Inside and outside combined type system and method for reinforcing hollow plate through prestressed steel wire ropes

A technology of steel wire rope and hollow slab, which is applied in the system field of internal and external combined prestressed steel wire rope to reinforce the hollow slab, which can solve the problems of increased self-weight, poor co-working ability, and affecting the reinforcement effect, so as to achieve convenient construction and improve bearing capacity and rigidity , The effect of high tension control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

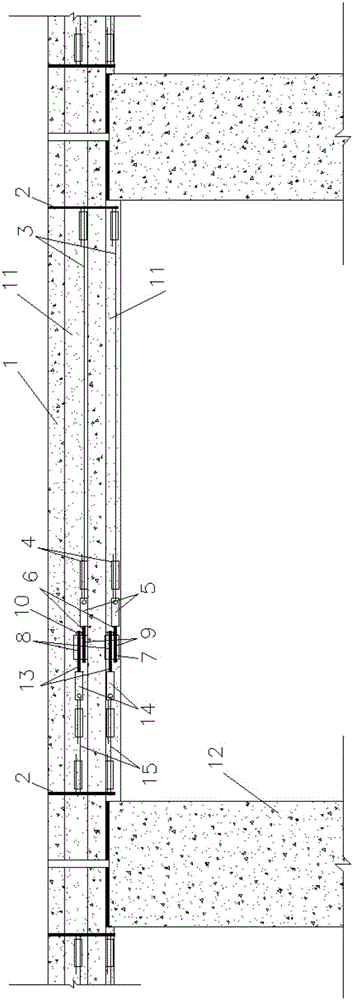

[0026] Such as figure 1 A system for reinforcing hollow slabs with internal and external combined prestressed steel wire ropes shown includes a hollow slab 1 installed on a wall or column 12 and a reinforcement structure arranged inside the hollow slab 1. The reinforcement structure includes anchors anchored in the hollow slab 1. A group of planting bars 2; the main steel wire rope 3 arranged in the hole of the hollow plate 1 and the bottom of the plate respectively, one end of the main steel wire rope 3 bypasses one of the planting bars and is anchored with an extruded anchor head 4, and the other end is connected to the main threaded sleeve 5 ; Also include connecting sleeve 7, connecting sleeve 7 is connected with main threaded rod 6 and secondary threaded rod 13, main threaded rod 6 connects main threaded sleeve 5, secondary threaded rod 13 connects secondary threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com