Cable conveyance tension adjustment method and device implementing same

A tension adjustment and adjustment device technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of affecting the quality of cable winding, reducing the service life of products, and inconsistent cable lengths, etc., to achieve improved The effect of enterprise competitiveness, quality assurance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

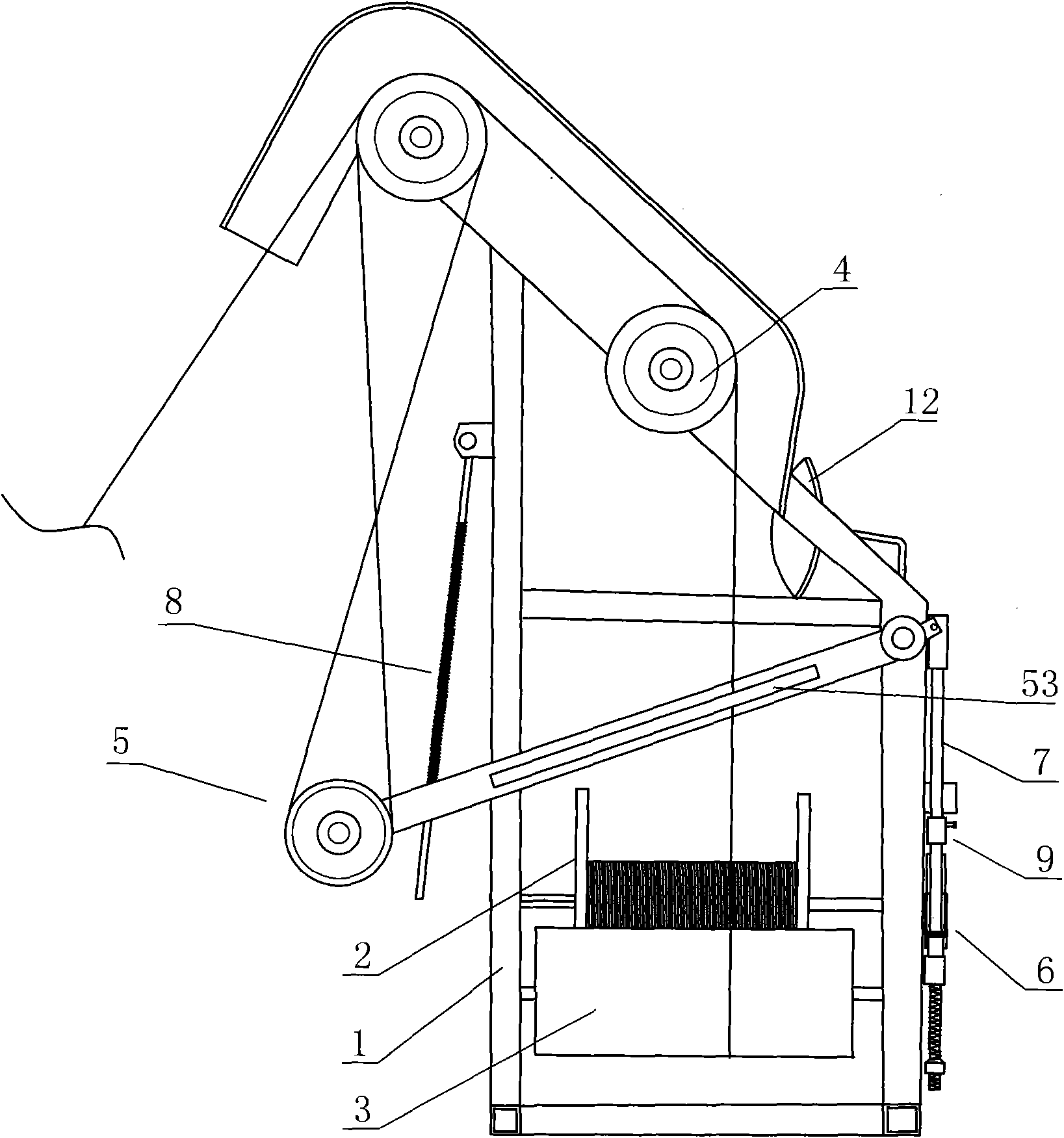

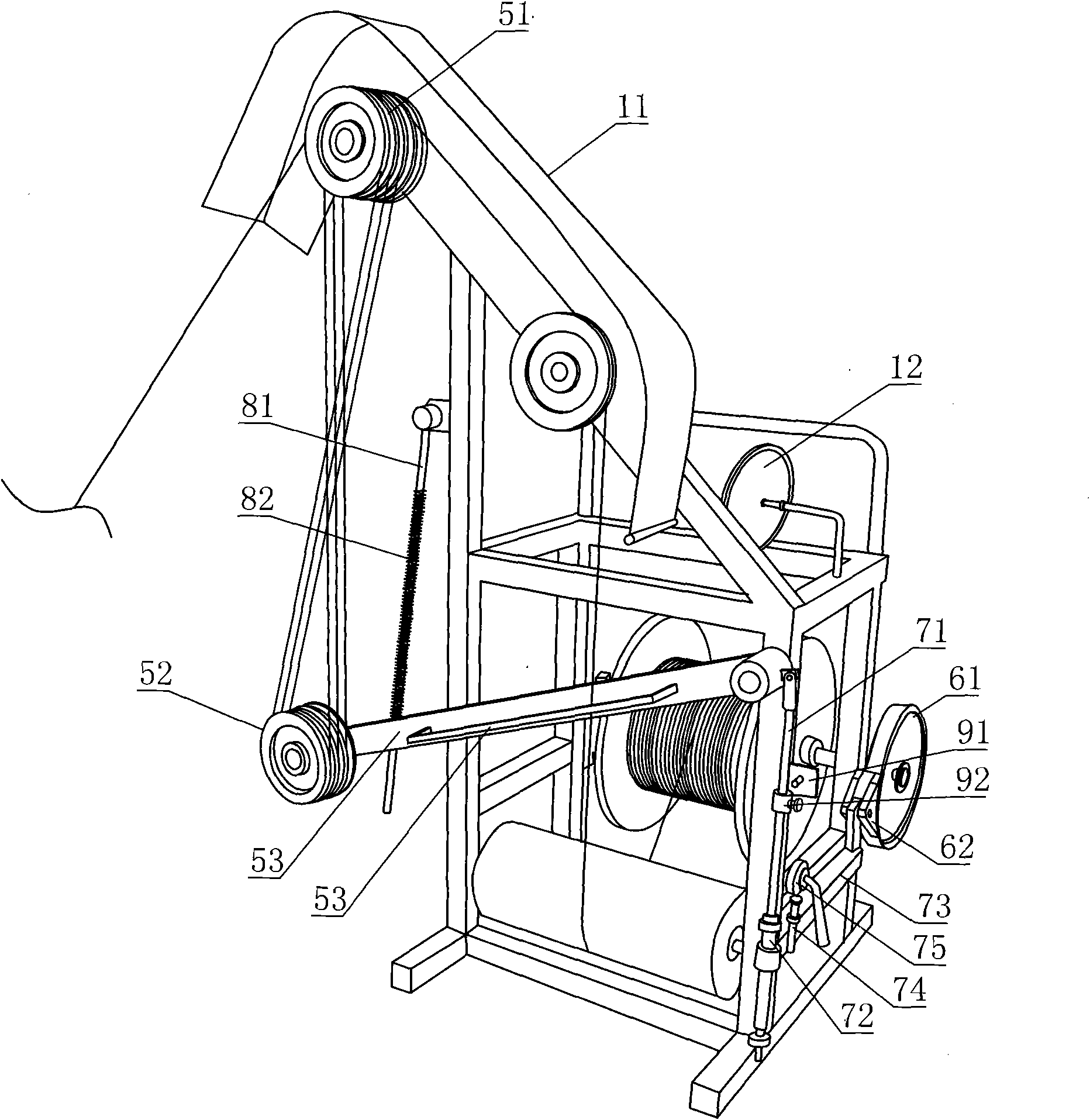

