Mechanical arm device

A technology of manipulators and rotating platforms, which is applied in the field of multi-manipulator cycle work devices, can solve the problems of low work efficiency, high labor intensity of workers, and high risk of workers, and achieve the effect of reducing labor intensity, stable and reliable working process, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

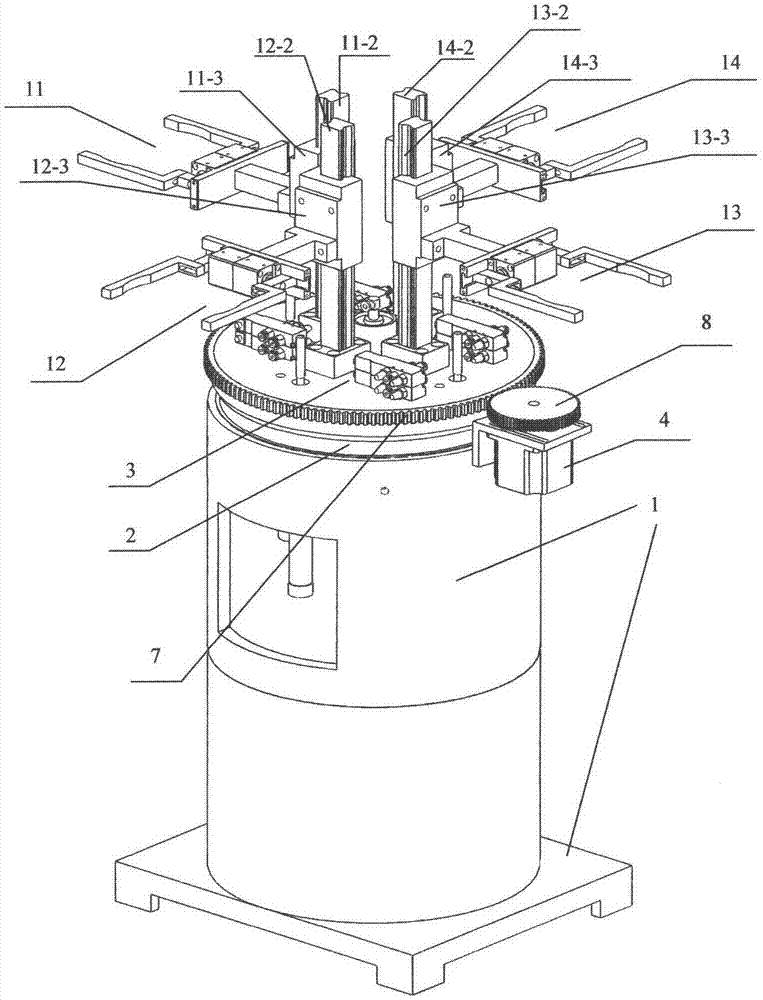

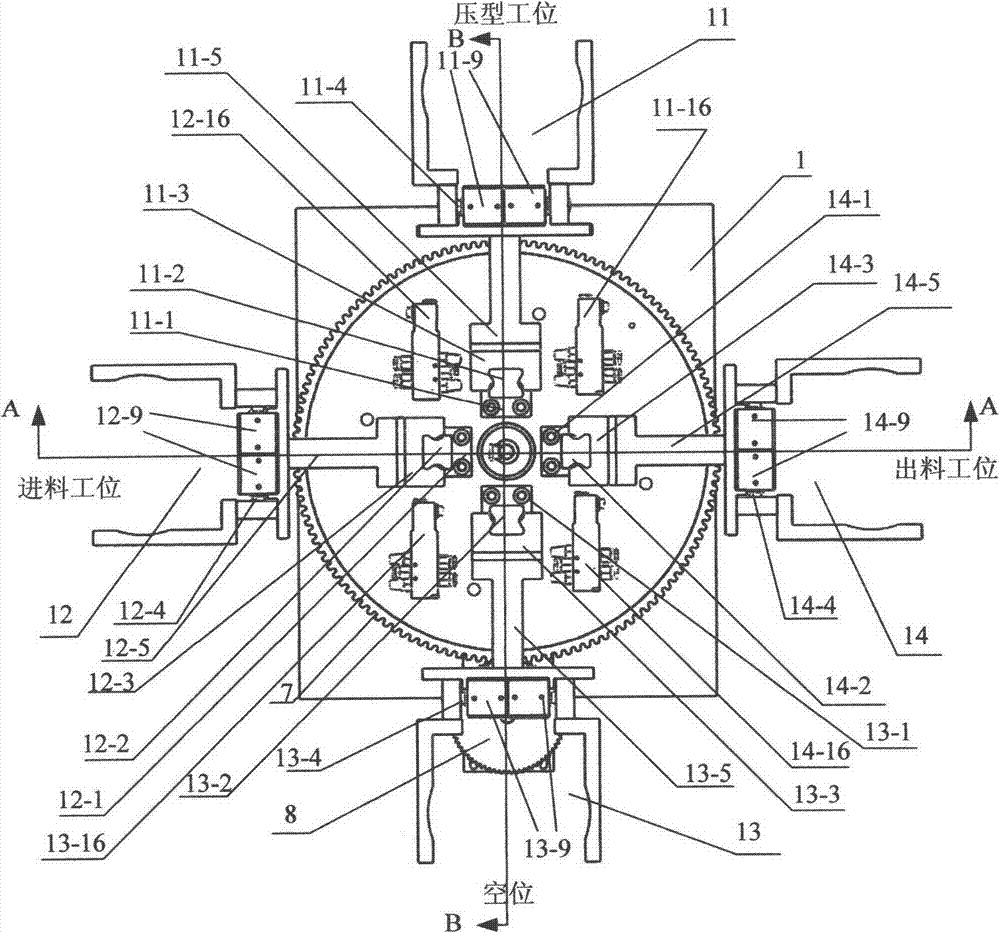

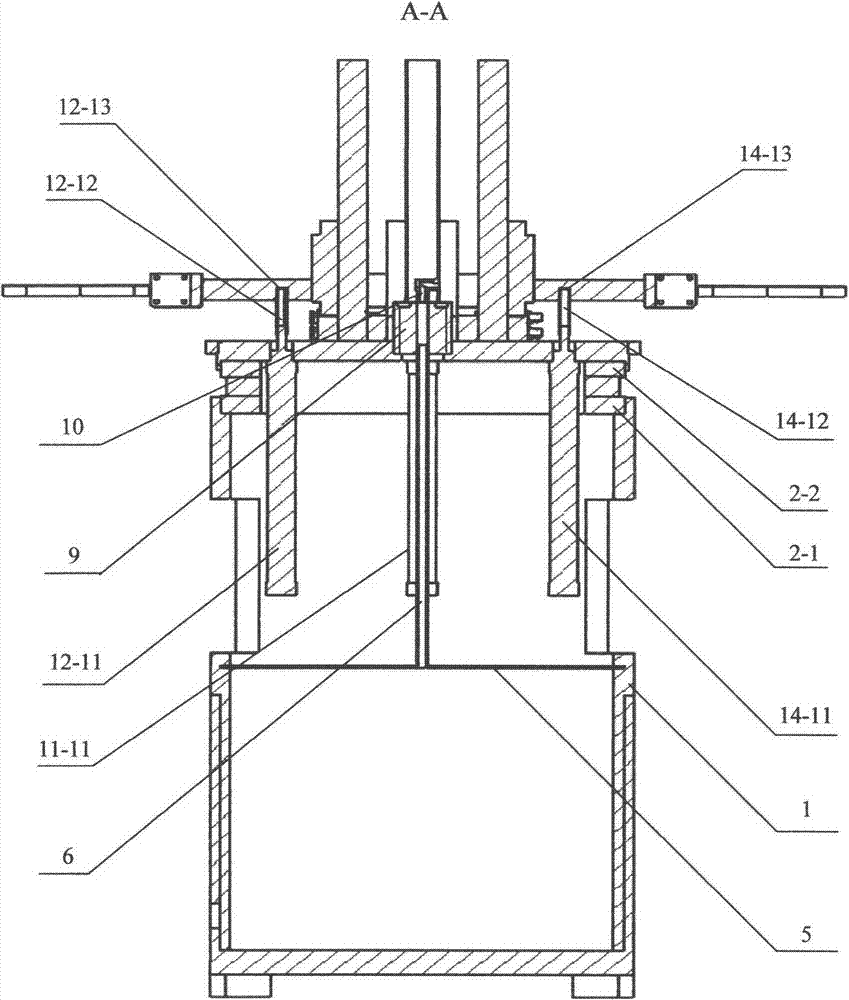

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown: the manipulator device is mainly composed of chassis 1, bearing 2, rotating platform 3, motor 4, No. 1 manipulator 11, No. 2 manipulator 12, No. 3 manipulator 13, No. 4 manipulator 14, guide rail 11-2, guide rail 12-2 , Guide rail 13-2, guide rail 14-2, slide block 11-3, slide block 12-3, slide block 13-3, slide block 14-3 form.

[0019] The bearing lower end surface 2-1 is fixedly connected to the chassis 1, and the bearing upper end surface 2-2 is fixedly connected to the rotating platform 3, so that the rotating platform 3 can rotate relative to the chassis 1. The ring gear 7 is fixedly connected to the rotating platform 3, and the motor 4 drives the ring gear 7 through the driving gear 8 installed thereon, and then drives the rotating platform 3 to rotate. Since No. 1 manipulator 11, No. 2 manipulator 12, No. 3 manipulator 13, and No. 4 manipulator 14 have the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com