Patents

Literature

59results about How to "High precision of tension control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

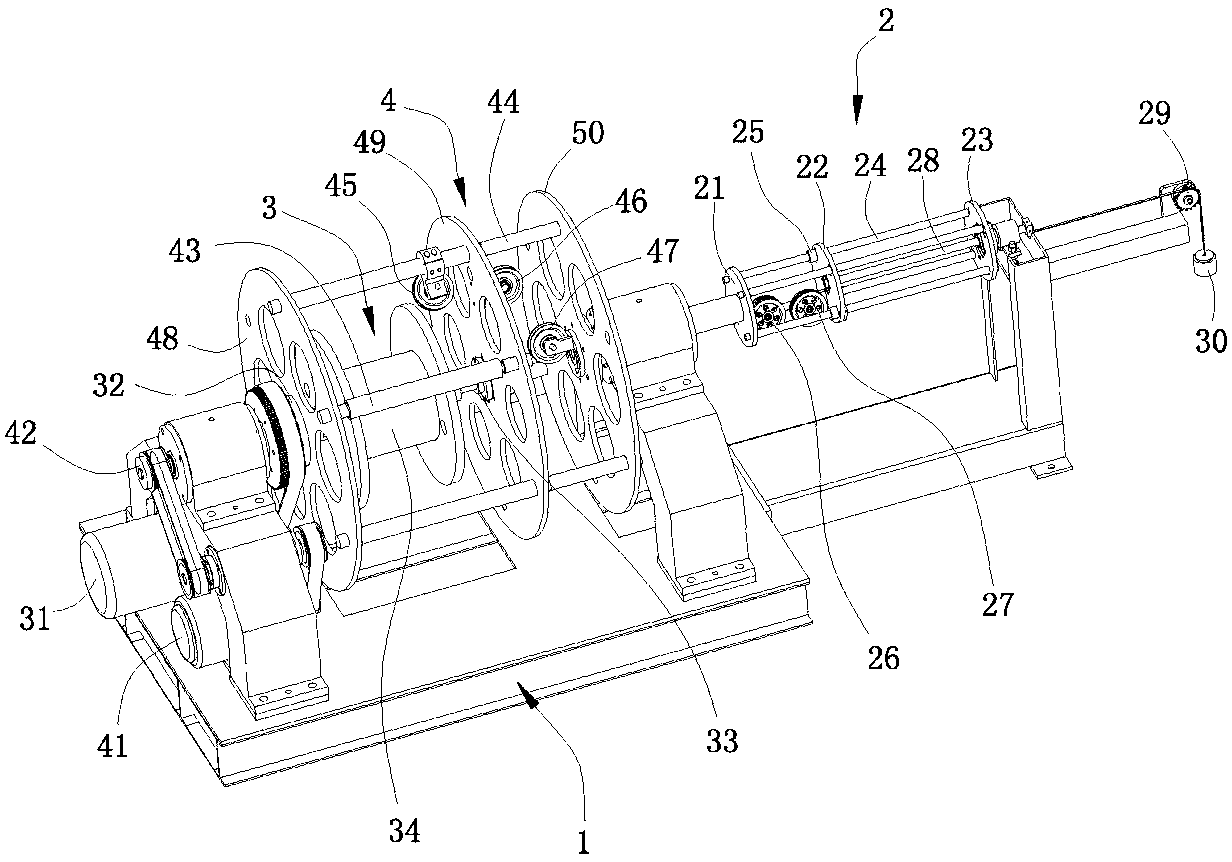

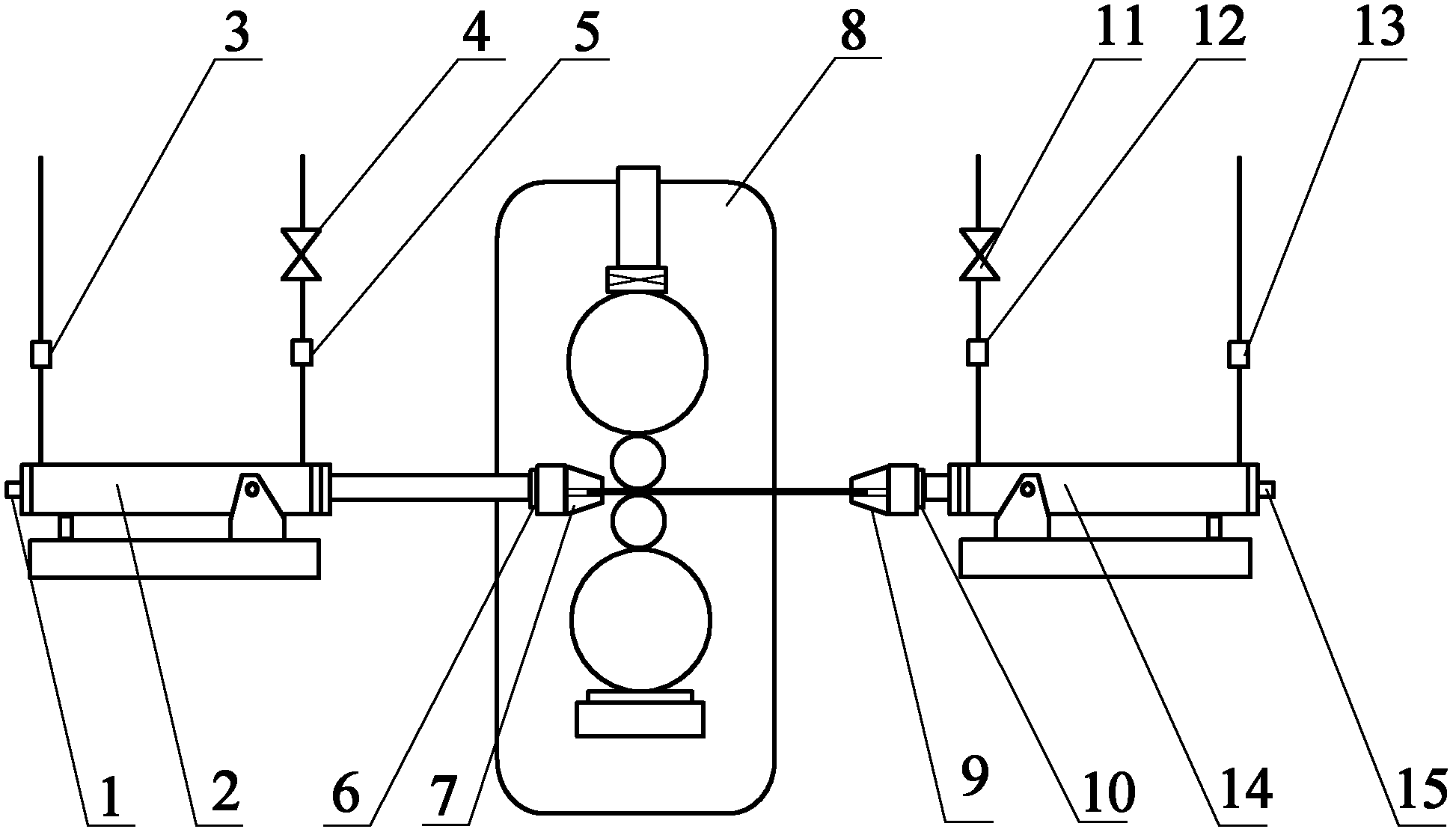

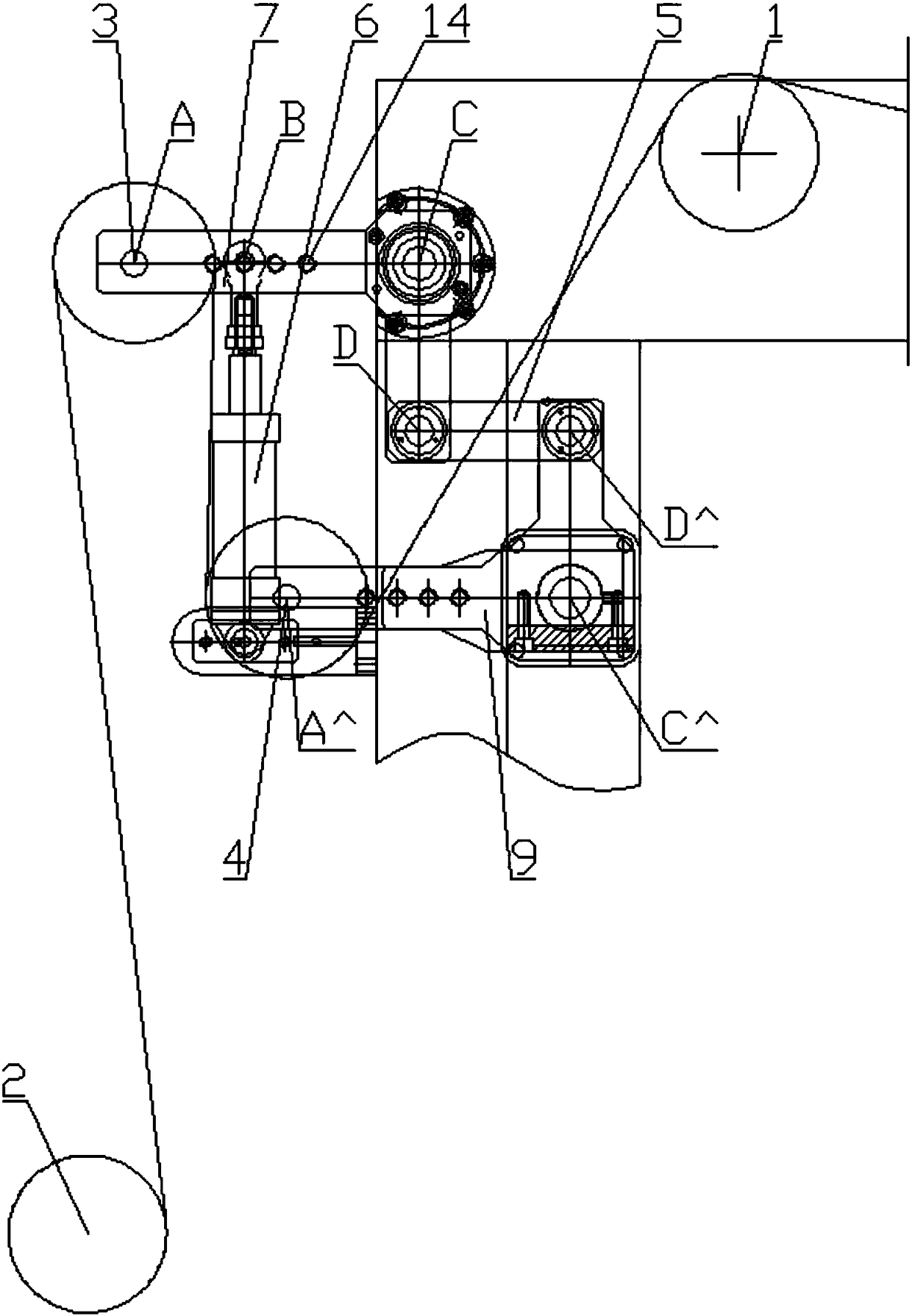

Cable conveyance tension adjustment method and device implementing same

InactiveCN101780905AEnsure personal safetyEasy to monitor working statusFilament handlingWinding machineCable transport

The invention discloses a cable conveyance tension adjustment method. In the method, a frame and a wire coil arranged on the frame are used. The method comprises the following steps: 1, preparing a cable guide roller; 2, preparing a cable guide wheel; 3, preparing a tension control device; 4, preparing a damping device; and 5, preparing an adjustment device so as to adjust the amplitude of swing of the tension control device and set corresponding damping force output by the damping device according to the amplitude of swing. The method provided by the invention has the advantages of quickly and uniformly conveying cables wound in the wire coil to a winding machine with constant tension. A device provided by the invention has a simple structure and high tension control and adjustment accuracy, automatically and continuously detects and adjusts the tension of the cables in the whole production process, keeps the tension constant all the time to actually realize cable transport with the constant tension, is convenient to operate, can automatically convey the cables wound in the wire coil to the winding machine with the constant tension only by starting the winding machine, and improves the production efficiency.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD +1

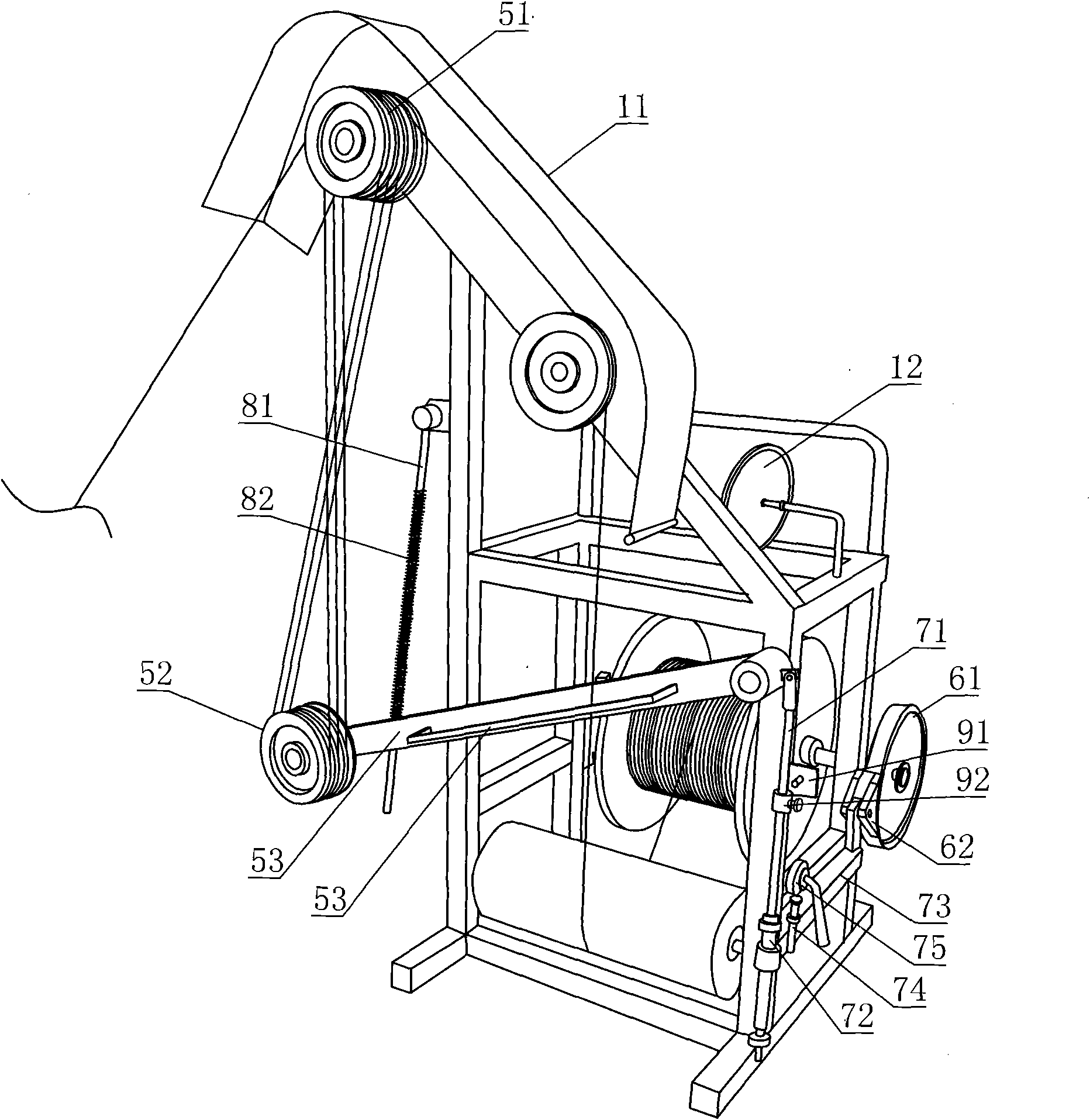

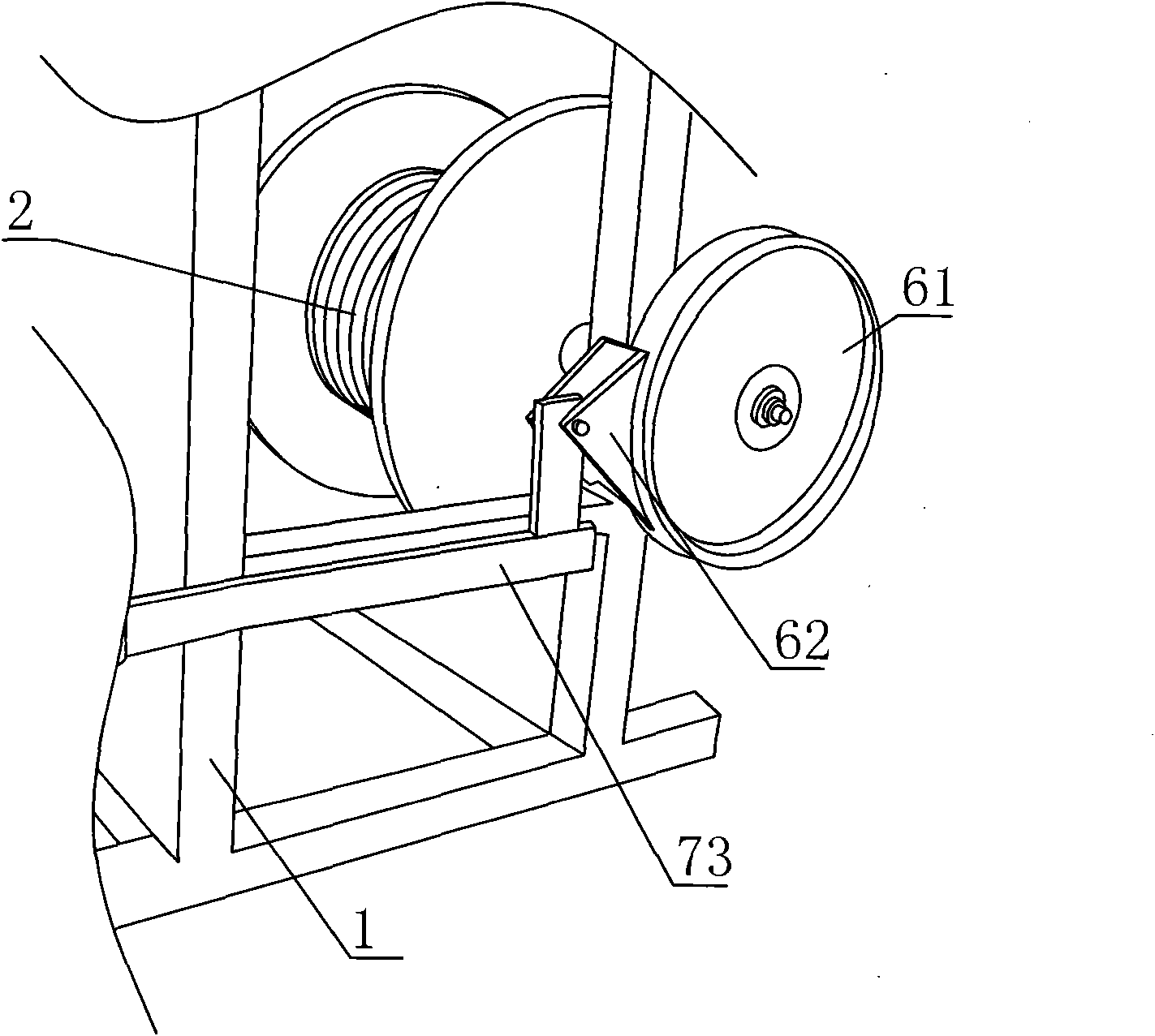

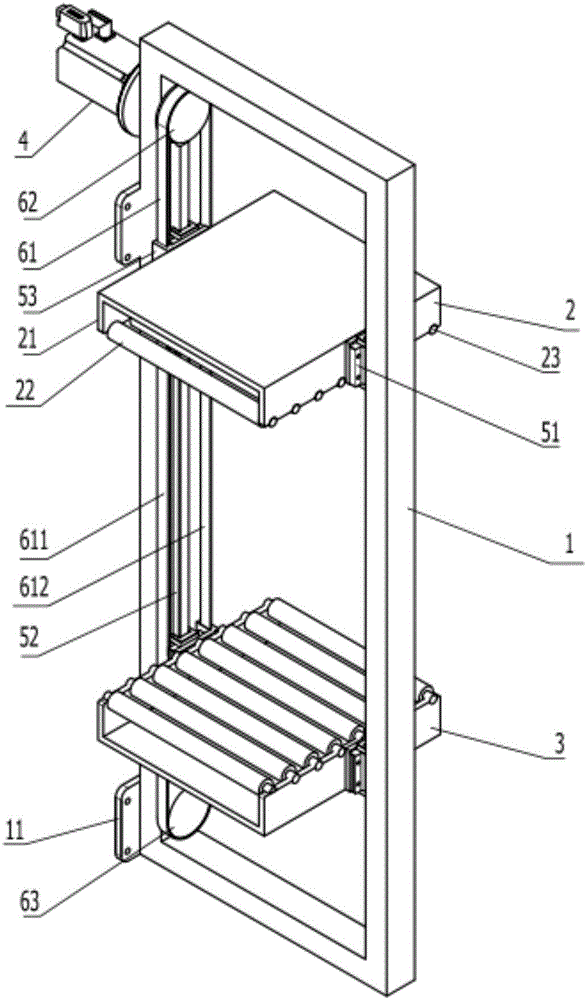

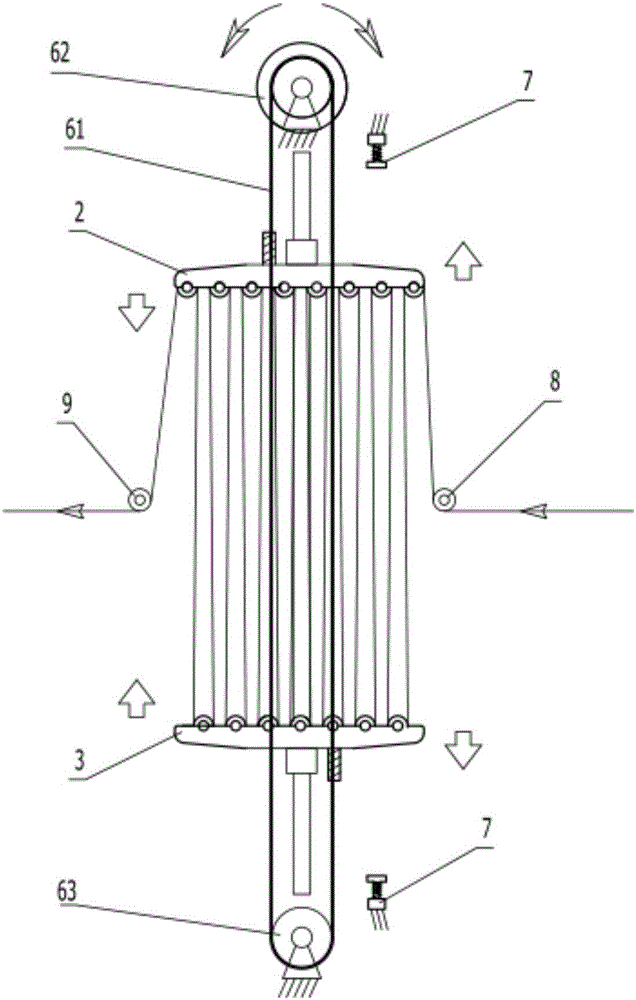

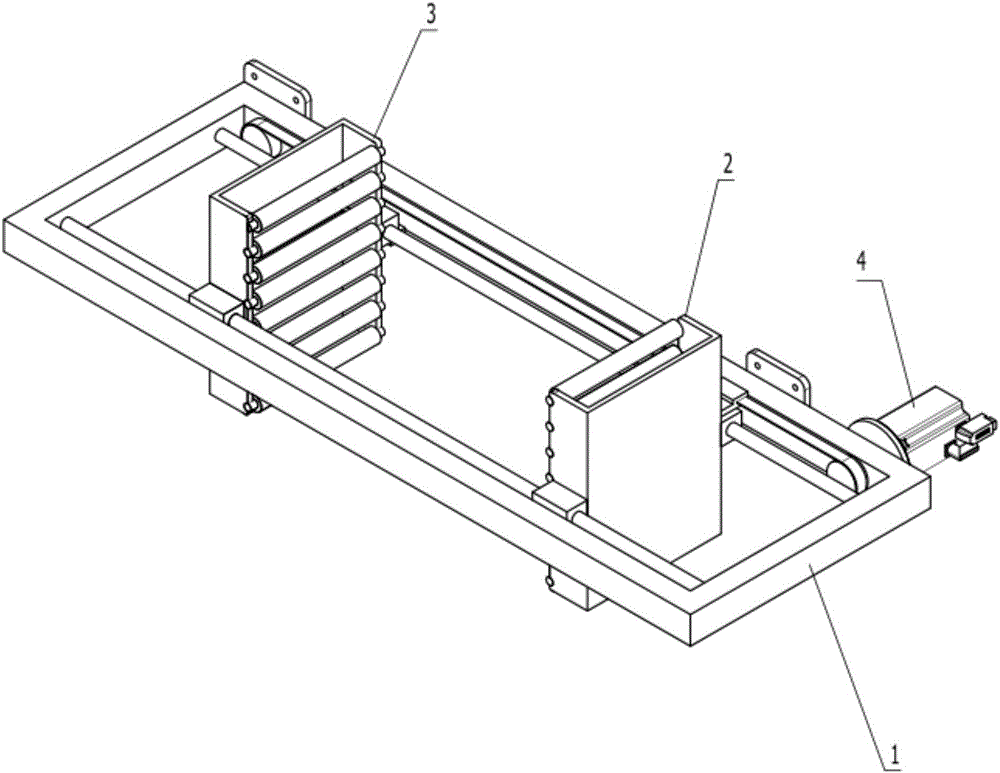

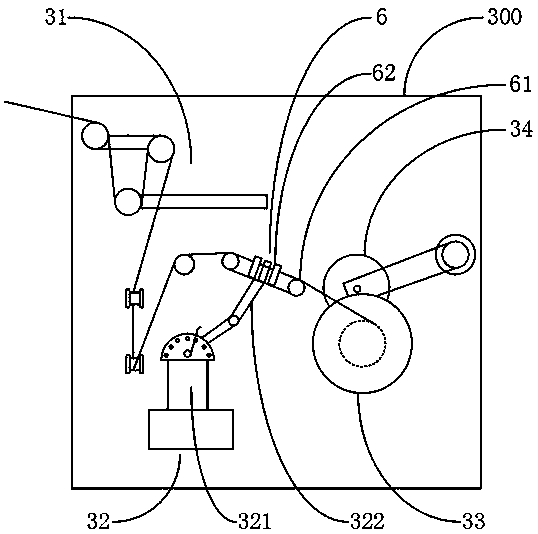

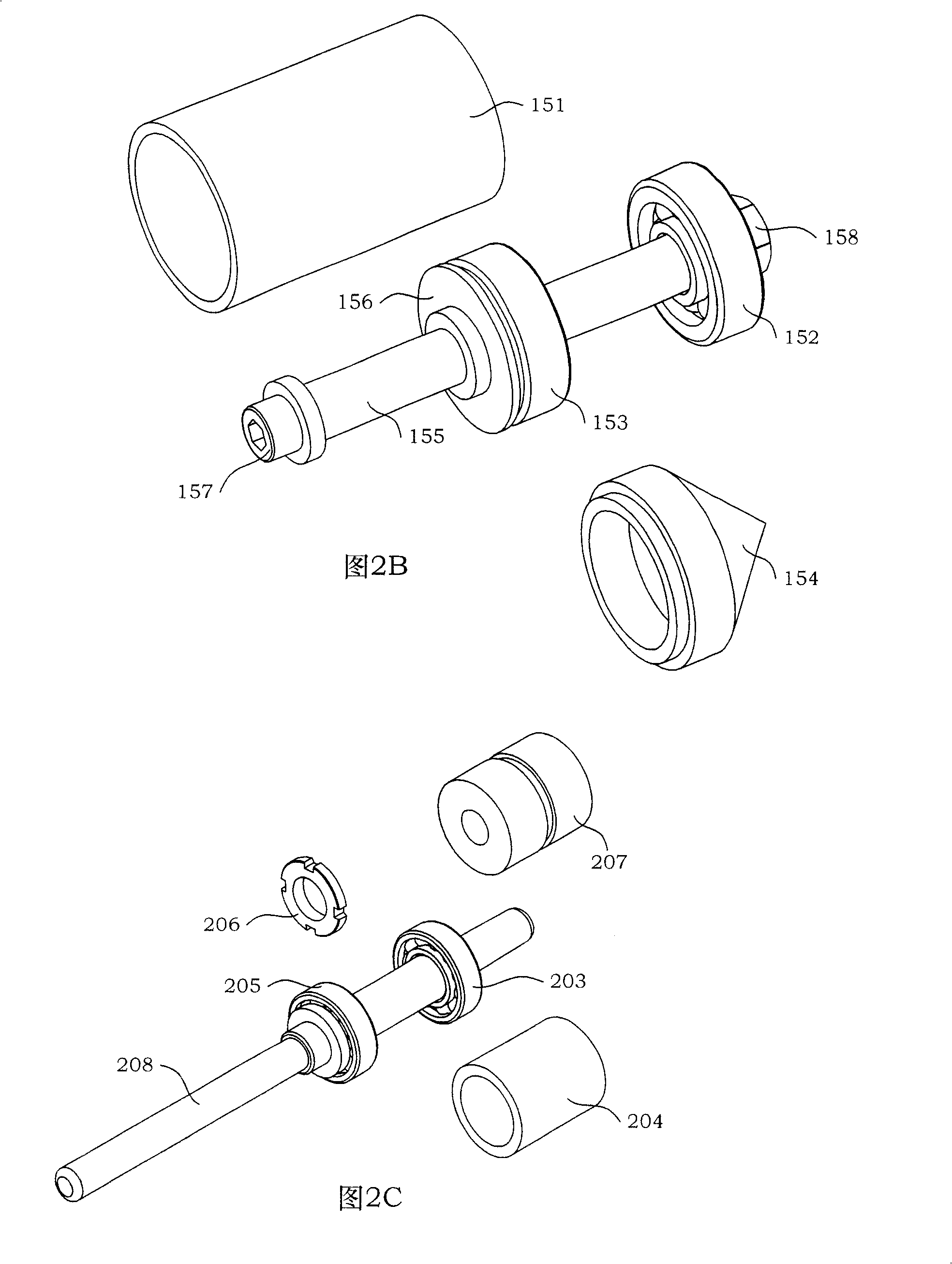

Active back-twist constant-force pay-off machine and production method thereof

ActiveCN103106982AReasonable structural designIngenious structural designCable/conductor manufactureConstant forceUltimate tensile strength

The invention discloses an active back-twist constant-force pay-off machine which comprises a machine frame, a back-twist pay-off device and a rotating tension device, wherein the back-twist pay-off device comprises a pay-off mechanism and a back-twist mechanism. The invention further discloses a production method of the active back-twist constant-force pay-off machine. The active back-twist constant-force pay-off machine is reasonable and ingenious in structural design and capable of quickly feeding a cable core to a stranding machine in a balanced mode with predetermined constant tension; at the same time, the rotating tension device and the stranding machine move in the same direction at the same rotation speed, and therefore the cable core can be effectively prevented from being damaged due to twist; in addition, regulating accuracy of the tension is high, the tension of the cable core can be automatically detected and adjusted in the whole production process, and therefore the tension of the cable core can always remain constant, and constant-tension cable feeding in a true sense is realized; and the active back-twist constant-force pay-off machine is convenient to operate, greatly lowers labor intensity, guarantees the quality of products, and is beneficial to improvement of the competitiveness of an enterprise. The production method of the active back-twist constant-force pay-off machine is simple in process, low in cost, easy to implement, and through the production method, the active back-twist constant-force pay-off machine can be produced rapidly.

