Method for detecting performance of RFID (radio frequency identification) labels

An RFID tag and detection method technology, applied in the field of RFID tag performance detection, can solve the problems of low efficiency, high labor intensity and high cost, and achieve the effect of solving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

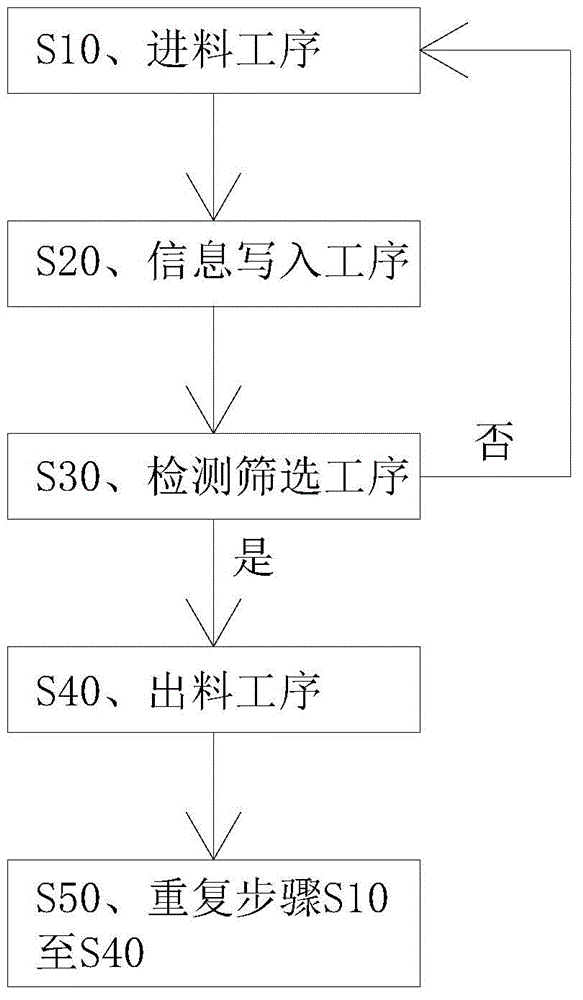

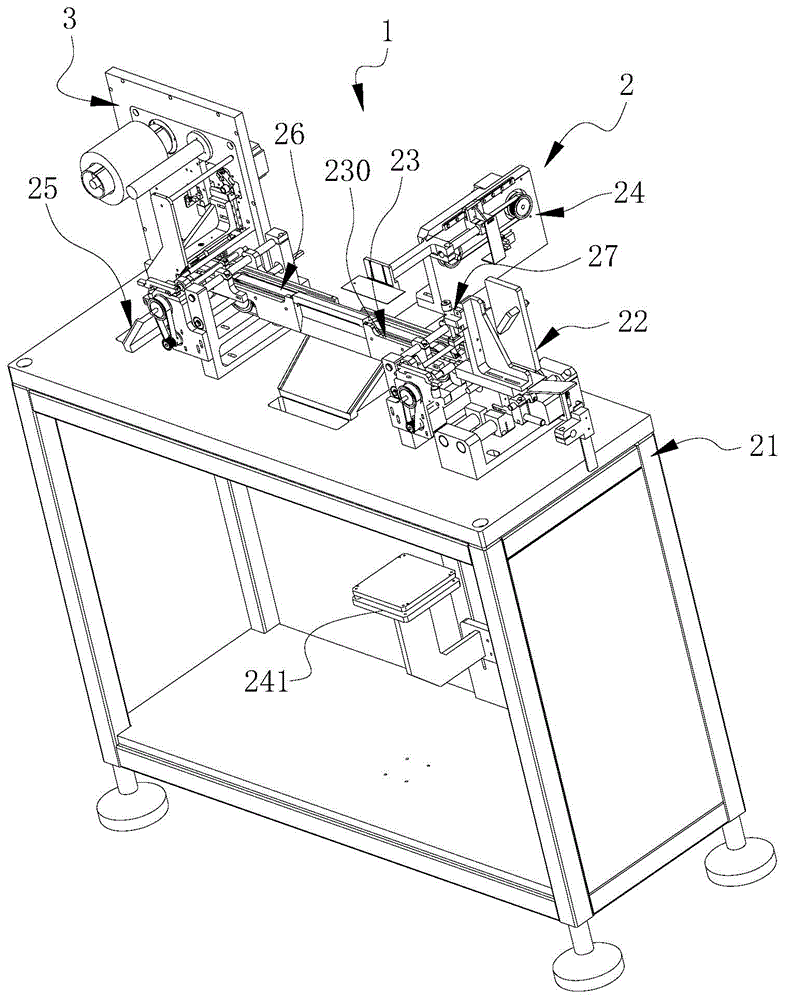

[0063] See figure 1 with figure 2 In the following, the method for detecting the performance of the RFID tag of this embodiment will be described.

