Full automatic dismantling equipment and method for power battery

A power battery, fully automatic technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of low degree of automatic disassembly of power batteries, easy access to battery waste liquid, battery short-circuit fire, etc. The effect of isolating noise and dust, improving dismantling efficiency and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

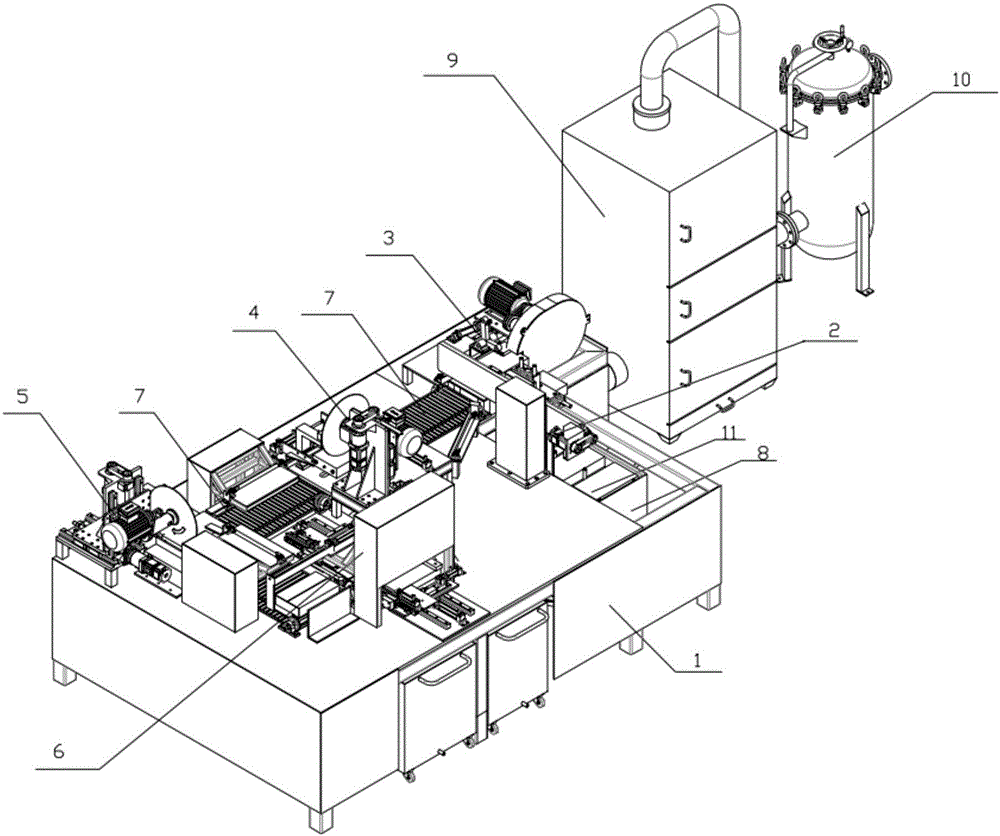

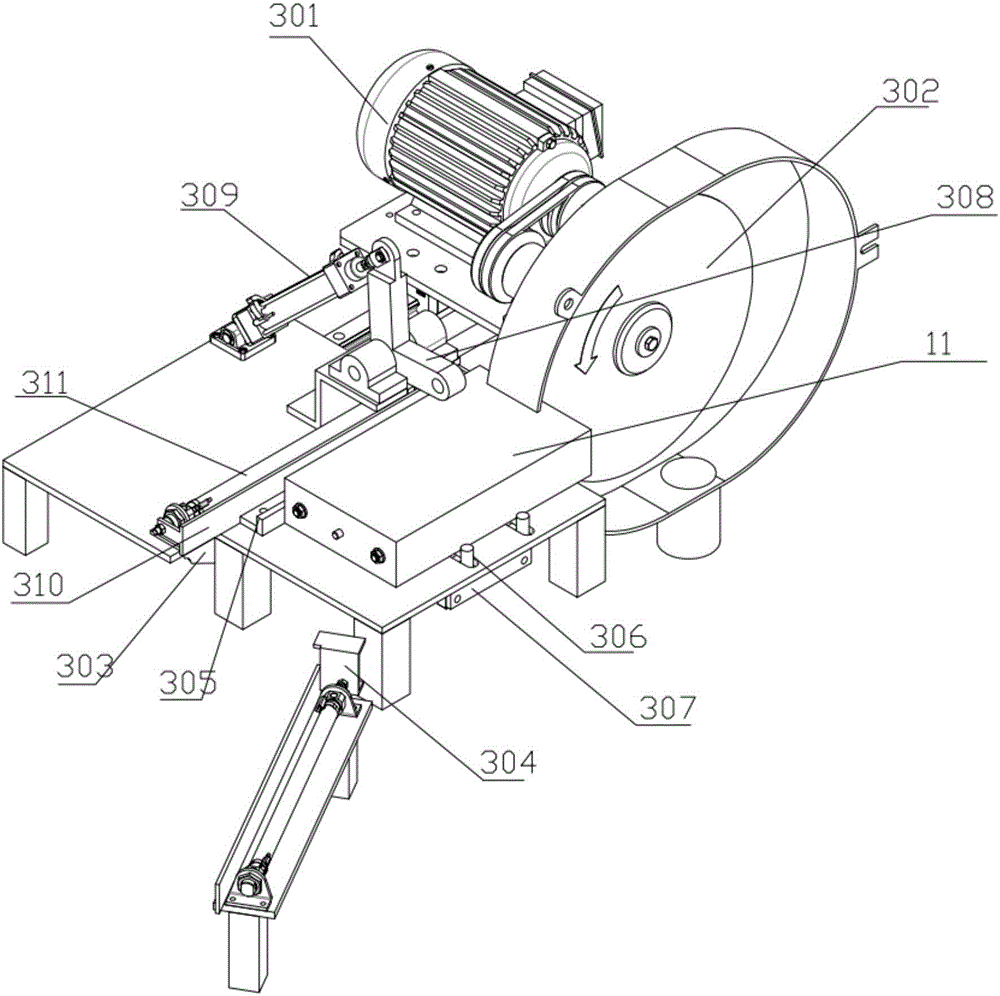

[0053] Such as figure 1 As shown, the power battery automatic disassembly equipment in this embodiment includes a frame 1, a feeding mechanism 2, a battery bottom slitting mechanism 3, a battery side slitting mechanism 4, a battery head cutting mechanism 5, a battery disassembly mechanism 