Owner:DONGGUAN JINGTIE MACHINERY

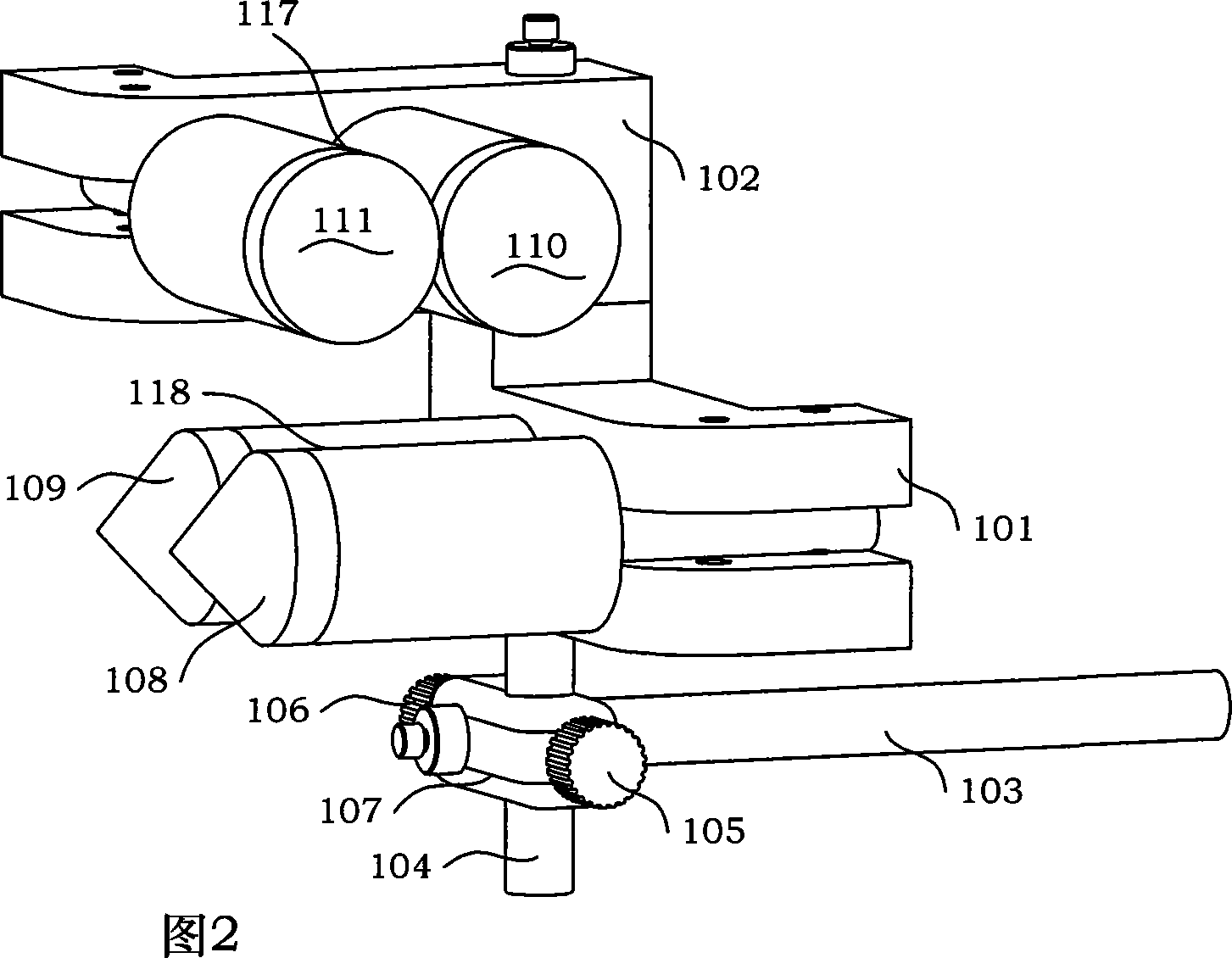

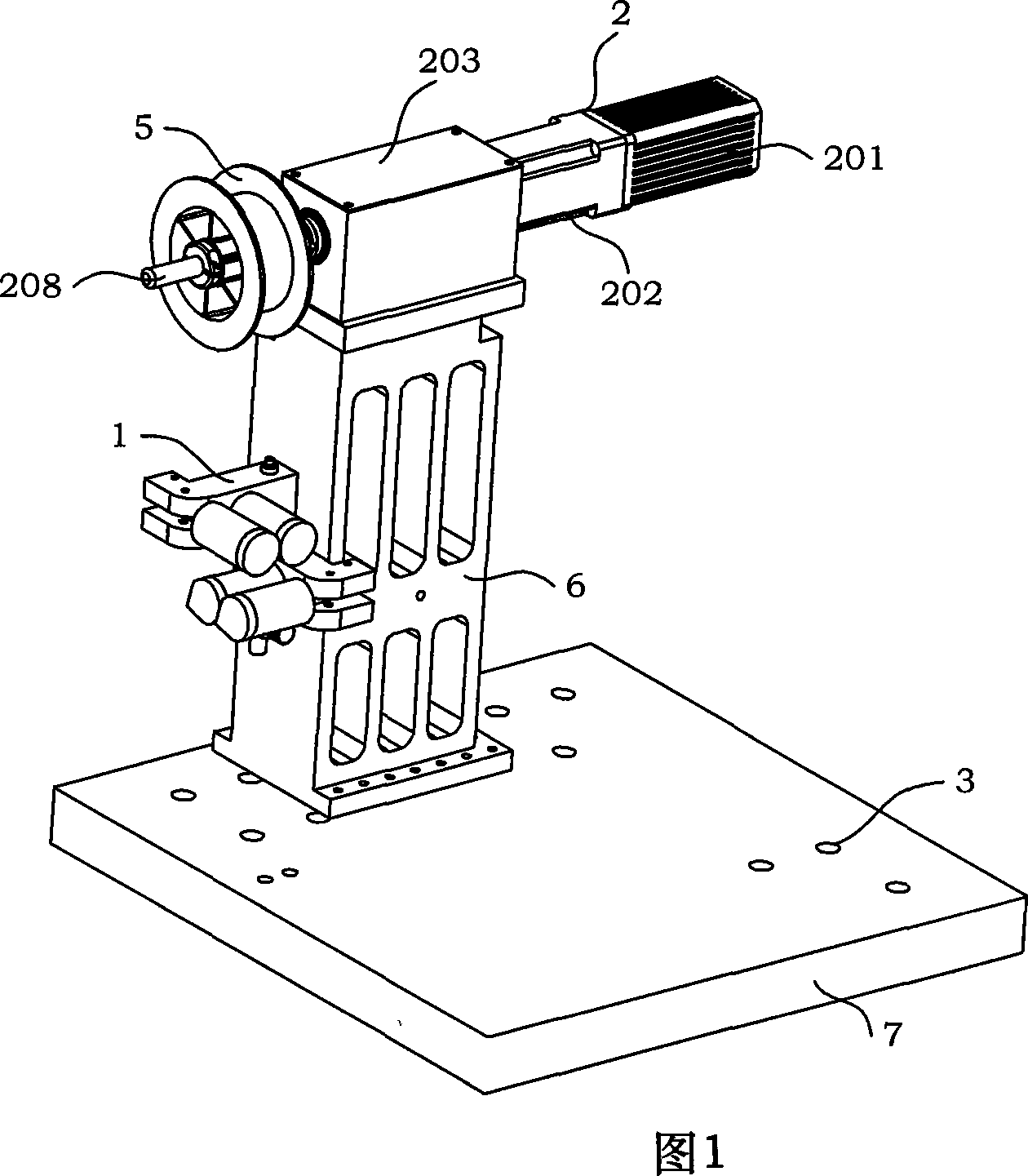

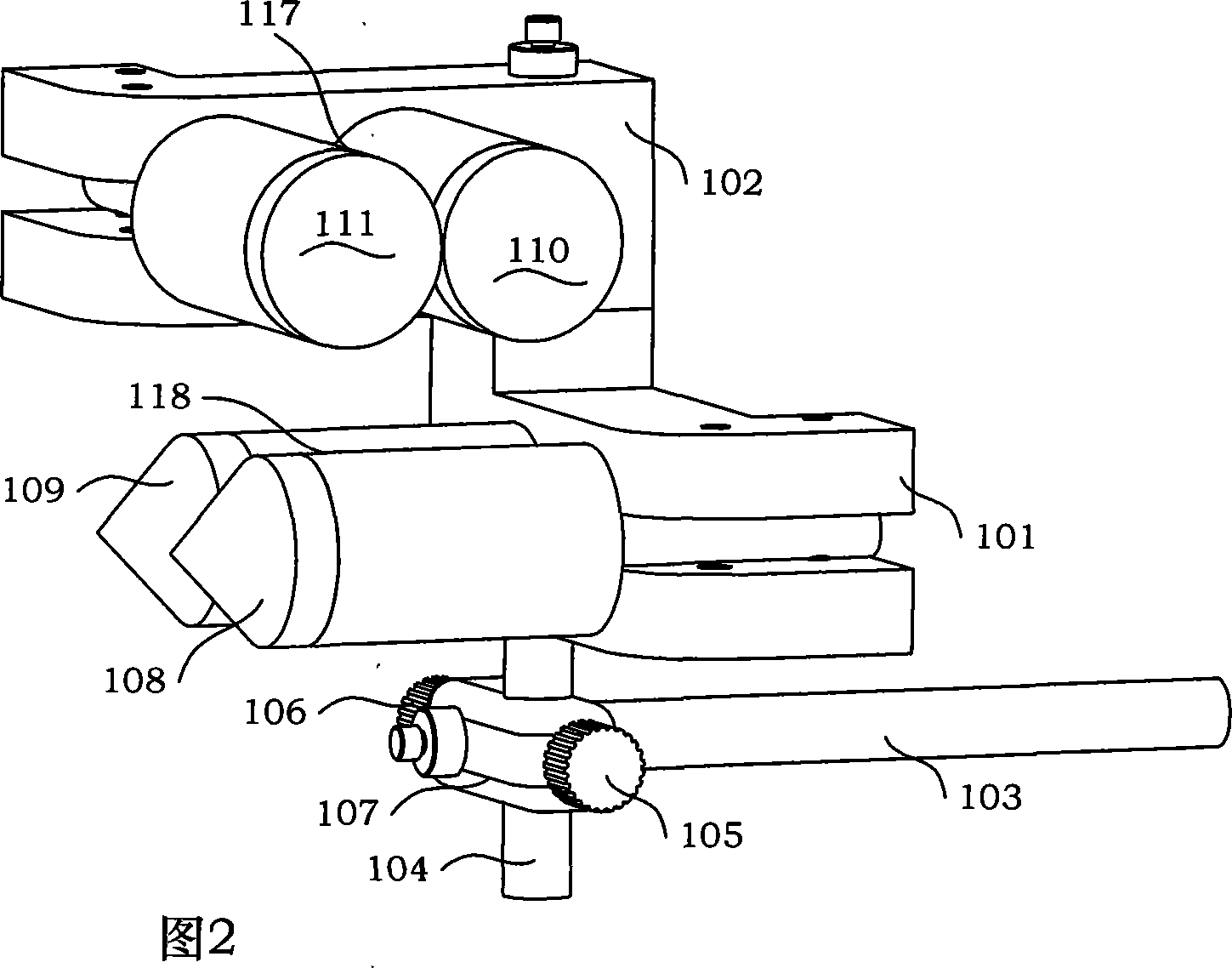

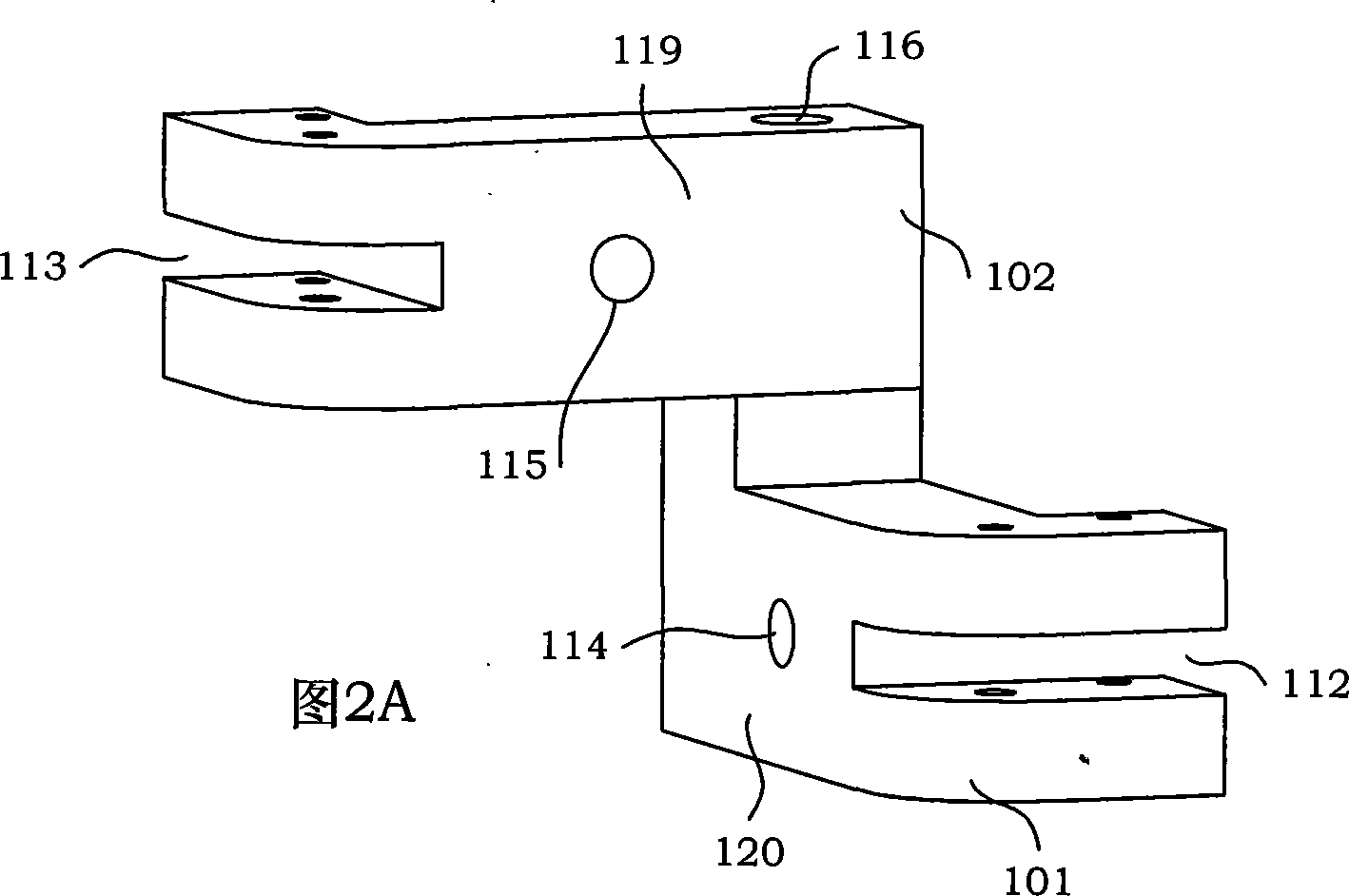

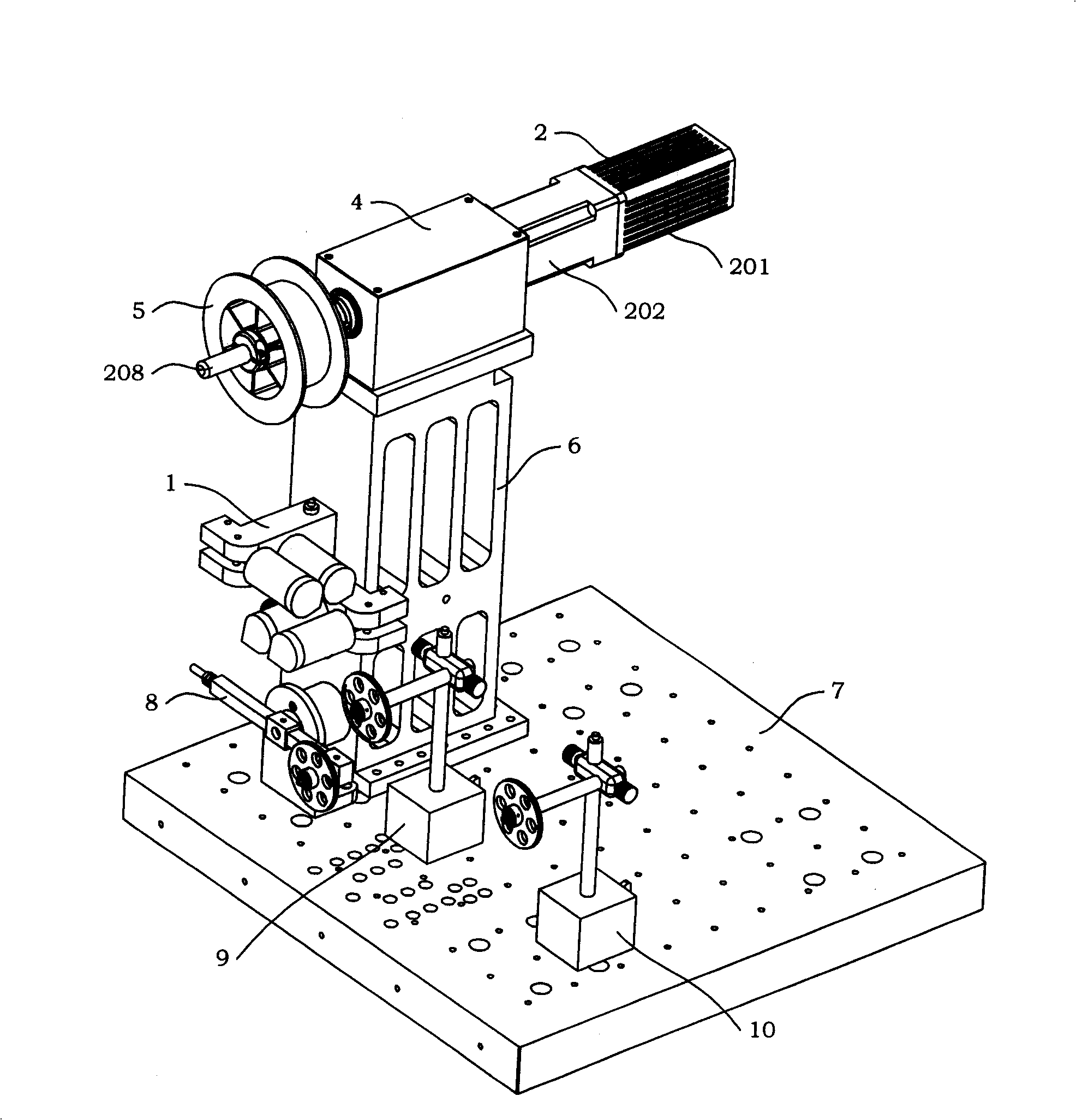

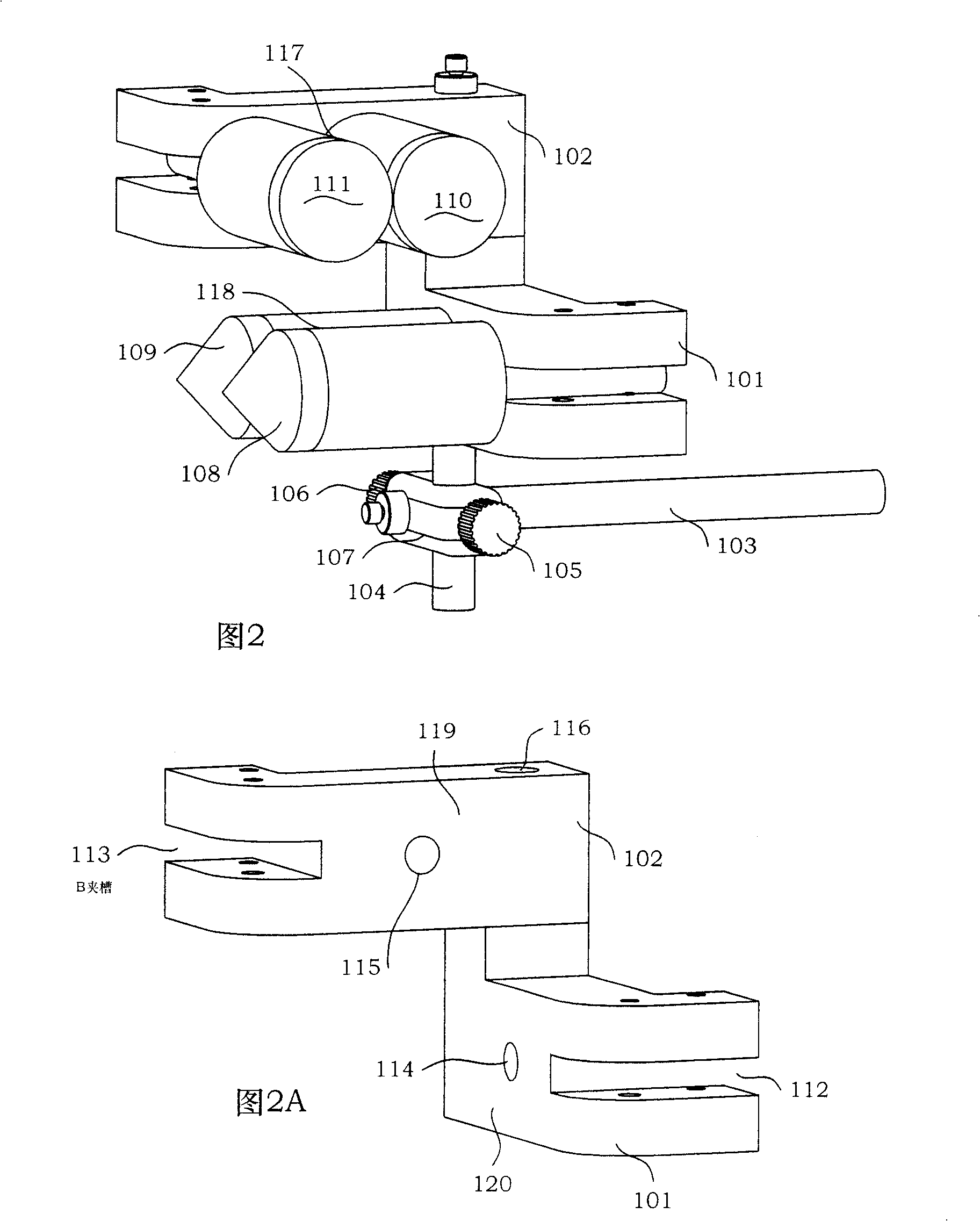

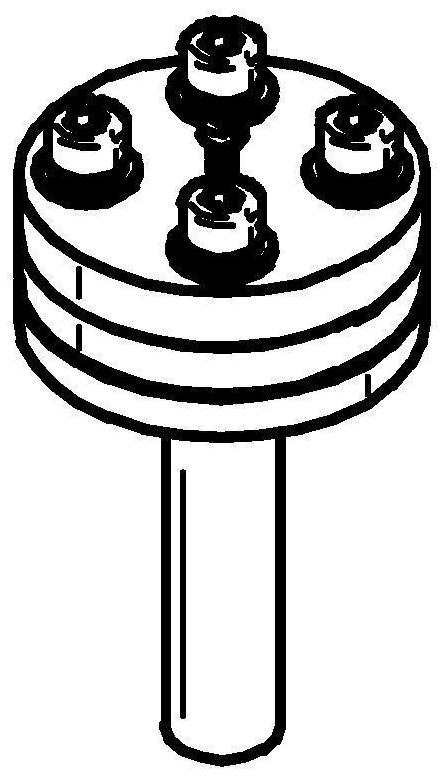

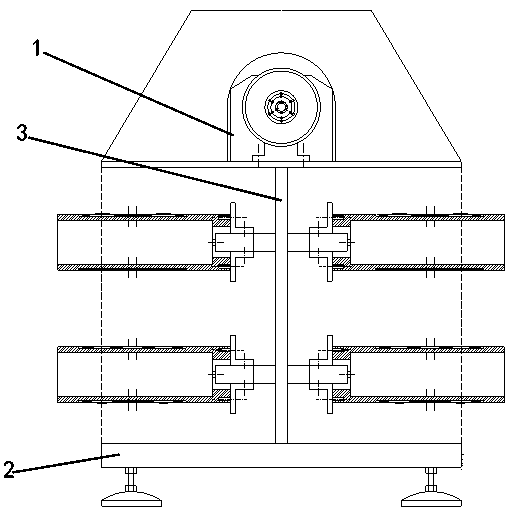

Tension mechanism adapted for automatic optical fiber winding machine

InactiveCN101059582ACompact designNo reverse dead zoneFilament handlingSagnac effect gyrometersWinding machineFiber

The invention discloses a tension structure used in automatic fiber coiler, composed of a fiber collector, a driver, a transmit box, a fiber discharge wheel, a support base, and a sliding table tension element, a first fiber guider and a second fiber guider, wherein the lower end of the support base via nut and screw is mounted on the sliding table, while the upper end is mounted with the transmit box, the driver is on the transmit box, while a motor and a speed reducer are mounted at the outer back of the transmit box, the accurate shaft of the driver is suspended at the outer front of the transmit box, which is mounted with the fiber discharge wheel, the fiber collector is at one side of the support base, vertically with the fiber discharge wheel, the sliding table is arranged with a plurality of mounting holes for fixing and mounting devices, the tension element, the first and the second fiber guiders via nut and screw are fixed on the sliding table, which guide grooves are in one plane. The inventive tension device has reasonable, compact and simple structure, without reverse dead area, but with stable transmission control, accurate tension control, non-zero-bias in force measurement, digit and closed tension control.