[0064] The method for detecting the performance of an RFID tag in this embodiment includes the steps:

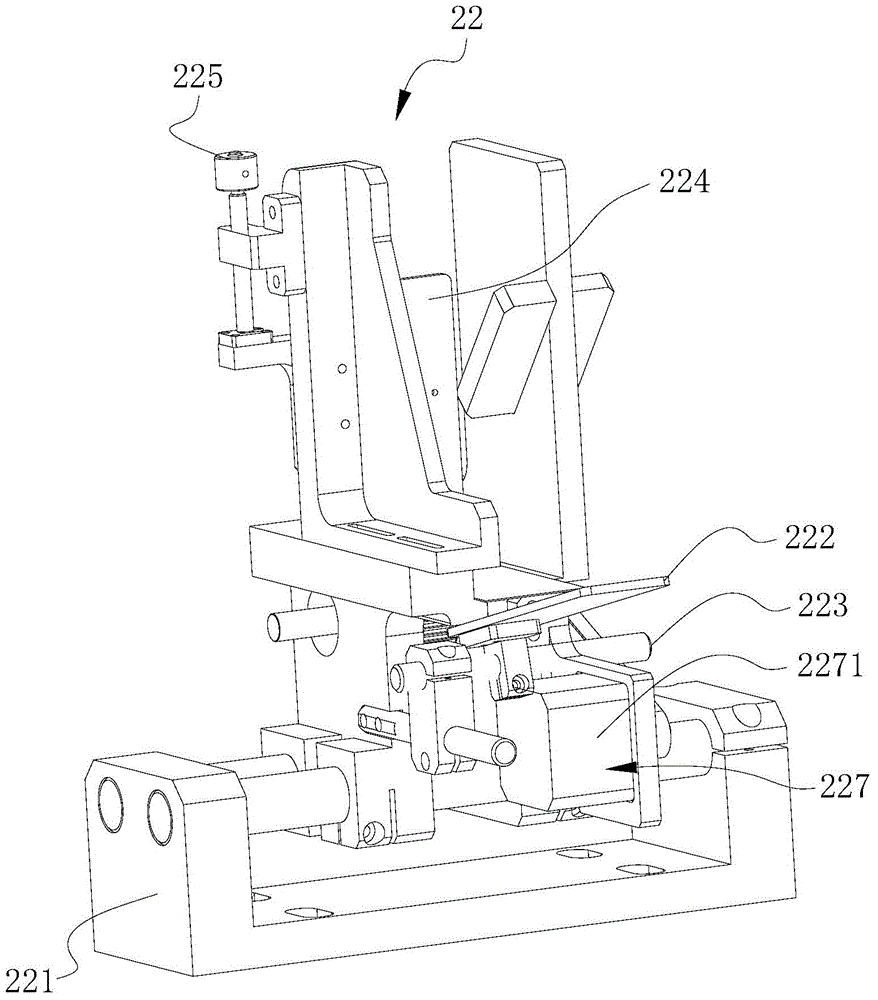

[0065] S10. In the feeding process, a plurality of RFID tags are stacked and placed on the feeding unit 22 that can feed the plurality of RFID tags, and the RFID tags are fed to the feeding unit 22 for transferring the RFID tags. RFID tag transmission unit 26;

[0066] S20. In the information writing process, the sheet-mounted RFID tag is transmitted to the information writing unit 23 for writing relevant information to the sheet-mounted RFID tag through the transmitting unit 26;

[0067] S30. In the detection and screening process, the sheet-mounted RFID tags with written information are transferred to the detection and screening unit 24 through the transfer unit 26, and the detection and screening unit 24 performs performance testing...

Embodiment 2

[0105] See Picture 11 And combine Figure 2 to Figure 10 The implementation of the second embodiment is similar to that of the first embodiment. For details, please refer to the first embodiment, which will not be described in detail here. The difference between the two is:

[0106] Between step S30 and step S40, it also includes step S31, the printing process, the transfer unit 26 transfers the sheet-packed RFID labels that are qualified by the inspection and screening unit 24 to the printing unit 3, and the printing unit 3 loads the sheets with the RFID tags Print

[0107] Wherein, the printing unit 3 is arranged on the installation cabinet 21 and is located between the detection and screening unit 24 and the discharge bin opening 25.

[0108] Specifically, the above-mentioned RFID label performance detection device 2 and printing unit 3 constitute the RFID label printer 1. Therefore, the specific operations are as follows:

[0109] A number of RFID tags are stacked and placed in t...

Embodiment 3

[0113] See Picture 12 And combine Figure 2 to Figure 10 The implementation of the third embodiment is similar to that of the second embodiment. For details, please refer to the second embodiment, which will not be detailed here. The difference between the two is:

[0114] Between step S30 and step S31, it also includes step S31', a printing judgment process, through the transmission unit 26, the sheet-packed RFID tags that have passed the inspection and screening unit 24 are sent to the printing judgment unit, and the printing judgment unit judges whether it is correct Attach RFID tags to print, if yes, go to step 31; if not, go to step S40;

[0115] Among them, the printing judgment unit is arranged on the installation cabinet 21 and located between the detection and screening unit 24 and the printing unit 3. With this printing judgment unit, the qualified sheets from the detection and screening unit 24 can be loaded with RFID labels according to user needs. The function of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com