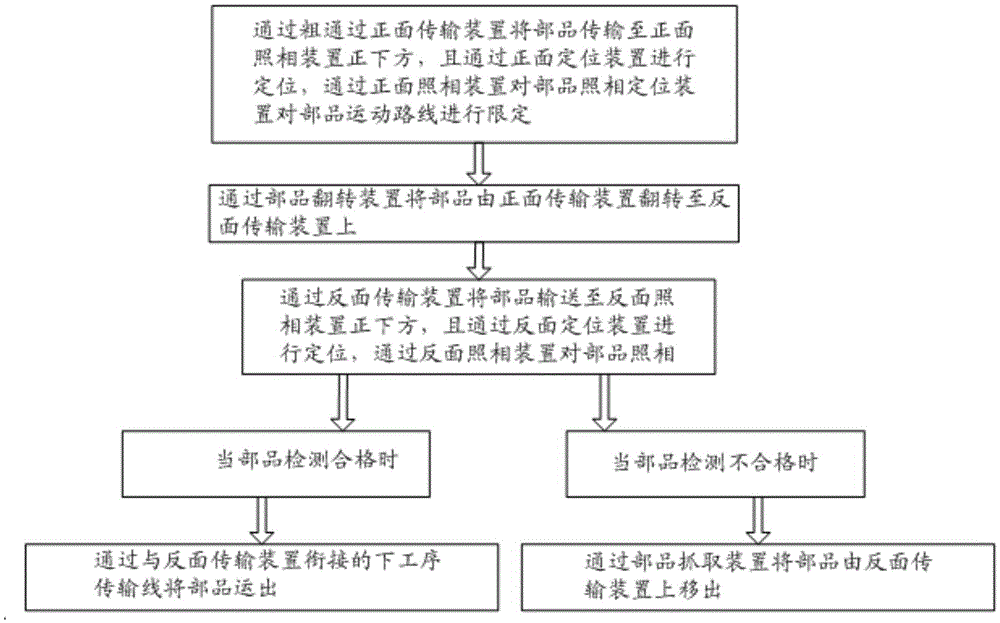

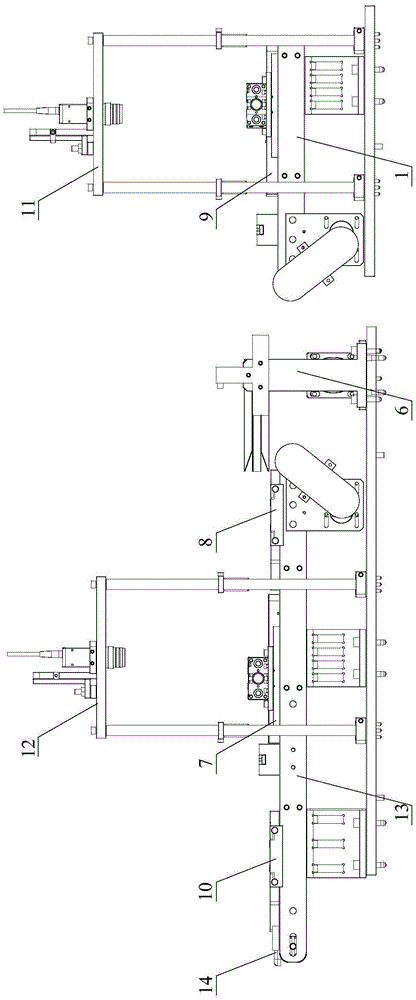

[0042] Please refer to Figure 1 to Figure 3 , in a specific embodiment, the CCD detection machine detection method that the specific embodiment of the present invention provides, comprises the steps:

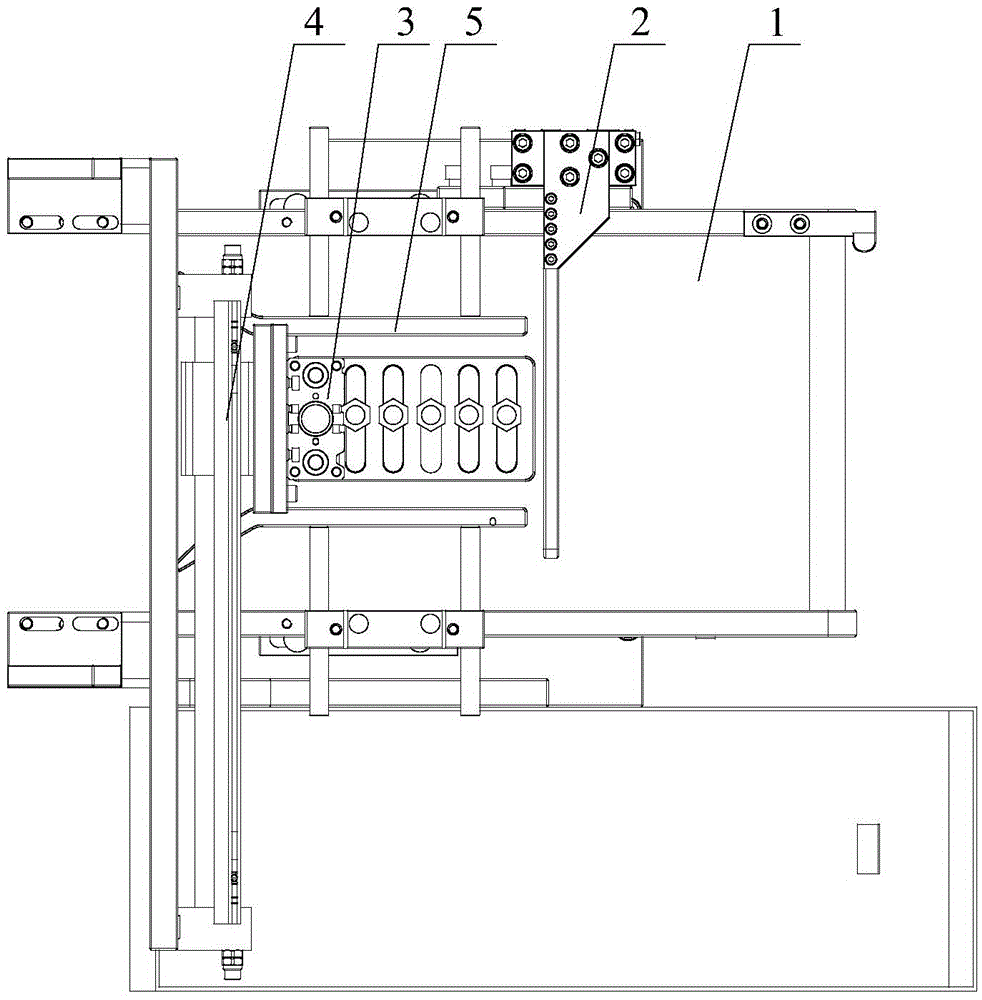

[0043]A1) The parts are transported directly under the front camera device 12 by the front transmission device, and positioned by the front positioning device, and the parts are photographed by the front camera device 12 . Specifically, after the front positioning device positions the parts, the front transmission device stops working, and the front positioning device is separated from the parts, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com