Owner:BEIHANG UNIV

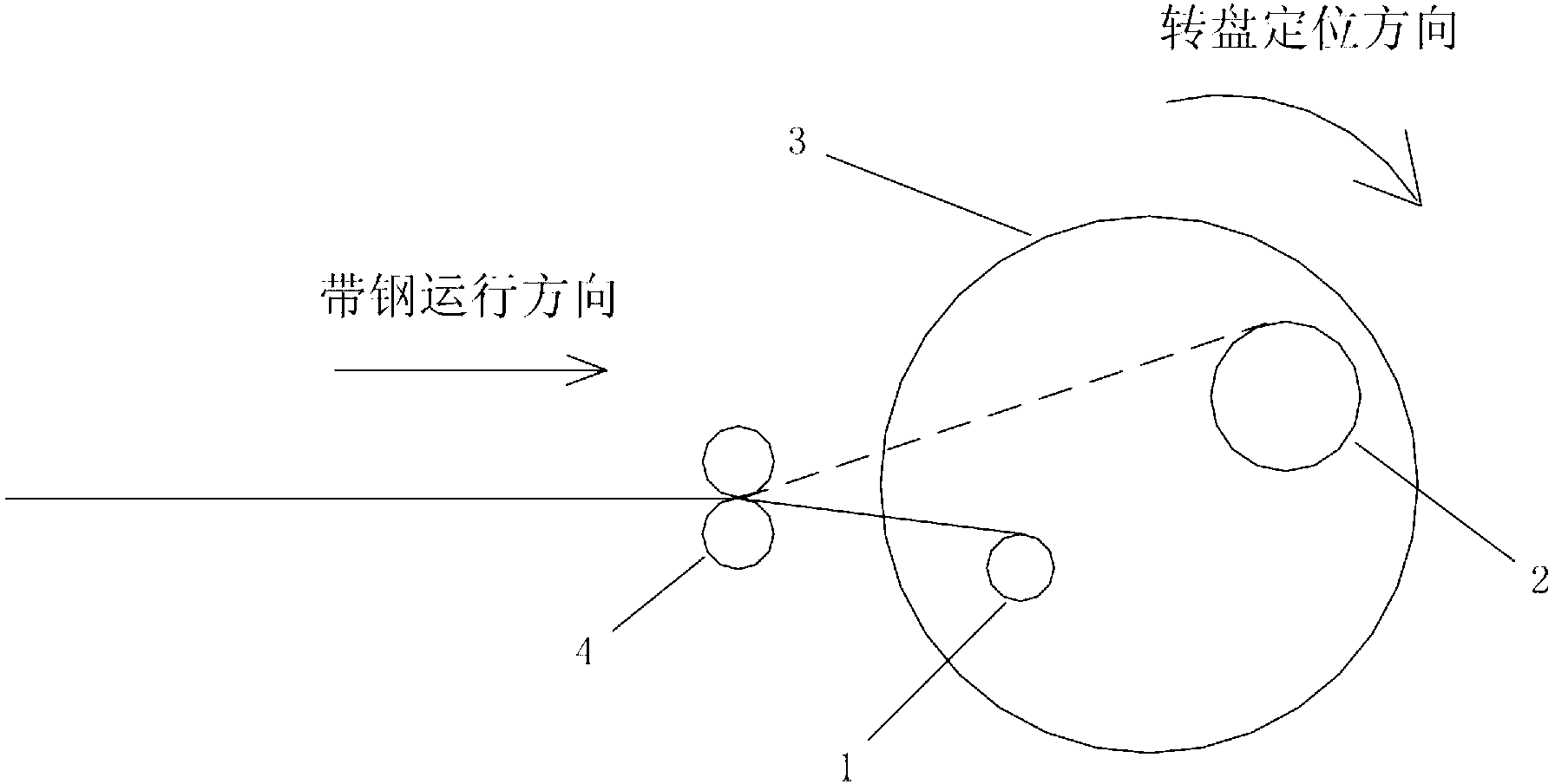

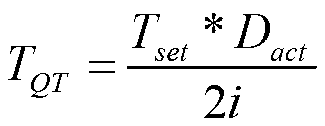

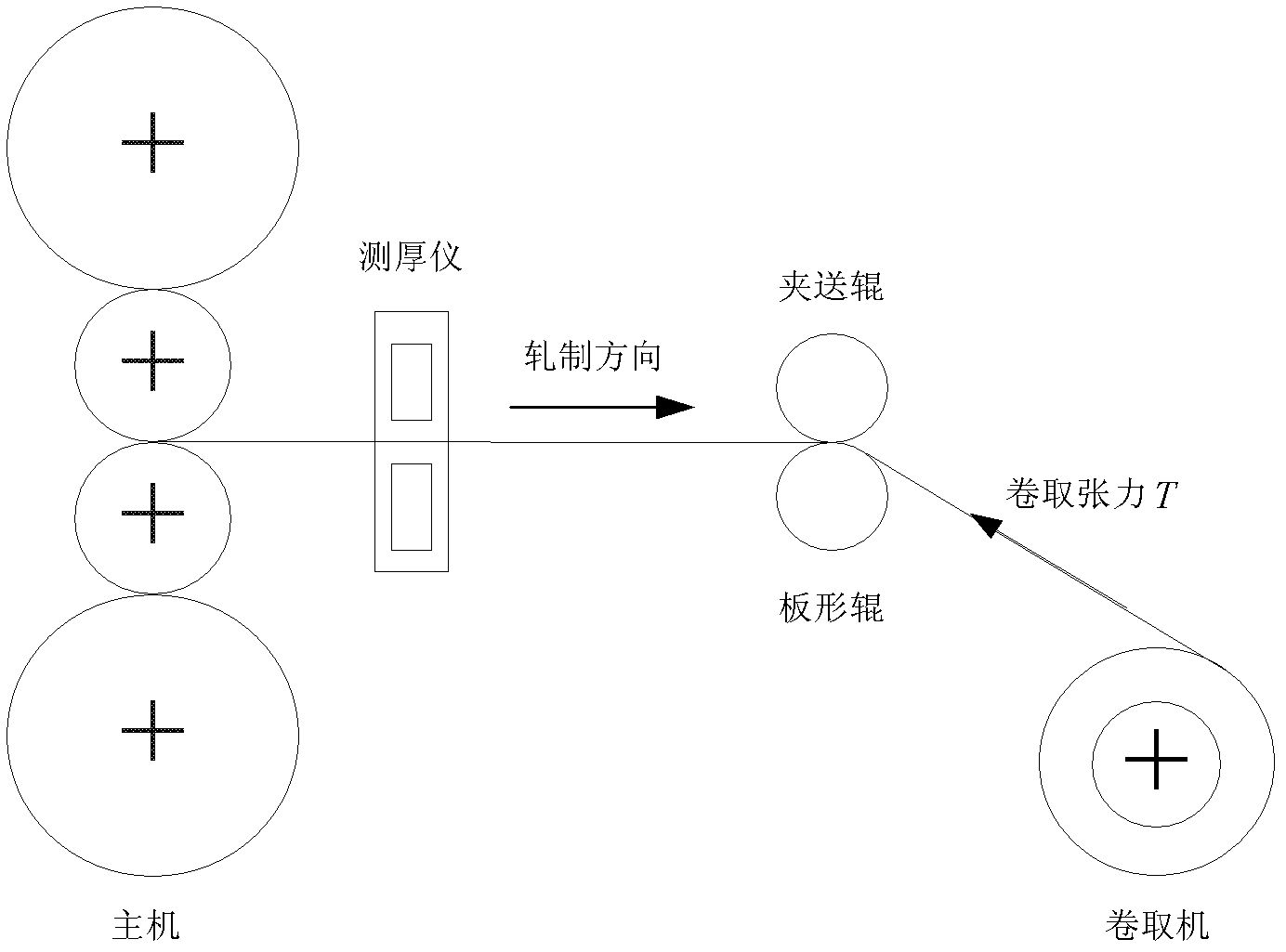

Turntable type high-speed reeling machine control method and system of cold continuous rolling production line

InactiveCN103170524AAchieve high precision controlHigh precision of tension controlProduction rateProduction line

The invention provides a turntable type high-speed reeling machine control method of a cold continuous rolling production line. The method comprises the following steps of: (1) obtaining an actual reeling diameter of a finished steel roll by calculating and correcting; (2) obtaining a precision rotation inert of a reeling machine by measuring and calculating; (3) converting a tension set value into a torque set value according to the actual reeling diameter and the rotation inert and then controlling an output torque of a motor to realize tension control; and (4) switching and controlling positions of two reeling machines, and realizing high-precision control of the cold continuous rolling production line turntable type high-speed reeling machine. The invention also provides a cold continuous rolling production line turntable type high-speed reeling machine control system. The system comprises an actual reeling diameter obtaining module, a rotation inert obtaining module, a band steel tension control module and a double-reeling-machine position switching control module. The invention has the beneficial effects that during high-speed production, the turntable reeling machine is precisely controlled; the actual reeling diameter is accurately calculated; band steel tension can be stably controlled; the fault rate is low; and the production rate is improved.

Owner:WISDRI WUHAN AUTOMATION

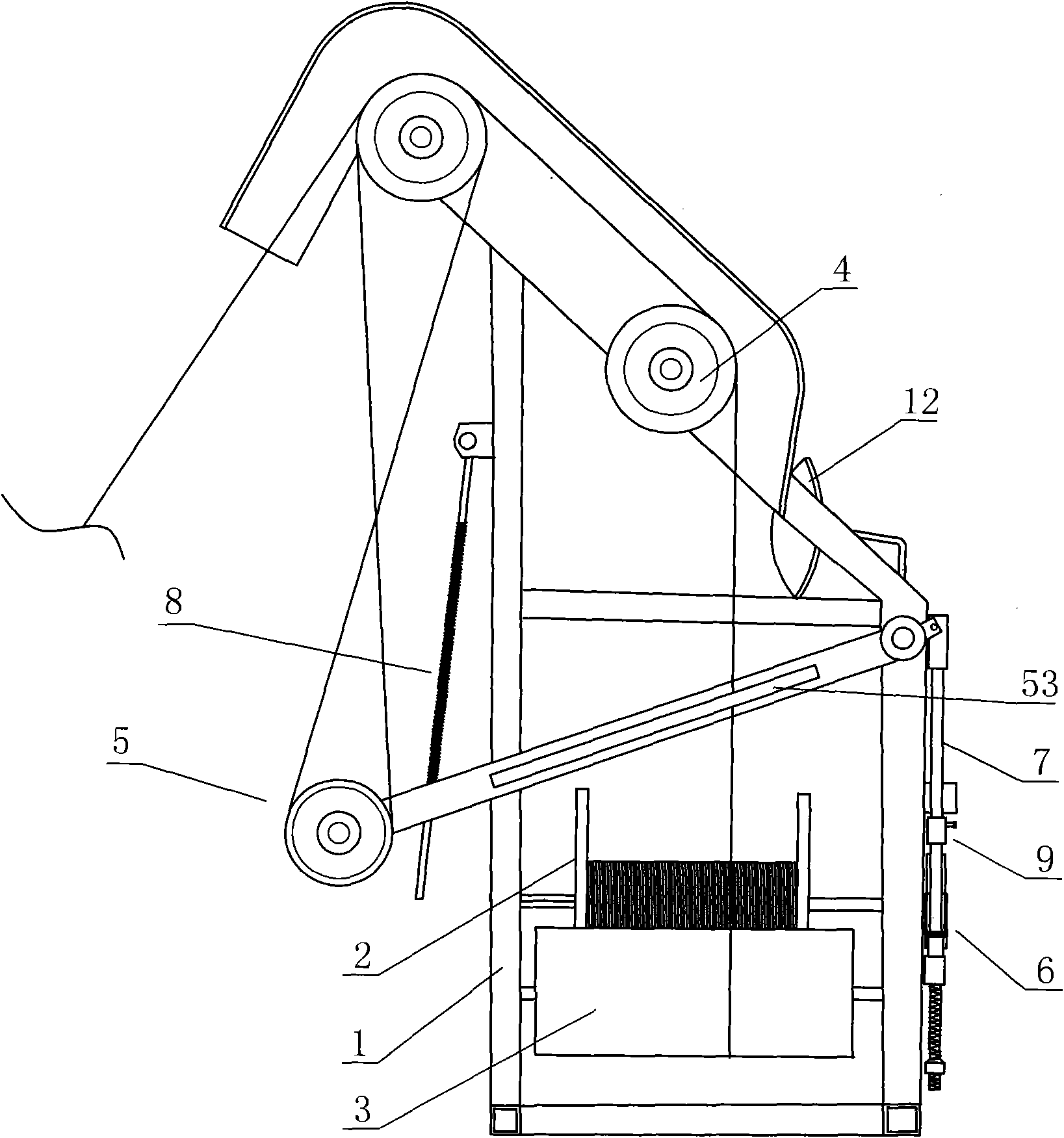

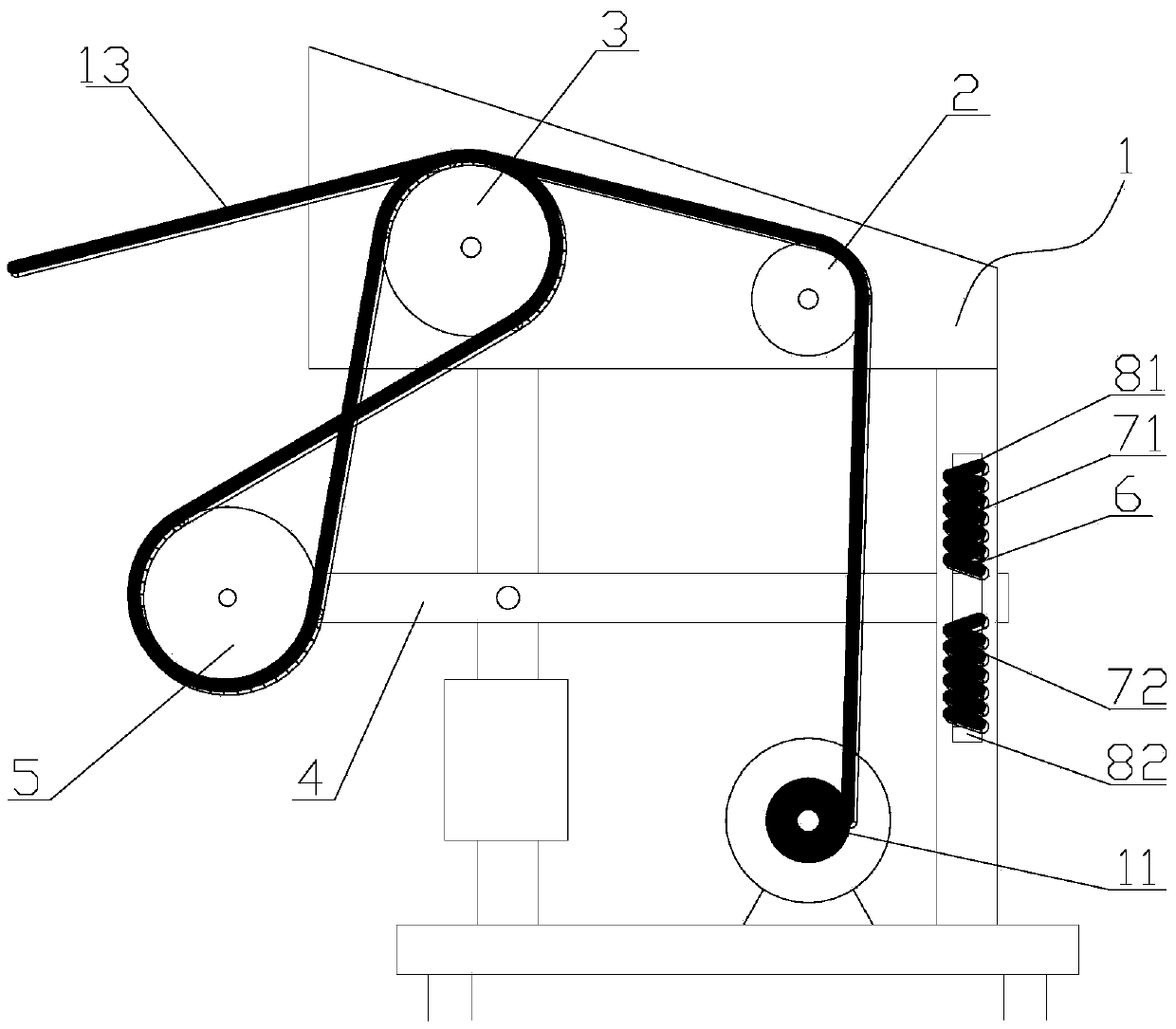

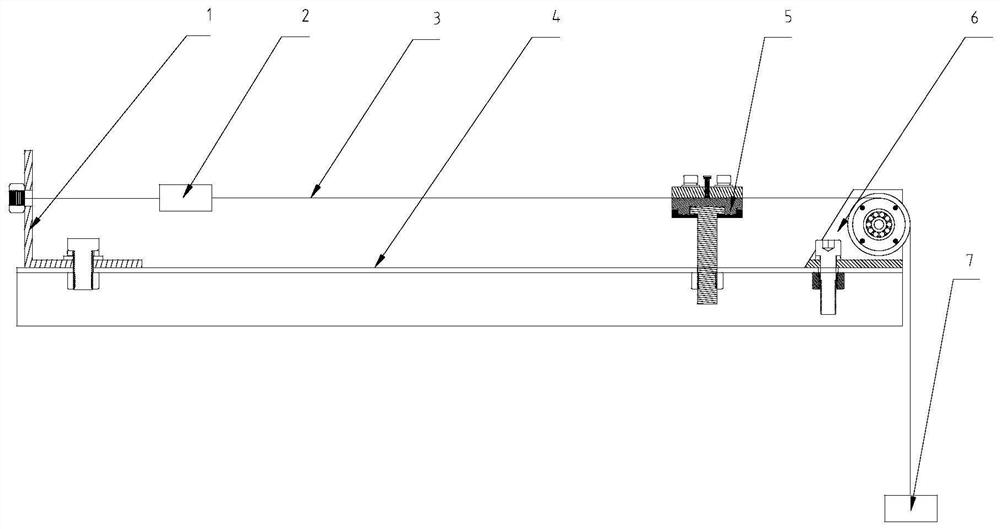

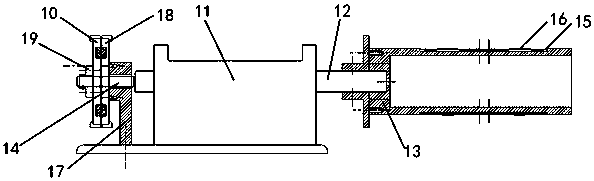

Automatic cable winding conveying tension adjusting device

ActiveCN103787148AQuality assuranceRealize automatic adjustmentFilament handlingEngineeringUltimate tensile strength

The invention provides an automatic cable winding conveying tension adjusting device. A cable on a wire spool sequentially passes through a cable guide wheel, a fixed cable winding wheel, a floating cable winding wheel and a fixed wire spool and then is output, the cable guide wheel and the fixed cable winding wheel are arranged at the upper portion of a machine frame, the fixed cable winding wheel is driven by a drive mechanism, the drive mechanism is connected with a control mechanism, a swing rod is arranged below the fixed cable winding wheel, the middle of the swing rod is connected to the machine frame in a rotating mode, one end of the swing rod is provided with the floating cable winding wheel corresponding to the fixed cable winding wheel, the other end of the swing rod is arranged in a swing hole in the machine frame, an upper spring and a lower spring are arranged at the upper end and the lower end of the swing hole respectively and make contact with the swing rod, the upper spring and the lower spring are connected with the machine frame through an upper pressure sensor and a lower pressure sensor respectively, and the upper pressure sensor and the lower pressure sensor are connected with the control mechanism. The automatic cable winding conveying tension adjusting device can keep constant conveying tension all the time, can adjust the conveying tension automatically, greatly relieves labor intensity and ensures the cable quality.

Owner:ANHUI HUAXI CABLE TECH

Constant-tension wire moving control device for micro electrospark wire cutting and control method thereof

InactiveCN103302370AEliminate jitterReduce measurement errorElectrical-based machining electrodesElectric circuitsWire cuttingElectric machinery

The invention provides a constant-tension wire moving control device for micro electrospark wire cutting. The constant-tension wire moving control device for the micro electrospark wire cutting comprises a machine frame, a movement control card and an industrial personal computer, wherein the machine frame is connected with a wire storage barrel clamping device, a tension pulley, a tension sensor, a guider and a wire drawing wheel which are sequentially arranged in an electrode wire moving sequence; the tension pulley is connected with a first driving motor; the first driving motor is connected with a first driver; the wire drawing wheel is connected with a second driving motor; the second driving motor is connected with a second driver; the first driver and the second driver are connected with the movement control card respectively; and the movement control card and the tension sensor are connected with the industrial personal computer respectively. The invention further provides a constant-tension wire moving control method for the micro electrospark wire cutting. The constant-tension wire moving control device and the constant-tension wire moving control method have the advantages as follows: the tension measuring error is greatly reduced; the tension control precision is improved; and the machining precision is ultimately improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