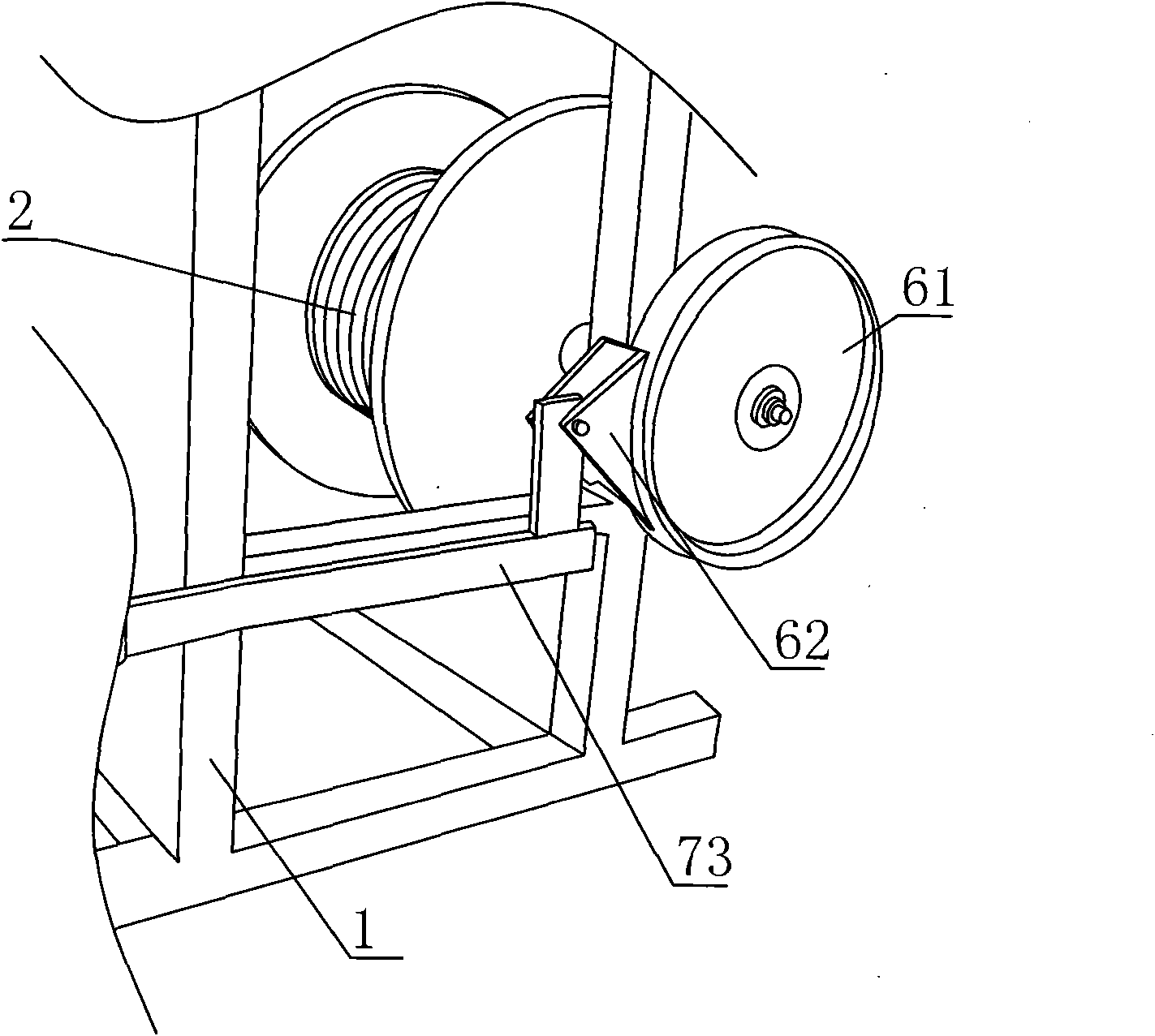

[0034] Example: see figure 1 , figure 2 and image 3 , a kind of cable conveying tension adjustment method that the embodiment of the present invention provides, it comprises a frame 1 and a reel 2 that is arranged on this frame 1, and it comprises the following steps:

[0035] (1) Prepare a wire roll 3, whose length is slightly longer than the wire reel 2, so as to realize the neat output of the cables on the wire reel 2;

[0036] (2) Prepare a conductor wheel 4, to realize the cable transported from the conductor roller 3, and output in the corresponding direction;

[0037] (3) Prepare a tension control device 5, which includes a fixed runner 51, a floating runner 52 and a suspended swing arm 53, the fixed runner 51 is at least provided with two wire grooves, and the floating runner 52 is at least There is a wire groove, the floating runner 52 is rotatably arranged at the end of the suspended swing arm 53, and can float up and down with the swing of the suspended swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com