Active back-twist constant-force pay-off machine and production method thereof

A pay-off machine and untwisting mechanism technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as simultaneous rotation, untimely release of twisted wires, twisted twisted wires, etc., to achieve high concentricity, Improve the competitiveness of enterprises and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

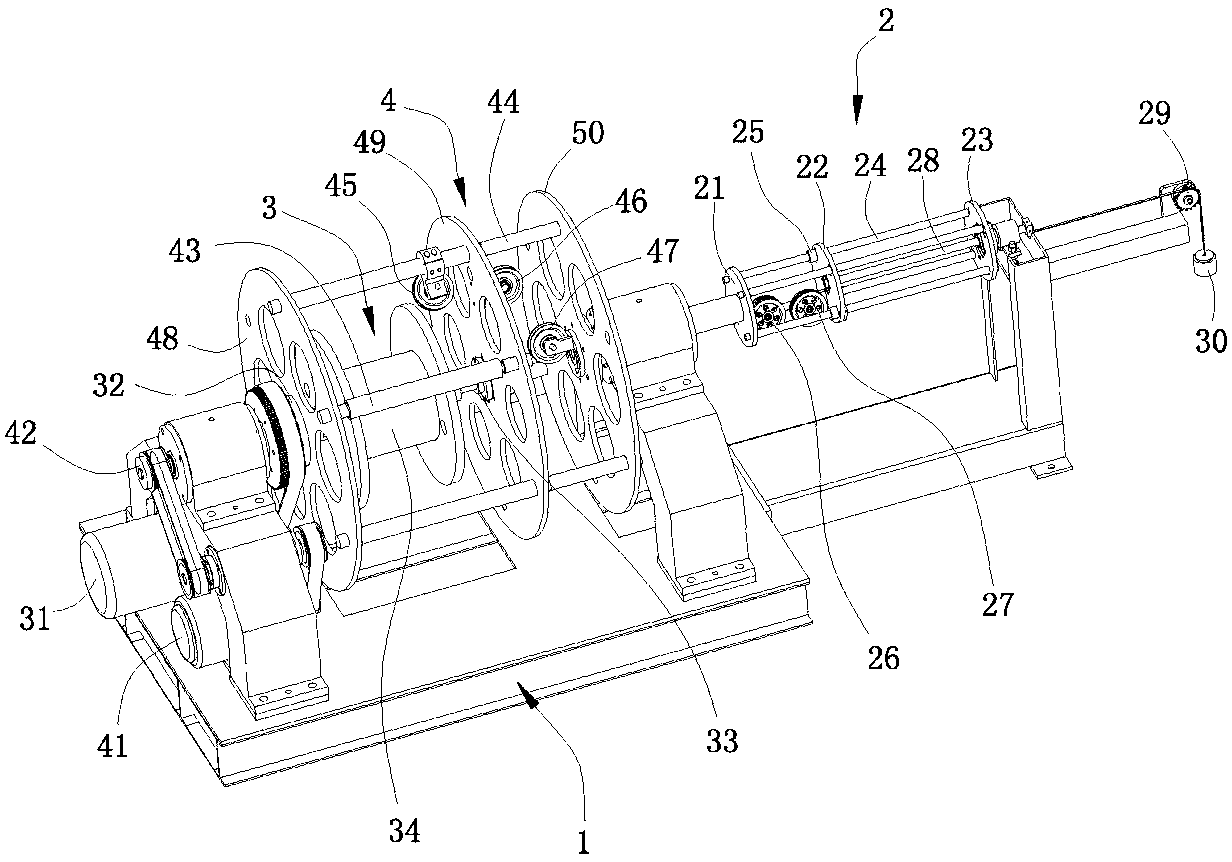

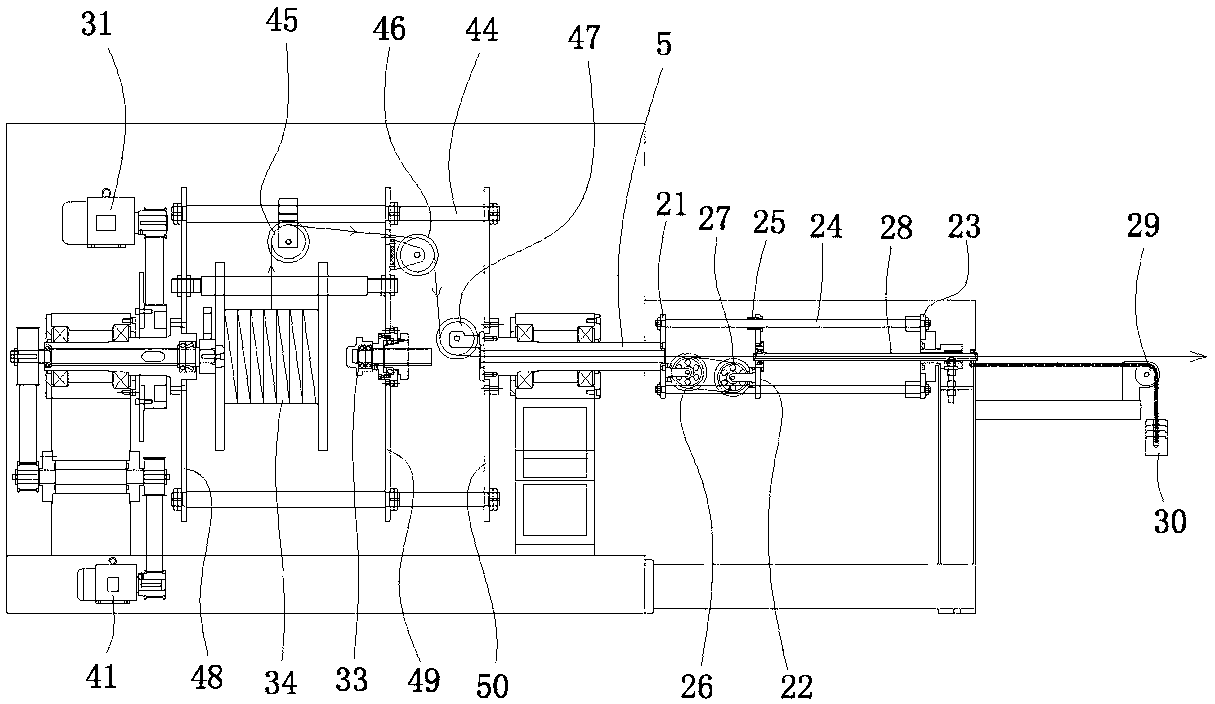

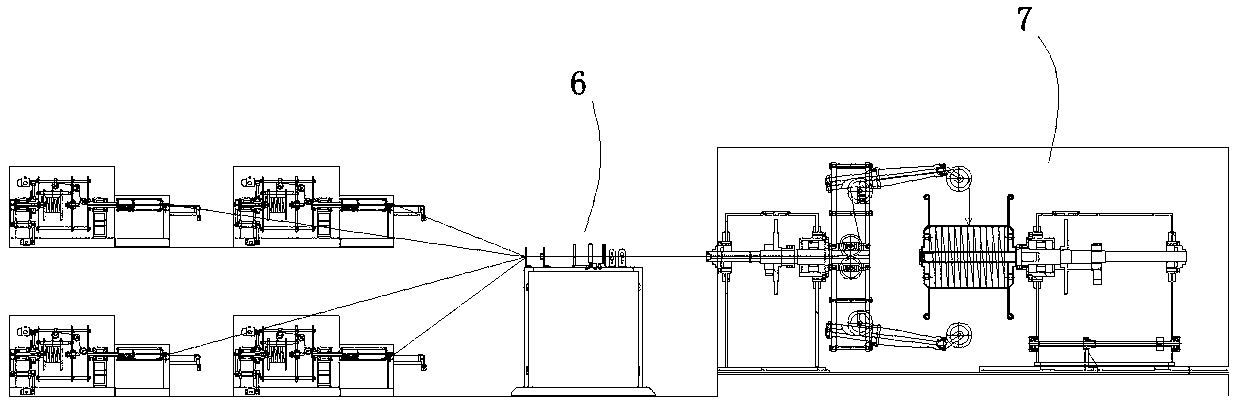

[0025] Example: see figure 1 , figure 2 and image 3 , an active untwisting constant force pay-off machine provided by the embodiment of the present invention, which includes a frame 1 and a back-twist pay-off device and a rotating tension device 2 arranged on the frame 1, the back-twist pay-off device It includes a pay-off mechanism 3 and a twist-back mechanism 4 coaxially arranged with the pay-off mechanism 3. The twist-back mechanism 4 is connected to the rotating tension device 2 through a twist-back driven shaft 5, and drives the rotating tension device 2 rotate synchronously.

[0026] The twist-back mechanism 4 includes a twist-back motor 41, a twist-back driving shaft group 42, a wire drum 43, a coupling rod 44, a first wire passing guide wheel 45, a second wire passing guide wheel 46, and a third wire passing guide wheel 47 , the first large disk 48, the second large disk 49 and the third large disk 50, the back-twist driving shaft group 42 is movably arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com