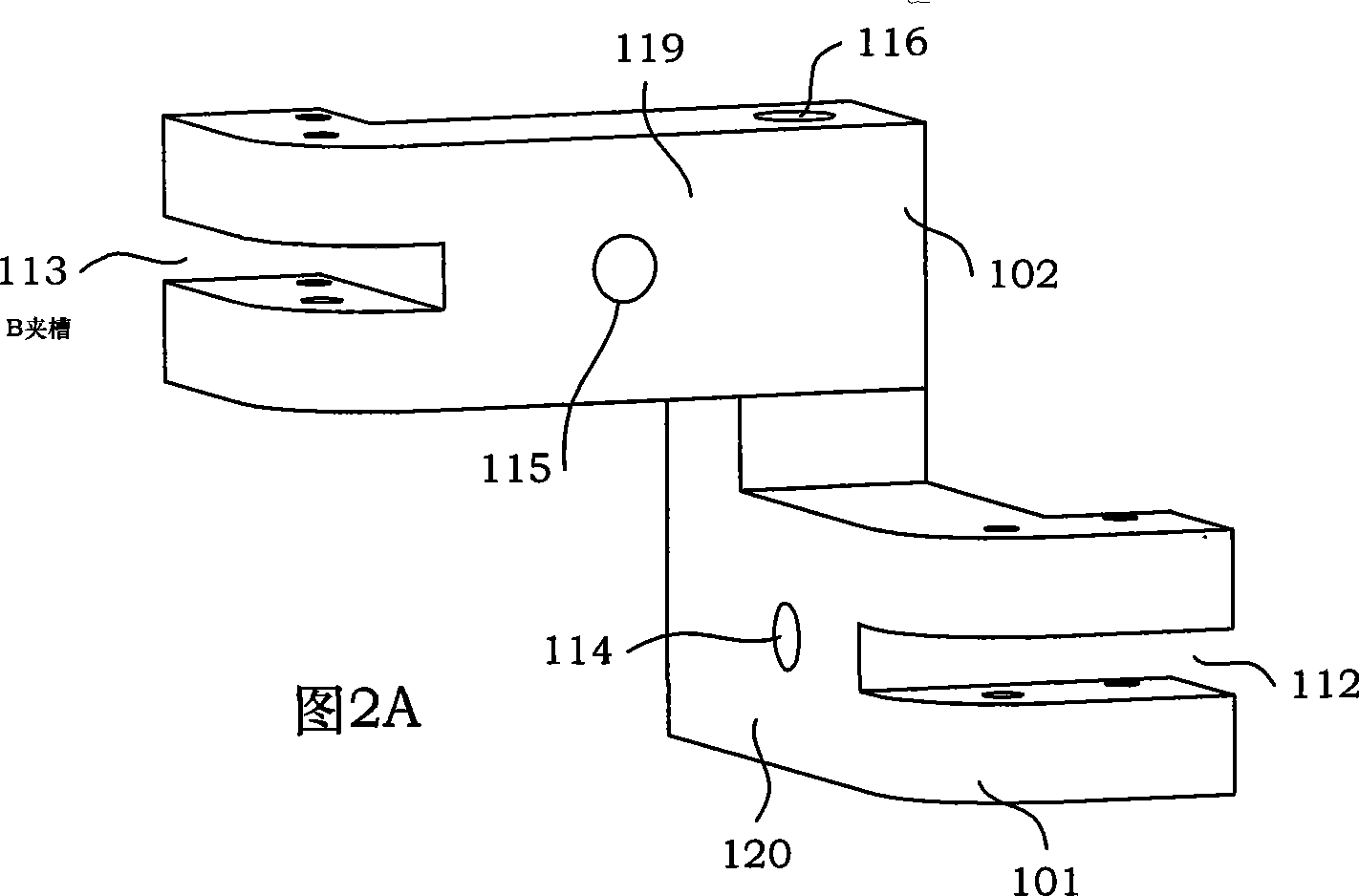

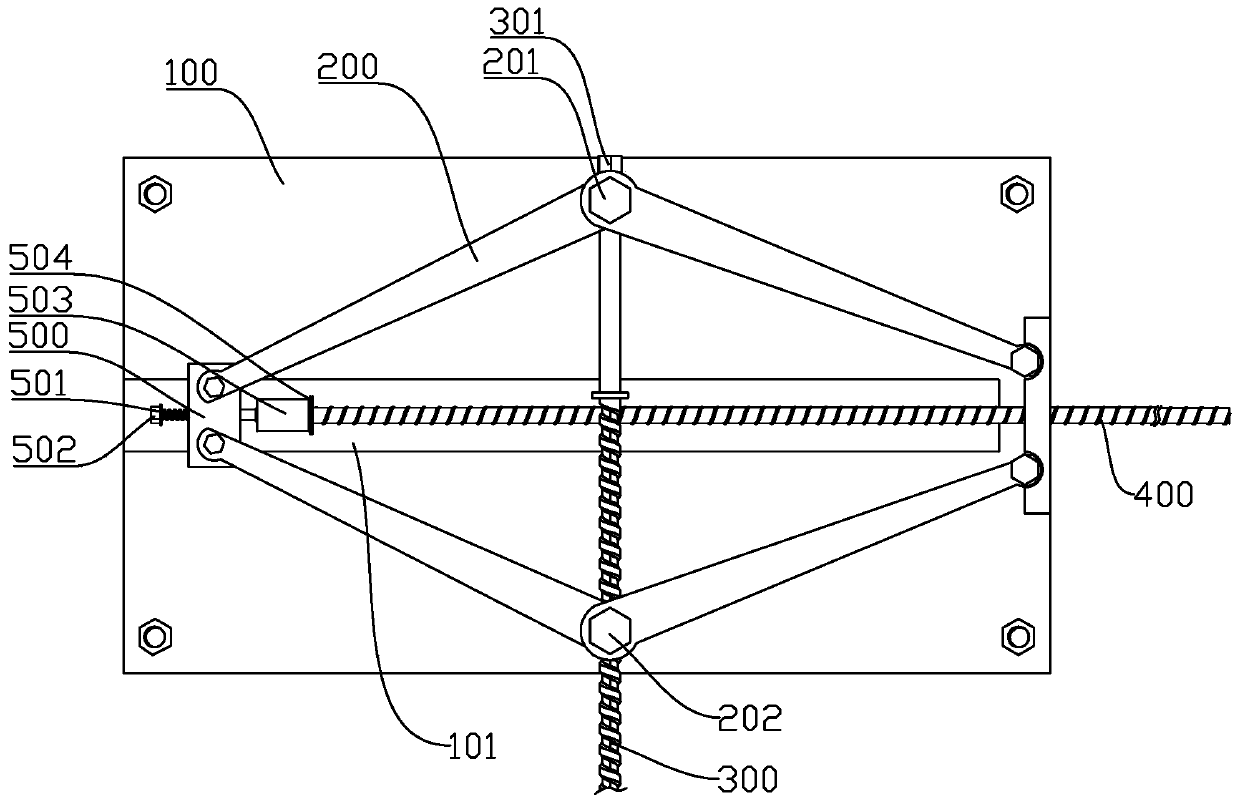

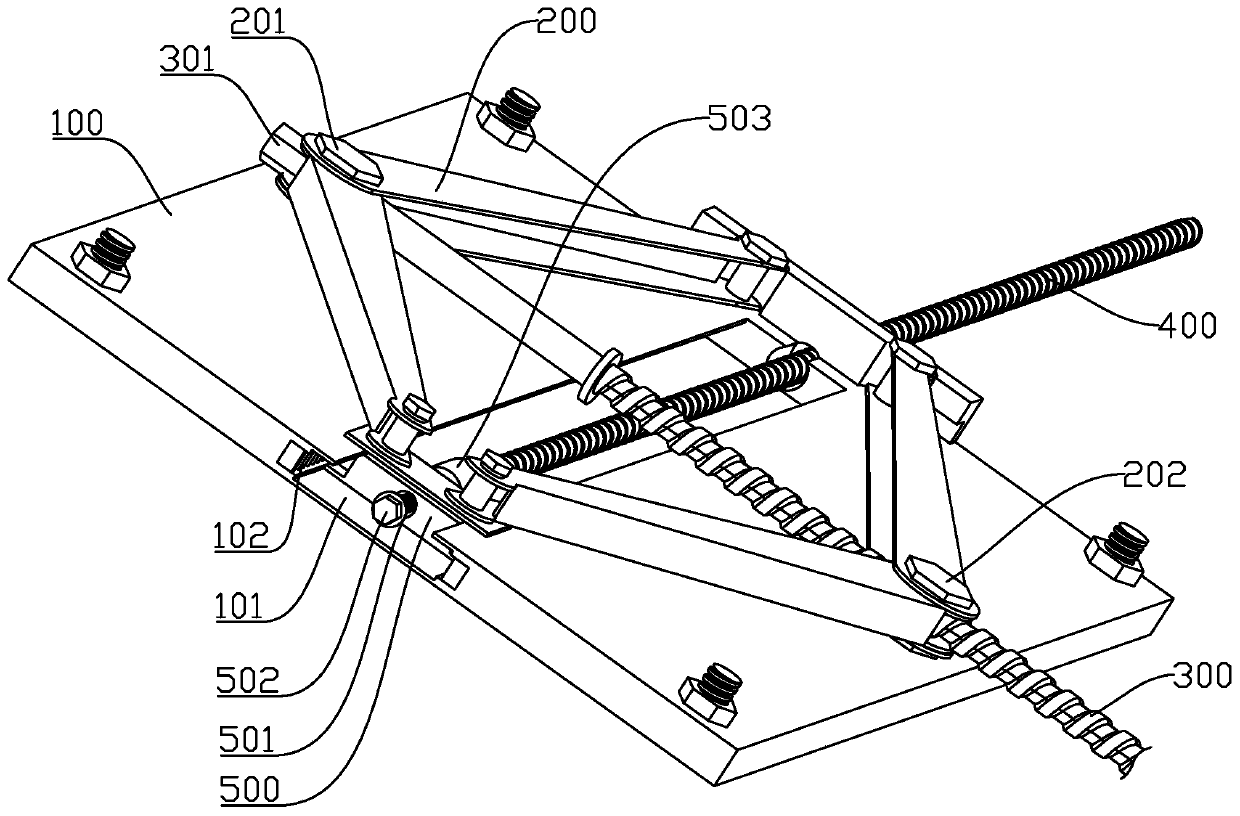

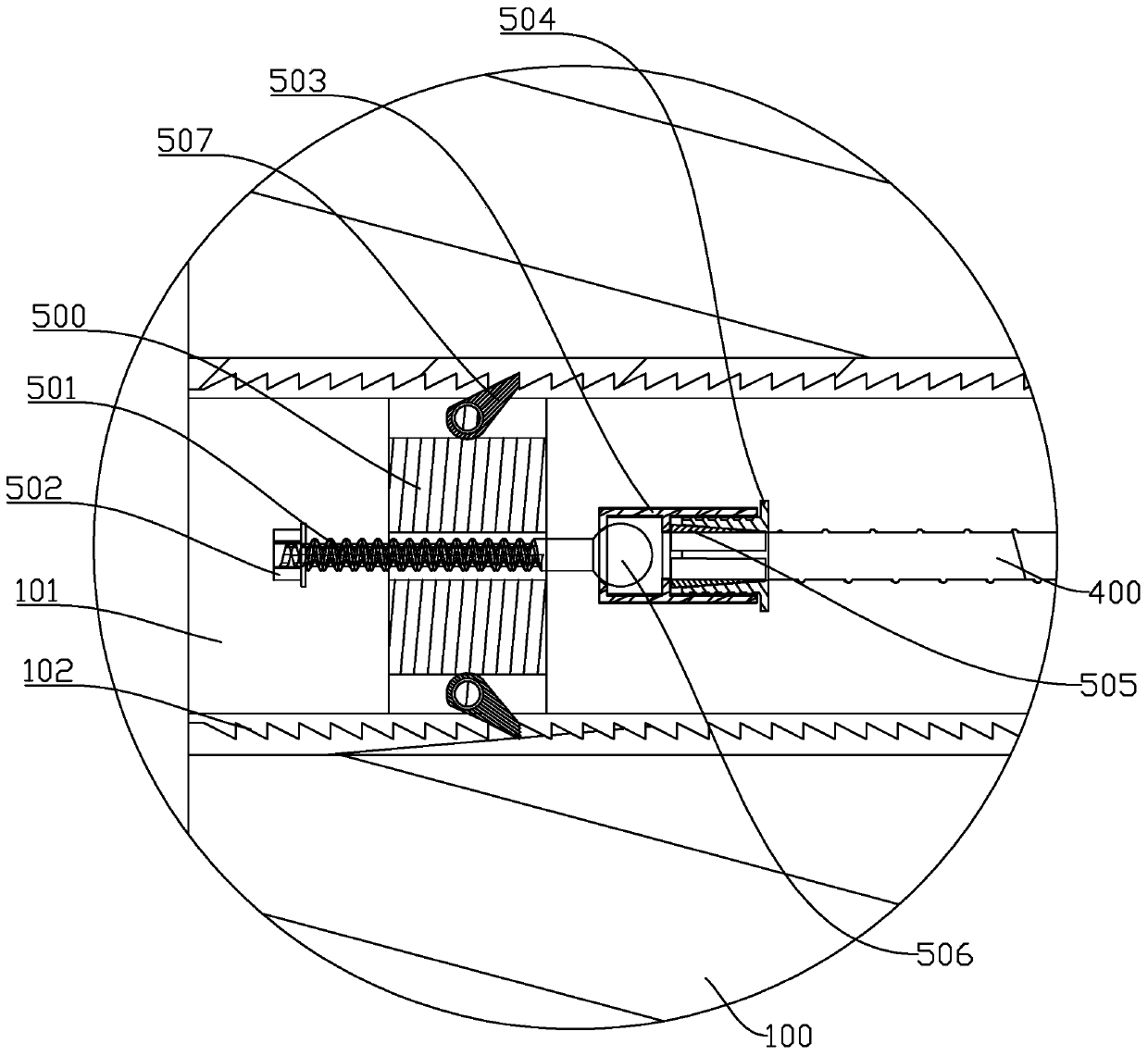

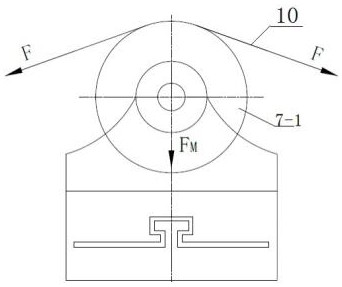

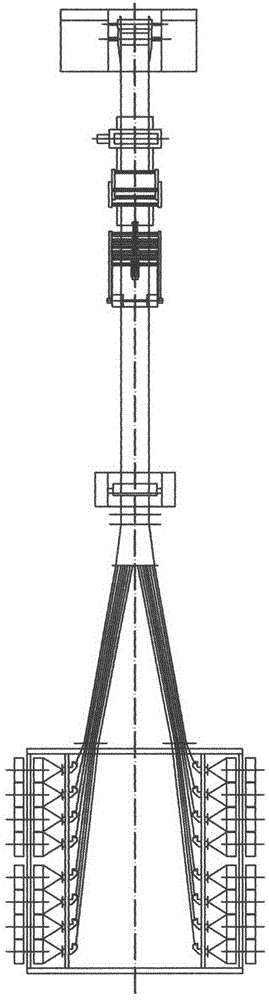

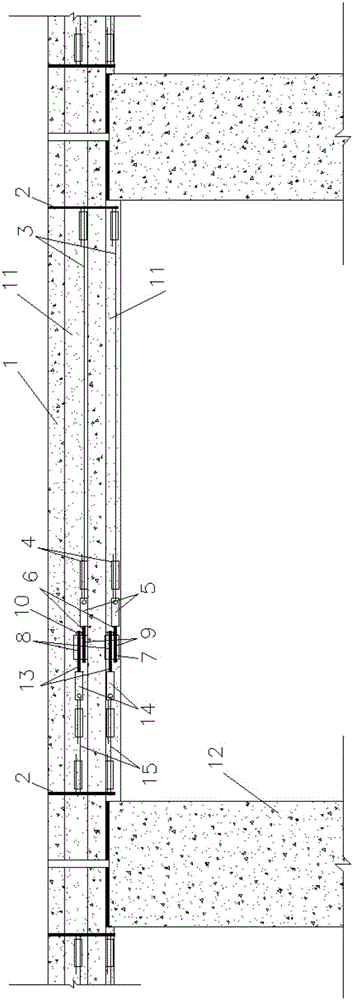

Externally prestressed FRP rebar tensioning anchorage device

PendingCN110029592AWon't breakSimple and fast operationBuilding repairsBridge erection/assemblyPre stressEngineering

The invention discloses an externally prestressed FRP rebar tensioning anchorage device. The externally prestressed FRP rebar tensioning anchorage device integrates externally prestressed FRP rebar tensioning, anchorage and prestress adjusting and is most suitable for external FRP rebar tensioning reinforcing of a bridge or a building structure. The externally prestressed FRP rebar tensioning anchorage device comprises an anchor backing plate, an anchorage device and a tensioning device, the anchorage device is used for clamping FRP rebars, the tensioning device is mounted on the anchor backing plate, is in transmission connection with the anchorage device and is used for pulling the anchorage device to move in the tensioning direction of the FRP rebars, and thus prestressed tensioning ofthe FRP rebars is achieved. The FRP rebars are fixed through the anchorage device, then prestressed tensioning is conducted through the tensioning device without the need of adopting a jack, operationis easy and convenient, the required space is small, and safety is high; meanwhile, tangential acting force borne by the FRP rebars can be eliminated through a ball hinge device, and the FRP rebars are prevented from shear failure; and the externally prestressed FRP rebar tensioning anchorage device can be demounted to be reused, thus the economic and environment-friendly effects are achieved, tensioning anchorage can be conducted again after prestress relaxation of the FRP rebars occurs, and practicability is high.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

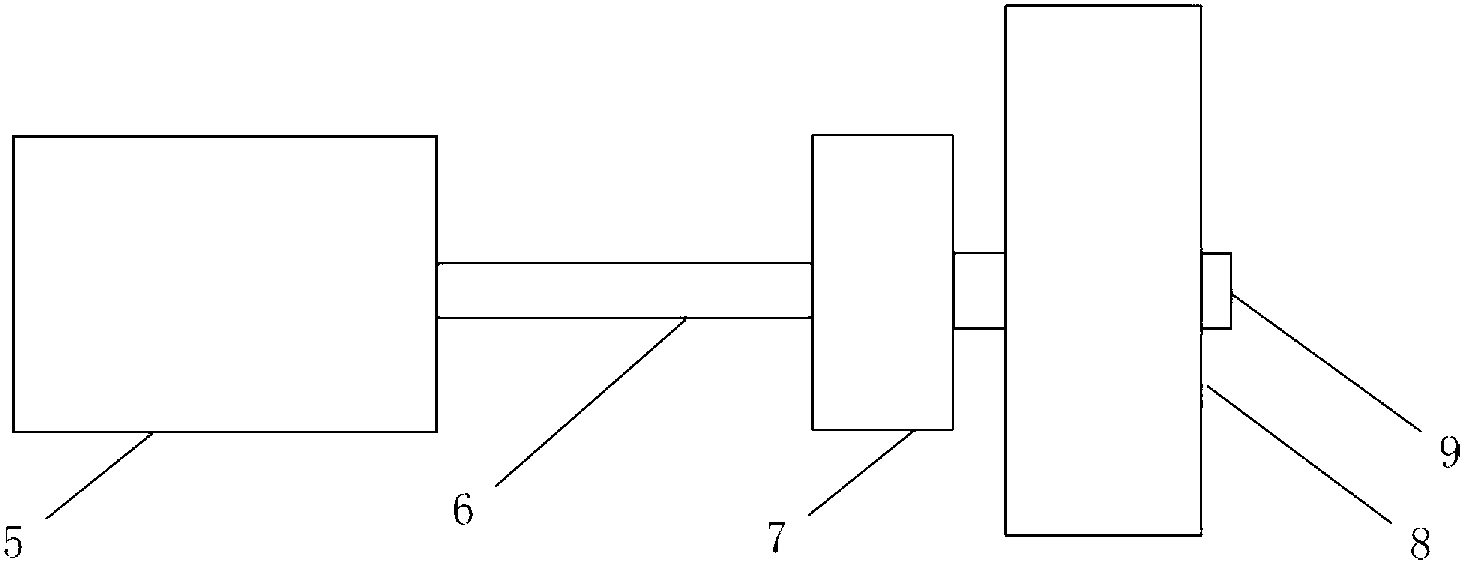

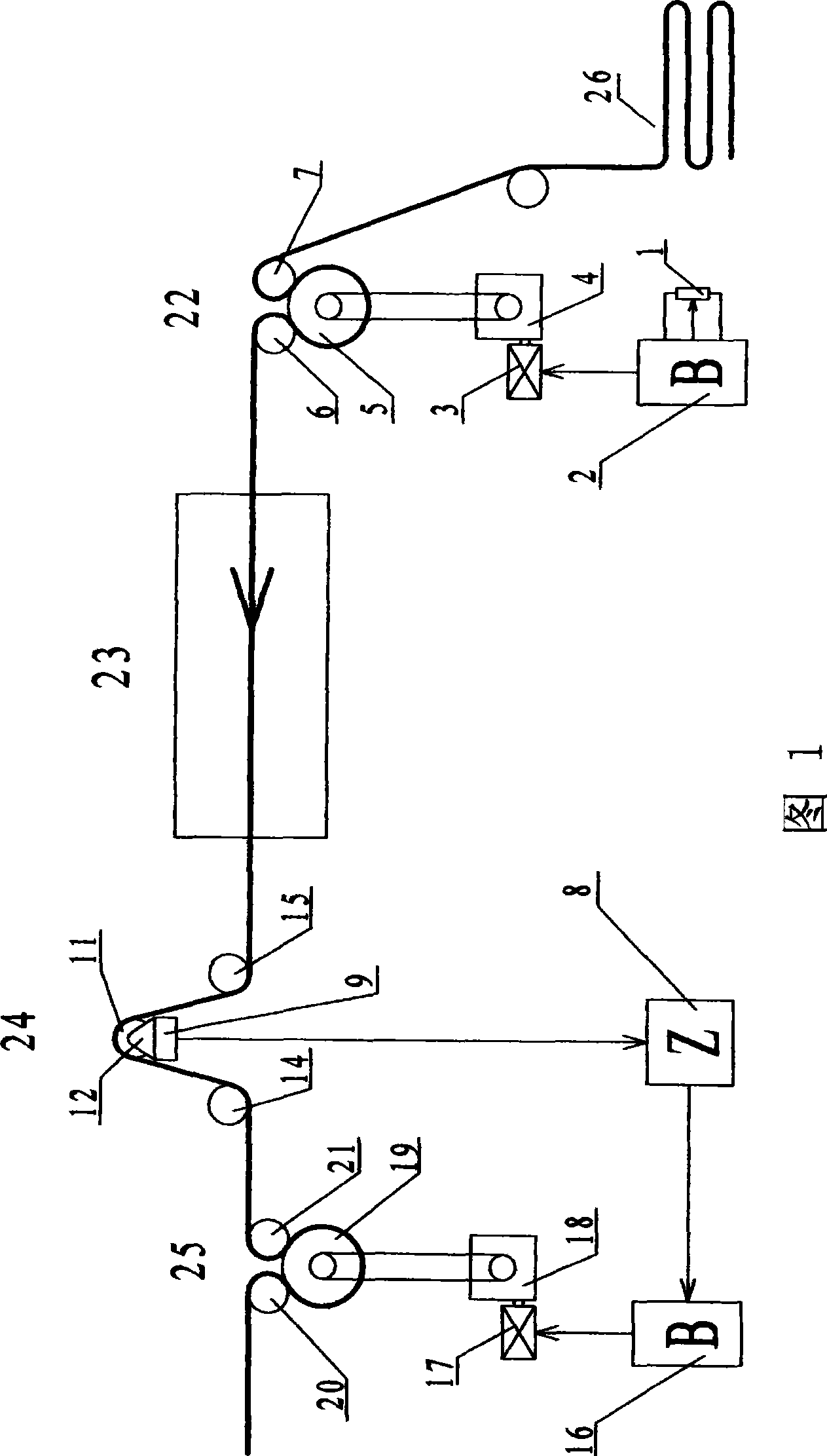

Carbon cloth tension automatic control device in low temperature carbonization furnace system

InactiveCN101419472AChange running speedChange speedHeating/cooling textile fabricsMechanical pressure/force controlFuel cellsAutomatic control

The invention relates to an automatic carbon cloth tension controlling device in a carbon cloth low-temperature carbide furnace system used by a fuel battery in the automatic control field. The device comprises a potentiometer, an inlet frequency variation controller, an inlet driving roller, a tension controller, a tension roller, an outlet frequency variation controller and an outlet driving roller. The inlet driving roller is positioned in front of a low-temperature carbide furnace; the inlet frequency variation controller, the potentiometer and the inlet driving roller form a closed loop feedback chain; the tension roller and the outlet driving roller are sequentially positioned behind the low-temperature carbide furnace; the tension controller is respectively connected with the tension roller and the outlet frequency variation controller; and the outlet frequency variation controller is connected with the outlet driving roller to output the carbon cloth. A tension sensor in the invention measures and obtains an instant tension value of the carbon cloth and is controlled by a feedback closed loop so that the carbon cloth tension control achieves high accuracy, satisfactory stability and fast response. Manual adjustment of the potentiometer can stabilize the invention in a new and balanced feedback loop so as to perform fine adjustment to the carbon cloth of different materials and to facilitate technical operations.

Owner:SHANGHAI SXCARBON TECH

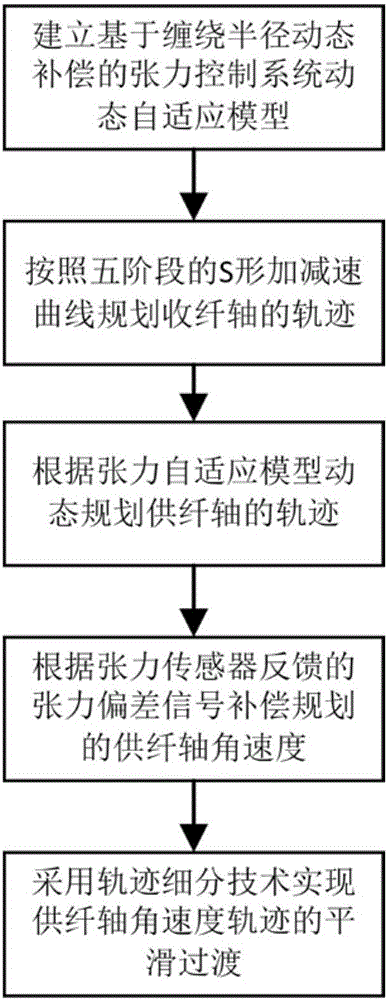

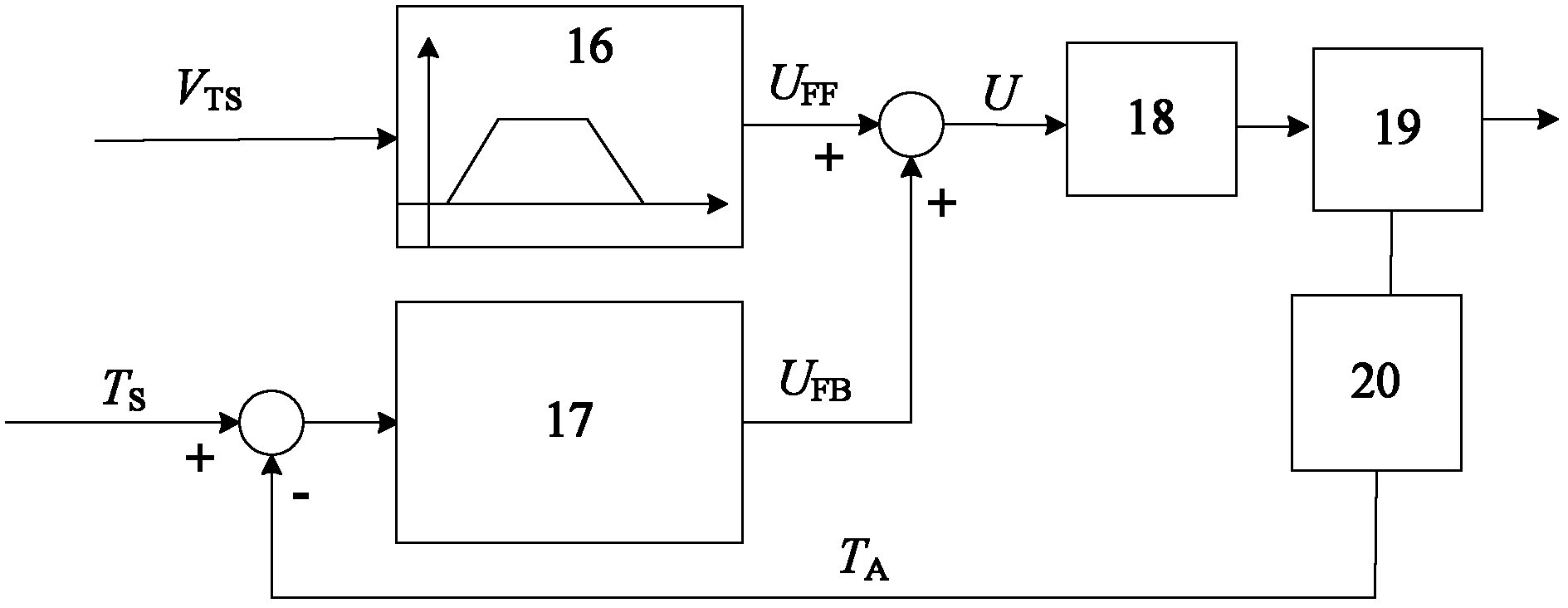

Straight-pull cold-rolling mill tension control method based on speed feedforward

ActiveCN102527740AExact speed matchHigh precision of tension controlTension/compression control deviceTension controlStraight pull

The invention discloses a straight-pull cold-rolling mill tension control method based on speed feedforward and belongs to the technical field of cold-rolling tension control. The straight-pull cold-rolling mill tension control method can be used for realizing the purpose of precisely matching the speeds of a tension hydraulic cylinder and a rolling mill and is high in tension control precision. The straight-pull cold-rolling mill tension control method comprises the following steps: 1. determining a linear velocity set value of a rolled piece on the input of a rolling machine and a linear velocity set value on an output; 2. determining the servo valve control amount of the speed feedforward control of an inlet tension hydraulic cylinder and an outlet tension hydraulic cylinder; 3. determining the servo valve control amount of the tension feedback control of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder; 4. determining the final servo valve control amounts of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder; and 5. sending the determined final servo valve control amounts of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder into a control system, and regulating the servo valves of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder by virtue of the control system.

Owner:NORTHEASTERN UNIV

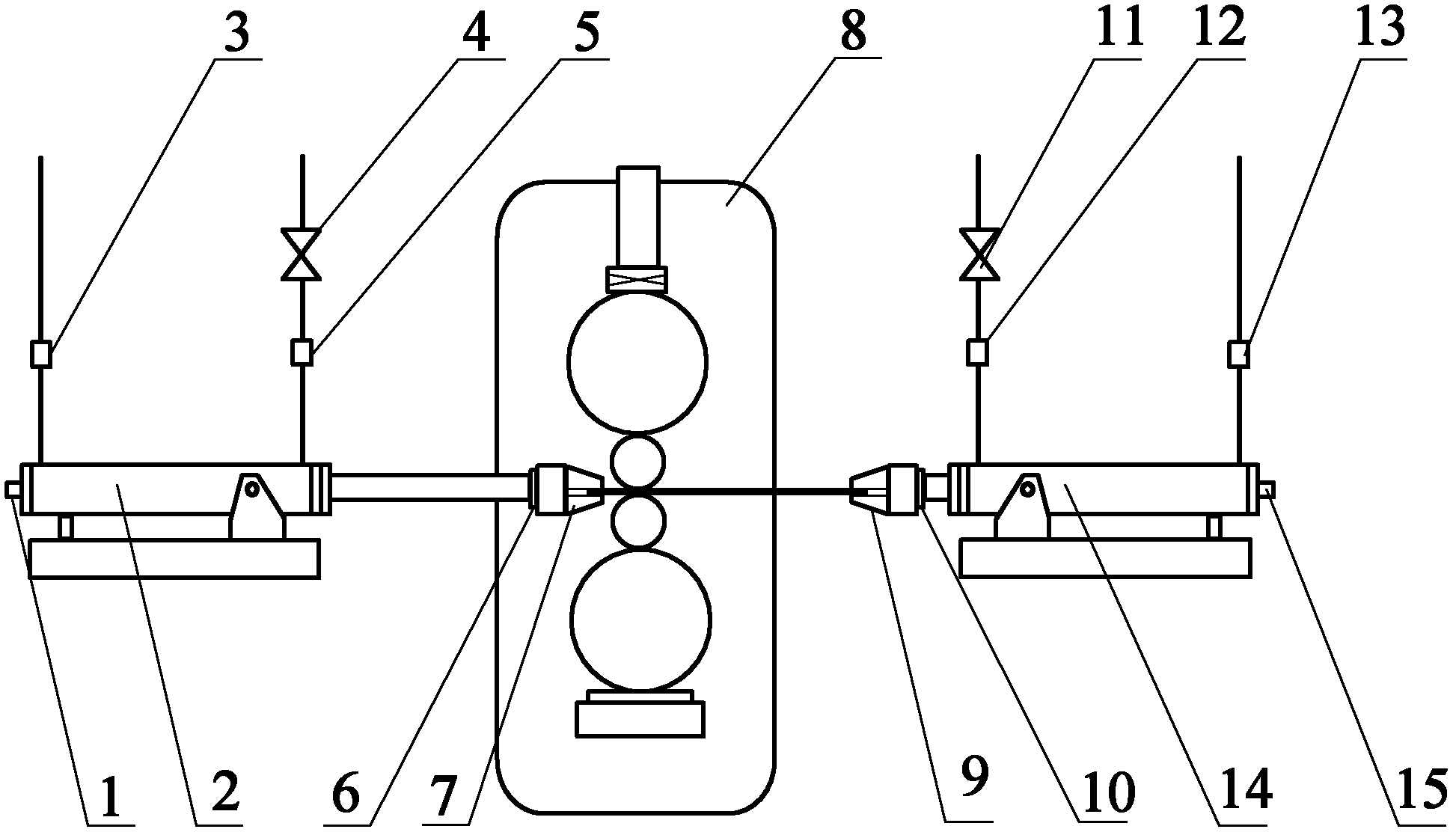

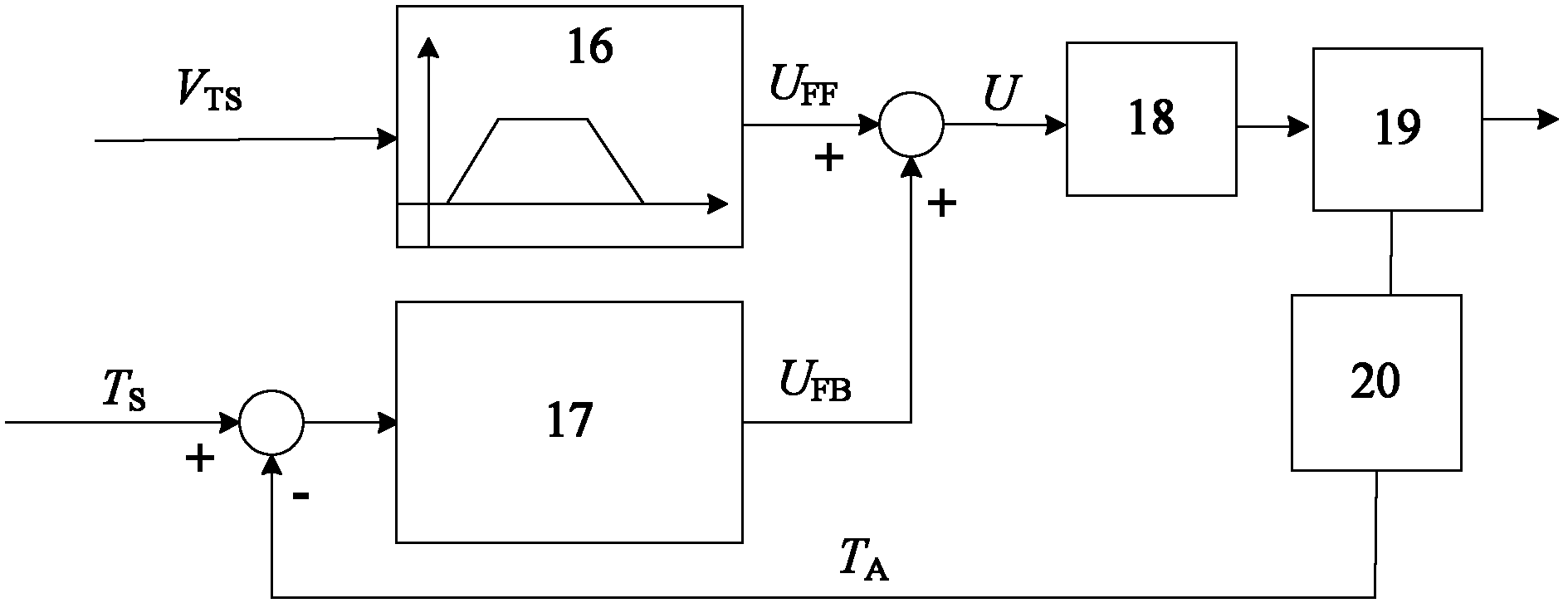

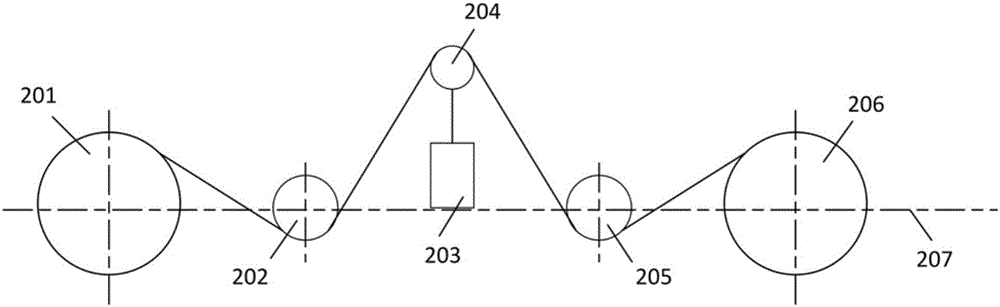

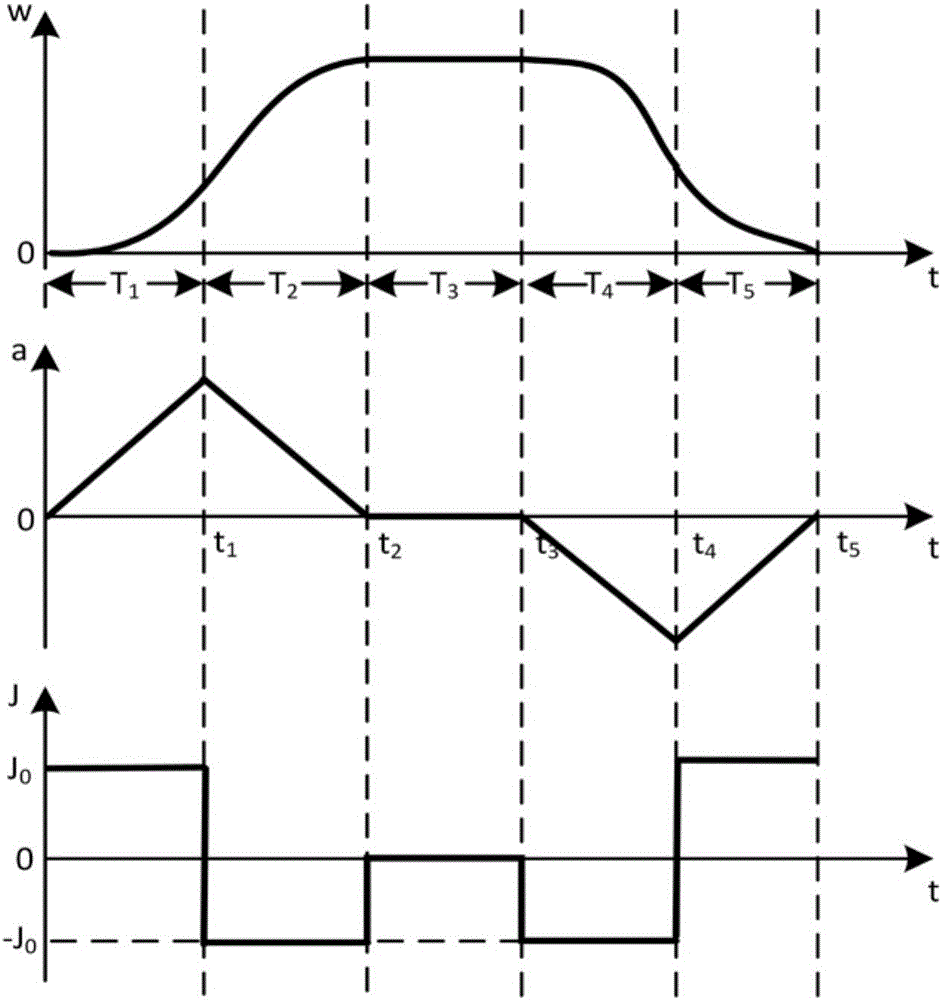

Method for adaptive control over optical fiber winding tension

ActiveCN105867135AHigh precision of tension controlReduce model errorAdaptive controlFiberWinding machine