6, and a battery Conveying mechanism 7, feeding bin 8, dust removal device 9, purification device 10. The power battery automatic dismantling equipment can realize a series of automatic processes such as power battery loading, bottom cutting, side cutting, battery head cutting, battery decomposition, and unloading. At the same time, it is equipped with a dust removal device and a purification device to remove generated dust, exhaust gas, etc.

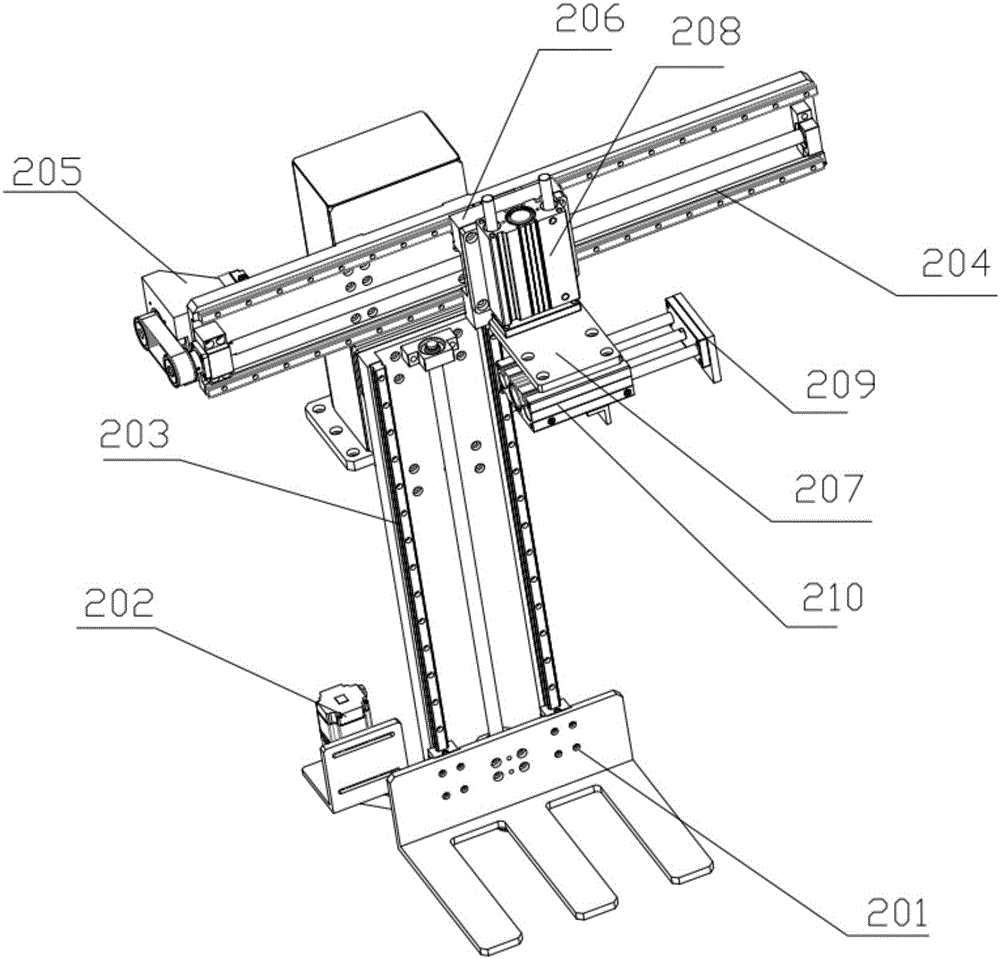

[0054] In this embodiment, the structural diagram of the feeding mechanism can be found in figure 2 , the feeding mechanism is mainly composed of a Y-axis manipulator, a Z-axis manipulator 207, a gripper device, and a lifting device to complete the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com