Automatic vacuum stirring device capable of realizing cleaning

An automatic stirring and vacuum technology, used in mixers with rotary stirring devices, mixer accessories, dissolution and other directions, can solve the problems of difficult production, low degree of automation, time-consuming and laborious, etc., to reduce labor costs, high degree of automation, and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

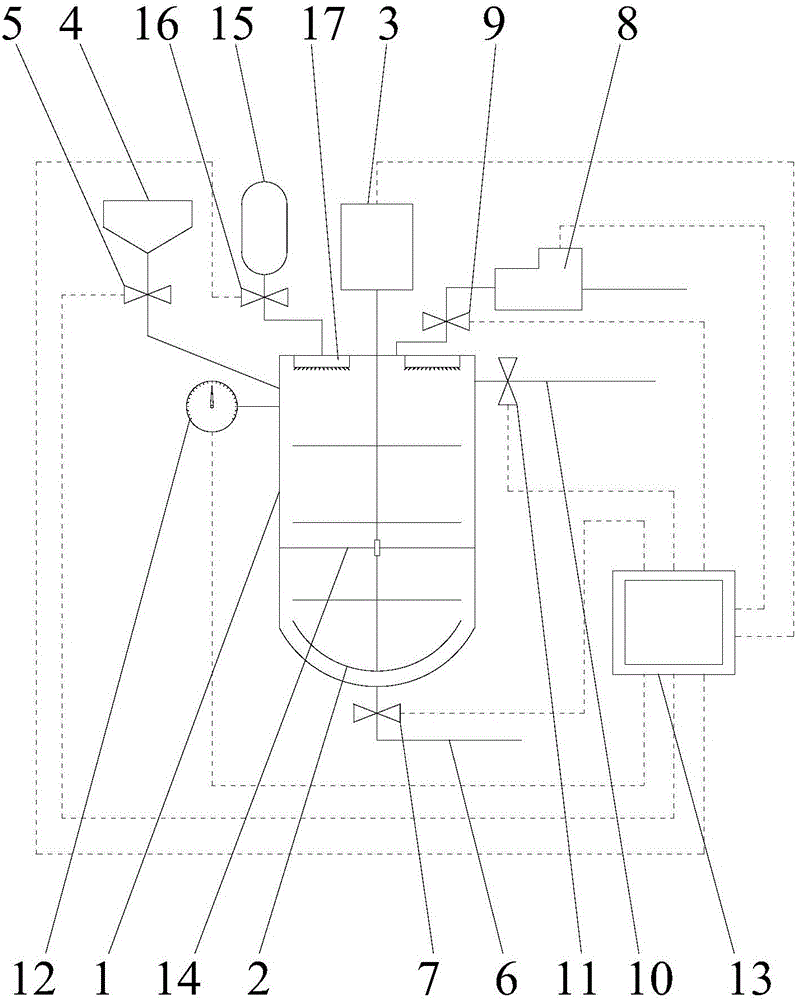

[0012] like figure 1 As shown, a cleanable vacuum automatic stirring device, it includes a stirring tank 1 and a stirring paddle 2; The outlet is connected to the stirring motor 3; the upstream position of the side wall of the stirring tank 1 is connected with a plurality of feeding hoppers 4 through the feed pipe; a feed flow control valve 5 is arranged between the feeding hopper 4 and the stirring tank 1 The bottom side of the stirred kettle 1 is provided with a discharge pipe 6, and a discharge switch 7 is provided on the discharge pipe 6; the top of the stirred kettle 1 is also provided with a vent pipe connected to the air pump 8, and A ventilation valve 9 is arranged on the vent pipe; an air pressure balance pipe 10 is also provided at the upstream position of the side wall of the stirred tank 1, and an air pressure balance switch 11 is arranged on the air pressure balance pipe 10; the described stirred tank 1 The upstream position of the side wall is also provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com