The invention discloses a method for adaptive control over optical fiber winding tension so as to improve a tracking angle velocity of a fiber supply shaft and control precision of optical fiber tension in the optical fiber winding process. A tension control system dynamic self-adapting model based on dynamic compensation on a winding radius is established; first a motion track of a fiber collecting shaft is planned according to an S-shaped acceleration and deceleration curve of five stages; an angle velocity track of the fiber supply shaft is dynamically planned according to the established tension dynamic self-adapting model, and the planned fiber supply shaft angle velocity is compensated according to tension deviation signals fed back by a tension sensor; and finally a track subdivision technology is adopted to achieve smooth transition of an angle velocity track in the acceleration and deceleration process of the fiber supply shaft. According to the method, the tension control precision is high, the overshoot and tension wave range are small, and the method is easy to implement and suitable for optical fiber winding machines and winding devices of various types and has high application values.

Owner:BEIHANG UNIV

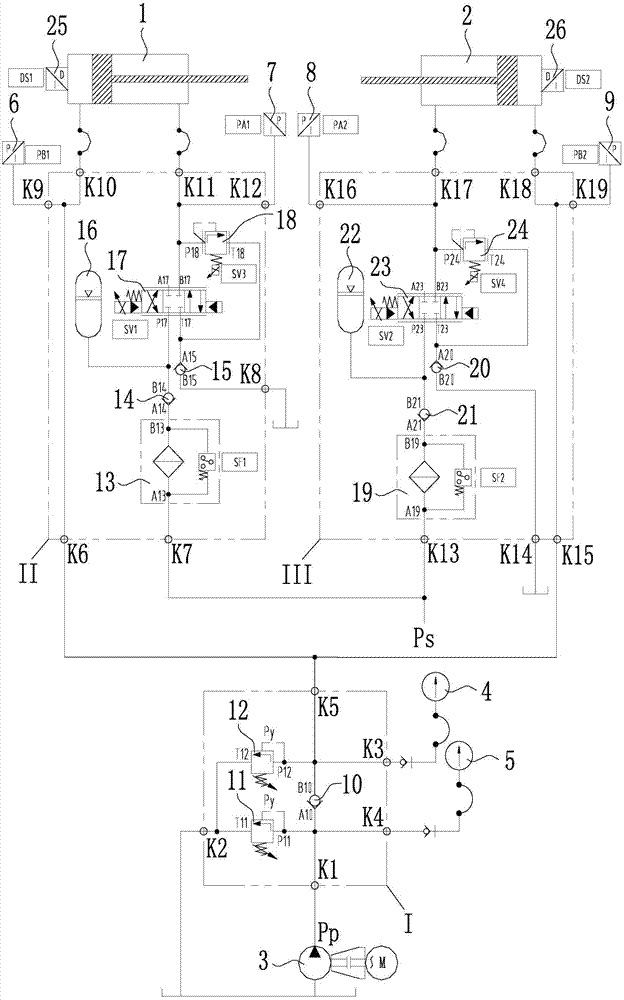

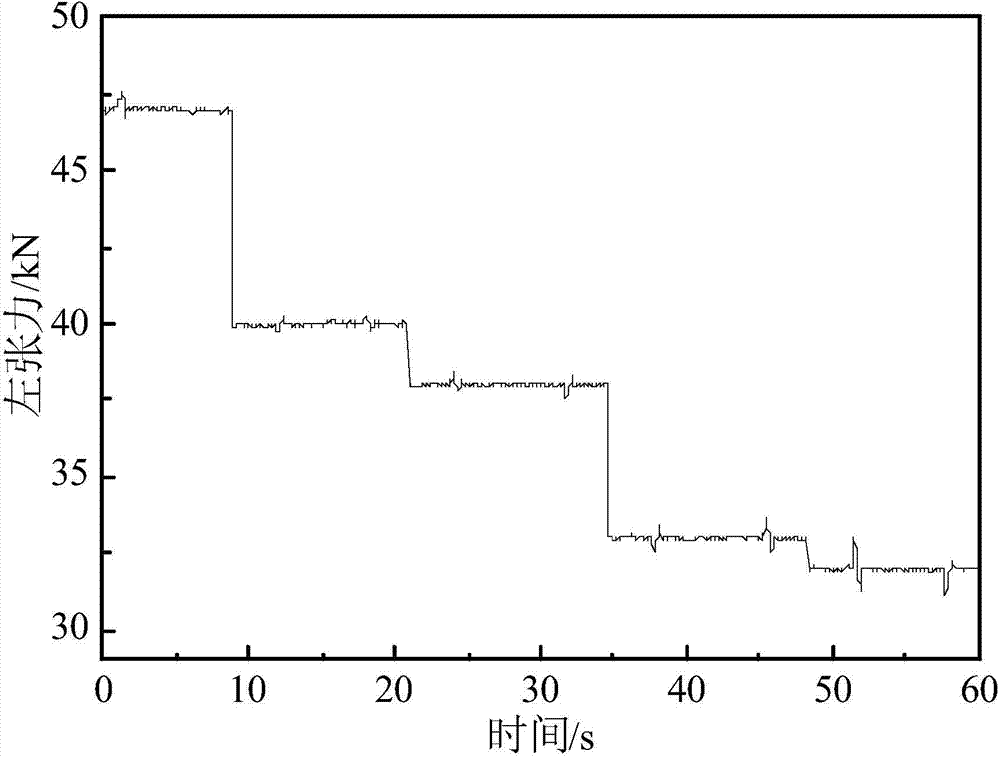

System and method for controlling hydraulic tension of straight-pull cold rolling experiment machine

ActiveCN104722587AImprove robustnessReduce overflowServomotor componentsServomotorsControl systemHydraulic cylinder

The invention discloses a system and method for controlling the hydraulic tension of a straight-pull cold rolling experiment machine, and belongs to the technical field of cold rolling tension. The system comprises a left tension hydraulic cylinder, a right tension hydraulic cylinder, a hydraulic pump, a constant-backpressure control unit, a left tension control unit and a right tension control unit. Compared with the prior art, in the system for controlling the hydraulic tension, the overflow amount of a proportional overflow valve on the outlet side and the overflow amount of a proportional overflow valve on the inlet side can be greatly reduced, and therefore the tension control accuracy can be greatly improved; when the proportional overflow valves work, nonlinear areas and dead zones can be effectively avoided, the performance of the proportional overflow valves can be easily achieved, and the tension control accuracy can be improved; according to the tension control system, the forward slip rate and the backward slip rate do not need to be predicted, the high-accuracy tension control is achieved by presetting the control amount of servo valves in cooperation with pressure control of the proportional overflow valves, and finally the robustness of the tension control system is improved.

Owner:NORTHEASTERN UNIV

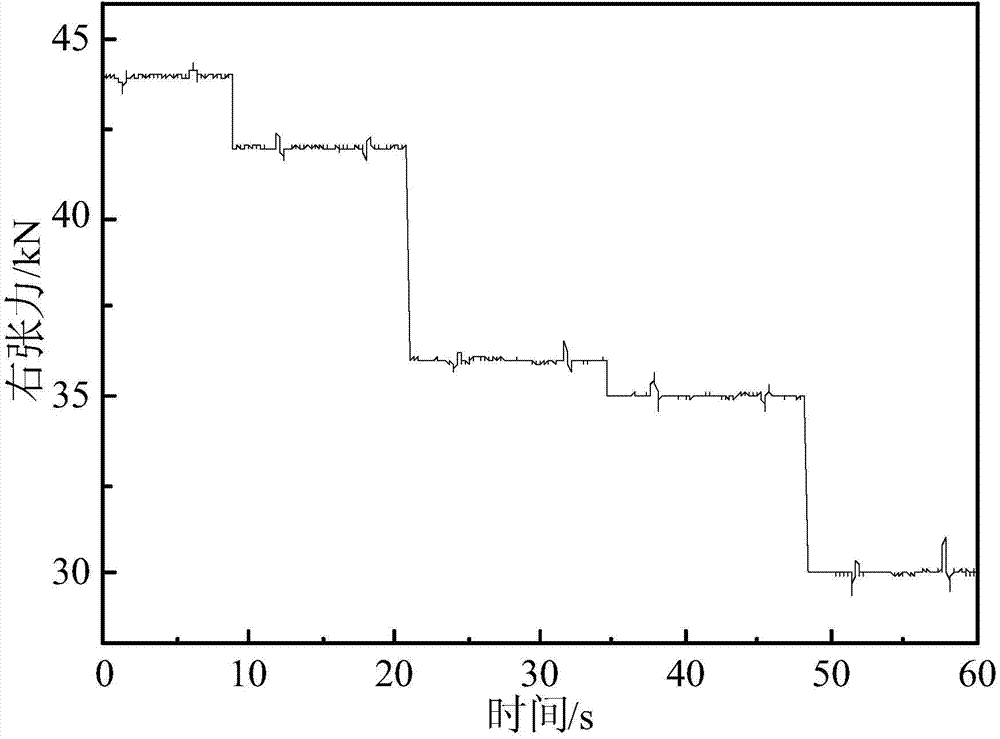

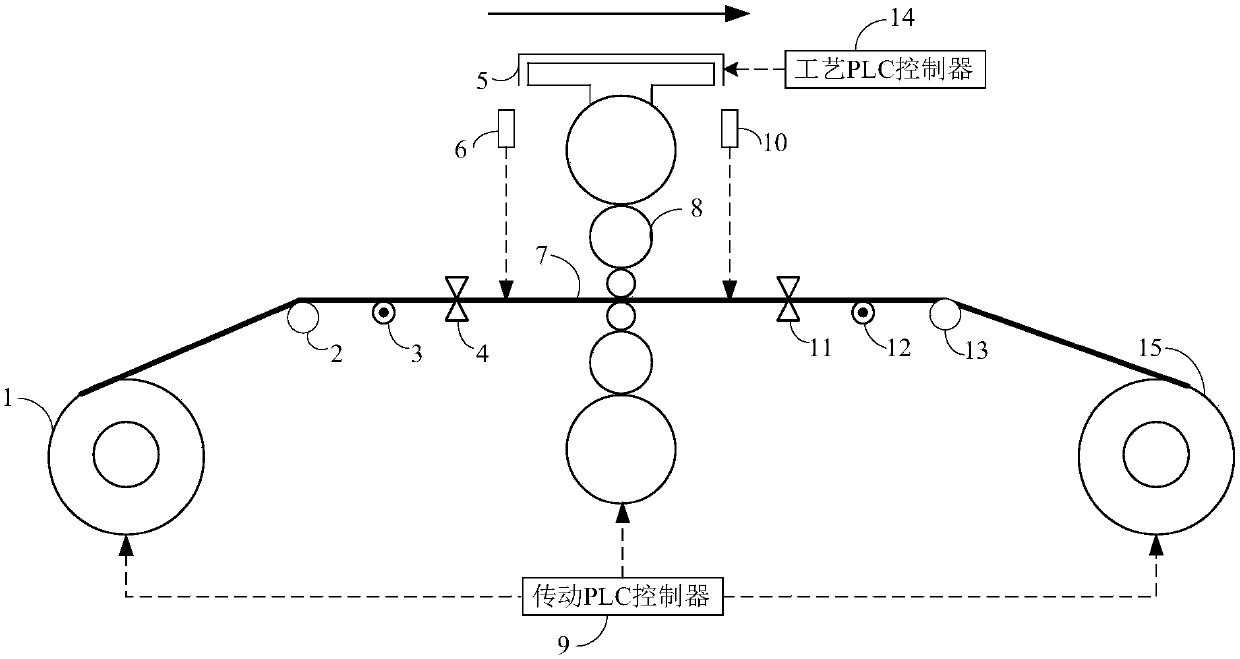

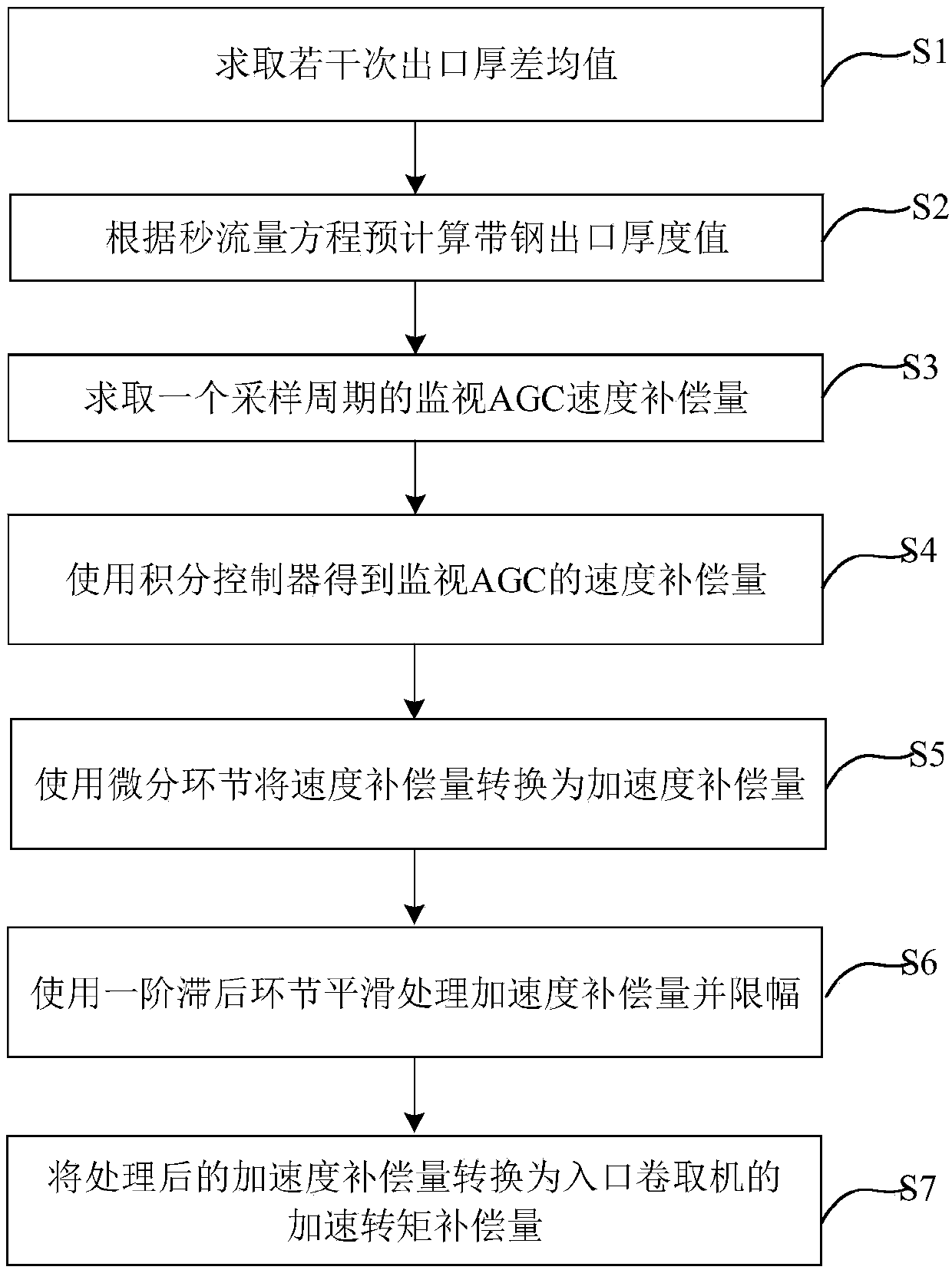

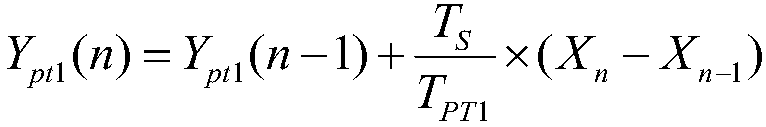

Inlet tension feed forward compensation method and system adopting monitoring automatic gauge control (AGC)

ActiveCN107913911AReduce strong couplingHigh control precisionTension/compression control deviceMetal rolling arrangementsAutomatic train controlAutomatic control

The invention provides an inlet tension feed forward compensation method adopting monitoring automatic gauge control (AGC). The strip steel outlet gauge differences are sampled continuously during rolling, and the average value of the strip steel outlet gauge differences sampled at the current moment and the moment of the former N<2>-1 time is worked out. The outlet gauge different average value is smoothened by using a first-order lag link. The monitoring AGC speed compensation amount in a sampling cycle is worked out. The monitoring AGC speed compensation amount is obtained by using an integral controller. The speed compensation amount is converted into an acceleration compensation amount by using a differential link. The acceleration compensation amount is smoothened by using the first-order lag link and subjected to amplitude limiting to be converted into the acceleration torque compensation amount of an inlet recoiling machine, the torque compensation amount is provided to a transmission control unit of the inlet recoiling machine, the torque of the inlet recoiling machine is controlled by the transmission control unit, and then the inlet tension can be subjected to feed forward compensation during monitoring AGC enabling. According to the inlet tension feed forward compensation method and system adopting monitoring AGC, the strong coupling relationship between monitoringAGC and inlet tension control is weakened, the accuracy of overall AGC and tension control is improved, and the yield is improved.

Owner:WISDRI ENG & RES INC LTD

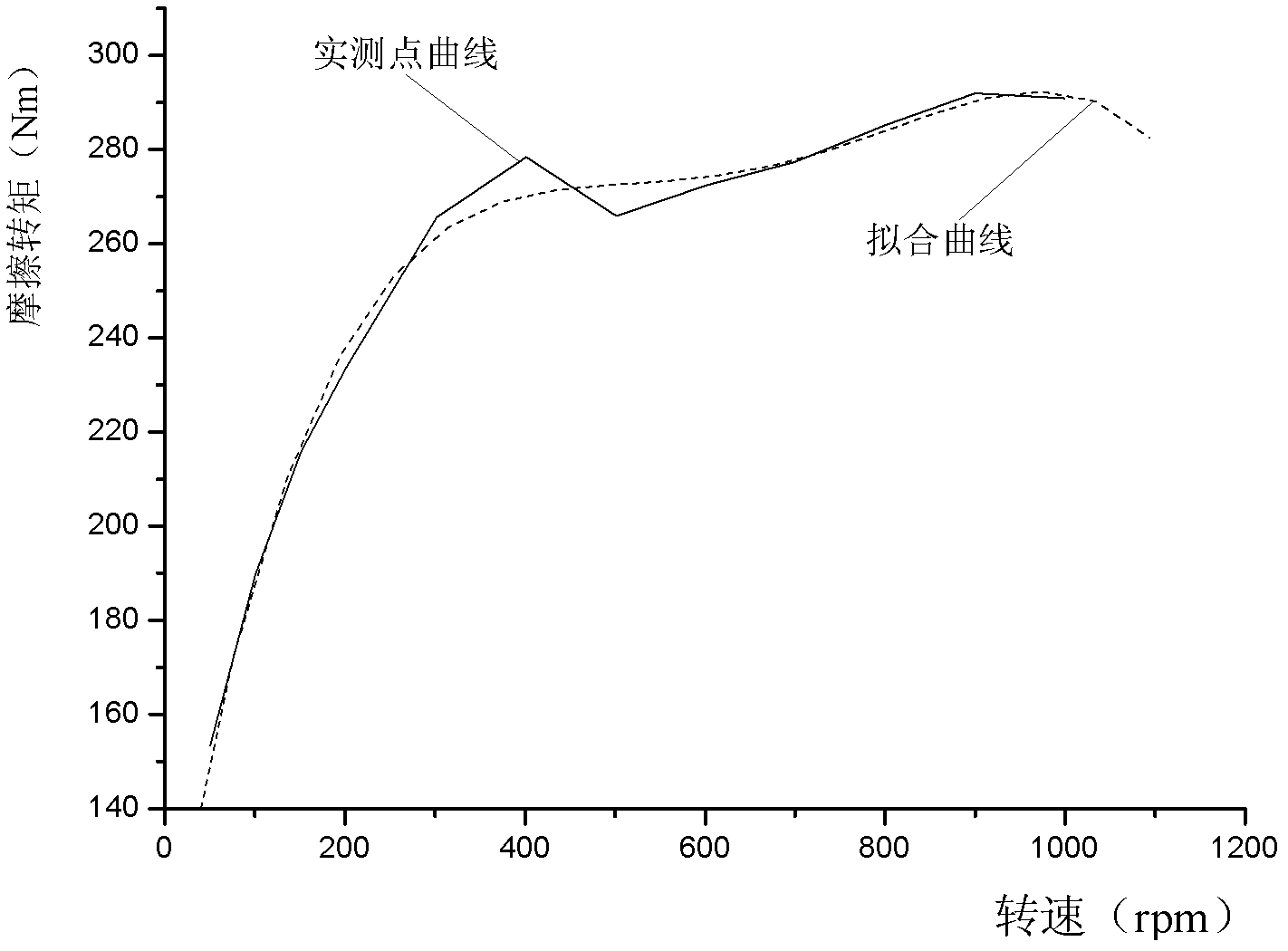

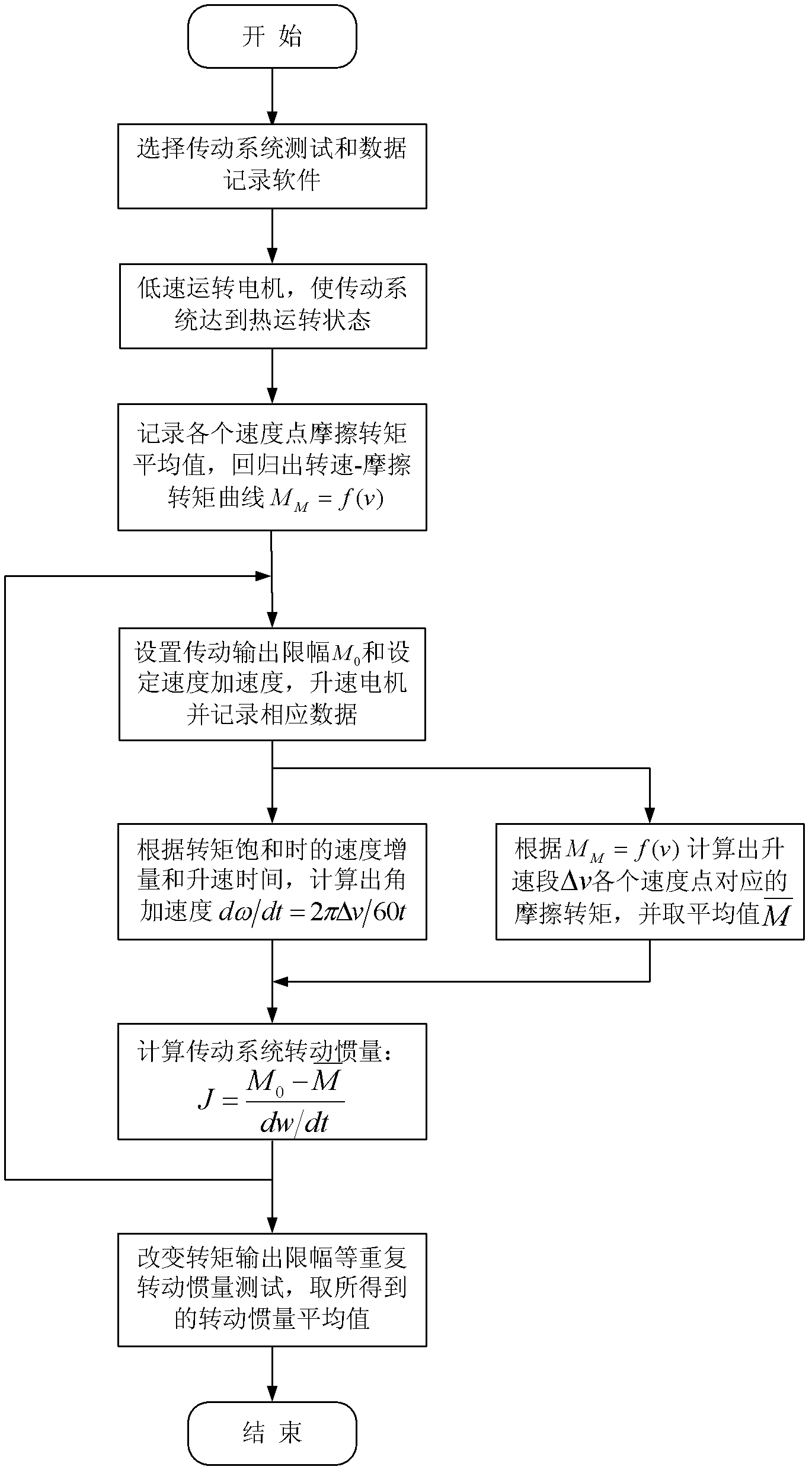

Method for measuring rotational inertia of transmission system

InactiveCN102500629AHigh precision of tension controlImprove stabilityMeasuring devicesMetal rolling arrangementsAutomatic controlFriction torque

The invention relates to a method for measuring the rotational inertia of a transmission system and belongs to the technical field of automatic control in the rolling process. A transmission device controls a motor to start; the motor drives a reeling machine to work; the motor is operated at a low speed, so that transmission mechanical equipment is in a hot operation state; the transmission mechanical equipment comprises the motor, a speed reducer and the reeling machine; friction torque of the transmission mechanical equipment is calculated; a rotating speed-friction torque curve is drawn; an output torque limit amplitude M0 is set and the rotational inertia of the transmission mechanical equipment is measured; calculation is performed respectively to obtain multiple groups of rotational inertia; and singular points are removed and the average value of the residual groups serves as the rotational inertias of the transmission mechanical equipment. The method can be implemented conveniently under many transmission measurement environments; cost investment is not required; after the rotational inertias of the transmission mechanical equipment are obtained accurately, tension control precision and stability of the rolling process can be improved greatly; and the method can be widely applied to plate strip foil rolling mills.

Owner:NORTHEASTERN UNIV

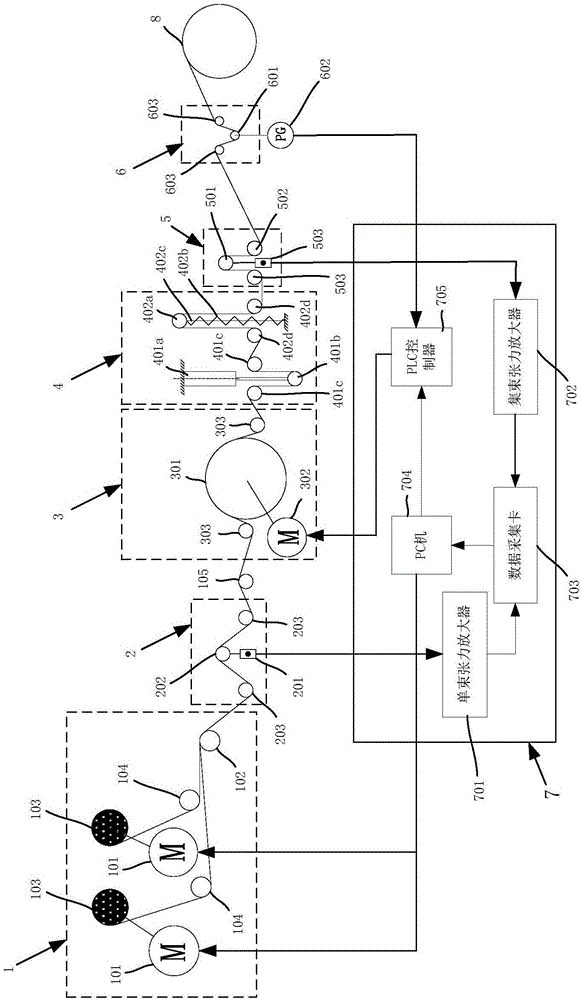

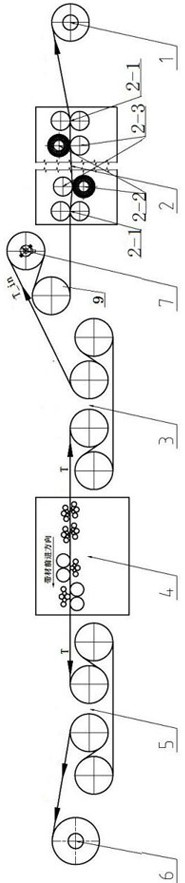

Modularized control system of carbon fiber winding tension

ActiveCN106217838ATension signal real-time monitoringHigh precision of tension controlFiber bundleCarbon fibers

The invention discloses a modularized control system of carbon fiber winding tension. An unwinding module has the unwinding function; a single fiber bundle tension detection module, an active speed adjusting module, a buffering module, a fiber bundle tension detection module and a speed measuring module are sequentially arranged between the unwinding module and a core mold; a console receives tension signals of the single fiber bundle tension detection module and the fiber bundle tension detection module and speed signals detected by the speed measuring module and controls the active speed adjusting module and the unwinding module after the signals are processed, and therefore the single fiber bundle tension and the fiber bundle tension can be maintained within the preset error range; and the buffering module is used for reducing fluctuation of the fiber tension in the fiber winding process. The modularized control system has the advantages that the tension control accuracy is high, the single fiber bundle tension and the fiber bundle tension can monitored and controlled simultaneously, the response speed is high, and operation is convenient.

Owner:BEIHANG UNIV

Tension closed loop control method with buffer and system

ActiveCN108572671AHigh precision of tension controlImprove stabilityControllers with particular characteristicsMechanical pressure/force controlLoop controlControl system

The invention relates to a tension closed loop control method with buffer and system, which belong to the technical field of metallurgical automation. The outlet of a galvanizing unit inlet loop is sequentially provided with a tension roll group, a tension stabilizer and a stokehole tension measurement roll. The tension value of a strip steel is detected in real time through a stokehole tension sensor, together with the tension roll group and the tension stabilizer, a two-closed loop tension adjustment control system is formed, the damping characteristics of the tension stabilizer are used toabsorb and buffer instantaneous disturbance of stokehole tension, the stable closed loop adjustment characteristics of the tension roll group are used to together stabilize and adjust strip steel tension fluctuation before an annealing furnace, the stokehole tension control precision and the stability are thus improved, and influences of impacts in dynamic processes of tension fluctuation in the case of charging and discharging of the inlet loop and other factors can be solved.

Owner:HUANGSHI SUNNY SCI & TECH CO LTD

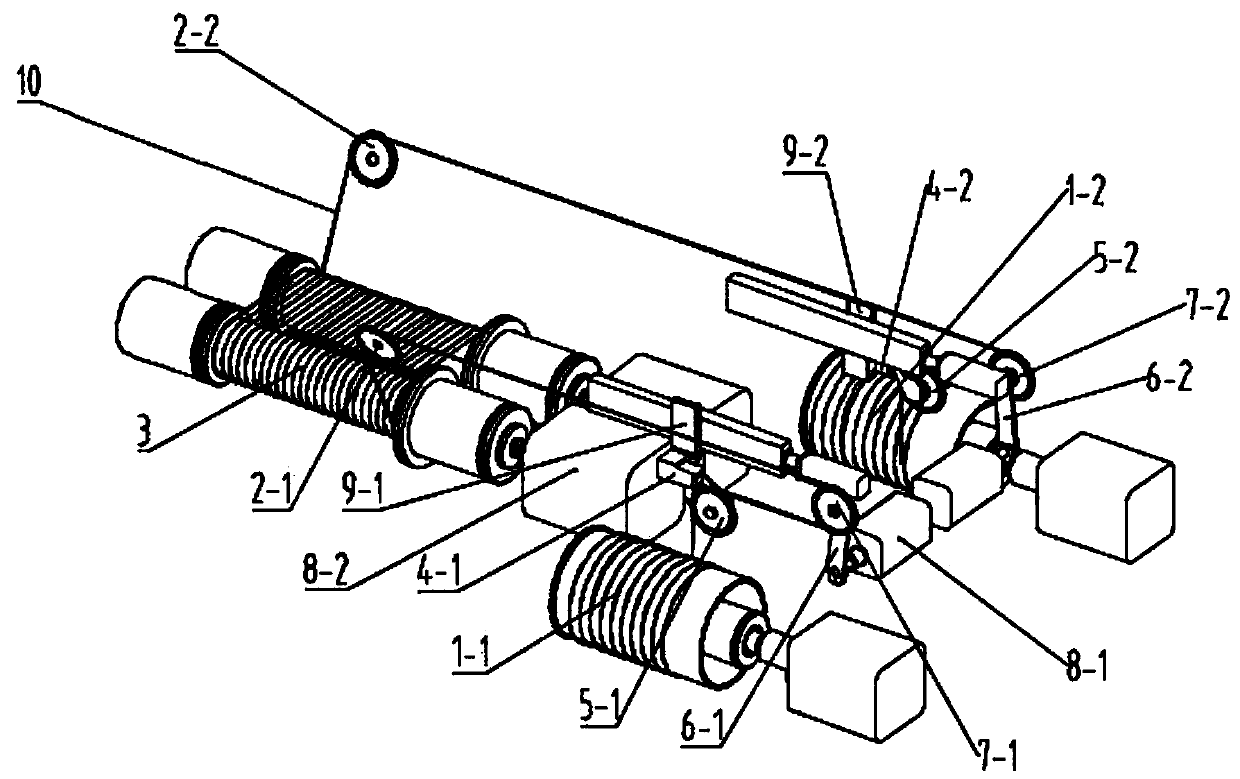

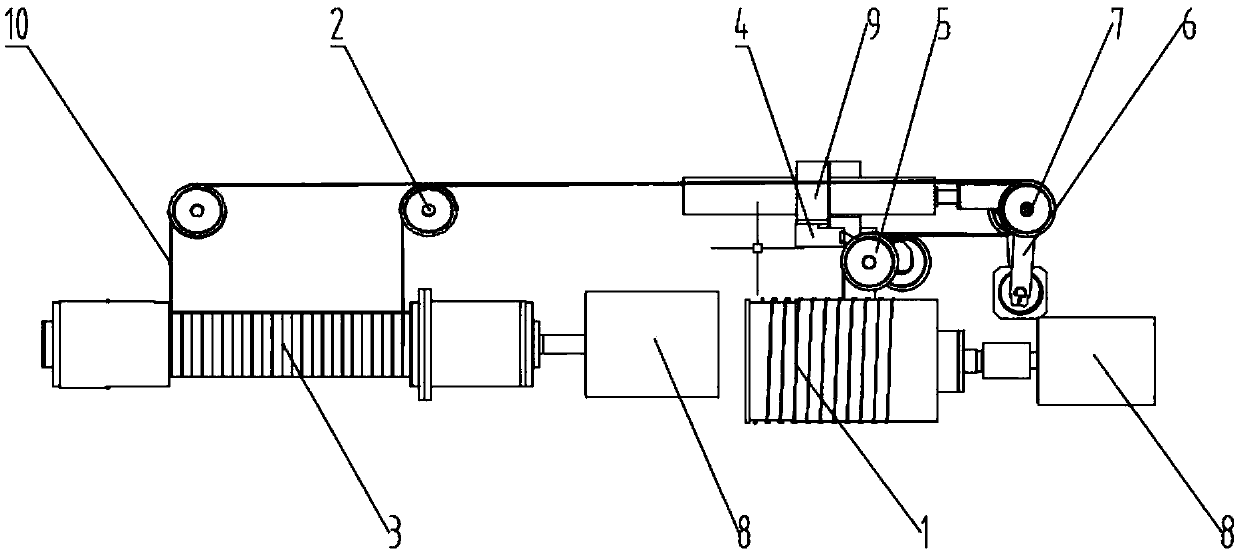

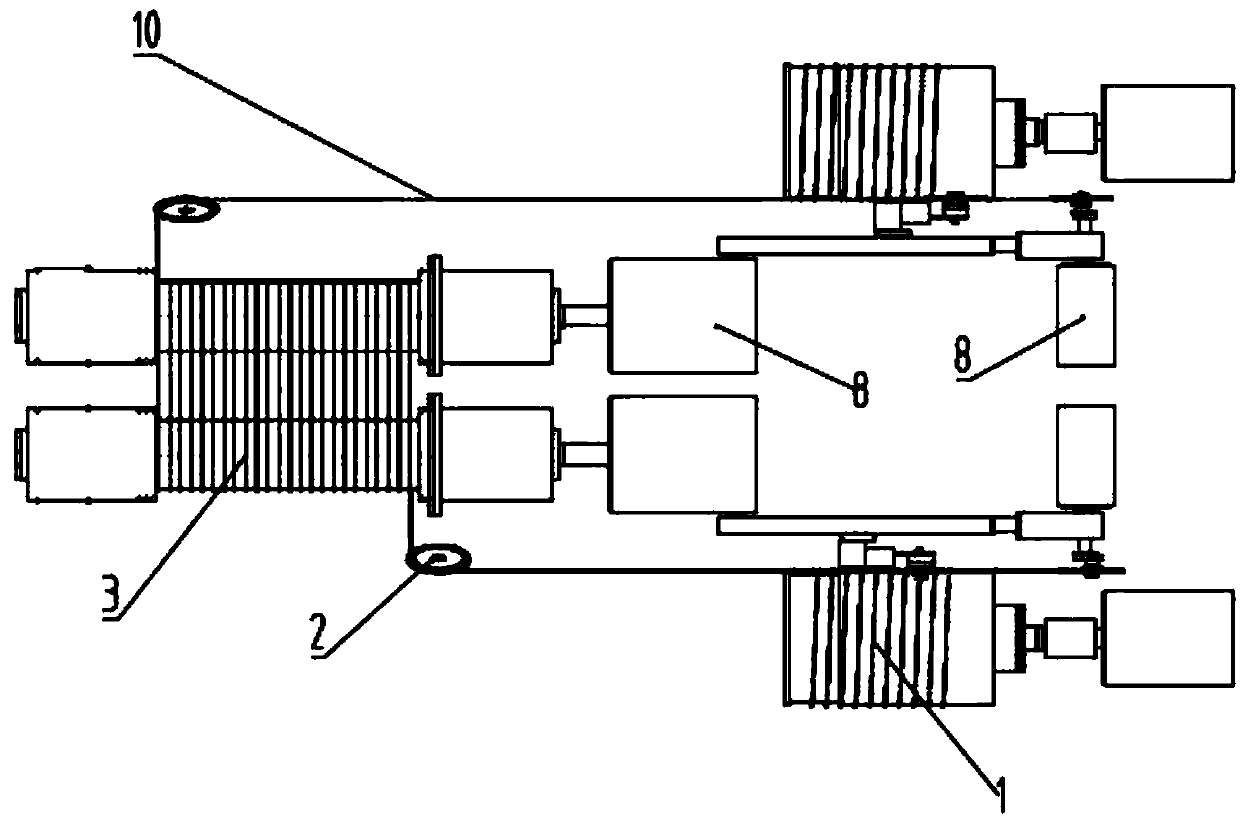

Tension control system for solar cell silicon wafer cutting

ActiveCN109664423AChange the tensionSimple structureFinal product manufactureWorking accessoriesControl systemSolar cell

The invention relates to a tension control system device for solar cell silicon wafer cutting. The tension control system device comprises a wire turn, a fixed wheel, a spindle, a tension sensor, a lead guide wheel, a swing rod, a floating wheel, a motor and a sliding assembly; the fixed wheel is arranged on the upper portion of the spindle; the spindle is provided with a spiral groove and is wound with a diamond cutting line; the motor is mounted on the rear portion of the spindle; the tension sensor and the lead guide wheel are fixed on the sliding assembly and can slide horizontally along with the sliding assembly; the sliding assembly is arranged on the upper portion of the wire turn; the swing rod is arranged on the right side of the wire turn; one end of the swing rod is provided with the floating wheel; and the swing rod is connected with the motor on the lower portion. The tension control effect is good, the production efficiency is high, the product quality is good, and the precision is high.

Owner:NANJING INST OF TECH

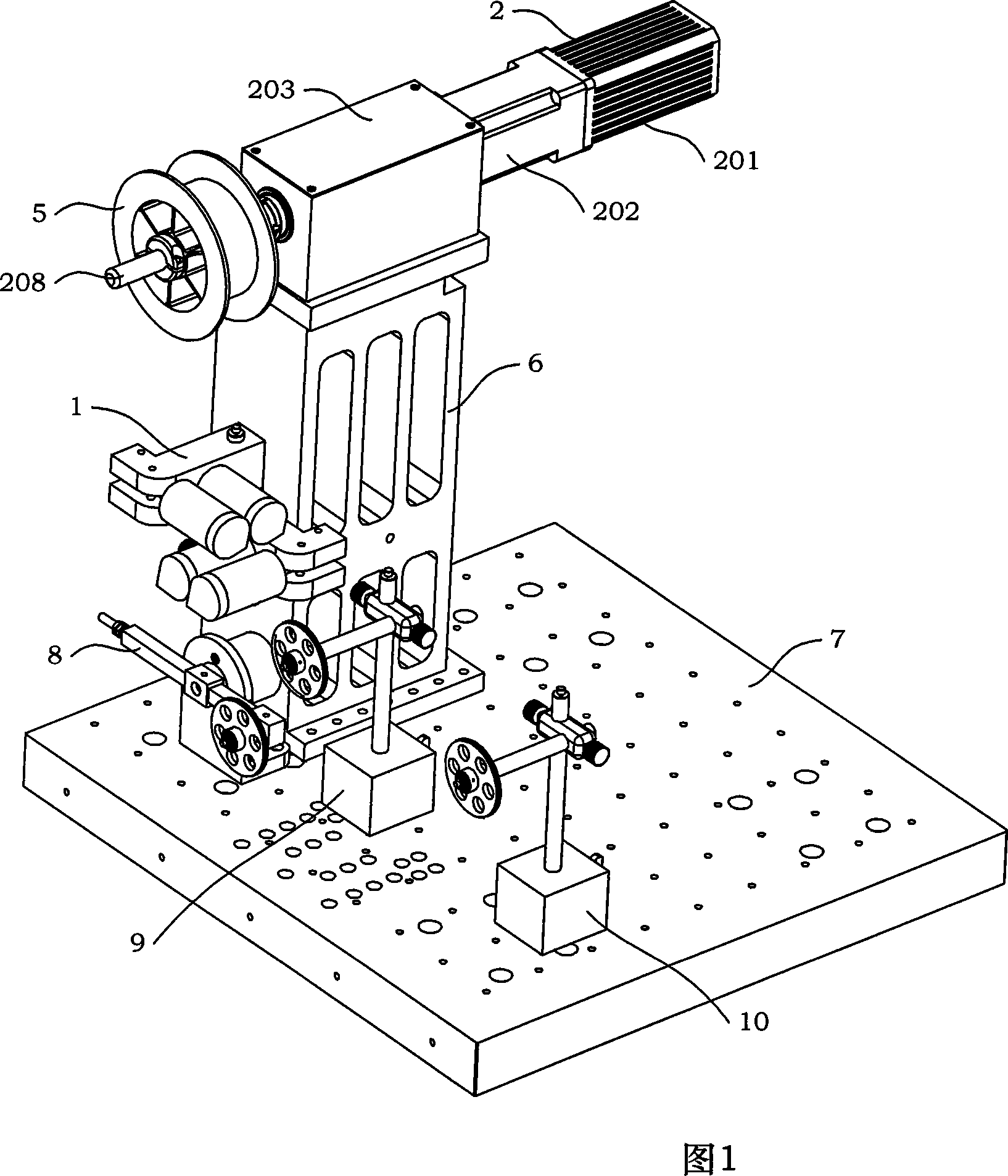

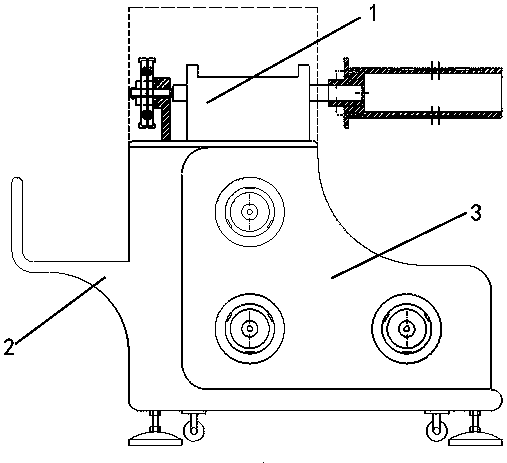

Fiber supply device of automatic optical fiber winding machine

InactiveCN101059583APrecise rotationStable controlFilament handlingSagnac effect gyrometersWinding machineFiber

The invention discloses a fiber feeder used in automatic fiber coiler, composed of a fiber collector, a driver, a transmit box, a fiber discharge wheel, a support base, and a sliding table, wherein the support base is mounted on the sliding table, while the upper end is mounted with the transmit box, the driver is on the transmit box, while a motor and a speed reducer are mounted at the outer back of the transmit box, the accurate shaft of the driver is suspended at the outer front of the transmit box, which is mounted with the fiber discharge wheel, the fiber collector is at one side of the support base, vertically with the fiber discharge wheel. The invention can feed fiber in various automatic fiber coilers, and in the machine as fiber repeat coiler and fiber selector. The invention uses the accurate suspended shaft to vertically support the fiber discharge wheel to discharge fiber, and arranges the fiber collector under the wheel to collect the fiber output by the wheel into a fixed point to be moved out, thereby confirming the feeding direction consistence of the tension wheel and confirming the tension consistence in the fiber coiling process.

Owner:BEIHANG UNIV

Straight-pull cold-rolling mill tension control method based on speed feedforward

ActiveCN102527740BExact speed matchHigh precision of tension controlTension/compression control deviceHydraulic cylinderControl system

The invention discloses a straight-pull cold-rolling mill tension control method based on speed feedforward and belongs to the technical field of cold-rolling tension control. The straight-pull cold-rolling mill tension control method can be used for realizing the purpose of precisely matching the speeds of a tension hydraulic cylinder and a rolling mill and is high in tension control precision. The straight-pull cold-rolling mill tension control method comprises the following steps: 1. determining a linear velocity set value of a rolled piece on the input of a rolling machine and a linear velocity set value on an output; 2. determining the servo valve control amount of the speed feedforward control of an inlet tension hydraulic cylinder and an outlet tension hydraulic cylinder; 3. determining the servo valve control amount of the tension feedback control of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder; 4. determining the final servo valve control amounts of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder; and 5. sending the determined final servo valve control amounts of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder into a control system, and regulating the servo valves of the inlet tension hydraulic cylinder and the outlet tension hydraulic cylinder by virtue of the control system.

Owner:NORTHEASTERN UNIV LIAONING

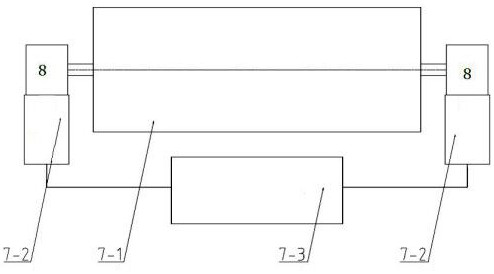

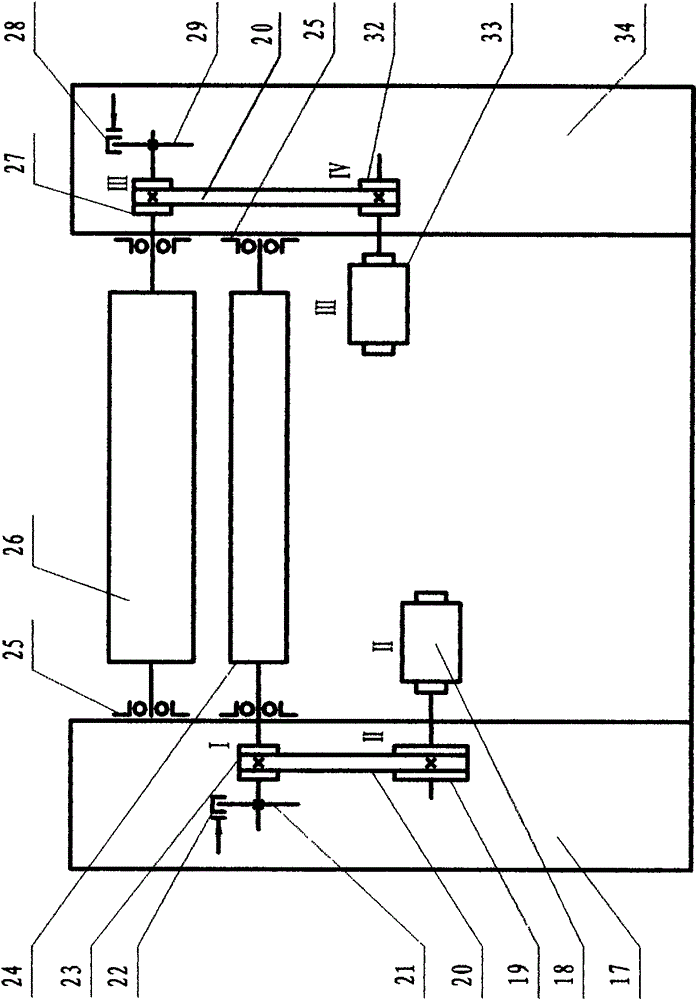

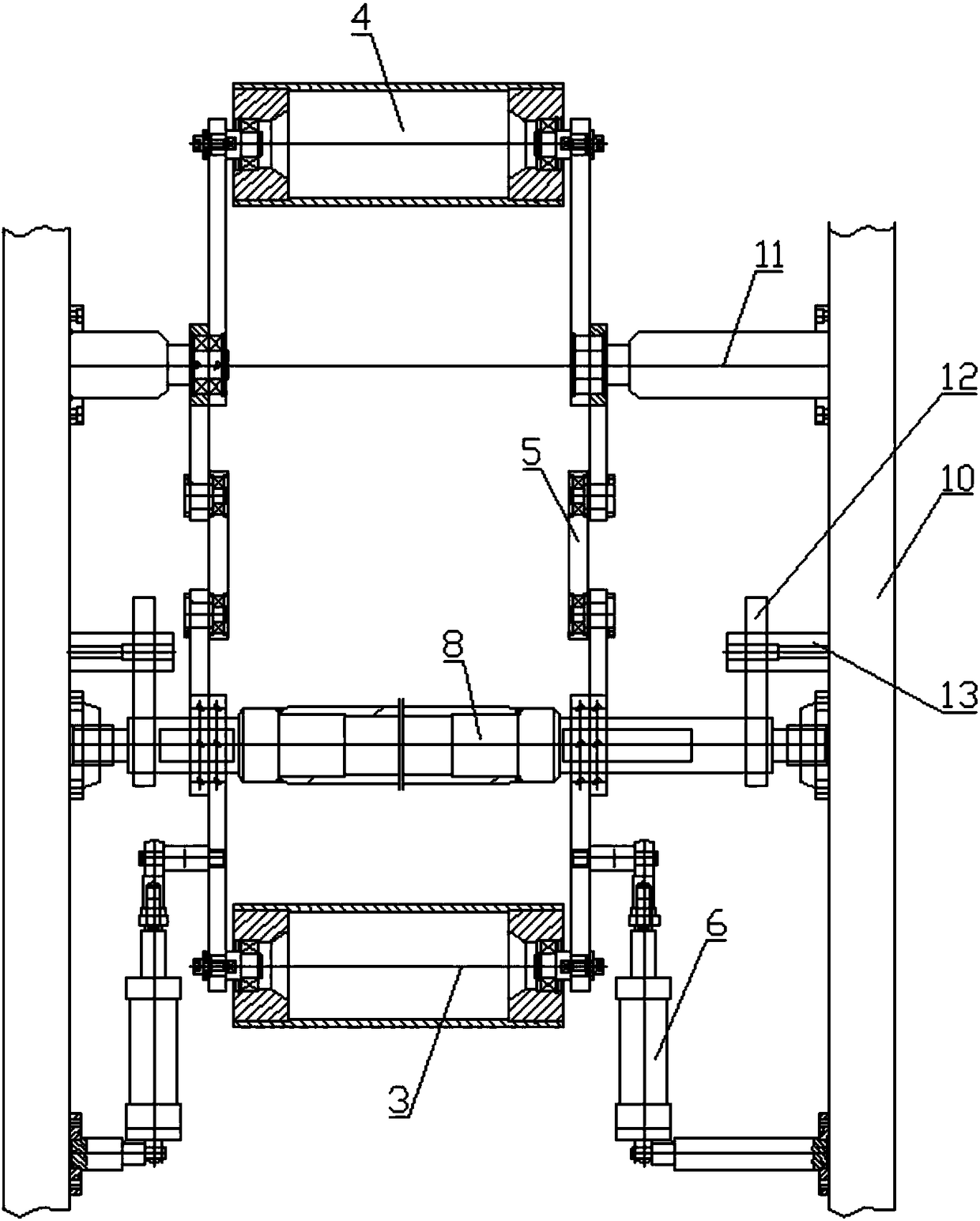

Material storage device for strip-shaped material

InactiveCN106115329AEasy to arrange and installQuick responseWebs handlingEngineeringMaterial storage

The invention relates to the technical field of mechanical equipment, in particular to a material storage device for a strip-shaped material. The material storage device comprises a frame. The frame is provided with a material storage wheel set I and a material storage wheel set II in a sliding manner. The strip-shaped material is connected to the material storage wheel set I and the material storage wheel set II in a winding manner. The frame is further provided with a driving device. The driving device is used for driving the material storage wheel set I and the material storage wheel set II to get away from each other or get close to each other through a transmission assembly. When the material storage wheel set I and the material storage wheel set I get away from each other, the strip-shaped material meeting the requirement is reserved between the material storage wheel set I and the material storage wheel set II, a material conveying device temporarily stops releasing the material during splicing, the material storage wheel set I and the material storage wheel set II get close to each other, and the strip-shaped material originally stored between the material storage wheel set I and the material storage wheel set II can be gradually released. The material storage device is integrated by itself, arrangement and installation are convenient, the installation angle can be set at will according to requirements, and in addition, the material storage device is not restrained by installation requirements of high-precision panels.

Owner:ANQING HENG CHANG MACHINERY

Tension measuring device, system and method for tension straightening of strip cleaning tension straightening unit

InactiveCN112129447AHigh precision of tension controlReduce tension fluctuationsApparatus for force/torque/work measurementControllers with particular characteristicsPhysicsEngineering

The invention belongs to the technical field of metal strip finishing, and particularly relates to a tension measuring device, system and method for tension straightening of a strip cleaning tension straightening unit. The tension measuring device comprises a tension measuring roller, tension measuring sensors, a tension transmitter and two shaft seats, wherein the two ends of the tension measuring roller are connected to the shaft seats arranged on the two sides correspondingly; the two tension measuring sensors are arranged and mounted on the two pairs of shaft seats correspondingly; the tension transmitter is in electric signal connection with the two tension measuring sensors; and the tension measuring device is arranged between a cleaning part and an inlet tension roller of the stripcleaning tension straightening unit, and the tension measuring system is formed. After the tension measuring device is used for measuring the inlet tension T_in of a tension straightening section actually, PI adjustment is applied, the torque of transmission equipment of the cleaning section is dynamically adjusted, inlet tension fluctuation of the tension straightening section is reduced to the maximum extent, and thus the tension control precision of the tension straightening section is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method of improving galvanizing unit vertical loop tension control precision

InactiveCN111378915AHigh precision of tension controlReduce investmentHot-dipping/immersion processesLoop controlRegulator

The invention discloses a method of improving galvanizing unit vertical loop tension control precision. The method comprises the steps that for vertical loop tension control, a measured value of a vertical loop outlet tensiometer is used as a feedback value, a set value is compared with the feedback value, a comparison difference value serves as an input value of a tension regulator, loop controlmotor torque is given through a PID algorithm, and closed-loop control over tension is realized. The invention aims to provide the method of improving the galvanizing unit vertical loop tension control precision, improve vertical loop tension control precision and make vertical loop tension control meet the production requirement of a continuous hot-dip galvanizing unit.

Owner:BAOTOU IRON & STEEL GRP

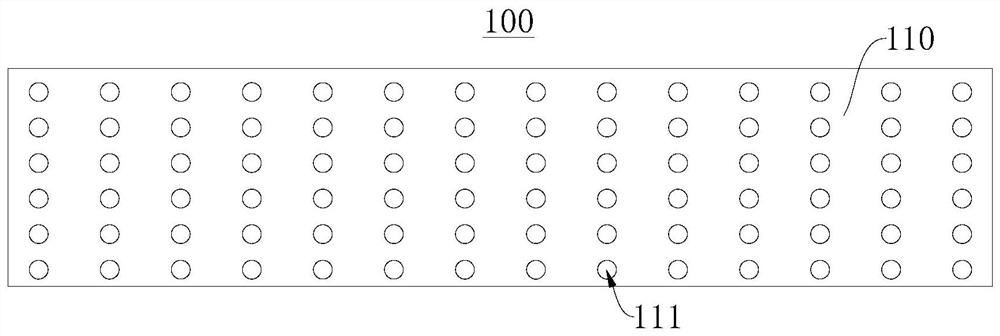

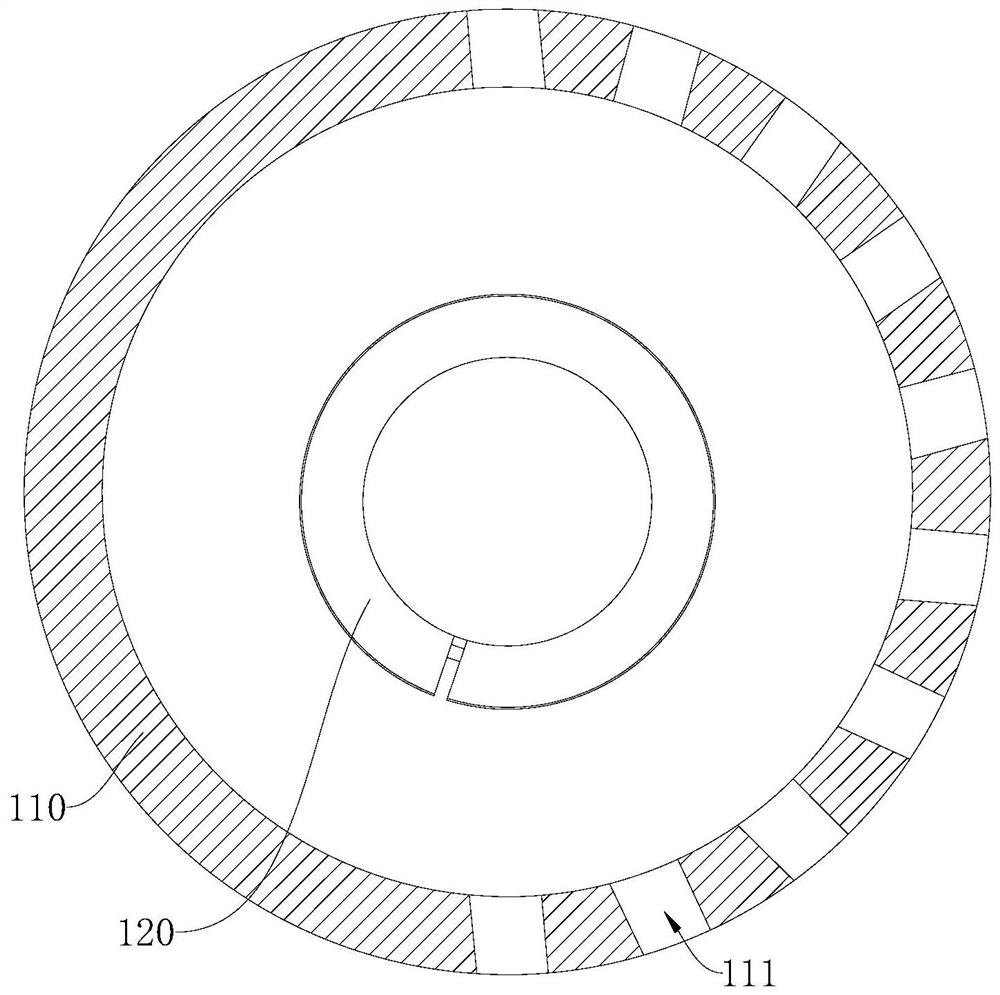

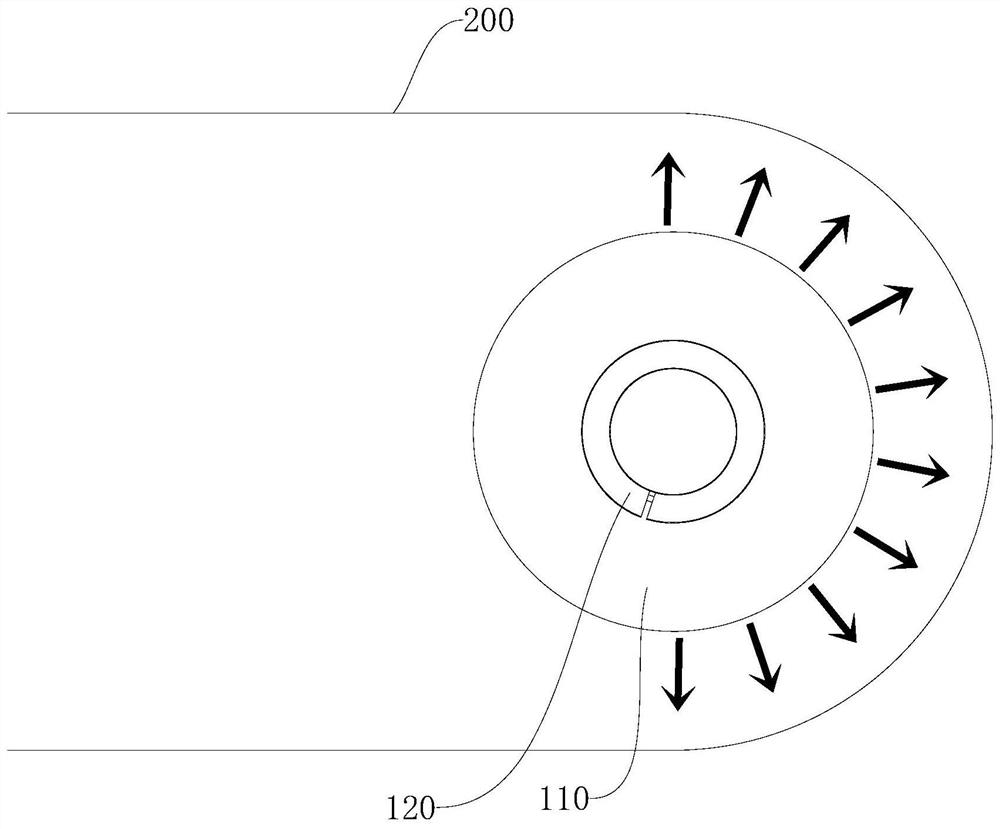

Airflow suspension device and lithium battery production equipment

PendingCN113335979ATension effectSimplify the tension control processFinal product manufactureElectrolyte accumulators manufactureThermodynamicsMechanical engineering

The invention discloses an airflow suspension device and lithium battery production equipment, and relates to the technical field of lithium battery production. The airflow suspension device comprises an outer shell and a fan. The fan is fixedly installed in the outer shell, a through hole is formed in the outer shell, and the fan is used for discharging air outwards through the through hole so that a strip can be suspended on the surface of the outer shell. Compared with the prior art, according to the airflow suspension device, the fan installed in the outer shell and the through hole formed in the outer shell are adopted, so that the influence on the tension of the strip can be avoided, a tension control process is simplified, the tension control precision is improved, the tension control delay is shortened, and the system response is accelerated.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

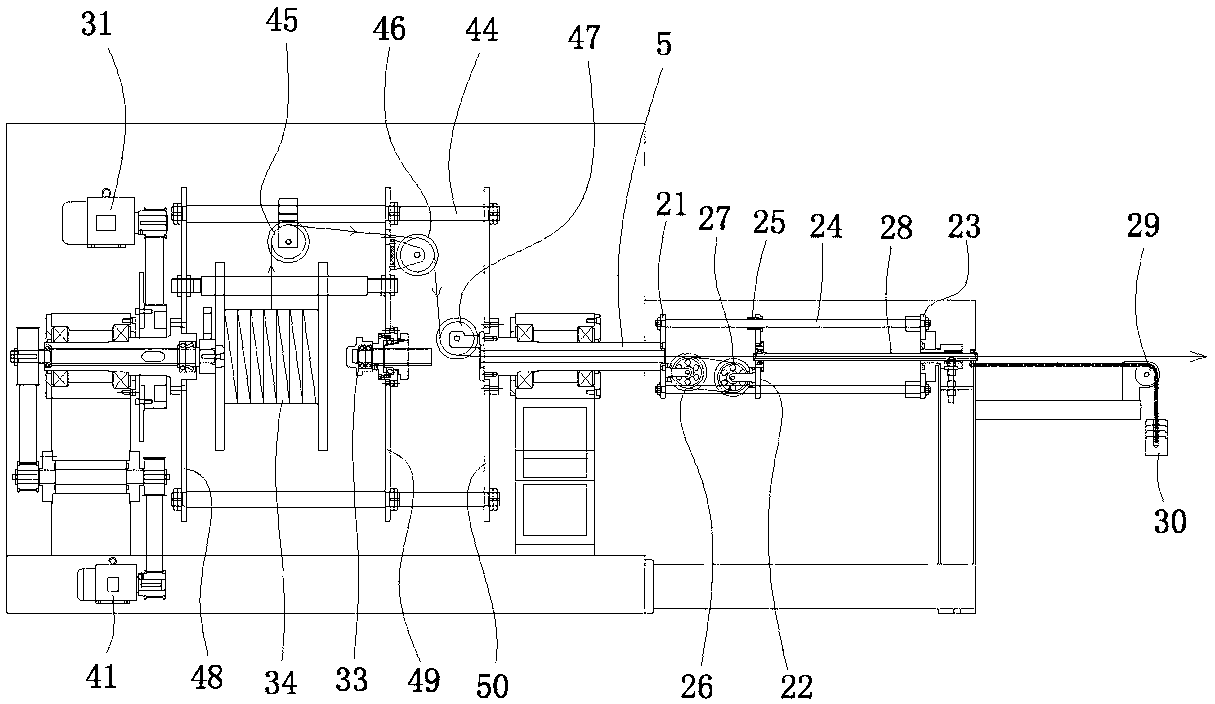

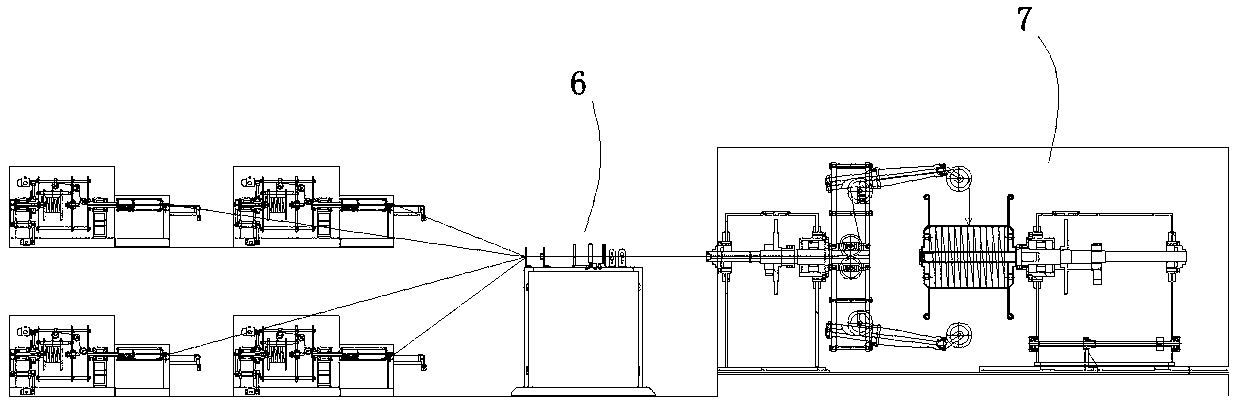

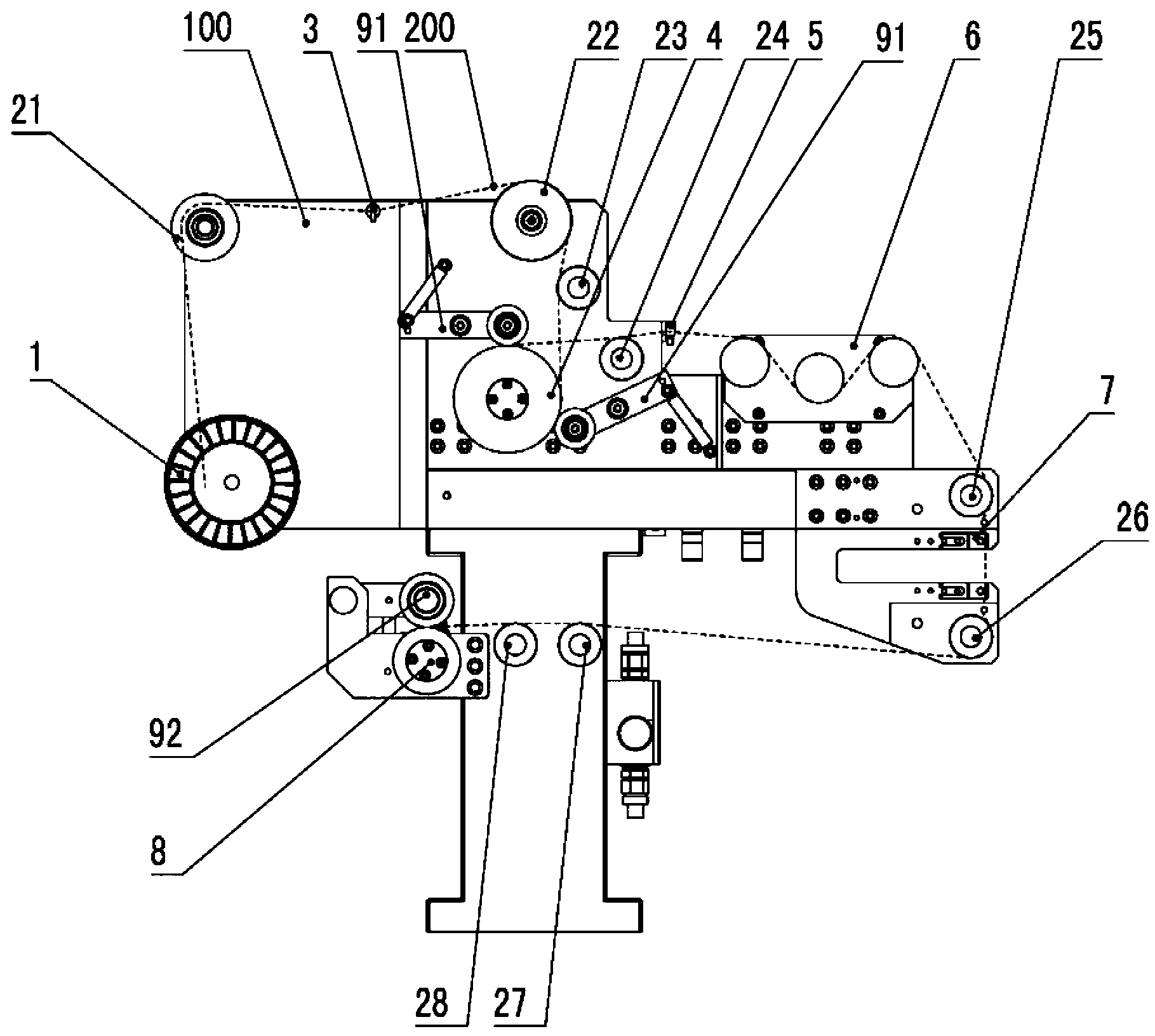

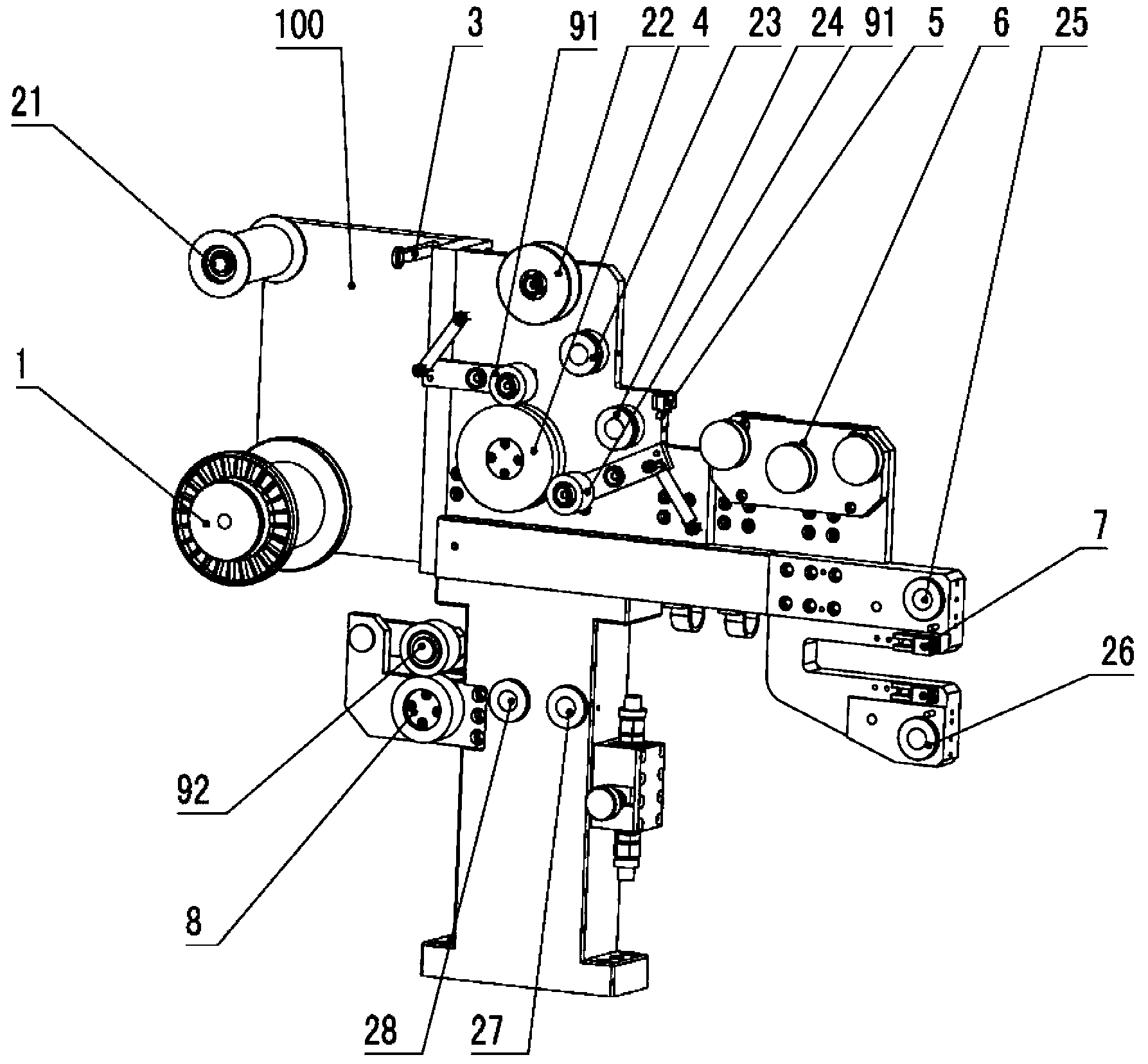

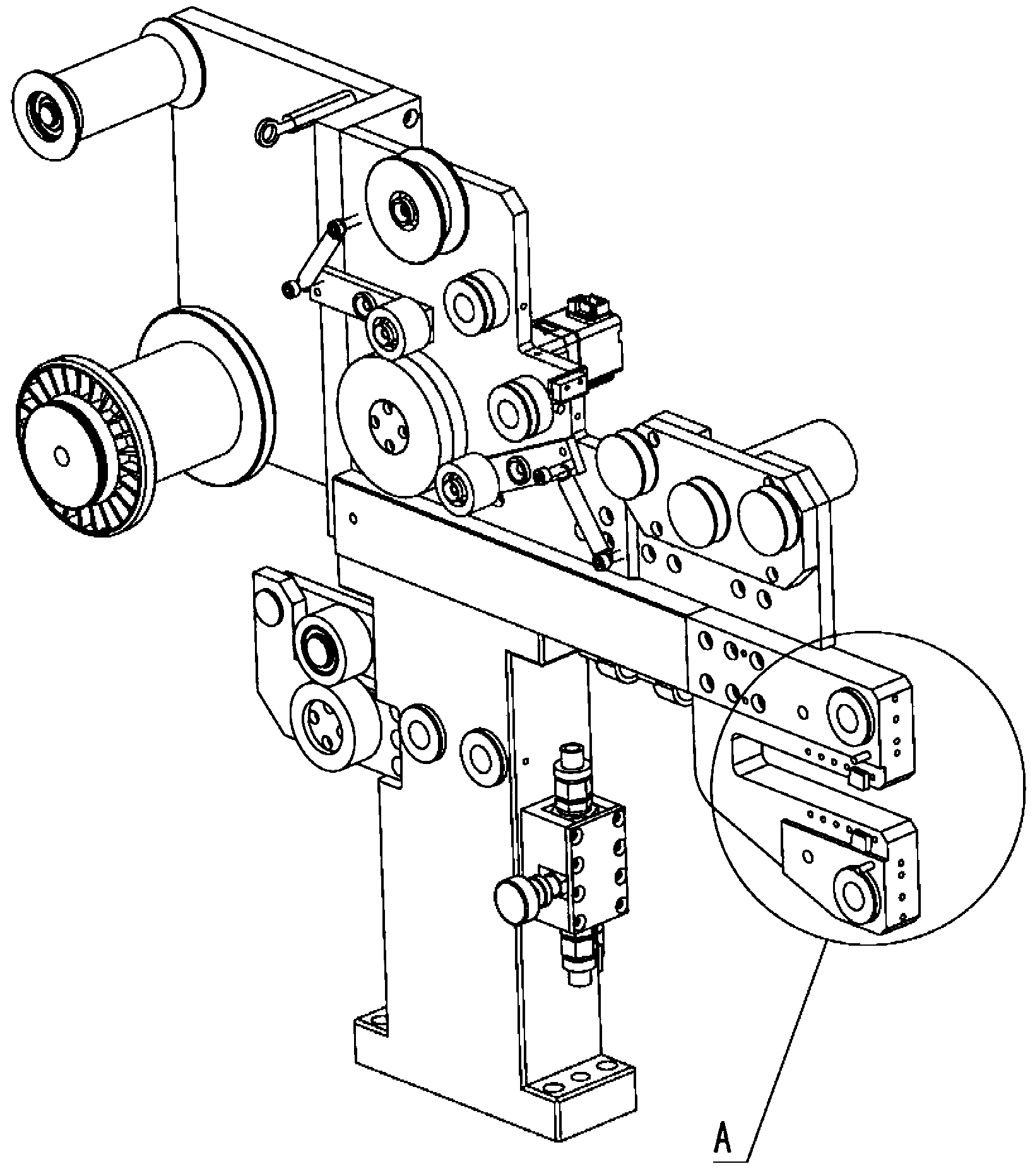

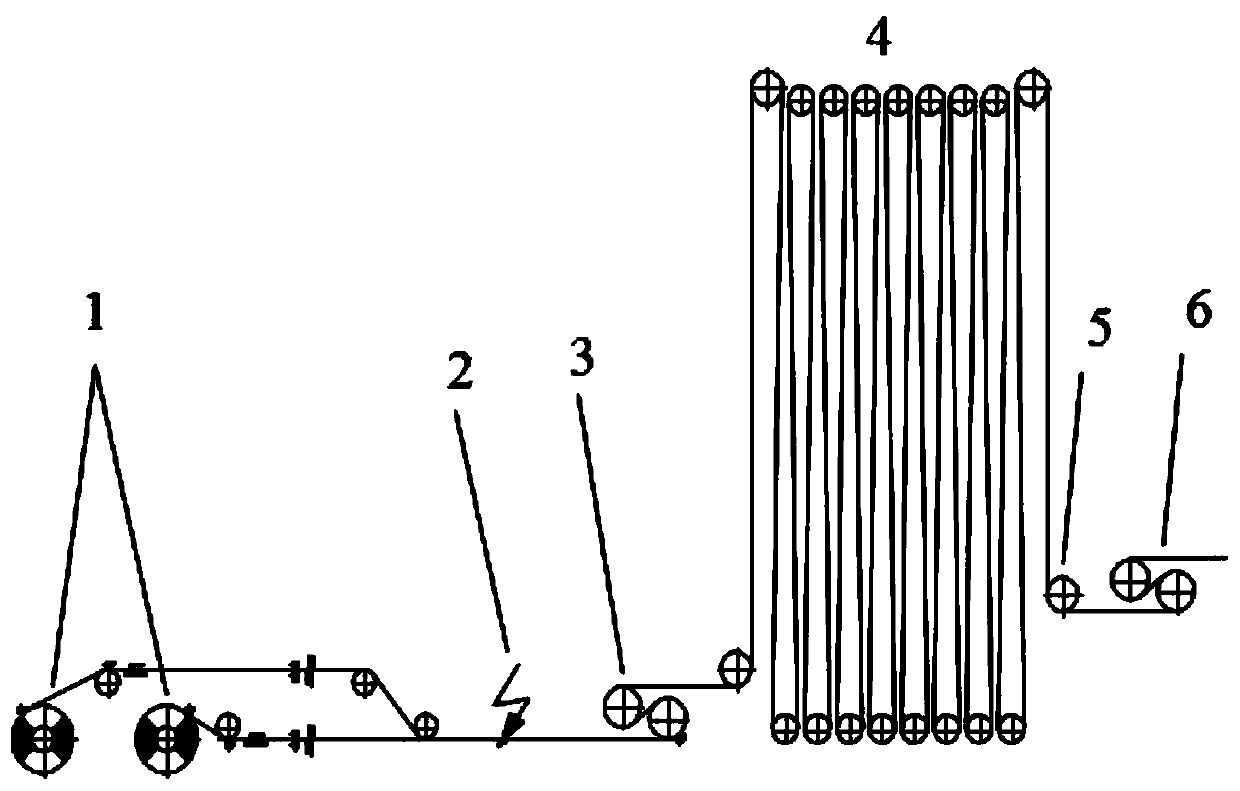

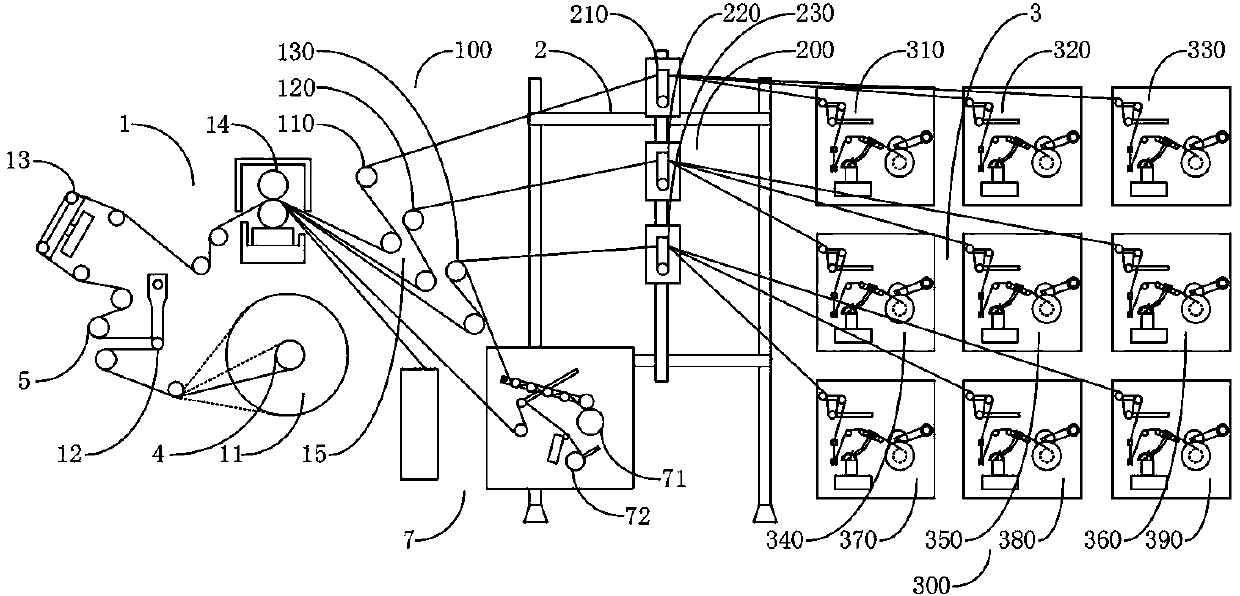

Slitting and winding apparatus and slitting and winding process for extremely-fine cable sheath film

ActiveCN107705922ARealize common operationIncrease productivityCable/conductor manufactureProcess engineeringWork unit

The invention discloses a slitting and winding apparatus and a slitting and winding process for an extremely-fine cable sheath film. The slitting and winding apparatus comprises a slitting unit, a guiding and shunting unit and a winding working set; by virtue of the guiding and shunting unit, the slitting unit and the winding working set are bridged; and the winding working set has winding and coiling functions. The slitting and winding apparatus comprises the slitting unit, the guiding and shunting unit and the winding working set; by virtue of the guiding and shunting unit, the slitting unitand the winding working set are bridged into an integrated body, so that joint operation of multiple groups is realized, and production efficiency and operational automation can be improved; any working unit can realize winding or coiling, and multiple groups of working units can perform different operations; section cutting for a reel of the extremely-fine cable sheath film is not needed, so that a section cutting process is omitted; the slitting and winding apparatus is high in tension control precision, capable of adapting the characteristic of the extremely-fine cable sheath film, and free of a band breaking phenomenon in the operation process; and the waste material is wound by the reel in the collection process, the wound waste material is small in size, and the reel is high in capacity, so that frequent waste material unloading is not needed.

Owner:苏州东利鸿电子科技有限公司

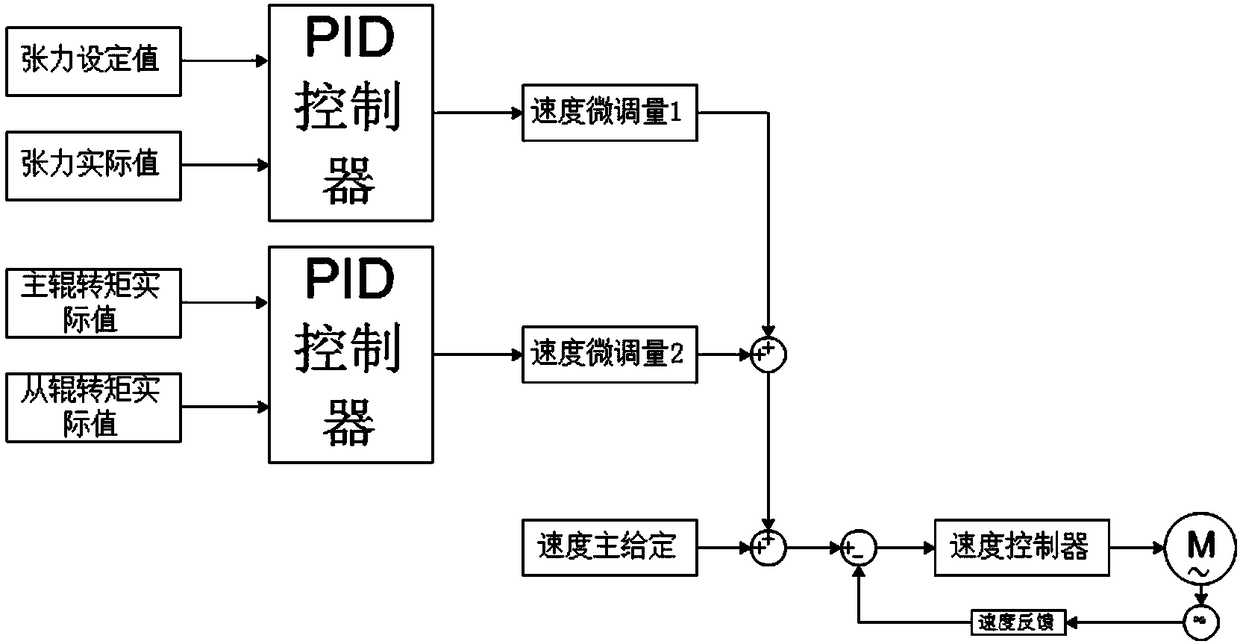

Warp Knitting Filament Warping Machine Tension Balance Device

ActiveCN102121152BThe speed is differentHigh precision of tension controlOther manufacturing equipments/toolsTextiles and paperEngineeringFriction force

The invention relates to a tension balancing device of a warp knitting filament warping machine. The device is characterized in that: two motors are arranged in front of a straight reed (16) and in back of a hairiness detector (6) to drive a tension balancing device (5) for an upper tension roll (26) and a lower tension roll (24) respectively so as to control the tension of sheet yarns (7) wound into a pan head (13). The tension balancing device is arranged in front of the straight reed and in back of the hairiness detector, the upper and lower tension rolls in the device are driven by the motors respectively, the motors for driving the upper and lower tension rolls to rotate can realize different rotating speeds and different surface yarn speeds under the control of a computer respectively, and meanwhile, warps are positively pulled out by using the friction force between the warps and the surfaces of the two tension rolls to form a stable controllable tension area, so the tension of the sheet yarns wound into the pan head is dynamically controlled in real time, constant-tension and high-speed beaming is realized, the tension control precision is high, and the controlled tension range is large; and the device is convenient for automatic and intelligent control and has simple and practical structure.

Owner:射阳县杰力纺织机械有限公司

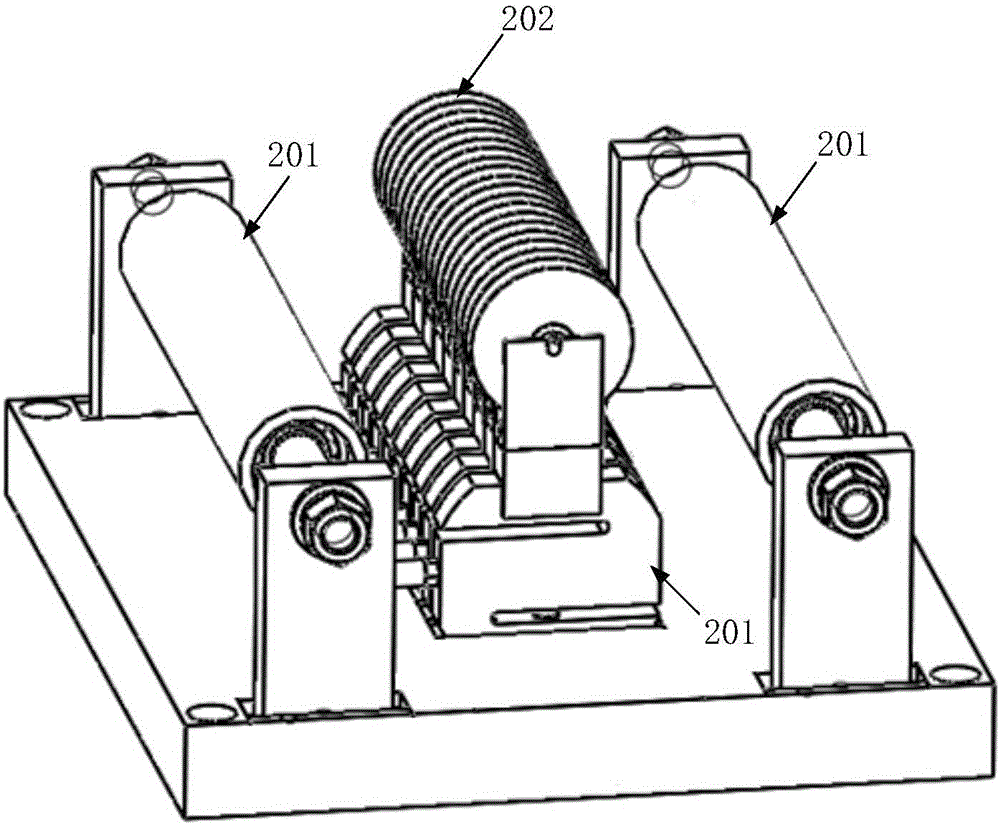

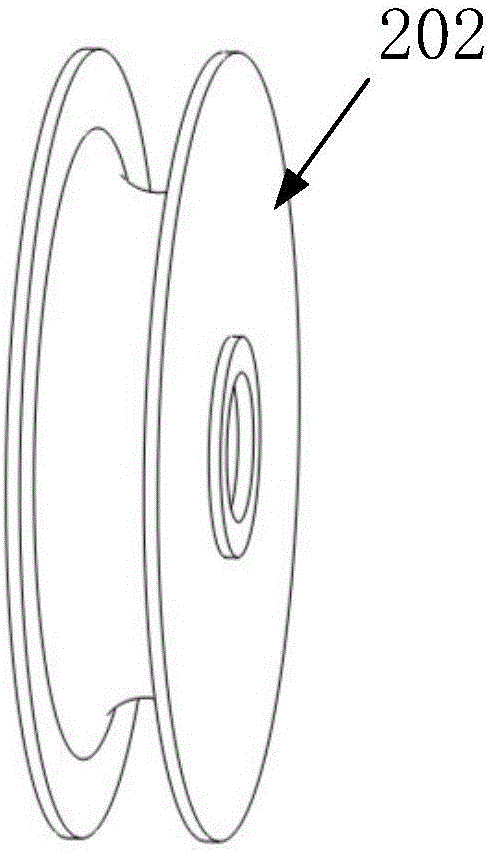

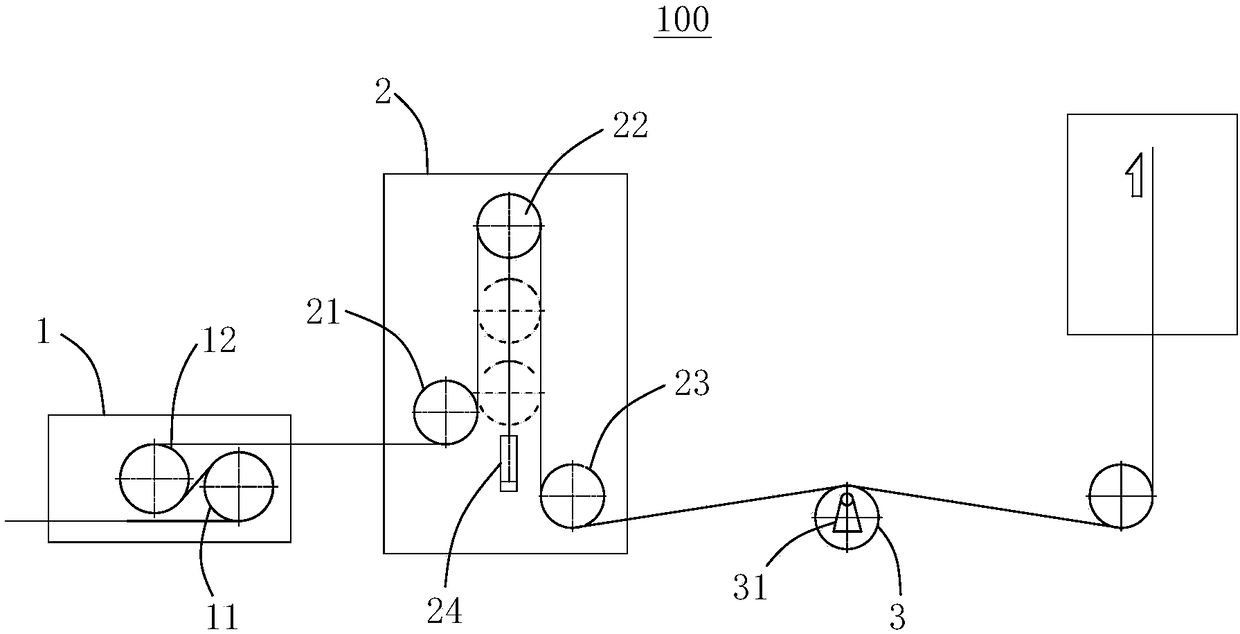

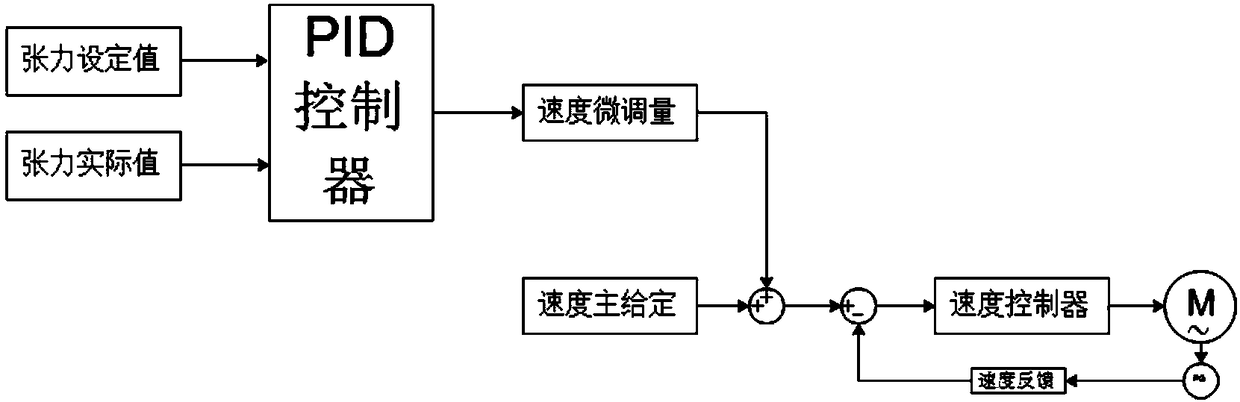

Splitting machine unwinding double-floating-roller mechanism and closed-loop control method thereof

ActiveCN108423470AGuaranteed synchronicityHigh precision of tension controlWebs handlingPotentiometerEngineering

The invention discloses a splitting machine unwinding double-floating-roller mechanism and a closed-loop control method thereof. The splitting machine unwinding double-floating-roller mechanism comprises a driving floating roller, a driven floating roller, a cylinder and a connecting rod. The driving floating roller is connected with a driving floating roller swing arm. The driving floating rollerswing arm swings round a first rotary shaft. The cylinder drives the driving floating roller swing arm to swing. The driven floating roller is connected with a driven floating roller swing arm. The driven floating roller swing arm swings round a second rotary shaft. The two ends of the connecting rod are hinged to the driving floating roller swing arm and the driven floating roller swing arm correspondingly. The cylinder is driven by a motor. The motor is connected with a controller. A linear potentiometer is fixedly installed on the cylinder. When tightness of materials changes, the cylinderstretches out or retracts, the linear potentiometer on the cylinder detects change of the position of the cylinder, a voltage change signal is fed back to the controller, the controller adjusts the rotation speed of the motor, and thus the cylinder returns to the balance position. The splitting machine unwinding double-floating-roller mechanism provided by the invention is good in responsiveness,high in tension control precision and good in static and dynamic balance.

Owner:浙江华创机电科技有限公司

Tension mechanism adapted for automatic optical fiber winding machine

InactiveCN100454056CCompact designNo reverse dead zoneFilament handlingSagnac effect gyrometersWinding machineFiber

Owner:BEIHANG UNIV

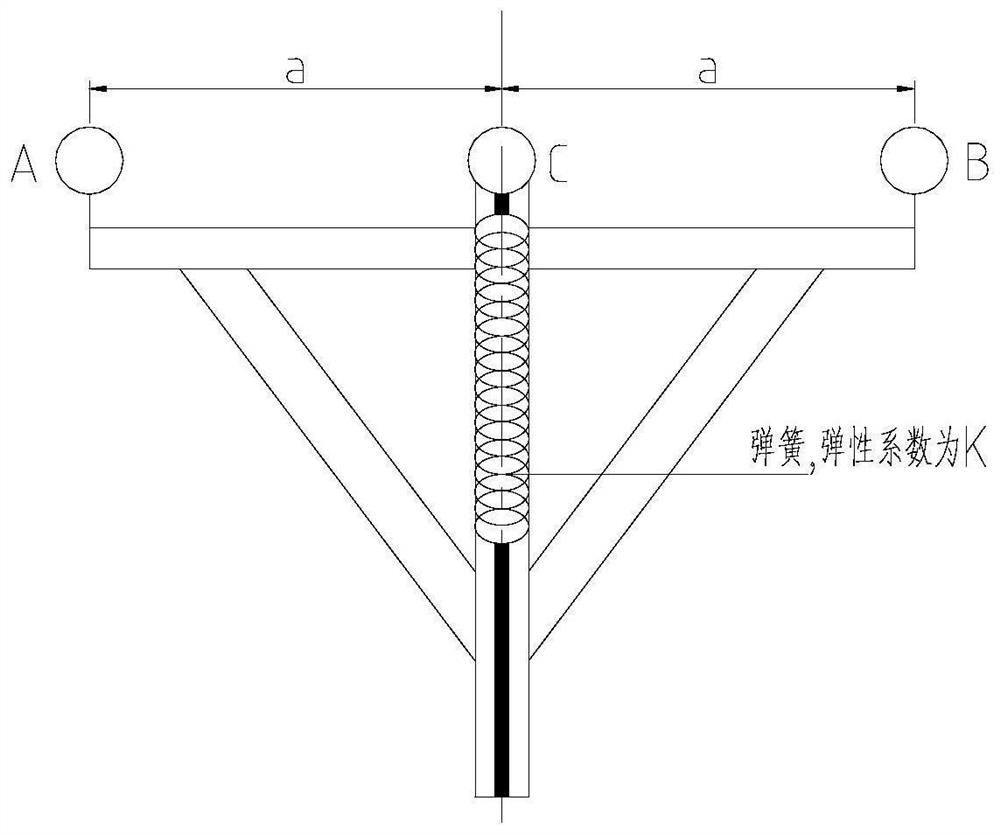

Device and method for quickly calibrating mechanical tensiometer

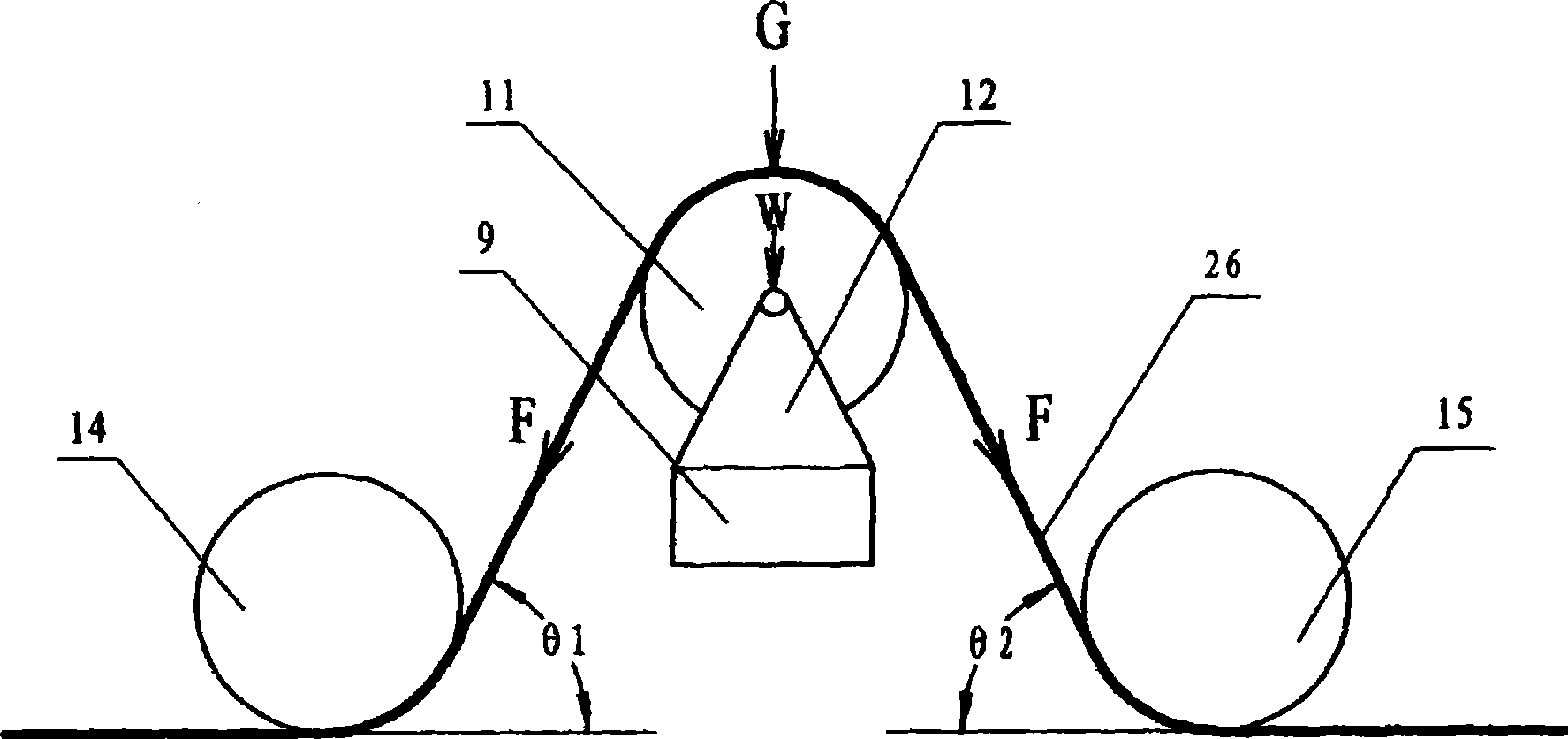

ActiveCN112362230AMeet the needs of different star lengthsAccurate measurementForce/torque/work measurement apparatus calibration/testingClassical mechanicsBlock and tackle

The invention relates to a device and method for quickly calibrating a mechanical tensiometer. The device comprises a connecting assembly, a sensor, a to-be-measured rope, a grooved rail, a fasteningassembly, a pulley assembly and a weight. The grooved rail is horizontally arranged; the connecting assembly is of an L-shaped structure and comprises a first side plate and a second side plate whichare perpendicular to each other, and the first side plate of the connecting assembly is attached to and fixed to one end of the grooved rail; the pulley assembly is fixed to the other end of the grooved rail; the bottom of the fastening assembly is fixedly located in the middle of the grooved rail; a square groove is formed in the top of the fastening assembly; the second side plate of the connecting assembly is perpendicular to the grooved rail and used for being fixedly connected with one end of the sensor; the other end of the sensor is fixedly connected with a to-be-measured rope; the to-be-measured rope penetrates through the square groove of the fastening assembly and is fastened to the fastening assembly; the to-be-measured rope changes to extend in a vertical direction through thepulley assembly; the weight is fixedly connected to the tail end of the to-be-measured rope; after being installed, the to-be-measured rope is just tangent to the bottom of the square groove of the fastening assembly and the pulley assembly.

Owner:BEIJING SATELLITE MFG FACTORY

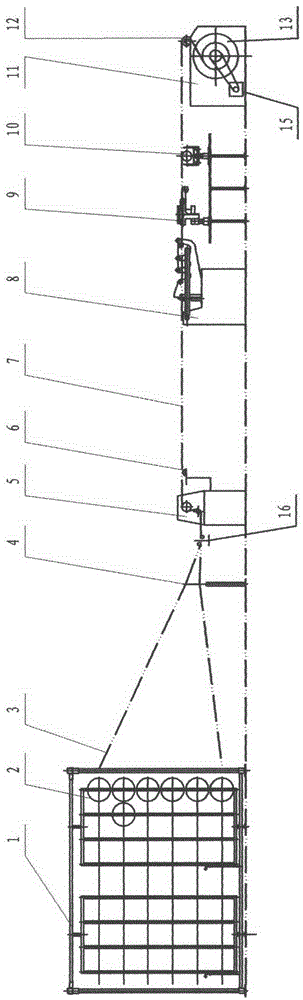

Inside and outside combined type system and method for reinforcing hollow plate through prestressed steel wire ropes

ActiveCN106223213ATo achieve reinforcementImprove carrying capacityBuilding repairsBridge erection/assemblyPre stressSteel bar

The invention discloses an inside and outside combined type system for reinforcing a hollow plate through prestressed steel wire ropes. The system comprises the hollow plate and a reinforcing structure. The reinforcing structure comprises a set of embedded steel bars anchored in the hollow plate. The main steel wire ropes are distributed in a hole of the hollow plate and on the plate bottom of the hollow plate correspondingly, one end of each main steel wire rope winds around one embedded steel bar and then is anchored with an extrusion anchor head, and the other end of each main steel wire rope is connected with a main threaded sleeve. The system further comprises connecting sleeves, each connecting sleeve is connected with a main threaded rod and an auxiliary threaded rod, each main threaded rod is connected with the corresponding main threaded sleeve, and each auxiliary threaded rod is connected with an auxiliary threaded sleeve. The auxiliary steel wire ropes are arranged between the auxiliary threaded sleeves and the other embedded steel bar. Grouting materials are arranged in the hole of the hollow plate and on the plate bottom of the hollow plate and wrap the reinforcing structure. After prestressing force is applied to the steel wire ropes, the hollow plate can be reinforced efficiently, and the bearing capacity and rigidity of the hollow plate can be remarkably improved; the surface and decoration of the hollow plate need not be destroyed; and construction is convenient and fast, large equipment is not needed, and tension control precision is high.

Owner:SOUTHEAST UNIV +1

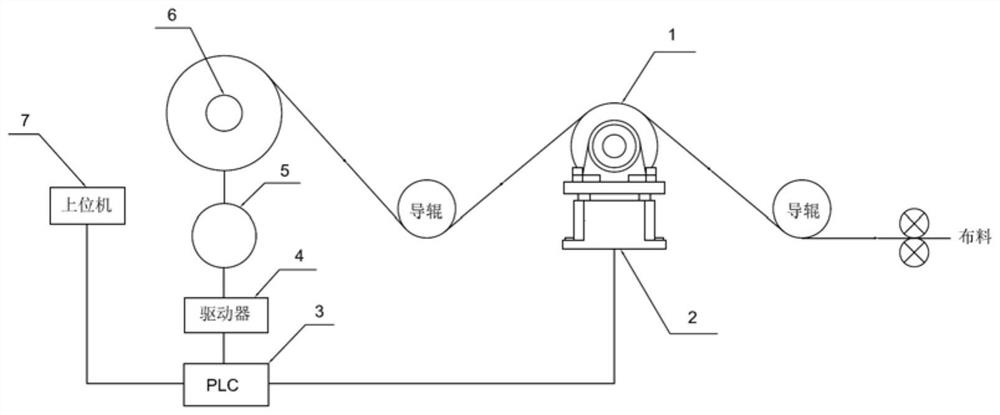

Constant tension control system of mask machine based on servo controller

PendingCN113911802ATension real-time controlAdjustable tensionWebs handlingControl systemControl engineering

The invention provides a constant tension control system of a mask machine based on a servo controller. The constant tension control system is provided with an upper computer and a constant tension control component; the constant tension control component comprises a tension sensor, a PLC, a servo motor and an unwinding shaft; the tension sensor, the servo motor and the unwinding shaft are electrically connected with the PLC; the tension sensor obtains an actual tension value generated when the mask machine transmits cloth in the production process, and transmits the actual tension value to the upper computer through the PLC; the upper computer conducts processing according to the received actual tension value and a set tension value, generates a corresponding instruction and issues the instruction to the PLC; and the PLC controls the working state of the unwinding shaft through the servo motor according to the received instruction, the tension of the cloth is controlled in real time by controlling the torque of the servo motor, the tension of the cloth can be rapidly adjusted, the problem that the adjusting speed is low in the prior art is solved, meanwhile, the tension control precision is improved, and the problem of low tension control precision in the prior art is solved.

Owner:FUJIAN METROLOGY INST

Portable tension-adjustable pay-off rack device for outdoor optical cable

PendingCN110027938AHigh control precisionImprove processing pass rateFilament handlingMagnetEngineering

The invention discloses a portable tension-adjustable pay-off rack device for an outdoor optical cable. The device comprises a pay-off assembly, a spare reel assembly and a pay-off rack support assembly. By using the portable tension-adjustable pay-off rack, pay-off tension control of an original tearing rope is greatly improved, the unqualified loss of products and the ineffectiveness working time of operators are greatly reduced, machine tables are convenient to temporarily transfer due to the portable design, an external power source is not needed by adding permanent magnet control, installation is extremely fast, and tension control can reach + / -0.5 N.

Owner:JIANGSU TRIGIANT OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com